Abstract

In this paper, results concerning hydrogen and deuterium plasma (RF, 13.56 MHz) interactions with tungsten surfaces, were reported. We used the Hollow-Cathode (HC) configuration for plasma–tungsten surface interaction experiments, along with the collection of tungsten dust, at different distances. Further on, the plasma-exposed tungsten surfaces and the collected dust were morphologically analyzed by contact profilometry, scanning electron microscopy, and energy dispersive spectroscopy measurements, along with chemical investigations by the X-ray photoelectron spectroscopy technique. The results showed that exposing the tungsten surfaces to the hydrogen plasma induces surface erosion phenomena along with the formation of dust and interconnected W structures. Herein, the mean ejected material volume was ~1.1 × 105 µm3. Deuterium plasma facilitated the formation of blisters at the surface level. For this case, the mean ejected material volume was ~3.3 × 104 µm3. For both plasma types, tungsten dust within nano- and micrometer sizes could be collected. The current study offers a perspective of lab-scaled plasma systems, which are capable of producing tungsten fusion-like surfaces and dust.

1. Introduction

Nowadays, tungsten (W) represents an important material used in the inner walls of dedicated fusion facilities [1] (e.g., ITER, WEST, and DEMO). Herein, tungsten was expected to be a suitable material for the divertor area, offering more stability to thermonuclear plasma’s lifetime due to its specific properties, e.g., low sputtering yields, high melting point, low reactivity, etc. However, due to specific instabilities, the plasma will interact with the inner vacuum vessel walls, promoting the formation of various structures, e.g. dust, fuzz, etc. [2,3]. The formation of dust (and other structures) is due to plasma–wall interaction from which the material is ejected, suffering changes in its morphology due to plasma conditions. Herein, dust, along with other newly formed structures, is capable of entrapping various gasses, depending upon the specific surface area. In addition, dust formation inside fusion facilities represents an important issue because of safety regulations. Various studies are focused on fusion-related gas retention studies of W dust (e.g., tritium gas) because of their capacity to trap a high amount of tritium during plasma cycles [2,3,4,5,6,7]. In this line, various research strategies are required, at all levels, to preserve the safety and security regulations of the process. For this purpose, elementary security algorithms [8,9,10] can offer the needed protection for data security (parameters, internal simulation/investigation codes, staff access, etc.). On the other hand, experimental simulations may offer a view of various experimental conditions promoting the key parameters of safe manipulation, e.g., hydrogen retention in plasma-facing components (monoblocks) [11], tritium adsorption/desorption [12], H2, D2, and T2 solubility, diffusion, and permeation in W [13], or deuterium bubble evolution in W material [14].

Therefore, special attention is given to the monoblock surfaces exposed to plasma. Herein, the surface monoblocks were damaged at different levels depending on their spatial arrangement. Important studies are represented by the D2 transport, for example, in ITER facility-graded tungsten [15] or in QUEST wherein hydrogen is taken into account for hydrogen retention studies in W [16]. Therefore, at the divertor level (where tungsten monoblocks are placed), the plasma interaction is achieved by a high particle flux. Taking into account the nature of the used gases, for the proposed fusion reaction (deuterium and tritium), it is worth mentioning the highlighted lab-scale experiments concerning diffusivity inside bulk materials, for example, in the case of deuterium. In this line, lab-scale experiments were conducted for both hydrogen and low-energetic deuterium plasma in order to establish the mechanisms of various phenomena, such as blistering, which lead to tungsten surface damage and further promotes the formation of dust and various structures capable of entrapping tritium [17,18,19,20,21,22,23,24,25,26]. Keeping the various issues related to the fusion facilities in mind, it is mandatory to engage in lab-scale plasma experiments with fusion-relevant gases and materials in order to understand the starting point of the occurrence of dust, for example, blistering, melting, evaporation, sputtering, etc. In this line, we conducted experiments with H2 and D2 cold plasmas upon W bulk surfaces in order to comprehensively evaluate the possible changes which could be related to fusion-related results.

In the current manuscript, we studied the interaction of H2 and D2 plasma with the surface of tungsten material in the frame of lab-scale fusion-related experiments. In addition, fusion-relevant gasses (hydrogen and deuterium) and materials (tungsten) were used. Herein, we used H2 and D2 plasma to study the preliminary effects which may occur on tungsten surface bulk material during the lifetime of plasma. The characterization of the used plasma was given by previous work. The radiative transitions from the interelectrode plasma were analyzed using optical emission spectroscopy (OES). In addition, the observed tungsten emission lines were W I (330 nm), W I (361.6 nm), W I (400.8 nm), W I (407.3 nm), and W I (429.3 nm). Likewise, there were emission lines due to the impurities derived from the chamber: O, γNO (A3Σ + X2Π), OH (A2Σ + −X2Π), and γNH (A3Π − X3Σ) [27,28,29].

