Cavitation Erosion Resistance of TiSiN/NiTiAlCoCrN Nanomultilayer Films with Different Modulation Periods

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Materials

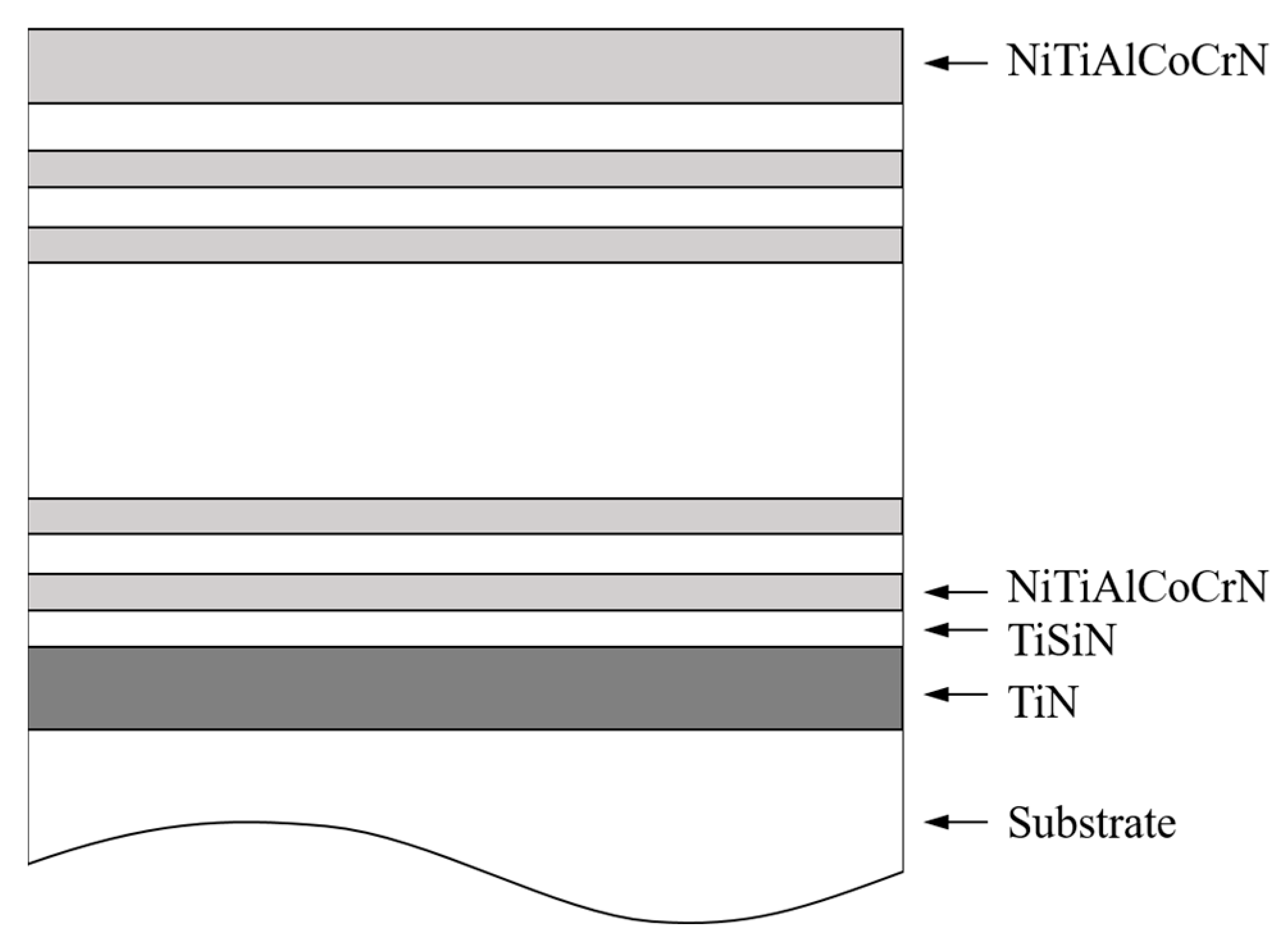

2.2. Film Deposition

2.3. Film Characterization

3. Results and Discuss

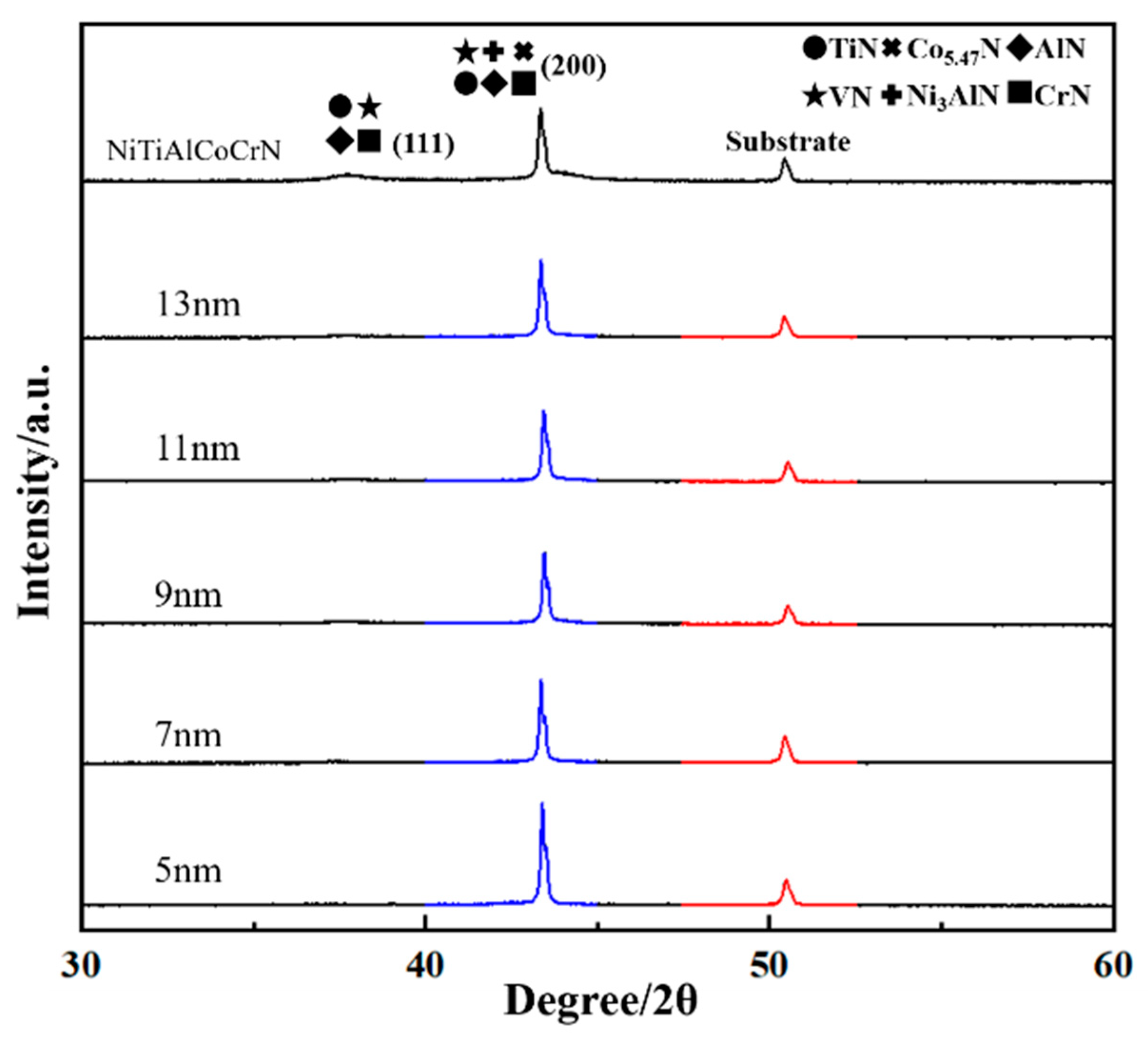

