Multifunctional Properties of PBAT with Hemp (Cannabis sativa) Micronised Fibres for Food Packaging: Cast Films and Coated Paper

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Material Production

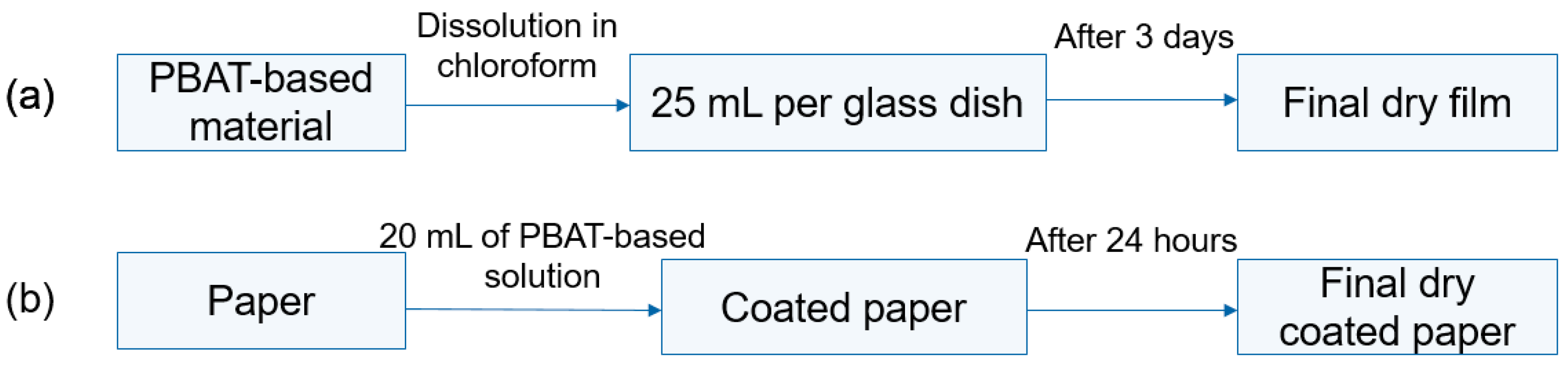

2.2.1. Cast Films

2.2.2. Coated Paper

2.3. Characterisation

2.3.1. Morphology

2.3.2. Lignocellulosic Components

2.3.3. GC-MS Screening

2.3.4. Elemental Analysis

2.3.5. Thermal Transitions

2.3.6. Water Vapour Permeability (WVP)

2.3.7. Mechanical Properties

2.3.8. Optical Properties

