Structural Optimized Design of a Powder Mixer for Multi-Material Directed Energy Deposition Based on CFD-DPM

Abstract

:1. Introduction

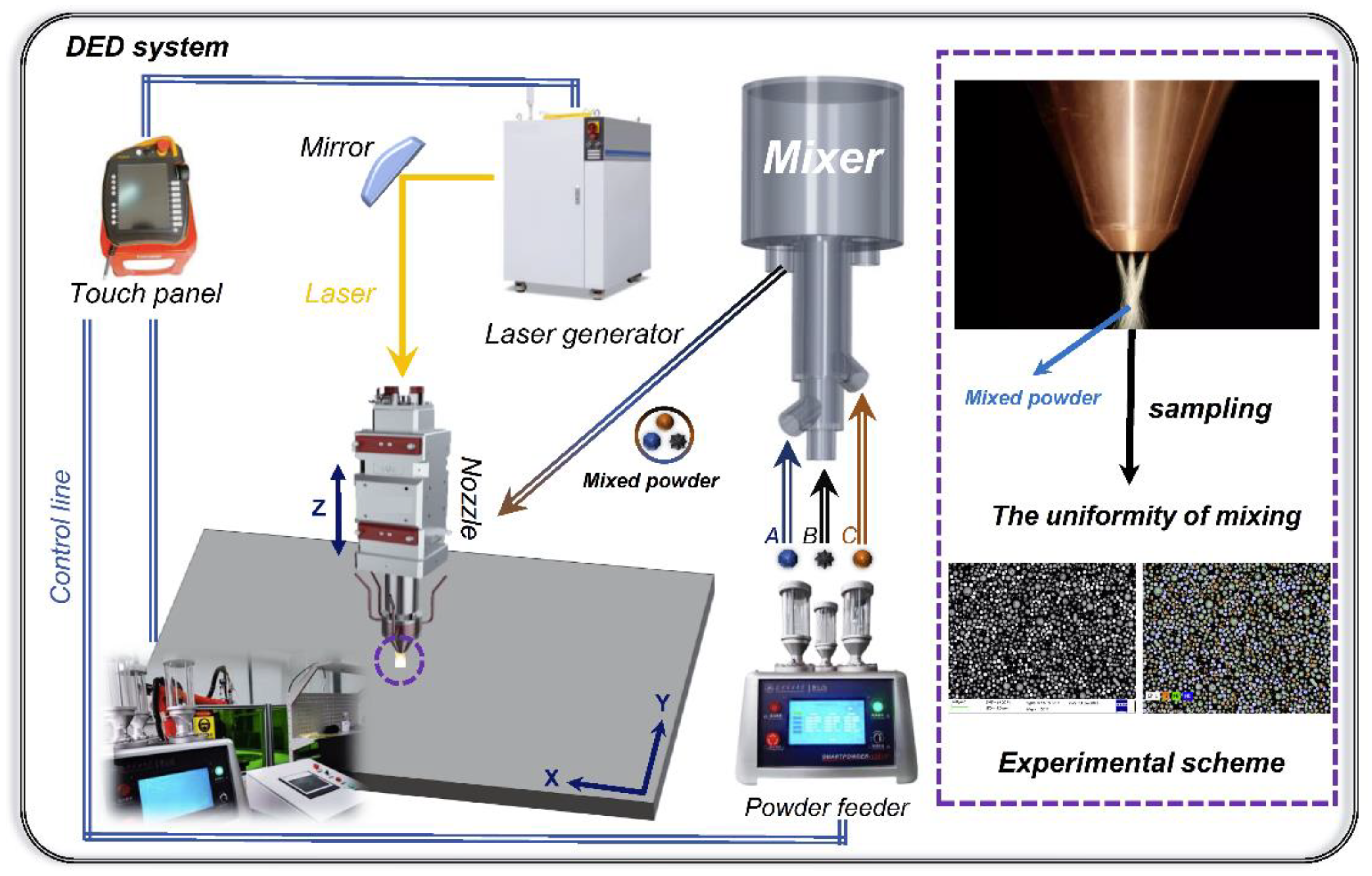

2. Materials and Methods

2.1. Synchronous Powder Mixing Principle

2.2. Numerical Simulation

3. Results and Discussion

