Influence of Thermo-Mechanical Process and Nb-V Microalloying on Microstructure and Mechanical Properties of Fe–Mn–Al–C Austenitic Steel

Abstract

:1. Introduction

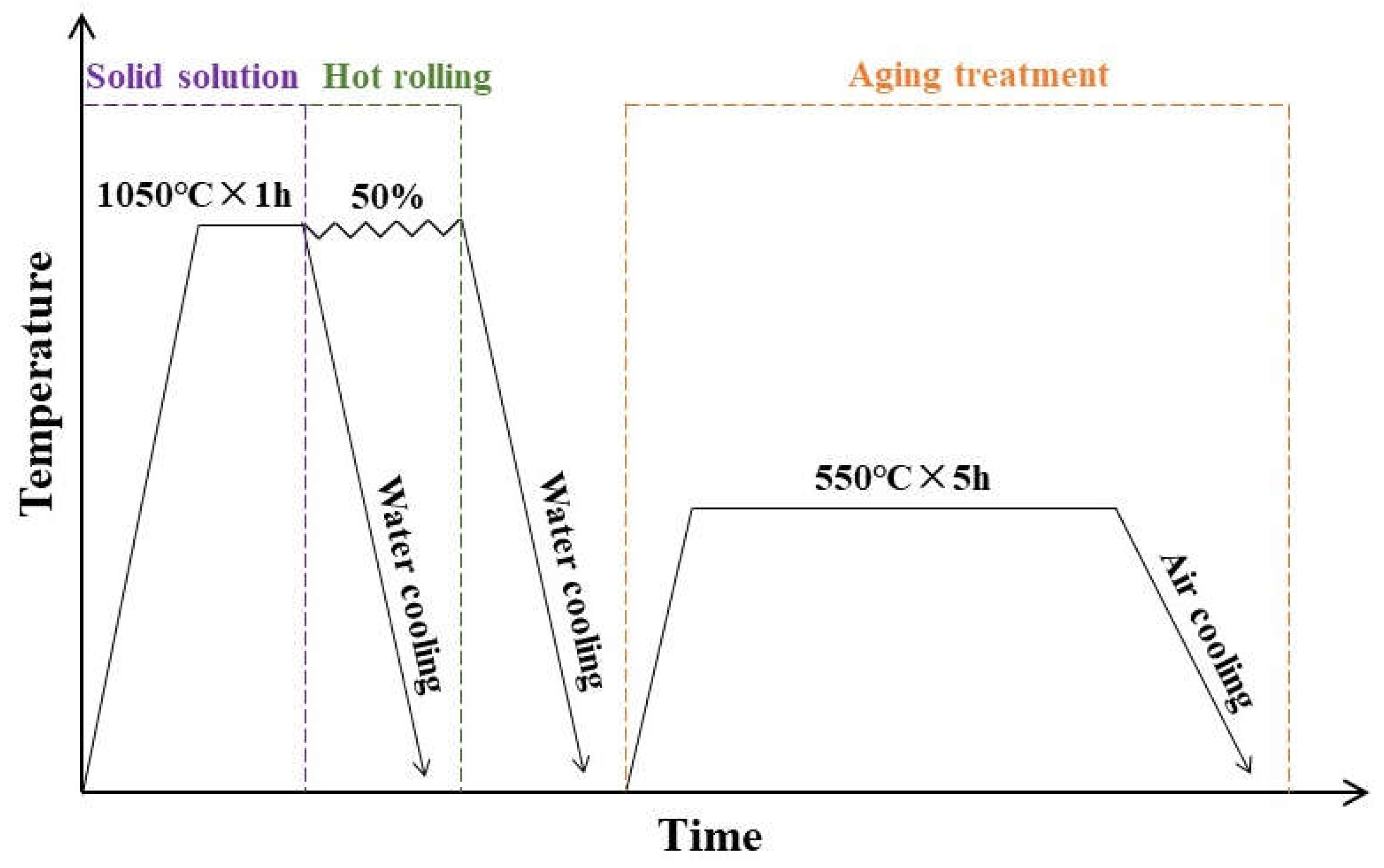

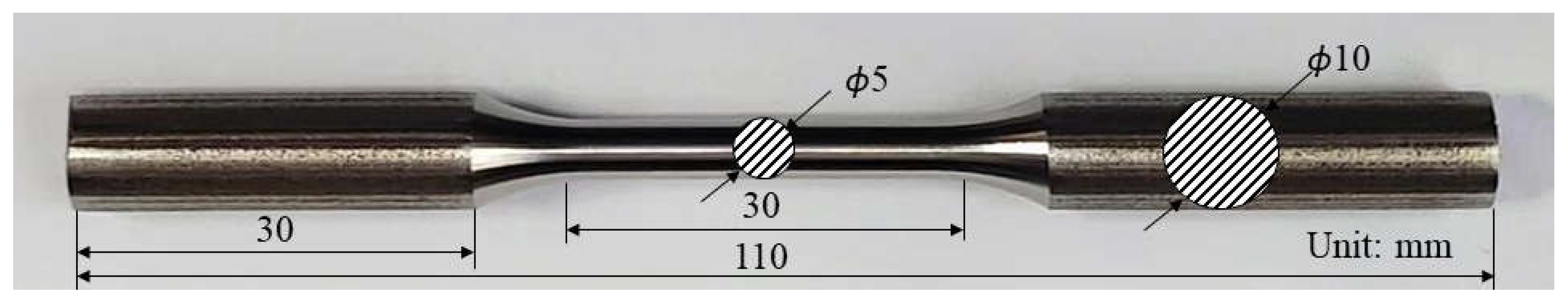

2. Materials and Methods

3. Results

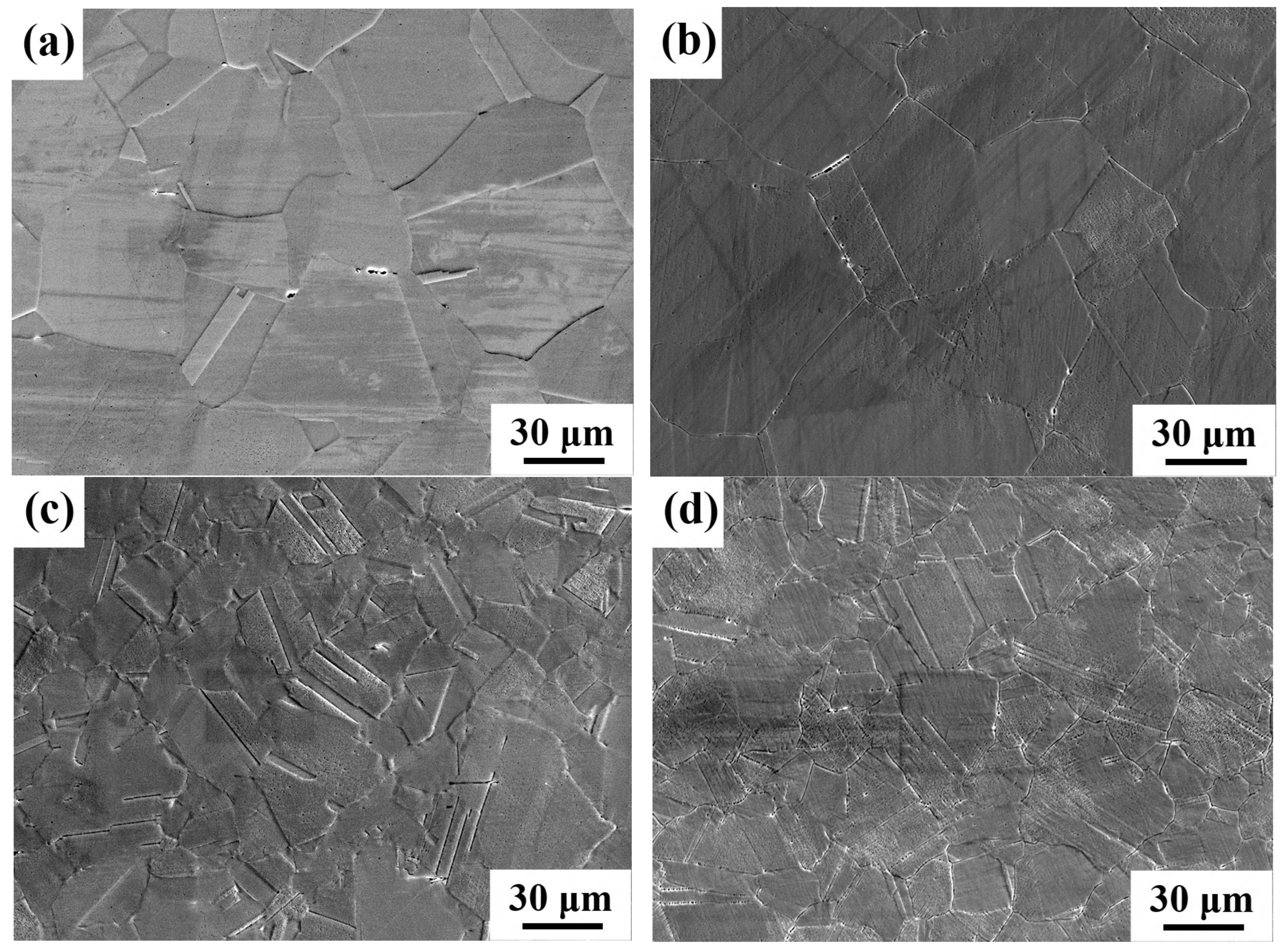

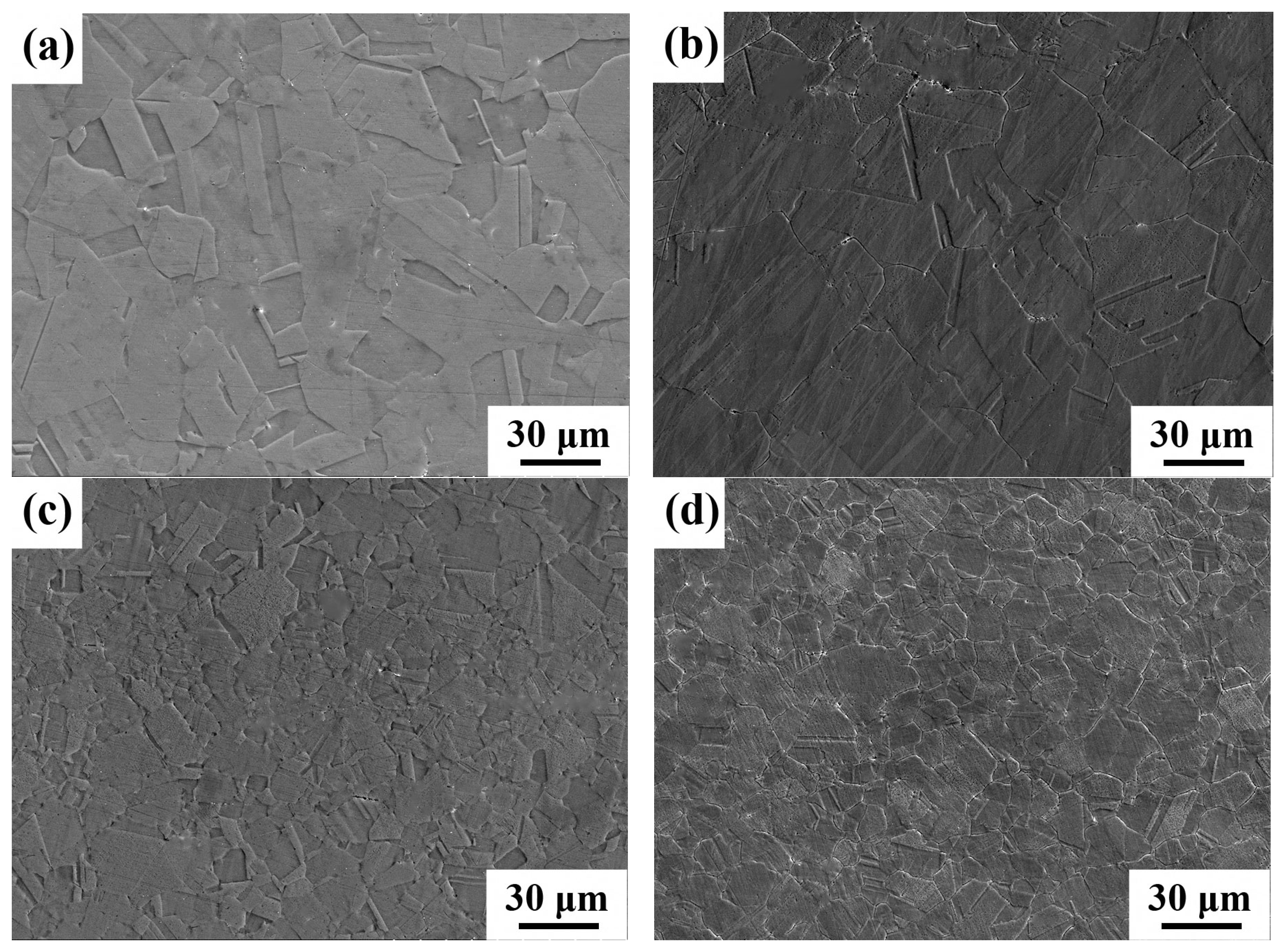

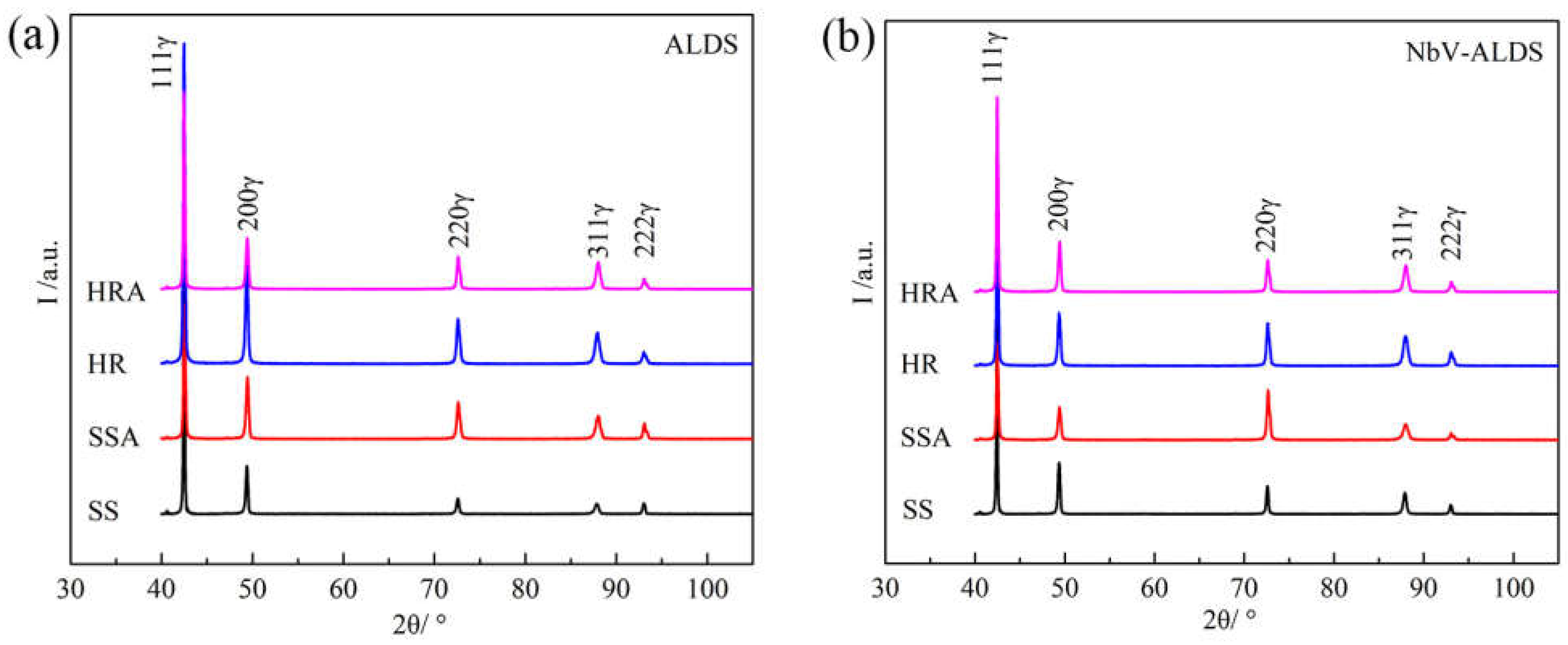

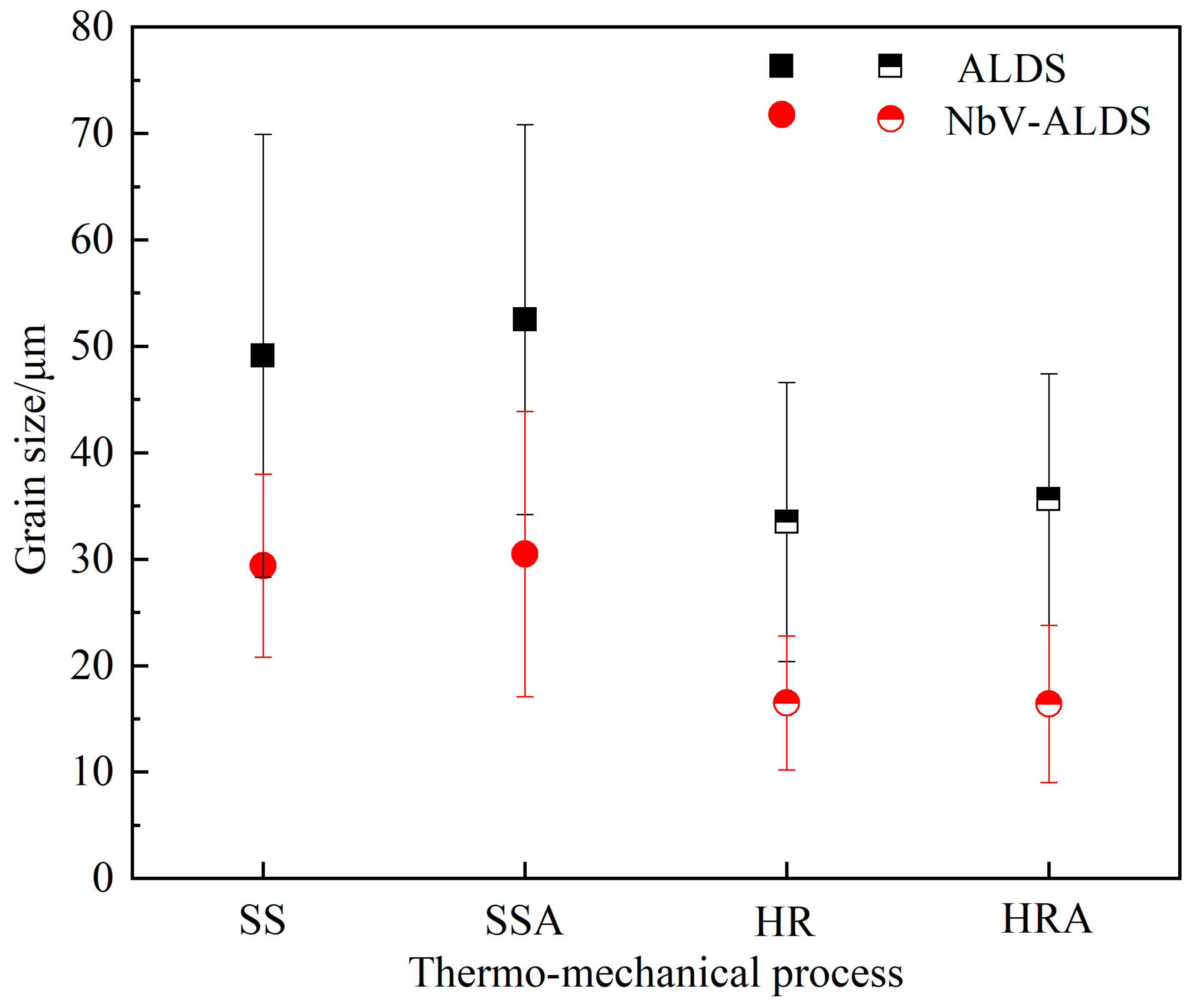

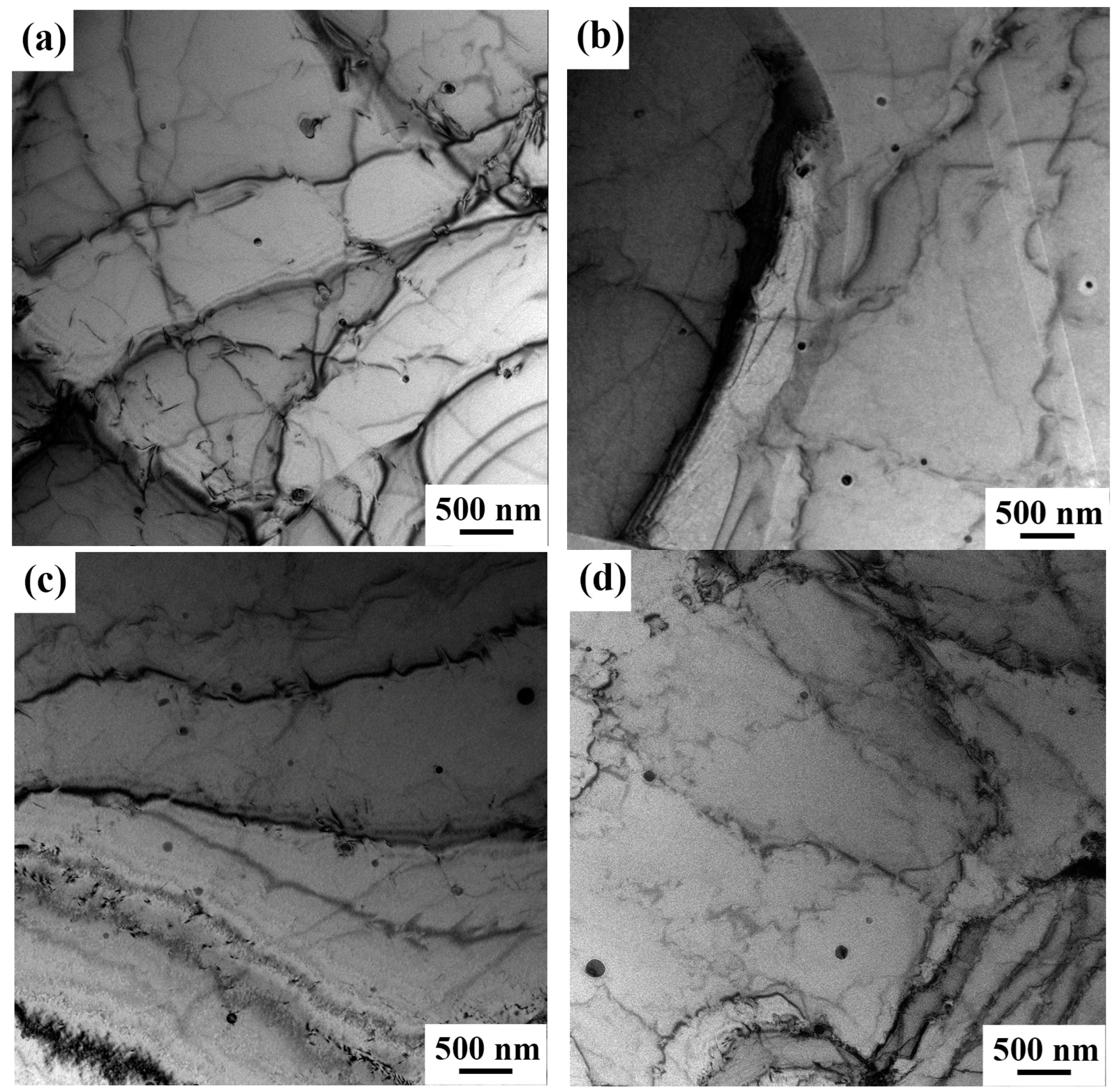

