Abstract

Nutrient resources account for an enormous quantity of the world’s waste materials. According to recent research, nuts and their byproducts are good for a variety of applications and are important natural resources for nutrition. Waste and nut residues in the environment could cause environmental problems. A critical issue is how this waste is employed in various applications. Nuts contain important chemicals that could be used to build catalytic nanomaterials. A variety of heterogeneous catalysts can be created directly from different parts of nuts, such as the shell, kernel, extracts, and so on, or they can be used as nanoparticle stabilizing and reducing agents. Nuts and their wastes can be particularly essential in evolution reactions, oxidation reactions, hydrolysis, pollutant degradation, and so on due to their extraordinary chemical properties. Natural substances such as biopolymers, zeolites, diatomites, agricultural wastes (such as rice husk, bagasse pith, coconut shell, and so on), and nut wastes are used to make inexpensive catalysts. This review focuses on the industrial benefits and future applications of these commercially feasible green resources to change, for the first time, the production of nanomaterials from nuts as environmentally friendly resources and their catalytic applications.

1. Introduction

The pursuit to achieve green chemistry stands as a fundamental objective in both research and business. Strategies to reduce environmental pollution and create environmentally friendly products have been developed. The goal of green chemistry can be met by developing and implementing environmentally sound solutions. Two of the most exciting new subjects in this sector are biowaste and its valorization. Waste occurs when a chemical is abandoned without a plan to recompense it for its intrinsic value [1,2,3].

Pollutants spread quickly in the ecosystem, causing irreversible damage to the environment. These wastes may have an impact on both the environment and living things if they are not properly managed, handled, transported, stored, or disposed of. Biowastes usually contain valuable compounds and chemicals that can serve as favorable substitutes for chemical compounds when used as starting materials. These biowastes are environmentally sustainable, capable of being naturally broken down, and offer economic benefits. Furthermore, utilizing them for diverse purposes does not pose any harm to living organisms. Biowaste can be disposed of in a variety of ways, including thermal deterioration, transport to landfills, and aerobic or anaerobic microbial decomposition. Academic and industry groups have given biowaste a lot of attention in order to find ways to turn low-value wastes into innovative molecules [4,5,6].

Nuts are one of the most commonly exploited natural resources in the world, and their leftover parts, including the leaf and shell as well as the fruit that is left on the ground, are still useless. The beneficial compounds found in nuts and their byproducts can help create cost-effective and environmentally friendly solutions. The various portions of different nuts, including the leaf cashew, contain compounds called polyphenols that can be used to decrease agents and prepare nanosystems. Cashew leaf extract’s quercetin and catechin polyphenols, for example, can be oxidized to proper quinone and converted into metal nanoparticles. Nano-based systems display extraordinary efficacy as catalysts in various organic synthesis reactions and the degradation of pollutants due to excellent features such as their huge surface area and high activity. Green approaches for creating nanomaterials that use green elements as reducing and/or stabilizing agents are becoming more popular [7,8,9].

There are various types of nuts used in various applications including adsorbents, separation substrates, catalysts, catalyst supports, and energy storage devices like supercapacitors. Some of those nuts include almonds, walnuts, cashews, peanuts, pistachios, macadamia nuts, etc. [10]. This review is based on macadamia nuts and their application in direct methanol fuel cells. Fuel cells provide a promising alternative to traditional fossil fuel systems, due to their high efficiency, minimal environmental impact, and versatile application. These cells are chemical devices that convert the chemical energy of a fuel (hydrogen, alcohols, etc.) to electrical energy directly. Fuel cells can be categorized based on the temperature at which they operate. Solid oxide fuel cells and molten carbonate fuel cells are examples of high-temperature fuel cells. Medium-temperature fuel cells include alkaline fuel cells and phosphoric acid fuel cells. Lastly, low-temperature fuel cells comprise proton exchange fuel cells and direct methanol fuel cells [11].

Direct methanol fuel cells (DMFCs) have a lot of promise as alternate power sources for portable gadgets, military applications, and small-scale vehicles. They accomplish this by electrochemically turning the chemical energy in methanol fuel into electricity. The membrane electrode assembly (MEA) is the essential component of DMFCs, where oxidation and reduction reactions occur, resulting in the generation of electricity. As illustrated in Equations (1)–(3), the fundamental principle of DMFCs is based on methanol and oxygen electrochemical reactions in the anode and cathode, respectively. Methanol fuel is oxidized in the presence of water at the anode catalyst layer, resulting in the release of electrons and protons, according to Equation (1). Electrons are subsequently transferred to the cathode via an external circuit, whereas protons are transported via the proton exchange membrane [12,13,14,15,16].

Despite having a lower power density than polymer electrolyte membrane fuel cells (PEMFCs) powered by hydrogen, direct methanol fuel cells (DMFCs) offer distinct advantages due to the ease of storing, delivering, and refilling liquid methanol fuel. These advantages position DMFCs as strong contenders in the realm of sustainable energy conversion and storage devices. Additionally, DMFCs can use the existing distribution infrastructure for fuel supply, which sets them apart from hydrogen-based systems [17].

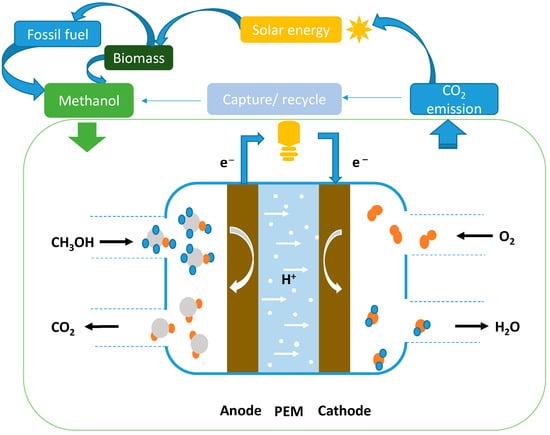

In addition, fuel cells powered by methanol offer advantages such as straightforward fuel processing systems and moderate operating conditions. Methanol, being a key product derived from the combination of carbon dioxide and solar energy, known as “liquid sunshine” (as shown in Figure 1), holds significant importance in addressing future energy and environmental challenges. DMFCs, with their high specific energy (up to 6000 Wh kg1 for pure methanol), have shown remarkable commercialization potential in various applications, including backup power for laptops, power sources for individual soldiers, forklifts, unmanned aerial vehicles, and stationary power plants [18,19].

Figure 1.

Designing various DMFC components on a multiscale and diagram showing the methanol cycle and how a single-cell DMFC functions.

Anode:

Cathode:

Overall:

CH3OH + 3/2O2 → CO2 + 2H2O

The thermodynamic potential of DMFC is 1.21 V at 25 °C, and the theoretical thermodynamic conversion efficiency of methanol via the foregoing electrochemical processes might reach as high as 96.4%, significantly above that of the internal combustion engine bound by the Carnot cycle [20]. The operation of a single-cell DMFC is depicted in Figure 1. Because of polarization loss induced by numerous resistances in the electrochemical processes and catalyst poisoning, the practical working potentials for a single-cell DMFC are lower than the theoretical value. Many papers [21,22] included quantitative studies of polarization loss in a single DMFC cell.

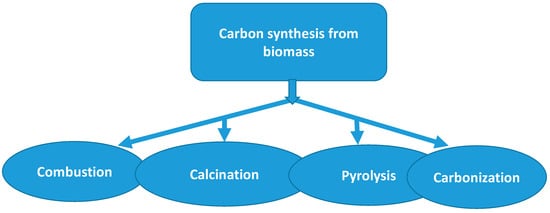

It is essential to select the appropriate type and amount of catalyst in fuel cell applications, as they play a significant role in determining the cell’s reaction rate and performance. As a result, numerous catalyst types have been studied and platinum (Pt) is one of the most commonly used catalysts. However, Pt is expensive and unstable, and requires an inert support to be stabilized. Furthermore, Pt prevents serious aggregation and coarsening during the catalytic reaction process, which reduces electrode lifetime. As a result, Pt is frequently supported on a carbon black matrix (Pt/C). This allows for improved reaction kinetics with lower Pt loadings, lowering costs [23,24]. Recently, there has been significant interest in biomass-derived carbonaceous materials because they are inexpensive, easy to prepare, and can be derived from different types (s) of biomass. Different thermochemical processes can be used to extract carbon compounds from biomass, as shown in Figure 2.