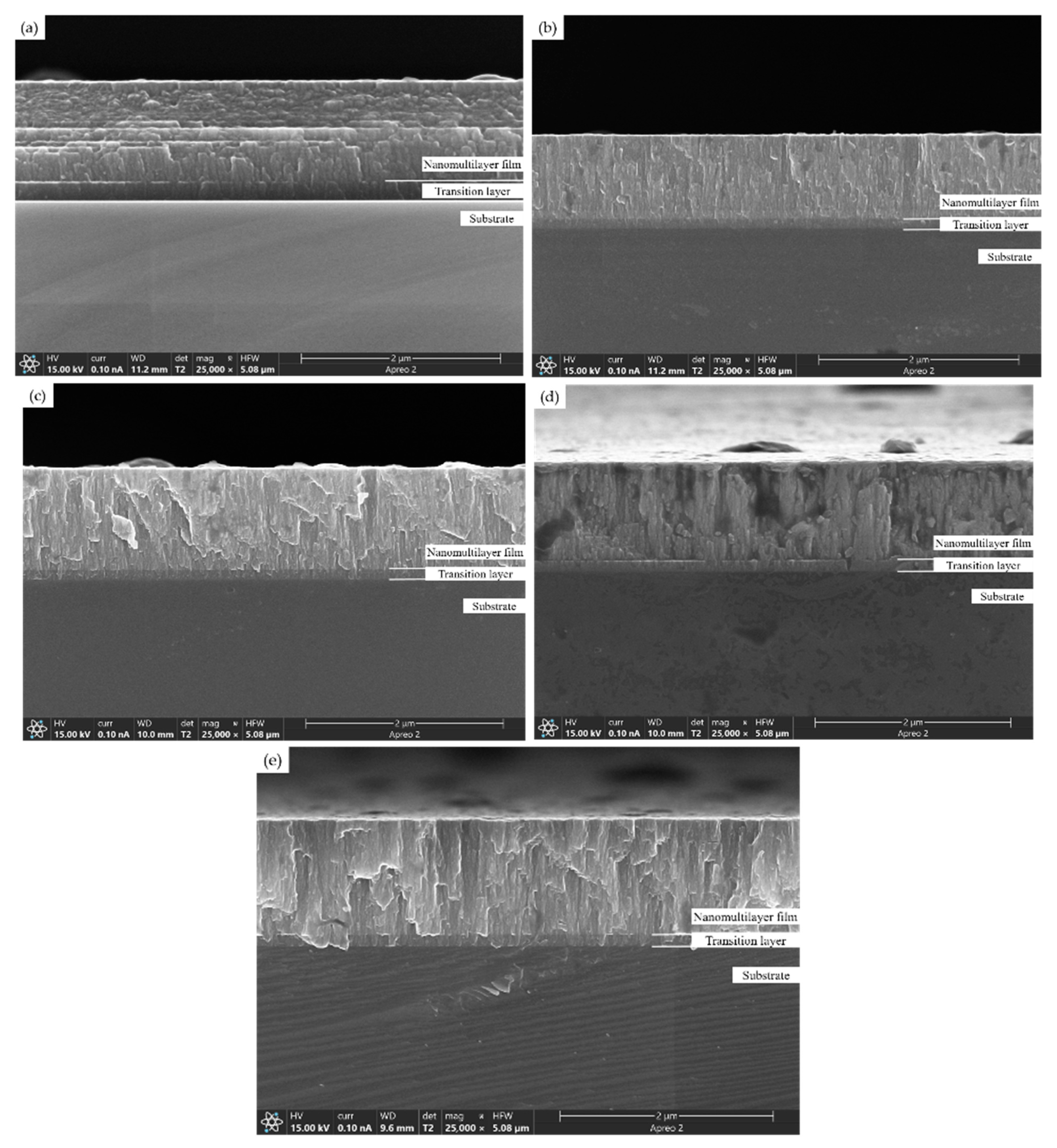

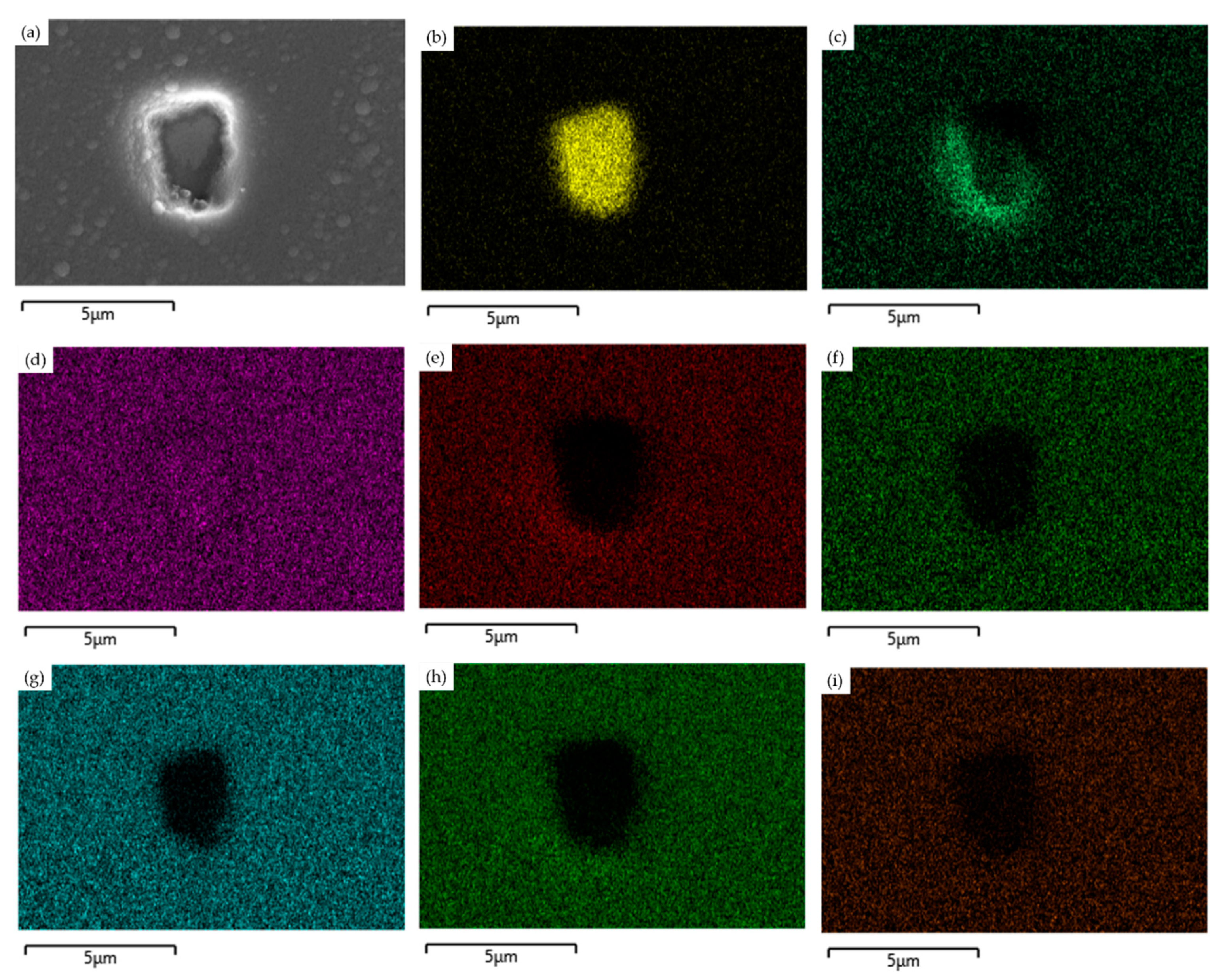

3.1. Microstructure

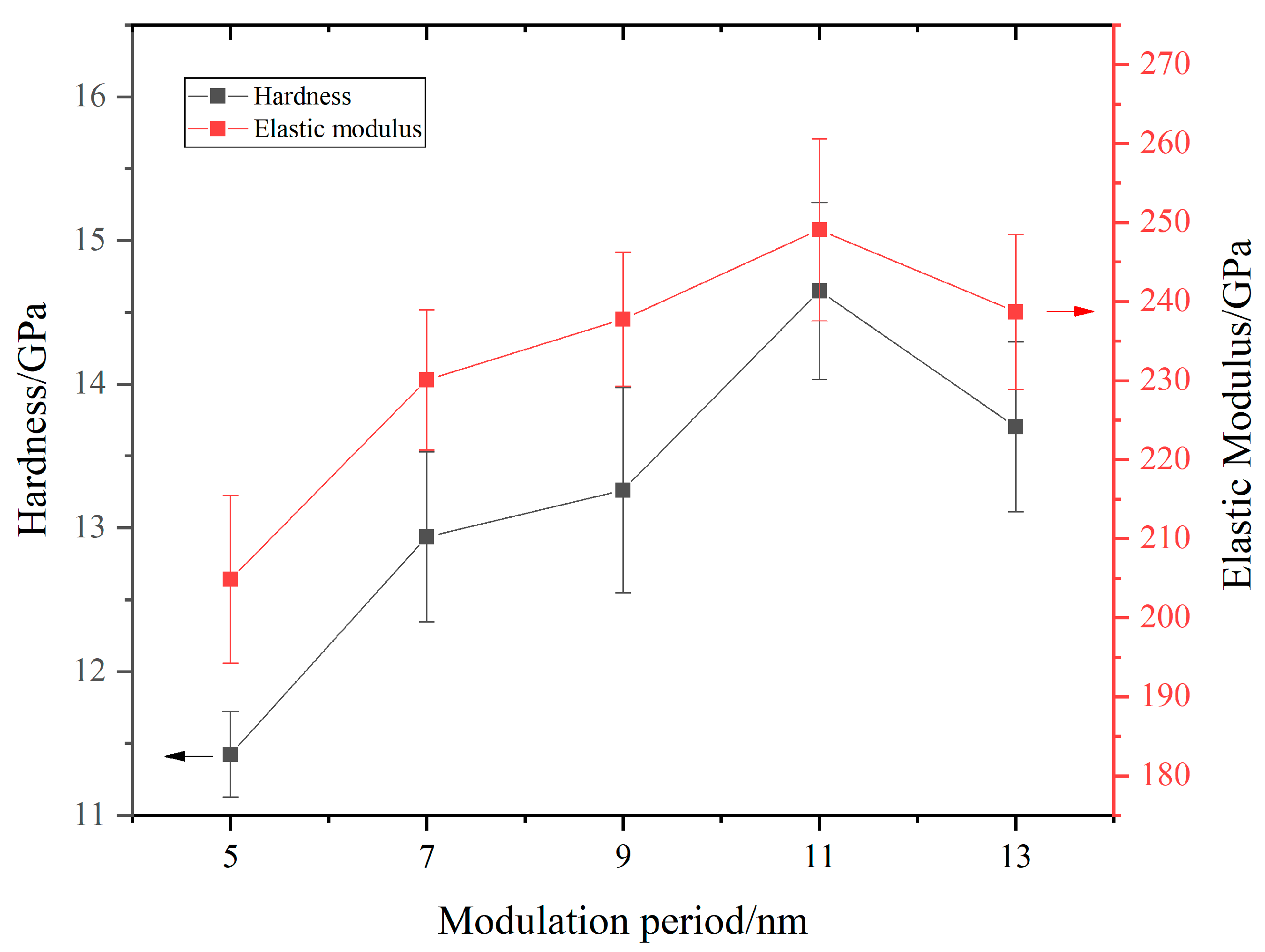

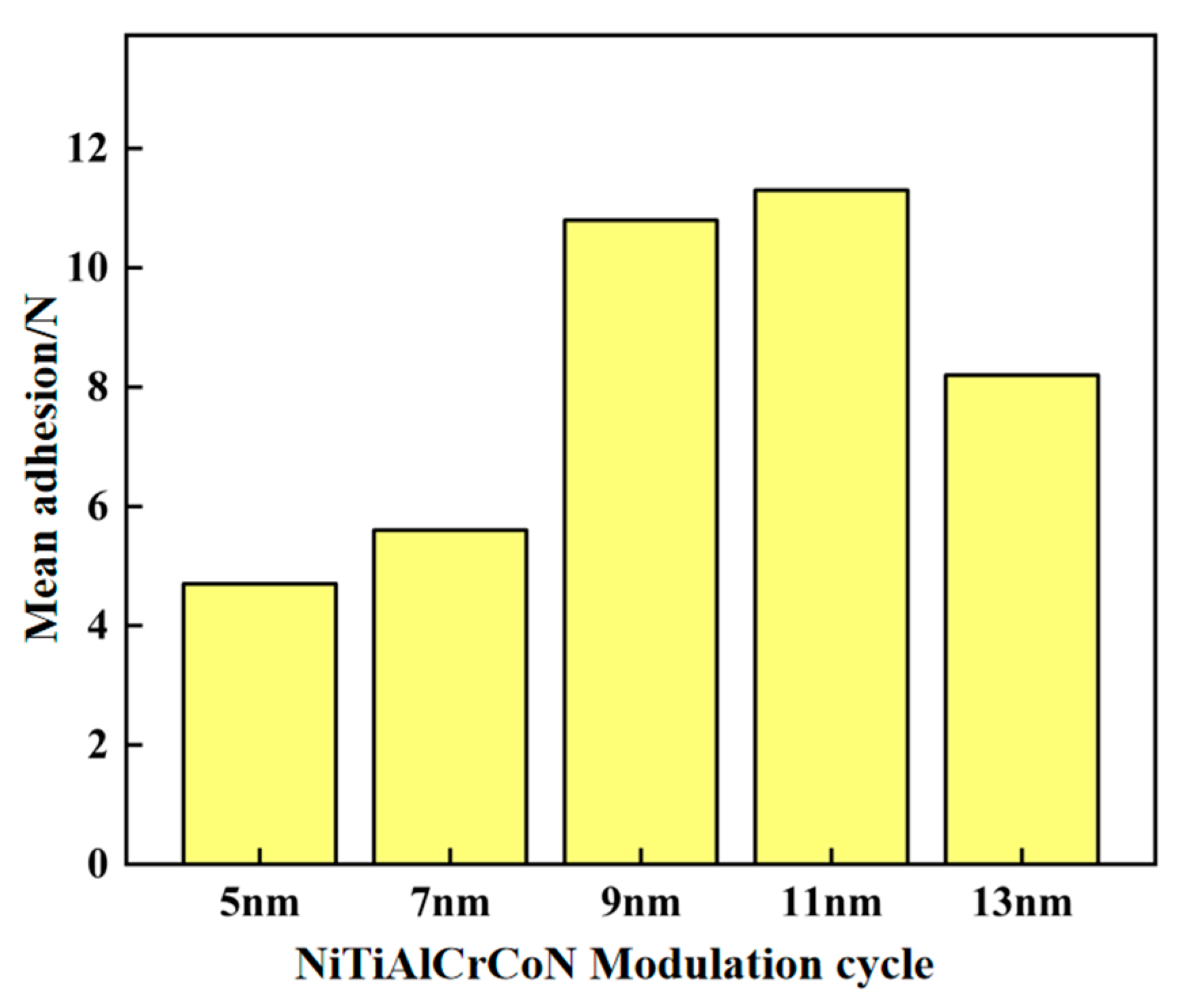

3.2. Mechanical Properties

3.3. Corrosion Erosion Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yin, D.; Liang, G.; Fan, S.; Li, S. Ultrasonic Cavitation Erosion Behavior