Abstract

In this research, developed linseed mucilage (M)-based films loaded with E. cardamom (MCA), C. officinalis (MCO), and co-loaded with both compounds (MCACO) were evaluated. The incorporation of the active compounds modified the color (redness–greenness, and yellowness); however, the thickness remained constant in all treatments (0.0042–0.0052 mm). In addition, the solubilization time of the films (in artificial saliva) to release the active compounds fluctuates between 9 and 12 min. Furthermore, the incorporation of bioactive compounds increased the total phenolic content and antioxidant activity (DPPH and ABTS, respectively), mainly in MCA (inhibition of 81.99 and 95.80%, respectively) and MCACO (inhibition of 47.15% and 39.73%, respectively). In addition, the incorporation of these compounds also decreased the hardness (39.50%–70.81%), deformation (49.16%–78.30%), and fracturability (39.58%–82.95%). On the other hand, it did not modify the adhesiveness, except in MCO. Moreover, SEM micrographs showed a more homogeneous structure in the MCO films among the films that contained CA in the formulation (heterogeneous structure with the presence of protuberances). Finally, due to the previously reported pharmacological properties of E. cardamomun and C. officinalis, the films developed in this study could have an application as a wound dressing in dentistry.

1. Introduction

Nowadays, there is a growing global trend towards developing new natural products, such as therapeutic options for the prevention and treatment of various diseases [1,2]. Due to this, numerous researchers have determined the properties of multiple natural products with active properties of interest to the medical area [3]. In addition, recent research has focused on studying phytotherapeutic products of interest to dentistry [4,5,6].

Cardamom (Elettaria cardamomum; CA) is a perennial, aromatic, herbaceous plant belonging to the Zingiberaceae family, whose use is culinary, domestic, and medicinal. It is a species native to southwest Asia (India, Sri Lanka, Malaysia, and Indonesia), Tanzania, and Guatemala, which has been used since ancient times due to its wide variety of antimicrobial, antifungal, antioxidant, analgesic, anti-inflammatory, and anticancer properties associated with the presence of components such as phenols, tannins, terpenoids, flavonoids, and sterols, among others [7,8,9]. Further, in dentistry, it has been reported that CA possesses anti-bad breath, anticaries, antiseptic, and antimicrobial properties [10]. Multiple studies have shown that CA has been effective against microorganisms that cause infections and dental cavities [11], such as Streptococcus mutans, Candida albicans, and Lactobacillus casei [12,13,14,15]. Additionally, it has been shown that the use of CA in combination with other extracts (black pepper/black cumin/cardamom and black pepper/black cumin/cardamom/cinnamon) has a high antibacterial susceptibility against microorganisms from oral isolates [16]. Finally, some reports indicated the potential therapeutic benefits of CA for periodontal infections [17].

Moreover, C. officinalis is a plant belonging to the Fabaceae family, distributed mainly in Latin America (Brazil, Bolivia, Colombia, Peru, and Venezuela) and West Africa [18,19,20]. The main uses of CO include medical applications, nutrition, cosmetics, fuels, and wood, among others [1]. CO has been widely used in folk medicine through topical and oral administration due to its antimicrobial, antifungal, antiseptic, anti-inflammatory, and antioxidant properties, among others [3,6,20]. Regarding dental applications, various studies have demonstrated the antibacterial activity of CO against Streptococcus spp., S. mutans [21,22,23], and other oral pathogens [4]. Likewise, it has been recognized that CO has anti-inflammatory and healing activity in the oral cavity [6] and for acting as a dentin biomodifier [19]. Finally, some studies in animal models report that CO oleoresin is a safe and effective alternative therapy for inflammation and tissue repair in oral wounds [24].

On the other hand, biopolymer-based delivery systems (e.g., nano-composites, microcapsules, emulsions, hydrogels, films, or membranes, among others) have been widely used for the incorporation of bioactive compounds [6,9,20,25,26,27,28]. Additionally, membranes or biodegradable films have been designed as controlled-release systems (e.g., would dressing) for various applications in the medical area [6,20,27,29,30]. A biodegradable film is a multi-component system made from polymers (e.g., polysaccharides, lipids, and proteins), which contain in their polymer matrix a plasticizing agent (e.g., glycerol, polyethylene glycol, and sorbitol, among others) and some active compounds of interest. The most widely used polymers for the development of these biomaterials are polysaccharides, such as cellulose and its derivatives, chitosan, pectin, alginate, and recently the use of plant mucilages, among others [31].

Linseed mucilage (Linum usitatissimum) is a natural polysaccharide composed of an acidic fraction of pectic-like material (L-galactose, L-fucose, L-rhamnose, and D-galacturonic acid) and a neutral fraction (arabinoxylan, D-galactose, L-arabinose, and D-xylose) [32]. This polymer has been used to produce biodegradable films in various applications, either as an individual polymer [33] or in combination with other polymers, such as chitosan [34,35], pectin [36,37], and polyvinyl alcohol [38]. Likewise, this mucilage has been used to produce active biodegradable films incorporated with carvacrol [39] and Hamamelis virginiana extract [31].

Finally, various studies have focused on the production of membranes or active films based on chitosan [20,27,30,40], poly (L-co-D, L lactic acid), and poly (lactic acid)/poly (vinyl pyrrolidone) [6] incorporated with CO for applications in the medical area, mainly as wound dressing. Furthermore, films based on mung bean protein-apple pectin [41] and soy protein isolate loaded with CA [42] have been developed, mainly for applications in the food area.

However, as far as we know, there are no reports of linseed mucilage-based films incorporated with CO and CA for dental applications. Therefore, in this context, this research aimed to produce and characterize films based on linseed mucilage (M) loaded with E. cardamomun (MCA), C. officinalis (MCO), and co-loaded with both compounds (MCACO) for future application in the dentistry area.

2. Materials and Methods

2.1. Vegetal Material

Linseed was purchased at a local supermarket (Mty NL, Mexico). On the other hand, the seeds of E. cardamomum (SKU: 209740-01) were purchased from Starwest Botanicals (Sacramento, CA, USA). Finally, C. officinalis essential oil was purchased from Young Living Essential Oils, LC Company (Lehi, UT, USA).

2.2. Obtaining the Extract of E. cardamomum

The extract was obtained by cold maceration without stirring [43]. Vegetable material (100 g) was placed in a flask containing 400 mL of absolute ethanol (99.5%, CTR Scientific, Mty NL, Mexico; extraction solvent). The sample was left to rest for a period of 24 h, filtered (Whatman™ qualitative filter paper, grade 1), and then placed in a rotary evaporator (IKA RV10, Hayward, CA, USA). Finally, the yield of the extract (% Yield = [final weight of dry extract/initial weight of the plant] × 100) was determined, and the product was stored in a dark container under refrigerated conditions (4.0 ± 2.0 °C) until its later use.

2.3. Linseed Mucilage Extraction

The linseed mucilage was extracted according to the methodology reported by Treviño-Garza et al. [31]. Briefly, the flaxseeds (300 g) were placed in distilled water (1000 mL) and kept under constant agitation (250 rpm, 25 ± 2 °C for 2 h). Next, the linseeds were removed with a strainer. Subsequently, ethanol (96%, 2000 mL; CTR Scientific, Mty N.L., Mexico) was added to the resulting aqueous suspension for mucilage precipitation. Finally, the precipitated mucilage was recovered with the help of a strainer and subsequently dried (55 ± 2 °C for 24 h), pulverized, and stored until later use.

