Investigating the Synergistic Effect of Electrochemical Texturing and MoSeC Coatings on the Frictional Behaviour of Lubricated Contacts

Abstract

1. Introduction

2. Materials and Methods

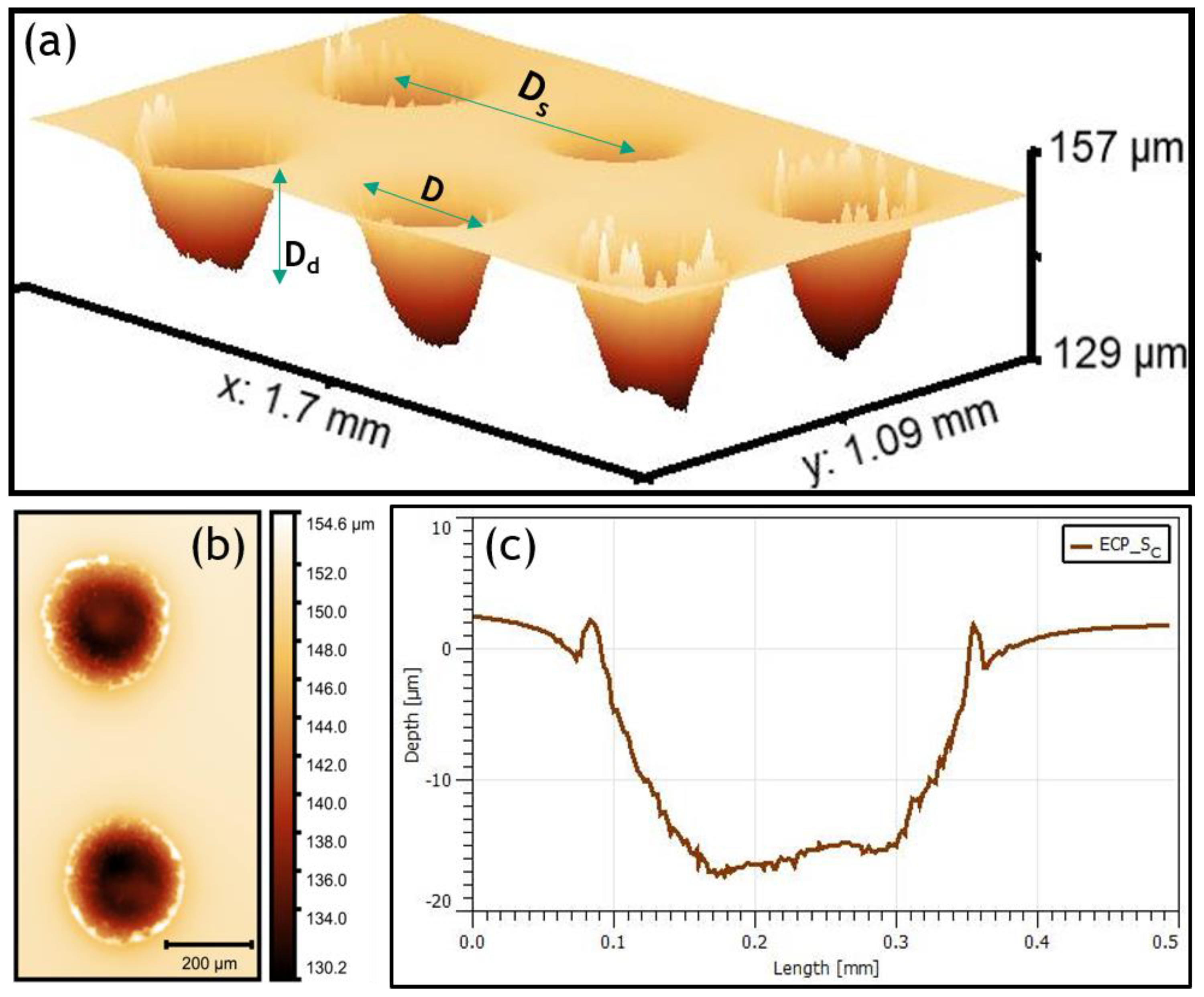

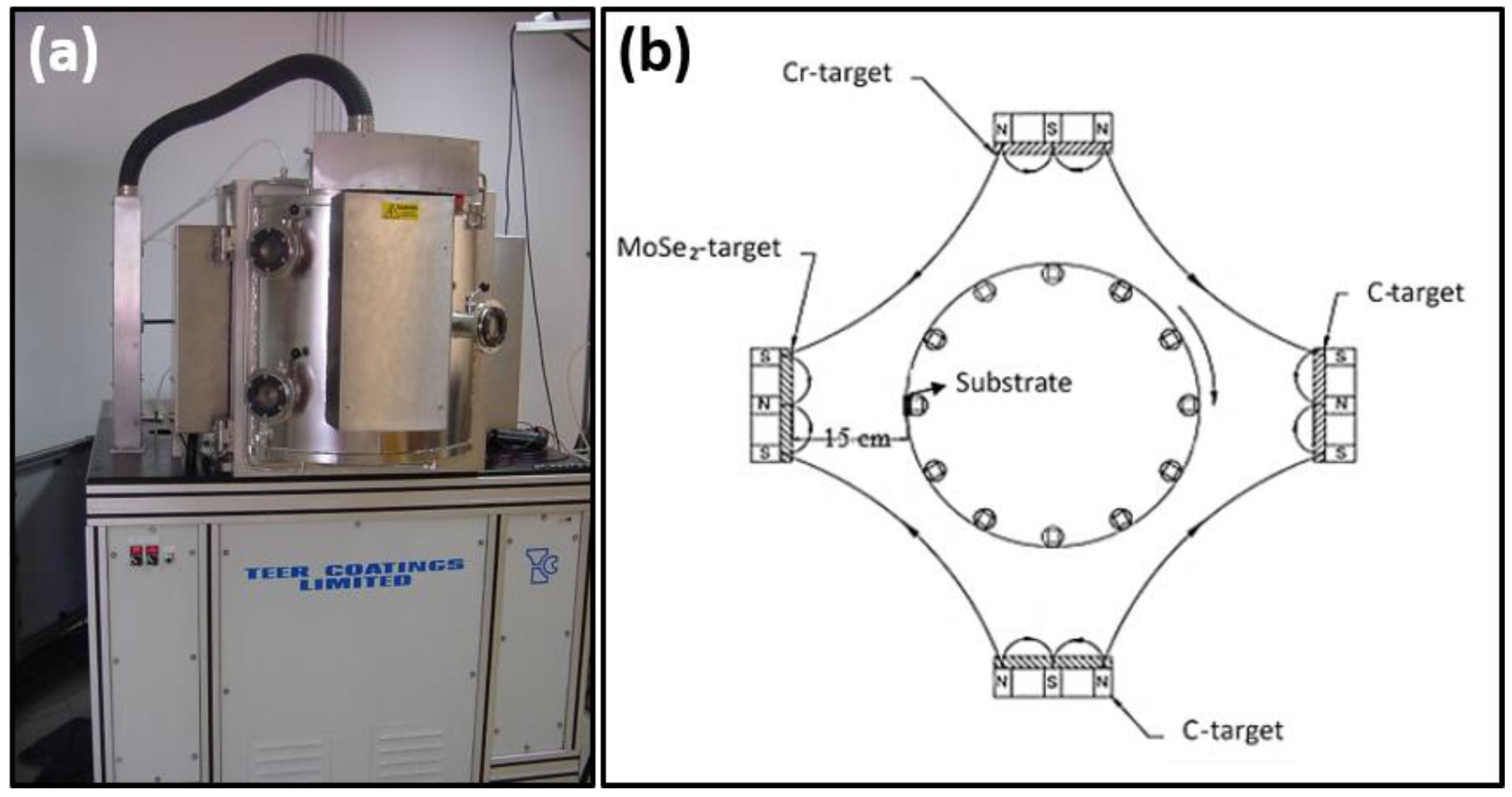

2.1. Specimens Preparation: Texturing & Coating