Figure 2.

Techniques for deriving carbon from biomass.

Finally, the current study presents and discusses the recent progress of carbon supports in fuel cells, giving insights into possible green technology emerging for synthesizing carbon from plants’ challenges, opportunities, and presumably futuristic breakthroughs. In this study, waste biomass (macadamia nut ash) will be used as a raw material for synthesizing defective carbon electrocatalysts for direct methanol fuel cells as support material using a microwave-assisted polyol method.

2. Types of Nuts and Their Profiles

2.1. Macadamia Nuts

It is reported that 50% of macadamia nuts are grown in South Africa and Australia followed by countries like China, Kenya, Guatemala, Malawi, Brazil, and Zimbabwe [25]. In South Africa, most macadamias are grown in KwaZulu-Natal, Mpumalanga, and Limpopo. To grow, macadamia trees need a hot, dry subtropical climate. Levubu and Tzaneen in the Limpopo Province, Hazyview, Nelspruit to Barberton in Mpumalanga, and coastal KwaZulu-Natal are where they are mostly grown in South Africa. It is a commercially cultivated crop that is harvested at temperatures between 16 and 25 °C. However, prolonged exposure to temperatures above 30 °C might impair new growth and result in early nut shedding. Nut quality is also higher when cultivated at elevations of 600 m or less. Southern African macadamia production is increasing. Macadamias have become South Africa’s fastest-growing tree crop industry, with production increasing more than 20-fold in the last 20 years. Production of nut-in-shell (NIS) increased from 1211 tons in 1991 to an estimated 61,288 tons in 2022. In South Africa, the average crack-out rate is 27.6%. This means that 72.4% of the weight of the nut in the shell is wasted as shells [10].

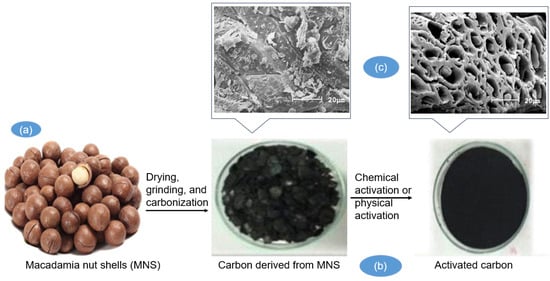

Macadamia is well-known for its tasty and nutritious nuts. The used macadamia nut shells (MNS) produce nut shells that could be hazardous waste if not handled properly. MNSs are used in various applications including adsorbents, supercapacitors, batteries, and as carbon-based, Figure 3a,b, support for low-temperature fuel cells (such as DMFCs) [26]. The MNS seems to be a promising candidate for producing microporous and mesoporous carbon materials that possess significant surface areas, distinct pore sizes, and substantial pore volumes; see Figure 3c. The presence of microstructures can improve the electrode materials’ electrochemical performance significantly by creating additional pathways for the rapid diffusion of ions [27].

Figure 3.

Activation process of carbon derived from macadamia nut shells. Adapted with permission from [28]. © 2020 Elsevier Ltd., [29] © 2018 The Chemical Industry and Engineering Society of China, and Chemical Industry Press, and [30] Copyright © 2014 Elsevier B.V.

Chang et al. [31] reported on MNS carbon material containing numerous micropores and mesopores, demonstrating improved conductivity for the infiltration of electrode materials by electrolyte. Additionally, Lu et al. [32] determined that the significant micropores and mesopores in MNS contribute to its high specific surface areas and large pore volumes, playing a crucial role in ion storage, transportation, and electrolyte penetration. This attribute also enables the materials to offer a greater number of active sites for various reactions that take place on catalyst surfaces within direct methanol fuel cells, such as the methanol oxidative reaction (MOR) and oxygen reduction reaction (ORR). The MNS is considered advantageous due to its abundance, straightforward processing methods, and durable fibrous structures [33,34,35].

2.2. Walnut

Global walnut production totals more than 3.7 Mt per year [36]. For instance, Iran ranked third in the world for walnut production in 2016 with 400,000 t. This nut’s shell contains cellulose (36%), lignin (30.1%), extractives (10.6%), and polysaccharides (49.7%) [36]. Walnut kernels are rich in polyunsaturated fatty acids, which make up around 60% of them, as well as proteins, minerals, and different polyphenols, flavonoids, and phenolic acids [37].

The walnut shell can be used as a raw material to create activated carbon and has a number of benefits. Its low ash content, outstanding chemical stability, and substantial surface area are just a few advantages. One of the most significant applications for walnut shells comprised of activated carbon is the adsorption of pollutants from aqueous solutions. Walnut-based adsorbents are the next-generation adsorbents for the removal of emerging pollutants, particularly heavy metal ions [38]. Gondhalekar and Shukla (2015) used an ion-exchange technique in their work to remove Cadmium (II) metal ions from aqueous solutions using untreated walnut shells [39]. Zhou et al. [40] reported a micro-mesoporous electrode material derived from walnuts, characterized by interconnected pores and a high surface area. These pores provided pathways for ion transport, leading to enhanced electrochemical performance supercapacitors.

2.3. Cashew

Tanzania, India, Thailand, Indonesia, Sri Lanka, Madagascar, Kenya, Senegal, Nigeria, Angola, Mozambique, and Malawi are the primary countries where cashews are harvested. The name of the plant’s tree is Anarcardium occidentale. The nuts are produced by native trees in about 97% of cases [41]. About 40% of a cashew nut is kernel, while 60% is shell. An essential by-product of cashew nut production is the cashew nut shell liquid (CNSL). It is a thick, caustic liquid that is one of the main sources of long-chain phenols in nature. Crude fat makes up 49.1% of it, followed by crude protein at 36.3%, moisture at 7.2%, crude fiber at 3.2%, ash at 2.8%, and carbohydrates at 1.4%. In addition, it contains lesser levels of zinc and iron, potassium (27.5%), calcium (21.5%), magnesium (19.3%), sodium (8.2%), and phosphorous (14.0%) [42].

When synthesizing heterogeneous catalysts, activated carbon can be produced from the shell of cashew nuts in a way that is efficient, environmentally friendly, and economical [43]. The carbon derived from cashew nuts possesses a hierarchical porous structure, which increases the active region during the ion transportation process. This expansion increases the rate of ion diffusion and decreases the distance required for charge diffusion. This unique structure also results in outstanding capacitance performance, highlighting its significant potential for use in energy storage systems [44,45,46].

2.4. Peanut

Peanuts, scientifically known as Arachis hypogaea L., are cultivated in both temperate and tropical regions. They possess seeds that are high in lipids, protein, and fatty acids [47]. These seeds are made up of fat, protein, fiber, moisture, and ash, and their sustainable, inexpensive, and abundant nature makes them suitable for producing carbonaceous compounds [48]. The peanut also contains essential elements like potassium (K), magnesium (Mg), phosphorus (P), iron (Fe), zinc (Zn), copper (Cu), and manganese (Mn) [49]. The kernels of peanuts consist of re-ducing sugars (0.2%), disaccharide sugars (4.5%), starch (4.0%), and pentosans (2.5%) [50]. Ground peanut hulls contain 39.42% cellulose, 34.56% lignin, 73.98% acid detergent fiber, and 86.16% neutral detergent fiber [51].