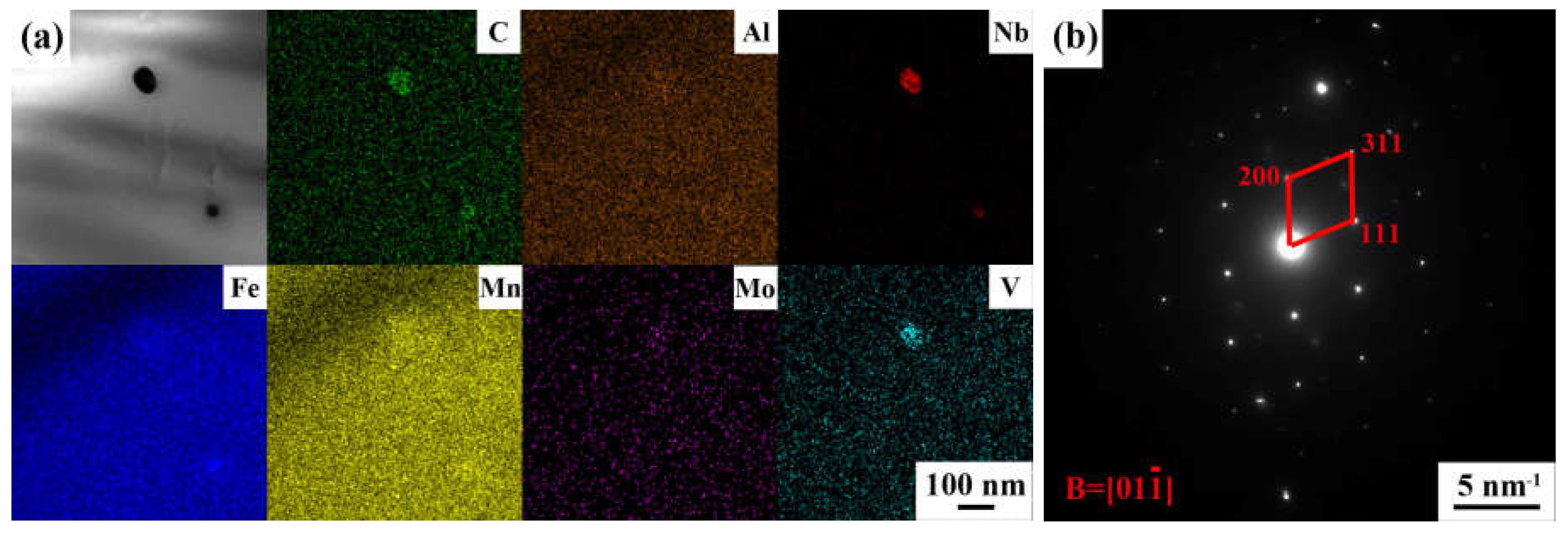

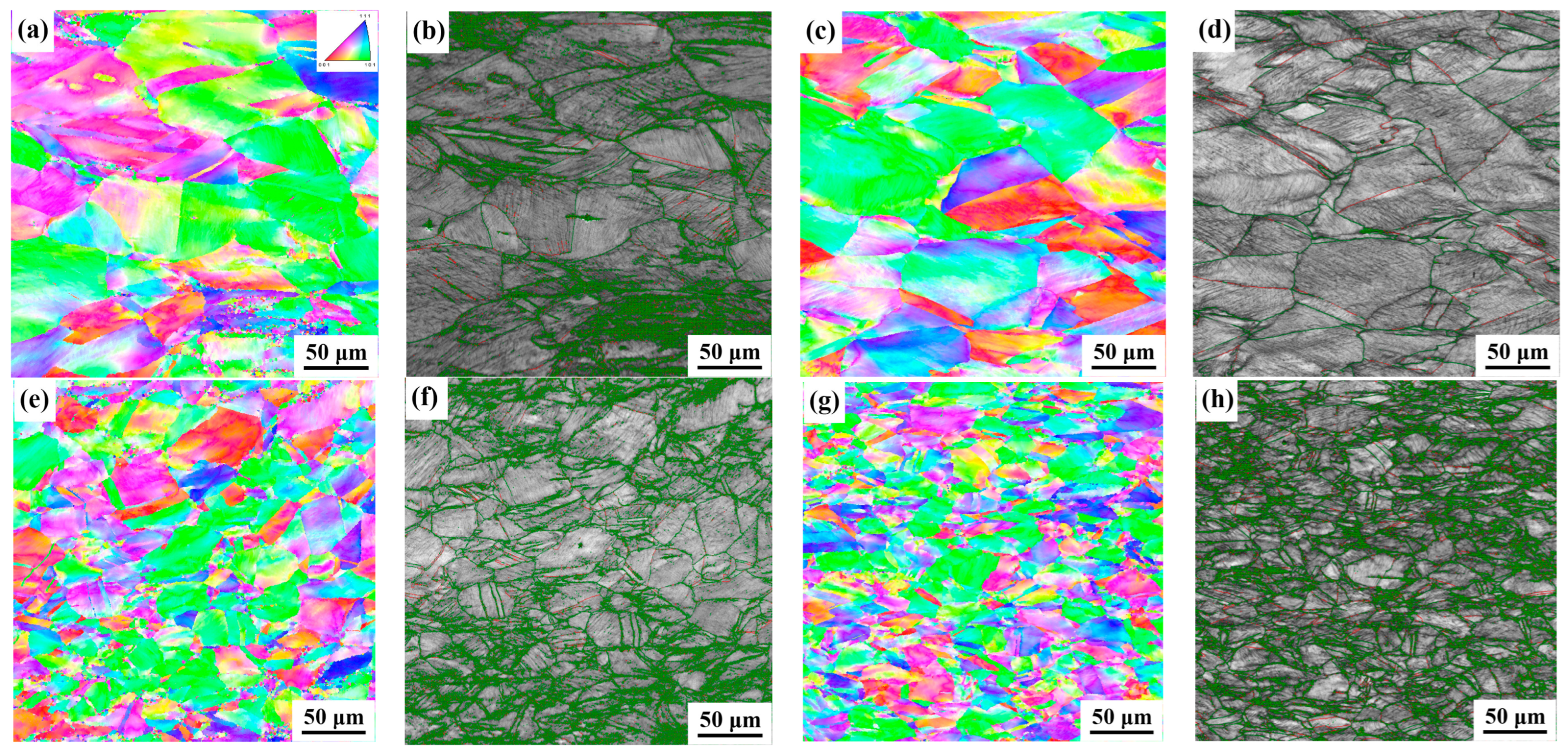

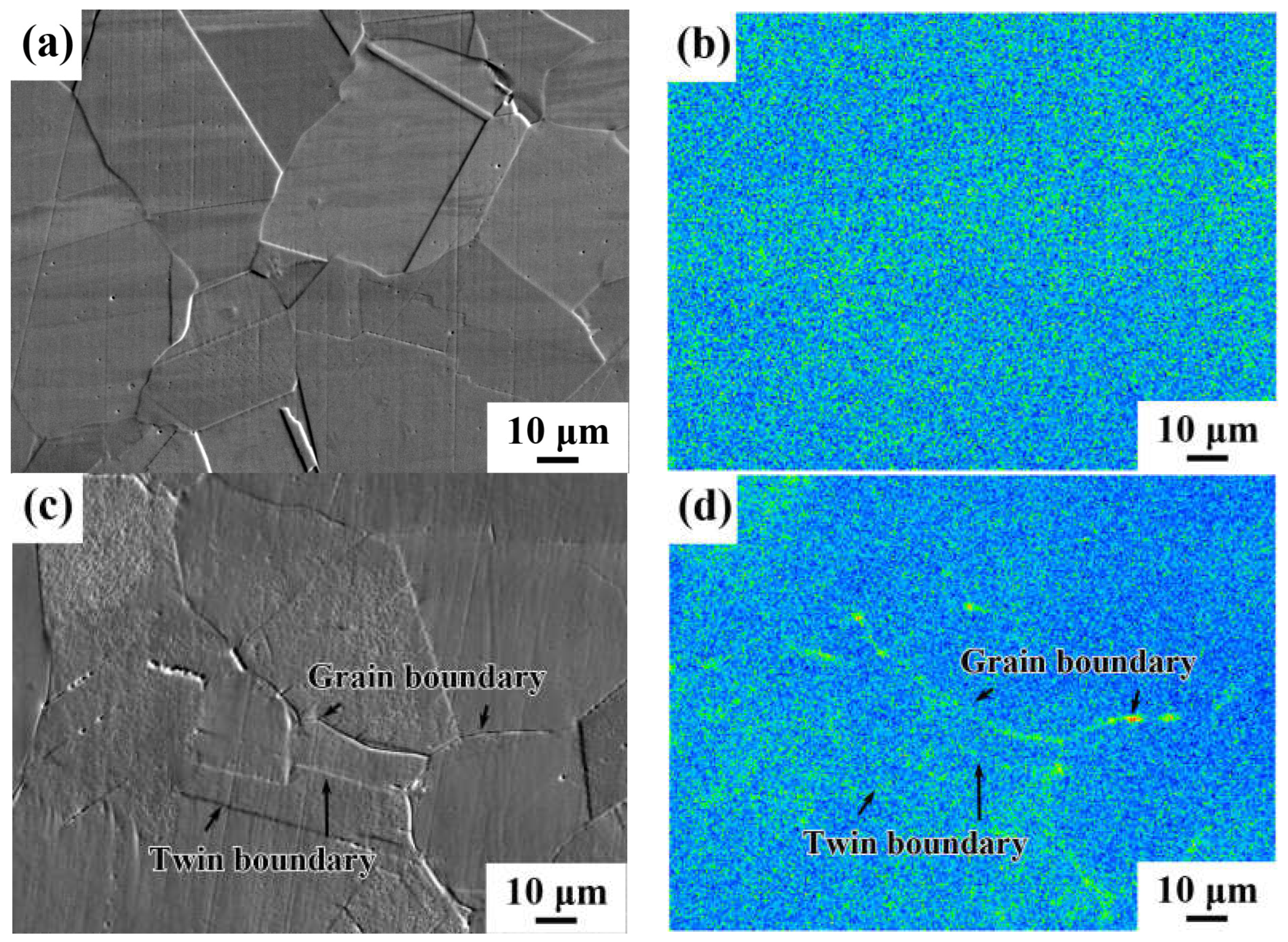

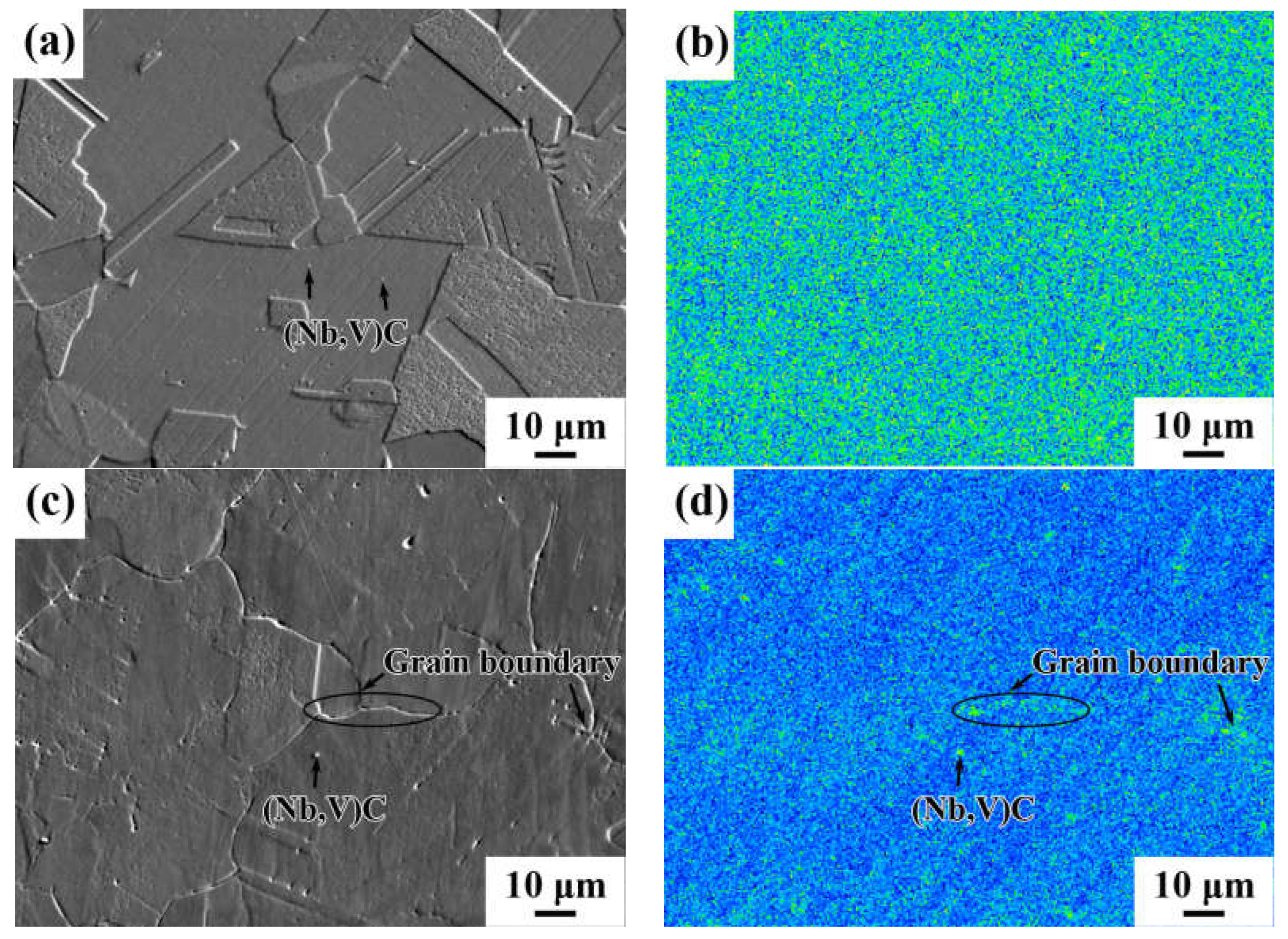

3.1. Microstructure of the Test Steels Treated by Different Thermo-Mechanical Processes

3.2. Mechanical Properties of the Test Steels Treated by Different Thermo-Mechanical Processes

4. Discussion

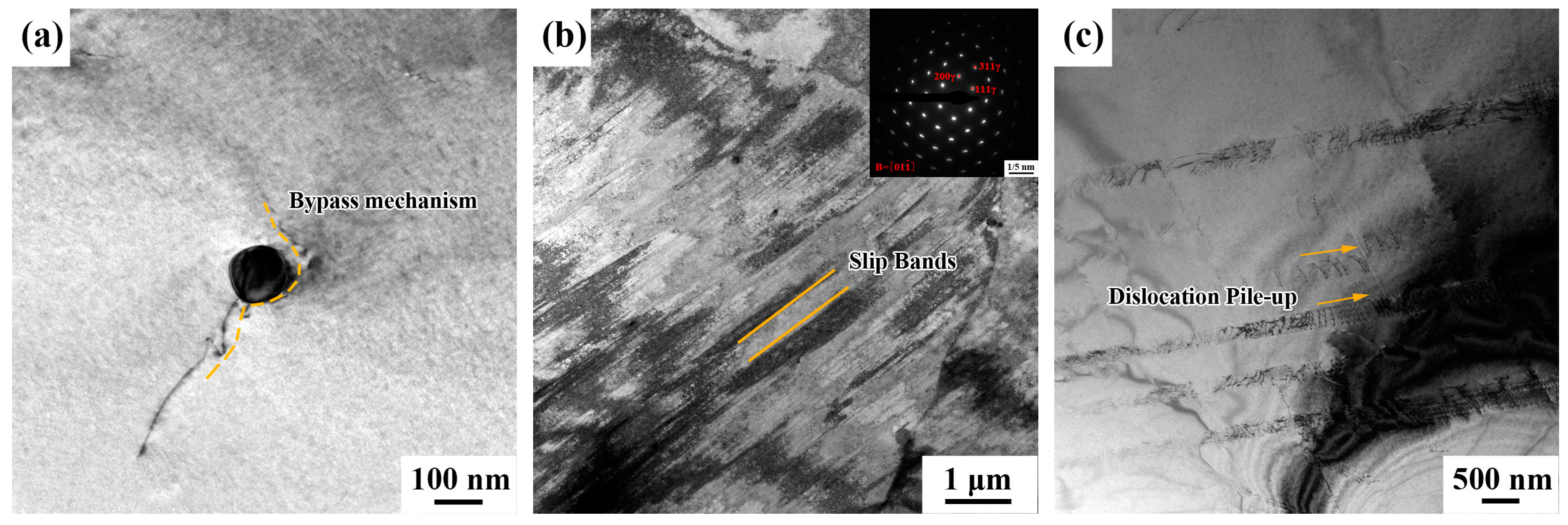

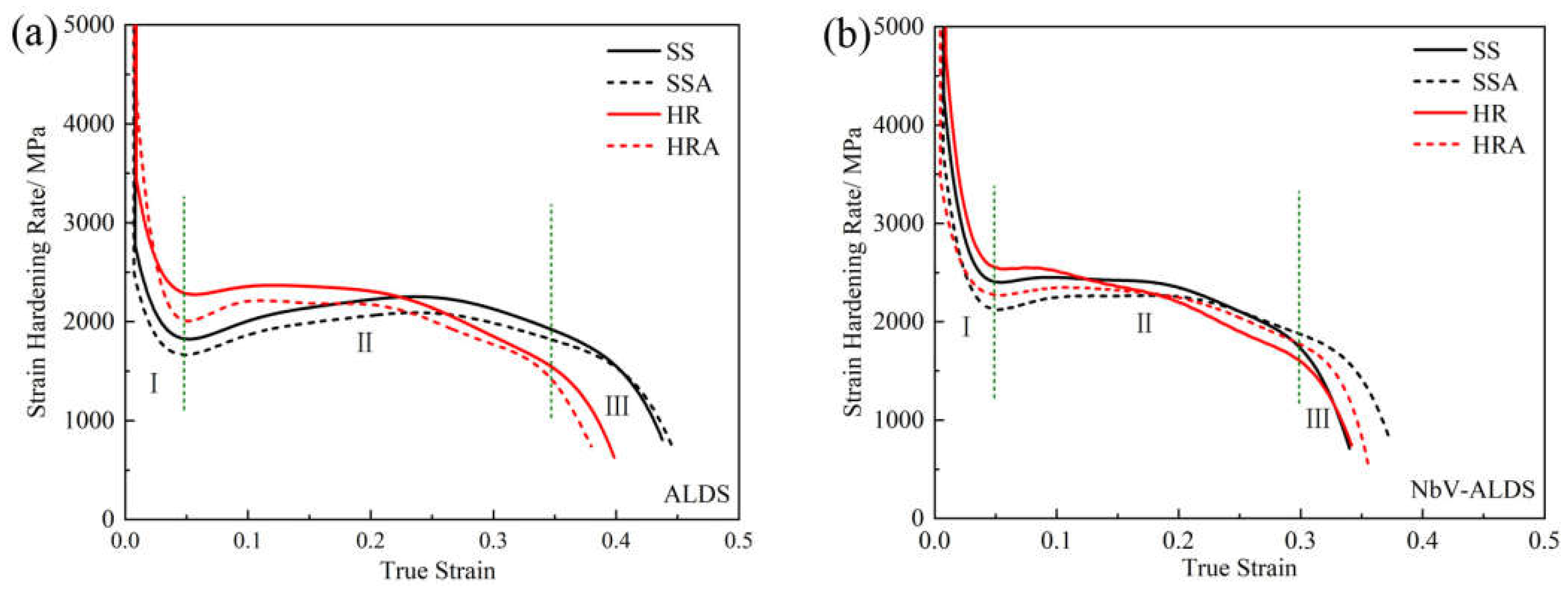

