Effects of the Ratio of Nano-Cu to Hydroxylated MWCNTs on Anticorrosion and Surface Conductivity of Cu/MWCNT Epoxy Coatings on a Steel Substrate

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Coatings

2.3. Electrical Conductivity

2.4. Electrochemical Test

3. Results and Discussion

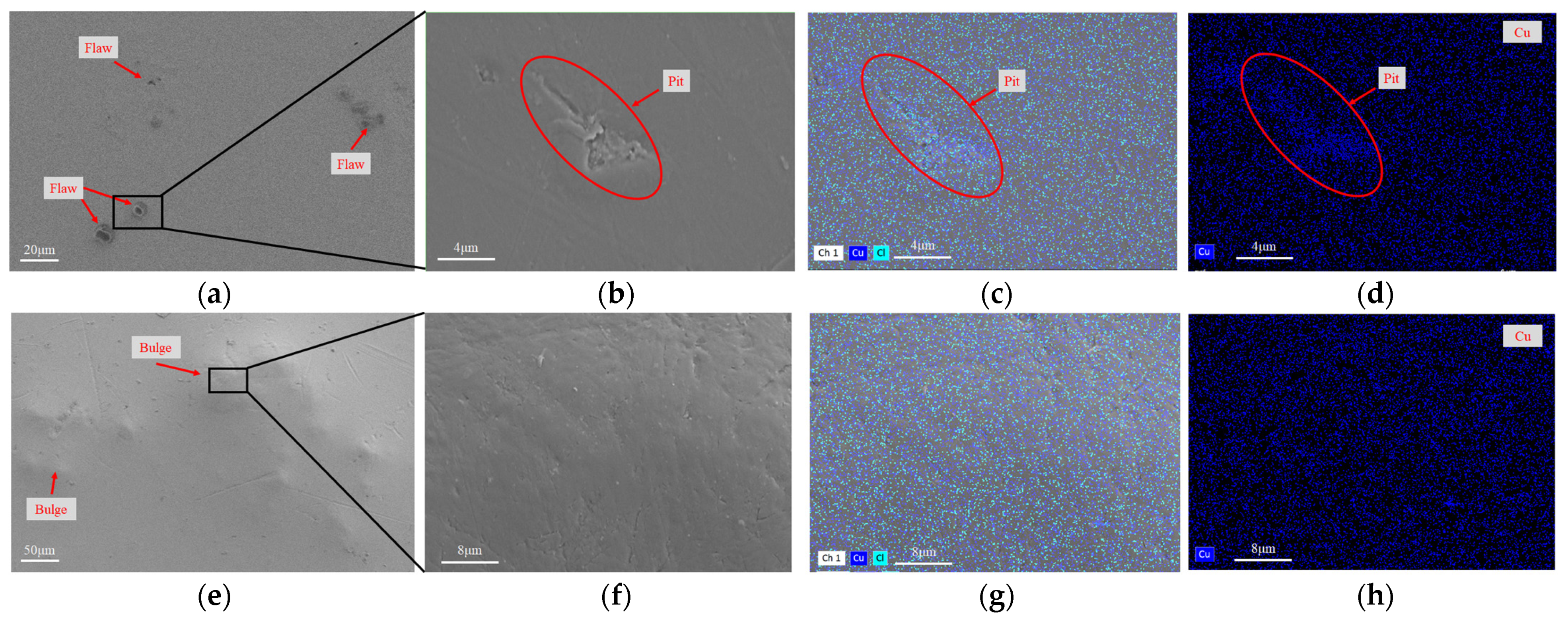

3.1. Morphology of Cu/MWCNT Epoxy Coatings

3.2. Electrical Conductivity

3.3. Polarization Curves

3.4. Electrochemical Impedance Spectroscopy

4. Conclusions

- The presence of a high content of MWCNTs (5%) promoted the dispersion of nano-Cu within the epoxy coating, effectively preventing the formation of coating defects.