Additionally, peanut shells exhibit excellent carbonaceous properties that make them suitable for synthesizing solid acid catalysts [52]. Activated carbon derived from peanut shells has been utilized for the absorption of various metal ions and organic compounds, as reported in studies [53]. The presence of micropores and mesopores within the resultant carbon structure significantly facilitates the transport of ions and electrons, consequently enhancing the electrochemical performance within energy storage devices [54,55]. Table 1 contains a list of compounds extracted from nuts that have good properties and are expected to be beneficial in the design of efficient catalytic systems.

Table 1.

Physical characteristics of compounds derived from nuts [47].

3. Nuts Derived for Nanomaterials Catalysis

Xuecheng Yan and co-workers [57] effectively transformed macadamia nut shells, a type of biomass, into an active electrocatalyst for use in fuel cells and supercapacitors. In alkaline electrolytes, the ORR activity of the synthetically produced defective carbon D-MNS-A exhibits a significant improvement over the pristine carbon MNS-A. It is also more stable than Pt/C and has superior methanol tolerance. This indicates its potential application as a cathodic electrode catalyst in direct methanol fuel cells. The onset potential was 29 mV lower than that of the commercial Pt/C. Interestingly, the durability was superior to that of Pt/C [57].

Additionally, Xiaowei Lu and colleagues [58] were able to extract a highly porous carbon material with multiple micropores and mesopores [58]. This carbon material with a high surface area was extracted from macadamia nuts using an immersion technique and exposed to high temperatures [58].

Yan et al. [59] reported on a novel and simple method of synthesizing a carbon-based catalyst (NSCL-900) derived from the walnut shell doped with urea. This process resulted in a highly effective oxygen reduction reaction (ORR) performance. When tested in an alkaline electrolyte, the half-wave potential achieved 0.86 V (vs. RHE), and the initial potential was 1.00 V (vs. RHE). The improved catalytic activity was attributed to the greater number of defects and the enhanced pore structure, both of which provided more active sites in the catalyst. It was also found that the NSCL-900 catalyst is more stable and resistant to methanol poisoning than Pt/C.

In another study, Sciarria et al. [60] used biochar derived from olives and pistachio nuts as catalysts in low-temperature fuel cells. They achieved a remarkable maximum power density of 0.271 Wm−2, outperforming most typical carbon black cathodes. This outstanding electrochemical performance is due to the biochar’s advantageous properties, which include diverse oxygen and nitrogen surface functionalities and a large electrochemical surface area, which were discovered to exhibit strong catalytic activity for the oxygen reduction reaction in neutral media. These studies demonstrated that different nuts and their derivatives can indeed influence ORR activity. They can serve as effective electrocatalysts, and their unique properties, such as diverse surface functionalities and enhanced pore structures, contribute to their catalytic performance. Other examples of (nano)materials derived from nuts used for catalytic applications are shown in Table 2.

Table 2.

(Nano)materials derived from nuts used for catalytic applications [47].

4. Metal Electrocatalysts and Their Impacts

The fulfillment and feasible electrochemical conversion energy devices are mainly based on several characteristic features including efficiency, durability, and economic factors of the electrocatalysts. These aspects are holistically beneficial in the quest for the full realization and commercialization of these technologies. Nonetheless, electrochemical catalysis is still at its maturity level. Below is the discussion of two electrochemical reactions that take place in the DMFC process, which are oxidation and reduction reactions, respectively occurring at the anode and cathode of the fuel cell.

4.1. Oxygen Reduction Reaction (ORR)

ORR is an important part of electrocatalysis and plays an essential role in electrochemical energy conversion and storage. It involves several reaction mechanisms and pathways. As shown in Equations (4) and (5), the two-electron and (6)–(8) four-electron pathways result in the formation of hydrogen peroxide (H2O2) involving intermediaries *OOH, *O, and *OH, and the four-electron system involves the maximum reduction O2 to H2O primarily as the product involving only *O and *OH in its reaction mechanism [71].

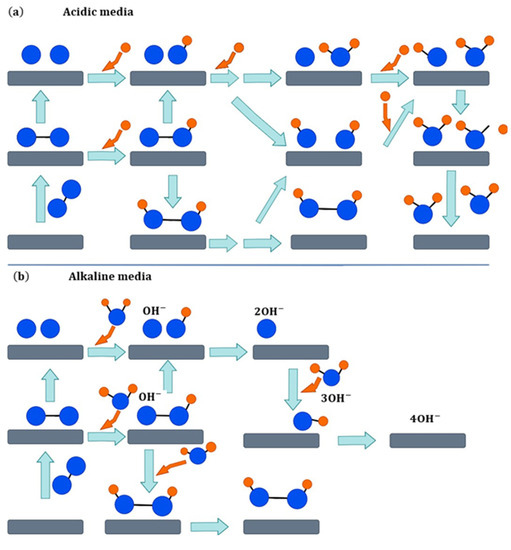

The choice between electrocatalyst and electrolyte frequently plays a crucial role in determining the path to be followed. The schematic representation shown below shows the aforementioned reactions in Scheme 1 acidic media (a) and alkaline media (b).

Scheme 1.

The ORR mechanism in both (a) acidic and (b) alkaline media. The blue and orange spheres represent oxygen and hydrogen atoms, respectively.

Amongst all the currently available catalysts, Pt-based catalysts exhibit the highest levels of performance towards ORR, making them nearly irreplaceable. However, their long-term stability is far from the application requirements, hindering the large-scale application of DMFcs. Corrosion of carbon support has been recognized as one of the interrelated factors affecting the degradation of Pt-based catalysts, resulting in their instability [72]. However, there is a possibility of catalyst degradation triggered by the electrochemical dissolution of bare Pt nanoparticles. Earlier studies on Pt degradation indicate that the mass of platinum remains constant within the operational potential range of 0–0.8 V vs. RHE. However, it experiences a substantial decrease when the potential exceeds 0.8 V vs. RHE, particularly under acidic conditions. Given the limited durability of Pt/C, improving the stability can be achieved through the optimization of platinum size and crystal structure.

This is because smaller particles are thermodynamically unstable and more susceptible to aggregation due to their higher surface energies [73,74]. Carbon corrosion at high voltage also causes the Pt/C system to degrade. Oxygenated components adhere more firmly to the Pt particles, causing them to detach from the support. This detachment can occur through particle migration or spillover on the surface, followed by particle redeposition and aggregation, hence reducing the ORR performance of the catalyst [75].

Research reported on the correction of carbon structure with oxidation kinetic rates. The results showed that graphitic carbon with smaller interplanar spacing was more resistant to electrochemical corrosion [76]. Increasing the degree of graphitization can improve the catalyst’s resistance to sintering, preventing the formation of Pt particles. With regard to this, carbon materials characterized by a high degree of graphitization, such as carbon nanotubes (CNTs), carbon nanofibers (CNFs), and reduced graphene oxide (rGO), have the potential to serve as stable support materials for fuel cell applications [77,78]. Li et al. [79] reported that the combination of carbon black (CB) and reduced graphene oxide (rGO) as a support material can substantially improve the stability of the Pt catalyst (Pt/RGO/CB). After 20,000 accelerated durability test (ADT) cycles, the Pt/RGO/CB catalyst exhibited a mere 5% reduction in its effective electrochemically active surface area (ECSA), whereas the commercial Pt/C catalyst experienced a nearly 50% ECSA decrease.