2.4. Phytochemical Tests of Plant Material

The phytochemical profile of plant material was carried out according to the methodology reported by Guillén-Meléndez et al. [44] and Rodríguez-Garza et al. [45]. In these determinations, the presence (+) or absence (−) of compound groups was analyzed using the following tests: Lieberman–Buchard (sterols, triterpenes), Shinoda (flavonoids), Baljet (sesquiterpene-lactones), sulfuric acid (quinones), ferric chloride (tannins), potassium permanganate (unsaturations), 2,4-dinitrophenylhydrazine (carbonyl group), Dragendorff (alkaloids), sodium hydroxide (coumarins, lactones), Molish (carbohydrates), and foam test (saponins).

2.5. Production and Preliminary Characterization of Films Based on Linseed Mucilage Loaded with CA and CO

Four film-forming solutions based on linseed mucilage and loaded with E. cardamom (MCA), C. officinalis (MCO), and co-loaded with both compounds (MCACO) were designed. Glycerol (99.50% purity, CTR Scientific, Mty N.L., Mexico) was used as a plasticizer and tween 20 (polyoxyethylene-20-sorbitan monolaurate; Sigma Aldrich, St. Louis, MO, USA) as a surfactant agent. The formulations were prepared with the concentrations indicated in Table 1 in distilled water and by constant mechanical stirring (500 rpm, 25 ± 2 °C) until complete dissolution of all the components was achieved. Subsequently, the films were prepared by the casting method; the film-forming solutions (~10 mL) were placed in plastic boxes (60 mm × 15 mm) to be later subjected to a drying process (55 ± 2 °C for 24 h). Finally, the films were manually retrieved and characterized, as indicated in the following sections.

Table 1.

Film-forming solutions based on linseed mucilage (M) and incorporated with E. cardamomum (CA) and C. officinalis (CO).

2.5.1. Color Determination

The color analysis of the films was performed using a colorimeter (Hunterlab model, Colorflex® EZ, Reston, VA, USA), based on the CIE L*a*b* color space (CIELAB; L* coordinate or lightness, 0 black—100 white; coordinate a*, (−) green and (+) red; coordinate b*, (−) blue and (+) yellow) [27,42].

2.5.2. Thickness Measurement

Thickness determinations were carried out using a digital micrometer (Quickmike Model Mitutoyo, Kawasaki, Japan); measurements were made at three random positions on each film, and the results were expressed in millimeters (mm) [40,42].

2.5.3. Solubility Tests in Artificial Saliva

For the solubility analysis, the films were cut into discs (20 mm in diameter) and placed in beakers containing 50 mL of artificial saliva (Viarden brand, 25 ± 2 °C). Subsequently, the solubilization time of the complete films (minutes, min) was determined [31].

2.5.4. Antioxidant Activity (DPPH, 1,1-Diphenyl-2-picrylhydrazyl, and ABTS, 2,2’-Azino-bis-3-ethylbenzothiazoline-6-sulfonic Acid) and Total Phenolic Content

The antioxidant activity was calculated by using the DPPH and ABTS free radical (Sigma Aldrich, St. Louis, MO, USA) methods based on previous studies with some modifications [31,46,47]. For sample preparation, films (1 cm × 1 cm) were cut, weighed, and placed in 1 mL of distilled water and vortexed until complete solubilization. Later, the samples were centrifuged (Spectrafuge 6C Labnet International, Inc., Edison, NJ, USA) at 6500 rpm for 10 min to recover the supernatant.

For the DPPH method, the sample (0.75 mL) was placed in conical tubes containing 2.25 mL of the DPPH ethanolic solution (0.039 mg/mL, absorbance = 1.0 ± 0.005). The samples were incubated at 25 °C in the dark for a period of 90 min to allow for the reaction. Subsequently, the samples were centrifuged (Spectrafuge 6C, Labnet International, Inc., 6500 rpm for 5–10 min), and the absorbance was determined with a UV-VIS spectrophotometer (Genesys 5, Thermo Spectronic, Rochester, NY, USA) at 517 nm. A calibration curve was made (y = −0.0052x + 0.7161, R2 = 0.99) using Trolox (Sigma Aldrich, St. Louis, MO, USA) as a standard.

For the ABTS method, the sample (0.30 mL) was added to conical tubes containing 2.70 mL of the ABTS radical solution (ABTS, 7.00 mM, and potassium persulfate, 2.45 mM, 1:1 ratio, absorbance = 0.7 ± 0.005). The samples were incubated at 25 °C in the dark for a period of 7 min to allow for the reaction. Subsequently, the samples were centrifuged (Spectrafuge 6C, Labnet International, Inc., 6500 rpm for 5–10 min), and the absorbance was determined with a UV-Vis spectrophotometer (Genesys 5, Thermo Spectronic, Rochester, NY, USA) at 734 nm (ABTS). A calibration curve was made (y = −0.0024x + 0.577, R2 = 0.99) using Trolox (Sigma Aldrich, St. Louis, MO, USA) as a standard.

Finally, the results were expressed as μM Trolox equivalents (TE)/g of film for both methods. Additionally, the antioxidant activity was also determined by the percentage of inhibition, according to the following equation: inhibition scavenging activity (%) = (absorbance of the radical solution − absorbance of the sample/absorbance of the radical solution) × 100.

The total phenolic content of the films was calculated using the Folin–Ciocalteu (Sigma Aldrich, St. Louis, MO, USA) technique with some modifications [48,49]. The samples (1.6 mL) were placed in conical polypropylene tubes (15 mL). Subsequently, the Folin–Ciocalteu reagent (0.1 mL) and sodium carbonate (20% w/v, 0.3 mL, CTR Scientific, Mty N.L., Mexico) were added, and the solutions were homogenized in a vortex (Mixer Labnet International, Inc., Edison, NJ, USA). The samples were kept at rest in dark conditions (90 min at 25 °C) and then were centrifuged (Spectrafuge 6C Labnet International, Inc., Edison, NJ, USA; 6500 rpm for 10 min) and analyzed at 760 nm in a UV-Vis spectrophotometer (Genesys 5, Thermo Spectronic, Rochester, NY, USA). Finally, a calibration curve was made using gallic acid (Sigma Aldrich, St. Louis, MO, USA) as a standard (y = 0.07x − 0.2533 R2 = 0.9958), and the total phenolic content was expressed as µg of gallic acid equivalents (GAE)/g of film.

2.5.5. Texture Profile Analysis (APT)

The texture analysis of the films was carried out with the help of a texturometer (Brookfield, CT3, Middleboro, MA, USA). The films (60 mm in diameter) were placed in the equipment and analyzed with the TA44 probe (cylinder 4 mm diameter), with an activation load of 0.070 N, a test speed of 0.50 mm/s, and a load range of 1000 g. The parameters evaluated were hardness (N; newtons), percentage deformation (%), adhesiveness (mJ; millijoules), and fracturability (N; newtons).