2.2. Tribology Testing

3. Results and Discussion

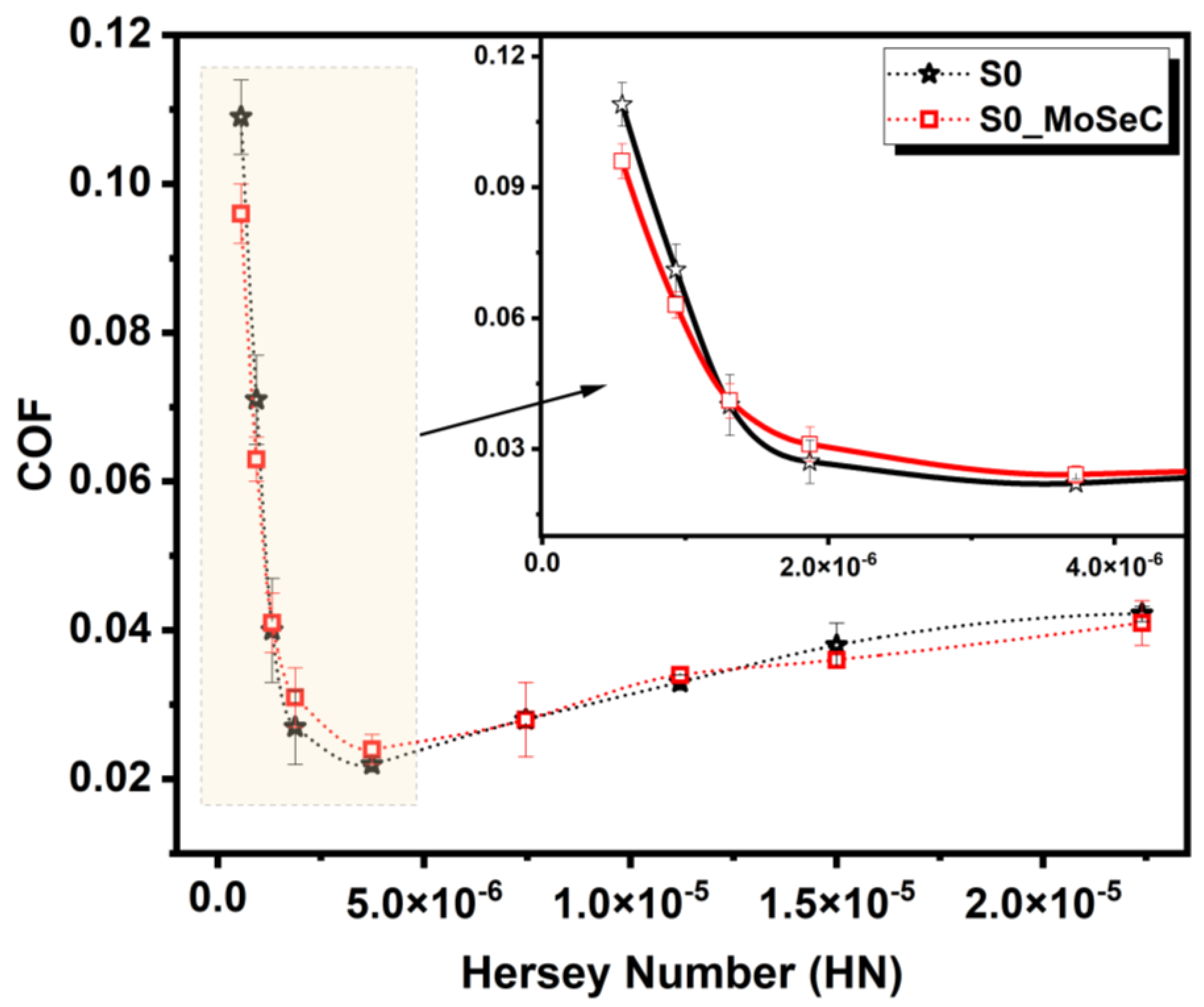

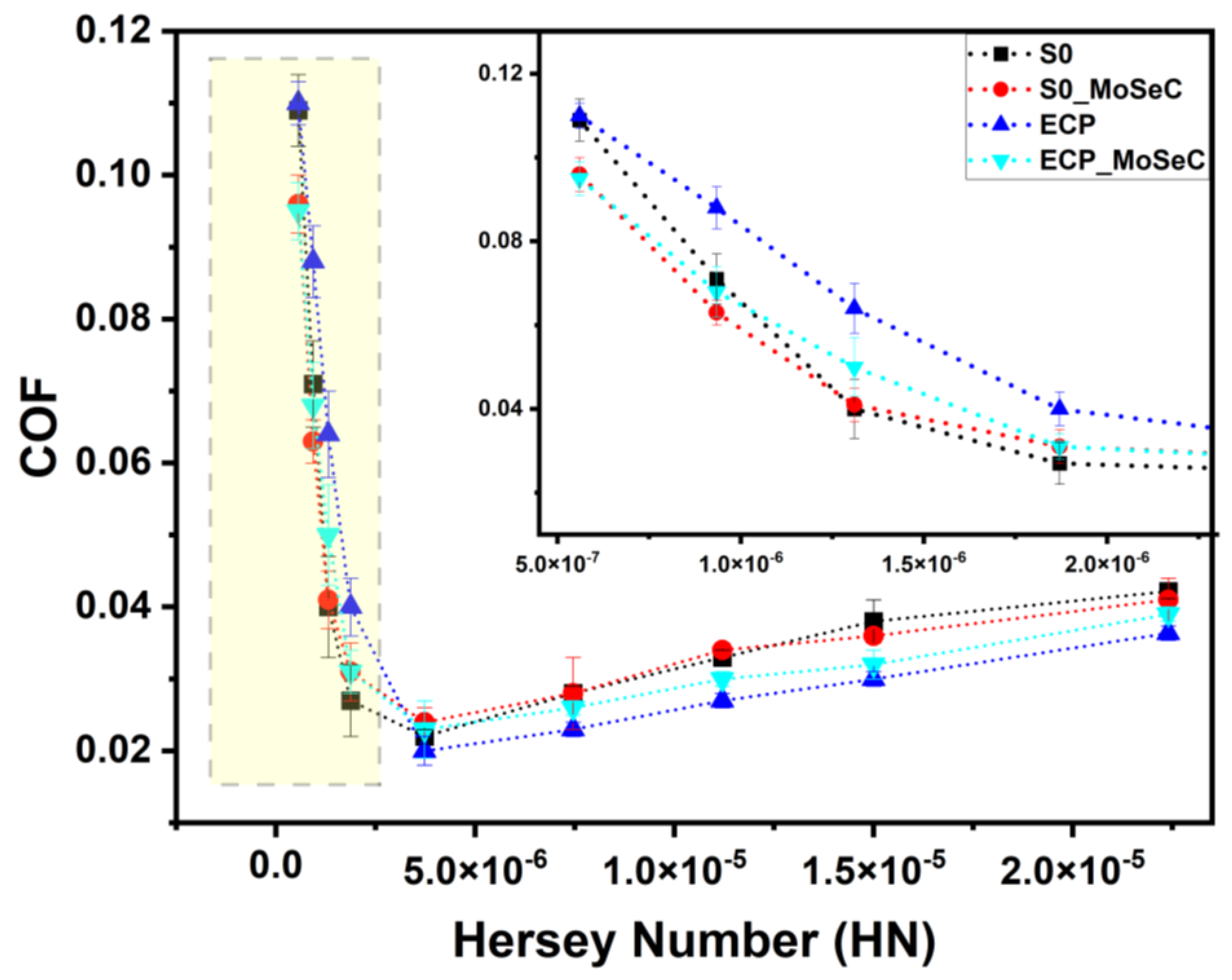

3.1. Friction Behaviour for Smooth and Smooth and Coated Specimens (S0 vs. S0_MoSeC)

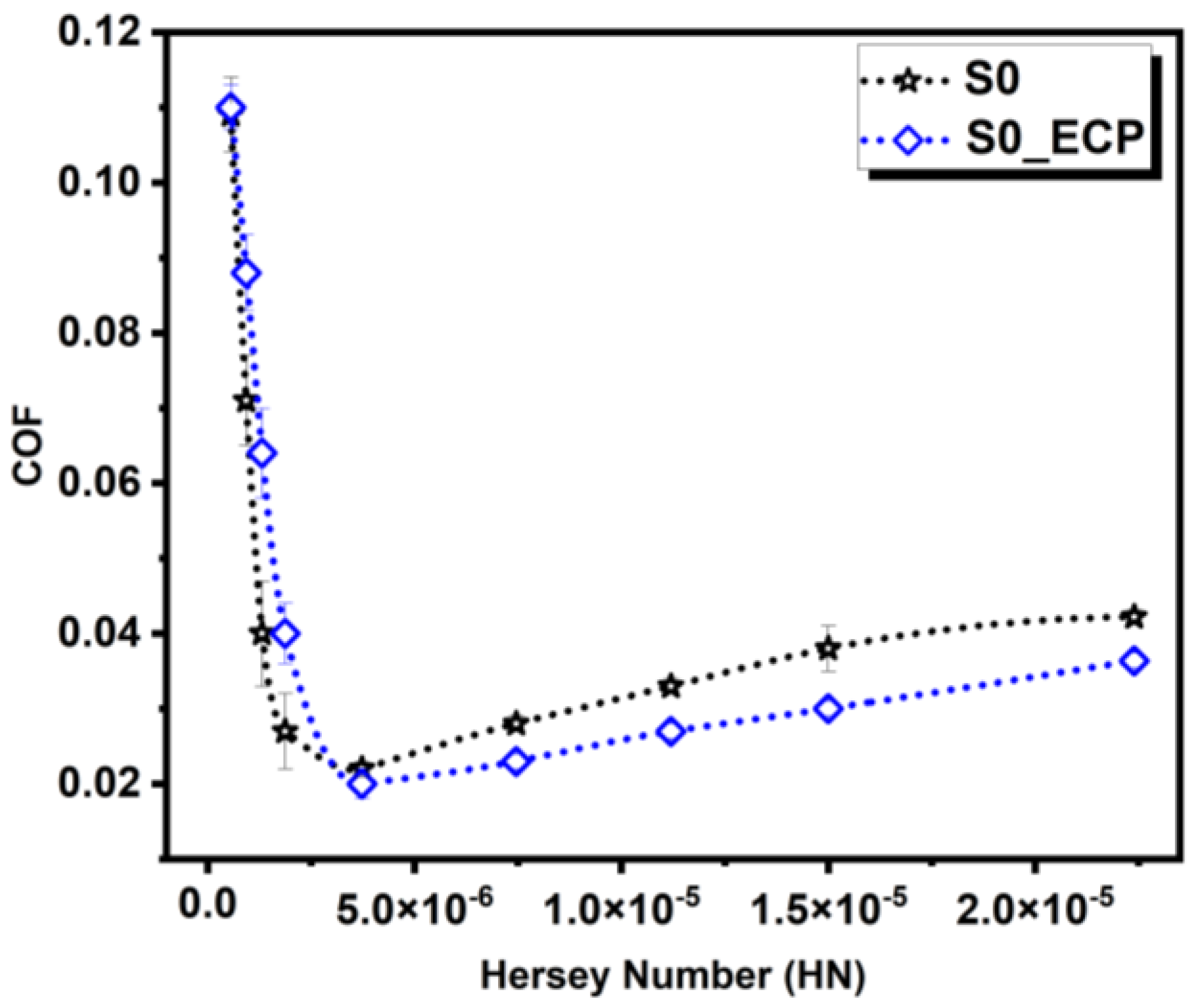