Low-temperature fuel cells use a 2 or 4 ORR system due to their high energy conversion efficiencies. A research study reported on a Pt-supported defective carbon black (Black Pearls 2000), denoted as Pt1.1/BPdefect, electrocatalyst with a Tafel slope of 93 mV/dec showed significant stability in an acidic environment. The researchers assembled a single cell using this electrocatalyst for H2O2 and achieved a high-power density of 520 mW/cm2. This observation highlighted the potential of polymer electrolyte membrane fuel cells. Through first principle calculations, it was determined that the Pt1.1/BPdefect electrocatalyst performed well in the oxygen reduction reaction (ORR) due to the presence of four carbon atoms and active coordinating species in the Pt catalyst. The 4 ORR in both alkaline and acidic conditions proved essential for the Pt1-N/BP electrocatalyst to be highly stable and active anchored by Pt on carbon black functionalized with N. The Pt1-N/BP electrocatalyst under 0.1 M KOH and 0.1 MHClO4 and the half-wave potentials of 0.87 V and 0.76 V (vs. RHE), respectively, were studied for ORR. Under this acidic condition H2/O2 fuel cells, Pt1-N/BP revealed moderate durability with a maximum power density of 1.02 W/cm2 [80].

4.2. Methanol Oxidation Reaction (MOR)

Depending on the catalyst being employed, electrooxidation of methanol is noticeable in either an alkaline medium or an acidic medium. MOR takes place sluggishly and gradually which then compelled researchers towards new electrocatalyst designs [80]. There are only a small number of electrode materials that can adsorb methanol. So far, platinum group metals (PGMs) and their alloys have proven to be the most effective materials for methanol electrooxidation. However, they face challenges in terms of reduced performance, selectivity, stability, and resistance to poison, and notably, their affordability is a concern for many. Among them, only platinum and platinum-based catalysts have been discovered to exhibit significant activity and stability in acid solutions [81]. Consequently, most mechanistic studies have focused on these materials. Methanol dehydrogenation, stripping, and oxidation of carbon-contained species are common pathways for methanol electrooxidation, and their reaction process is as follows [82]:

Absorbed intermediates produced by methanol dehydrogenation

Oxygenated species generated by water degradation

Removal of carbon-contained species to free active Pt sites

Pt3-COH + Pt-OH → 3Pt + Pt-COOH + C

Pt-CO + Pt-OH → Pt + Pt-COOH

Formation of carbon dioxide to complete the overall reaction

The above-mentioned reactions are all possible in MOR and their intermediates can be confirmed by Fourier transform infrared spectroscopy (FTIR) and differential electrochemical mass spectroscopy (DEMS). MOR exhibits distinct reaction mechanisms in alkaline environments, leading to more rapid kinetics due to the ease of forming Pt-OHads species. This helps to effectively address the issue of poisoning caused by strongly adsorbed carbonous species and results in improved performance. However, one limitation of MOR in alkaline media is that carbonate and bicarbonate inevitably form on the electrode surface, decreasing the amount of OH adsorption and causing a significant reduction in reaction activity [82].

Platinum (Pt) is a monometallic catalyst with exceptional catalytic activity for methanol oxidation processes (MOR). Nonetheless, the use of pure Pt in a direct methanol fuel cell (DMFC) can expose it to poisoning by intermediary species such as carbon monoxide (CO). Furthermore, the high cost of Pt catalysts limits their widespread use in electrocatalytic applications, reducing the rate of methanol oxidation in DMFC systems. These are the primary challenges and limits of utilizing Pt alone as an electrocatalyst in DMFC. Nonetheless, researchers have conducted several experiments aimed at producing Pt-based alloy and Pt-supported electrocatalysts to overcome these challenges, with the goal of improving electrocatalytic performance while reducing the amount of Pt required [83,84,85].

To date, the Pt–Ru system stands out as the most widely adopted bimetallic system due to its ability to generate a synergistic impact, enhance tolerance to carbon monoxide, and exhibit superior catalytic activity for methanol oxidation reactions. However, the potential toxicity resulting from the inclusion of ruthenium (Ru) metal remains unclear. [85,86]. Löffler and colleagues [87] successfully created a PtRu catalyst for DMFCs that demonstrated remarkable electrocatalytic activity for methanol electrooxidation, particularly when the Ru content was around 50 at.%. Furthermore, Ramli et al. [88] reported that a PtRu ratio of 1:1 exhibited stronger metallic behavior and higher electrocatalytic performance in methanol oxidation (MOR). The effectiveness of these catalysts appears to be influenced by the following factors: maximizing the catalyst’s surface area and ensuring that the catalyst surface contains a maximum number of metal alloy sites with an atomic ratio close to 1:1. They also proposed that carbon monoxide (CO) intermediate species formed on the active Pt surface sites can be converted into carbon dioxide (CO2) by active oxygen atoms generated on secondary elements like Ru, Sn, and Mo, especially at lower concentrations.

Researchers reported on a microwave-assisted polyol method of synthesizing a Pt/reduced graphene oxide (Pt/rGO) electrocatalyst, which accelerated the reduction in graphene oxide (GO) and the creation of Pt nanoparticles. They compared Pt/rGO with commercial carbon support (Pt/C). Pt/rGO exhibited high tolerance to carbon monoxide (CO), a large electrochemically active surface area, and strong electrocatalytic performance MOR [89]. Zhao et al. [90] revealed that a three-dimensional Pt/C/graphene aerogel (Pt/C/GA) exhibited enhanced stability during MOR without a decrease in electrocatalytic activity. Additionally, the Pt/C/GA demonstrated significantly superior performance in preventing methanol crossover at high potentials in an acidic environment when compared to the commercial Pt/C electrocatalyst. During the initial catalytic phase, the Pt/C electrocatalyst experienced a reduction in performance of around 40% after 1000 cyclic voltammetry (CV) cycles. Conversely, the Pt/C/GA only exhibited a 16% decrease in initial catalytic activity under the same conditions. After 200 CV cycles, the Pt/C/GA maintained a much higher current density and displayed remarkably better stability compared to the Pt/C electrocatalyst.

In another study, researchers investigated the use of graphene sheets as a support for Pt single-atom catalysts (SACs) employing the atomic layer deposition (ALD) method. They examined the catalytic activity based on the number of ALD cycles and found that catalysts synthesized with 50, 100, and 150 ALD cycles exhibited similar performance levels, showing lower onset and E1/2 peak potentials compared to commercial Pt/C, which is advantageous for reducing the over-potential in methanol oxidation reactions (MOR). This improved performance was attributed to both surface oxygen moieties and the intrinsic activity of Pt single atoms (Pt SAs). Furthermore, the researchers assessed the CO tolerance of these catalysts, crucial for MOR, by analyzing the forward anodic peak current density (If) to backward anodic peak current density (Ib) ratio, If/Ib. The 50 ALD Pt/graphene nanosheets (GNS) catalyst demonstrated a significantly higher If/Ib ratio of 2.23, indicating reduced poisoning by CO. Additionally, complementary CO stripping voltammetry experiments confirmed that CO adsorption rates on Pt/GNS catalysts were much slower compared to commercial Pt/C, further highlighting the superior CO tolerance of Pt/GNS catalysts [91]. Moreover, Li et al. [92] reported the utilization of a Ni2P nanosheet array combined with Cu2O-Cu dendrites on nickel foam (Cu2O-Cu@Ni2P/NF) as an efficient and stable electrocatalyst for MOR. This electrocatalyst achieved a low potential of 1.41 V at a current density of 100 mA . with a Tafel slope of 44.99 mV c. It maintained excellent stability for at least 24 h in a solution containing 1.0 M KOH and 1.0 M methanol.

5. Difficulties, Prospects, and Views

In our view, the electrocatalysts show promising and excellent electrochemical reactions. This review highlights the noteworthy progress in using noble and non-noble supports attached to metal electrocatalyst materials, as discussed. These supports are emerging as competitive alternatives to traditional carbon-based supports in various energy electrocatalysis processes. Therefore, there’s a desire to develop and bridge the gap between bio-activated carbon support materials with more active sites. The potential for groundbreaking advancements in the development of a novel DMFC catalyst lies in the synergy between platinum, recognized as the most effective metal catalyst for DMFC, and high-quality carbon support. Given the high cost of platinum, it is critical to limit its usage in the electrocatalyst. The primary challenges associated with the platinum electrocatalyst, such as the creation of carbon monoxide during the methanol oxidation process and the sluggish kinetics of methanol oxidation, could be effectively overcome through the incorporation of supplementary materials and a variety of support systems, as outlined in the research findings presented in this paper.