- As the MWCNT content increased, the resistivity of the Cu/MWCNT epoxy coatings decreased. Specimen Cu65/MWCNT2.5 exhibited higher resistivity than coating MWCNT2.5, while specimen Cu65/MWCNT5 displayed lower resistivity than coating MWCNT5.

- By incorporating MWCNTs, the surface resistance stability of nano-Cu epoxy coating can be enhanced. After being immersed in a 3.5 wt % NaCl solution for 30 days, the resistivity of Cu65/MWCNT5 only increased by 10.7%.

- The Tafel and EIS results were in agreement. The epoxy coating comprising 5% hydroxylated MWNCTs and 65% nano-Cu exhibited the most robust anticorrosion properties on the steel substrate, with a corrosion current of 0.0413 nA/cm², a corrosion rate of 4.79 × 10−⁷ mm/year, and an impedance of 9.67 × 104 kΩ·cm².

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alhozaimy, A.; Hussain, R.R.; Al-Negheimish, A. Electro-chemical investigation for the effect of rebar source and surface condition on the corrosion rate of reinforced concrete structures under varying corrosive environments. Constr. Build. Mater. 2020, 244, 118317. [Google Scholar] [CrossRef]

- Soufeiani, L.; Foliente, G.; Nguyen, K.T.; San Nicolas, R. Corrosion protection of steel elements in façade systems–A review. J. Build. Eng. 2020, 32, 101759. [Google Scholar] [CrossRef]

- Qu, F.; Li, W.; Dong, W.; Tam, V.W.; Yu, T. Durability deterioration of concrete under marine environment from material to structure: A critical review. J. Build. Eng. 2021, 35, 102074. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C.; Hong, B. Mechanical properties of carbon/glass fiber reinforced polymer plates with sandwich structure exposed to freezing-thawing environment: Effects of water immersion, bending loading and fiber hybrid mode. Mech. Adv. Mater. Struct. 2022, 30, 814–834. [Google Scholar] [CrossRef]

- Lyon, S.B.; Bingham, R.; Mills, D.J. Advances in corrosion protection by organic coatings: What we know and what we would like to know. Prog. Org. Coat. 2017, 102, 2–7. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, K.; Ghosh, P.K.; Yadav, K. MWCNT/TiO2 hybrid nano filler toward high-performance epoxy composite. Ultrason. Sonochemistry 2018, 41, 37–46. [Google Scholar] [CrossRef]

- Hu, Q.; Chen, Z.; Xi, L.; Wang, X.; Wang, H. The application of epoxy resin coating in grounding grid. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; p. 012110. [Google Scholar]

- Zhang, C.; Liao, Y.; Gao, X.; Zhao, J.; Yuan, Y.; Liao, R. Research advances of soil corrosion of grounding grids. Micromachines 2021, 12, 513. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Bi, R.; Wang, J.; Chen, H. Review of grounding grids corrosion diagnosis. Int. J. Comput. Electr. Eng. 2013, 5, 309. [Google Scholar] [CrossRef]

- Liang, G. The research of the power plant and substation grounding network reconstruction Inner Mongolia region. In Proceedings of the 2014 China International Conference on Electricity Distribution (CICED), Shenzhen, China, 23–26 September 2014; pp. 388–395. [Google Scholar]

- Ranjith, R.; Rai, V.; Temizel, C. State-of-the-art materials in petroleum facilities and pipelines. In Sustainable Materials for Oil and Gas Applications; Elsevier: Amsterdam, The Netherlands, 2021; pp. 207–246. [Google Scholar]

- Hu, H.; Luo, R.; Fang, M.; Zeng, S.; Hu, F. A new optimization design for grounding grid. Int. J. Electr. Power Energy Syst. 2019, 108, 61–71. [Google Scholar] [CrossRef]

- Shen, W.; Feng, L.; Liu, X.; Luo, H.; Liu, Z.; Tong, P.; Zhang, W. Multiwall carbon nanotubes-reinforced epoxy hybrid coatings with high electrical conductivity and corrosion resistance prepared via electrostatic spraying. Prog. Org. Coat. 2016, 90, 139–146. [Google Scholar] [CrossRef]