3.2. Friction Behaviour for the Smooth vs. ECP Textured Specimens

3.3. Synergistic Effect of Coating and Texturing

3.3.1. Block on Ring

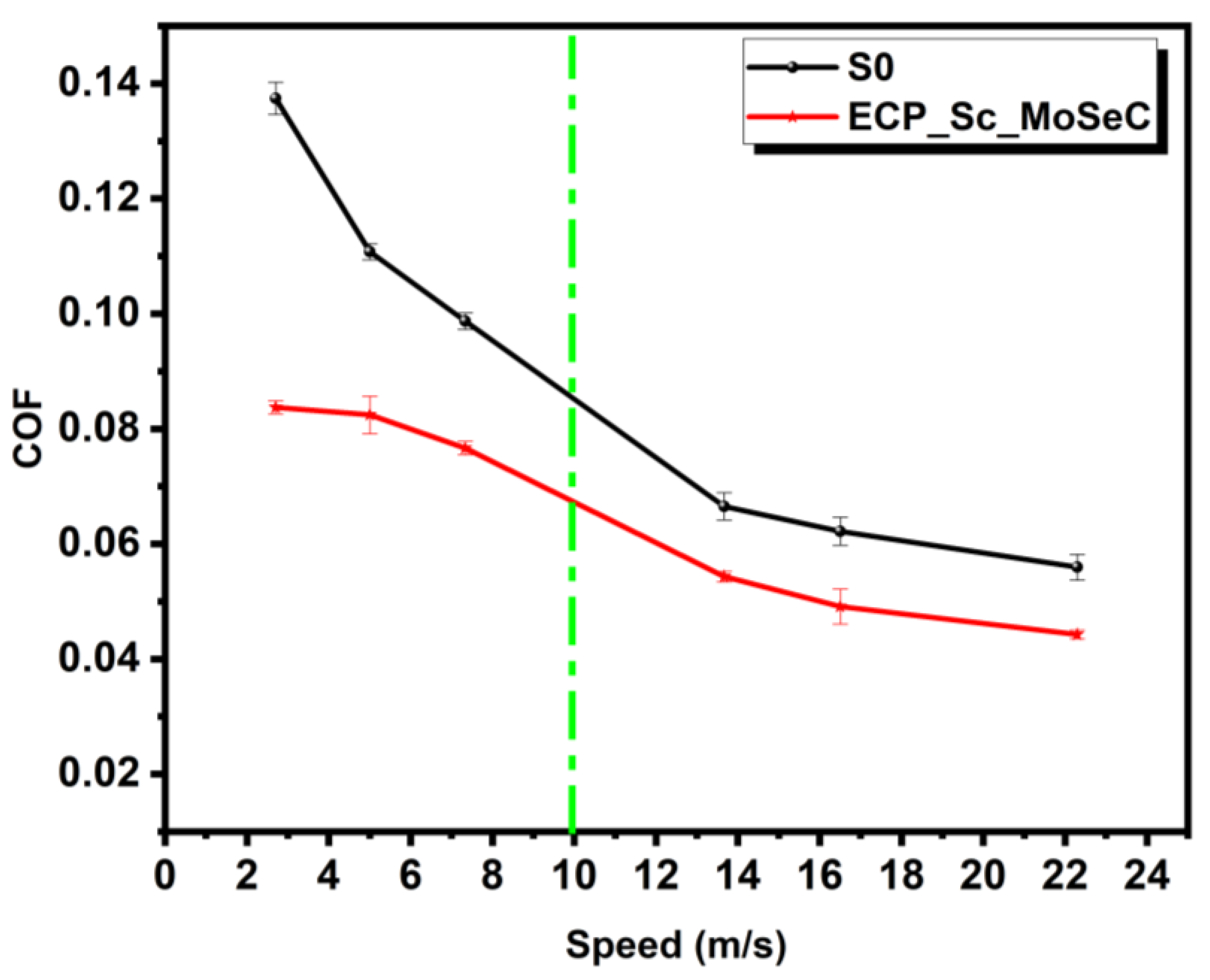

3.3.2. Reciprocating Sliding Test

4. Characterization of the Wear Mechanisms from the Textured Specimen (ECP_SC) and Textured/Coated Specimen (ECP_SC_MoSeC)