2.3.9. Compostability

2.3.10. FTIR Spectroscopy

2.3.11. Statistical Analyses

3. Results and Discussion

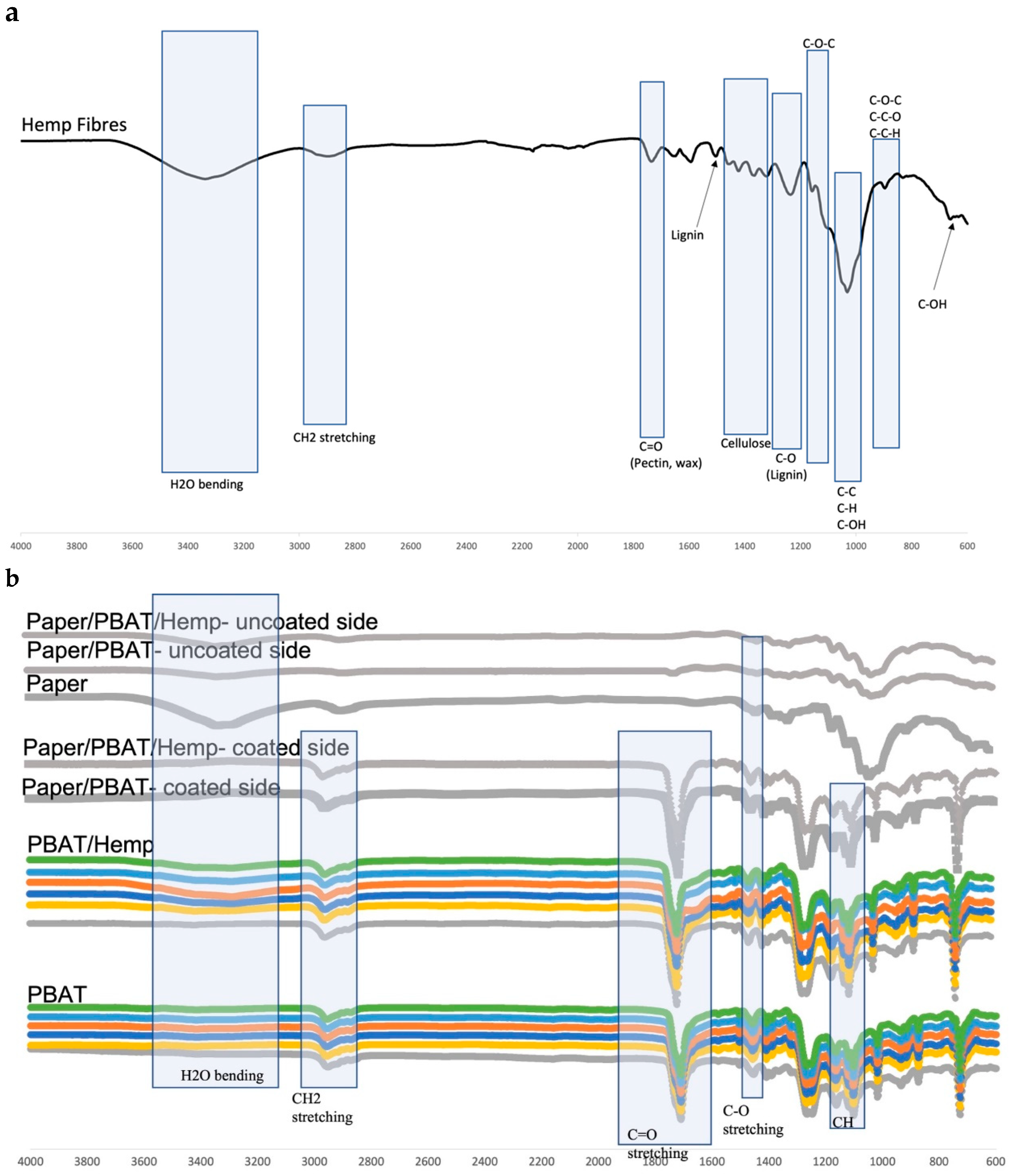

3.1. Hemp Characterisation

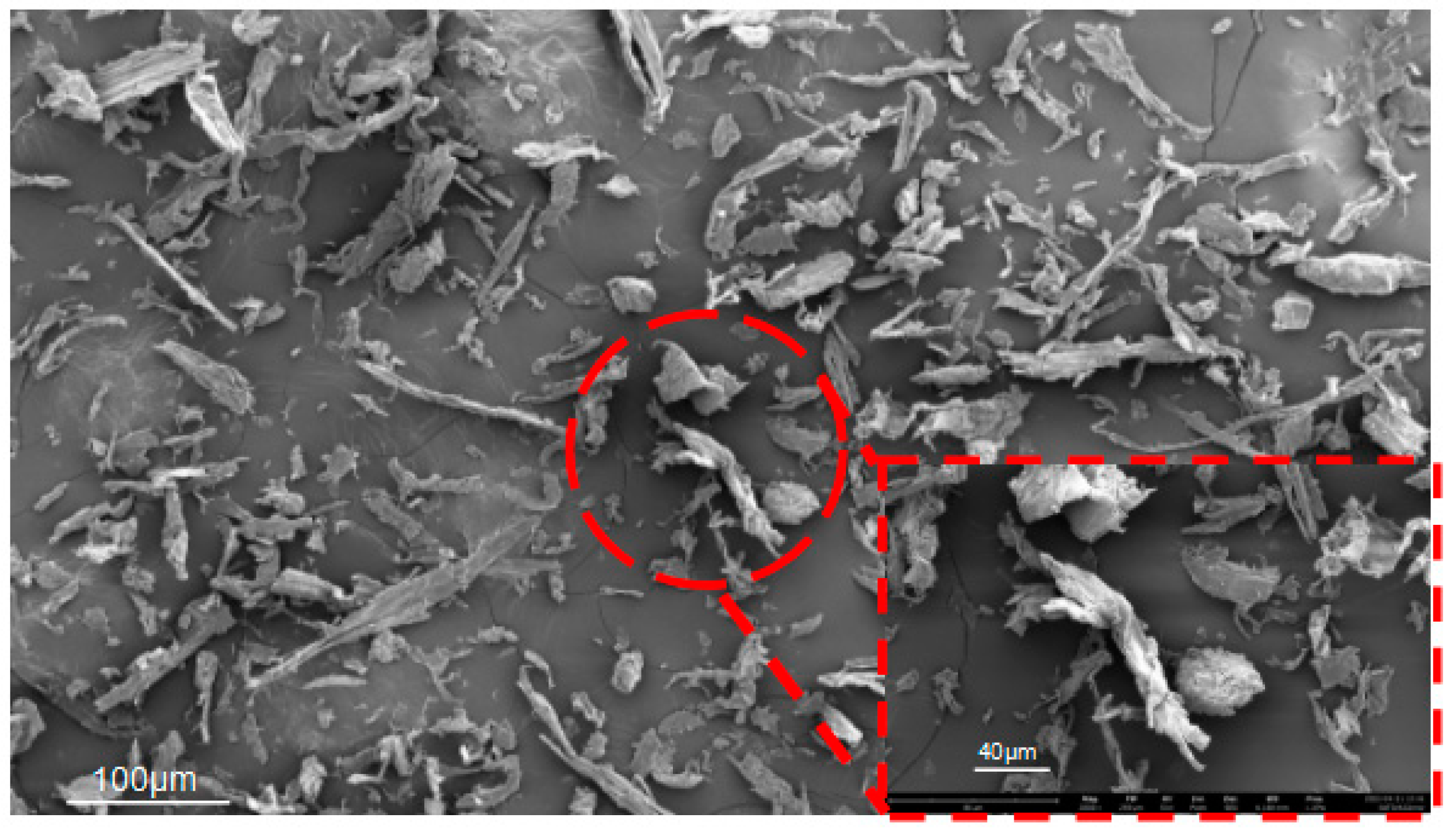

3.1.1. Morphology

3.1.2. Lignocellulosic Components

3.1.3. GC-MS Screening for Bioactive Components

3.1.4. Elemental Analysis

3.2. Characterization of PBAT/Hemp Materials

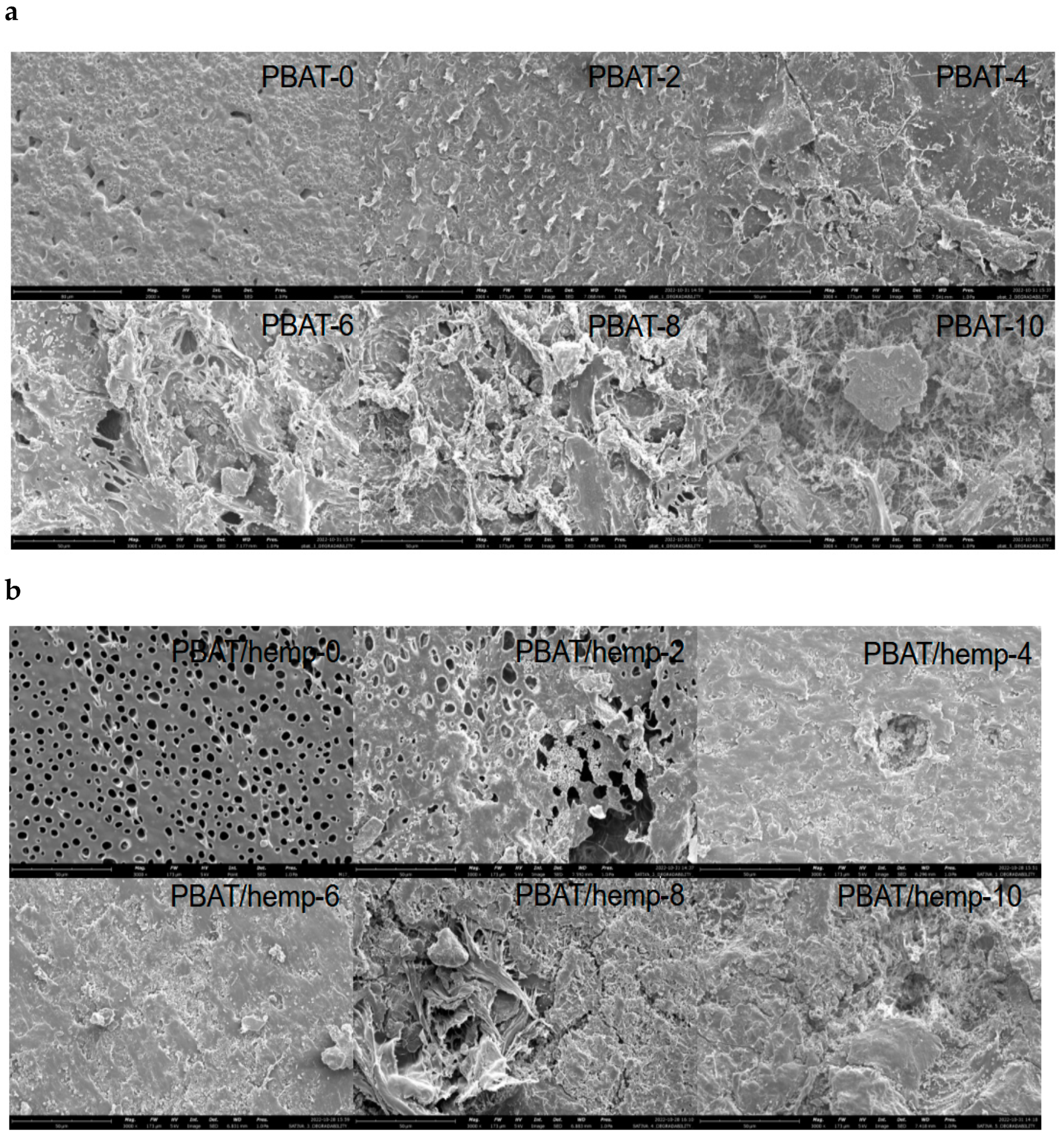

3.2.1. Morphology

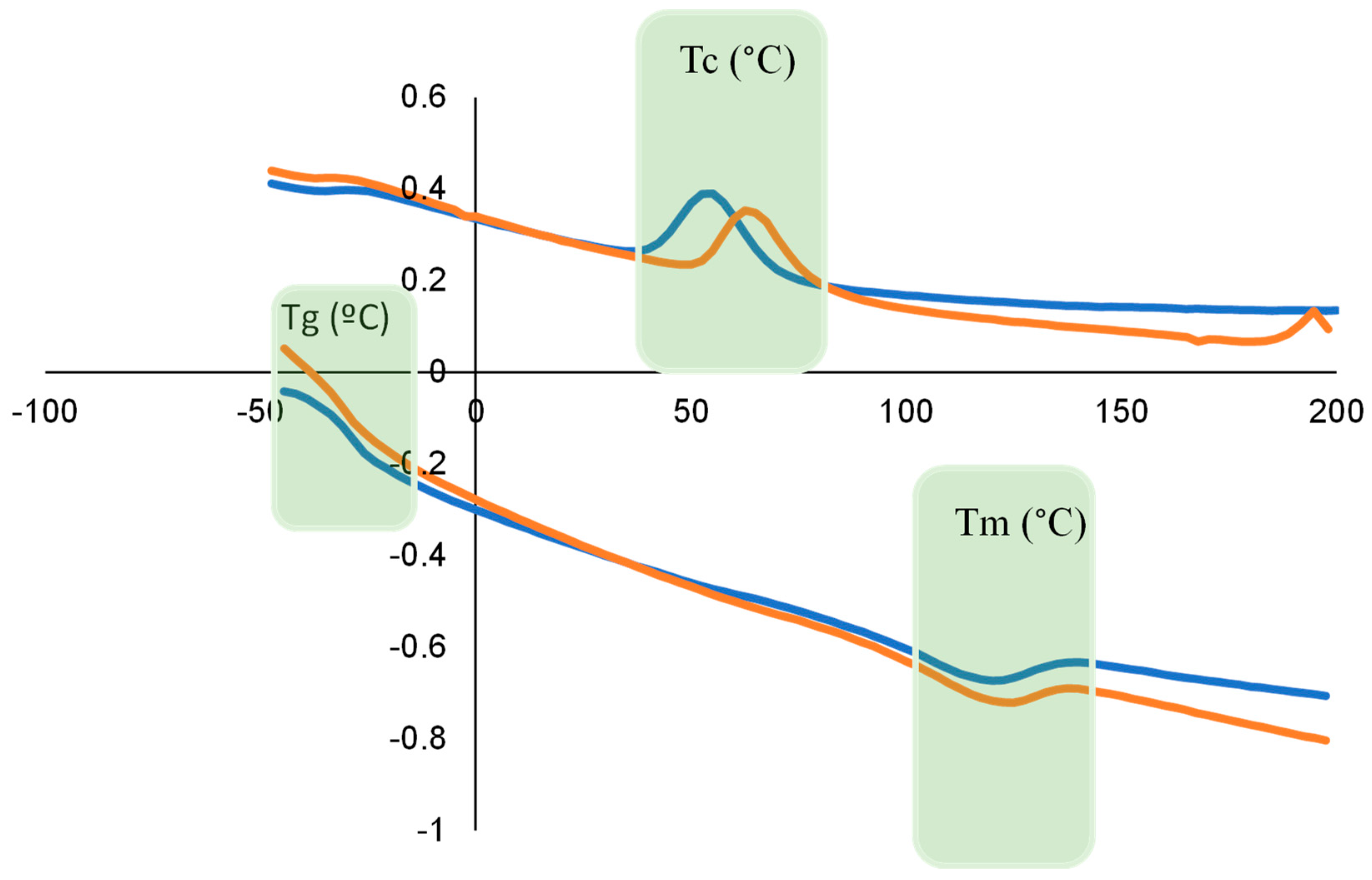

3.2.2. Thermal Transitions