The above stresses the issue of an increased electrochemically active surface area through carbonaceous materials widely used in low-temperature fuel cells. Due to their excellent set of physical properties, the carbon materials can significantly affect the electrochemical properties of the fuel cell catalyst. Interestingly, it has been reported that carbon possessing high surface area as well as good crystallinity proved not only good but also provided high dispersibility of Pt nanoparticles, facilitating electron transfer, ultimately resulting in better overall device performance. On this basis, novel non-conventional carbon-based materials such as macadamia nuts have attracted humongous interest as an electrocatalyst support due to their excellent electrical and mechanical properties and versatility in pore size and distribution.

The use of carbonaceous materials as catalyst supports for precious metals has been extensively studied in recent years due to the rapid advancement and development of fuel cells. The primary requirement of ideal suitable supports for fuel cell catalysts includes high surface area, suitable porosity to facilitate good reactant flux, good electrical conductivity, and significant stability in the fuel cell environment. Carbon blacks are the most intensively and commonly used for low-temperature fuel cell catalyst support. They are subjected to chemical activation to improve anchoring centers for metal catalysts and to increase metal loading and dispersion. The availability and low cost make carbon blacks the most utilized support for fuel cell catalysts. The shortcoming of these carbons is associated with the presence of a high number of micropores, which can reduce the reactant flow. In addition, these materials present unstable features at temperatures higher than 100 °C.

Few works have been carried out on bioactivated carbonaceous materials as a potential fuel cell catalyst support, with promising and excellent properties of these materials in fuel cells.

6. Summary

Biowastes, which are produced in vast quantities each year all around the world, are a serious problem. Environment and ecosystems have suffered significant harm as a result of the manufacture and use of conventional chemical systems. The (bio)waste can be transformed entirely into a vast array of end products by physical, chemical, or biological processes. Numerous substances can be categorized as (bio)waste, but nut waste is the most significant. The research, development, and usage of biocompatible and renewable systems are the focus of the field of “green chemistry”, which has drawn the interest of scientists and is the subject of a wide range of recent studies.

As valuable nutrients, nuts are widely farmed in a variety of climates and nations. They include a variety of minerals and organic substances, including lipids, proteins, fiber, and carbs. In order to prevent the usage of expensive commercial chemicals in catalytic processes, a variety of wastes have been employed to create catalytically active compounds. Each year, a sizable amount of them are still seen as waste. The nuts and all of their many parts, including the shell, leaf, hull, etc., are rich in nutrients that can also be used to create various catalytic systems. Nuts can be used to make surfactants, carbon precursors, reducing, stabilizing, and enticing agents, as well as simple and effective heterogeneous catalysts.

Chemicals generated from nuts can be combined with other substances, such as nanoparticles like Cu, Ag, CuO, TiO2, etc., to create heterogeneous catalysts. Metal nanoparticles can be created by extracting various nut components. It is also typical practice to prepare carbonaceous chemicals from nuts for use in the manufacture of nanoparticles. It has been documented numerous times that nuts can be used to obtain activated carbons (ACs). These ACs have been used to synthesize heterogeneous carbon-based catalysts in an effective, environmentally friendly, and economically viable manner. These studies demonstrate that nuts can be utilized to make a variety of environmentally friendly, sustainable catalysts that can be employed in a variety of reactions. The catalysts made of nuts can be used for environmental purposes like the degradation of organic pollutants. pollutants. The heterogeneous catalysts or adsorbents were synthesized using activated carbon, which was made from nuts.

While fuel cells are a promising alternative to fossil fuels, several challenges must be addressed in the future, including improving carbon durability against corrosion in electrochemical processes, scaling up fuel cell applications for industrial use, particularly in the automotive industry, investigating cost-effective and environmentally friendly electrocatalysts as alternatives to platinum-based catalysts, and understanding issues related to cathodic corrosion in fuel cells.

In this review, the most recent developments in the use of nuts for the synthesis of bio(nano) catalysts and the use of these effective, green, affordable, and cost-effective catalysts for low-temperature fuel cells have been reviewed. The uses of these nuts in the area of catalytic applications have been examined. The bio(nano)catalysts are used as support materials in catalytic applications.

Author Contributions

Conceptualization, N.A.M. and N.S.S.; methodology, N.A.M.; software, L.K.; validation, Mojapelo N.A, N.S.S. and L.K.; formal analysis, N.S.S.; investigation, N.A.M.; resources, L.K.; data curation, Mojapelo N.A; writing—original draft preparation, N.A.M.; writing—review and editing, N.S.S.; visualization, N.S.S.; supervision, L.K.; project administration, L.K.; funding acquisition, L.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Research Foundation: 138079 and Eskom (South Africa): 2002/015527/0.

Acknowledgments

This research work was supported by the University of the Western Cape and the Sustainable and Renewable Energy Nanomaterials research group.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rosales Martinez, A.; Rodríguez-García, I.; López-Martínez, J.L. Green reductive regioselective opening of epoxides: A green chemistry laboratory experiment. J. Chem. Educ. 2022, 99, 2710–2714. [Google Scholar] [CrossRef]

- Lim, J.S.; Li, C.; Van Fan, Y.; Klemeš, J.J. How circular economy and green technology can address Sustainable Development Goals? J. Clean. Prod. 2022, 333, 130161. [Google Scholar] [CrossRef]

- Ren, X.; Wang, J.; Yu, J.; Song, B.; Feng, H.; Shen, M.; Zhang, H.; Zou, J.; Zeng, G.; Tang, L.; et al. Waste valorization: Transforming the fishbone biowaste into biochar as an efficient persulfate catalyst for degradation of organic pollutant. J. Clean. Prod. 2021, 291, 125225. [Google Scholar] [CrossRef]

- Goodman, B.A. Utilization of waste straw and husks from rice production: A review. J. Bioresour. Bioprod. 2020, 5, 143–162. [Google Scholar] [CrossRef]

- Li, H.; Liang, Y.; Li, P.; He, C. Conversion of biomass lignin to high-value polyurethane: A review. J. Bioresour. Bioprod. 2020, 5, 163–179. [Google Scholar] [CrossRef]

- Ashrafi, G.; Nasrollahzadeh, M.; Jaleh, B.; Sajjadi, M.; Ghafuri, H. Biowaste-and nature-derived (nano) materials: Biosynthesis, stability and environmental applications. Adv. Colloid Interface Sci. 2022, 301, 102599. [Google Scholar] [CrossRef] [PubMed]

- Mahata, S.; Sahu, A.; Shukla, P.; Rai, A.; Singh, M.; Rai, V.K. Bio-inspired unprecedented synthesis of reduced graphene oxide: A catalytic probe for electro-/chemical reduction of nitro groups in an aqueous medium. New J. Chem. 2018, 42, 2067–2073. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Y.; Cai, Y.; Wang, S.; Hu, B.; Li, B.; Ding, X.; Zhuang, L.; Wang, X. Application of covalent organic frameworks and metal–organic frameworks nanomaterials in organic/inorganic pollutants removal from solutions through sorption-catalysis strategies. Carbon Res. 2023, 2, 8. [Google Scholar] [CrossRef]

- Borah, N.; Tamuly, C. Emerging nano photo-catalysts for degradation of paracetamol and its prospective: A short review. Int. J. Environ. Anal. Chem. 2023, 1–16. [Google Scholar] [CrossRef]

