Abstract

The snow falling on the surface of photovoltaic modules tends to reduce the output power. In order to understand the process of snow accumulating on solar photovoltaic modules and reveal the impact of snow accumulation on photovoltaic conversion efficiency, the snow-cover process was simulated on the surface of photovoltaic modules with different tilt angles by computational fluid dynamics (CFD). On this basis, the relationship between the amount of snow and tilt angle was explored. The snow effect of photovoltaic modules on photoelectric conversion efficiency was studied by building a test platform. At the same time, a measurement platform of snow accumulation on photovoltaic modules and photoelectric conversion efficiency was constructed. Through the experiment of the relationship between snow thickness and snow sliding distance and the power generation efficiency of photovoltaic (PV) modules, the influence of snow thickness and snow area on the power generation efficiency of PV modules is discussed. The results show that the larger angle between the photovoltaic panel and the ground is adverse to the accumulation of snow on the panel. When the thickness of snow reaches 1 cm, the power generation efficiency of the entire photovoltaic module reduces to 7.1% of that as normal. At the same time, the sliding of snow on the photovoltaic panel improves the efficiency of photoelectric conversion. Through the analysis of numerical simulation and experimental results, targeted suggestions are made on how to improve the efficiency of power generation for photovoltaic power stations under snowy conditions, which may provide a reference for engineering work.

1. Introduction

At present, many countries around the world are actively promoting the development of renewable energy. As a major source of clean energy in the future, photovoltaic systems offer considerable policy support, showing a promising prospect [1,2,3,4,5,6]. However, the shielding of snow on photovoltaic modules could cause the failure of photovoltaic panels, which has a major impact on photovoltaic power generation. It not only reduces photovoltaic output but also hampers the prompt resumption of normal operation, which puts the stability of the power grid at risk. In cold, snowy areas, when photovoltaic panels are covered with snow, it can result in a complete power outage, and the total photovoltaic power generation can be reduced by one-third throughout the winter [7,8]. In winter months, the decline of power generation efficiency means that the grid-connected photovoltaic power stations face difficulty maintaining their power output as normal, which easily causes light abandonment and is detrimental to the long-term development of the whole photovoltaic industry [9,10,11].

According to Bill and Loren et al., it is not uncommon for snow to remain on photovoltaic panels for days or even weeks [11,12]. As demonstrated by Brench et al., photovoltaic system generation was reduced by 4% to 56% due to snow cover on the day after snowfall, even in relatively mild weather [13]. Heidari et al. explored the impact of snow cover on photovoltaic power generation, revealing that the energy loss caused by snowfall was largely affected by the tilt angle and the severity of ground interference. According to the study, the annual energy loss can be effectively reduced from 34% to 5% by increasing the tilt angle of the barrier-free system from 0° to 45° [14]. By simulating the effect of snow on the performance of photovoltaic systems, Loren et al. found out that for the fixed inclination arrays installed at inclination angles ranging from 39° to 0° (flat), the annual loss in typical years was expected to reach 12%–18%. Moreover, monthly losses are much more severe, and when the snow is several feet thick, the PV panel output is lost for a month due to the small tilt angle of the PV panel [12]. In order to prevent the impact of snow on the output power of photovoltaic panels, Wang et al. studied the snow-removing coating on the surface of photovoltaic modules. The results show that the presence of surface coating can mitigate the impact of snow on photovoltaic panels by reducing adhesion and friction or by partially absorbing solar irradiance to decompose snow [15,16]. Rahmatmand and Yan et al. put forward the method of removing snow by electric heating for photovoltaic panels, and the results show that this is a beneficial and practical method for removing snow for photovoltaic panels, when the thickness of the snow is greater than the equivalent height and the inclination angle of the photovoltaic panel is greater than the minimum inclination angle [17,18]. Anadol introduced a method of snow melt on the surface of photovoltaic modules heated by polyvinyl butyral interlayer transparent resistance wire. Based on economic viability analysis results, it was concluded that the surface-heating method is cost-effective when it is compared to the mechanical stripping method, as it only uses electricity that is already available [19]. Amer et al. developed an electric curtain to cover the surface of photovoltaic modules at night and during sandstorms. The system successfully reduced the effects of condensation and dirt accumulation that may affect the performance of photovoltaic panels and reduce their efficiency. This study also studied the use of super-hydrophobic and super-hydrophilic coatings on the surface of photovoltaic modules to reduce the impact of pollution through experiments. These two recommendations can significantly reduce the frequency of cleaning photovoltaic panels, thereby reducing water use, especially in areas with limited water supply [20].

However, most studies have used experiments to study the impact of snow cover on photovoltaic power generation, and there are few studies on the simulation of the snow-cover process through computational fluid dynamics (CFD). Based on numerical simulation, this paper studies the influence of snow cover on the surface of a series of solar photovoltaic modules with different tilt angles analyzes the snow-cover process on the surface of solar photovoltaic modules and discusses the relationship between the snow cover and the tilt angle of photovoltaic modules. On this basis, the impact of snow cover on photovoltaic modules on the efficiency of photoelectric conversion was studied through experimentation. At the same time, the test platform of photovoltaic snow and photovoltaic conversion efficiency was constructed. Through the experiment of the relationship between snow thickness and snow sliding distance and the power generation efficiency of PV modules, the influence of snow thickness and snow area on the power generation efficiency of PV modules is discussed.

2. Numerical Simulation and Result Analysis

In order to study the change of the flow field, it is necessary to consider the impact of various variables such as pressure and the density of flow, establish a theoretical model of the flow field, and solve the partial differential equations in the model through the numerical iteration assisted by a computer [21]. To describe the flow field, there are three basic laws involved: the law of conservation of momentum, the law of conservation of mass, and the law of conservation of energy. Expressed as some basic mathematical equations, these physical laws are also the governing equations of the flow field.

The following is the momentum conservation equation:

where represents the mass force on the fluid, in N; indicates the fluid density, in kg/m3; denotes the static pressure, in Pa; refers to the kinematic viscosity of the fluid, in m2/s; and stands for the velocity of the fluid, in m/s.