- Aradhana, R.; Mohanty, S.; Nayak, S.K. A review on epoxy-based electrically conductive adhesives. Int. J. Adhes. Adhes. 2020, 99, 102596. [Google Scholar] [CrossRef]

- Stewart, I.E.; Ye, S.; Chen, Z.; Flowers, P.F.; Wiley, B.J. Synthesis of Cu–Ag, Cu–Au, and Cu–Pt core–shell nanowires and their use in transparent conducting films. Chem. Mater. 2015, 27, 7788–7794. [Google Scholar] [CrossRef]

- Hjortstam, O.; Isberg, P.; Söderholm, S.; Dai, H. Can we achieve ultra-low resistivity in carbon nanotube-based metal composites? Appl. Phys. A 2004, 78, 1175–1179. [Google Scholar] [CrossRef]

- Dekker, C. Carbon nanotubes as molecular quantum wires. Phys. Today 1999, 52, 22–30. [Google Scholar] [CrossRef]

- Jayathilaka, W.; Chinnappan, A.; Ramakrishna, S. A review of properties influencing the conductivity of CNT/Cu composites and their applications in wearable/flexible electronics. J. Mater. Chem. 2017, 5, 9209–9237. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Cao, X.; Gong, S.; Xie, Z.; Li, T.; Wu, C.; Zhu, Z.; Li, Z. Effect of nano-scale Cu particles on the electrical property of CNT/polymer nanocomposites. Compos. Part A: Appl. Sci. Manuf. 2021, 143, 106325. [Google Scholar] [CrossRef]

- Chai, Y.; Chan, P.C. High electromigration-resistant copper/carbon nanotube composite for interconnect application. In Proceedings of the 2008 IEEE International Electron Devices Meeting, San Francisco, CA, USA; 5–17 December 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 1–4. [Google Scholar]

- Shi, X.; Nguyen, T.A.; Suo, Z.; Liu, Y.; Avci, R. Effect of nanoparticles on the anticorrosion and mechanical properties of epoxy coating. Surf. Coat. Technol. 2009, 204, 237–245. [Google Scholar] [CrossRef]

- Navik, R.; Ding, X.; Huijun, T.; Zhao, Y. Facile synthesis of highly oxidation stable nanosilver-coated copper nanowires for transparent flexible electrodes. Ind. Eng. Chem. Res. 2020, 60, 263–272. [Google Scholar] [CrossRef]

- Cubides, Y.; Su, S.S.; Castaneda, H. Influence of zinc content and chloride concentration on the corrosion protection performance of zinc-rich epoxy coatings containing carbon nanotubes on carbon steel in simulated concrete pore environments. Corrosion 2016, 72, 1397–1423. [Google Scholar] [CrossRef]

- Jeon, H.; Park, J.; Shon, M. Corrosion protection by epoxy coating containing multi-walled carbon nanotubes. J. Ind. Eng. Chem. 2013, 19, 849–853. [Google Scholar] [CrossRef]

- Fu, S.; Chen, X.; Liu, P.; Liu, W.; Liu, P.; Zhang, K.; Chen, H. Electrodeposition and properties of composites consisting of carbon nanotubes and copper. J. Mater. Eng. Perform. 2018, 27, 5511–5517. [Google Scholar] [CrossRef]

- Mohammed, M.M.; Elsayed, E.M.; El-Kady, O.A.; Alsaleh, N.A.; Elsheikh, A.H.; Essa, F.A.; Ahmadein, M.; Djuansjah, J. Electrochemical Behavior of Cu-MWCNT Nanocomposites Manufactured by Powder Technology. Coatings 2022, 12, 409. [Google Scholar] [CrossRef]

- Song, R.; Zhang, S.; He, Y.; Li, H.; Fan, Y.; He, T.; Zhang, Y.; Xiang, Y.; Zhang, H. Effect of H-MWCNTs addition on anti-corrosion performance and mechanical character of Ni-Cu/H-MWCNTs composite coatings prepared by pulse electrodeposition technique. Colloids Surf. A: Physicochem. Eng. Asp. 2021, 630, 127519. [Google Scholar] [CrossRef]