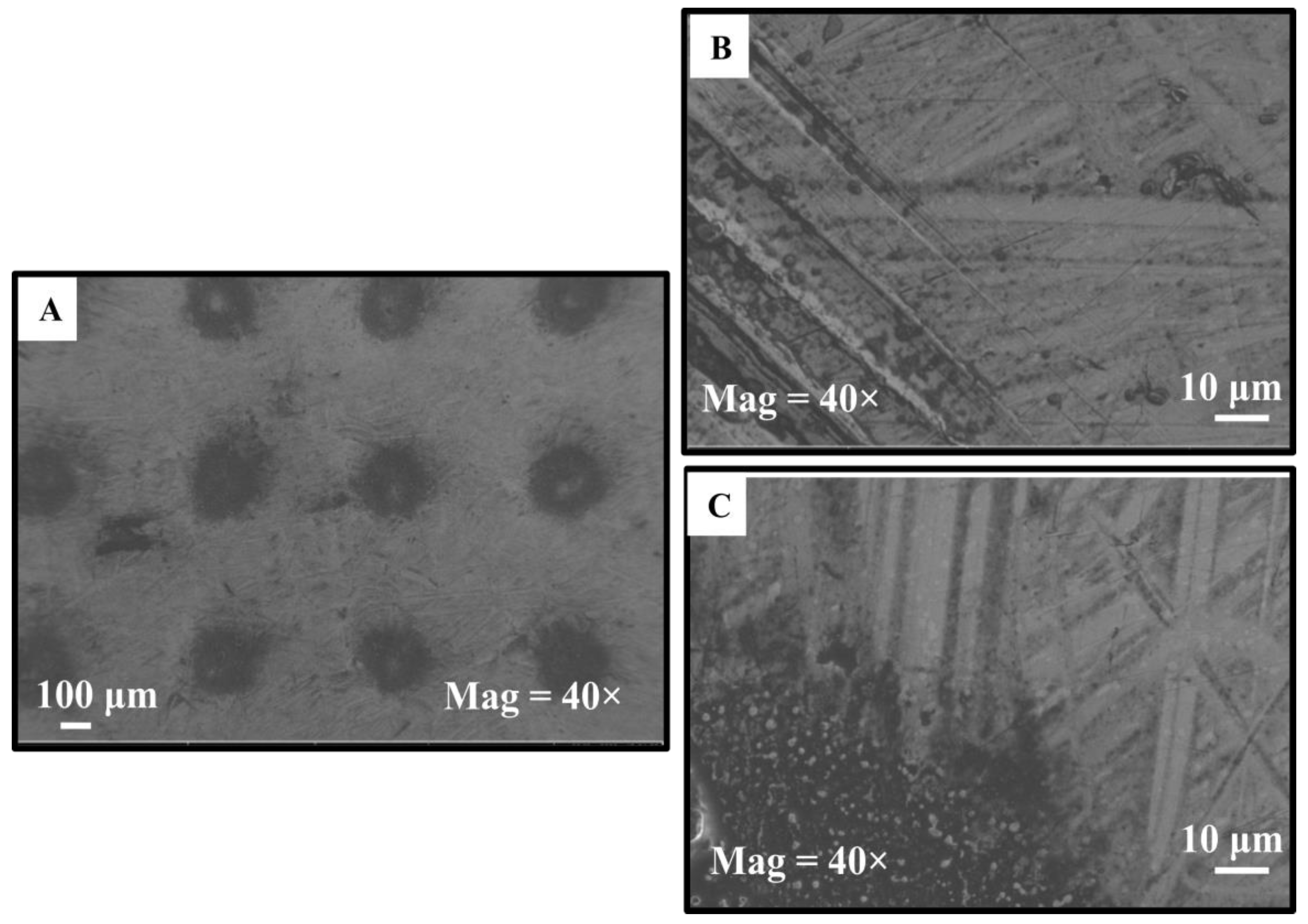

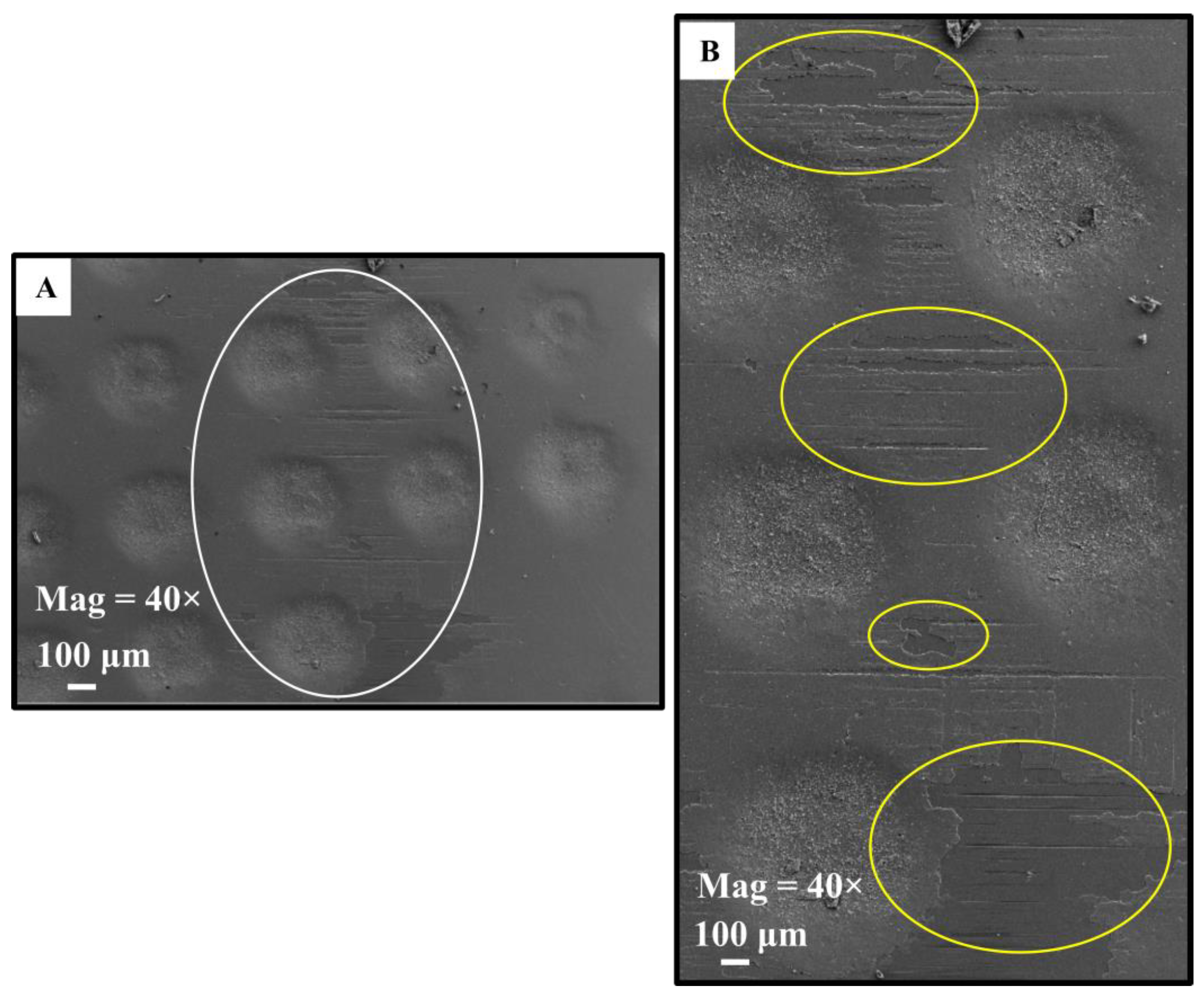

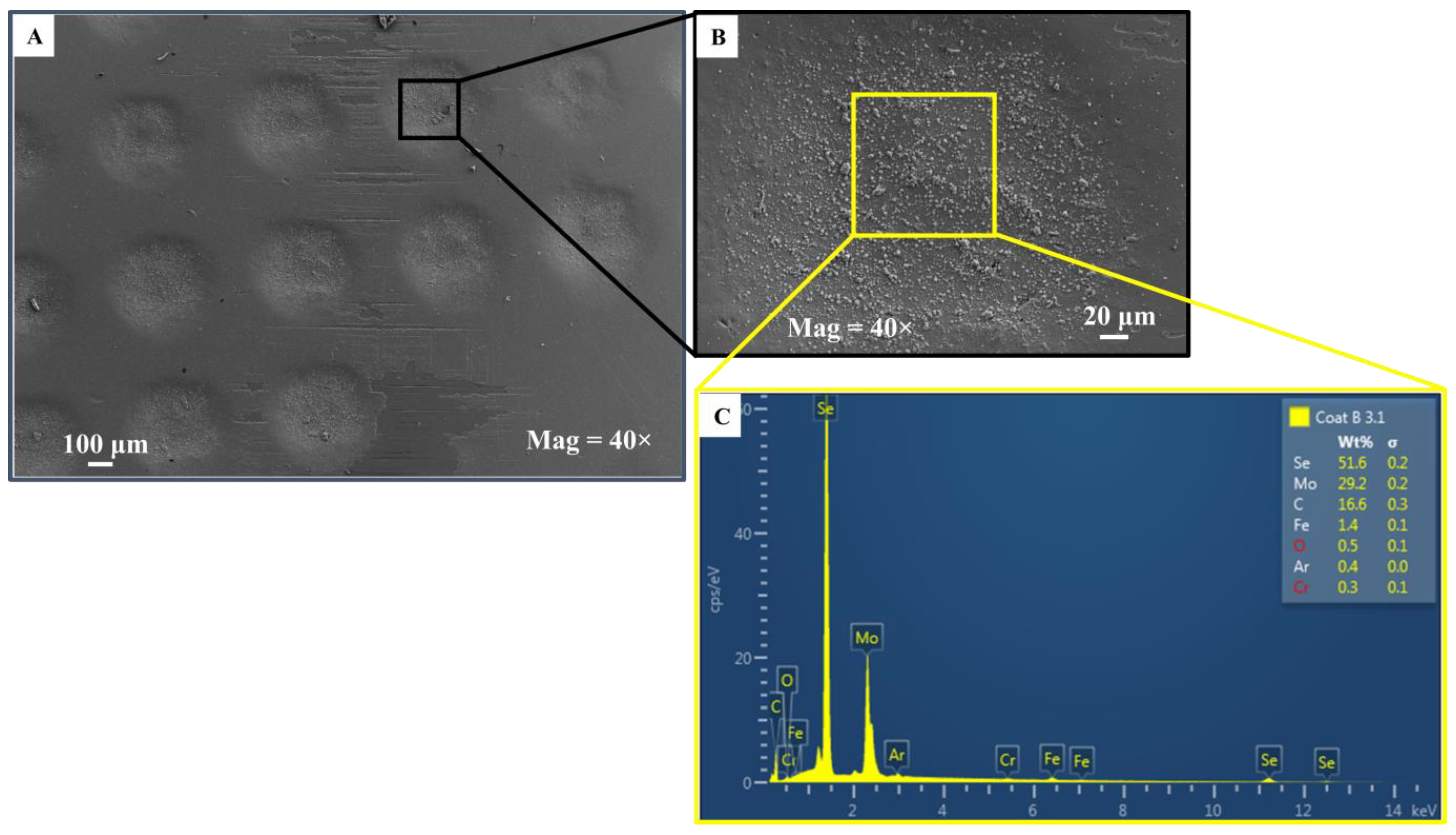

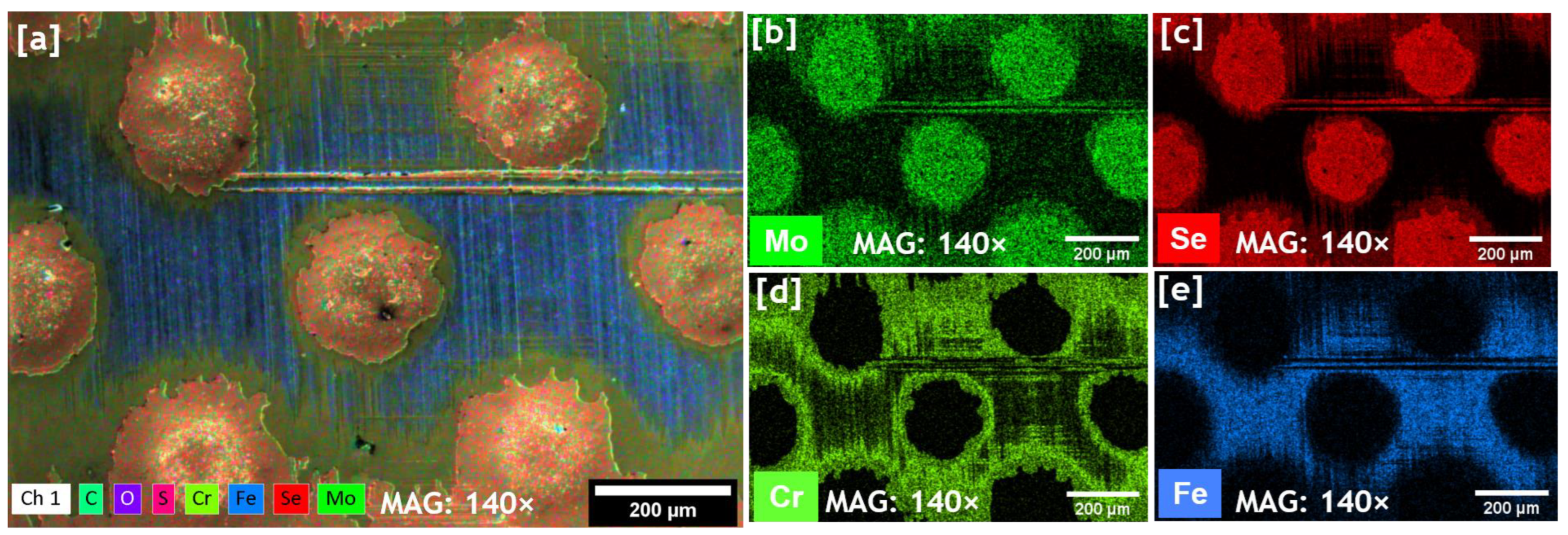

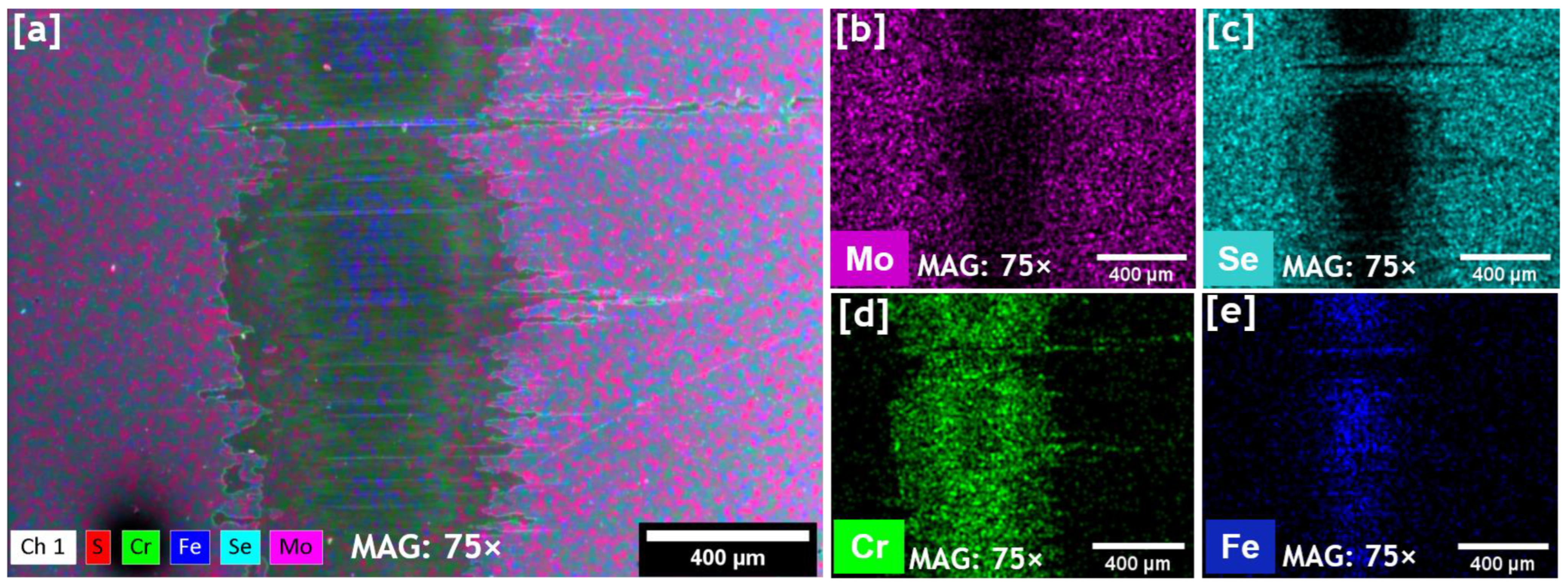

4.1. ECP_SC Specimen

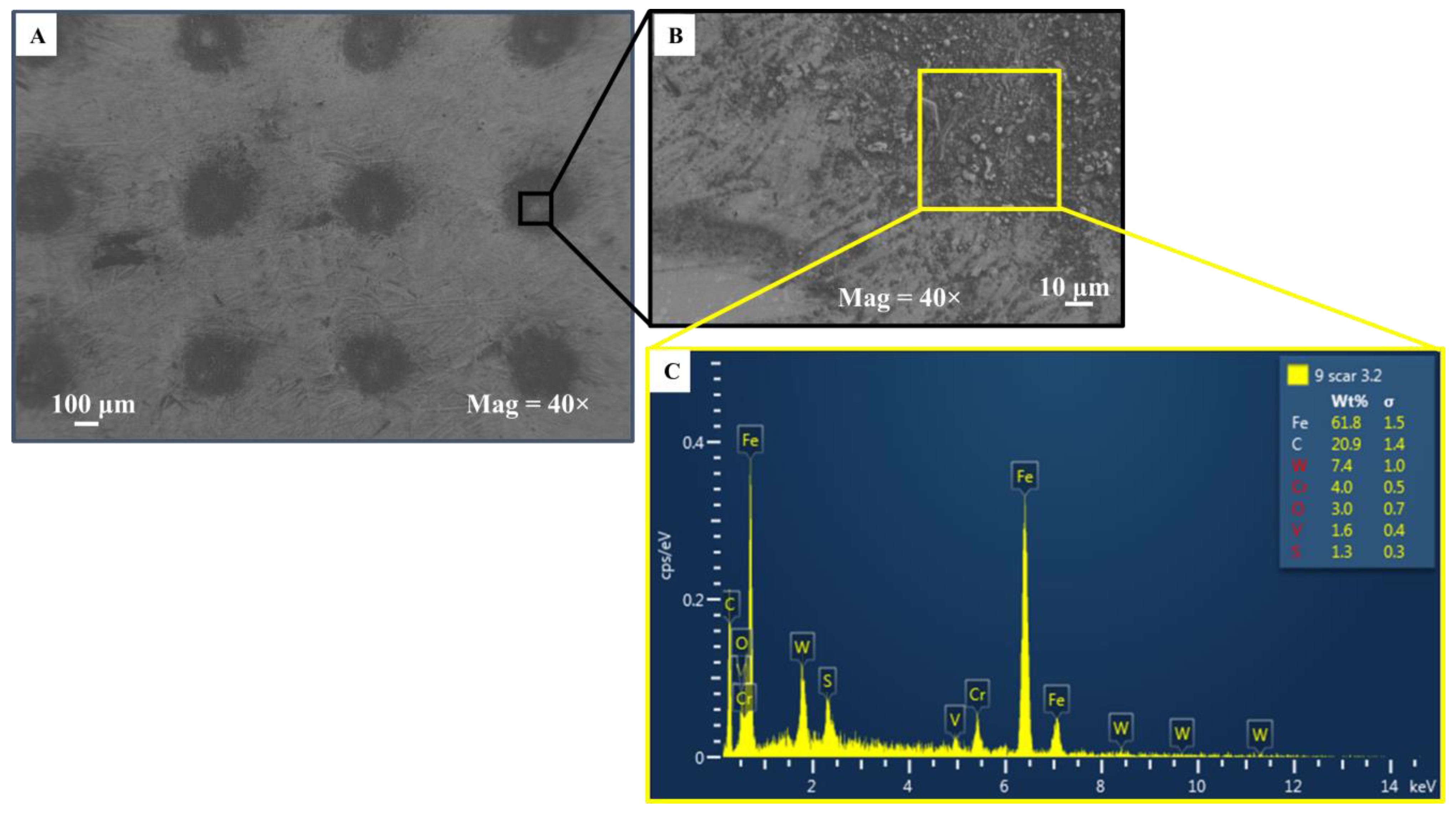

4.2. ECP_SC_MoSeC Specimen

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bruzzone, A.A.; Costa, H.L.; Lonardo, P.M.; Lucca, D.A. Advances in engineered surfaces for functional performance. CIRP Ann. 2008, 57, 750–769. [Google Scholar] [CrossRef]

- He, D.; Zheng, S.; Pu, J.; Zhang, G.; Hu, L. Improving tribological properties of titanium alloys by combining laser surface texturing and diamond-like carbon film. Tribol. Int. 2015, 82, 20–27. [Google Scholar] [CrossRef]

- Mao, B.; Siddaiah, A.; Liao, Y.; Menezes, P.L. Laser surface texturing and related techniques for enhancing tribological performance of engineering materials: A review. J. Manuf. Process. 2020, 53, 153–173. [Google Scholar] [CrossRef]

- Shum, P.; Zhou, Z.; Li, K. Investigation of the tribological properties of the different textured DLC coatings under reciprocating lubricated conditions. Tribol. Int. 2013, 65, 259–264. [Google Scholar] [CrossRef]

- Meng, R.; Deng, J.; Liu, Y.; Duan, R.; Zhang, G. Improving tribological performance of cemented carbides by combining laser surface texturing and WSC solid lubricant coating. Int. J. Refract. Met. Hard Mater. 2018, 72, 163–171. [Google Scholar] [CrossRef]