The following is the mass conservation equation:

where represents time, in s, and , and refer to the components of the velocity vector in the , and directions, respectively.

The energy conservation equation is expressed as

where represents the specific heat capacity at constant pressure, in J/(kg.K); indicates the heat transfer coefficient of the fluid, in W/m2.K; denotes the thermodynamic temperature, in K; and refers to the viscous dissipation term.

According to the heat balance equation, the liquid-dust particles in the snow accumulation process of PV modules meet the following equation:

where d/dt is the total time derivative, K is the kinetic energy of the substance in the control volume, Ne is the power of external forces, and Q is the energy supply from external sources per unit time.

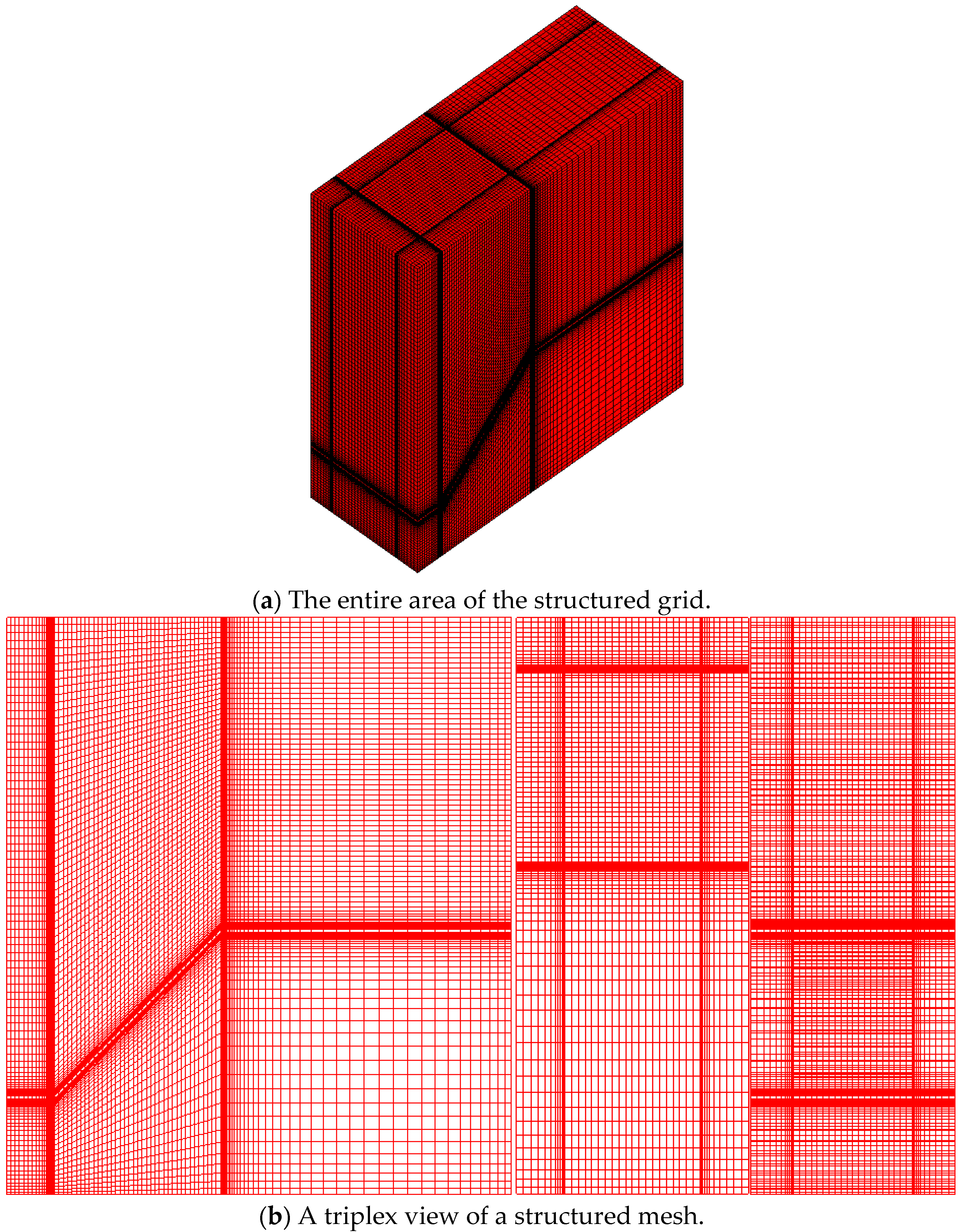

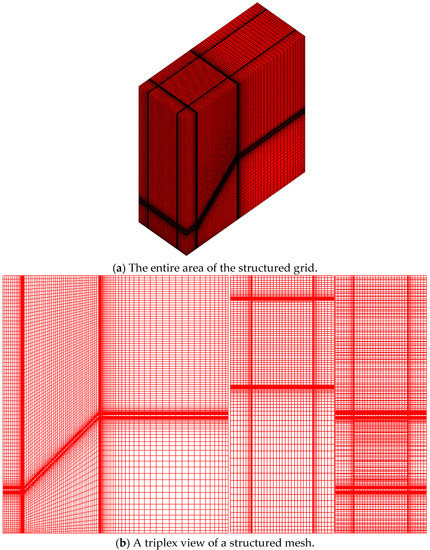

In the computational domain, a structured grid developed by ANSYS ICEM 21.0 is adopted, as shown in Figure 1. Only the whole area of the computing grid is shown in the 3D model in Figure 1a, and the three views of the computing grid are presented in Figure 1b. The number of grids is 640,866, that of the quadrilateral is 48,620, and that of the hexagon is 617,100. The mesh growth factor is 1.2, the mesh quality is 0.91, and the mesh angle quality is 56.30. The finite volume method is applied to solve the conservation equation of the wind field, while the SIMPLE algorithm is adopted to decouple the pressure field from the velocity field. The convection and diffusion terms are discretized by the second-order upwind scheme and the second-order central difference scheme, respectively. Moreover, the Runge–Kutta method is used to solve the equation of motion of dust particles.