4.1. Effect of the Thermo-Mechanical Process and Nb-V Microalloying on Microstructure and Tensile Deformation Behavior

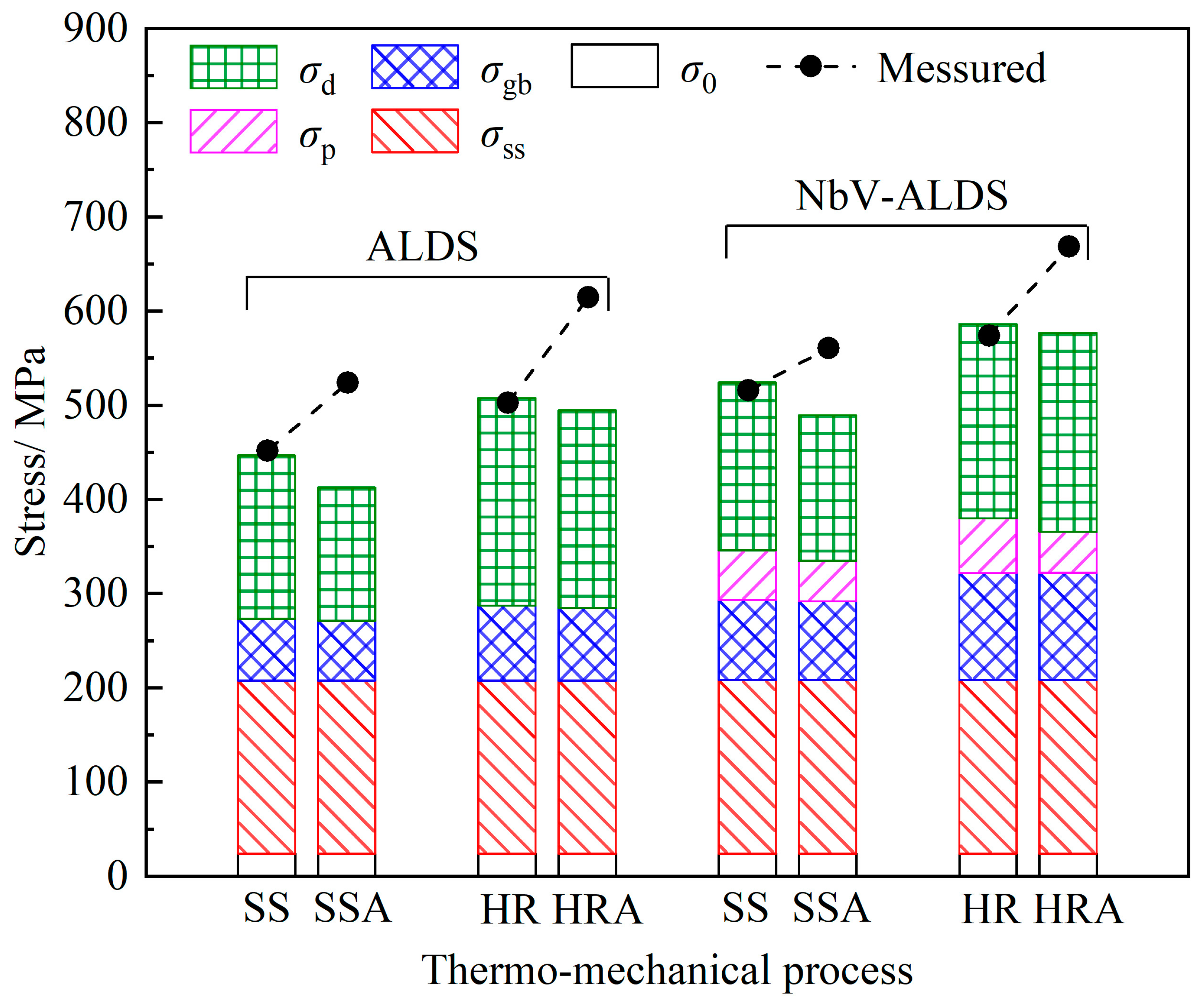

4.2. Contribution of Various Strengthening Effects to the Yield Strength

- (1)

- Lattice friction stress

- (2)

- Solid solution strengthening

- (3)

- Grain boundary strengthening

- (4)

- Precipitation strengthening

- (5)

- Dislocation strengthening

5. Conclusions

- (1)