- Etsion, I.; Kligerman, Y.; Halperin, G. Analytical and experimental investigation of laser-textured mechanical seal faces. Tribol. Trans. 1999, 42, 511–516. [Google Scholar] [CrossRef]

- Wang, Q.J.; Zhu, D. Virtual texturing: Modeling the performance of lubricated contacts of engineered surfaces. J. Tribol. 2005, 127, 722–728. [Google Scholar] [CrossRef]

- Vilhena, L.; Podgornik, B.; Vižintin, J.; Možina, J. Influence of texturing parameters and contact conditions on tribological behaviour of laser textured surfaces. Meccanica 2011, 46, 567–575. [Google Scholar] [CrossRef]

- Vilhena, L.; Sedlaček, M.; Podgornik, B.; Rek, Z.; Žun, I. CFD modeling of the effect of different surface texturing geometries on the frictional behavior. Lubricants 2018, 6, 15. [Google Scholar] [CrossRef]

- Etsion, I. State of the art in laser surface texturing. J. Trib. 2005, 127, 248–253. [Google Scholar] [CrossRef]

- Ranjan, P.; Hiremath, S.S. Role of textured tool in improving machining performance: A review. J. Manuf. Process. 2019, 43, 47–73. [Google Scholar] [CrossRef]

- Kirchner, V.; Cagnon, L.; Schuster, R.; Ertl, G. Electrochemical machining of stainless-steel microelements with ultrashort voltage pulses. Appl. Phys. Lett. 2001, 79, 1721–1723. [Google Scholar] [CrossRef]