Figure 1.

Structured grid of high-speed airflow on the photovoltaic surface.

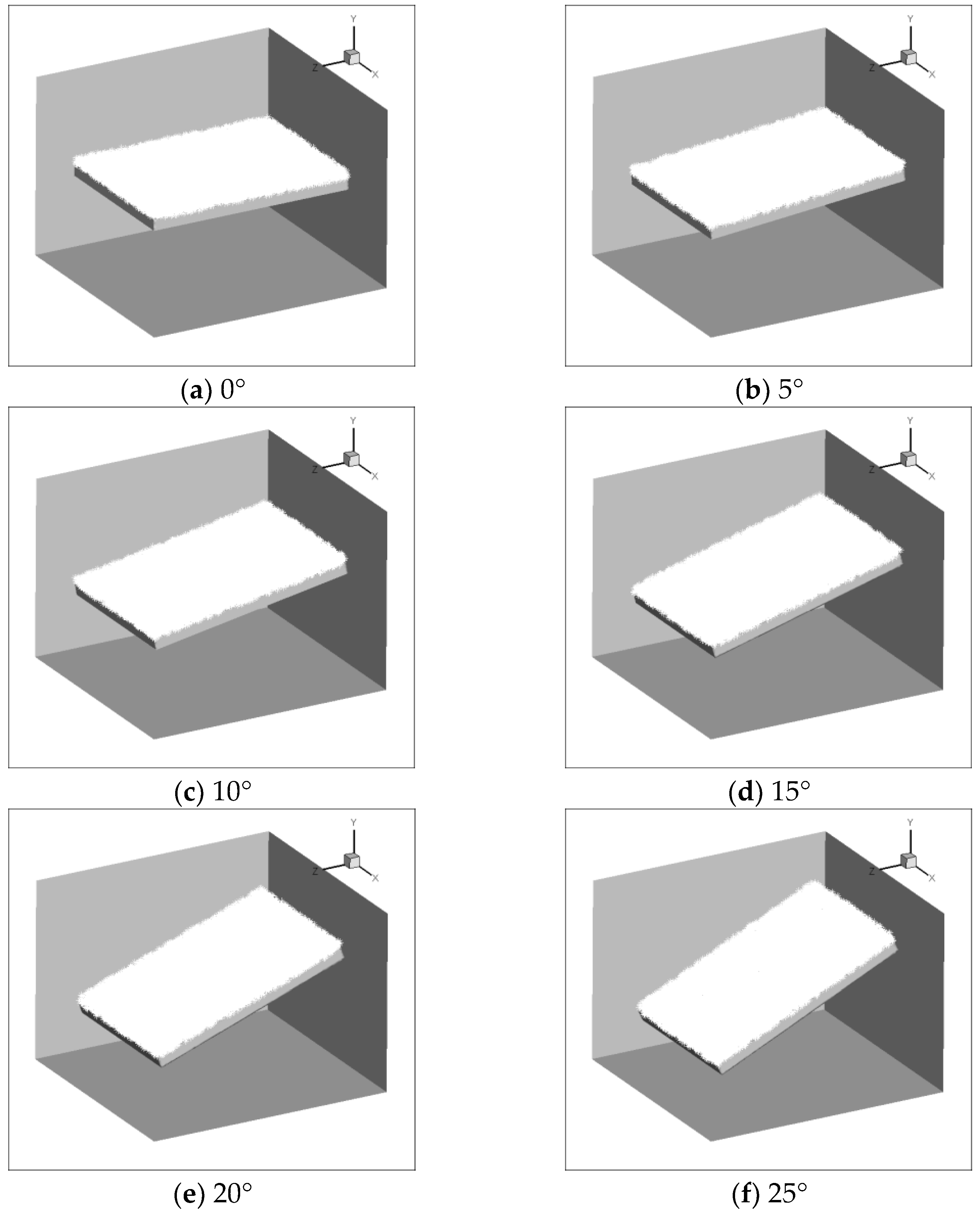

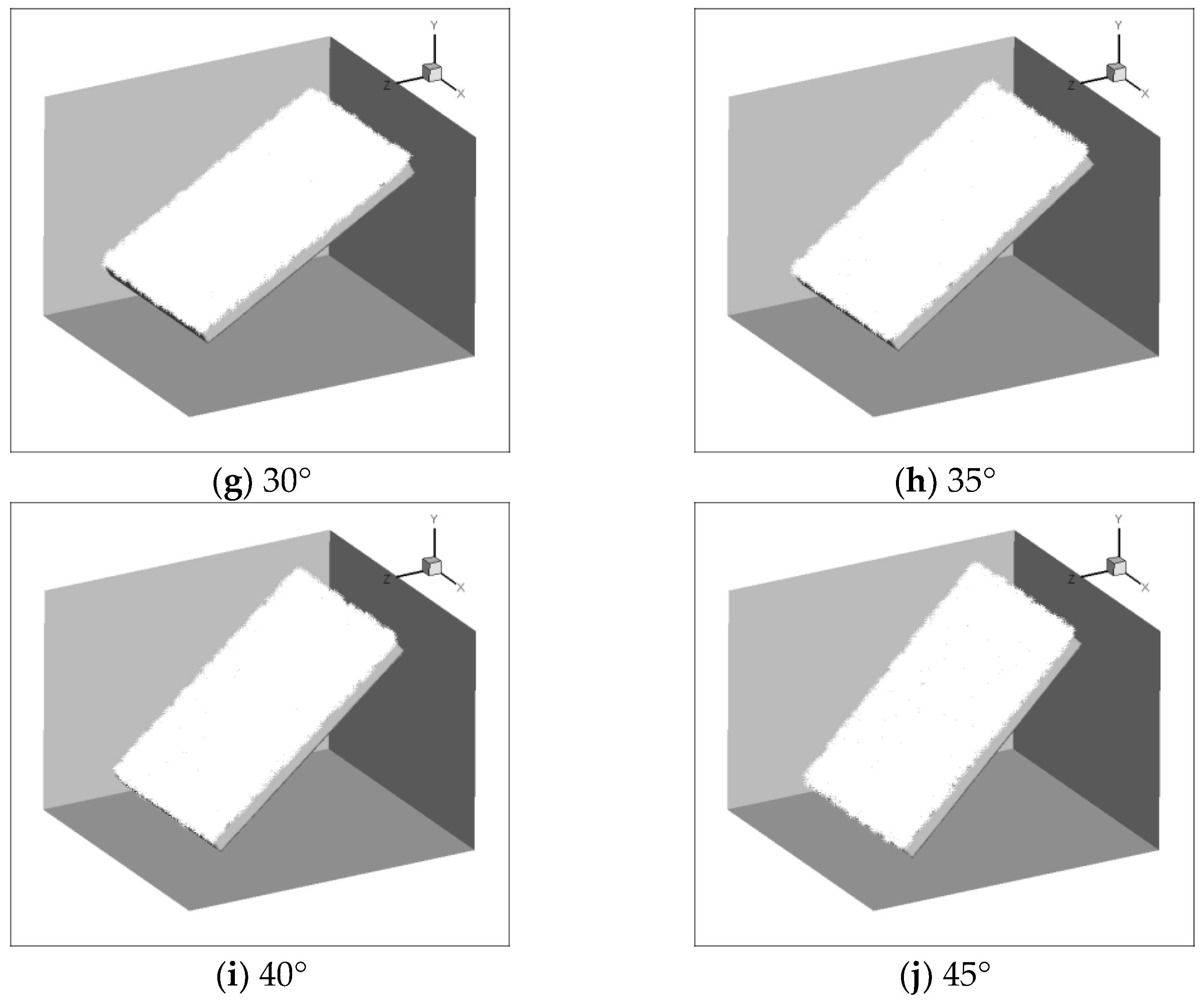

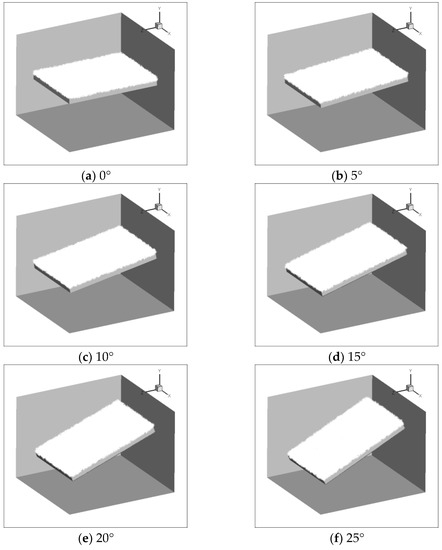

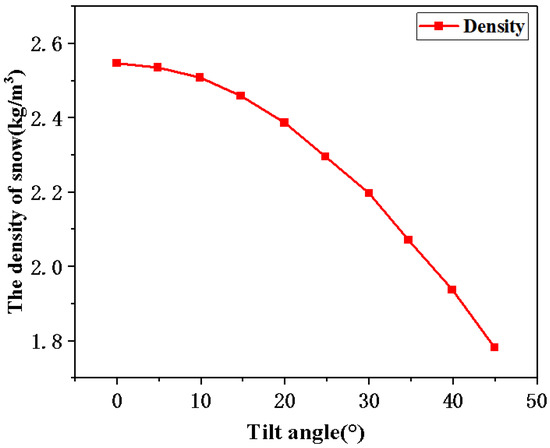

Figure 2 shows the effect of snow at different tilt angles, and Figure 3 shows the relationship between the amount of snow on the surface of a PV module and the tilt angle. According to the number of particles deposited on the photovoltaic module with different tilt angles, the load applied to the photovoltaic module under snowy conditions can be calculated. With each snowflake assigned a weight of 0.1 g, the load change curve of the photovoltaic module in 10 sets of simulated data can be calculated. As suggested by the calculation results, a larger tilt angle of the photovoltaic module leads to a smaller number of snow particles deposited on the photovoltaic panel. The result shows the load applied to the photovoltaic module decreases; this is because the larger the tilt angle, the greater the gravity component of the downward motion of the snow particles. In practice, an increase in the tilt angle is adverse to snow accumulation but conducive to snow removal. The large tilt angle makes it easier for snow to slide quickly on the photovoltaic module. Therefore, in those areas prone to heavy snowfall, the tilt angle can be increased to reduce snow accumulation, which facilitates snow removal.

Figure 2.

Snow-cover renderings of photovoltaic modules with different tilt angles.

Figure 3.

Relationship between the density of snow on PV module surface and tilt angle.