2.5.6. Field Emission Scanning Electron Microscopy (FE-SEM)

Film microscopy (10 × 10 mm) was performed with a field emission scanning electron microscope (Zeiss Sigma 300 VP, Jena, Germany) under high vacuum conditions, with a secondary electron detector considering a voltage of 5 kV, and at a working distance of 6 mm. Prior to analysis, the films were coated with gold (sputtering) to obtain better imaging conditions. Finally, micrographs were taken at 200× and 1500× magnification.

2.6. Statistical Analysis

The results of color, thickness, solubility, antioxidant activity, total phenols, and texture profile were analyzed by analysis of variance (ANOVA) and Tukey’s test, with a significance level of p ≤ 0.05, using the SPSS software (IBM version 22, SPSS Inc., Chicago, IL, USA).

3. Results and Discussion

3.1. Phytochemical Analysis of Plant Extracts

In the first place, the yield of the CA extract was 5.80%, in agreement with that reported by Cárdenas-Garza et al. [2]. Moreover, the phytochemical analysis showed that the plant material contains a complex mixture of various components [45]. Table 2 shows that E. cardamomum and linseed mucilage were positive for eight of the phytochemical tests, except for quinones, coumarins, and saponins. Additionally, the chemical composition of the cardamom extract (α-terpinyl acetate, mainly) has been reported in previous studies by our working group [2]. In addition, C. officinalis was positive only for six tests performed (sterols and triterpenes, flavonoids, unsaturations, carbonyl group, alkaloids, and carbohydrates). These results agree with what was reported by Hanaa et al. [50] and Yasmeen et al. [51], who have found some of these components in the linseed. In addition, the presence of some of these phytochemical compounds has also been reported in the essential oil of C. officinalis [52] and natural extracts of E. cardamomum [2,53,54]. Finally, this type of phytochemical compound has been characterized by having multiple pharmacological properties, among which stand out anti-inflammatory, anticancer, antiseptic, antimicrobial, and antioxidant activities, among others [2,4]. Likewise, due to its composition, copaiba oil has been characterized by reducing the formation of dental biofilm [21], thus counteracting some oral pathogens [4], presenting an anti-inflammatory effect and healing in the oral cavity [55], and acting as a dentin biomodifier [19]. On the other hand, cardamom is efficient in reducing the levels of microbial viability in the dental biofilm [15], having a potential therapeutic effect on periodontal infections [17], and improving oral hygiene [16].

Table 2.

Partial phytochemical screening of plant extracts.

3.2. Development and Partial Characterization of Films Based on Linseed Mucilage Loaded with CA and CO

3.2.1. Film Production

The control films and those incorporated with the extracts (MCA, MCO, MCACO) were successfully produced (Table 3). The films obtained (60 mm in diameter) were thin and slightly flexible, with an opaque appearance, a light brown hue (control and MCO), and a more intense brown color (MCA and MCOCA). These results are similar to those reported in previous studies [30,31,42].

Table 3.

Macroscopic characteristics of films based on linseed mucilage (M) and incorporated with E. cardamomum (CA) and C. officinalis (CO).

3.2.2. Physicochemical Properties

Color and Thickness

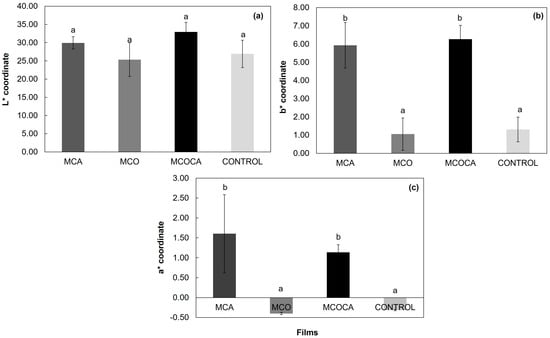

The color properties affect the visual appearance and could influence the patient’s perception of the product. Regarding color, no significant difference (p > 0.05) was found in the luminosity values between the different treatments, whose values fluctuated between 25.33 and 32.93 (Figure 1). This finding agrees with the literature since Hajirostamloo et al. [42] reported that the L* values remain constant at a concentration of 1% CO but increase at a concentration of 5% in protein isolate films containing cardamom essential oil. Likewise, Rodrigues et al. [56] indicated that the addition of CO oil (10%) does not affect the luminosity of starch-based films incorporated with copaiba oil. On the contrary, for the values of a* and b*, a significant difference (p < 0.05) was found between the treatments; the values in both coordinates were highest for MCA (a* = 1.60 ± 0.98 and b* = 5.93 ± 1.25) and MCOCA (a* = 1.14 ± 0.19 and b* = 6.27 ± 0.76), while the lowest values were for MCO (a* = −0.40 ± 0.03 and b* = 1.05 ± 0.88) and the control (a* = −0.31 ± 0.02 and b* = 1.31 ± 0.68) (Figure 1). According to what was reported by Hajirostamloo et al. [42], the incorporation of CO into the films affected the optical attributes, increasing the values of a* and b* coordinates, as observed in the MCO and MCACO treatments. On the other hand, Rodrigues et al. [56] reported that the color of the films was directly related to the color of the polymer and the oil or extract incorporated into the formulation. In addition, they also reported that the CO oil provided a slightly yellowish coloration to the films, which was more accentuated as the concentration of CO in the polymer matrix increased. Therefore, it is likely that, since the color of CO is similar to that of linseed mucilage, the MCO and control films are very similar in the a* and b* coordinate values.

Figure 1.

Color properties (a) luminosity, (b) blueness (−)—yellowness (+), and (c) redness (−)–greenness (+) of films based on linseed mucilage (M) and incorporated with E. cardamomum (CA) and C. officinalis (CO). Different letters (a,b) indicate significant differences (p < 0.05) between treatments.

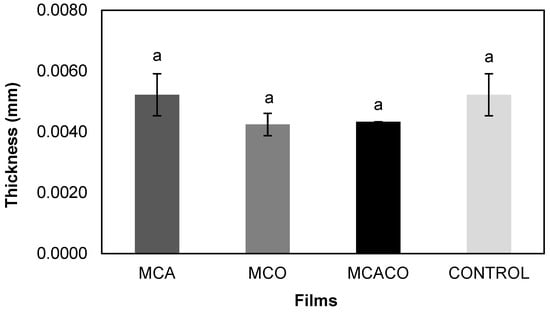

The thickness is an important parameter since thin films tend to be less uncomfortable for the patient. In the thickness parameter, no significant difference (p < 0.05) was found between the treatments, and the values fluctuated between 0.0043 and 0.0052 mm (Figure 2). These results agree with those found by Herrera Brandelero et al. [57] and Rodrigues et al. [56], who reported that the incorporation of CO oil did not modify the thickness of films made from starch/PVOH/alginate and starch, respectively. Moreover, Hajirostamloo et al. [42] reported an increase in the thickness of the films when incorporating CA; this parameter increases with the increase in the amount of extract (5–20%) in a polymeric matrix of soy protein isolate.

Figure 2.

Thickness of films based on linseed mucilage (M) and incorporated with E. cardamomum (CA) and C. officinalis (CO). Letters (a) indicate no significant differences (p > 0.05) between treatments.

