Progress on the Properties of Ceramic Phase-Reinforced High-Entropy Alloy Composite Coatings Produced via Laser Cladding

Abstract

1. Introduction

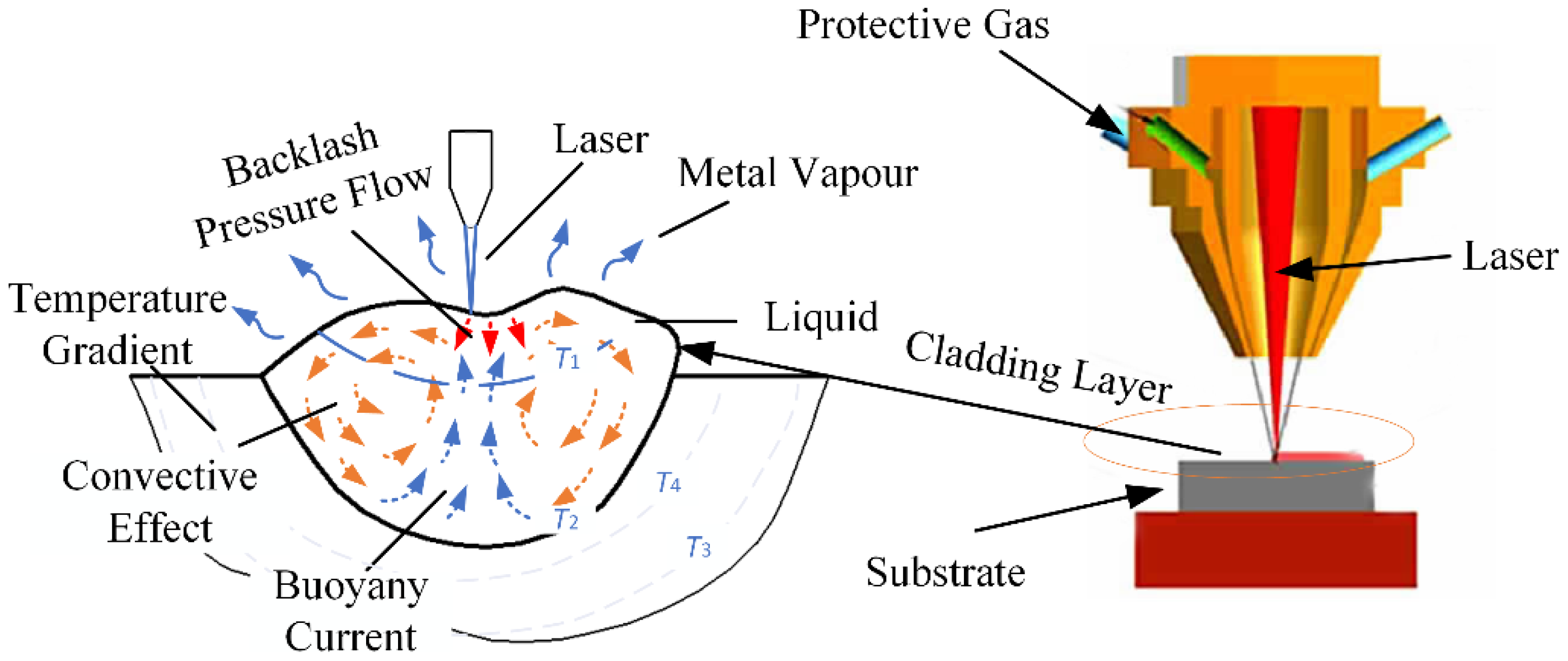

2. Preparation of Ceramic Phase-Reinforced High-Entropic Alloy Composite Coatings

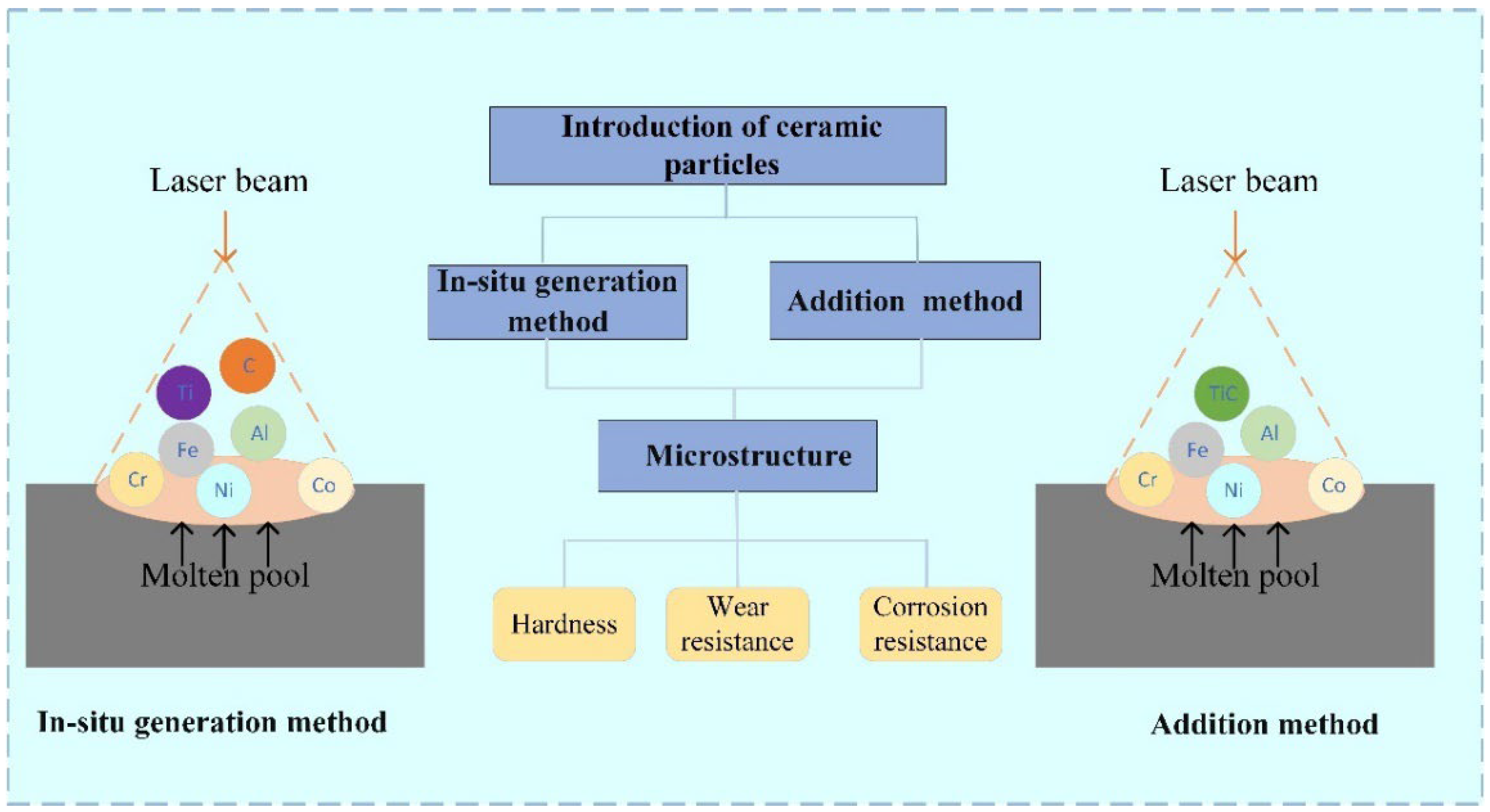

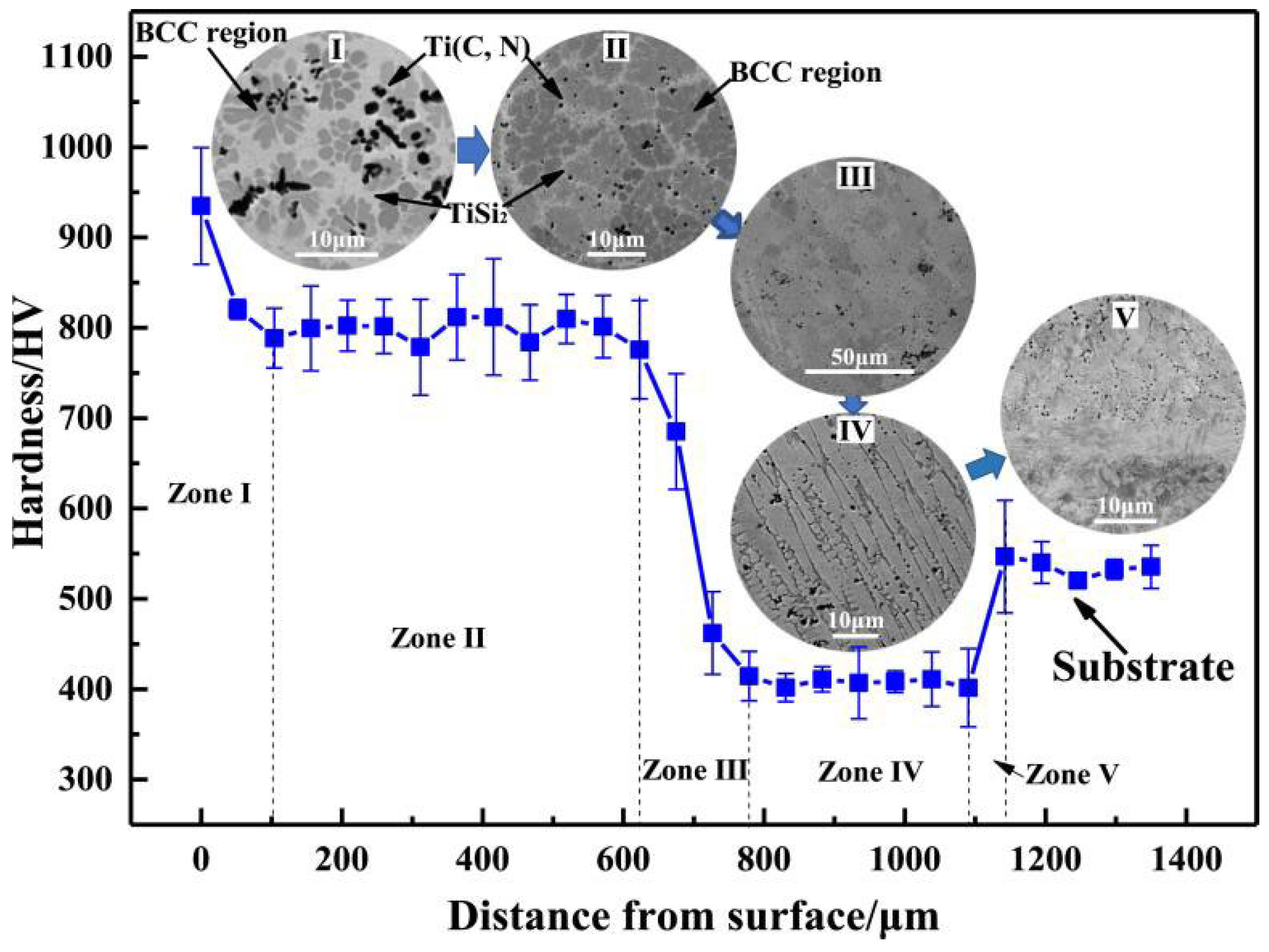

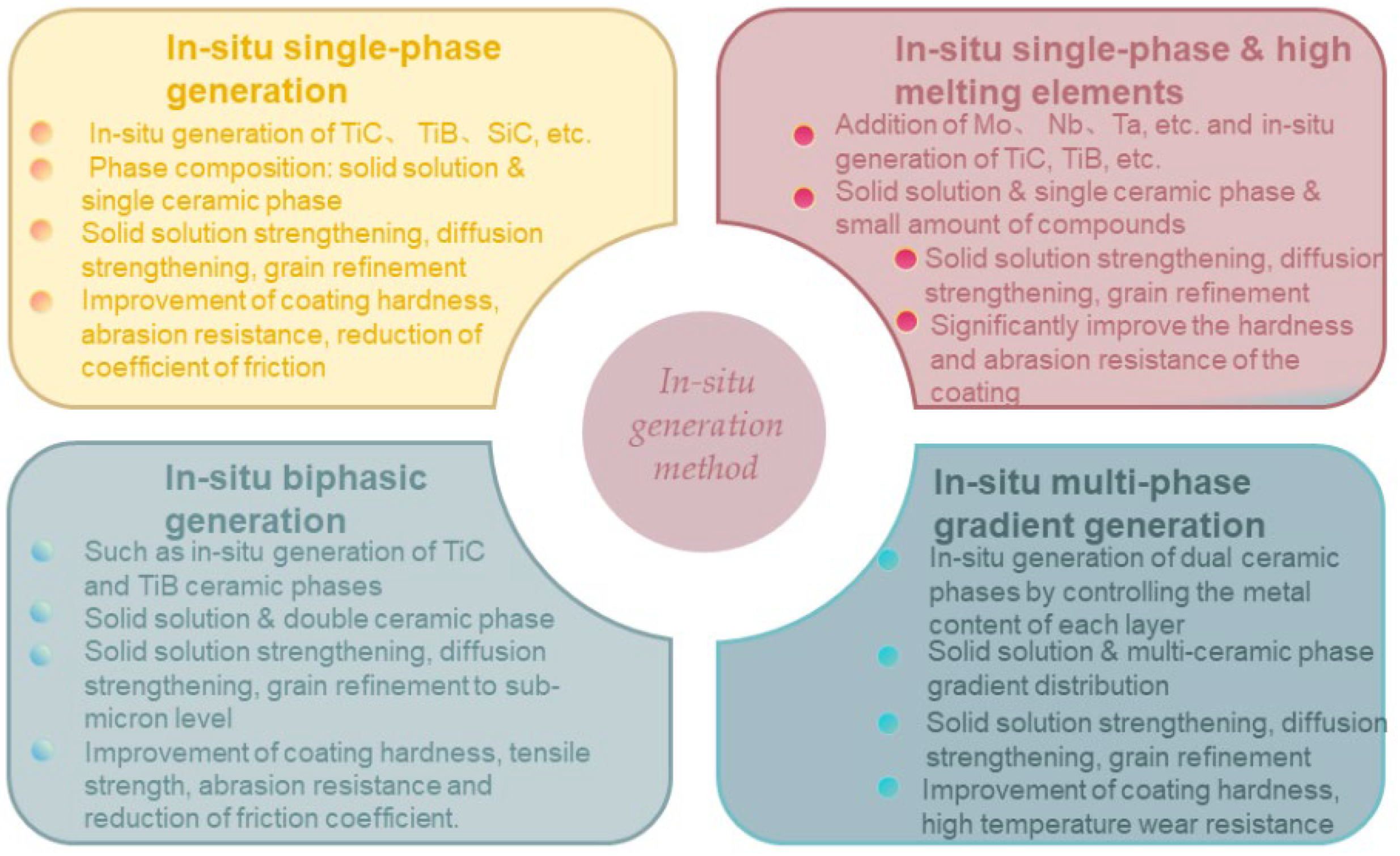

2.1. In Situ Generation Method

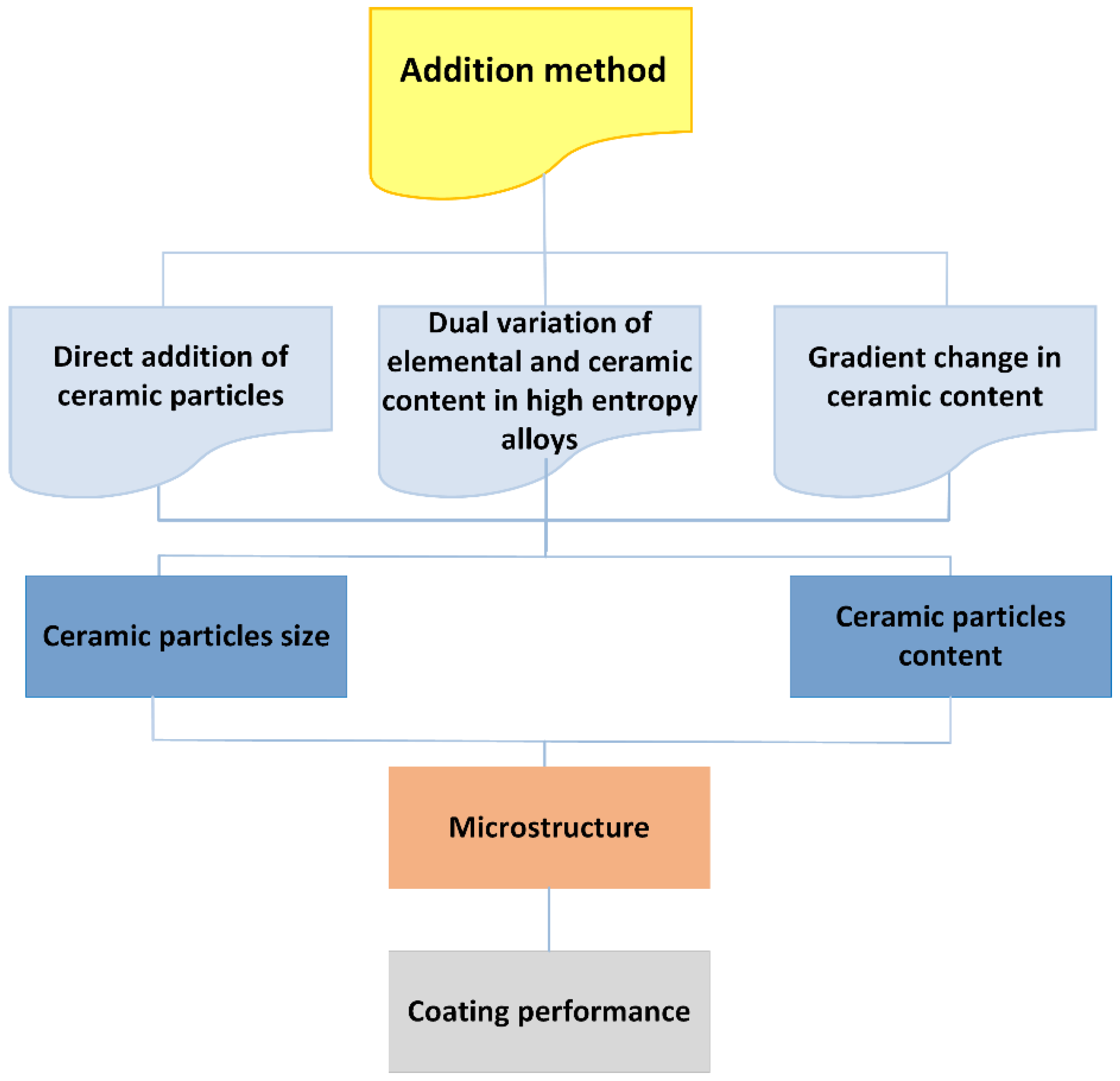

2.2. Addition Method

3. Discussion

4. Conclusions

- (1)

- Simulation research of high-entropy alloy composite coating. The current simulation of high-entropy alloy coating is primarily based on first principle calculation, molecular dynamics simulation, and phase diagram calculation. These methods aim to predict the formation behavior of high-entropy alloy and simulate the melting process of the coating. However, the existing simulation software lacks accuracy in simulating the coupling of multiple physical fields (such as temperature, fluid, and stress) during the laser melting and cladding of high-entropy alloy composite coatings. Additionally, it does not have a comprehensive selection of coating materials, including powder particle size and preparation process. As a result, most research on high-entropy alloy composite coatings still relies on repeated experiments. To overcome these limitations, it is necessary to enhance the simulation software by introducing new options for material parameters and preparation processes. This will enable a flexible, efficient, and cost-effective research and development process.

- (2)

- High-entropy alloy composite coatings in extreme conditions. Existing research on the performance of ceramic phase-reinforced high-entropy alloy composite coatings mostly focuses on mechanical properties, friction properties, and electrochemical corrosion properties at room temperature. Research on extreme conditions such as thermal fatigue performance, ultra-low temperature performance, irradiation resistance, and other properties is less. Via the study of its performance under extreme conditions, it is expected to be applied to the surface protection of key components under special conditions, such as aerospace turbine blades, oil drilling parts, biomedical fields, superconducting materials, etc.