In this line, in our approach, the plasma was a cold, low-energetic plasma with an electron temperature much higher than the gas temperature. Herein, if one considers that the main mechanism of excitation is electron impact, the energy distribution of the electrons should have a maximum of a few eV. Additionally, taking the estimated gas temperature into account (approximately 0.05 eV), which is much smaller than the electron temperature, we can conclude that the plasma used for particle generation is cold and in a non-equilibrium state. The current studies are complementary to our previous work [28,30] wherein He and Ar plasmas were used in hollow-cathode geometry. Herein, the core of the experimental plasma system is represented by hollow-cathode geometry (and the corresponding method), which was especially used to constrain the plasma between tungsten plates. This method represents an advantage in the frame of large-scale (millimetric domain) plasma exposure studies. Collected substrates made from pure titanium were used to catch the possible ejected material at different distances (6 mm, 10 mm, 20 mm, and 40 mm). Additionally, dust dimensions could be obtained from morphological measurements taken via dedicated image-processing algorithms [31].

By using fusion-relevant gasses and materials, one can discern tungsten surface changes (blisters, dust, nano-structures) similar to the fusion facilities. Using our dedicated parameters, the collected structures offer a starting view of the material’s ejection until 40 mm. In addition, the following sections demonstrate results concerning H2 and D2 plasma–tungsten interaction phenomena from the perspective of morphology and chemical investigations.

2. Materials and Methods

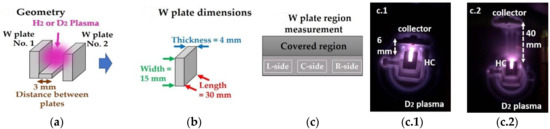

The experimental system consisted of a hollow-cathode (HC) assembly [28,30] with a dust collector attached and was placed inside a water-cooled vacuum chamber. The hollow-cathode assembly was composed of two parallel tungsten plates (with a purity of 99.97%, PLANSEE supplier) with a 3 mm distance between them (Figure 1a). Each tungsten plate had a length of 30 mm, a width of 15 mm, and a thickness of 4 mm (Figure 1b), and was polished to a mirror-like state before the experiments [28]. The dust collector (from Ti material, with a purity of 99.9%, NEYCO supplier, Paris, France) was placed above the HC assembly (see Figure 1c.1) at the following distances: 6 mm, 10 mm, 20 mm, and 40 mm. Figure 1c.1 and 1c.2 show an example of our experimental setup, with the collector placed at 6 mm and 40 mm distances from the HC assembly, respectively, in a deuterium plasma discharge. Tungsten plates were measured at 30 min and 60 min after plasma exposure. The dust was collected for 15 min for each distance. For each experiment, we used a mass flow rate of 300 sccm, hydrogen gas (with a purity of 99.8% H2, SIAD supplier, Bucharest, Romania) or deuterium (99.8% D2, SIAD supplier), and maintained an internal chamber pressure of 4 × 103 Pa, which was necessary for discerning the plasma hollow-cathode phenomenon. We used the plasma discharge with an input power of 200 W in the radiofrequency domain (13.56 MHz) for all our experiments.

Figure 1.

(a) Geometry of the hollow-cathode (HC) discharge; (b) tungsten plate dimensions; (c) W plate region measurements; (c.1) typical D2 plasma in the HC configuration, along with the substrate collector placed vertically at 6 mm above the HC; (c.2) typical D2 plasma in HC configuration, along with the substrate collector placed vertically at 40 mm above the HC.

To discern the surface changes and the removed volume of the material, W plates were analyzed with a contact profilometer before and after plasma exposures (30 min and 60 min). We used the KLA Tencor P-7 contact mode profilometer equipped with a diamond tip with a radius of 0.150 µm. W surfaces were scanned for an area of 1.5 mm × 1.5 mm, with a distance of 10 µm between profiles, an applied force of 1 mg, and a scanning rate of 100 µm/s. The measurement procedures were obtained with the KLA Tencor P-7 instrument, and the results were analyzed with the software package APEX 3D BASIC V7, Digital Surf, Besançon, France, under ISO 25178 [28].

Physical and elemental composition analysis of the tungsten plates and the collected dust was performed using a JSM-531 Inspect S SEM (Hillsboro, OR, USA) at an accelerating voltage of 20 kV. An EDX (Element 2CB) attached to an FEI Inspect S SEM operating at 20 kV was used to characterize the elemental composition of the collected dust qualitatively and quantitatively; at least three runs were compiled. The chemical composition of the collected dust was analyzed with the X-ray Photoelectron Spectrometer (XPS) K-Alpha Thermo Scientific instrument (ES-CALABTM XI+, East Grinstead, UK) containing a monochromatic AlKα X-ray source; 100 eV pass energy was used to measure the XPS spectra, along with a spot diameter of 900 µm, and Advantage software (version 5.976) was used to evaluate the results [28].

3. Results

The experiments concerning plasma–tungsten interaction showed details regarding the morphological changes that occur for the dedicated experimental parameters. In this section, the results concerning tungsten’s surface morphology and chemical investigations are presented.

3.1. Morphological Investigations of Tungsten Surfaces Exposed to H2 and D2 Plasmas

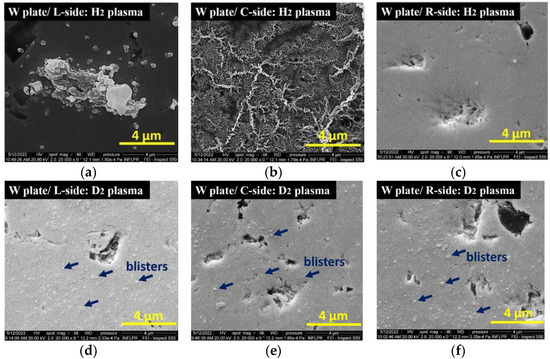

Herein, the surfaces of both gases, H2, and D2, were analyzed in three regions: left-hand side (L-side), center side (C-side), and right-hand side (R-side). Figure 2 shows the SEM images of the exposed tungsten surfaces after 60 min of exposure in H2 and D2 plasma discharges. It is worth mentioning that all SEM images were taken with a 20,000× magnification.