Solubility Tests in Artificial Saliva

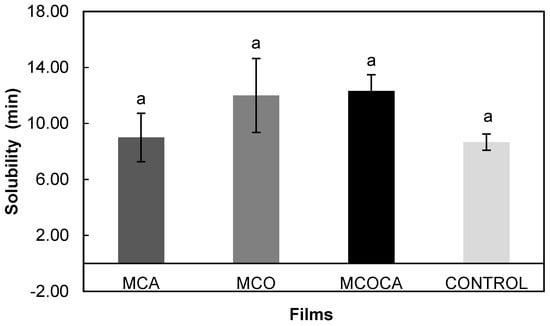

In the case of the solubility of the films, although the values were higher for MCO (12.00 ± 2.65 min) and MCA (9.00 ± 1.73 min), no significant difference (p < 0.05) was found between the treatments (MCOCA = 12.33 ± 1.15 and control = 8.67 ± 0.58), indicating that the incorporation of the extracts into the polymeric matrix does not modify this property (Figure 3).

Figure 3.

Solubility in artificial saliva of films based on linseed mucilage (M) and incorporated with E. cardamomum (CA) and C. officinalis (CO). Letters (a) indicate no significant differences (p > 0.05) between treatments.

According to what was reported by Puligundla and Lim [32], linseed mucilage shows a high degree of swelling and solubility in aqueous solutions. The water absorption leads to swelling and solubilization of the films, allowing the complete release of the active compounds incorporated within the polymeric matrix towards the artificial saliva. This behavior is directly associated with the hydrophilic nature of the polysaccharide and with the slightly branched structure of the linseed mucilage, which leads to the film dissolving and losing its structure over time [37]. In addition, the difference in the solubility time of the MCO and MCACO films could be related to the low solubility of the CO oil in water (the main component of artificial saliva) [3,26,30]. Likewise, Rodrigues et al. [56] reported that the addition of CO oil decreased the hydrophilic character of the films, leading to lower solubility. This behavior can be attributed to the fact that the interaction between the hydroxyl groups of the polymeric matrix and the oil components makes the -OH groups less available and, consequently, the solubility time of the films in artificial saliva increases.

Antioxidant Activity (DPPH and ABTS) and Total Phenolic Content

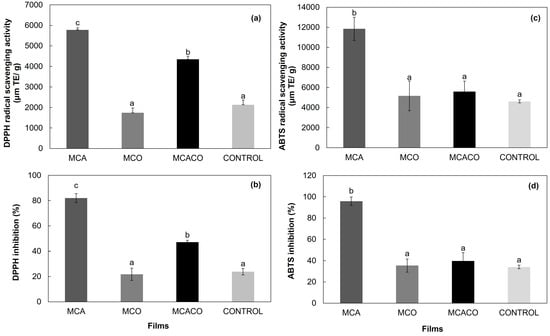

Regarding the antioxidant activity of the films, significantly higher values (p < 0.05) were for MCA (DPPH = 5781.38 ± 92.10 μm TE/g, 81.99 ± 3.56% inhibition and ABTS = 11,855.82 ± 1159.46 μm TE/g, 95.80 ± 3.98% inhibition), followed by MCACO treatment (DPPH = 4345.29 ± 150.87 μm TE/g, 47.15 ± 1.46% inhibition and ABTS = 5598.14 ± 1051.41, 39.73 ± 7.77% inhibition). The lowest values were for MCO (DPPH = 1740.18 ± 236.51 μm TE/g, 21.78 ± 4.83% inhibition and ABTS = 5174.77 ± 1487.98 μm TE/g, 35.38 ± 6.22% inhibition) and the control (DPPH = 2132. 39 ± 229.87 μm TE/g, 23.85 ± 2.57% inhibition and ABTS = 4615.74 ± 154.00 μm TE/g, 34.04 ± 1.66% inhibition) (Figure 4).

Figure 4.

(a,b) DPPH and (c,d) ABTS radical scavenging activity and inhibition (%) of films based on linseed mucilage (M) and incorporated with E. cardamomum (CA) and C. officinalis (CO). Different letters (a,b,c) indicate significant differences (p < 0.05) between treatments.

These results agree with what was found by Hajirostamloo et al. [42], who reported that the incorporation of CA significantly increased the antioxidant activity of the films, which is accentuated by the increase in the concentration of CA in the polymeric matrix (% of inhibition of 9.10–63.61% with concentrations of 1–20% of CA, respectively), as we found in the MCA and MCACO films (Figure 4). Furthermore, the antioxidant activity provided by CO has also been previously reported in other applications [58], similar to that found in MCO films. Finally, the antioxidant activity reported in the control films is higher than that reported in other films made from linseed mucilage [31]; this behavior could be related to the polymer extraction processes, as well as the variety of seeds used for its recovery.

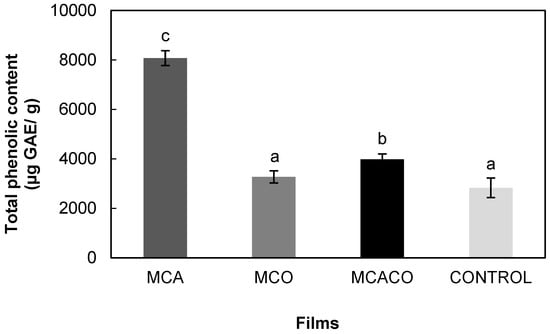

In the case of the total phenolic content (Figure 5), the highest values were for MCA (8076.49 ± 297.66 µg GAE/g), followed by MCACO (3985.25 ± 213.21 µg GAE/g), while the lowest values were for MCO and the control (3270.18 ± 243.99 and 2831.16 ± 392.69 µg GAE/g, respectively). These results agree with what was found in the DPPH and ABTS antioxidant activity analyses (Figure 4), which reflect a higher activity in MCA and MCACO, which can be associated with a higher total phenolic content in CA. In general, the antioxidant properties of the films developed in this study can be attributed to the content of antioxidant compounds present in the extract, oil, and linseed mucilage, such as sterols, triterpenes, flavonoids, tannins, phenols, and alkaloids, among others (Table 1), which have been reported in previous studies [2,18,52,59,60]. In addition, the mechanism for the action of these compounds is associated with the donation of a hydrogen atom and/or electrons to free radical chemical species to prevent cell damage by reducing oxidative stress, reactive oxygen species (ROS) and nitrogen (RON), oxidation of lipids, proteins, and DNA [58,61].

Figure 5.

Total phenolic content of films based on linseed mucilage (M) and incorporated with E. cardamomum (CA) and C. officinalis (CO). Different letters (a,b,c) indicate significant differences (p < 0.05) between treatments.

3.3. Texture Profile Analysis (TPA)

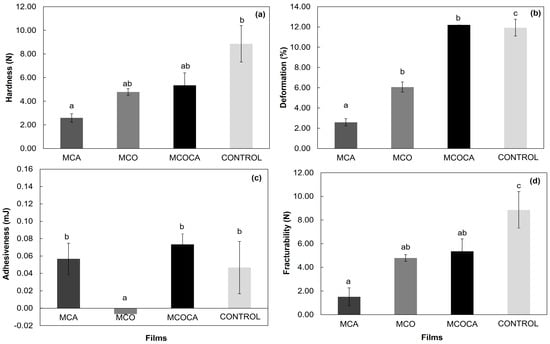

Hardness, Deformation, Adhesiveness and Fracturability

The textural properties of the films provide information to understand the behavior of materials. Regarding the texture analysis of the films, it was observed that the incorporation of CA or CO decreased (p < 0.05) the hardness of the films (Figure 6a). Hardness refers to the maximum force required to compress the films between the molars, the tongue, or the palate [62]. The control film presented the highest hardness value (8.86 ± 1.54 N), and the MCA film had the lowest value (2.59 ± 0.35 N). In addition, the MCOCA and MCO films presented similar values, fluctuating between 4.78 and 5.35 N. According to the report by [31], the incorporation of extracts and essential oils into the films provides them a plasticizing effect since they reduce the interchain interaction forces of the polymer, increasing the mobility of the chains and providing greater flexibility. Consequently, the film has a less rigid and more malleable structure; this behavior can be attributed to the presence of hydroxyl groups (-OH) that form H bonds with the mucilage, increasing the mobility and decreasing the hardness of the polymeric matrix.