- Orooji, Y.; Han, N.; Nezafat, Z.; Shafiei, N.; Shen, Z.; Nasrollahzadeh, M.; Karimi-Maleh, H.; Luque, R.; Bokhari, A.; Klemeš, J.J. Valorisation of nuts biowaste: Prospects in sustainable bio (nano) catalysts and environmental applications. J. Clean. Prod. 2022, 347, 131220. [Google Scholar] [CrossRef]

- Van Biert, L.; Visser, K. Fuel cells systems for sustainable ships. In Sustainable Energy Systems on Ships; Elsevier: Amsterdam, The Netherlands, 2022; pp. 81–121. [Google Scholar]

- Ramadhani, F.; Hussain, M.A.; Mokhlis, H.; Erixno, O. Solid Oxide Fuel Cell-Based Polygeneration Systems in Residential Applications: A Review of Technology, Energy Planning and Guidelines for Optimizing the Design. Processes 2022, 10, 2126. [Google Scholar] [CrossRef]

- Sajid, A.; Pervaiz, E.; Ali, H.; Noor, T.; Baig, M.M. A perspective on development of fuel cell materials: Electrodes and electrolyte. Int. J. Energy Res. 2022, 46, 6953–6988. [Google Scholar] [CrossRef]

- Zuo, Y.; Sheng, W.; Tao, W.; Li, Z. Direct methanol fuel cells system—A review of dual-role electrocatalysts for oxygen reduction and methanol oxidation. J. Mater. Sci. Technol. 2022, 114, 29–41. [Google Scholar] [CrossRef]

- Ahmed, A.A.; Al Labadidi, M.; Hamada, A.T.; Orhan, M.F. Design and Utilization of a Direct Methanol Fuel Cell. Membranes 2022, 12, 1266. [Google Scholar] [CrossRef] [PubMed]

- Chibac-Scutaru, A.L.; Coseri, S. Advances in the use of cellulose-based proton exchange membranes in fuel cell technology: A review. Int. J. Biol. Macromol. 2023, 247, 125810. [Google Scholar] [CrossRef]

- Xia, Z.; Zhang, X.; Sun, H.; Wang, S.; Sun, G. Recent advances in multi-scale design and construction of materials for direct methanol fuel cells. Nano Energy 2019, 65, 104048. [Google Scholar] [CrossRef]

- Liu, X.; Hong, H.; Zhang, H.; Cao, Y.; Qu, W.; Jin, H. Solar methanol by hybridizing natural gas chemical looping reforming with solar heat. Appl. Energy 2020, 277, 115521. [Google Scholar] [CrossRef]

- Akin, M.; Erduran, V.; Altuner, E.E.; Timuralp, C.; Isik, I.; Şen, F. Fundamentals of alcohol fuel cells. In Nanomaterials for Direct Alcohol Fuel Cells; Elsevier: Amsterdam, The Netherlands, 2021; pp. 75–94. [Google Scholar]

- Güler, S.; Yavaş, A.; Mustafov, S.D.; Şen, F. The material development and characterization of direct alcohol fuel cells. In Nanomaterials for Direct Alcohol Fuel Cells; Elsevier: Amsterdam, The Netherlands, 2021; pp. 53–73. [Google Scholar]

- Acres, G.J. Recent advances in fuel cell technology and its applications. J. Power Sources 2001, 100, 60–66. [Google Scholar] [CrossRef]

- Ren, X.; Wilson, M.S.; Gottesfeld, S. High performance direct methanol polymer electrolyte fuel cells. J. Electrochem. Soc. 1996, 143, L12. [Google Scholar] [CrossRef]

- Shih, C.F.; Zhang, T.; Li, J.; Bai, C. Powering the future with liquid sunshine. Joule 2018, 2, 1925–1949. [Google Scholar] [CrossRef]

- Kim, J.; Henao, C.A.; Johnson, T.A.; Dedrick, D.E.; Miller, J.E.; Stechel, E.B.; Maravelias, C.T. Methanol production from CO2 using solar-thermal energy: Process development and techno-economic analysis. Energy Environ. Sci. 2011, 4, 3122–3132. [Google Scholar] [CrossRef]

- Bandason, W.; Parwada, C.; Mushunje, A. Macadamia nuts (Macadamia intergrifolia) value chain and technical efficiency among the small-scale farmers in Zimbabwe. Res. World Agric. Econ. 2022, 3, 700. [Google Scholar] [CrossRef]

- Fan, F.; Yang, Z.; Li, H.; Shi, Z.; Kan, H. Preparation and properties of hydrochars from macadamia nut shell via hydrothermal carbonization. R. Soc. Open Sci. 2018, 5, 181126. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Liu, R.; Zhao, J.; Fan, Z. Advanced carbon materials with different spatial dimensions for supercapacitors. Nano Mater. Sci. 2021, 3, 241–267. [Google Scholar] [CrossRef]

- Dao, T.M.; Le Luu, T. Synthesis of activated carbon from macadamia nutshells activated by H2SO4 and K2CO3 for methylene blue removal in water. Bioresour. Technol. Rep. 2020, 12, 100583. [Google Scholar] [CrossRef]

- Wongcharee, S.; Aravinthan, V.; Erdei, L. Mesoporous activated carbon-zeolite composite prepared from waste macadamia nut shell and synthetic faujasite. Chin. J. Chem. Eng. 2019, 27, 226–236. [Google Scholar] [CrossRef]

- Martins, A.C.; Pezoti, O.; Cazetta, A.L.; Bedin, K.C.; Yamazaki, D.A.; Bandoch, G.F.; Asefa, T.; Visentainer, J.V.; Almeida, V.C. Removal of tetracycline by NaOH-activated carbon produced from macadamia nut shells: Kinetic and equilibrium studies. Chem. Eng. J. 2015, 260, 291–299. [Google Scholar] [CrossRef]

- Chang, Y.; Ren, Y.; Zhu, L.; Li, Y.; Li, T.; Ren, B. Preparation of macadamia nut shell porous carbon and its electrochemical performance as cathode material for lithium–sulfur batteries. Electrochim. Acta 2022, 420, 140454. [Google Scholar] [CrossRef]

- Lu, X.; Xiang, K.; Zhou, W.; Zhu, Y.; He, Y.; Chen, H. Graphene-like carbon derived from macadamia nut shells for high-performance supercapacitor. Russ. J. Electrochem. 2019, 55, 242–246. [Google Scholar] [CrossRef]

- Scott, K.; Taama, W.; Cruickshank, J. Performance and modelling of a direct methanol solid polymer electrolyte fuel cell. J. Power Sources 1997, 65, 159–171. [Google Scholar] [CrossRef]

- Scott, K.; Taama, W.M.; Kramer, S.; Argyropoulos, P.; Sundmacher, K. Limiting current behaviour of the direct methanol fuel cell. Electrochim. Acta 1999, 45, 945–957. [Google Scholar] [CrossRef]

- Queirós, C.S.; Cardoso, S.; Lourenço, A.; Ferreira, J.; Miranda, I.; Lourenço, M.J.V.; Pereira, H. Characterization of walnut, almond, and pine nut shells regarding chemical composition and extract composition. Biomass Convers. Biorefin. 2020, 10, 175–188. [Google Scholar] [CrossRef]

- Abdallah, I.B.; Tlili, N.; Martinez-Force, E.; Rubio, A.G.P.; Perez-Camino, M.C.; Albouchi, A.; Boukhchina, S. Content of carotenoids, tocopherols, sterols, triterpenic and aliphatic alcohols, and volatile compounds in six walnuts (Juglans regia L.) varieties. Food Chem. 2015, 173, 972–978. [Google Scholar] [CrossRef] [PubMed]

- Albatrni, H.; Qiblawey, H.; Al-Marri, M.J. Walnut shell based adsorbents: A review study on preparation, mechanism, and application. J. Water Process Eng. 2022, 45, 102527. [Google Scholar] [CrossRef]