- (3)

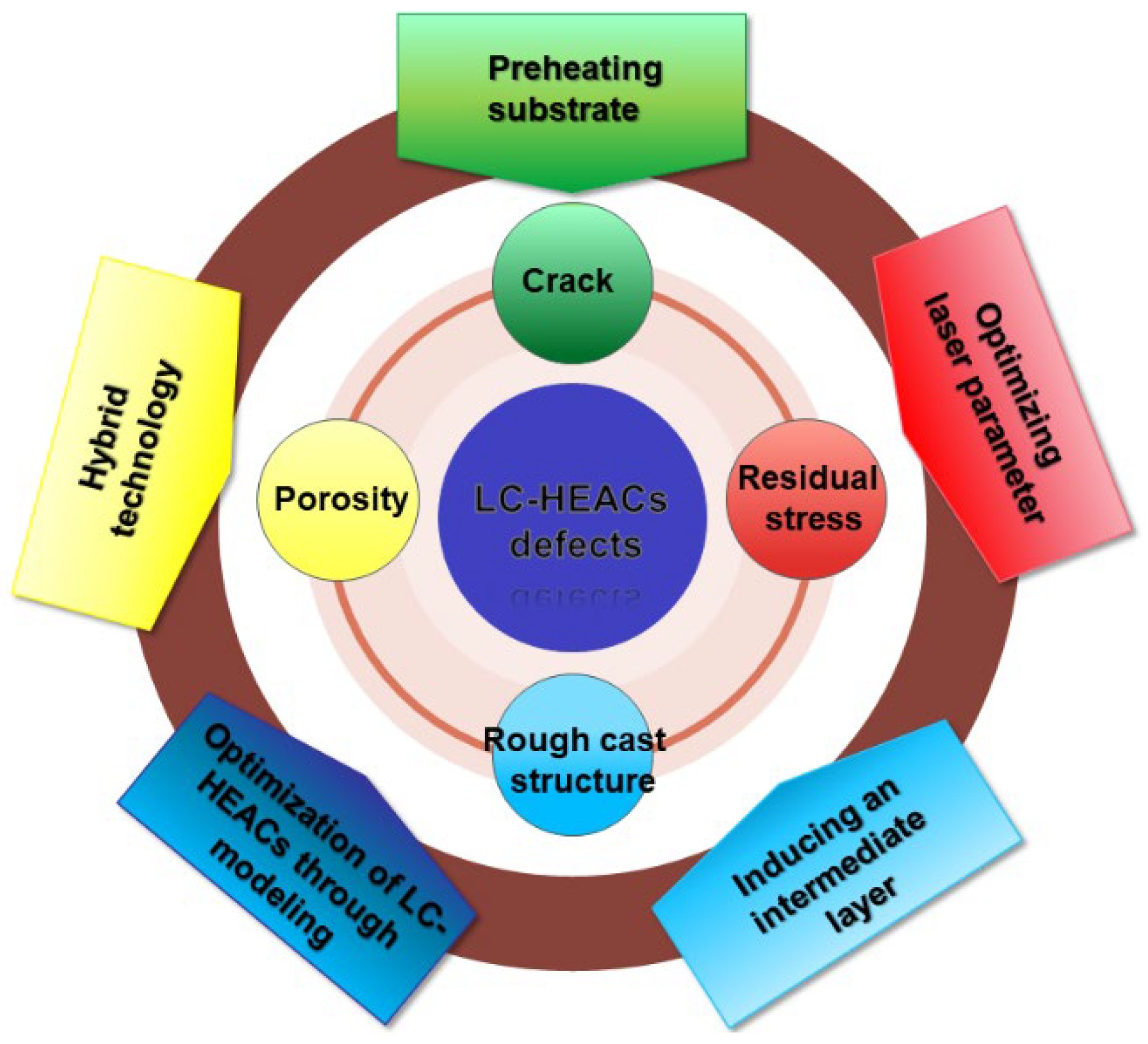

- New process research. Ceramic phase-reinforced high-entropy alloy composite coatings are prone to defects such as porosity and cracks in the coating during laser melting and cladding. The development of new processes such as laser–ultrasonic vibration composite, electric field–magnetic field synergism, and other multi-physical field composite processing processes can effectively mitigate the generation of coating defects. Obtaining high-quality coatings via new processes may facilitate industrialized production applications.

- (4)

- The study of different kinds of ceramic contents and self-lubricating phases in high-entropy alloy composite coatings. With the increase of ceramic content in high-entropy alloys or the mismatch between the selected ceramic phase and the high-entropy alloy system, will lead to defects such as porosity and cracks in the fusion coating process. This is due to differences in chemical potentials, thermal coefficients of linear expansion, etc. A self-lubricating phase is usually introduced to improve coating defects. Thus, it is of great interest to further investigate the different types of ceramic contents and suitable self-lubricating phases in composite coatings to improve coating defects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-Solution Phase Formation Rules for Multi-component Alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Yeh, J.-W.; Chen, S.-K.; Lin, S.-J. Nanostructured Hight-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, Y.L.; Lin, S.J.; Chen, S.K. High-Entropy Alloys—A New Era of Exploitation. Mater. Sci. Forum 2007, 560, 1–9. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Liu, K.; Komarasamy, M.; Gwalani, B.; Shukla, S.; Mishra, R.S. Fatigue behavior of ultrafine grained triplex Al0.3CoCrFeNi high entropy alloy. Scr. Mater. 2019, 158, 116–120. [Google Scholar] [CrossRef]

- Wang, W.; Wang, J.; Sun, Z.; Li, J.; Li, L.; Song, X.; Wen, X.; Xie, L.; Yang, X. Effect of Mo and aging temperature on corrosion behavior of (CoCrFeNi)100−xMox high-entropy alloys. J. Alloys Compd. 2020, 812, 152139. [Google Scholar] [CrossRef]

- Chuang, M.-H.; Tsai, M.-H.; Wang, W.-R.; Lin, S.-J.; Yeh, J.-W. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Mater. 2011, 59, 6308–6317. [Google Scholar] [CrossRef]

- Li, Y.; Shi, Y. Microhardness, wear resistance, and corrosion resistance of AlxCrFeCoNiCu high-entropy alloy coatings on aluminum by laser cladding. Opt. Laser Technol. 2021, 134, 106632. [Google Scholar] [CrossRef]

- Rogal, Ł.; Kalita, D.; Tarasek, A.; Bobrowski, P.; Czerwinski, F. Effect of SiC nano-particles on microstructure and mechanical properties of the CoCrFeMnNi high entropy alloy. J. Alloys Compd. 2017, 708, 344–352. [Google Scholar] [CrossRef]