Figure 6.

Textural properties: (a) hardness, (b) deformation, (c) adhesiveness and (d) fracturability of films based on linseed mucilage (M) and incorporated with E. cardamomum (CA) and C. officinalis (CO). Different letters (a,b,c) indicate significant differences (p < 0.05) between treatments.

Furthermore, it was found that the incorporation of CA and CO significantly decreased (p < 0.05) the deformation of the films (Figure 6b). In general, the deformation of the film occurs when the applied compressive stress changes the internal structure of the material, which prevents it from returning to its structural or dimensional original. The highest deformation values were found in MCACO and control treatments (11.93 ± 0.83% and 12.20 ± 0.00%, respectively). The lowest deformation values were obtained for MCA and MCO (2.59 ± 0.35% and 6.07 ± 0.49%, respectively). The improvement in this property could be related to the ability of the essential oil or extract to induce the reorganization of the polymeric network in the film matrix, which leads to the formation of films with a more stable structure [63].

The adhesiveness parameter refers to the work required to overcome the attractive force between the film and a surface [62]. The lowest value (p < 0.05) was obtained for the MCO treatment (−0.01 ± 0.00 mJ). The control, MCA, and MCO films presented similar values that fluctuated between 0.05 and 0.07 mJ (Figure 6c). In general, most of the films (MCA, MCOCA, and control) showed very similar adhesiveness values; the low values found for MCO could be related to the characteristics of the CO oil, which influence the final properties of the film.

Finally, fracturability refers to the force necessary to fracture the film [62]. In this parameter, it was found that the incorporation of the extracts decreased the fracturability of the films. The highest values were for the control (8.86 ± 1.54 N), followed by MCOCA (5.35 ± 1.05 N), MCO (4.78 ± 0.28 N), and MCA (1.51 ± 0.75) (Figure 6d). As previously mentioned, the incorporation of essential oils and extracts into the film matrix can cause a rearrangement of the polymer chains, as well as a plasticizing effect that provides a film with a more stable and fracture-resistant polymer structure [63].

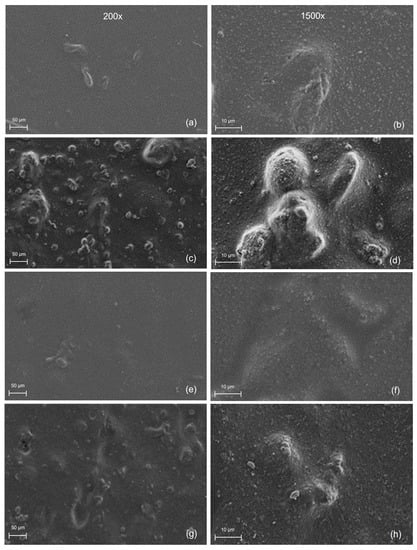

3.4. Microscopic Analysis

The FE-SEM analysis is an essential tool for analyzing the films at the microscopic level. Regarding the microscopic analysis of the control and MCO, the films presented a more homogeneous microstructure, as well as a smooth (with few bulges) and continuous surface, similar to that reported by Karami et al. (chitosan-linseed mucilage films) [35], Debone et al. (chitosan/copaiba oleoresin films) [27], Norcino et al. (pectin films loaded with copaiba oil nanoemulsions) [36], and Pinto et al. (copaiba essential oil loaded-nanocapsules films) [40]. Otherwise, the MCA and MCACO films presented a more heterogeneous microstructure, a rough surface with the presence of discontinuous matter (bulges) in the polymer matrix associated with the presence of components of the CA extract; this effect has also been reported in protein isolate films containing cardamom essential oil [42] (Figure 7).

Figure 7.

Surface micrographs (200× and 1500×) of films based on linseed mucilage (M) and incorporated with E. cardamomum (CA) and C. officinalis (CO); control (a,b), MCA (c,d), MCO (e,f), and MCOCA (g,h).

4. Conclusions

In their composition, E. cardamomum and C. officinalis compounds had evidence of the presence of phytochemicals, such as sterols, triterpenes, flavonoids, alkaloids, tannins, and phenols, among others. Moreover, it was possible to produce linseed mucilage-based films incorporated with E. cardamomun, C. officinalis, and co-loaded with both bioactive compounds. The addition of the active compounds in the films modified the color (redness–greenness and yellowness). However, the thickness parameter remained constant in all treatments (0.0042–0.0052 mm). In addition, the solubility time was higher for films containing CO (~12 min). Furthermore, the addition of the bioactive compounds increased the antioxidant activity and the total phenolic content, mainly in the films incorporated with CA. Regarding the texture analysis, the incorporation of the active ingredients decreased the hardness (39.50%–70.81%), deformation (49.16%–78.30%), and fracturability (39.58%–82.95%); however, it did not modify the adhesiveness, except in MCO. On the other hand, the FE-SEM micrographs showed a more homogeneous structure for the MCO films with respect to the films that contained CA in the formulation (heterogeneous structure with the presence of protuberances). Finally, due to the previously reported pharmacological properties of E. cardamomun and C. officinalis (anti-inflammatory, antimicrobial, antioxidant, among others), the films developed in this research could have a potential application in the area of dentistry as a wound dressing. However, it is necessary to continue with this research to evaluate the mechanical (tensile strength and elongation at break), antimicrobial, anti-inflammatory, and cytotoxic properties, as well as consider the development of in-vivo studies to broadly understand the properties of the films.