Figure 2.

SEM images (20,000 × magnification) of the W surface plates. The first row is dedicated to the W plates exposed to H2 plasma and changes can be observed in the (a) left-hand side (L-side); (b) center side (C-side); and (c) right-hand side (R-side). The second row is dedicated to the W plates exposed to D2 plasma and changes can be observed in the (d) left-hand side (L-side); (e) center side (C-side); and (f) right-hand side (R-side).

In the case of using H2 plasma, the tungsten surface behaved differently depending on the measured geometric place. Herein, one of the edges of the sample (Figure 2a, L-side) was detected as comprising dust-like structures placed on the surface. From their morphological arrangement, we may suggest that a part of the loose material was not transported on the collector. The newly formed W-interconnected structures, which were formed directly from the material surface, can be observed in Figure 2b, C-side. Image (c) from Figure 2 shows several dust-like structures which were present on the tungsten’s surface.

By exposing the tungsten surfaces to D2 plasma, we can discern a well-known phenomenon called blistering, as shown in the SEM images from Figure 2d–f. In short lines, during the plasma’s lifetime, deuterium ions along with deuterium molecules (the cathode is heated between 1200 and 1400 °C by applying a power of 200 W) diffuse inside the exposed bulk tungsten and remain trapped inside it at different levels. Further on, the trapped deuterium starts to migrate to the tungsten’s surface, forming blister morphologies on its surface. More details are provided in Section 4.

It is worth mentioning that the morphological changes of the tungsten plates exposed to both H2 and D2 plasma appeared gradually, meaning that after 60 min, the surfaces were more affected compared with the results after 30 min of plasma exposure. Herein, to highlight the SEM results, we analyzed the tungsten surfaces with the contact profiler to calculate the volume of removed material. Two types of phenomena occurred during the plasma–tungsten interaction: tungsten surface modification and the occurrence of dust on the collectors. Table 1 shows the results concerning contact profilometry measurements. As a protocol of the investigations, the tungsten plates were analyzed at three time points (similar to the SEM investigations): before plasma exposure (initially), after 30 min of plasma exposure, and after 60 min of plasma exposure. For each measurement, the results were obtained by implementing the algorithm-processing images of the profilometer software.

Table 1.

Profilometry measurement results. Tungsten plate surfaces were analyzed with the profiler at three independent time points, and the exposed results in this table represent the mean of those three measurement points. The obtained results are approved by ISO 25178.

In addition, the final results are presented as a mean ejected volume. Herein, for each plasma condition, the tungsten plate was measured in three zones (1.5 mm × 1.5 mm), obtaining the volume for each zone. To obtain a volume value for each plate at the dedicated plasma conditions, the mean value of the measured areas was calculated.

Tungsten plates were dedicated for each plasma exposure type, meaning for H2 plasma exposure (code HC-H2), one used the initial tungsten plate with the code W ini 1, and for D2 plasma exposure (code HC-D2), one used the initial tungsten plate with the code W ini 2.

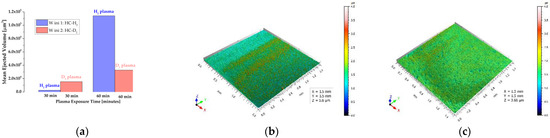

Herein, after 30 min plasma exposure, we identified a removed material of 2.6 × 103 µm3 in the case of using hydrogen compared with 1.5 × 104 µm3 in the case of deuterium plasma exposure. After 60 min, the removed material from the tungsten surfaces was around 1.1 × 105 µm3 in the case of using hydrogen, and around 3.3 × 104 µm3 when using deuterium plasma (Figure 3). Further investigations are ongoing to observe the behavior of both plasma types for a longer exposure time.

Figure 3.

Contact profilometer measurements of the W surface plates: (a) the dependence of the mean ejected material volume related to the exposure time; (b) 3D measurements on the left-hand side (L-side) after 60 min of exposure to the H2 plasma; (c) 3D measurements on the left-hand side (L-side) after 60 min of exposure to the D2 plasma. The obtained results are under ISO 25178.

3.2. Morphological Investigations of the Collected Tungsten Film-like Structure and Dust

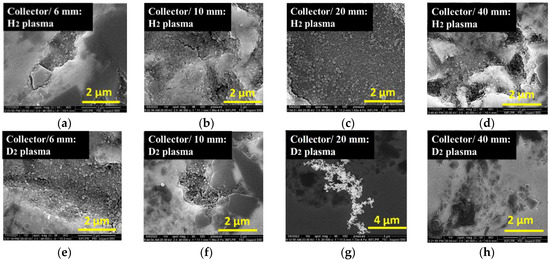

During the plasma–tungsten interaction, surface modification of the exposed tungsten plate occurred, along with dust formation. Dust was collected at different distances from tungsten plates, namely, 6 mm, 10 mm, 20 mm, and 40 mm. Figure 4 shows the SEM results concerning dust morphology on the collectors.