- Yang, J.; Liu, W.; Fu, M.; Wen, J.; Li, K.; Lin, P.; Wang, C.; He, P.; Lin, T.; Mei, H.; et al. Joining SiCf/SiC composites to Al0.3CoCrFeNi high-entropy alloys with a Cu–Ti filler alloy: Interfacial reactions, high-entropy effects, and mechanical properties. Mater. Sci. Eng. A 2023, 881, 145390. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Muthuramalingam, T.; Anbuchezhiyan, G. Effect of B4C and MOS2 reinforcement on micro structure and wear properties of aluminum hybrid composite for automotive applications. Compos. Part B Eng. 2019, 176, 107329. [Google Scholar] [CrossRef]

- Arif, Z.U.; Khalid, M.Y.; ur Rehman, E.; Ullah, S.; Atif, M.; Tariq, A. A review on laser cladding of high-entropy alloys, their recent trends and potential applications. J. Manuf. Process. 2021, 68, 225–273. [Google Scholar] [CrossRef]

- Yang, S.; Yan, X.; Yang, K.; Fu, Z. Effect of the addition of nano-Al2O3 on the microstructure and mechanical properties of twinned Al0.4FeCrCoNi1.2Ti0.3 alloys. Vacuum 2016, 131, 69–72. [Google Scholar] [CrossRef]

- Braic, M.; Braic, V.; Vladescu, A.; Zoita, C.N.; Balaceanu, M. Solid solution or amorphous phase formation in TiZr-based ternary to quinternary multi-principal-element films. Prog. Nat. Sci. Mater. Int. 2014, 24, 305–312. [Google Scholar] [CrossRef]

- Ji, X.; Duan, H.; Zhang, H.; Ma, J. Slurry Erosion Resistance of Laser Clad NiCoCrFeAl3High-Entropy Alloy Coatings. Tribol. Trans. 2015, 58, 1119–1123. [Google Scholar] [CrossRef]

- Yao, C.-Z.; Zhang, P.; Liu, M.; Li, G.-R.; Ye, J.-Q.; Liu, P.; Tong, Y.-X. Electrochemical preparation and magnetic study of Bi–Fe–Co–Ni–Mn high entropy alloy. Electrochim. Acta 2008, 53, 8359–8365. [Google Scholar] [CrossRef]

- Yue, T.; Xie, H.; Lin, X.; Yang, H.; Meng, G. Microstructure of Laser Re-Melted AlCoCrCuFeNi High Entropy Alloy Coatings Produced by Plasma Spraying. Entropy 2013, 15, 2833–2845. [Google Scholar] [CrossRef]

- Mu, Y.; Zhang, L.; Xu, L.; Prashanth, K.; Zhang, N.; Ma, X.; Jia, Y.; Xu, Y.; Jia, Y.; Wang, G. Frictional Wear and Corrosion Behavior of AlCoCrFeNi High-Entropy Alloy Coatings Synthesized by Atmospheric Plasma Spraying. Entropy 2020, 22, 740. [Google Scholar] [CrossRef]

- Cai, Y.; Zhu, L.; Cui, Y.; Geng, K.; Manladan, S.M.; Luo, Z.; Han, J. Strengthening mechanisms in multi-phase FeCoCrNiAl1.0 high-entropy alloy cladding layer. Mater. Charact. 2020, 159, 110037. [Google Scholar] [CrossRef]

- Sun, S.; Durandet, Y.; Brandt, M. Parametric investigation of pulsed Nd: YAG laser cladding of stellite 6 on stainless steel. Surf. Coat. Technol. 2005, 194, 225–231. [Google Scholar] [CrossRef]

- Menghani, J.; Vyas, A.; Patel, P.; Natu, H.; More, S. Wear, erosion and corrosion behavior of laser cladded high entropy alloy coatings—A review. Mater. Today Proc. 2021, 38, 2824–2829. [Google Scholar] [CrossRef]

- Liu, Y.; Xiang, D.; Wang, K.; Yu, T. Corrosion of Laser Cladding High-Entropy Alloy Coatings: A Review. Coatings 2022, 12, 1669. [Google Scholar] [CrossRef]

- Cheng, W.; Ji, L.; Zhang, L.; Wang, H.; Sun, W. Refractory high-entropy alloys fabricated using laser technologies: A concrete review. J. Mater. Res. Technol. 2023, 24, 7497–7524. [Google Scholar] [CrossRef]

- Xie, H.; Tong, Y.; Bai, Y.; Li, X.; Han, Y.; Hua, K.; Wang, H. Wear-Resistance of High-Entropy Alloy Coatings and High-Entropy Alloy-Based Composite Coatings Prepared by the Laser Cladding Technology: A Review. Adv. Eng. Mater. 2023, 25, 2300426. [Google Scholar] [CrossRef]

- Kołodziejczak, P.; Bober, M.; Chmielewski, T. Wear Resistance Comparison Research of High-Alloy Protective Coatings for Power Industry Prepared by Means of CMT Cladding. Appl. Sci. 2022, 12, 4568. [Google Scholar] [CrossRef]

- Liang, J.; Yin, X.; Lin, Z.; Chen, S.; Liu, C.; Wang, C. Microstructure and wear behaviors of laser cladding in-situ synthetic (TiBx+TiC)/(Ti2Ni+TiNi) gradient composite coatings. Vacuum 2020, 176, 109305. [Google Scholar] [CrossRef]

- Feng, Y.; Feng, K.; Yao, C.; Li, Z.; Sun, J. Microstructure and properties of in-situ synthesized (Ti3Al + TiB)/Ti composites by laser cladding. Mater. Des. 2018, 157, 258–272. [Google Scholar] [CrossRef]

- Yang, L.; Yu, T.; Li, M.; Zhao, Y.; Sun, J. Microstructure and wear resistance of in-situ synthesized Ti(C, N) ceramic reinforced Fe-based coating by laser cladding. Ceram. Int. 2018, 44, 22538–22548. [Google Scholar] [CrossRef]

- Lin, Y.; Jiang, C.; Lin, Z.; Chen, Q.; Lei, Y.; Fu, H. Laser in-situ synthesis of high aspect ratio TiB fiber bundle reinforced titanium matrix composite coating. Opt. Laser Technol. 2019, 115, 364–373. [Google Scholar] [CrossRef]

- Guo, Y.; Li, C.; Zeng, M.; Wang, J.; Deng, P.; Wang, Y. In-situ TiC reinforced CoCrCuFeNiSi0.2 high-entropy alloy coatings designed for enhanced wear performance by laser cladding. Mater. Chem. Phys. 2020, 242, 122522. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Chen, P.; Yang, H. Microstructure and high temperature wear behaviour of in-situ TiC reinforced AlCoCrFeNi-based high-entropy alloy composite coatings fabricated by laser cladding. Opt. Laser Technol. 2019, 118, 140–150. [Google Scholar] [CrossRef]