- Hot rolling significantly reduces the austenitic grain size of both test steels by 30%–45%. The grain size of the NbV-ALDS decreases by 40%–55% compared with that of the ALDS at the same thermo-mechanical process since the precipitation of nanoscale (Nb,V)C particles inhibits the growth of austenite grains. The (Nb,V)C particles hardly change in size and content during high temperature and hot rolling treatment because of their high thermal stability.

- (2)

- The strength of the test steels treated by hot rolling or aging is improved. The strength of the Fe–Mn–Al–C steel with Nb-V microalloying increases by 55 MPa due to the precipitation strengthening and fine grain strengthening of (Nb,V)C particles. However, the elongation is decreased. The test steels, after hot rolling + aging treatment, obtain the maximum strength. The yield and tensile strength of the ALDS are 615 MPa and 966 MPa, respectively, while the yield and tensile strength of the NbV-ALDS are 669 MPa and 1001 MPa, respectively.

- (3)

- The strengthening mechanisms contributing appreciably to the yield strength are solid solution and dislocation strengthening. These strengthening effects contribute 185 MPa and 211 MPa, respectively, to the yield strength for the NbV-ALDS steel after hot rolling + aging treatment. The segregation of carbon atoms to boundaries during aging also improves the yield strength of the test steels. The primary deformation mechanism is microband induced plasticity.