Figure 4.

SEM images (20,000× and 40,000× magnifications) of the W dust collectors. The first row is dedicated to W dust collected at the following distances: (a) 6 mm, (b) 10 mm, (c) 20 mm, and (d) 40 mm during H2 plasma’s existence. The second row is dedicated to W dust collected at the following distances: (e) 6 mm, (f) 10 mm, (g) 20 mm, and (h) 40 mm during D2 plasma’s existence.

The images (a), (b), (c), and (d) from Figure 4 correspond to the dust obtained at distances 6–40 mm after hydrogen plasma exposure. Herein, a double effect of the plasma can be observed, meaning the formation of a film-like structure, along with dust occurrence on the collector. This effect can be seen in images (b) and (c); herein, we can observe a discontinued film along with dust in its structure. In the case of deuterium plasma exposure, one can observe the same phenomena, meaning a film-like structure along with dust occurrence, the results of which being shown in images (e), (f), (g), and (h) in Figure 4. The size of the particles is nanometric, i.e., in terms of tens to hundreds of nanometers for the agglomerated shapes. The amount of dust is related to the nature of the used gas. The film cannot be clearly distinguished from the collector surfaces in the SEM images, so the chemistry of the collector surfaces was examined using XPS. Since the amount of dust was not high on the collector, and the measurement spot was 900 µm, it was only possible to measure tungsten signals from a film-like structure. It is worth mentioning that our collectors were pure titanium; any tungsten detected can be attributed, without a doubt, to the film-like structure formed from the ejected tungsten material.

3.3. Chemical and Compositional Investigations of the Collected Tungsten Dust

The tungsten film-like structures and dust obtained from the ejected tungsten material due to plasma exposure were chemically investigated. Herein, due to the possibility of the occurrence of a thin tungsten layer, XPS investigation analysis was chosen. The signal was acquired only for the surface of the layer, after a pre-sputtering process, to clean the possible contamination due to ambient atmosphere exposure. Table 2 shows the atomic contributions of the materials collected at different distances from the cathode W plates for both plasma discharges in H2 and D2 gas.

Table 2.

XPS measurement results. The collected materials at the following nozzle-to-collector distances were chemically investigated: 6 mm, 10 mm, 20 mm, and 40 mm.

The results shown in Table 2 emphasize the fact that by using hydrogen, or deuterium plasma, the chemical signal of tungsten decreased with the increasing distance from the cathode. In addition, at small distances, e.g., 6 mm, the atomic contribution of W4f was between 44 and 48%, decreasing at 40 mm around 29–30%. After all, by increasing the distance and stably maintaining all other processes parameters, the ejected material was not able to reach the collector and remained inside the experimental system chamber.

Compared to our previous work [28], the XPS results showed the same tendency, meaning that by using H2, D2, He, or Ar plasma, in hollow-cathode geometry, we obtained the maximum tungsten material on the collectors at a distance between 6 and 10 mm [28]. The oxidation of the samples occurred at a small percentage during their fabrication (we used a process pressure of 4 × 103 Pa), and at a higher percentage because of ambient atmosphere interaction. A small amount of carbon and nitrogen was observed and associated with exposure to the ambient atmosphere. For this reason, a pre-sputtering process was necessary.

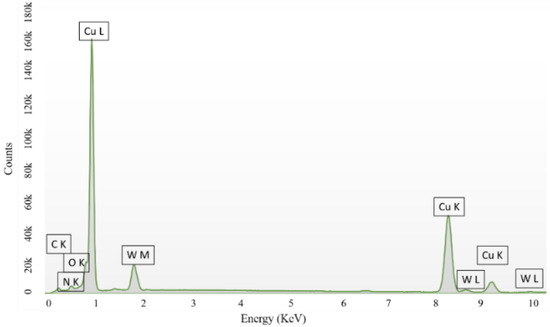

EDS measurements were performed to highlight the presence of tungsten in the collected material. For this analysis, we used a copper substrate to collect the material. Figure 5 depicts the EDS spectrum of the deposited material. The elemental compositions of the deposit unveiled tungsten as the main chemical element originating from the W plates. The peaks of Cu from the EDS spectrum (Figure 5) are characteristics of the substrate used for deposition and those of C, O, and N were a result of exposure to ambient air.

Figure 5.

EDS spectrum of the W collected at 10 nm during D2 plasma exposure.

Table 3 highlights the weight% of the materials collected at different distances from the cathode W plates, for both plasma discharges, in H2 and D2 gas.

Table 3.

Element average weight percent of the collected materials at the following nozzle-to-collector distances: 6 mm, 10 mm, 20 mm, and 40 mm.

4. Discussion

Plasma–tungsten interaction studies reveal important behaviors of the exposed surfaces in terms of surface morphological changes. In addition, both hydrogen and deuterium plasmas were conducive to phenomena such as blisters, interconnected tungsten structures, dust occurrence, and film-like structures.