3.2.3. Water Vapour Permeability (WVP)

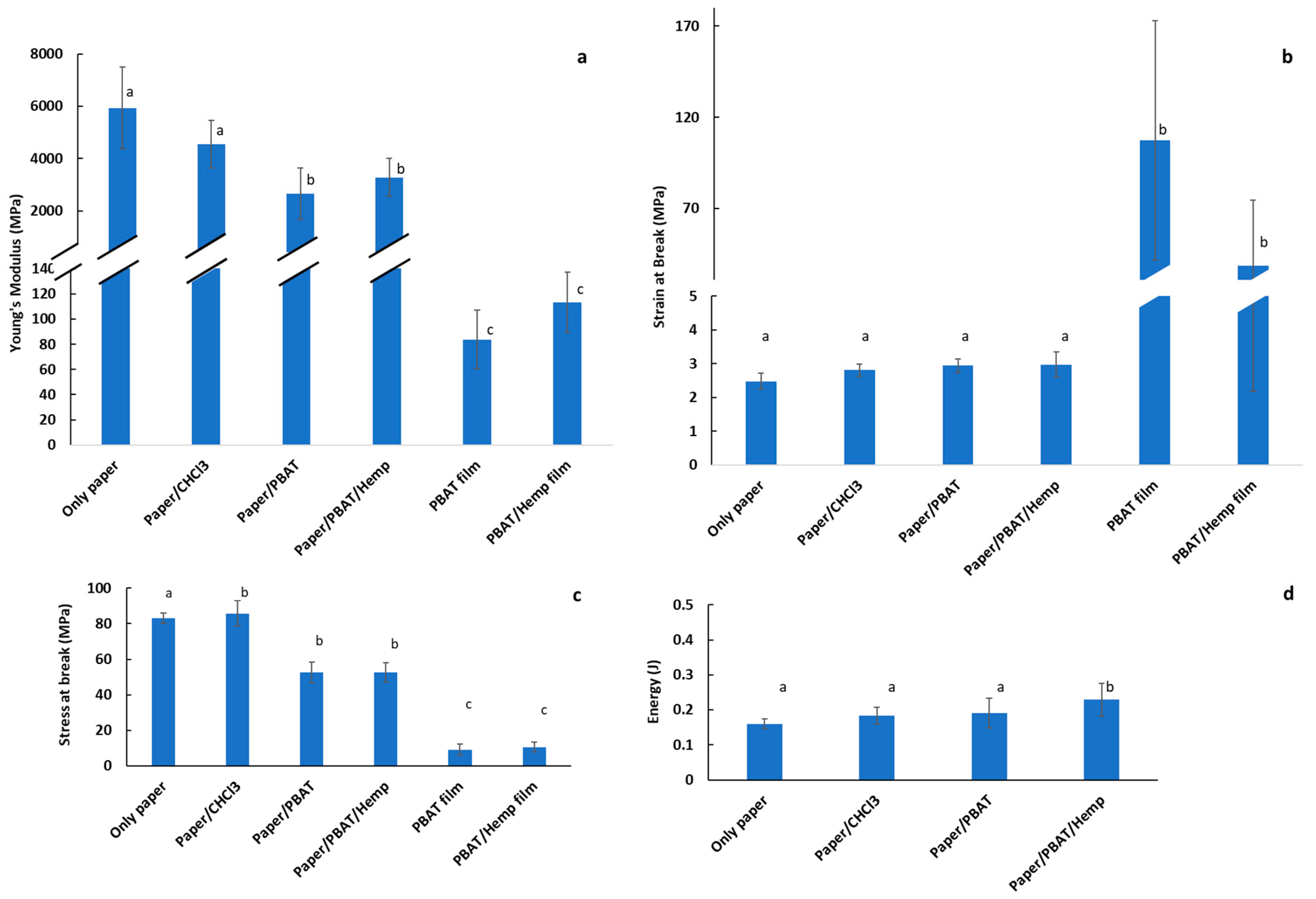

3.2.4. Mechanical Properties

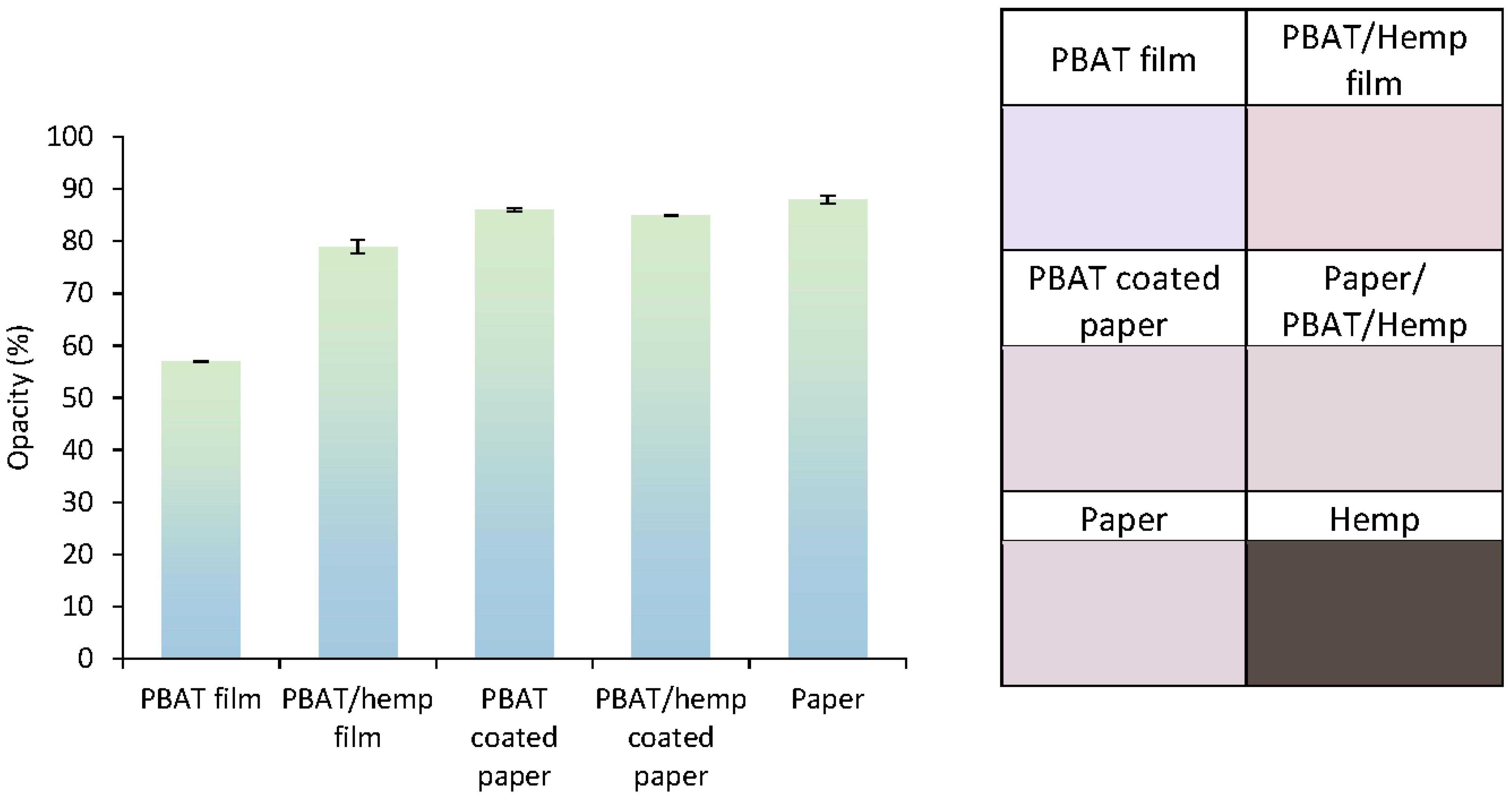

3.2.5. Optical Properties

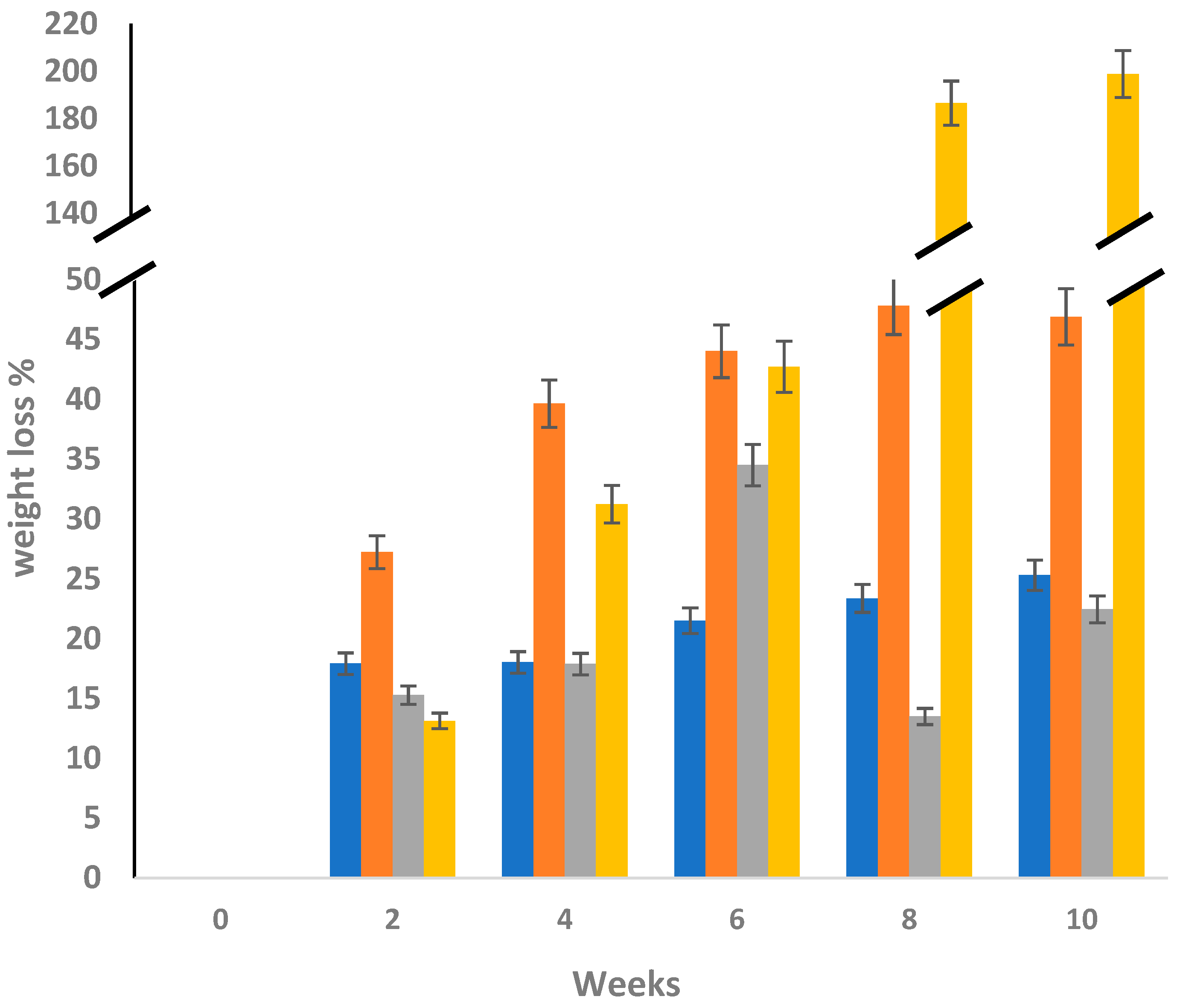

3.2.6. Compostability Test

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Promhuad, K.; Srisa, A.; San, H.; Laorenza, Y.; Wongphan, P.; Sodsai, J.; Tansin, K.; Phromphen, P.; Chartvivatpornchai, N.; Ngoenchai, P.; et al. Applications of Hemp Polymers and Extracts in Food, Textile and Packaging: A Review. Polymers 2022, 14, 4274. [Google Scholar] [CrossRef] [PubMed]

- Manaia, J.P.; Manaia, A.T.; Rodriges, L. Industrial Hemp Fibers: An Overview. Fibers 2019, 7, 106. [Google Scholar] [CrossRef]

- Khan, B.A.; Wang, J.; Warner, P.; Wang, H. Antibacterial properties of hemp hurd powder against E. coli. J. Appl. Polym. Sci. 2015, 132, 41588/1–41588/6. [Google Scholar] [CrossRef]

- Plastics Europe. Plastics—The Facts 2019. An Analysis of European Plastics Production, Demand and Waste Data. 2016. Available online: https://plasticseurope.org/wp-content/uploads/2021/10/2019-Plastics-the-facts.pdf (accessed on 17 January 2023).

- Silva, F.A.G.S.; Dourado, F.; Gama, M.; Poças, F. Nanocellulose Bio-Based Composites for Food Packaging. Nanomaterials 2020, 10, 2041. [Google Scholar] [CrossRef] [PubMed]

- European Commission Press. Release Plastic Waste: A European Strategy to Protect the Planet, Defend Our Citizens and Empower Our Industries. 2018. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_18_5 (accessed on 17 January 2023).