- Gondhalekar, S.C.; Shukla, S.R. Biosorption of cadmium metal ions on raw and chemically modified walnut shells. Environ. Prog. Sustain. Energy 2015, 34, 1613–1619. [Google Scholar] [CrossRef]

- Zhou, M.; Yan, S.X.; Wang, Q.; Tan, M.X.; Wang, D.Y.; Yu, Z.Q.; Luo, S.H.; Zhang, Y.H.; Liu, X. Walnut septum-derived hierarchical porous carbon for ultra-high-performance supercapacitors. Rare Met. 2022, 41, 2280–2291. [Google Scholar] [CrossRef]

- Akinhanmi, T.F.; Atasie, V.N.; Akintokun, P.O. Chemical composition and physicochemical properties of cashew nut (Anacardium occidentale) oil and cashew nut shell liquid. J. Agric. Food Environ. Sci. 2008, 2, 1–10. [Google Scholar]

- Ragupathy, S.; Raghu, K.; Prabu, P. Synthesis and characterization of TiO2 loaded cashew nut shell activated carbon and photocatalytic activity on BG and MB dyes under sunlight radiation. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2015, 138, 314–320. [Google Scholar] [CrossRef]

- Grosso, N.R.; Guzman, C.A. Chemical composition of aboriginal peanut (Arachis hypogaea L.) seeds from Peru. J. Agric. Food Chem. 1995, 43, 102–105. [Google Scholar] [CrossRef]

- Cai, N.; Cheng, H.; Jin, H.; Liu, H.; Zhang, P.; Wang, M. Porous carbon derived from cashew nut husk biomass waste for high-performance supercapacitors. J. Electroanal. Chem. 2020, 861, 113933. [Google Scholar] [CrossRef]

- Aigbodion, V.S. Explicit microstructure and electrical conductivity of epoxy/carbon nanotube and green silver nanoparticle enhanced hybrid dielectric composites. Nanocomposites 2021, 7, 35–43. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, X.; Wang, N. Recent Progress in Piezoelectric-Triboelectric Effects Coupled Nanogenerators. Nanomaterials 2023, 13, 385. [Google Scholar] [CrossRef]

- Jonnala, R.S.; Dunford, N.T.; Chenault, K. Nutritional composition of genetically modified peanut varieties. J. Food Sci. 2005, 70, S254–S256. [Google Scholar] [CrossRef]

- Khalil, J.K.; Chughtai, M.I.D. Chemical composition and nutritional quality of five peanut cultivars grown in Pakistan. Plant Foods Hum. Nutr. 1983, 33, 63–70. [Google Scholar] [CrossRef]

- Hoffpauir, C.L. Peanut composition, relation to processing and utilization. J. Agric. Food Chem. 1953, 1, 668–671. [Google Scholar] [CrossRef]

- Childs, E.; Abajian, A. Physico-chemical characterization of peanut hull as a potential fiber additive. J. Food Sci. 1976, 41, 1235–1236. [Google Scholar] [CrossRef]

- Zeng, D.; Liu, S.; Gong, W.; Wang, G.; Qiu, J.; Chen, H. Synthesis, characterization and acid catalysis of solid acid from peanut shell. Appl. Catal. A Gen. 2014, 469, 284–289. [Google Scholar] [CrossRef]

- Zhou, L.; Ma, J.; Zhang, H.; Shao, Y.; Li, Y. Fabrication of magnetic carbon composites from peanut shells and its application as a heterogeneous Fenton catalyst in removal of methylene blue. Appl. Surf. Sci. 2015, 324, 490–498. [Google Scholar] [CrossRef]

- Yan, X.; Jia, Y.; Zhuang, L.; Zhang, L.; Wang, K.; Yao, X. Defective carbons derived from macadamia nut shell biomass for efficient oxygen reduction and supercapacitors. ChemElectroChem 2018, 5, 1874–1879. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, H.; Kimura, H.; Wu, D.; Xie, X.; Yang, X.; Hou, C.; Sun, X.; Du, W. Facile synthesis, microstructure and electrochemical performance of peanut shell derived porous activated carbon/Co3O4 composite for hybrid supercapacitors. Ceram. Int. 2022, 48, 34576–34583. [Google Scholar] [CrossRef]

- Guo, P.Z.; Ji, Q.Q.; Zhang, L.L.; Zhao, S.Y.; Zhao, X.S. Preparation and characterization of peanut shell-based microporous carbons as electrode materials for supercapacitors. Acta Phys.-Chim. Sin. 2011, 27, 2836–2840. [Google Scholar]

- Ahsaine, H.A.; Zbair, M.; Anfar, Z.; Naciri, Y.; El Alem, N.; Ezahri, M.J.M.T.C. Cationic dyes adsorption onto high surface area ‘almond shell’activated carbon: Kinetics, equilibrium isotherms and surface statistical modeling. Mater. Today Chem. 2018, 8, 121–132. [Google Scholar] [CrossRef]

- Xu, Y.; Yang, Z.; Zhang, G.; Zhao, P. Excellent CO2 adsorption performance of nitrogen-doped waste biocarbon prepared with different activators. J. Clean. Prod. 2020, 264, 121645. [Google Scholar] [CrossRef]

- Kaya, N.; Arslan, F.; Yildiz Uzun, Z. Production and characterization of carbon-based adsorbents from waste lignocellulosic biomass: Their effectiveness in heavy metal removal. Fuller. Nanotub. Carbon Nanostruct. 2020, 28, 769–780. [Google Scholar] [CrossRef]

- Benítez, A.; Morales, J.; Caballero, Á. Pistachio shell-derived carbon activated with phosphoric acid: A more efficient procedure to improve the performance of Li–S batteries. Nanomaterials 2020, 10, 840. [Google Scholar] [CrossRef]

- Akçakal, Ö.; Şahin, M.; Erdem, M. Synthesis and characterization of high-quality activated carbons from hard-shelled agricultural wastes mixture by zinc chloride activation. Chem. Eng. Commun. 2019, 206, 888–897. [Google Scholar] [CrossRef]

- Lu, X.; Xiang, K.; Zhou, W.; Zhu, Y.; Chen, H. Biomass carbon materials derived from macadamia nut shells for high-performance supercapacitors. Bull. Mater. Sci. 2018, 41, 138. [Google Scholar] [CrossRef]

- Xu, X.; Matsumura, Y.; Stenberg, J.; Antal, M.J. Carbon-catalyzed gasification of organic feedstocks in supercritical water. Ind. Eng. Chem. Res. 1996, 35, 2522–2530. [Google Scholar] [CrossRef]

- Yan, L.; Liu, Y.; Hou, J. High-Efficiency Oxygen Reduction Reaction Revived from Walnut Shell. Molecules 2023, 28, 2072. [Google Scholar] [CrossRef]

- Sciarria, T.P.; de Oliveira, M.A.C.; Mecheri, B.; D’Epifanio, A.; Goldfarb, J.L.; Adani, F. Metal-free activated biochar as an oxygen reduction reaction catalyst in single chamber microbial fuel cells. J. Power Sources 2020, 462, 228183. [Google Scholar] [CrossRef]

- Fan, L.; Chen, J.; Guo, J.; Jiang, X.; Jiang, W. Influence of manganese, iron and pyrolusite blending on the physiochemical properties and desulfurization activities of activated carbons from walnut shell. J. Anal. Appl. Pyrolysis 2013, 104, 353–360. [Google Scholar] [CrossRef]

- Moussavi, G.; Khosravi, R. Preparation and characterization of a biochar from pistachio hull biomass and its catalytic potential for ozonation of water recalcitrant contaminants. Bioresour. Technol. 2012, 119, 66–71. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Bai, Q.; Ding, C. NiMoO4 nanoparticles embedded in nanoporous carbon nanosheets derived from peanut shells: Efficient electrocatalysts for urea oxidation. Colloids Surf. A Physicochem. Eng. Asp. 2020, 604, 125276. [Google Scholar] [CrossRef]