Author Contributions

Conceptualization, O.E.R.-L., M.Z.T.-G. and A.K.S.-V.; methodology, A.K.S.-V., M.Z.T.-G., J.G.B.-G., J.H.E.-L. and M.d.R.L.-B.; software, O.E.R.-L., J.G.B.-G. and M.Z.T.-G.; validation, O.E.R.-L., J.G.B.-G. and M.Z.T.-G.; formal analysis, O.E.R.-L., M.Z.T.-G., A.C.-M., S.M.L.-V., J.G.B.-G., J.H.E.-L. and M.d.R.L.-B.; investigation, A.K.S.-V., M.Z.T.-G., J.G.B.-G. and O.E.R.-L.; resources, O.E.R.-L., J.G.B.-G. and M.Z.T.-G.; data curation, O.E.R.-L., J.G.B.-G. and M.Z.T.-G.; writing—original draft preparation, M.Z.T.-G. and A.K.S.-V.; writing—review and editing, M.Z.T.-G., O.E.R.-L. and J.G.B.-G.; visualization, O.E.R.-L., A.K.S.-V. and M.Z.T.-G.; supervision, M.Z.T.-G., O.E.R.-L. and J.G.B.-G.; project administration, O.E.R.-L. and M.Z.T.-G.; funding acquisition, O.E.R.-L., M.Z.T.-G. and J.G.B.-G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Scientific and Technological Research Support Program of the Universidad Autónoma de Nuevo Leon (UANL), PAICYT CT1600-21 and CN1930-21.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

To the CONAHCYT, National Council of Humanities, Sciences, and Technologies, for the support granted through scholarship 003989.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Da Trindade, R.; Da Silva, J.K.; Setzer, W.N. Copaifera of the Neotropics: A review of the phytochemistry and pharmacology. Int. J. Mol. Sci. 2018, 19, 1511. [Google Scholar] [CrossRef] [PubMed]

- Cárdenas-Garza, G.R.; Elizondo-Luévano, J.H.; Bazaldúa-Rodríguez, A.F.; Chávez-Montes, A.; Pérez-Hernández, R.A.; Martínez-Delgado, A.J.; López-Villarreal, S.M.; Rodríguez-Rodríguez, J.; Sánchez-Casas, R.M.; Castillo-Velázquez, U.; et al. Benefits of cardamom (Elettaria cardamomum (L.) Maton) and turmeric (Curcuma longa L.) extracts for their applications as natural anti-inflammatory adjuvants. Plants 2021, 10, 1908. [Google Scholar] [CrossRef]

- De Medeiros, M.L.; Xavier-Júnior, F.H.; Araújo-Filho, I.; Rêgo, A.C.; Veiga-Júnior, V.F.; Maciel, M.A. Copaiba oil for nano-pharmaceutics and drug delivery. Encycl. Nanosci. Nanotechnol. 2019, 27, 165–189. [Google Scholar]

- Diefenbach, A.L.; Muniz, F.W.M.G.; Oballe, H.J.R.; Rösing, C.K. Antimicrobial activity of copaiba oil (Copaifera ssp.) on oral pathogens: Systematic review. Phytother. Res. 2018, 32, 586–596. [Google Scholar] [CrossRef]

- Ilyas, H.; Iqbal, M.J. Importance of some therapeutic plants and their antimicrobial activity to maintain oral health. Biochem. Pharmacol. An. Open Access J. 2021, 10, 08. [Google Scholar]

- Pinto, M.F.; Quevedo, B.V.; Asami, J.; Komatsu, D.; Hausen, M.D.A.; Duek, E.A.D.R. Electrospun membrane based on poly(L-co-D,L lactic acid) and natural rubber containing copaiba oil designed as a dressing with antimicrobial properties. Antibiotics 2023, 12, 898. [Google Scholar] [CrossRef] [PubMed]

- Noumi, E.; Snoussi, M.; Alreshidi, M.M.; Rekha, P.D.; Saptami, K.; Caputo, L.; De Martino, L.; Souza, L.F.; Msaada, K.; Mancini, E.; et al. Chemical and biological evaluation of essential oils from cardamom species. Molecules 2018, 23, 2818. [Google Scholar] [CrossRef] [PubMed]

- Moulai-Hacene, F.; Boufadi, M.Y.; Keddari, S.; Homrani, A. chemical composition and antimicrobial properties of Elettaria cardamomum extract. Pharmacogn. J. 2020, 12, 1058–1063. [Google Scholar] [CrossRef]

- Souza, A.G.; Ferreira, R.R.; de Oliveira, E.R.; Kato, M.M.; Mitra, S.K.; Rosa, D.D.S. Chemical stabilization behind cardamom pickering emulsion using nanocellulose. Polysaccharides 2022, 3, 200–216. [Google Scholar] [CrossRef]

- Meenakshi, M.; Muralidharan, N.P. The role of cardamom oil in oral health. IJLSR 2015, 1, 322–325. [Google Scholar]

- Aneja, K.R.; Joshi, R. Antimicrobial activity of Amomum subulatum and Elettaria cardamomum against dental caries causing microorganisms. Ethnobotanical Leaflets 2009, 7, 3. [Google Scholar]

- Ibrahim, G.A.; Al–Obaidi, W.A. Effect of small cardamom extracts on Mutans streptococci in comparison to chlorhexidine gluconate and de-ionized water (in vitro study). J. Bagh Coll. Dent. 2013, 25, 104–108. [Google Scholar]

- Dahigaonkar, K.; Yelpure, S.C.; Syed, F.N.; Wajid, A.F. Use of spices in treatment of dental infections. World J. Pharm. Res. 2018, 7, 360–371. [Google Scholar] [CrossRef]

- Karimi, N.; Jabbari, V.; Nazemi, A.; Ganbarov, K.; Karimi, N.; Tanomand, A.; Karimi, S.; Abbasi, A.; Yousefi, B.; Khodadadi, E.; et al. Thymol, cardamom and Lactobacillus plantarum nanoparticles as a functional candy with high protection against Streptococcus mutans and tooth decay. Microb. Pathog. 2020, 148, 104481. [Google Scholar] [CrossRef]

- Binimeliz, M.F.; Martins, M.L.; Filho, J.C.C.F.; Cabral, L.M.; Da Cruz, A.G.; Maia, L.C.; Fonseca-Gonçalves, A. Antimicrobial effect of a cardamom ethanolic extract on oral biofilm: An ex vivo study. Nat. Oral. Care Dent. Ther. 2020, 121–131. [Google Scholar] [CrossRef]

- Makky, E.A.; Ali, M.J.; Yusoff, M.M. Oral Hygiene Improvement using Combined Mouthwash with Plant extracts. MATEC Web Conf. 2018, 150, 06034. [Google Scholar] [CrossRef][Green Version]

- Souissi, M.; Azelmat, J.; Chaieb, K.; Grenier, D. Antibacterial and anti-inflammatory activities of cardamom (Elettaria cardamomum) extracts: Potential therapeutic benefits for periodontal infections. Anaerobe 2019, 61, 102089. [Google Scholar] [CrossRef]

- Leandro, L.M.; De Sousa, V.F.; Barbosa, P.C.S.; Neves, J.K.O.; Da Silva, J.A.; Da Veiga-Junior, V.F. Chemistry and biological activities of terpenoids from copaiba (Copaifera spp.) Oleoresins. Molecules 2012, 17, 3866–3889. [Google Scholar] [CrossRef]

- Bandeira, M.F.C.L.; Freitas, A.L.; Menezes, M.D.S.C.; Silva, J.D.S.; Sombra, G.A.D.; Araújo, E.A.M.; Toda, C.; Moreschi, A.R.C.; Conde, N.C.O. Adhesive resistance of a copaiba oil-based dentin biomodifier. Braz. Oral. Res. 2020, 34, e001. [Google Scholar] [CrossRef]

- Genesi, B.P.; De Melo Barbosa, R.; Severino, P.; Rodas, A.C.; Yoshida, C.M.; Mathor, M.B.; Lopes, P.S.; Viseras, C.; Souto, E.B.; Da Silva, C.F. Aloe vera and copaiba oleoresin-loaded chitosan films for wound dressings: Microbial permeation, cytotoxicity, and in vivo proof of concept. Int. J. Pharm. 2023, 634, 122648. [Google Scholar] [CrossRef]