4.1. Tungsten Surfaces Exposed to H2 and D2 Plasma

In the present study, tungsten surface behavior represented “the core” highlighting the possible damages during hydrogen and deuterium plasma exposures, producing a lab-scale model of possible phenomena related to the divertor area in future fusion facilities. Herein, exposure to H2 plasma in time steps (30 min and 60 min) could draw the starting phenomena in terms of tungsten surface damage. Based on Figure 2, we can see that the surface morphologies were concentrated in three areas, namely, the center of the plate and the margins (left-hand side and right-hand side).

In the case of using H2 plasma exposure, a major change in morphology was observed in the center of the tungsten plate (Figure 2b). This is an important aspect because, in the SEM measurements related to 30 min. plasma exposures, we could not find any major structures formed on the tungsten’s surface. From our previous studies, in argon and helium plasma [28], we observed an inhomogeneity of the plasma discharge in terms of roughness measurements, meaning that, in the central part, the surface was more damaged than in the margins. In addition, the existence of the solidified dust structures (Figure 2a) implies the existence of an inhomogeneous plasma temperature, which will be demonstrated in future experiments. Further on, in the current studies, the formation of interconnected tungsten structures (Figure 2b) could appear in the following constraints. Hydrogen gas is well-known as a high-diffusivity gas [32,33], meaning that it can easily enter the bulk matrix, forming bubbles of the trapped hydrogen in the material’s vacancies. Since cold plasma is used in the experiments, we deal with two types of hydrogen: that ionized from the plasma and that unionized from the gas. Ionized hydrogen, having higher energy, will travel inside the tungsten bulk matrix much more than the unionized hydrogen from the inlet gas. In our case, the diffusivity was enhanced by the higher cathode temperature (which can reach 1200–1400 °C [28]). The more hydrogen that was trapped inside bulk tungsten, the more the bubble formation increased, producing plastic deformations inside it. Herein, the hydrogen bubbles migrated toward the tungsten plate’s surface. Assuming that this phenomenon of hydrogen bubble migration toward the surface occurs simultaneously as more hydrogen is injected from the plasma with a higher energy level, the continuous injection of hydrogen ions will cause deformation of the surface material, as well as an enhancement of it. These phenomena, of interconnected tungsten structure formation, are thermally enhanced by the plasma and cathode temperature. Image (c) from Figure 2 shows several dust-like structures, again indicating an inhomogeneous behavior of the used plasma.

In the case of using D2 plasma, the SEM results showed an interesting result, i.e., the appearance of blistering phenomena, which are specific to deuterium plasma behavior [21,22,23,24]. Compared with the results obtained in the hydrogen plasma exposure case, and also in argon and helium plasma cases from our previous work [28], here, the deuterium plasma seemed to be stable at the margin zones of the tungsten plate, and not in the central part. The plate exposed to deuterium plasma was morphologically investigated before and after plasma treatment (for 30 min and 60 min). Figure 2d–f show the occurrence of blisters more predominant in the margin zones. Deuterium, like hydrogen, can diffuse inside the bulk matrix [34,35,36], but less compared with hydrogen [13]. In addition, being in the same experimental conditions as in the case of hydrogen plasma, the deuterium diffused inside the tungsten plate, remaining trapped inside it, but not far away from the plate surface (because of low diffusivity compared with hydrogen). Herein, deuterium bubbles started to migrate toward the lower tungsten surface. Assuming the deuterium trapping occurs near the plate surface, the possibility of major plastic deformation from the deuterium bubble merging inside the bulk matrix is low compared with the hydrogen case. Further on, the small deuterium bubbles migrate toward the surface, forming small blisters on top of the surface material. Thus, a different plasma type can produce a higher blistering degree on the surface.

4.2. Tungsten Film-like Structure and Dust Collected at Different Distances

As abovementioned, during plasma–tungsten surface interactions, along with the formation of new structures, the material is ejected from the surface and collected. In our current studies, the ejected material was collected on pure titanium substrates. This choice was based on the high melting point of titanium, which is cheaper compared with other pure metals with a high melting point, and, more importantly, in the case of chemical investigations, titanium will not overlap the signal of tungsten. As in our previous work [28] we used the same conditions for the material collecting range distances, namely, 6 mm, 10 mm, 20 mm, and 40 mm. Thus, it is worth mentioning that one cannot collect all the ejected material because the titanium substrate collector has a smaller diameter of 20 mm compared with the length of the cathode tungsten plates, which are 30 mm. Adding the fact that the substrates are placed at different distances from the cathode, an important part of the ejected material was not collected. In this line, the collected material represents the results that came from the central part and slightly from the margin zones of the cathode tungsten plates.

Generally, the dust collected in this line consists of nanometer-sized particles with low particle density. Furthermore, in SEM images, dust is presented as a dust-like film, as one can observe inside the craters in Figure 4b–f. The craters are made from a tungsten film layer from the ejected material. Employing chemical investigations of the film surface in the next section, we checked if a tungsten layer was formed on the substrates. The collected material offers precise clues concerning plasma–tungsten interactions followed by material ejection. In addition, the formation of a film layer along with nanometric dust opens new hazardous issues concerning future fusion-like facilities. Herein, the formation of a film layer could be conducive to exfoliation and flake formations, which may contaminate the plasma’s core and incorporate tritium inside it. The formation of nanometric dust represents a challenging issue because it has a greater surface area and is more capable of trapping tritium than micrometer dust. Nevertheless, nanometric dust is a challenge to remove from the fusion facility’s inner vessel, leading to dangerous situations in case of inhalations by the operators [37].