of AlCoCrxCuFe High Entropy Alloy Coatings Synthesized by Laser Cladding. Materials 2020, 13, 4067. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Xiang, D.; Wang, K.; Yu, T. Corrosion of Laser Cladding High-Entropy Alloy Coatings: A Review. Coatings 2022, 12, 1669. [Google Scholar] [CrossRef]

- Singh, R.; Tiwari, S.K.; Mishra, S.K. Cavitation Erosion in Hydraulic Turbine Components and Mitigation by Coatings: Current Status and Future Needs. J. Mater. Eng. Perform. 2011, 21, 1539–1551. [Google Scholar] [CrossRef]

- Wei, X.; Zhu, W.; Ban, A.; Zhu, D.; Zhang, C.; Dong, H. Effects of Co addition on microstructure and cavitation erosion resistance of plasma sprayed TiNi based coating. Surf. Coat. Technol. 2021, 409, 126838. [Google Scholar] [CrossRef]

- Ma, D.; Harvey, T.; Wellman, R.; Ehiasarian, A.; Hovsepian, P.E.; Sugumaran, A.; Purandare, Y.; Wood, R. Cavitation erosion performance of CrAlYN/CrN nanoscale multilayer coatings deposited on Ti6Al4V by HIPIMS. J. Alloys Compd. 2019, 788, 719–728. [Google Scholar] [CrossRef]