- Zhou, X.; He, L.; Zhang, M.; Wang, P. Effect of ceramic particles on microstructure and properties of CoCrMoNbTi high-entropy alloy coating fabricated by laser cladding. Optik 2023, 285, 170987. [Google Scholar] [CrossRef]

- Zhu, J.M.; Fu, H.M.; Zhang, H.F.; Wang, A.M.; Li, H.; Hu, Z.Q. Microstructures and compressive properties of multicomponent AlCoCrFeNiMox alloys. Mater. Sci. Eng. A 2010, 527, 6975–6979. [Google Scholar] [CrossRef]

- Chang, R.; Fang, W.; Bai, X.; Xia, C.; Zhang, X.; Yu, H.; Liu, B.; Yin, F. Effects of tungsten additions on the microstructure and mechanical properties of CoCrNi medium entropy alloys. J. Alloys Compd. 2019, 790, 732–743. [Google Scholar] [CrossRef]

- Xiang, K.; Chen, L.-Y.; Chai, L.; Guo, N.; Wang, H. Microstructural characteristics and properties of CoCrFeNiNbx high-entropy alloy coatings on pure titanium substrate by pulsed laser cladding. Appl. Surf. Sci. 2020, 517, 146214. [Google Scholar] [CrossRef]

- Liu, H.; Gao, Q.; Dai, J.; Chen, P.; Gao, W.; Hao, J.; Yang, H. Microstructure and high-temperature wear behavior of CoCrFeNiWx high-entropy alloy coatings fabricated by laser cladding. Tribol. Int. 2022, 172, 107574. [Google Scholar] [CrossRef]

- Li, Z.; Jing, C.; Feng, Y.; Wu, Z.; Lin, T.; Zhao, J. Microstructure evolution and properties of laser cladding Nb containing eutectic high entropy alloys. Int. J. Refract. Met. Hard Mater. 2023, 110, 105992. [Google Scholar] [CrossRef]

- Zhao, W.; Yu, K.; Ma, Q.; Song, C.; Xiao, G.; Zhang, H.; Lv, Y.; Guo, N.; Li, Z. Synergistic effects of Mo and in-situ TiC on the microstructure and wear resistance of AlCoCrFeNi high entropy alloy fabricated by laser cladding. Tribol. Int. 2023, 188, 108827. [Google Scholar] [CrossRef]

- Zhao, Y.; Yu, T.; Chen, L.; Chen, Y.; Guan, C.; Sun, J. Microstructure and wear resistance behavior of Ti–C–B4C-reinforced composite coating. Ceram. Int. 2020, 46, 25136–25148. [Google Scholar] [CrossRef]

- Ye, F.; Yang, Y.; Lou, Z.; Feng, L.; Guo, L.; Yu, J. Microstructure and wear resistance of TiC reinforced AlCoCrFeNi2.1 eutectic high entropy alloy layer fabricated by micro-plasma cladding. Mater. Lett. 2021, 284, 128859. [Google Scholar] [CrossRef]

- Patil, A.S.; Hiwarkar, V.D.; Verma, P.K.; Khatirkar, R.K. Effect of TiB2 addition on the microstructure and wear resistance of Ti-6Al-4V alloy fabricated through direct metal laser sintering (DMLS). J. Alloys Compd. 2019, 777, 165–173. [Google Scholar] [CrossRef]

- Geng, L.; Ni, D.R.; Zhang, J.; Zheng, Z.Z. Hybrid effect of TiBw and TiCp on tensile properties of in situ titanium matrix composites. J. Alloys Compd. 2008, 463, 488–492. [Google Scholar] [CrossRef]

- Song, R.; Li, J.; Shao, J.Z.; Bai, L.L.; Chen, J.L.; Qu, C.C. Microstructural evolution and wear behaviors of laser cladding Ti2 Ni/α(Ti) dual-phase coating reinforced by TiB and TiC. Appl. Surf. Sci. 2015, 355, 298–309. [Google Scholar] [CrossRef]

- He, L.; Zhang, M.; Wang, D.; Ye, X.; Zhou, Y.; Ruan, D.; Zhang, W. Microstructure and mechanical properties of in-situ dual ceramic phase synergistic strengthened CoCrMoNbTi(B4C)x high entropy alloy coating. Opt. Laser Technol. 2023, 161, 109172. [Google Scholar] [CrossRef]