- Omri, A.; Benzina, M.; Bennour, F. Industrial application of photocatalysts prepared by hydrothermal and sol–gel methods. J. Ind. Eng. Chem. 2015, 21, 356–362. [Google Scholar] [CrossRef]

- Rechnia, P.; Malaika, A.; Krzyżyńska, B.; Kozłowski, M. Decomposition of methane in the presence of ethanol over activated carbon catalyst. Int. J. Hydrogen Energy 2012, 37, 14178–14186. [Google Scholar] [CrossRef]

- Ai, J.; Wu, X.; Wang, Y.; Zhang, D.; Zhang, H. Treatment of landfill leachate with combined biological and chemical processes: Changes in the dissolved organic matter and functional groups. Environ. Technol. 2019, 40, 2225–2231. [Google Scholar] [CrossRef]

- Guo, F.; Liang, S.; Jia, X.; Peng, K.; Jiang, X.; Qian, L. One-step synthesis of biochar-supported potassium-iron catalyst for catalytic cracking of biomass pyrolysis tar. Int. J. Hydrogen Energy 2020, 45, 16398–16408. [Google Scholar] [CrossRef]

- Xu, J.; Yang, Y.; Zhou, W.; Ma, X.; Xu, J.; Cao, Y.; Chai, H. Anchoring CoFe2O4 nanospheres on two-dimensional microporous carbon from walnut shell as efficient multifunctional electrocatalyst. J. Solid State Chem. 2021, 299, 122106. [Google Scholar] [CrossRef]

- Kulkarni, A.; Siahrostami, S.; Patel, A.; Nørskov, J.K. Understanding catalytic activity trends in the oxygen reduction reaction. Chem. Rev. 2018, 118, 2302–2312. [Google Scholar] [CrossRef]

- Chen, M.Y.; Li, Y.; Wu, H.R.; Lu, B.A.; Zhang, J.N. Highly Stable Pt-Based Oxygen Reduction Electrocatalysts toward Practical Fuel Cells: Progress and Perspectives. Materials 2023, 16, 2590. [Google Scholar] [CrossRef]

- Lin, Z.; Huang, H.; Cheng, L.; Hu, W.; Xu, P.; Yang, Y.; Li, J.; Gao, F.; Yang, K.; Liu, S.; et al. Tuning the p-Orbital Electron Structure of s-Block Metal Ca Enables a High-Performance Electrocatalyst for Oxygen Reduction. Adv. Mater. 2021, 33, 2107103. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Minelli, S.; Vertova, A.; Minguzzi, A. Nanostructured Pt-based catalysts for oxygen reduction reaction in alkaline media. Curr. Opin. Electrochem. 2022, 36, 101166. [Google Scholar] [CrossRef]

- Zaman, S.; Huang, L.; Douka, A.I.; Yang, H.; You, B.; Xia, B.Y. Oxygen reduction electrocatalysts toward practical fuel cells: Progress and perspectives. Angew. Chem. 2021, 133, 17976–17996. [Google Scholar] [CrossRef]

- Qiao, Z.; Wang, C.; Zeng, Y.; Spendelow, J.S.; Wu, G. Advanced nanocarbons for enhanced performance and durability of platinum catalysts in proton exchange membrane fuel cells. Small 2021, 17, 2006805. [Google Scholar] [CrossRef] [PubMed]

- Yan, L.; Xiang, J.; Guan, G.; Zhang, H.; Zhang, Y.; Zhang, K. Tunable high-performance microwave absorption of cobalt nanoparticles wrapped in N-self-doped carbon nanofibers at ultralow filler loadings. J. Alloys Compd. 2023, 933, 167808. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.; Zhu, E.; McLouth, T.; Chiu, C.Y.; Huang, X.; Huang, Y. Stabilization of high-performance oxygen reduction reaction Pt electrocatalyst supported on reduced graphene oxide/carbon black composite. J. Am. Chem. Soc. 2012, 134, 12326–12329. [Google Scholar] [CrossRef] [PubMed]

- Yuan, W.; Ma, Y.; Wu, H.; Cheng, L. Single-atom catalysts for CO oxidation, CO2 reduction, and O2 electrochemistry. J. Energy Chem. 2022, 65, 254–279. [Google Scholar] [CrossRef]

- Tong, Y.; Yan, X.; Liang, J.; Dou, S.X. Metal-based electrocatalysts for methanol electro-oxidation: Progress, opportunities, and challenges. Small 2021, 17, 1904126. [Google Scholar] [CrossRef]

- Gong, L.; Yang, Z.; Li, K.; Xing, W.; Liu, C.; Ge, J. Recent development of methanol electrooxidation catalysts for direct methanol fuel cell. J. Energy Chem. 2018, 27, 1618–1628. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Javed, R.M.N.; Al-Othman, A.; Almomani, F. The novel contribution of non-noble metal catalysts for intensified carbon dioxide hydrogenation: Recent challenges and opportunities. Energy Convers. Manag. 2023, 279, 116755. [Google Scholar] [CrossRef]

- Rauf, M.; Wang, J.; Handschuh-Wang, S.; Zhou, Z.; Iqbal, W.; Khan, S.A.; Zhuang, L.; Ren, X.; Li, Y.; Sun, S. Highly stable N-containing polymer-based Fe/Nx/C electrocatalyst for alkaline anion exchange membrane fuel cell applications. Prog. Nat. Sci. Mater. Int. 2022, 32, 27–33. [Google Scholar] [CrossRef]

- Guo, W.; Wang, J.; Yan, H. Rhombic dodecahedral PtCo nanocrystals as a highly active electrocatalyst for methanol oxidation reaction. Funct. Mater. Lett. 2022, 15, 2251018. [Google Scholar] [CrossRef]

- Ramli, Z.A.C.; Kamarudin, S.K. Platinum-based catalysts on various carbon supports and conducting polymers for direct methanol fuel cell applications: A review. Nanoscale Res. Lett. 2018, 13, 410. [Google Scholar] [CrossRef] [PubMed]

- Löffler, M.S.; Natter, H.; Hempelmann, R.; Wippermann, K. Preparation and characterisation of Pt–Ru model electrodes for the direct methanol fuel cell. Electrochim. Acta 2003, 48, 3047–3051. [Google Scholar] [CrossRef]

- Ramli, Z.A.C.; Shaari, N.; Saharuddin, T.S.T. Progress and major BARRIERS of nanocatalyst development in direct methanol fuel cell: A review. Int. J. Hydrogen Energy 2022, 47, 22114–22146. [Google Scholar] [CrossRef]

- Stevanović, S.I.; Jovanović, V.M. Graphene as Catalyst Support for the Reactions in Fuel Cells. Handb. Graphene Energy Healthc. Environ. Appl. 2019, 5, 339. [Google Scholar]

- Zhao, L.; Wang, Z.B.; Li, J.L.; Zhang, J.J.; Sui, X.L.; Zhang, L.M. Hybrid of carbon-supported Pt nanoparticles and three dimensional graphene aerogel as high stable electrocatalyst for methanol electrooxidation. Electrochim. Acta 2016, 189, 175–183. [Google Scholar] [CrossRef]

- Sun, S.; Zhang, G.; Gauquelin, N.; Chen, N.; Zhou, J.; Yang, S.; Chen, W.; Meng, X.; Geng, D.; Banis, M.N.; et al. Single-atom catalysis using Pt/graphene achieved through atomic layer deposition. Sci. Rep. 2013, 3, 1775. [Google Scholar] [CrossRef]

- Li, L.; Zhang, L.; Gou, L.; Wei, S.; Hou, X.; Wu, L. High-performance methanol electrolysis towards energy-saving hydrogen production: Using Cu2O-Cu decorated Ni2P nanoarray as bifunctional monolithic catalyst. Chem. Eng. J. 2023, 454, 140292. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).