- (4)

- The addition of forceful carbide-forming microalloying elements is expected to become the focus of research in the Fe–Mn–Al–C austenitic low-density steel field, utilizing the advantages of fine precipitates. It is recommended to optimize the chemical composition of microalloyed Fe–Mn–Al–C austenitic steel and explore its various application properties, such as magnetism, corrosion resistance, fatigue, and wear properties, in future studies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Frommeyer, G.; Brüx, U.; Neumann, P. Supra-ductile and high-strength manganese-TRIP/TWIP steels for high energy absorption purposes. ISIJ Int. 2003, 43, 438–446. [Google Scholar] [CrossRef]

- Kim, H.; Suh, D.W.; Kim, N.J. Fe–Al–Mn–C lightweight structural alloys: A review on the microstructures and mechanical properties. Sci. Technol. Adv. Mater. 2013, 14, 014205. [Google Scholar] [CrossRef]

- Chen, S.; Rana, R.; Haldar, A.; Ray, R.K. Current state of Fe-Mn-Al-C low density steels. Prog. Mater. Sci. 2017, 89, 345–391. [Google Scholar] [CrossRef]

- Chang, K.M.; Chao, C.G.; Liu, T.F. Excellent combination of strength and ductility in a Fe–9Al–28Mn–1.8C alloy. Scr. Mater. 2010, 63, 162–165. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. Influence of Al content and precipitation state on the mechanical behaviour of austenitic high-Mn low-density steels. Scr. Mater. 2013, 68, 343–347. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, M.-X.; Zhang, J.-K.; Yang, L.; Zhang, Y.-H.; Song, C.-J.; Zhai, Q.-J. Effect of annealing treatment on microstructures and properties of austenite-based Fe-28Mn-9Al-0.8C lightweight steel with addition of Cu. China Foundry 2021, 18, 207–216. [Google Scholar] [CrossRef]

- He, W.; Wang, B.-L.; Yang, Y.; Zhang, Y.-H.; Duan, L.; Luo, Z.-P.; Song, C.-J.; Zhai, Q.-J. Microstructure and mechanical behavior of a low-density Fe–12Mn–9Al–1.2C steel prepared using centrifugal casting under near-rapid solidification. J. Iron Steel Res. Int. 2018, 25, 830–838. [Google Scholar] [CrossRef]

- Sohn, S.S.; Lee, B.-J.; Lee, S.; Kim, N.J.; Kwak, J.-H. Effect of annealing temperature on microstructural modification and tensile properties in 0.35C-3.5Mn-5.8Al lightweight steel. Acta Mater. 2013, 61, 5050–5066. [Google Scholar] [CrossRef]

- Lee, K.; Park, S.-J.; Lee, J.; Moon, J.; Kang, J.-Y.; Kim, D.-I.; Suh, J.-Y.; Han, H.N. Effect of aging treatment on microstructure and intrinsic mechanical behavior of Fe-31.4Mn-11.4Al-0.89C lightweight steel. J. Alloys Compd. 2016, 656, 805–811. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.; Cheng, X.; Li, Z.; Gao, C.; Li, S. The effect of rolling and subsequent aging on microstructures and tensile properties of a Fe-Mn-Al-C austenitic steel. Mater. Sci. Eng. A 2021, 822, 141683. [Google Scholar] [CrossRef]

- Lu, W.J.; Zhang, X.F.; Qin, R.S. κ-carbide hardening in a low-density high-Al high-Mn multiphase steel. Mater. Lett. 2015, 138, 96–99. [Google Scholar] [CrossRef]

- Jeong, S.; Park, G.; Kim, B.; Moon, J.; Park, S.-J.; Lee, C. Precipitation behavior and its effect on mechanical properties in weld heat affected zone in age hardened FeMnAlC lightweight steels. Mater. Sci. Eng. A 2019, 742, 61–68. [Google Scholar] [CrossRef]

- Zhang, G.F.; Shi, H.Y.; Wang, S.T.; Tang, Y.H.; Zhang, X.Y.; Jing, Q.; Liu, R.P. Ultrahigh strength and high ductility lightweight steel achieved by dual nanoprecipitate strengthening and dynamic slip refinement. Mater. Lett. 2023, 330, 133366. [Google Scholar] [CrossRef]

- Haase, C.; Zehnder, C.; Ingendahl, T.; Bikar, A.; Tang, F.; Hallstedt, B.; Hu, W.P.; Bleck, W.; Molodov, D.A. On the deformation behavior of k-carbide-free and k-carbide containing high-Mn light-weight steel. Acta Mater. 2017, 122, 332–343. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.C.; Cheng, X.W.; Li, Z.Y.; Du, J.K.; Li, S.K. The effect of Ti-Mo-Nb on the microstructures and tensile properties of a Fe-Mn-Al-C austenitic steel. Mater. Sci. Eng. A 2020, 780, 139220. [Google Scholar] [CrossRef]

- Salas-Reyes, A.E.; Mejía, I.; Bedolla-Jacuinde, A.; Boulaajaj, A.; Calvo, J.; Cabrera, J.M. Hot ductility behavior of high-Mn austenitic Fe-22Mn-1.5Al-1.5Si-0.45C TWIP steels microalloyed with Ti and V. Mater. Sci. Eng. A 2014, 611, 77–89. [Google Scholar] [CrossRef]

- Gwon, H.; Kim, J.-K.; Shin, S.; Cho, L.; De Cooman, B.C. The effect of vanadium micro-alloying on the microstructure and the tensile behavior of TWIP steel. Mater. Sci. Eng. A 2017, 696, 416–428. [Google Scholar] [CrossRef]

- Ma, T.; Li, H.R.; Gao, J.X.; Wang, X.F.; Song, H.W.; Li, Y.G. Progress on strengthening mechanism and tensile properties of Fe-Mn-Al-C low density steel and prospect of Nb microalloying. Mater. Rep. 2020, 34, 23154–23164. [Google Scholar]

- Zhou, N.P.; Song, R.B.; Song, R.F.; Li, X.; Li, J.J. Influence of Nb addition on microstructure and mechanical properties of medium-Mn low-density steels. Steel Res. Int. 2018, 89, 1700552. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Tong, Q.G.; Liu, Y.S. Effect of rolling process parameters on precipitation strengthening of V and Nb microalloyed steel. J. Northeast Univ. Technol. 1992, 13, 363–367. [Google Scholar]

- Yoo, J.D.; Park, K.T. Microband-induced plasticity in a high Mn-Al-C light steel. Mater. Sci. Eng. A 2008, 496, 417–424. [Google Scholar] [CrossRef]

- Fu, J.; Li, G.; Mao, X.; Fang, K. Nanoscale cementite precipitates and comprehensive strengthening mechanism of steel. Metall. Mater. Trans. A 2011, 42, 3797–3812. [Google Scholar] [CrossRef]

- Park, K.T. Tensile deformation of low-density Fe-Mn-Al-C austenitic steels at ambient temperature. Scr. Mater. 2013, 68, 375–379. [Google Scholar] [CrossRef]

- Zhao, T.; Rong, S.; Hao, X.; Wang, Y.; Chen, C.; Wang, T. Effect of Nb-V microalloying on hot deformation characteristics and microstructures of Fe-Mn-Al-C austenitic steel. Mater. Charact. 2022, 183, 111595. [Google Scholar] [CrossRef]

- Castan, C.; Montheillet, F.; Perlade, A. Dynamic recrystallization mechanisms of an Fe–8% Al low density steel under hot rolling conditions. Scr. Mater. 2013, 68, 360–364. [Google Scholar] [CrossRef]

- Yang, F.Q.; Song, R.B.; Li, Y.P.; Sun, T.; Wang, K.K. Tensile deformation of low density duplex Fe-Mn-Al-C steel. Mater. Design 2015, 76, 32–39. [Google Scholar] [CrossRef]

- Ji, F.; Song, W.; Ma, Y.; Li, C.; Bleck, W.; Wang, G. Recrystallization behavior in a low-density high-Mn high-Al austenitic steel undergone thin strip casting process. Mater. Sci. Eng. A 2018, 733, 87–97. [Google Scholar] [CrossRef]

- Dini, G.; Najafizadeh, A.; Ueji, R.; Monir-Vaghefi, S. Tensile deformation behavior of high manganese austenitic steel: The role of grain size. Mater. Des. 2010, 31, 3395–3402. [Google Scholar] [CrossRef]