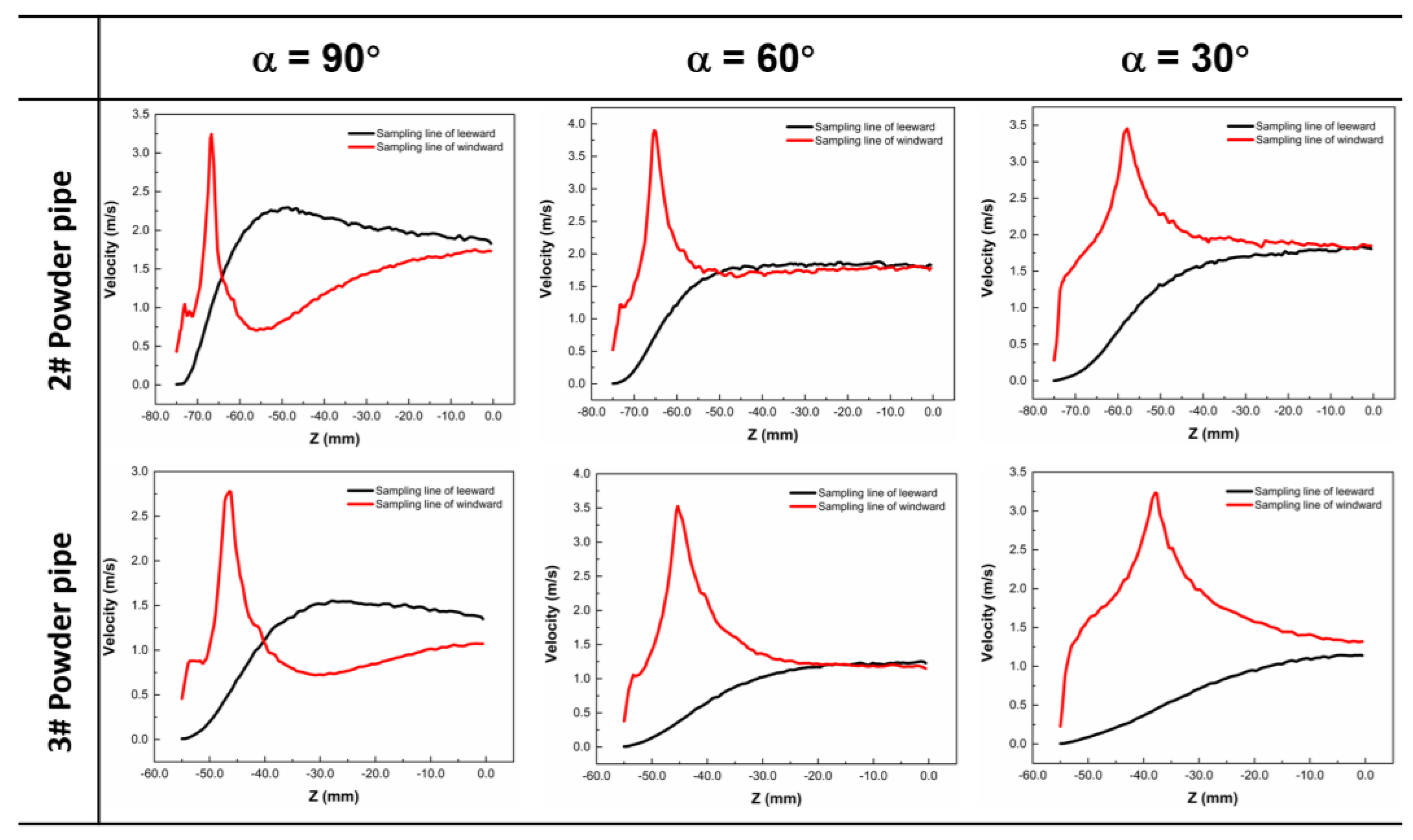

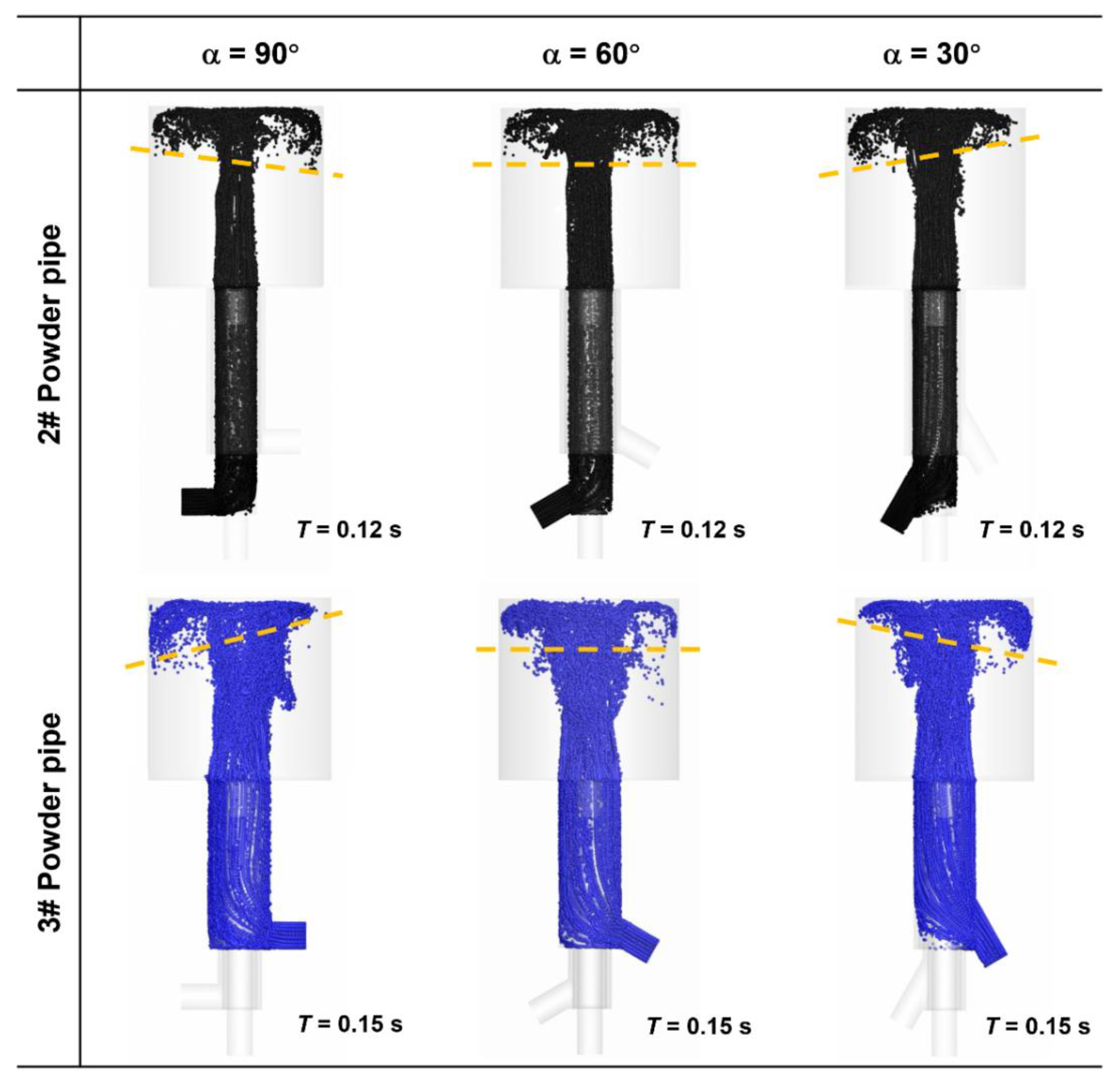

3.1. The Angle of the Inlet and the Length of the Powder Conveying Pipe

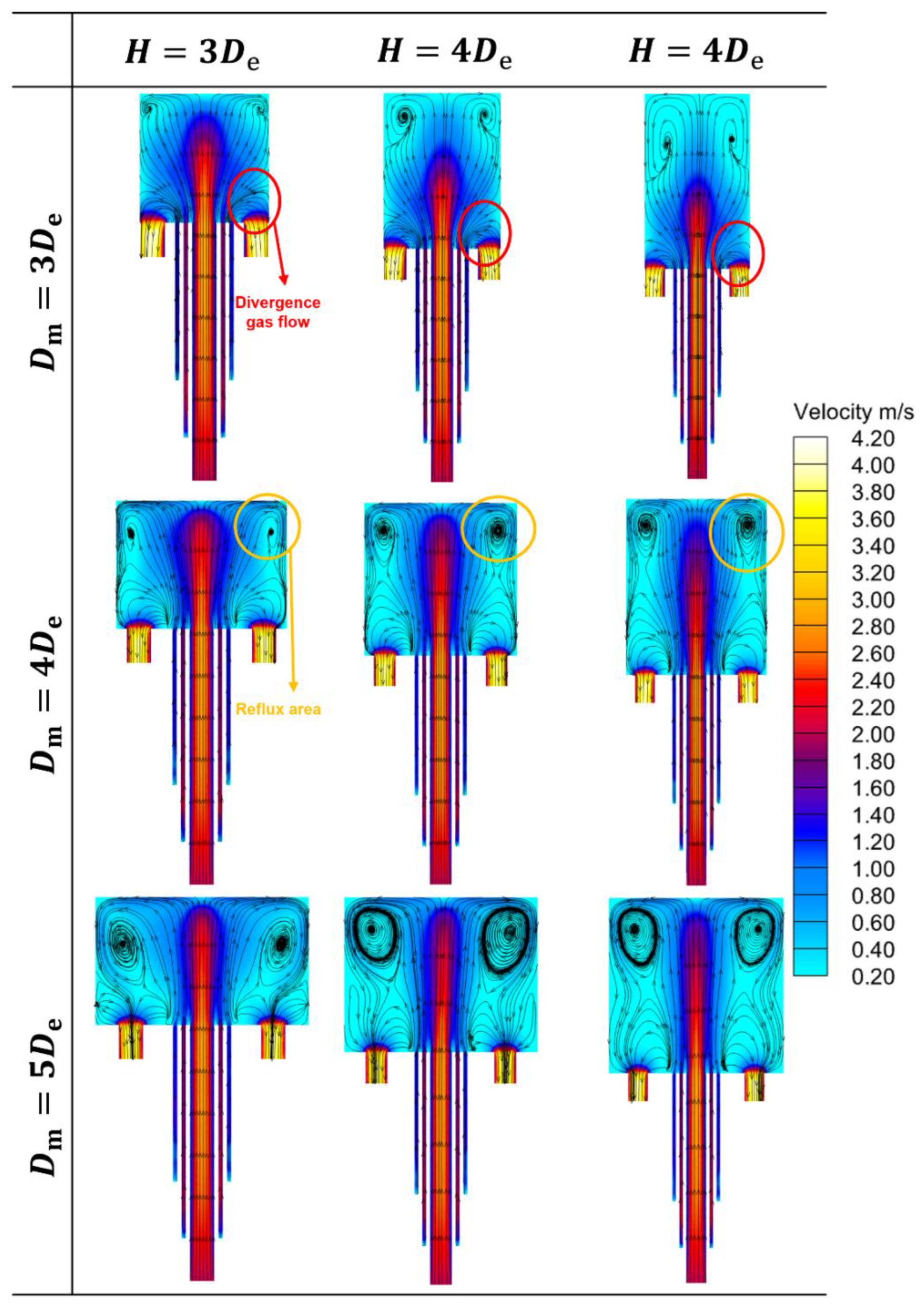

3.2. The Mixing Chamber Size Range

3.3. The Bottom Height

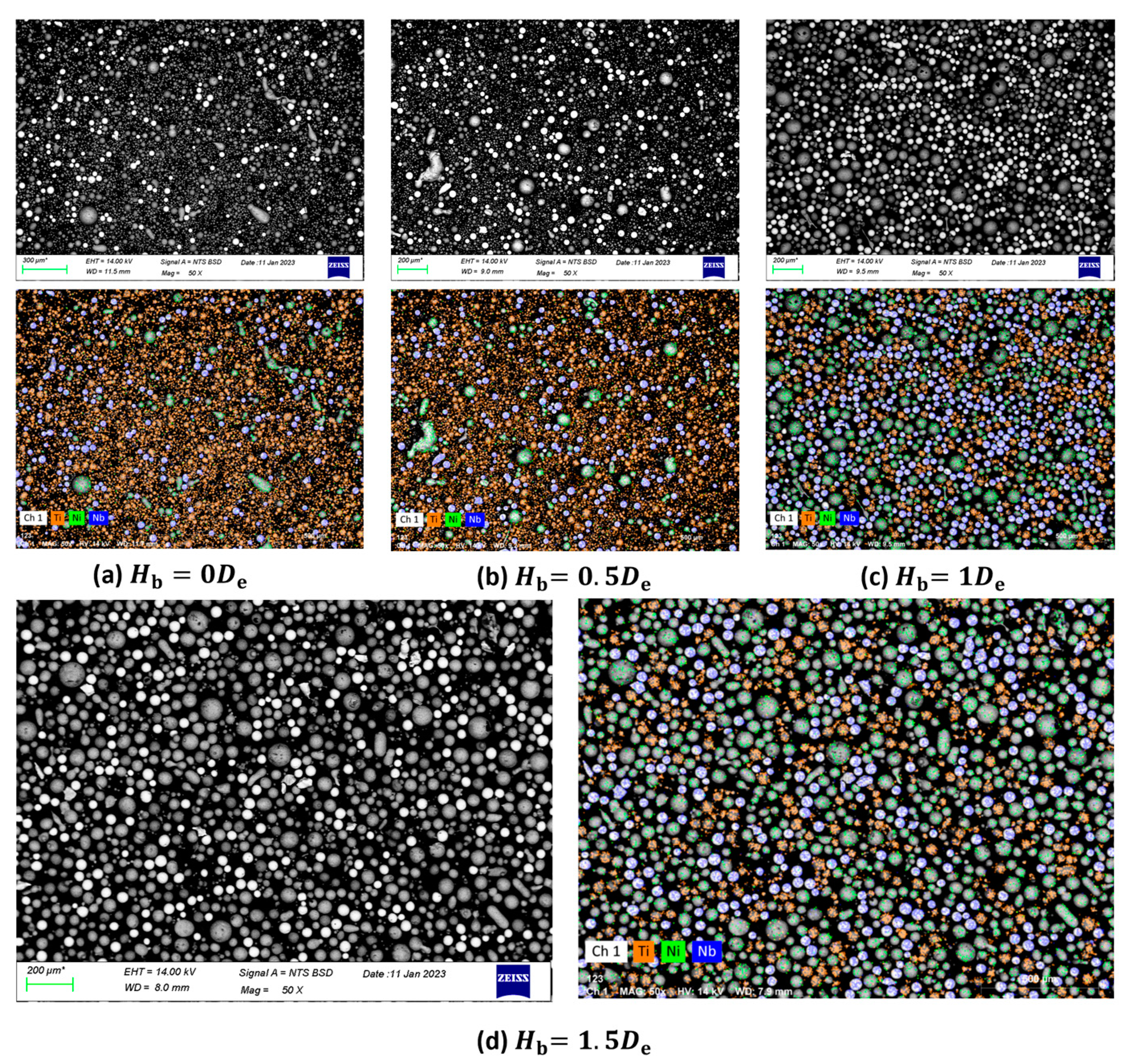

3.4. Experimental Results of Powder Mixing Uniformity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vecchio, K.S.; Dippo, O.F.; Kaufmann, K.R.; Liu, X. High-throughput rapid experimental alloy development (HT-READ). Acta Mater. 2021, 221, 117352. [Google Scholar] [CrossRef]

- Islam, Z.; Nelaturu, P.; Thoma, D.J. A dimensionless number for high-throughput design of multi-principal element alloys in directed energy deposition. Appl. Phys. Lett. 2021, 119, 231901. [Google Scholar] [CrossRef]

- Kim, C.K.; Jeong, J.I.; Choi, S.G.; Kim, J.H.; Cho, Y.T. High-throughput directed energy deposition process with an optimized scanning nozzle. J. Mater. Process. Technol. 2021, 295, 117165. [Google Scholar] [CrossRef]

- Pan, Q.; Kapoor, M.; Mileski, S.; Carsley, J.; Lou, X. Technical basis of using laser direct energy deposition as a high-throughput combinatorial method for DC-cast Al-Mn alloy development. Mater. Des. 2021, 212, 110290. [Google Scholar] [CrossRef]