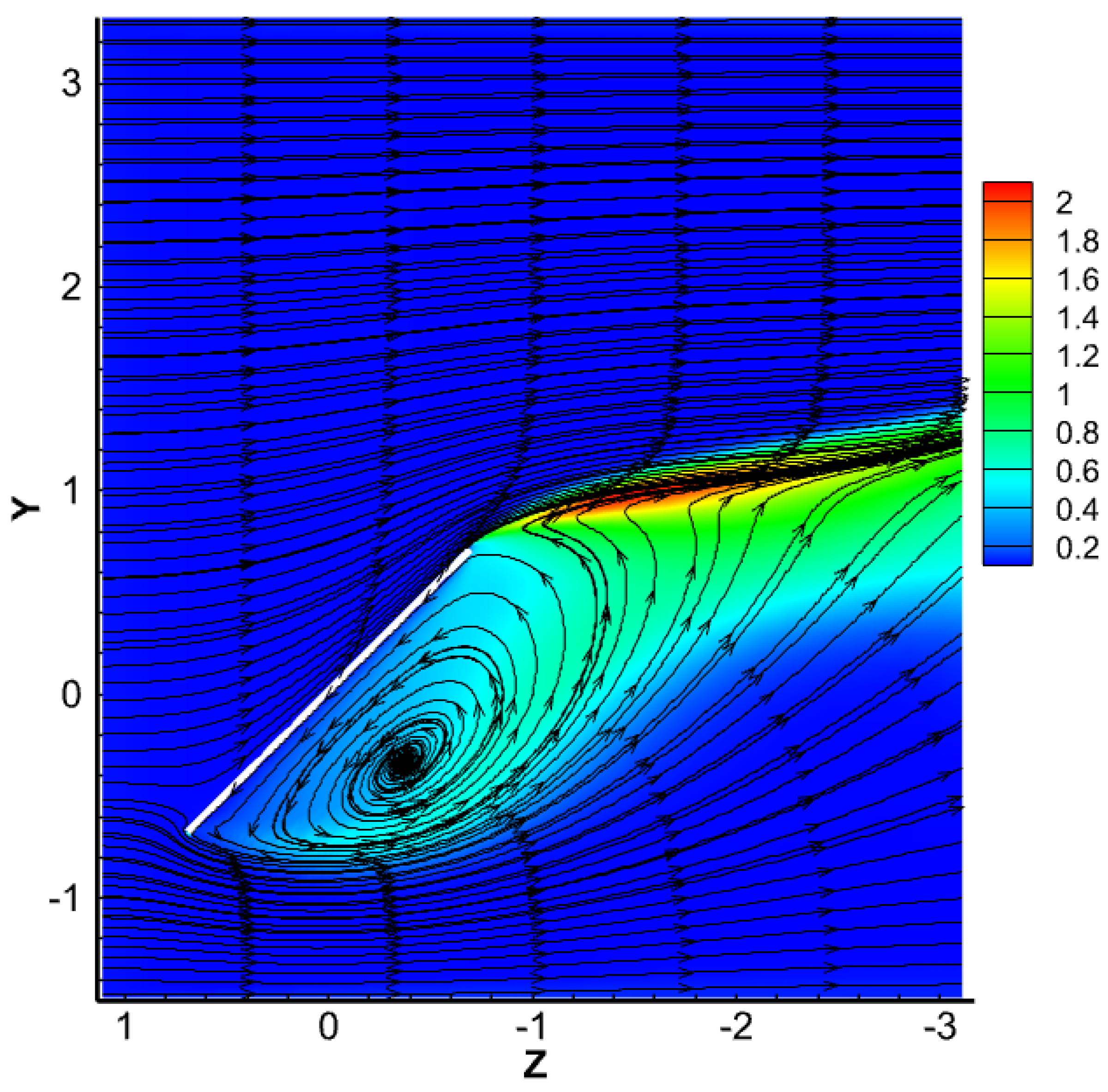

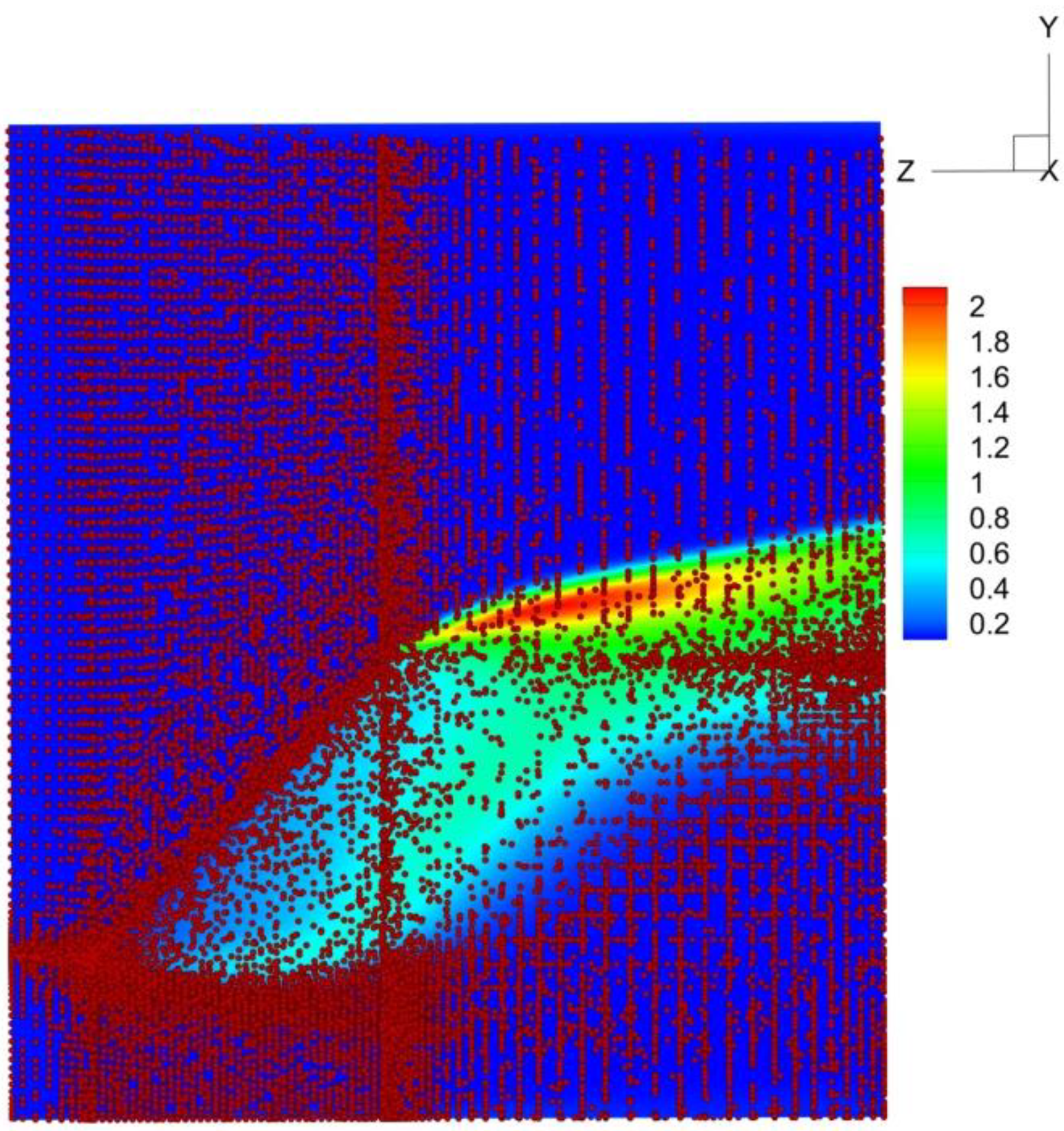

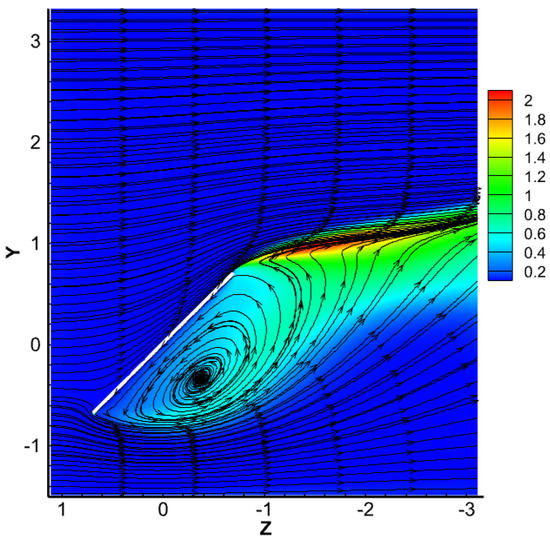

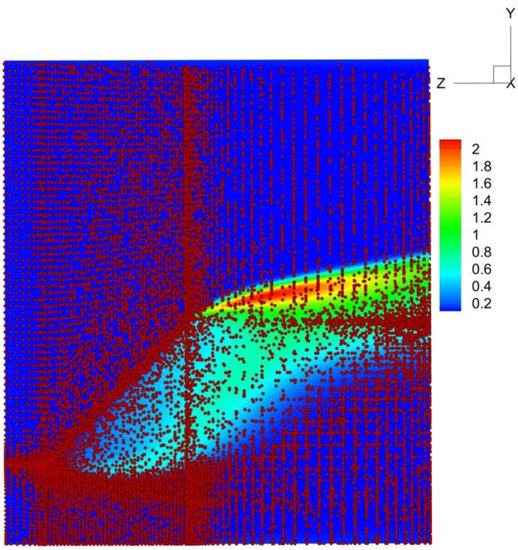

The airflow streamlines on the photovoltaic array are shown in Figure 4. As can be seen from Figure 3, the streamlines in the area away from the solar PV panel are quite stable and parallel to the ground wall. However, solar PV panels generate a large number of turbulent eddies in the near-wall region. The largest turbulent eddies are behind solar photovoltaic panels. This is consistent with the results of Lu et al. ‘s study on the effect of dust deposition on ground-mounted solar PV arrays [22]. The trajectory distribution of snow particles is shown in Figure 5. Snow particles mainly accumulate on the surface of photovoltaic panels and the ground at the junction, which is caused by snow falling and accumulating on the ground under the influence of gravity. At the same time, snow accumulates on the ground below the photovoltaic panels due to turbulence on the back of the photovoltaic panels. Therefore, in practical engineering, we can increase the height of the panel from the ground to increase the sliding of snow.

Figure 4.

Streamlines for airflow around solar PV panel.

Figure 5.

Snow particle trajectory distribution map.