- Simões, C.; Conde, N.; Venâncio, G.; Milério, P.; Fulgência, M.; Veiga, V. Antibacterial activity of copaiba oil gel on dental biofilm. Open Dent. J. 2016, 10, 188–195. [Google Scholar] [CrossRef]

- Valadas, L.A.R.; Gurgel, M.F.; Mororó, J.M.; Da Cruz Fonseca, S.G.; Fonteles, C.S.R.; De Carvalho, C.B.M.; Fechine, F.V.; Neto, E.M.R.; De França Fonteles, M.M.; Chagas, F.O.; et al. Dose-response evaluation of a copaiba-containing varnish against Streptococcus mutans in vivo. Saudi Pharm. J. 2019, 27, 363–367. [Google Scholar] [CrossRef]

- Valadas, L.A.R.; Lobo, P.L.D.; Fonseca, S.G.D.C.; Fechine, F.V.; Rodrigues Neto, E.M.; Fonteles, M.M.D.F.; Aguiar Trévia, L.R.D.; Vasconcelos, H.L.P.; Lima, S.M.D.S.; Lotif, M.A.L.; et al. Clinical and antimicrobial evaluation of Copaifera langsdorffii Desf. dental varnish in children: A clinical study. Evid.-Based Complement. Altern. Med. 2021, 2021, 6647849. [Google Scholar] [CrossRef]

- Alvarenga, M.O.P.; Bittencourt, L.O.; Mendes, P.F.S.; Ribeiro, J.T.; Lameira, O.A.; Monteiro, M.C.; Barboza, C.A.G.; Martins, M.D.; Lima, R.R. Safety and effectiveness of copaiba oleoresin (C. reticulata Ducke) on inflammation and tissue repair of oral wounds in rats. Int. J. Mol. Sci. 2020, 21, 3568. [Google Scholar] [CrossRef]

- Mehyar, G.F.; Al-Isamil, K.M.; Al-Ghizzawi, H.A.M.; Holley, R.A. Stability of cardamom (Elettaria Cardamomum) essential oil in microcapsules made of whey protein isolate, guar gum, and carrageenan. J. Food Sci. 2014, 79, C1939–C1949. [Google Scholar] [CrossRef]

- Jamil, B.; Abbasi, R.; Abbasi, S.; Imran, M.; Khan, S.U.; Ihsan, A.; Javed, S.; Bokhari, H.; Imran, M. Encapsulation of cardamom essential oil in chitosan nano-composites: In-vitro efficacy on antibiotic-resistant bacterial pathogens and cytotoxicity studies. Front. Microbiol. 2016, 7, 1580. [Google Scholar] [CrossRef]

- Debone, H.; Lopes, P.; Severino, P.; Yoshida, C.; Souto, E.B.; Silva, C. Chitosan/copaiba oleoresin films for would dressing application. Int. J. Phar. 2019, 555, 146–152. [Google Scholar] [CrossRef]

- Dehghani, S.; Noshad, M.; Rastegarzadeh, S.; Hojjati, M.; Fazlara, A. Electrospun chia seed mucilage/PVA encapsulated with green cardamonmum essential oils: Antioxidant and antibacterial property. Int. J. Biol. Macromol. 2020, 161, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Bonan, R.F.; Bonan, P.R.; Batista, A.U.; Perez, D.E.; Castellano, L.R.; Oliveira, J.E.; Medeiros, E.S. Poly (lactic acid)/poly (vinyl pyrrolidone) membranes produced by solution blow spinning: Structure, thermal, spectroscopic, and microbial barrier properties. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Paranhos, S.B.; Ferreira, E.D.; Canelas, C.A.; Da Paz, S.P.; Passos, M.F.; Da Costa, C.E.; Da Silva, A.C.; Monteiro, S.N.; Candido, V.S. Chitosan membrane containing copaiba oil (Copaifera spp.) for skin wound treatment. Polymers 2021, 14, 35. [Google Scholar] [CrossRef]

- Treviño-Garza, M.Z.; Yañez-Echeverría, S.; García, S.; Mora-Zúñiga, A.; Arévalo, N.K. Physico-mechanical, barrier and antimicrobial properties of linseed mucilage films incorporated with H. virginiana extract. Rev. Mex. Ing. Quim. 2019, 19, 983–996. [Google Scholar] [CrossRef]

- Puligundla, P.; Lim, S. A Review of extraction techniques and food applications of flaxseed mucilage. Foods 2022, 11, 1677. [Google Scholar] [CrossRef] [PubMed]

- Tee, Y.B.; Wong, J.; Tan, M.C.; Talib, R.A. Development of edible film from flaxseed mucilage. BioResources 2016, 11, 10286–10295. [Google Scholar] [CrossRef]

- Salamanca, L.E.L.; Cabreta, L.E.P.; Narveaz, G.C.D.; de Alba, L.R.B. Linseed mucilage and chitosan composite films: Preparation, physical, mechanical, and microstructure properties. In Proceedings of the 11th International Congress on Engineering and Food, Athens, Greece, 22–26 May 2011. [Google Scholar]

- Karami, N.; Kamkar, A.; Shahbazi, Y.; Misaghi, A. Effects of active chitosan-flaxseed mucilage-based films on the preservation of minced trout fillets: A comparison among aerobic, vacuum, and modified atmosphere packaging. Pack. Technol. Sci. 2020, 33, 469–484. [Google Scholar] [CrossRef]

- Norcino, L.B.; Mendes, J.F.; Natarelli, C.V.L.; Manrich, A.; Oliveira, J.E.; Mattoso, L.H.C. Pectin films loaded with copaiba oil nanoemulsions for potential use as bio-based active packaging. Food Hydrocoll. 2020, 106, 105862. [Google Scholar] [CrossRef]

- Bangar, S.P.; Singh, A.; Trif, M.; Kumar, M.; Kumar, P.; Kaur, R.; Kaur, N. Process parameter optimization and characterization for an edible film: Flaxseed concern. Coatings 2021, 11, 1106. [Google Scholar] [CrossRef]

- De Paiva, P.H.; Correa, L.G.; Paulo, A.F.; Balan, G.C.; Ida, E.I.; Shirai, M.A. Film production with flaxseed mucilage and polyvinyl alcohol mixtures and evaluation of their properties. J. Food Sci. Technol. 2021, 58, 3030–3038. [Google Scholar] [CrossRef] [PubMed]

- Fang, S.; Qiu, W.; Mei, J.; Xie, J. Effect of sonication on the properties of flaxseed gum films incorporated with carvacrol. Int. J. Mol. Sci. 2020, 21, 1637. [Google Scholar] [CrossRef] [PubMed]

- Pinto, E.P.; Menezes, R.P.; Tavares, W.D.S.; Ferreira, A.M.; de Sousa, F.F.O.; Da Silva, G.A.; Zamora, R.R.; Araújo, R.S.; Souza, T.M. Copaiba essential oil loaded-nanocapsules film as a potential candidate for treating skin disorders: Preparation, characterization, and antibacterial properties. Int. J. Pharm. 2023, 633, 122608. [Google Scholar] [CrossRef]