- Jain, V. Micromachining: An Introduction; Narosa Publishing House: New Delhi, India, 2010; pp. 1.1–1.27. [Google Scholar]

- Byun, J.W.; Shin, H.S.; Kwon, M.H.; Kim, B.H.; Chu, C.N. Surface texturing by micro ECM for friction reduction. Int. J. Precis. Eng. Manuf. 2010, 11, 747–753. [Google Scholar] [CrossRef]

- Zeng, Z.; Wang, Y.; Wang, Z.; Shan, D.; He, X. A study of micro-EDM and micro-ECM combined milling for 3D metallic micro-structures. Precis. Eng. 2012, 36, 500–509. [Google Scholar] [CrossRef]

- Chen, X.; Qu, N.; Hou, Z.; Wang, X.; Zhu, D. Friction reduction of chrome-coated surface with micro-dimple arrays generated by electrochemical micromachining. J. Mater. Eng. Perform. 2017, 26, 667–675. [Google Scholar] [CrossRef]

- Yaqub, T.B.; Vuchkov, T.; Evaristo, M.; Cavaleiro, A. DCMS Mo-Se-C solid lubricant coatings–Synthesis, structural, mechanical and tribological property investigation. Surf. Coat. Technol. 2019, 378, 124992. [Google Scholar] [CrossRef]

- Herdan, J. Lubricating oil additives and the environment—An overview. Lubr. Sci. 1997, 9, 161–172. [Google Scholar] [CrossRef]

- Scharf, T.; Prasad, S. Solid lubricants: A review. J. Mater. Sci. 2013, 48, 511–531. [Google Scholar] [CrossRef]

- Fusaro, R.L. Effect of substrate surface finish on the lubrication and failure mechanisms of molybdenum disulfide films. ASLE Trans. 1982, 25, 141–156. [Google Scholar] [CrossRef]