4.3. Chemical and Compositional Analyses of Tungsten Surfaces, Film-like Structures, and Dust

In the chemistry (XPS) of the collected materials, the oxidation of dust occurs during the dust’s time of flight to the collector. Detailed results concerning the XPS investigations are presented in Table 2. EDS investigations are required in these types of studies as a first confirmation of the collected tungsten material. Based on the elemental compositions of the samples recorded by EDS, it also became apparent that while all samples contained tungsten, carbon, oxygen, and nitrogen as a result of exposure to ambient air, there were recorded decreases in W and slight increases in O with the increasing nozzle–collector distance, suggesting slight oxidation of the collected materials (Table 3). Usually, carbon and nitrogen exist in small quantities, being necessary for the pre-sputtering cleaning process before conducting the XPS analyses. In addition, the signal is collected from the collector surfaces, after a pre-sputtering process, to clean the carbon and nitrogen. As can be observed from the results in Table 2, there were no significant changes in terms of new chemical bond formation. Compared to the collected dust from argon and helium plasma experiments [28], the chemistry behavior was similar; the tungsten’s W4f atomic concentration decreased with the increase of the distance. The collected materials at distances between 20 and 40 mm were more oxidized compared with the collected materials between 6 and 20 mm. As a main remark, by using hollow-cathode geometry, hydrogen, deuterium, helium, and argon plasmas will eject tungsten material with same chemical behavior in the distance range of 6–40 mm from the cathode.

5. Conclusions

In summary, we emphasized a method using low-energy H2 and D2 plasma in hollow-cathode geometry for plasma–tungsten surface material interaction studies. Fusion-relevant gases (hydrogen and deuterium) and materials (tungsten) were used. For the established experimental parameters, we tracked the changes from the W surface after plasma interaction for different time exposures. Herein, in the case of hydrogen plasma exposure, the tungsten surface emphasized the occurrence of dust and new W-interconnected structures. For deuterium plasma exposure, the main result was the occurrence of brittles, similar to the dedicated literature. Further on, for each plasma type, the ejected tungsten material was collected on titanium substrate collectors at different distances: 6 mm, 10 mm, 20 mm, and 40 mm. For both plasma types, hydrogen, and deuterium, this study succeeded in obtain nano- and micro-metric dust with various morphologies and thin films. The chemical investigations of the collected materials showed the occurrence of the oxidized tungsten material. In this line, we demonstrated the synthesis possibility of fusion-relevant tungsten surfaces and ejected materials.

Author Contributions

Conceptualization, V.M., C.S.; methodology, V.M. and C.S.; validation, V.M., and C.S.; formal analysis, V.M., C.S.; investigation, V.M., A.B.; data curation, V.M., A.B.; writing—original draft preparation, V.M.; writing—review and editing, V.M., C.S., T.A., C.C. and G.D. All authors have read and agreed to the published version of the manuscript.

Funding

This work has been carried out within the framework of the EURO fusion Consortium, funded by the European Union via the Euratom Research and Training Programme (Grant Agreement No. 101052200—EURO fusion). Views and opinions expressed are however those of the authors only and do not necessarily reflect those of the European Union or the European Commission. Neither the European Union nor the European Commission can be held responsible for them. Part of this research was supported (or financed) by Romanian Ministry of Research, Innovation 409 and Digitalization under Romanian National Core Program LAPLAS VII–contract no. 30N/2023.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Acknowledgments

We gratefully acknowledge the effort of Dr. Veronica Satulu (National Institute for Laser, Plasma and Radiation Physics, 409 Atomistilor Street, RO-077125, Magurele, Romania, https://www.researchgate.net/profile/Veronica-Satulu), for the XPS measurements.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bigot, B. ITER assembly phase: Progress toward first plasma. Fusion Eng. Des. 2021, 164, 112207. [Google Scholar] [CrossRef]

- Rubel, M.; Widdowson, A.; Grzonka, J.; Fortuna-Zalesna, E.; Moon, S.; Petersson, P.; Ashikawa, N.; Asakura, N.; Hamaguchi, D.; Hatano, Y.; et al. Dust generation in tokamaks: Overview of beryllium and tungsten dust characterization in JET with the ITER-like wall. Fusion Eng. Des. 2018, 136, 579–586. [Google Scholar] [CrossRef]

- Grisolia, C.; Rosanvallon, S.; Sharpe, P.; Winter, J. Micro-particles in ITER: A comprehensive review. J. Nucl. Mater. 2009, 386–388, 871–873. [Google Scholar] [CrossRef]

- El-Kharbachi, A.; Chêne, J.; Garcia-Argote, S.; Marchetti, L.; Martin, F.; Miserque, F.; Vrel, D.; Redolfi, M.; Malard, V.; Grisolia, C.; et al. Tritium absorption/desorption in ITER-like tungsten particles. Int. J. Hydrogen Energy 2014, 39, 10525–10536. [Google Scholar] [CrossRef]