- Shukla, A.; Nayan, N.; Murty, S.; Sharma, S.; Chandran, P.; Bakshi, S.R.; George, K.M. Processing of copper–carbon nanotube composites by vacuum hot pressing technique. Mater. Sci. Eng. A 2013, 560, 365–371. [Google Scholar] [CrossRef]

- Zhu, Z.; Kang, S.; Chen, H.; Zhao, Q.; Huo, Z.; Li, P.; Cao, Q.; Lu, C. Preparation and properties of CNTs-Cu hybrids/epoxy superhydrophobic and anticorrosive coatings. J. Ind. Eng. Chem. 2023, 119, 605–618. [Google Scholar] [CrossRef]

- GB/T 1499.1-2017; State General Administration of the People’s Republic of China. Steel for the Reinforcement of Concrete—Part 1: Hot Rolled Plain Bars. China Standard Press: Beijing, China, 2017.

- Dang, Z.-M.; Zhang, B.; Li, J.; Zha, J.-W.; Hu, G.-H. Copper particles/epoxy resin thermosetting conductive adhesive using polyamide resin as curing agent. Appl. Polym. Sci. 2012, 126, 815–821. [Google Scholar] [CrossRef]

- Zhang, F.; Qian, H.; Wang, L.; Wang, Z.; Du, C.; Li, X.; Zhang, D. Superhydrophobic carbon nanotubes/epoxy nanocomposite coating by facile one-step spraying. Surf. Coat. Technol. 2018, 341, 15–23. [Google Scholar] [CrossRef]

- Ranjbar, Z.; Yari, H. Modeling of electrical conductive graphene filled epoxy coatings. Prog. Org. Coat. 2018, 125, 411–419. [Google Scholar]

- Uthaman, A.; Lal, H.M.; Li, C.; Xian, G.; Thomas, S. Mechanical and water uptake properties of epoxy nanocomposites with surfactant-modified functionalized multiwalled carbon nanotubes. Nanomaterials 2021, 11, 1234. [Google Scholar] [CrossRef]

- Hirata, M.; Gotou, T.; Horiuchi, S.; Fujiwara, M.; Ohba, M. Thin-film particles of graphite oxide 1: High-yield synthesis and flexibility of the particles. Carbon 2004, 42, 2929–2937. [Google Scholar] [CrossRef]

- Qian, H.; Xu, Z.; Chen, S.; Liu, Y.; Yan, D. Silicon carbide/enamel composite coatings for steel corrosion protection: Microstructure, thermal expansion behavior, and anti-corrosion performance. Surf. Coat. Technol. 2022, 434, 128172. [Google Scholar] [CrossRef]

- Cui, C.Q.; Tay, H.; Chai, T.; Ggopalakrishan, R.; Lim, T. Surface Treatment of Copper for the Adhesion Improvement to Epoxy Mold Compounds, 1998 Proceedings. 48th Electronic Components and Technology Conference (Cat. No. 98CH36206); IEEE: Piscataway, NJ, USA, 1998; pp. 1162–1166. [Google Scholar]

- Ramezanzadeh, B.; Attar, M. Studying the corrosion resistance and hydrolytic degradation of an epoxy coating containing ZnO nanoparticles. Mater. Chem. Phys. 2011, 130, 1208–1219. [Google Scholar] [CrossRef]

- Alishahi, M.; Monirvaghefi, S.M.; Saatchi, A.; Hosseini, S.M. The effect of carbon nanotubes on the corrosion and tribological behavior of electroless Ni–P–CNT composite coating. Appl. Surf. Sci. 2012, 258, 2439–2446. [Google Scholar] [CrossRef]

- Gojny, F.H.; Wichmann, M.H.G.; Köpke, U.; Fiedler, B.; Schulte, K. Carbon nanotube-reinforced epoxy-composites: Enhanced stiffness and fracture toughness at low nanotube content. Compos. Sci. Technol. 2004, 64, 2363–2371. [Google Scholar] [CrossRef]