3. Experiment and Results Analysis

3.1. Effects of Snow-Cover Thickness on the Photoelectric Conversion Efficiency

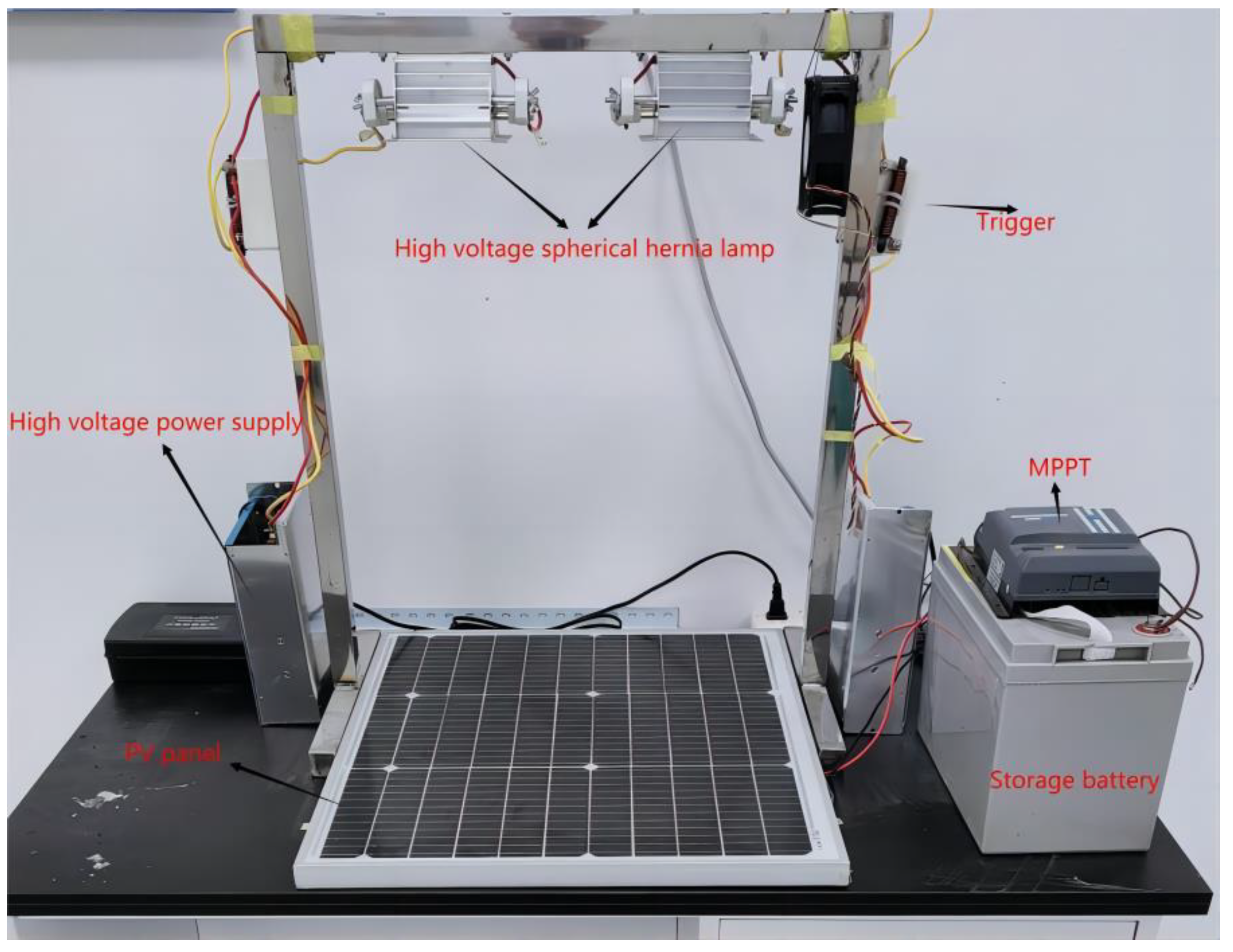

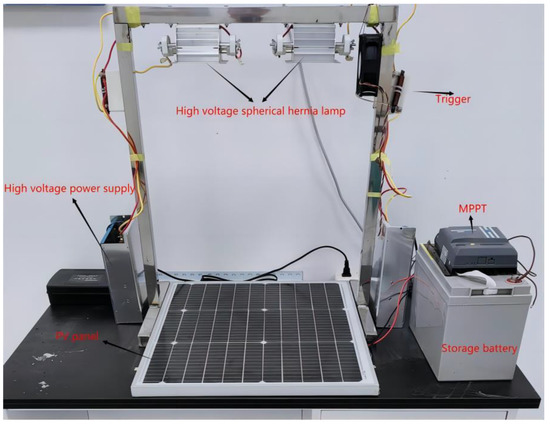

In order to measure the output power of the photovoltaic panel, a measurement test bench was developed, as shown in Figure 6. In this experiment, two 1000 W high-voltage spherical hernia lamps were used to simulate solar radiation, while a voltage regulator was employed to avoid voltage fluctuations by maintaining the output voltage as a constant and avoid the change of the radiation light of the high-voltage spherical hernia lamp. The trigger was applied to the anode and cathode of the xenon lamp at high frequency and high voltage to make the xenon in the lamp ionization discharge, and a conductive channel was established. The low-voltage DC current from the power supply of the xenon lamp could continuously pass through the originally non-conductive xenon lamp, and the lighting of the xenon lamp was triggered. As part of the solar-source simulation device, the dimmer was used to adjust the intensity of the lighting for simulating the different intensities of solar radiation. We conducted the experiment on the roof of the Electrical Engineering College of Xinjiang University. The surface temperature was −12 ℃, and the average snowfall rate was 69.3%. The temperature of the PV module was −10 ℃, and the ambient temperature was −12 ℃. The solar cells used in the experiment were monocrystalline silicon solar cells, with dimensions of 650 mm × 350 mm, maximum power Pmax of 100 W, open-circuit voltage Voc of 22.1 V, working voltage Vdc of 18.5 V, short-circuit current Isc of 6 A, and working current Imp of 5.4 A. The MPPT controller was used in combination to determine the maximum power point on the solar panel, and the energy-storage battery was used to store the output energy of the photovoltaic panel as the system load. The photovoltaic-power-generation power measurement system was constructed to measure the output power of the photovoltaic panel accurately in the process of snow accumulation under fixed lighting. The snow used in this experiment was a natural storm [23].

Figure 6.

Experimental system layout.