- Polcar, T.; Nossa, A.; Evaristo, M.; Cavaleiro, A. Nanocomposite Coatings of Carbon-Based and Transition Metal Dichalcogenides Phases: A Review. Adv. Mater. Sci 2007, 15, 118–126. [Google Scholar]

- Brainard, W.A. The Thermal Stability and Friction of the Disulfides, Diselenides, and Ditellurides of Molybdenum and Tungsten in Vacuum (109 to 106 Torr); National Aeronautics and Space Administration: Washington, DC, USA, 1968.

- Vitu, T.; Huminiuc, T.; Doll, G.; Bousser, E.; Matthews, A.; Polcar, T. Tribological properties of Mo-SC coating deposited by pulsed dc magnetron sputtering. Wear 2021, 480, 203939. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Song, J.; Ding, Q. Study on tribological properties of TMDs-coated copper from the nanoscale. Mater. Today Commun. 2022, 31, 103815. [Google Scholar] [CrossRef]

- Kubart, T.; Polcar, T.; Kopecký, L.; Novák, R.; Nováková, D. Temperature dependence of tribological properties of MoS2 and MoSe2 coatings. Surf. Coat. Technol. 2005, 193, 230–233. [Google Scholar] [CrossRef]

- Polcar, T.; Evaristo, M.; Cavaleiro, A. Comparative study of the tribological behavior of self-lubricating W–S–C and Mo–Se–C sputtered coatings. Wear 2009, 266, 388–392. [Google Scholar] [CrossRef]

- Vilhena, L.; Ramalho, A.; Cavaleiro, A. Grooved surface texturing by electrical discharge machining (EDM) under different lubrication regimes. Lubr. Sci. 2017, 29, 493–501. [Google Scholar] [CrossRef]