- Szkodo, M.; Stanisławska, A.; Komarov, A.; Bolewski, Ł. Effect of MAO coatings on cavitation erosion and tribological properties of 5056 and 7075 aluminum alloys. Wear 2021, 474–475, 203709. [Google Scholar] [CrossRef]

- Lin, J.; Hong, S.; Zheng, Y.; Sun, W.; Kang, M.; Fu, X. Cavitation erosion resistance in NaCl medium of HVOF sprayed WC-based cermet coatings at various flow velocities: A comparative study on the effect of Ni and CoCr binder phases. Int. J. Refract. Met. Hard Mater. 2021, 94, 105407. [Google Scholar] [CrossRef]

- Fan, Q.; Chen, C.; Fan, C.; Liu, Z.; Cai, X.; Lin, S.; Yang, C. Ultrasonic induces grain refinement in gas tungsten arc cladding AlCoCrFeNi high-entropy alloy coatings. Mater. Sci. Eng. A 2021, 821, 141607. [Google Scholar] [CrossRef]

- Zhu, Z.-X.; Liu, X.-B.; Liu, Y.-F.; Zhang, S.-Y.; Meng, Y.; Zhou, H.-B. Effects of Cu/Si on the microstructure and tribological properties of FeCoCrNi high entropy alloy coating by laser cladding. Wear 2023, 512–513, 204533. [Google Scholar] [CrossRef]

- Ma, G.L.; Zhao, Y.; Cui, H.Z.; Song, X.J.; Wang, M.L.; Lee, K.M.; Gao, X.H.; Song, Q.; Wang, C.M. Addition Al and/or Ti induced modifications of microstructures, mechanical properties, and corrosion properties in CoCrFeNi high-entropy alloy coatings. Acta Metall. Sin. 2021, 34, 1087–1102. [Google Scholar] [CrossRef]

- Qiu, X.W. Microstructure and corrosion properties of Al2CrFeCoxCuNiTi high entropy alloys prepared by additive manufacturing. J. Alloys Compd. 2021, 887, 161422. [Google Scholar] [CrossRef]

- Liang, H.; Hou, J.X.; Cao, Z.Q.; Jiang, L. Interesting ‘island-like’ microstructure and tribological evaluation of Al1.5CrFeNiWTi0.5 high entropy alloy coating manufactured by laser cladding. Tribol. Int. 2023, 179, 108171. [Google Scholar] [CrossRef]

- Xiao, J.K.; Li, T.T.; Wu, Y.Q.; Chen, J.; Zhang, C. Microstructure and tribological properties of plasma-sprayed CoCrFeNi-based high-entropy alloy coatings under dry and oil-lubricated sliding conditions. J. Therm. Spray Technol. 2021, 30, 926–936. [Google Scholar] [CrossRef]

- Huang, Y.; Hu, Y.; Zhang, M.; Mao, C.; Tong, Y.; Zhang, J.; Li, K.; Wang, K. On the enhanced wear resistance of laser-clad CoCrCuFeNiTix high-entropy alloy coatings at elevated temperature. Tribol. Int. 2022, 174, 107767. [Google Scholar] [CrossRef]

- Lin, D.-Y.; Zhang, N.-N.; He, B.; Jin, B.-Q.; Zhang, Y.; Li, D.-Y.; Dong, F.-Y. Influence of laser re-melting and vacuum heat treatment on plasma-sprayed FeCoCrNiAl alloy coatings. J. Iron Steel Res. Int. 2017, 24, 1199–1205. [Google Scholar] [CrossRef]

- Doan, D.-Q.; Nguyen, V.-H.; Tran, T.-V.; Hoang, M.-T. Atomic-scale analysis of mechanical and wear characteristics of AlCoCrFeNi high entropy alloy coating on Ni substrate. J. Manuf. Process 2023, 85, 1010–1023. [Google Scholar] [CrossRef]

- Wei, Z.; Wu, Y.; Hong, S.; Cheng, J.; Qiao, L.; Cheng, J.; Zhu, S. Ultrasonic cavitation erosion behaviors of high-velocity oxygen-fuel (HVOF) sprayed AlCoCrFeNi high-entropy alloy coating in different solutions. Surf. Coat. Technol. 2021, 409, 126899. [Google Scholar] [CrossRef]

- Xu, J.; Peng, S.; Li, Z.; Jiang, S.; Xie, Z.-H.; Munroe, P.; Lu, H. Remarkable cavitation erosion–corrosion resistance of CoCrFeNiTiMo high-entropy alloy coatings. Corros. Sci. 2021, 190, 109663. [Google Scholar] [CrossRef]

- Straumal, B.; Rabkin, E.; Lopez, G.A.; Korneva, A.; Kuzmin, A.; Gornakova, A.; Straumal, A.; Baretzky, B. Grain Boundary Wetting Phenomena in High Entropy Alloys Containing Nitrides, Carbides, Borides, Silicides, and Hydrogen: A Review. Crystals 2021, 11, 1540. [Google Scholar]