- Grisolia, C.; Hodille, E.; Chene, J.; Garcia-Argote, S.; Pieters, G.; El-Kharbachi, A.; Marchetti, L.; Martin, F.; Miserque, F.; Vrel, D.; et al. Tritium absorption and desorption in ITER relevant materials: Comparative study of tungsten dust and massive samples. J. Nucl. Mater. 2015, 463, 885–888. [Google Scholar] [CrossRef]

- Bernard, E.; Sakamoto, R.; Hodille, E.; Kreter, A.; Autissier, E.; Barthe, M.-F.; Desgardin, P.; Schwarz-Selinger, T.; Burwitz, V.; Feuillastre, S.; et al. Tritium retention in W plasma-facing materials: Impact of the material structure and helium irradiation. Nucl. Mater. Energy 2019, 19, 403–410. [Google Scholar] [CrossRef]

- Peillon, S.; Dougniaux, G.; Payet, M.; Bernard, E.; Pieters, G.; Feuillastre, S.; Garcia-Argote, S.; Gensdarmes, F.; Arnas, C.; Miserque, F.; et al. Dust sampling in WEST and tritium retention in tokamak-relevant tungsten particles. Nucl. Mater. Energy 2020, 24, 100781. [Google Scholar] [CrossRef]

- Mihailescu, M.I.; Nita, S.L. A Searchable Encryption Scheme with Biometric Authentication and Authorization for Cloud Environments. Cryptography 2022, 6, 8. [Google Scholar] [CrossRef]

- Nita, S.L.; Mihailescu, M.I.; Pau, V.C. Security and Cryptographic Challenges for Authentication Based on Biometrics Data. Cryptography 2018, 2, 39. [Google Scholar] [CrossRef]

- Nita, S.L.; Mihailescu, M.I. A Searchable Encryption Scheme Based on Elliptic Curves. In Web, Artificial Intelligence and Network Applications, WAINA 2020; Barolli, L., Amato, F., Moscato, F., Enokido, T., Takizawa, M., Eds.; Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2020; Volume 1150. [Google Scholar] [CrossRef]

- Delaporte-Mathurin, R.; Hodille, E.; Mougenot, J.; Charles, Y.; Grisolia, C. Finite element analysis of hydrogen retention in ITER plasma facing components using FESTIM. Nucl. Mater. Energy 2019, 21, 100709. [Google Scholar] [CrossRef]

- Hodille, E.A.; Payet, M.; Marascu, V.; Peillon, S.; Mougenot, J.; Ferro, Y.; Delaporte-Mathurin, R.; Leblond, F.; Bernard, E.; Grisolia, C. Modelling tritium adsorption and desorption from tungsten dust with a surface kinetic model. Nucl. Fusion 2021, 61, 086030. [Google Scholar] [CrossRef]

- Boda, A.; Sk, M.A.; Shenoy, K.; Mohan, S. Diffusion, permeation and solubility of hydrogen, deuterium and tritium in crystalline tungsten: First principles DFT simulations. Int. J. Hydrogen Energy 2020, 45, 29095–29109. [Google Scholar] [CrossRef]

- Xiang, Y.; Zhang, B.; Shi, L. Evolution of bubble in tungsten irradiated by deuterium of low energy and high flux by molecular dynamics simulations. Appl. Surf. Sci. 2022, 606, 154715. [Google Scholar] [CrossRef]

- Byeon, W.; Noh, S. Deuterium transport in ITER-grade tungsten. J. Nucl. Mater. 2021, 544, 152675. [Google Scholar] [CrossRef]

- Koike, A.; Nakata, M.; Yamazaki, S.; Wada, T.; Sun, F.; Zhao, M.; Yoshida, N.; Hanada, K.; Oya, Y. Evaluation of hydrogen retention behavior in tungsten exposed to hydrogen plasma in QUEST. Nucl. Mater. Energy 2021, 26, 100856. [Google Scholar] [CrossRef]

- Sizyuk, T.; Abrams, T. Dynamics of deuterium retention and desorption from plasma-facing materials in fusion reactor-relevant conditions. J. Nucl. Mater. 2022, 572, 154095. [Google Scholar] [CrossRef]

- Chen, W.; Wang, X.; Chiu, Y.; Morgan, T.; Guo, W.; Li, K.; Yuan, Y.; Xu, B.; Liu, W. Growth mechanism of subsurface hydrogen cavities in tungsten exposed to low-energy high-flux hydrogen plasma. Acta Mater. 2020, 193, 19–27. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, S.; Li, C.; Guo, W.; Yuan, Y.; Zhang, H.; Wang, P.; Cheng, L.; Lu, G.-H. Dependence of deuterium retention and surface blistering on deuterium plasma exposure temperature and fluence in lanthanum oxide doped tungsten. Nucl. Mater. Energy 2022, 32, 101217. [Google Scholar] [CrossRef]

- Shi, Y.; Jiang, Z.; Xia, T.; Wang, Z.; Wu, J.; Cao, X.; Zhu, K. Deuterium retention and desorption behavior of W-Ta-Cr-V high entropy alloy. J. Nucl. Mater. 2022, 568, 153897. [Google Scholar] [CrossRef]

- Zhang, X.; Qiao, L.; Zhang, H.; Yao, W.; He, W.; Li, Y.; Wang, P. Surface modification and deuterium retention of tungsten and tungsten-rhenium alloys exposed to deuterium plasma. Nucl. Mater. Energy 2021, 29, 101079. [Google Scholar] [CrossRef]