- Chen, X.-C.; Ren, K.-F.; Lei, W.-X.; Zhang, J.-H.; Martins, M.C.L.; Barbosa, M.A.; Ji, J. Self-healing spongy coating for drug “cocktail” delivery. ACS Appl. Mater. Interfaces 2016, 8, 4309–4313. [Google Scholar] [CrossRef]

- Park, M.; Kim, B.-H.; Kim, S.; Han, D.-S.; Kim, G.; Lee, K.-R. Improved binding between copper and carbon nanotubes in a composite using oxygen-containing functional groups. Carbon 2011, 49, 811–818. [Google Scholar] [CrossRef]

- Mandal, P.; Mondal, S.C. Investigation of Electro-Thermal property for Cu-MWCNT composite coating on anodized 6061 aluminium alloy. Appl. Surf. Sci. 2018, 454, 138–147. [Google Scholar] [CrossRef]

- Tian, J.; Li, C.; Xian, G. A layered superhydrophobic coating with excellent mechanical robustness and anti-corrosion performances. J. Mater. Res. Technol. 2022, 21, 4281–4298. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Z. Investigation of the anticorrosion layer of reinforced steel based on graphene oxide in simulated concrete pore solution with 3 wt.% NaCl. J. Build. Eng. 2021, 44, 103302. [Google Scholar] [CrossRef]

- Wang, F.; Feng, L.; Huang, Y.; Li, G.; Zhai, Z. Effect of coating process on the properties of multi-walled carbon nanotubes/waterborne polyurethane anticorrosive and conductive coating. AIP Adv. 2019, 9, 035241. [Google Scholar] [CrossRef]

- Ollik, K.; Lieder, M. Review of the application of graphene-based coatings as anticorrosion layers. Coatings 2020, 10, 883. [Google Scholar] [CrossRef]

- Chen, X.; Chen, C.; Xiao, H.; Cheng, F.; Zhang, G.; Yi, G. Corrosion behavior of carbon nanotubes–Ni composite coating. Surf. Coat. Technol. 2005, 191, 351–356. [Google Scholar] [CrossRef]

- Sharma, N.; Sharma, S.; Sharma, S.K.; Mahajan, R.L.; Mehta, R. Evaluation of corrosion inhibition capability of graphene modified epoxy coatings on reinforcing bars in concrete. Constr. Build. Mater. 2022, 322, 126495. [Google Scholar] [CrossRef]

- Li, J.; Gan, L.; Liu, Y.; Mateti, S.; Lei, W.; Chen, Y.; Yang, J. Boron nitride nanosheets reinforced waterborne polyurethane coatings for improving corrosion resistance and antifriction properties. Eur. Polym. J. 2018, 104, 57–63. [Google Scholar] [CrossRef]

- Ramezanzadeh, B.; Moghadam, M.M.; Shohani, N.; Mahdavian, M. Effects of highly crystalline and conductive polyaniline/graphene oxide composites on the corrosion protection performance of a zinc-rich epoxy coating. Chem. Eng. J. 2017, 320, 363–375. [Google Scholar] [CrossRef]

- Cai, G.; Xiao, S.; Deng, C.; Jiang, D.; Zhang, X.; Dong, Z. CeO2 grafted carbon nanotube via polydopamine wrapping to enhance corrosion barrier of polyurethane coating. Corros. Sci. 2021, 178, 109014. [Google Scholar] [CrossRef]

- Chen, S.; Wang, X.; Zhu, G.; Lu, Z.; Zhang, Y.; Zhao, X.; Hou, B. Developing multi-wall carbon nanotubes/Fusion-bonded epoxy powder nanocomposite coatings with superior anti-corrosion and mechanical properties. Colloids Surf. A Physicochem. Eng. Asp. 2021, 628, 127309. [Google Scholar] [CrossRef]

- Qu, L.; Wang, Q.; Xu, S.; Wang, N.; Shi, Z. Chloride corrosion resistance of double-layer anticorrosive coating in simulated concrete pore solution. Constr. Build. Mater. 2021, 295, 123682. [Google Scholar] [CrossRef]