- Veltkamp, B.; Velikov, K.; Venner, C.; Bonn, D. Lubricated friction and the Hersey number. Phys. Rev. Lett. 2021, 126, 044301. [Google Scholar] [CrossRef] [PubMed]

- Tallian, T. Rolling bearing life modifying factors for film thickness, surface roughness, and friction. J. Lubr. Technol. 1981, 103, 509–516. [Google Scholar] [CrossRef]

- Caessa, J.; Vuchkov, T.; Yaqub, T.B.; Cavaleiro, A. On the microstructural, mechanical and tribological properties of Mo-Se-C coatings and their potential for friction reduction against rubber. Materials 2021, 14, 1336. [Google Scholar] [CrossRef]

- Amoroso, P.J.; Ramalho, A.; Richhariya, V.; Silva, F.S.; Cavaleiro, A. Tribological performance of laser-textured steel surfaces in unidirectional sliding line-contact (block-on-ring). Lubr. Sci. 2021, 33, 417–431. [Google Scholar] [CrossRef]

- Hudec, T.; Izai, V.; Satrapinskyy, L.; Huminiuc, T.; Roch, T.; Gregor, M.; Grančič, B.; Mikula, M.; Polcar, T. Structure, mechanical and tribological properties of MoSe2 and Mo-Se-N solid lubricant coatings. Surf. Coat. Technol. 2021, 405, 126536. [Google Scholar] [CrossRef]

| Elements | C | Cr | Mn | Mo | Ni | V | Si | W | |

|---|---|---|---|---|---|---|---|---|---|

| Specimen | AISI M2 | 1.00 | 4.15 | 0.30 | 5.00 | - | 1.95 | 0.30 | 6.25 |

| Counter Body | AISI 3415 | 0.17 | 0.75 | 0.55 | - | 3.25 | - | <0.20 | - |

| Specimens | D (μm) | Dd (μm) | Ds (μm) |

|---|---|---|---|

| ECP_SC | 262.7 ± 3.5 | 19.4 ± 1.4 | 306.6 ± 3.2 |

| Coating | Elemental Composition (At. %) | Thickness (µm) | Deposition Time (min) | Deposition Rate (nm/min) | Hardness (GPa) | ||||

|---|---|---|---|---|---|---|---|---|---|

| C | Se | O | Mo | Cr | |||||

| MoSeC | 58.0 | 26.9 | 0.9 | 12.5 | 0.2 | 1.8 | 120 | 13.8 | 4.3 |

| Speed (m/s) | HN | (λ) | Lubrication Regimes |

|---|---|---|---|

| 0.01 | 2.24 × 10−5 | 0.7 | Boundary Lubrication (BL) |

| 0.02 | 1.49 × 10−5 | 1.1 | Mixed Lubrication (ML) |

| 0.03 | 1.12 × 10−5 | 1.4 | |

| 0.04 | 7.46 × 10−6 | 1.7 | |

| 0.07 | 3.73 × 10−6 | 2.5 | |

| 0.12 | 1.87 × 10−6 | 4.4 | Hydrodynamic Lubrication (HL) |

| 0.23 | 1.31 × 10−6 | 5.7 | |

| 0.31 | 9.33 × 10−7 | 7.0 | |

| 0.47 | 5.60 × 10−7 | 9.2 |

| Test | Load (N) | Frequency (Hz) | Sliding Distance (mm) | Sliding Speed (×10−3 m/s) | Sliding Time (s) |

|---|---|---|---|---|---|

| 1 | 30 | 0.67 | 2000 | 2.7 | 746 |

| 2 | 30 | 1.25 | 2000 | 5.0 | 400 |

| 3 | 30 | 1.82 | 2000 | 7.3 | 275 |

| 4 | 30 | 3.40 | 2000 | 13.6 | 147 |

| 5 | 30 | 4.12 | 2000 | 16.5 | 121 |

| 6 | 30 | 5.57 | 2000 | 22.3 | 90 |

| Speed (m/s) | 0.01 | 0.02 | 0.03 | 0.04 | 0.07 | 0.16 | 0.23 | 0.31 | 0.47 |

|---|---|---|---|---|---|---|---|---|---|

| S0_MoSeC | 11.9% | 10.7% | −2.5% | −14.8% | −9.1% | −1.2% | −1.5% | 5.2% | 2.3% |

| S0 | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| Speed (m/s) | 0.01 | 0.02 | 0.03 | 0.04 | 0.07 | 0.16 | 0.23 | 0.31 | 0.47 |

|---|---|---|---|---|---|---|---|---|---|

| ECP_SC | −0.9% | −23.9% | −60.0% | −48.1% | 9.1% | 17.8% | 18.2% | 21.0% | 14.3% |

| S0 | - | - | - | - | - | - | - | - | - |

| Speed (m/s) | 0.01 | 0.02 | 0.03 | 0.04 | 0.07 | 0.16 | 0.23 | 0.31 | 0.47 |

|---|---|---|---|---|---|---|---|---|---|

| ECP_SC_MoSeC | 12.8% | 4.2% | −25.0% | −14.8% | −4.5% | 7.1% | 9.1% | 15.8% | 7.1% |

| ECP_SC | −0.9% | −23.9% | −60.0% | −48.1% | 9.1% | 17.8% | 18.2% | 21.0% | 14.3% |

| S0_MoSeC | 11.9% | 10.7% | −2.5% | −14.8% | −9.1% | −1.2% | −1.5% | 5.2% | 2.3% |

| S0 | - | - | - | - | - | - | - | - | - |

| Speed (mm/s) | 2.7 | 5 | 7.3 | 13.6 | 16.5 | 22.3 |

|---|---|---|---|---|---|---|

| ECP_SC_MoSeC | 39.1% | 25.6% | 22.4% | 18.4% | 21.0% | 20.9% |

| S0 | - | - | - | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahadeshwara, M.R.; Rosa, F.; Vuchkov, T.; Vilhena, L.; Ramalho, A.; Sharma, P.; Cavaleiro, A. Investigating the Synergistic Effect of Electrochemical Texturing and MoSeC Coatings on the Frictional Behaviour of Lubricated Contacts. Coatings 2023, 13, 692. https://doi.org/10.3390/coatings13040692

Mahadeshwara MR, Rosa F, Vuchkov T, Vilhena L, Ramalho A, Sharma P, Cavaleiro A. Investigating the Synergistic Effect of Electrochemical Texturing and MoSeC Coatings on the Frictional Behaviour of Lubricated Contacts. Coatings. 2023; 13(4):692. https://doi.org/10.3390/coatings13040692

Chicago/Turabian StyleMahadeshwara, Manoj Rajankunte, Fátima Rosa, Todor Vuchkov, Luís Vilhena, Amílcar Ramalho, Pooja Sharma, and Albano Cavaleiro. 2023. "Investigating the Synergistic Effect of Electrochemical Texturing and MoSeC Coatings on the Frictional Behaviour of Lubricated Contacts" Coatings 13, no. 4: 692. https://doi.org/10.3390/coatings13040692

APA StyleMahadeshwara, M. R., Rosa, F., Vuchkov, T., Vilhena, L., Ramalho, A., Sharma, P., & Cavaleiro, A. (2023). Investigating the Synergistic Effect of Electrochemical Texturing and MoSeC Coatings on the Frictional Behaviour of Lubricated Contacts. Coatings, 13(4), 692. https://doi.org/10.3390/coatings13040692