- Wu, T.; Chen, Y.; Lin, B.; Yu, L.; Gui, W.; Li, J.; Wu, Y.; Zeng, D. Effects of WC on the Microstructure, Wear and Corrosion Resistance of Laser-Deposited CoCrFeNi High Entropy Alloy Coatings. Coatings 2022, 12, 985. [Google Scholar] [CrossRef]

- Wei, Z.; Wu, Y.; Hong, S.; Cheng, J.; Qiao, L.; Cheng, J.; Zhu, S. Effect of WC-10Co on cavitation erosion behaviors of AlCoCrFeNi coatings prepared by HVOF spraying. Ceram. Int. 2021, 47, 15121–15128. [Google Scholar] [CrossRef]

- Bao, Y.; Guo, L.; Zhong, C.; Song, Q.; Yang, K.; Jiang, Y.; Wang, Z. Effects of WC on the cavitation erosion resistance of FeCoCrNiB0.2 high entropy alloy coating prepared by laser cladding. Mater. Today Commun. 2021, 26, 102154. [Google Scholar] [CrossRef]

- Lan, L.; Wang, X.; Guo, R.; Yang, H.; Qiao, J. Effect of environments and normal loads on tribological properties of nitrided Ni45(FeCoCr)40(AlTi)15 high-entropy alloys. J. Mater. Sci. Technol. 2019, 42, 85–96. [Google Scholar] [CrossRef]

- Xu, Y.; Li, G.; Xia, Y. Synthesis and characterization of super-hard AlCrTiVZr high-entropy alloy nitride films deposited by HiPIMS. Appl. Surf. Sci. 2020, 523, 146529. [Google Scholar] [CrossRef]

- Chen, L.Q.; Li, W.; Liu, P.; Zhang, K.; Ma, F.C.; Chen, X.H.; Zhou, H.L.; Liu, X.K. Microstructure and mechanical properties of (AlCrTiZrV)Nx high-entropyalloy nitride films by reactive magnetron sputtering. Vacuum 2020, 181, 109706. [Google Scholar] [CrossRef]

- Chen, W.; Yan, A.; Wang, C.; Deng, Y.; Chen, D.; Xiao, H.; Zhang, D.; Meng, X. Microstructures and mechanical properties of AlCrN/TiSiN nanomultilayer coatings consisting of fcc single-phase solid solution. Appl. Surf. Sci. 2020, 509, 145303. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Yang, Y.-J.; Weng, S.-Y. Effect of interlayer design on the mechanical properties of AlTiCrN and multilayered AlTiCrN/TiSiN hard coatings. Surf. Coat. Technol. 2020, 389, 125637. [Google Scholar] [CrossRef]

- Krella, A.K.; Czyzniewski, A.; Gilewicz, A.; Gajowiec, G. Experimental Study of the Influence of Deposition of Multilayer CrN/CrCN PVD Coating on Austenitic Steel on Resistance to Cavitation Erosion. Coatings 2020, 10, 487. [Google Scholar] [CrossRef]

- Li, B.H.; Ma, X.; Li, W.; Zhai, Q.; Liu, P.; Zhang, K.; Ma, F.; Wang, J. Effect of SiC thickness on microstructure and mechanical properties of (AlCrTiZrV)N/SiC nano-multilayers film synthesized by reactive magnetron sputtering. Thin Solid Film. 2021, 730, 138724. [Google Scholar] [CrossRef]

- Bagdasaryan, A.A.; Pshyk, A.V.; Coy, L.E.; Kempinski, M.; Pogrebnjak, A.D.; Beresnev, V.M.; Jurga, S. Structural and mechanical characterization of (TiZrNbHfTa)N/WN multilayered nitride coatings. Mater. Lett. 2018, 229, 364–367. [Google Scholar] [CrossRef]

- Lu, Z.; Mao, Y.; Ren, S.; Pu, J.; Fu, Z.; Fan, X.; Gao, S.; Fan, J. A novel design of VAlTiCrCu/WC alternate multilayer structure to enhance the mechanical and tribo-corrosion properties of the high-entropy alloy coating. Mater. Charact. 2021, 176, 111115. [Google Scholar] [CrossRef]

- He, H.J.; Liu, C.H.; He, L.X.; Wang, G.C.; Zhang, W.; Zhao, S.; Xiang, Y.; Yi, J. Microstructure, mechanical properties and high temperature corrosion of [AlTiCrNiTa/(AlTiCrNiTa)N]20 high entropy alloy multilayer coatings for nuclear fuel cladding. Vacuum 2023, 212, 112057. [Google Scholar] [CrossRef]

- Yan, H.J.; Liu, Y.F.; Mi, Z.F.; Si, L.N.; Dou, Z.L.; Liu, F.B. Effect of nitrogen-argon flow ratio on cavitation resistance of NiTiAlCrN coating. J. Funct. Mater. 2023, 54, 01007–01011. [Google Scholar]

- Sui, X.; Li, G.; Jiang, C.; Wang, K.; Zhang, Y.; Hao, J.; Wang, Q. Improved toughness of layered architecture TiAlN/CrN coatings for titanium high speed cutting. Ceram. Int. 2018, 44, 5629–5635. [Google Scholar] [CrossRef]