- Ballesteros, L.F.; Lamsaf, H.; Sebastian, C.V.; Cerqueira, M.A.; Pastrana, L.; Teixeira, J.A. Active Packaging Systems Based on Metal and Metal Oxide Nanoparticles. In Nanotechnology-Enhanced Food Packaging; Wiley: Hoboken, NJ, USA, 2021. [Google Scholar] [CrossRef]

- Jian, J.; Xiangbin, Z.; Xianbo, H. An overview on synthesis, properties and applications of poly(butylene-adipate-co-terephthalate)–PBAT. Adv. Ind. Eng. Polym. Res. 2020, 3, 19–26. [Google Scholar] [CrossRef]

- Venkatesan, R.; Rajeswari, N. ZnO/PBAT nanocomposite films: Investigation on the mechanical and biological activity for food packaging. Polym. Adv. Technol. 2016, 28, 20–27. [Google Scholar] [CrossRef]

- Pulikkalparambil, H.; Parameswaranpillai, J.; George, J.J.; Yorseng, K.; Siengchin, S. Physical and thermo-mechanical properties of bionano reinforced poly(butylene adipate-co-terephthalate), hemp/CNF/Ag-NPs composites. AIMS Mater. Sci. 2017, 4, 814–831. [Google Scholar] [CrossRef]

- Venkatesan, R.; Rajeswari, N.; Tamilselvi, A. Antimicrobial, mechanical, barrier, and thermal properties of bio-based poly (butylene adipate-co -terephthalate) (PBAT)/Ag2 O nanocomposite films for packaging application. Polym. Adv. Technol. 2017, 29, 61–68. [Google Scholar] [CrossRef]

- Seligra, P.G.; Moura, L.E.; Famá, L.; Druzian, J.I.; Goyanes, S. Influence of incorporation of starch nanoparticles in PBAT/TPS composite films. Polym. Int. 2016, 65, 938–945. [Google Scholar] [CrossRef]

- Kian, L.K.; Jawaid, M.; Mahmoud, M.H.; Saba, N.; Fouad, H.; Alothman, O.Y.; Karim, Z. PBAT/PBS Blends Membranes Filled with Nanocrystalline Cellulose for Heavy Metal Ion Separation. J. Polym. Environ. 2022, 30, 5263–5273. [Google Scholar] [CrossRef]

- Phothisarattana, D.; Harnkarnsujarit, N. Migration, aggregations and thermal degradation behaviors of TiO2 and ZnO incorporated PBAT/TPS nanocomposite blown films. Food Packag. Shelf Life 2022, 33, 100901. [Google Scholar] [CrossRef]

- Laorenza, Y.; Harnkarnsujarit, N. Carvacrol, citral and α-terpineol essential oil incorporated biodegradable films for functional active packaging of Pacific white shrimp. Food Chem. 2021, 363, 130252. [Google Scholar] [CrossRef] [PubMed]

- Leelaphiwat, P.; Pechprankan, C.; Siripho, P.; Bumbudsanpharoke, N.; Harnkarnsujarit, N. Effects of nisin and EDTA on morphology and properties of thermoplastic starch and PBAT biodegradable films for meat packaging. Food Chem. 2021, 369, 130956. [Google Scholar] [CrossRef] [PubMed]

- Wangprasertkul, J.; Siriwattanapong, R.; Harnkarnsujarit, N. Antifungal packaging of sorbate and benzoate incorporated biodegradable films for fresh noodles. Food Control. 2020, 123, 107763. [Google Scholar] [CrossRef]

- Olonisakin, K.; Wen, A.; He, S.; Lin, H.; Tao, W.; Chen, S.; Lin, W.; Li, R.; Zhang, X.-X.; Yang, W. The Development of Biodegradable PBAT-Lignin-Tannic Acid Composite Film: Properties, Biodegradability, and Potential Barrier Application in Food Packaging. Food Bioprocess Technol. 2023, 16, 1525–1540. [Google Scholar] [CrossRef]

- Moustafa, H.; Guizani, C.; Dupont, C.; Martin, V.; Jeguirim, M.; Dufresne, A. Utilization of Torrefied Coffee Grounds as Reinforcing Agent To Produce High-Quality Biodegradable PBAT Composites for Food Packaging Applications. ACS Sustain. Chem. Eng. 2017, 5, 1906–1916. [Google Scholar] [CrossRef]

- Mohanty, S.N.; Nayak, S.K. Biodegradable Nanocomposites of Poly(butylene adipate-co-terephthalate) (PBAT) and Organically Modified Layered Silicates. J. Polym. Environ. 2012, 20, 195–207. [Google Scholar] [CrossRef]

- Fukushima, K.; Wu, M.-H.; Bocchini, S.; Rasyida, A.; Yang, M.-C. PBAT based nanocomposites for medical and industrial applications. Mater. Sci. Eng. C 2012, 32, 1331–1351. [Google Scholar] [CrossRef]

- Correa, J.P.; Bacigalupe, A.; Maggi, J.; Eisenberg, P. Biodegradable PLA/PBAT/Clay Nanocomposites: Morphological, Rheological and Thermomechanical Behavior. J. Renew. Mater. 2016, 4, 258–265. [Google Scholar] [CrossRef]

- Dhakal, H.; Zhang, Z.; Bennett, N. Influence of fibre treatment and glass fibre hybridisation on thermal degradation and surface energy characteristics of hemp/unsaturated polyester composites. Compos. Part B Eng. 2012, 43, 2757–2761. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Nicolae, C.A.; Vuluga, Z.; Vitelaru, C.; Sanporean, C.G.; Zaharia, C.; Florea, D.; Vasilievici, G. Influence of hemp fibers with modified surface on polypropylene composites. J. Ind. Eng. Chem. 2016, 37, 137–146. [Google Scholar] [CrossRef]

- Phongam, N.; Dangtungee, R.; Siengchin, S. Comparative Studies on the Mechanical Properties of Nonwoven- and Woven-Flax-Fiber-Reinforced Poly(Butylene Adipate-Co-Terephthalate)-Based Composite Laminates. Polym. Mech. 2015, 51, 17–24. [Google Scholar] [CrossRef]

- Zeng, D.; Zhang, L.; Jin, S.; Zhang, Y.; Xu, C.; Zhou, K.; Lu, W. Mechanical Properties and Tensile Model of Hemp-Fiber-Reinforced Poly(butylene adipate-co-terephthalate) Composite. Materials 2022, 15, 2445. [Google Scholar] [CrossRef] [PubMed]

- Marcuello, C.; Chabbert, B.; Berzin, F.; Bercu, N.B.; Molinari, M.; Aguié-Béghin, V. Influence of Surface Chemistry of Fiber and Lignocellulosic Materials on Adhesion Properties with Polybutylene Succinate at Nanoscale. Materials 2023, 16, 2440. [Google Scholar] [CrossRef] [PubMed]