- Han, W.; Zhu, K.; Yan, J.; Xia, T.; Wang, Z.; Ye, X.; Chen, C.A.; Wu, J.; Ma, Y. Blistering and deuterium retention in Nb-doped W exposed to low-energy deuterium plasma. Nucl. Mater. Energy 2020, 23, 100741. [Google Scholar] [CrossRef]

- Zhu, X.-L.; Zhang, Y.; Kreter, A.; Shi, L.-Q.; Yuan, Y.; Cheng, L.; Linsmeier, C.; Lu, G.-H. Aggravated blistering and increased deuterium retention in iron-damaged tungsten after exposure to deuterium plasma with various surface temperatures. Nucl. Fusion 2018, 58, 106005. [Google Scholar] [CrossRef]

- Shu, W.; Nakamichi, M.; Alimov, V.; Luo, G.-N.; Isobe, K.; Yamanishi, T. Deuterium retention, blistering and local melting at tungsten exposed to high-fluence deuterium plasma. J. Nucl. Mater. 2009, 390–391, 1017–1021. [Google Scholar] [CrossRef]

- Choi, D.-S.; Uebing, C.; Gomer, R. Diffusion of hydrogen and deuterium on stepped tungsten surfaces I. W(123). Surf. Sci. 1991, 259, 139–150. [Google Scholar] [CrossRef]

- Uebing, C.; Gomer, R. Diffusion of hydrogen and deuterium on stepped tungsten surfaces II. W(O23). Surf. Sci. 1991, 259, 151–161. [Google Scholar] [CrossRef]

- Teodorescu, M.; Bazavan, M.; Ionita, E.R.; Dinescu, G. Characterization of an argon radiofrequency plasma jet discharge continuously passing from low to atmospheric pressure. Plasma Sources Sci. Technol. 2012, 21, 055010. [Google Scholar] [CrossRef]

- Marascu, V.; Stancu, C.; Satulu, V.; Bonciu, A.; Grisolia, C.; Dinescu, G. Material Erosion and Dust Formation during Tungsten Exposure to Hollow-Cathode and Microjet Discharges. Appl. Sci. 2020, 10, 6870. [Google Scholar] [CrossRef]

- Marascu, V.; Lazea–Stoyanova, A.; Bonciu, A.; Satulu, V.; Dinescu, G. Tungsten particles fabrication by a microjet discharge. Mater. Res. Express 2020, 7, 066509. [Google Scholar] [CrossRef]

- Stancu, C.; Stokker-Cheregi, F.; Moldovan, A.; Dinescu, M.; Grisolia, C.; Dinescu, G. Modification of W surfaces by exposure to hollow cathode plasmas. Appl. Phys. A 2017, 123, 618. [Google Scholar] [CrossRef]

- Mărăscu, V.; Chiţescu, I.; Barna, V.; Ioniţă, M.D.; Lazea-Stoyanova, A.; Mitu, B.; Dinescu, G. Application of image recognition algorithms for the statistical description of nano- and microstructured surfaces. AIP Conf. Proc. 2016, 1722, 290006. [Google Scholar] [CrossRef]

- Wang, M.; Yang, F.; Chen, Y.; Gao, T.; Wei, J.; Ye, Z.; Gou, F. Hydrogen diffusion on the tin-covered tungsten surface: A first-principles study. J. Nucl. Mater. 2023, 577, 154282. [Google Scholar] [CrossRef]

- Tondro, A.; Taherijam, M.; Abdolvand, H. Diffusion and redistribution of hydrogen atoms in the vicinity of localized deformation zones. Mech. Mater. 2023, 177, 104544. [Google Scholar] [CrossRef]

- Wang, T.; Ren, M.; Zhu, X.-L.; Ma, X.; Yuan, Y.; Cheng, L.; Lu, G.-H. Effect of initial exposure temperature on the deuterium retention and surface blistering in tungsten. Nucl. Mater. Energy 2022, 33, 101245. [Google Scholar] [CrossRef]

- Zhu, X.-L.; Ke, Z.-H.; Cheng, L.; Yuan, Y.; Zhang, Y.; Wang, Z.; Lu, G.-H. The effect of pre-damage distribution on deuterium-induced blistering and retention in Tungsten. Fusion Eng. Des. 2023, 189, 113494. [Google Scholar] [CrossRef]

- Zhu, X.-L.; Cheng, L.; De Temmerman, G.; Shi, L.-Q.; Yuan, Y.; Wang, B.-Y.; Cao, X.-Z.; Lu, E.-Y.; Zhang, Y.; Lu, G.-H. Effects of stress-relief pre-annealing on deuterium trapping and diffusion in tungsten. Fusion Eng. Des. 2017, 125, 526–530. [Google Scholar] [CrossRef]

- George, I.; Uboldi, C.; Bernard, E.; Sobrido, M.S.; Dine, S.; Hagège, A.; Vrel, D.; Herlin, N.; Rose, J.; Orsière, T.; et al. Toxicological Assessment of ITER-Like Tungsten Nanoparticles Using an In Vitro 3D Human Airway Epithelium Model. Nanomaterials 2019, 9, 1374. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).