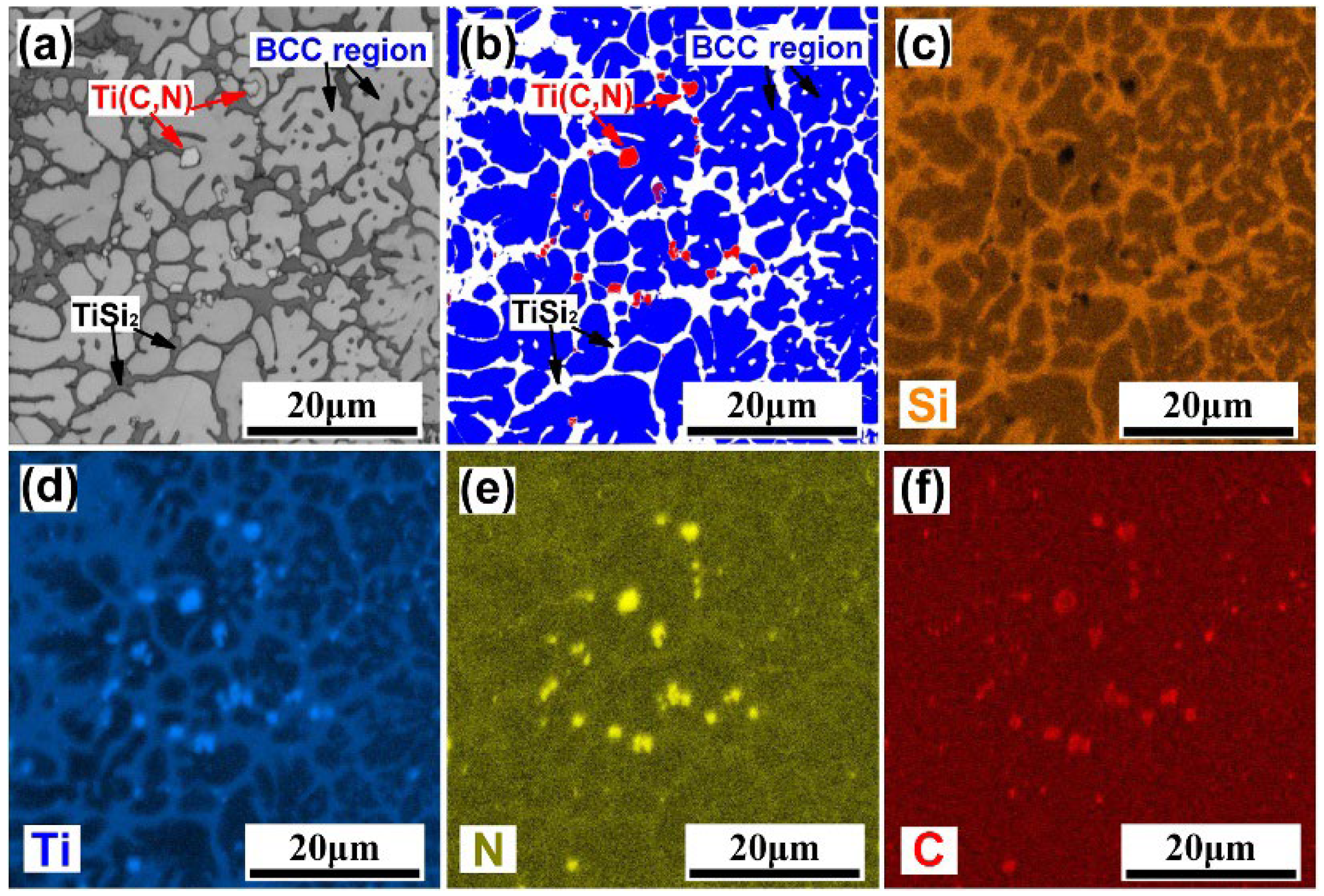

- Yan, G.; Zheng, M.; Ye, Z.; Gu, J.; Li, C.; Wu, C.; Wang, B. In-situ Ti(C, N) reinforced AlCoCrFeNiSi-based high entropy alloy coating with functional gradient double-layer structure fabricated by laser cladding. J. Alloys Compd. 2021, 886, 161252. [Google Scholar] [CrossRef]

- Liu, S.S.; Zhang, M.; Zhao, G.L.; Wang, X.H.; Wang, J.F. Microstructure and properties of ceramic particle reinforced FeCoNiCrMnTi high entropy alloy laser cladding coating. Intermetallics 2022, 140, 107402. [Google Scholar] [CrossRef]

- Wang, J.; Yang, H.; Huang, H.; Ruan, J.; Ji, S. Microstructure and mechanical properties of SiC whisker reinforced CoCrNi medium entropy alloys. Mater. Lett. 2019, 254, 77–80. [Google Scholar] [CrossRef]

- Li, B.; Zhang, L.; Yang, B. Grain refinement and localized amorphization of additively manufactured high-entropy alloy matrix composites reinforced by nano ceramic particles via selective-laser-melting/remelting. Compos. Commun. 2020, 19, 56–60. [Google Scholar] [CrossRef]

- Xi, L.; Gu, D.; Guo, S.; Wang, R.; Ding, K.; Prashanth, K.G. Grain refinement in laser manufactured Al-based composites with TiB2 ceramic. J. Mater. Res. Technol. 2020, 9, 2611–2622. [Google Scholar] [CrossRef]

- Cai, Y.; Zhu, L.; Cui, Y.; Shan, M.; Li, H.; Xin, Y.; Han, J. Fracture and wear mechanisms of FeMnCrNiCo + x(TiC) composite high-entropy alloy cladding layers. Appl. Surf. Sci. 2021, 543, 148794. [Google Scholar] [CrossRef]

- Li, X.; Feng, Y.; Liu, B.; Yi, D.; Yang, X.; Zhang, W.; Chen, G.; Liu, Y.; Bai, P. Influence of NbC particles on microstructure and mechanical properties of AlCoCrFeNi high-entropy alloy coatings prepared by laser cladding. J. Alloys Compd. 2019, 788, 485–494. [Google Scholar] [CrossRef]

- Xu, L.; Du, H.; Liu, J.; Feng, D.; Xia, S. Microstructure, Mechanical, and Electrochemical Properties of SiC Particle Reinforced CoCrFeNiCu High-Entropy Alloy Coatings. Coatings 2022, 12, 519. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, G.; Song, Q.; Lu, X.; Li, Z.; Zhao, Q.; Chen, Y. Microstructure, mechanical properties, and corrosion resistance of SiC reinforced AlxCoCrFeNiTi1−x high-entropy alloy coatings prepared by laser cladding. Surf. Coat. Technol. 2022, 437, 128349. [Google Scholar] [CrossRef]

- Ma, Q.; Lu, B.; Zhang, Y.; Wang, Y.; Yan, X.; Liu, M.; Zhao, G. Crack-free 60 wt% WC reinforced FeCoNiCr high-entropy alloy composite coating fabricated by laser cladding. Mater. Lett. 2022, 324, 132667. [Google Scholar] [CrossRef]

- Taleghani, P.R.; Valefi, Z.; Ehsani, N. Evaluation of oxidation and thermal insulation capability of nanostructured La2(Zr0.7Ce0.3)2O7/YSZ functionally graded coatings. Ceram. Int. 2021, 47, 8915–8929. [Google Scholar] [CrossRef]

- Sopronyi, M.; Nita, C.; Le Meins, J.-M.; Vidal, L.; Jipa, F.; Axente, E.; Matei Ghimbeu, C.; Sima, F. Laser-assisted synthesis of carbon coatings with cobalt oxide nanoparticles embedded in gradient of composition and sizes. Surf. Coat. Technol. 2021, 419, 127301. [Google Scholar] [CrossRef]

- Li, L.; Wang, J.; Lin, P.; Liu, H. Microstructure and mechanical properties of functionally graded TiCp/Ti6Al4V composite fabricated by laser melting deposition. Ceram. Int. 2017, 43, 16638–16651. [Google Scholar] [CrossRef]

- Guévenoux, C.; Hallais, S.; Balit, Y.; Charles, A.; Charkaluk, E.; Constantinescu, A. Plastic strain localization induced by microstructural gradient in laser cladding repaired structures. Theor. Appl. Fract. Mech. 2020, 107, 102520. [Google Scholar] [CrossRef]

- Cui, Y.; Shen, J.; Geng, K.; Hu, S. Fabrication of FeCoCrNiMnAl0.5-FeCoCrNiMnAl gradient HEA coating by laser cladding technique. Surf. Coat. Technol. 2021, 412, 127077. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Q.; Zhang, L.; Chen, D.X.; Jin, H.; Li, J.D.; Zhang, J.W.; Ban, C.Y. Microstructure and properties of Ni-WC gradient composite coating prepared by laser cladding. Ceram. Int. 2022, 48, 7905–7917. [Google Scholar] [CrossRef]

- Chen, L.; Chen, Y.; Chen, X.; Yu, T.; Wang, Z. Microstructure and properties of in situ TiC/Ni functionally gradient coatings by powder-fed laser cladding. Ceram. Int. 2022, 48, 36789–36801. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, Y.; Cheng, W.; Chen, Y.; Gu, J.; Chen, G. Microstructure and tribological behavior of CoCrFeNiMo0.2/SiC high-entropy alloy gradient composite coating prepared by laser cladding. Surf. Coat. Technol. 2023, 467, 129681. [Google Scholar] [CrossRef]