- Sani, K.I.; Alizadeh, M. Isolated mung bean protein-pectin nanocomposite film containing true cardamom extract microencapsulation/CeO2 nanoparticles/graphite carbon quantum dots: Investigating fluorescence, photocatalytic and antimicrobial properties. Food Packag. Shelf Life 2022, 33, 100912. [Google Scholar] [CrossRef]

- Hajirostamloo, B.; Molaveisi, M.; Jafarian Asl, P.; Rahman, M.M. Novel soy protein isolate film containing cardamom essential oil microcapsules: Study of physicochemical properties and its application in Iranian white cheese packaging. J. Food Meas. Charact. 2023, 17, 324–336. [Google Scholar] [CrossRef]

- Castillo, N.E.T.; Teresa-Martínez, G.D.; Alonzo-Macías, M.; Téllez-Pérez, C.; Rodríguez-Rodríguez, J.; Sosa-Hernández, J.E.; Parra-Saldívar, R.; Melchor-Martínez, E.M.; Cardador-Martínez, A. Antioxidant activity and GC-MS profile of cardamom (Elettaria cardamomum) essential oil obtained by a combined extraction method-instant controlled pressure drop technology coupled with sonication. Molecules 2023, 28, 1093. [Google Scholar] [CrossRef] [PubMed]

- Guillén-Meléndez, G.A.; Villa-Cedillo, S.A.; Pérez-Hernández, R.A.; Castillo-Velázquez, U.; Salas-Treviño, D.; Saucedo-Cárdenas, O.; Montes-de-Oca-Luna, R.; Gómez-Tristán, C.A.; Garza-Arredondo, A.J.; Zamora-Ávila, D.E.; et al. Cytotoxic effect in vitro of Acalypha monostachya extracts over human tumor cell lines. Plants 2021, 10, 2326. [Google Scholar] [CrossRef]

- Rodríguez-Garza, N.E.; Quintanilla-Licea, R.; Romo-Sáenz, C.I.; Elizondo-Luevano, J.H.; Tamez-Guerra, P.; Rodríguez-Padilla, C.; Gomez-Flores, R. In vitro biological activity and lymphoma cell growth inhibition by selected mexican medicinal plants. Life 2023, 13, 958. [Google Scholar] [CrossRef] [PubMed]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT—Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Guzmán-Díaz, D.A.; Treviño-Garza, M.Z.; Rodríguez-Romero, B.A.; Gallardo-Rivera, C.T.; Amaya-Guerra, C.A.; Báez-González, J.G. Development and characterization of gelled double emulsions based on chia (Salvia hispanica L.) mucilage mixed with different biopolymers and loaded with green tea extract (Camellia sinensis). Foods 2019, 8, 677. [Google Scholar] [CrossRef]

- Folin, O.; Ciocalteu, V. On tyrosine and tryptophane determinations in proteins. J. Biol. Chem. 1927, 73, 627–650. [Google Scholar] [CrossRef]

- Drosou, C.; Kyriakopoulou, K.; Bimpilas, A.; Tsimogiannis, D.; Krokida, M.A. Comparative study on different extraction techniques to recover red grape pomace polyphenols from vinification by products. Ind. Crops Prod. 2015, 75, 141–149. [Google Scholar] [CrossRef]

- Hanaa, M.H.; Ismail, H.A.; Mahmoud, M.E.; Ibrahim, H.M. Antioxidant activity and phytochemical analysis of flaxseeds (Linum usitatisimum L). Minia J. Agric. Res. Develop. 2017, 37, 129–140. [Google Scholar]

- Yasmeen, M.; Nisar, S.; Tavallali, V.; Khalid, T. A review of phytochemicals and uses of flaxseed. Int. J. Chem. Biochem. Sci. 2018, 13, 70–75. [Google Scholar]

- Arroyo, J.; Almora, Y.; Quino, M.; Martínez, J.; Condorhuamán, M.; Flores, M.; Bonilla, P. Copaifera officinalis oil cytoprotector and antisecretory effects in induced gastric lesions in rats. An. Fac. Med. 2009, 70, 89–96. [Google Scholar] [CrossRef]

- Bano, S.; Ahmad, N.; Sharma, A.K. Phytochemical screening and evaluation of anti-microbial and anti-oxidant activity of Elettaria cardamom (Cardamom). J. Appl. Nat. Sci. 2016, 8, 1966–1970. [Google Scholar] [CrossRef]

- Khatri, P.; Rani, A.; Hameed, S.; Chandra, S.; Chang, C.-M.; Pandey, R.P. Current understanding of the molecular basis of spices for the development of potential antimicrobial medicine. Antibiotics 2023, 12, 270. [Google Scholar] [CrossRef] [PubMed]

- Dos Santos, M.A.C.; Alves, L.D.B.; Goldemberg, D.C.; De Melo, A.C.; Antunes, H.S. Anti-inflammatory and wound healing effect of Copaiba oleoresin on the oral cavity: A systematic review. Heliyon 2022, 8, e08993. [Google Scholar] [CrossRef]

- Rodrigues, G.M.; Filgueiras, C.T.; Garcia, V.A.D.S.; Carvalho, R.A.; Velasco, J.I.; Fakhouri, F.M. Antimicrobial activity and GC-MS profile of copaiba oil for incorporation into Xanthosoma mafaffa Schott starch-based films. Polymers 2020, 12, 2883. [Google Scholar] [CrossRef]

- Brandelero, R.P.H.; Brandelero, E.M.; Almeida, F.M.D. Biodegradable films of starch/PVOH/alginate in packaging systems for minimally processed lettuce (Lactuca sativa L.). Cien Agrotec. 2016, 40, 510–521. [Google Scholar] [CrossRef]

- Monteschio, J.D.O.; De Vargas Junior, F.M.; Alves Da Silva, A.L.; Das Chagas, R.A.; Fernandes, T.; Leonardo, A.P.; Kaneko, I.N.; De Moraes Pinto, L.A.; Guerrero, A.; De Melo Filho, A.A.; et al. Effect of copaíba essential oil (Copaifera officinalis L.) as a natural preservative on the oxidation and shelf life of sheep burgers. PLoS ONE 2021, 16, e0248499. [Google Scholar] [CrossRef]

- Kasote, D.M. Flaxseed phenolics as natural antioxidants. Int. Food Res. J. 2013, 20, 27–34. [Google Scholar]

- Bouaziz, F.; Koubaa, M.; Barba, F.J.; Roohinejad, S.; Chaabouni, S.E. Antioxidant properties of water-soluble gum from flaxseed hulls. Antioxidants 2016, 5, 26. [Google Scholar] [CrossRef]

- Arias, A.; Feijoo, G.; Moreira, M.T. Exploring the potential of antioxidants from fruits and vegetables and strategies for their recovery. IFSET 2022, 77, 102974. [Google Scholar] [CrossRef]

- González, A.; Alvis, A.; Arrázola, G. Effect of edible coating on the properties of sweet potato slices (Ipomoea Batatas Lam) cooked by deep-fat frying: Part 1: Texture. Inf. Technol. 2015, 26, 95–102. [Google Scholar] [CrossRef]

- Hashim, R.H.R.; Gunny, A.A.N.; Sam, S.T.; Kamaludin, N.H.I.; Shamsuddin, M.R. Effects of incorporation of essential oil into film for fruit packaging application. IOP Conf. Ser. Earth Environ. Sci. 2021, 765, 012020. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).