- Wei, Y.Q.; Zong, X.Y.; Jiang, Z.Q. Characterization and mechanical properties of TiN/TiAlN multilayer coatings with different modulation periods. Int. J. Adv. Manuf. Technol. 2018, 96, 1677–1683. [Google Scholar]

- Zhai, Q.Q.; Li, W.; Liu, P. Mechanical Behavior and Thermal Stability of (AlCrTiZrMo)N/ZrO2 Nano-Multilayered High-Entropy Alloy Film Prepared by Magnetron Sputtering. Crystals 2022, 12, 232. [Google Scholar] [CrossRef]

- Chen, W.J.; Wang, J.j.; Liu, P. Effects of Y addition on the microstructures and mechanical behavior of ZrOxNy/V2O3-Y nano-multilayered films. Mater. Sci. Eng. A 2023, 864, 144555. [Google Scholar] [CrossRef]

- Koehler, J.S. Attempt to Design a Strong Solid. Phys. Rev. B 1970, 2, 547–551. [Google Scholar] [CrossRef]

- Xu, Y.X.; Chen, L.; Pei, F.; Du, Y. Structure and thermal properties of TiAlN/CrN multilayered coatings with various modulation ratios. Surf. Coat. Technol. 2016, 304, 512–518. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Chang, H.; Jhao, L.-J.; Chuang, C.-C. Tribological and mechanical properties of multilayered TiVN/TiSiN coatings synthesized by cathodic arc evaporation. Surf. Coat. Technol. 2018, 350, 1071–1079. [Google Scholar] [CrossRef]

- Yu, P.; Li, W.; Liu, P.; Zhang, K.; Ma, F.; Chen, X.; Feng, R.; Liaw, P.K. Microstructural and electrical behavior of NiCr/Al nanomultilayered films prepared by magnetron sputtering. J. Alloys Compd. 2022, 911, 165012. [Google Scholar] [CrossRef]

| Modulation Period/nm | Ni /at.% | Error /at.% | Ti /at.% | Error /at.% | Al /at.% | Error /at.% | Cr /at.% | Error /at.% | Co /at.% | Error /at.% | N /at.% | Error /at.% |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 mm | 10.60 | 0.03 | 10.78 | 0.02 | 11.1 | 0.03 | 11.38 | 0.04 | 10.54 | 0.03 | 45.60 | 0.02 |

| 7 mm | 10.88 | 0.06 | 14.53 | 0.05 | 10.77 | 0.06 | 12.10 | 0.02 | 10.54 | 0.06 | 41.18 | 0.03 |

| 9 mm | 11.39 | 0.05 | 12.31 | 0.03 | 11.31 | 0.05 | 12.58 | 0.05 | 11.11 | 0.04 | 41.30 | 0.06 |

| 11 mm | 11.59 | 0.07 | 12.02 | 0.03 | 11.65 | 0.04 | 12.47 | 0.08 | 11.35 | 0.02 | 40.92 | 0.04 |

| 13 mm | 11.66 | 0.04 | 12.18 | 0.08 | 11.52 | 0.07 | 12.76 | 0.03 | 11.36 | 0.05 | 40.52 | 0.03 |

| Modulation Period/nm | Diffraction Angle 2θ/(°) | Plane Spacing d/nm | Half-Width Height B/rad |

|---|---|---|---|

| 5 nm | 43.360 | 2.0851 | 0.173 |

| 7 nm | 43.400 | 2.0833 | 0.184 |

| 9 nm | 43.457 | 2.0807 | 0.186 |

| 11 nm | 43.381 | 2.0841 | 0.153 |

| 13 nm | 43.360 | 2.0851 | 0.176 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, H.; Si, L.; Dou, Z.; Yang, Y.; Li, H.; Liu, F. Cavitation Erosion Resistance of TiSiN/NiTiAlCoCrN Nanomultilayer Films with Different Modulation Periods. Coatings 2023, 13, 1431. https://doi.org/10.3390/coatings13081431

Yan H, Si L, Dou Z, Yang Y, Li H, Liu F. Cavitation Erosion Resistance of TiSiN/NiTiAlCoCrN Nanomultilayer Films with Different Modulation Periods. Coatings. 2023; 13(8):1431. https://doi.org/10.3390/coatings13081431

Chicago/Turabian StyleYan, Hongjuan, Lina Si, Zhaoliang Dou, Ye Yang, Hong Li, and Fengbin Liu. 2023. "Cavitation Erosion Resistance of TiSiN/NiTiAlCoCrN Nanomultilayer Films with Different Modulation Periods" Coatings 13, no. 8: 1431. https://doi.org/10.3390/coatings13081431

APA StyleYan, H., Si, L., Dou, Z., Yang, Y., Li, H., & Liu, F. (2023). Cavitation Erosion Resistance of TiSiN/NiTiAlCoCrN Nanomultilayer Films with Different Modulation Periods. Coatings, 13(8), 1431. https://doi.org/10.3390/coatings13081431