- Liu, J.; Lei, Y.; Qiu, Z.; Li, D.; Liu, T.; Zhang, F.; Sun, S.; Chang, X.; Fan, R.; Yin, Y. Insight into the impact of conducting polyaniline/graphene nanosheets on corrosion mechanism of zinc-rich epoxy primers on low alloy DH32 steel in artificial sea water. J. Electrochem. Soc. 2018, 165, C878. [Google Scholar] [CrossRef]

| Type of Steel | C | Mn | Si | S | P | Fe |

|---|---|---|---|---|---|---|

| HPB300 | 0.21 | 0.63 | 0.35 | 0.024 | 0.021 | 98.765 |

| Specimens | MWCNTs (g) | Cu (g) | Epoxy (g) | PVP (g) |

|---|---|---|---|---|

| MWCNT2.5 | 1.0 | - | 40.0 | 0.1 |

| MWCNT5 | 2.0 | - | 40.0 | 0.2 |

| Cu65 | - | 26.0 | 40.0 | - |

| Cu65/MWCNT2.5 | 1.0 | 26.0 | 40.0 | 0.1 |

| Cu65/MWCNT5 | 2.0 | 26.0 | 40.0 | 0.2 |

| Specimens | Thickness (µm) | Square Resistance (MΩ/□) | Resistivity (Ω·m) |

|---|---|---|---|

| Cu65-0D | 293 ± 12 | 90.294 | 26,456.142 |

| MWCNT2.5-0D | 317 ± 17 | 9.205 | 2917.985 |

| MWCNT5-0D | 299 ± 9 | 9.023 | 2697.877 |

| Cu65/MWCNT2.5-0D | 310 ± 12 | 32.476 | 10,067.56 |

| Cu65/MWCNT5-0D | 307 ± 14 | 2.933 | 900.431 |

| Cu65-30D | 293 ± 18 | - | - |

| MWCNT2.5-30D | 317 ± 6 | 9.358 | 2966.486 |

| MWCNT5-30D | 299 ± 12 | 9.144 | 2734.056 |

| Cu65/MWCNT2.5-30D | 310 ± 8 | 50.372 | 15,615.32 |

| Cu65/MWCNT5-30D | 307 ± 8 | 3.248 | 997.136 |

| Specimens | Ecorr (V(SCE)) | Icorr (A/cm2) | βa (mV) | βc (mV) | Corrosion Rate (mm/year) |

|---|---|---|---|---|---|

| Cu65 | −0.808 | 4.98 × 10−8 | 177.35 | 169.03 | 5.78 × 10−4 |

| MWCNT2.5 | −0.122 | 1.17 × 10−9 | 536.79 | 191.25 | 1.36 × 10−5 |

| MWCNT5 | −0.072 | 7.07 × 10−11 | 1498 | 191.78 | 8.20 × 10−7 |

| Cu65/MWCNT2.5 | −0.423 | 4.89 × 10−8 | 1097 | 2569.7 | 5.67 × 10−4 |

| Cu65/MWCNT5 | −0.218 | 4.13 × 10−11 | 96.565 | 104.19 | 4.79 × 10−7 |

| Specimen | Time | Rc (Ω·cm2) | Cc (F·cm2) | n1 | Rct (Ω·cm2) | Cdl (F·cm2) | n2 | Model |

|---|---|---|---|---|---|---|---|---|

| Cu65 | 3 h | 2.39 × 109 | 3.12 × 10−9 | 0.87 | - | - | - | (a) |

| 3 days | 4.23 × 108 | 1.78 × 10−9 | 0.93 | - | - | - | (a) | |

| 8 days | 5.95 × 104 | 6.01 × 10−13 | 0.97 | 1.47 × 106 | 3.79 × 10−6 | 0.57 | (b) | |

| 15 days | 2.98 × 104 | 4.52 × 10−9 | 0.86 | 9.59 × 105 | 1.58 × 10−6 | 0.77 | (b) | |