- Li, W.; Zhang, J.; Zhang, X.; Liou, F. Effect of optimizing particle size on directed energy deposition of Functionally Graded Material with blown Pre-Mixed Multi-Powder. Manuf. Lett. 2017, 13, 39–43. [Google Scholar] [CrossRef]

- Zhang, X.; Yin, J.; Lei, Q.; Meng, X.; Chen, X.; Li, Z. High-throughput directed energy deposition-based manufacturing combined with machine learning to fabricate gradient-composition Cu-Fe-Cr alloys. Mater. Lett. 2022, 308, 131247. [Google Scholar] [CrossRef]

- Kelly, J.P.; Elmer, J.W.; Ryerson, F.J.; Lee, J.R.I.; Haslam, J.J. Directed energy deposition additive manufacturing of functionally graded Al-W composites. Addit. Manuf. 2021, 39, 101845. [Google Scholar] [CrossRef]

- Chen, J.; Xie, S.; He, H. A novel method of utilizing static mixer to obtain mixing homogeneity of multi-species powders in laser metal deposition. Chin. J. Aeronaut. 2023, 36, 423–433. [Google Scholar] [CrossRef]

- Han, Y.; Zhang, X.; Liu, H.; Xu, M.; Gao, G. Structural design, numerical examination and experimental approach of the multi-powder mixer for directed energy deposition. Powder Technol. 2022, 398, 117144. [Google Scholar] [CrossRef]

- del Val, J.; Arias-González, F.; Barro, O.; Riveiro, A.; Comesaña, R.; Penide, J.; Lusquiños, F.; Bountinguiza, M.; Quintero, F.; Pou, J. Functionally graded 3D structures produced by laser cladding. Procedia Manuf. 2017, 13, 169–176. [Google Scholar] [CrossRef]

- Xin, B.; Cheng, G.; Yao, J.; Gong, Y. Powder Mixing Mechanism of Laser Cladding Forming for Adaptive FGM. J. Northeast. Univ. (Nat. Sci.) 2020, 41, 1123. [Google Scholar] [CrossRef]

- Koyunoğlu, C.; Gündüz, F.; Karaca, H.; Çınar, T.; Soyhan, G.G. Developing an adaptive catalyst for an FCC reactor using a CFD RSM, CFD DPM, and CFD DDPM-EM approach. Fuel 2023, 334, 126550. [Google Scholar] [CrossRef]

| Powder | Composition (wt.%) | Size Range (μm) | D50 (μm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | N | O | Si | Ti | Nb | Ni | Fe | Cr | |||

| Ti | 0.009 | 0.025 | 0.012 | 0 | bal | 0 | 0 | 0.032 | 0 | 15–53 | 28 |

| Nb | 0.009 | 0.009 | 0.073 | 0.002 | 0.002 | bal | 0.003 | 0.008 | 0.003 | 15–45 | 36 |

| Ni65 | 1.100 | 0 | 0.080 | 4.260 | 0 | 0 | bal | 14.620 | 18.620 | 25–100 | 43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, G.; Zhang, X.; Xu, M.; Han, Y.; Ao, J.; Cai, Y.; Wang, J. Structural Optimized Design of a Powder Mixer for Multi-Material Directed Energy Deposition Based on CFD-DPM. Coatings 2023, 13, 773. https://doi.org/10.3390/coatings13040773

Gao G, Zhang X, Xu M, Han Y, Ao J, Cai Y, Wang J. Structural Optimized Design of a Powder Mixer for Multi-Material Directed Energy Deposition Based on CFD-DPM. Coatings. 2023; 13(4):773. https://doi.org/10.3390/coatings13040773

Chicago/Turabian StyleGao, Guochao, Xiaowei Zhang, Meng Xu, Yibo Han, Jingxuan Ao, Yaozeng Cai, and Jinzhe Wang. 2023. "Structural Optimized Design of a Powder Mixer for Multi-Material Directed Energy Deposition Based on CFD-DPM" Coatings 13, no. 4: 773. https://doi.org/10.3390/coatings13040773

APA StyleGao, G., Zhang, X., Xu, M., Han, Y., Ao, J., Cai, Y., & Wang, J. (2023). Structural Optimized Design of a Powder Mixer for Multi-Material Directed Energy Deposition Based on CFD-DPM. Coatings, 13(4), 773. https://doi.org/10.3390/coatings13040773