- Rao, M.P.; Sarma, V.S.; Sankaran, S. Development of high strength and ductile ultra fine grained dual phase steel with nano sized carbide precipitates in a V–Nb microalloyed steel. Mater. Sci. Eng. A 2013, 568, 171–175. [Google Scholar] [CrossRef]

- Park, K.-T.; Kim, G.; Kim, S.K.; Lee, S.W.; Hwang, S.W.; Lee, C.S. On the transitions of deformation modes of fully austenitic steels at room temperature. Met. Mater. Int. 2010, 16, 1–6. [Google Scholar] [CrossRef]

- Zambrano, O.A. Stacking fault energy maps of Fe-Mn-Al-C-Si steels: Effect of temperature, grain Size, and variations in compositions. J. Eng. Mater. Technol. 2016, 138, 041010. [Google Scholar] [CrossRef]

- Park, D.-B.; Huh, M.-Y.; Shim, J.-H.; Suh, J.-Y.; Lee, K.-H.; Jung, W.-S. Strengthening mechanism of hot rolled Ti and Nb microalloyed HSLA steels containing Mo and W with various coiling temperature. Mater. Sci. Eng. A 2013, 560, 528–534. [Google Scholar] [CrossRef]

- Pavel, K.; Andrey, B.; Dmitri, A.; Rustam, K. On the effect of chemical composition on yield strength of TWIP steels. Mater. Sci. Eng. A 2017, 687, 82–84. [Google Scholar]

- Kaye, G.W.C.; Laby, T.H. Tables of Physical and Chemical Constants, 14th ed.; Longman: London, UK, 1973. [Google Scholar]

- Ding, H.; Li, H.Y.; Misra, R.D.K.; Wu, Z.Q.; Cai, M.H. Strengthening mechanisms in low density Fe-26Mn-xAl-1C steels. Steel Res. Int. 2018, 89, 1700381. [Google Scholar] [CrossRef]

- Cao, J.; Yong, Q.; Liu, Q.; Sun, X. Precipitation of MC phase and precipitation strengthening in hot rolled Nb-Mo and Nb-Ti steels. J. Mater. Sci. 2007, 42, 10080–10084. [Google Scholar] [CrossRef]

- Seok, M.-Y.; Choi, I.-C.; Moon, J.; Kim, S.; Ramamurty, U.; Jang, J.-I. Estimation of the Hall-Petch strengthening coefficient of steels through nanoindentation. Scr. Mater. 2014, 87, 49–52. [Google Scholar] [CrossRef]

- Scott, C.; Remy, B.; Collet, J.-L.; Cael, A.; Bao, C.; Danoix, F.; Malard, B.; Curfs, C. Precipitation strengthening in high manganese austenitic TWIP steels. Int. J. Mater. Res. 2011, 102, 538–549. [Google Scholar] [CrossRef]

- Wang, X.J.; Sun, X.J.; Song, C.; Chen, H.; Han, W.; Pan, F. Enhancement of yield strength by chromium/nitrogen alloying in high-manganese cryogenic steel. Mater. Sci. Eng. A 2017, 698, 110–116. [Google Scholar] [CrossRef]

- Bouaziz, O.; Guelton, N. Modelling of TWIP effect on work-hardening. Mater. Sci. Eng. A 2001, 319, 246–249. [Google Scholar] [CrossRef]

- Liang, Z.Y.; Li, Y.Z.; Huang, M.X. The respective hardening contributions of dislocations and twins to the flow stress of a twinning-induced plasticity steel. Scr. Mater. 2016, 112, 28–31. [Google Scholar] [CrossRef]

- Chen, C.; Lv, B.; Feng, X.; Zhang, F.; Beladi, H. Strain hardening and nanocrystallization behaviors in Hadfield steel subjected to surface severe plastic deformation. Mater. Sci. Eng. A 2018, 729, 178–184. [Google Scholar] [CrossRef]

- Wen, Y.; Xiao, H.; Peng, H.; Li, N.; Raabe, D. Relationship between damping capacity and variations of vacancies concentration and segregation of carbon atom in an Fe-Mn alloy. Metall. Mater. Trans. A 2015, 46, 4828–4833. [Google Scholar] [CrossRef]

- Shen, T.; Schwarz, R.; Feng, S.; Swadener, J.; Huang, J.; Tang, M.; Zhang, J.; Vogel, S.; Zhao, Y. Effect of solute segregation on the strength of nanocrystalline alloys: Inverse Hall–Petch relation. Acta Mater. 2007, 55, 5007–5013. [Google Scholar] [CrossRef]

- Vo, N.; Schäfer, J.; Averback, R.; Albe, K.; Ashkenazy, Y.; Bellon, P. Reaching theoretical strengths in nanocrystalline Cu by grain boundary doping. Scr. Mater. 2011, 65, 660–663. [Google Scholar] [CrossRef]

- Bobylev, S.; Enikeev, N.; Sheinerman, A.; Valiev, R. Strength enhancement induced by grain boundary solute segregations in ultrafine-grained alloys. Int. J. Plast. 2019, 123, 133–144. [Google Scholar] [CrossRef]

| Test Steels | C | Al | Mn | Mo | Nb | V | S | P |

|---|---|---|---|---|---|---|---|---|

| ALDS | 1.05 | 7.29 | 27. 67 | 0.64 | — | — | 0.042 | 0.013 |

| NbV-ALDS | 1.05 | 7.33 | 27. 92 | 0.62 | 0.16 | 0.16 | 0.037 | 0.014 |

| Test Steel | Thermo-Mechanical Process | Yield Strength (MPa) | Tensile Strength (MPa) | Yield Ratio | Elongation (%) |

|---|---|---|---|---|---|

| ALDS | SS | 452 | 872 | 0.52 | 64.0 |

| SSA | 524 | 879 | 0.60 | 63.7 | |

| HR | 503 | 923 | 0.54 | 58.2 | |

| HRA | 615 | 966 | 0.64 | 54.0 | |

| NbV-ALDS | SS | 516 | 938 | 0.55 | 48.8 |

| SSA | 561 | 940 | 0.60 | 52.4 | |

| HR | 574 | 973 | 0.59 | 48.0 | |

| HRA | 669 | 1001 | 0.67 | 49.0 |

| Test Steel | Thermo-Mechanical Process | ||||||

|---|---|---|---|---|---|---|---|

| ALDS | SS | 23.6 | 183.9 | 65.7 | 0 | 173.5 | 446.7 |

| SSA | 23.6 | 183.9 | 63.5 | 0 | 141.6 | 412.6 | |

| HR | 23.6 | 183.9 | 79.5 | 0 | 220.5 | 507.5 | |

| HRA | 23.6 | 183.9 | 77.1 | 0 | 210.0 | 494.6 | |

| NbV-ALDS | SS | 23.6 | 184.7 | 84.9 | 52.8 | 178.1 | 524.1 |

| SSA | 23.6 | 184.7 | 83.3 | 43.0 | 154.6 | 489.2 | |

| HR | 23.6 | 184.7 | 113.3 | 58.2 | 206.4 | 586.2 | |

| HRA | 23.6 | 184.7 | 113.6 | 43.5 | 211.3 | 576.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, T.; Hao, X.; Wang, Y.; Chen, C.; Wang, T. Influence of Thermo-Mechanical Process and Nb-V Microalloying on Microstructure and Mechanical Properties of Fe–Mn–Al–C Austenitic Steel. Coatings 2023, 13, 1513. https://doi.org/10.3390/coatings13091513

Zhao T, Hao X, Wang Y, Chen C, Wang T. Influence of Thermo-Mechanical Process and Nb-V Microalloying on Microstructure and Mechanical Properties of Fe–Mn–Al–C Austenitic Steel. Coatings. 2023; 13(9):1513. https://doi.org/10.3390/coatings13091513

Chicago/Turabian StyleZhao, Ting, Xiaohong Hao, Yuefeng Wang, Chen Chen, and Tiansheng Wang. 2023. "Influence of Thermo-Mechanical Process and Nb-V Microalloying on Microstructure and Mechanical Properties of Fe–Mn–Al–C Austenitic Steel" Coatings 13, no. 9: 1513. https://doi.org/10.3390/coatings13091513

APA StyleZhao, T., Hao, X., Wang, Y., Chen, C., & Wang, T. (2023). Influence of Thermo-Mechanical Process and Nb-V Microalloying on Microstructure and Mechanical Properties of Fe–Mn–Al–C Austenitic Steel. Coatings, 13(9), 1513. https://doi.org/10.3390/coatings13091513