- Shorey, R.; Mekonnen, T.H. Sustainable paper coating with enhanced barrier properties based on esterified lignin and PBAT blend. Int. J. Biol. Macromol. 2022, 209, 472–484. [Google Scholar] [CrossRef]

- Khwaldia, K.; Arab-Tehrany, E.; Desobry, S. Biopolymer Coatings on Paper Packaging Materials. Compr. Rev. Food Sci. Food Saf. 2009, 9, 82–91. [Google Scholar] [CrossRef]

- Zang, X.; Jiang, Y.; Wang, X.; Wang, X.; Ji, J.; Xue, M. Highly sensitive pressure sensors based on conducting polymer-coated paper. Sens. Actuators B Chem. 2018, 273, 1195–1201. [Google Scholar] [CrossRef]

- Mendes, T.P.P.; Pereira, I.; Ferreira, M.R.; Chaves, A.R.; Vaz, B.G. Molecularly imprinted polymer-coated paper as a substrate for highly sensitive analysis using paper spray mass spectrometry: Quantification of metabolites in urine. Anal. Methods 2017, 9, 6117–6123. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 Years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Tang, C.-H.; Ten, Z.; Wang, X.-S.; Yang, X.-Q. Physicochemical and Functional Properties of Hemp (Cannabis sativa L.) Protein Isolate. J. Agric. Food Chem. 2006, 54, 8945–8950. [Google Scholar] [CrossRef]

- Mansor, A.M.; Lim, J.S.; Ani, F.N.; Hashim, H.; Ho, W.S. Characteristics of cellulose, hemicellulose and lignin of MD2 pineapple biomass. Chem. Eng. Trans. 2019, 72, 79–84. [Google Scholar] [CrossRef]

- Casariego, A.; Souza, B.; Cerqueira, M.; Teixeira, J.; Cruz, L.; Díaz, R.; Vicente, A. Chitosan/clay films’ properties as affected by biopolymer and clay micro/nanoparticles’ concentrations. Food Hydrocoll. 2009, 23, 1895–1902. [Google Scholar] [CrossRef]

- Liu, M.; Thygesen, A.; Summerscales, J.; Meyer, A.S. Targeted pre-treatment of hemp bast fibres for optimal performance in biocomposite materials: A review. Ind. Crop. Prod. 2017, 108, 660–683. [Google Scholar] [CrossRef]

- Leizer, C.; Ribnicky, D.; Poulev, A.; Dushenkov, S.; Raskin, I. The Composition of Hemp Seed Oil and Its Potential as an Important Source of Nutrition. J. Nutraceuticals Funct. Med. Foods 2000, 2, 35–53. [Google Scholar] [CrossRef]

- Ovidi, E.; Masci, V.L.; Taddei, A.R.; Torresi, J.; Tomassi, W.; Iannone, M.; Tiezzi, A.; Maggi, F.; Garzoli, S. Hemp (Cannabis sativa L., Kompolti cv.) and Hop (Humulus lupulus L., Chinook cv.) Essential Oil and Hydrolate: HS-GC-MS Chemical Investigation and Apoptotic Activity Evaluation. Pharmaceuticals 2022, 15, 976. [Google Scholar] [CrossRef]

- Wiebelhaus, N.; Hamblin, D.; Kreitals, N.M.; Almirall, J.R. Differentiation of marijuana headspace volatiles from other plants and hemp products using capillary microextraction of volatiles (CMV) coupled to gas-chromatography–mass spectrometry (GC–MS). Forensic Chem. 2016, 2, 1–8. [Google Scholar] [CrossRef]

- Exley, C.; Begum, A.; Woolley, M.P.; Bloor, R.N. Aluminum in Tobacco and Cannabis and Smoking-Related Disease. Am. J. Med. 2006, 119, 276.e9–276.e11. [Google Scholar] [CrossRef]

- Fermo, P.; Soddu, G.; Miani, A.; Comite, V. Quantification of the Aluminum Content Leached into Foods Baked Using Aluminum Foil. Int. J. Environ. Res. Public Health 2020, 17, 8357. [Google Scholar] [CrossRef]

- Stahl, T.; Taschan, H.; Brunn, H. Aluminium content of selected foods and food products. Environ. Sci. Eur. 2011, 23, 37. [Google Scholar] [CrossRef]

- European Food Safety Authority (EFSA). Safety of aluminium from dietary intake—Scientific Opinion of the Panel on Food Additives, Flavourings, Processing Aids and Food Contact Materials (AFC). EFSA J. 2008, 6, 754. [Google Scholar] [CrossRef]

- Shen, Z.; Rajabi-Abhari, A.; Oh, K.; Yang, G.; Youn, H.J.; Lee, H.L. Improving the Barrier Properties of Packaging Paper by Polyvinyl Alcohol Based Polymer Coating—Effect of the Base Paper and Nanoclay. Polymers 2021, 13, 1334. [Google Scholar] [CrossRef] [PubMed]

- Pal, A.K.; Katiyar, V. Nanoamphiphilic Chitosan Dispersed Poly(lactic acid) Bionanocomposite Films with Improved Thermal, Mechanical, and Gas Barrier Properties. Biomacromolecules 2016, 17, 2603–2618. [Google Scholar] [CrossRef] [PubMed]

- Gupta, A.; Chudasama, B.; Chang, B.P.; Mekonnen, T. Robust and sustainable PBAT—Hemp residue biocomposites: Reactive extrusion compatibilization and fabrication. Compos. Sci. Technol. 2021, 215, 109014. [Google Scholar] [CrossRef]

- Stelea, L.; Filip, I.; Lisa, G.; Ichim, M.; Drobotă, M.; Sava, C.; Mureșan, A. Characterisation of Hemp Fibres Reinforced Composites Using Thermoplastic Polymers as Matrices. Polymers 2022, 14, 481. [Google Scholar] [CrossRef]

- Cetin, M.S.; Aydogdu, R.B.; Toprakci, O.; Toprakci, H.A.K. Sustainable, Tree-Free, PLA Coated, Biodegradable, Barrier Papers from Kendir (Turkish Hemp). J. Nat. Fibers 2022, 19, 13802–13814. [Google Scholar] [CrossRef]

- Bastarrachea, L.; Dhawan, S.; Sablani, S.S. Engineering Properties of Polymeric-Based Antimicrobial Films for Food Packaging: A Review. Food Eng. Rev. 2011, 3, 79–93. [Google Scholar] [CrossRef]