- Hao, X.; Liu, H.; Zhang, X.; Tao, J.; Wang, Y.; Yang, C.; Liu, Y. Microstructure and wear resistance of in-situ TiN/(Nb, Ti)5Si3 reinforced MoNbTaWTi-based refractory high entropy alloy composite coatings by laser cladding. Appl. Surf. Sci. 2023, 626, 157240. [Google Scholar] [CrossRef]

- Sun, D.; Zhu, L.; Cai, Y.; Yan, Y.; Ge, F.; Shan, M.; Tian, Y.; Han, J.; Jiang, Z. Tribology comparison of laser-cladded CrMnFeCoNi coatings reinforced by three types of ceramic (TiC/NbC/B4C). Surf. Coat. Technol. 2022, 450, 129013. [Google Scholar] [CrossRef]

- Huang, C.; Zhang, Y.; Vilar, R.; Shen, J. Dry sliding wear behavior of laser clad TiVCrAlSi high entropy alloy coatings on Ti–6Al–4V substrate. Mater. Des. 2012, 41, 338–343. [Google Scholar] [CrossRef]

- Wen, X.; Cui, X.; Jin, G.; Zhang, X.; Zhang, Y.; Zhang, D.; Fang, Y. Design and characterization of FeCrCoAlMn0.5Mo0.1 high-entropy alloy coating by ultrasonic assisted laser cladding. J. Alloys Compd. 2020, 835, 155449. [Google Scholar] [CrossRef]

| Preparation Method | Process Parameters | Substrate Materials | HEAs | Ceramic Particles | Phase (Minor–Major) | Optimal Performance | Ref. |

|---|---|---|---|---|---|---|---|

| In situ | LP 1500 W SR 7.5 mm/s SD 3 mm OR 40% | 304 stainless steel | CoCrCuFeNiSi0.2 | TiC | FCC,TiC | H = 498.5 HV WV = 0.42 mm3 | [31] |

| LP 2400 W SR 5 mm/s SD4.6 mm OR 40% | AISI 1045 steel | AlCoCrFeNiTix (x = 0, 0.2, 0.4, 0.6, 0.8, 1.0) | TiC | Two BCC,TiC | H = 860.1 HV HWR = 5.8 × 10−8 mm3N−1m−1 | [32] | |

| LP 1500 W SR 5 mm/s SD 3 mm OR 35% | Ti-6Al-4 V titanium alloy | CoCrMoNbTi | TiC | BCC1 and BCC2,TiC | H = 886.9 HV WR = 3.83 × 10−4 mm3N−1m−1 | [34] | |

| LP 1000 W SR 18 mm/s SD 35 mm OR 30% | Q235 steel | AlCoCrFeNi | Mo,TiC | BCC,TiC, | H = 1006.3 HV = 243.3 Gpa | [39] | |

| LP 1500 W SR 5 mm/s SD 3 mm OR 35% | Ti-6Al-4V titanium alloy | CoCrMoNbTi | TiC,TiB | BCC,TiC,TiB | H = 954.11 HV = 240.35 Gpa | [45] | |

| LP 600 W SR 8 mm/s SD 1 mm | H13 steel | AlCoCrFeNiSi | Ti(C, N) | FCC,BCC,B2 | H = 934 HV WL = 12 mg | [46] | |

| LP 1500 W SR 800 mm/min SD 2 mm | Ti-6Al-4V titanium alloy | MoNbTaW | TiN/(Nb, Ti)5Si3 | TiN/(Nb, Ti)5Si3,BCC | H = 628.07 HV WV = 0.95× 10−7 um3 | [64] | |

| Addition | LP 1300 W SR 5 mm/s SD 3 mm OR 30% | 4Cr5MoSiV1 die steel | FeMnCrNiCo | TiC | FCC,TiC | H = 288.3 HV | [51] |

| LP 2500 W SR 4 mm/s SD 3 mm OR 30% | Q235 steel | AlCoCrFeNi | NbC | FCC,BCC,NbC | H = 525 HV WL = 12 mg FC = 1.023 | [52] | |

| LP 2000 W SR 180 mm/min SD 20.4 mm | 316 L stainless steel | CoCrFeNiCu | SiC | FCC,SiC,Cr7C3 | H = 563.4 HV Ba = 471.6 mv CR = 0.040087 mm/a | [53] | |

| LP 2000 W SR 11 mm/s SD 4 mm | AISI1045 steel | AlxCoCrFeNiTi1-x | SiC | FCC,BCC,L21-Ni2AlTi | H = 743 HV FC = 0.31 | [54] | |

| LP 1600 W SR 10 mm/s SD 4 mm OR 50% | 316 L stainless steel | FeCoNiCr | WC | FCC,WC,W2C,Co4W2C | H = 506 HV WV = 0.041 | [55] | |

| LP 2100 W SR 800 mm/s SD 3 × 3 mm | 45 steel | CoCrFeNiMo0.2 | SiC | FCC,BCC,M23C6,M7C3 | H = 788 HV | [63] | |

| LP 1300 W SR 6 mm/s SD 3 mm OR 30% | 304 stainless steel | CrMnFeCoNiM (M = TiC, NbC, B4C) | TiC, NbC, B4C | TiC:FCC,TiC NbC:FCC,NbC B4C:M2B, M23C6,FCC | COF = 0.15–0.25 | [65] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Yong, Y.; Wang, F.; Liang, Y.; Liu, L.; Liu, H.; Gao, Y. Progress on the Properties of Ceramic Phase-Reinforced High-Entropy Alloy Composite Coatings Produced via Laser Cladding. Coatings 2024, 14, 127. https://doi.org/10.3390/coatings14010127

Zhang H, Yong Y, Wang F, Liang Y, Liu L, Liu H, Gao Y. Progress on the Properties of Ceramic Phase-Reinforced High-Entropy Alloy Composite Coatings Produced via Laser Cladding. Coatings. 2024; 14(1):127. https://doi.org/10.3390/coatings14010127

Chicago/Turabian StyleZhang, Haoran, Yaowei Yong, Fuwei Wang, Yuan Liang, Lin Liu, Hong Liu, and Yang Gao. 2024. "Progress on the Properties of Ceramic Phase-Reinforced High-Entropy Alloy Composite Coatings Produced via Laser Cladding" Coatings 14, no. 1: 127. https://doi.org/10.3390/coatings14010127

APA StyleZhang, H., Yong, Y., Wang, F., Liang, Y., Liu, L., Liu, H., & Gao, Y. (2024). Progress on the Properties of Ceramic Phase-Reinforced High-Entropy Alloy Composite Coatings Produced via Laser Cladding. Coatings, 14(1), 127. https://doi.org/10.3390/coatings14010127