| 30 days | 2.00 × 104 | 1.83 × 10−9 | 0.95 | 7.12 × 105 | 2.63 × 10−6 | 0.71 | (b) | |

| MWCNT2.5 | 3 h | 7.26 × 105 | 1.61 × 10−10 | 0.98 | - | - | - | (a) |

| 3 days | 7.50 × 105 | 5.01 × 10−10 | 0.66 | - | - | - | (a) | |

| 8 days | 8.36 × 105 | 1.41 × 10−9 | 0.96 | - | - | - | (a) | |

| 15 days | 8.16 × 106 | 2.15 × 10−8 | 0.89 | - | - | - | (a) | |

| 30 days | 8.77 × 106 | 3.01 × 10−8 | 0.89 | - | - | - | (a) | |

| MMWCNT5 | 3 h | 1.13 × 108 | 3.06 × 10−8 | 0.69 | - | - | - | (a) |

| 3 days | 7.22 × 107 | 1.61 × 10−8 | 0.65 | - | - | - | (a) | |

| 8 days | 2.76 × 107 | 9.55 × 10−8 | 0.35 | - | - | - | (a) | |

| 15 days | 3.65 × 107 | 1.61 × 10−7 | 0.65 | - | - | - | (a) | |

| 30 days | 2.60 × 107 | 8.13 × 10−7 | 0.79 | - | - | - | (a) | |

| Cu65/MWCNT2.5 | 3 h | 1.30 × 1010 | 1.33 × 10−9 | 0.91 | - | - | - | (a) |

| 3 days | 6.39 × 108 | 1.20 × 10−9 | 0.93 | - | - | - | (a) | |

| 8 days | 3.07 × 108 | 1.15 × 10−9 | 0.95 | - | - | - | (a) | |

| 15 days | 2.09 × 107 | 2.41 × 10−9 | 0.85 | - | - | - | (a) | |

| 30 days | 5.23 × 106 | 3.20 × 10−9 | 0.80 | - | - | - | (a) | |

| Cu65/MWCNT5 | 3 h | 1.16 × 108 | 2.60 × 10−9 | 0.85 | - | - | - | (a) |

| 3 days | 1.66 × 108 | 2.06 × 10−9 | 0.88 | - | - | - | (a) | |

| 8 days | 1.69 × 108 | 2.69 × 10−9 | 0.84 | - | - | - | (a) | |

| 15 days | 1.31 × 108 | 4.17 × 10−9 | 0.78 | - | - | - | (a) | |

| 30 days | 7.29 × 107 | 2.52 × 10−9 | 0.87 | - | - | - | (a) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Liang, M.; Pan, Y. Effects of the Ratio of Nano-Cu to Hydroxylated MWCNTs on Anticorrosion and Surface Conductivity of Cu/MWCNT Epoxy Coatings on a Steel Substrate. Coatings 2023, 13, 1116. https://doi.org/10.3390/coatings13061116

Yu Y, Liang M, Pan Y. Effects of the Ratio of Nano-Cu to Hydroxylated MWCNTs on Anticorrosion and Surface Conductivity of Cu/MWCNT Epoxy Coatings on a Steel Substrate. Coatings. 2023; 13(6):1116. https://doi.org/10.3390/coatings13061116

Chicago/Turabian StyleYu, Yixun, Mengmeng Liang, and Yunfeng Pan. 2023. "Effects of the Ratio of Nano-Cu to Hydroxylated MWCNTs on Anticorrosion and Surface Conductivity of Cu/MWCNT Epoxy Coatings on a Steel Substrate" Coatings 13, no. 6: 1116. https://doi.org/10.3390/coatings13061116

APA StyleYu, Y., Liang, M., & Pan, Y. (2023). Effects of the Ratio of Nano-Cu to Hydroxylated MWCNTs on Anticorrosion and Surface Conductivity of Cu/MWCNT Epoxy Coatings on a Steel Substrate. Coatings, 13(6), 1116. https://doi.org/10.3390/coatings13061116