- Zhang, Y.; Remadevi, R.; Hinestroza, J.P.; Wang, X.; Naebe, M. Transparent Ultraviolet (UV)-Shielding Films Made from Waste Hemp Hurd and Polyvinyl Alcohol (PVA). Polymers 2020, 12, 1190. [Google Scholar] [CrossRef]

- Khwaldia, K.; Basta, A.H.; Aloui, H.; El-Saied, H. Chitosan–caseinate bilayer coatings for paper packaging materials. Carbohydr. Polym. 2014, 99, 508–516. [Google Scholar] [CrossRef]

- Zumstein, M.T.; Schintlmeister, A.; Nelson, T.F.; Baumgartner, R.; Woebken, D.; Wagner, M.; Kohler, H.-P.E.; McNeill, K.; Sander, M. Biodegradation of synthetic polymers in soils: Tracking carbon into CO2 and microbial biomass. Sci. Adv. 2018, 4, eaas9024. [Google Scholar] [CrossRef]

- Ren, Y.; Hu, J.; Yang, M.; Weng, Y. Biodegradation Behavior of Poly (Lactic Acid) (PLA), Poly (Butylene Adipate-Co-Terephthalate) (PBAT), and Their Blends Under Digested Sludge Conditions. J. Polym. Environ. 2019, 27, 2784–2792. [Google Scholar] [CrossRef]

- Fu, Y.; Wu, G.; Bian, X.; Zeng, J.; Weng, Y. Biodegradation Behavior of Poly(Butylene Adipate-Co-Terephthalate) (PBAT), Poly(Lactic Acid) (PLA), and Their Blend in Freshwater with Sediment. Molecules 2020, 25, 3946. [Google Scholar] [CrossRef] [PubMed]

- Weng, Y.-X.; Jin, Y.-J.; Meng, Q.-Y.; Wang, L.; Zhang, M.; Wang, Y.-Z. Biodegradation behavior of poly(butylene adipate-co-terephthalate) (PBAT), poly(lactic acid) (PLA), and their blend under soil conditions. Polym. Test. 2013, 32, 918–926. [Google Scholar] [CrossRef]

PBAT;

PBAT;  PBAT/hemp), where Tc is the crystallisation temperature, Tg is the glass transition temperature, and Tm is the melting temperature.

PBAT/hemp), where Tc is the crystallisation temperature, Tg is the glass transition temperature, and Tm is the melting temperature.

PBAT;

PBAT;  PBAT/hemp), where Tc is the crystallisation temperature, Tg is the glass transition temperature, and Tm is the melting temperature.

PBAT/hemp), where Tc is the crystallisation temperature, Tg is the glass transition temperature, and Tm is the melting temperature.

PBAT film,

PBAT film,  PBAT/hemp film,

PBAT/hemp film,  Paper/PBAT, and

Paper/PBAT, and  Paper/PBAT/hemp).

Paper/PBAT/hemp).

PBAT film,

PBAT film,  PBAT/hemp film,

PBAT/hemp film,  Paper/PBAT, and

Paper/PBAT, and  Paper/PBAT/hemp).

Paper/PBAT/hemp).

—0,

—0,  —2,

—2,  —4,

—4,  —6,

—6,  —8,

—8,  —10 weeks of degradation.

—10 weeks of degradation.

—0,

—0,  —2,

—2,  —4,

—4,  —6,

—6,  —8,

—8,  —10 weeks of degradation.

—10 weeks of degradation.

| Peak | CAS | Name of Compound |

|---|---|---|

| 1 | 496-16-2 | 2,3-dihydro-benzofuran |

| 2 | 121-33-5 | Vanillin |

| 3 | 134-96-3 | 4-hydroxy-3,5-dimethoxy-benzaldehyde |

| 4 | 32811-40-8 | Trans-coniferyl alcohol |

| 5 | 57-10-3 | n-hexadecanoic acid |

| 6 | 60-33-3 | Linoleic acid |

| 7 | 112-80-1 | Oleic Acid |

| 8 | 506-30-9 | Eicosanoic acid |

| 9 | 20675-51-8 | Cannabichromene |

| 10 | 54002-78-7 | Related to Cannabielsoin |

| 11–14, 16 | 593-49-7 | Saturated alkanes |

| 15 | 22725-64-0 | Octacosanal |

| 17 | 474-62-4 | Campesterol |

| 18 | 83-48-7 | Stigmasterol |

| 19 | 83-47-6 | γ-sitosterol |

| 20 | 20817-72-5 | Stigmastadienone |

| 21 | 84924-96-9 | γ-Sitostenone |

| 22 | 123-28-4 | Didodecyl 3,3′-thiodipropionate |

| 23 | 22149-69-5 | Stigmastane-3,6-dione |

| Sample | Tg (°C) | Tc (°C) | Tm (°C) |

|---|---|---|---|

| PBAT | −27.3 | 53.9 | 120.6 |

| PBAT/hemp | −31.1 | 63.3 | 124.1 |

| Method | Material | Total Thickness (µm) |

|---|---|---|

| Casting | Pure PBAT | 180 ± 19 |

| PBAT/hemp | 173 ± 15 | |

| Coating | Pure paper | 85 ± 2 |

| Paper/PBAT | 144 ± 2 | |

| Paper/PBAT/hemp | 159 ± 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lamsaf, H.; Singh, S.; Pereira, J.; Poças, F. Multifunctional Properties of PBAT with Hemp (Cannabis sativa) Micronised Fibres for Food Packaging: Cast Films and Coated Paper. Coatings 2023, 13, 1195. https://doi.org/10.3390/coatings13071195

Lamsaf H, Singh S, Pereira J, Poças F. Multifunctional Properties of PBAT with Hemp (Cannabis sativa) Micronised Fibres for Food Packaging: Cast Films and Coated Paper. Coatings. 2023; 13(7):1195. https://doi.org/10.3390/coatings13071195

Chicago/Turabian StyleLamsaf, Hafsae, Srishti Singh, Joel Pereira, and Fátima Poças. 2023. "Multifunctional Properties of PBAT with Hemp (Cannabis sativa) Micronised Fibres for Food Packaging: Cast Films and Coated Paper" Coatings 13, no. 7: 1195. https://doi.org/10.3390/coatings13071195

APA StyleLamsaf, H., Singh, S., Pereira, J., & Poças, F. (2023). Multifunctional Properties of PBAT with Hemp (Cannabis sativa) Micronised Fibres for Food Packaging: Cast Films and Coated Paper. Coatings, 13(7), 1195. https://doi.org/10.3390/coatings13071195