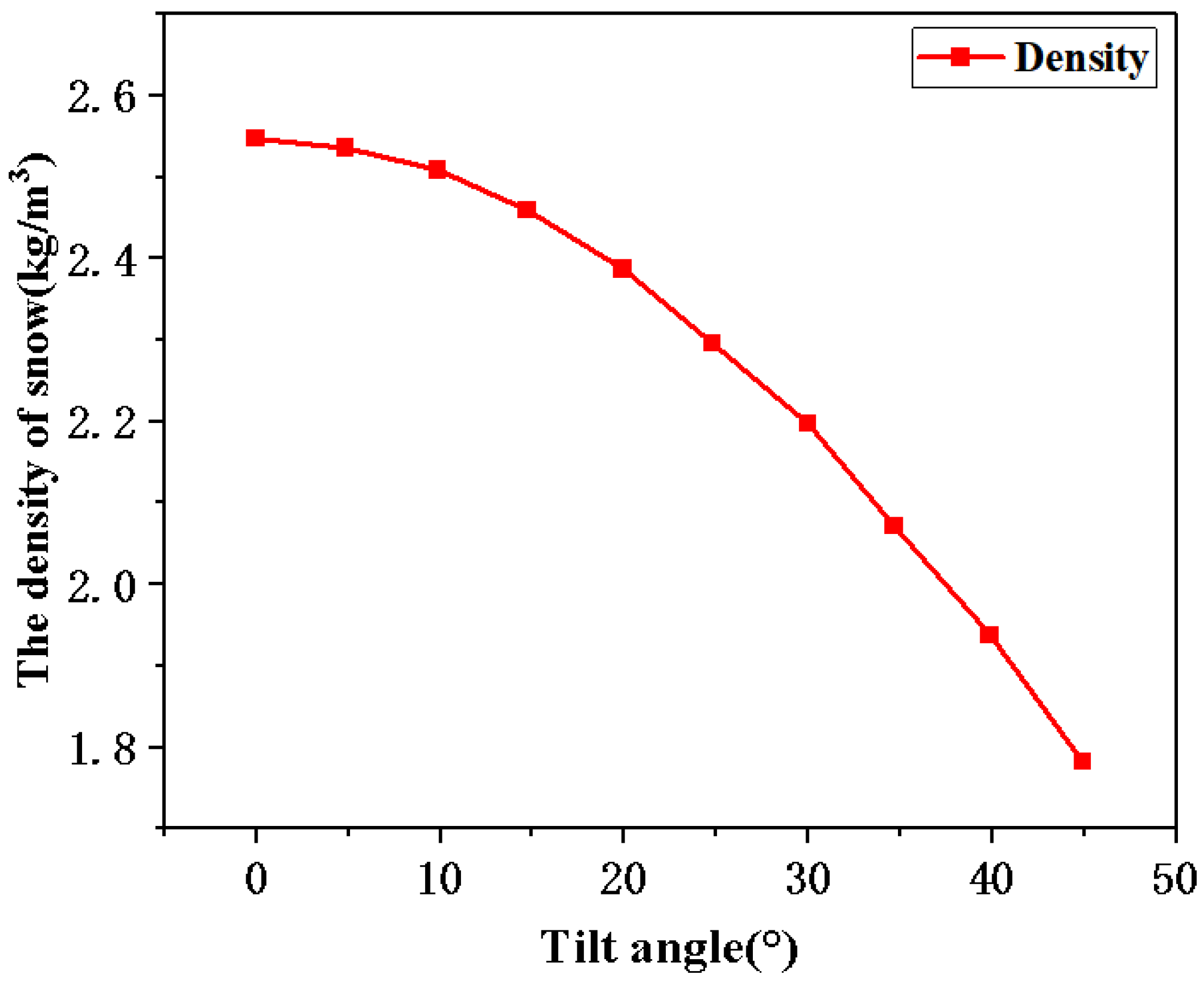

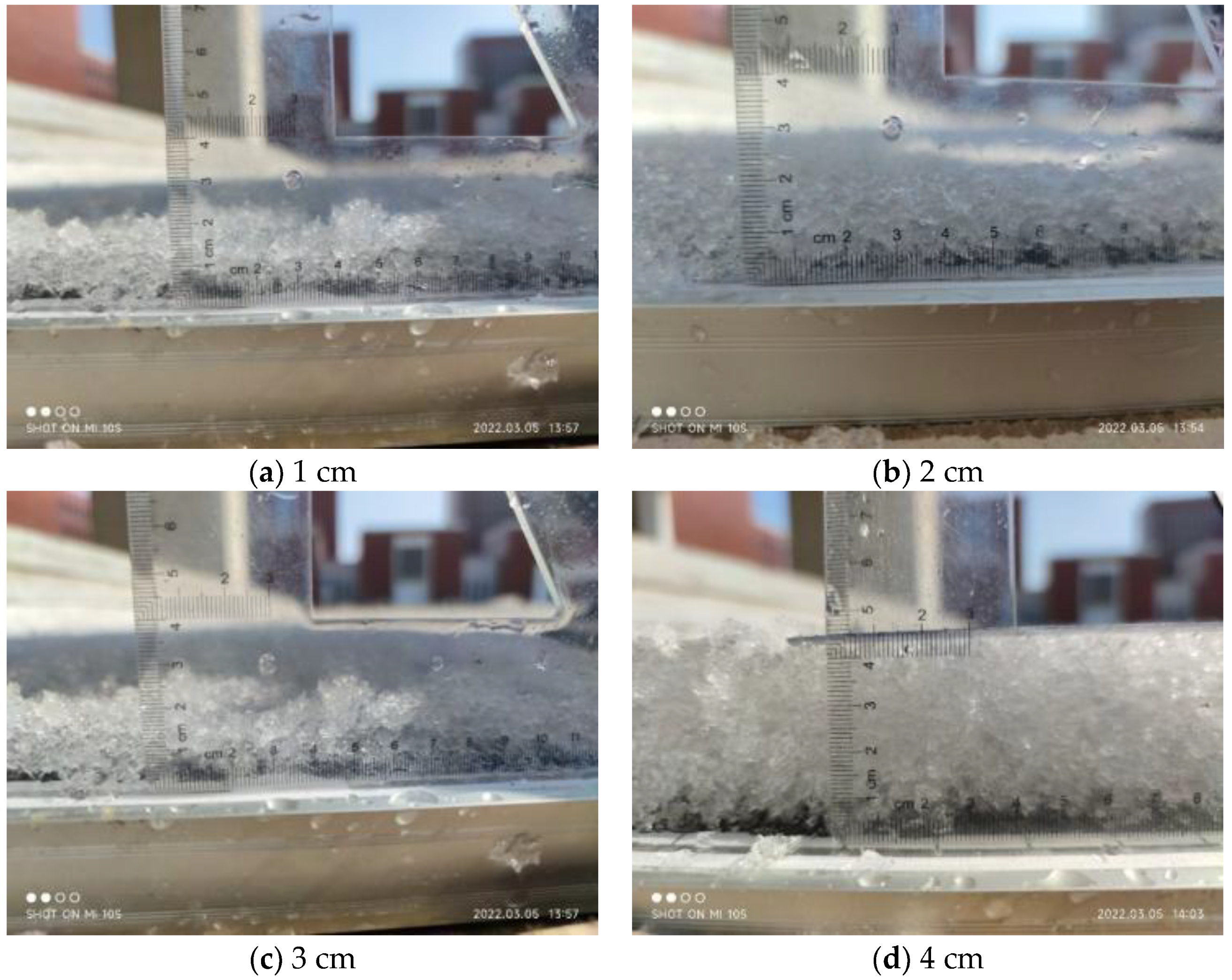

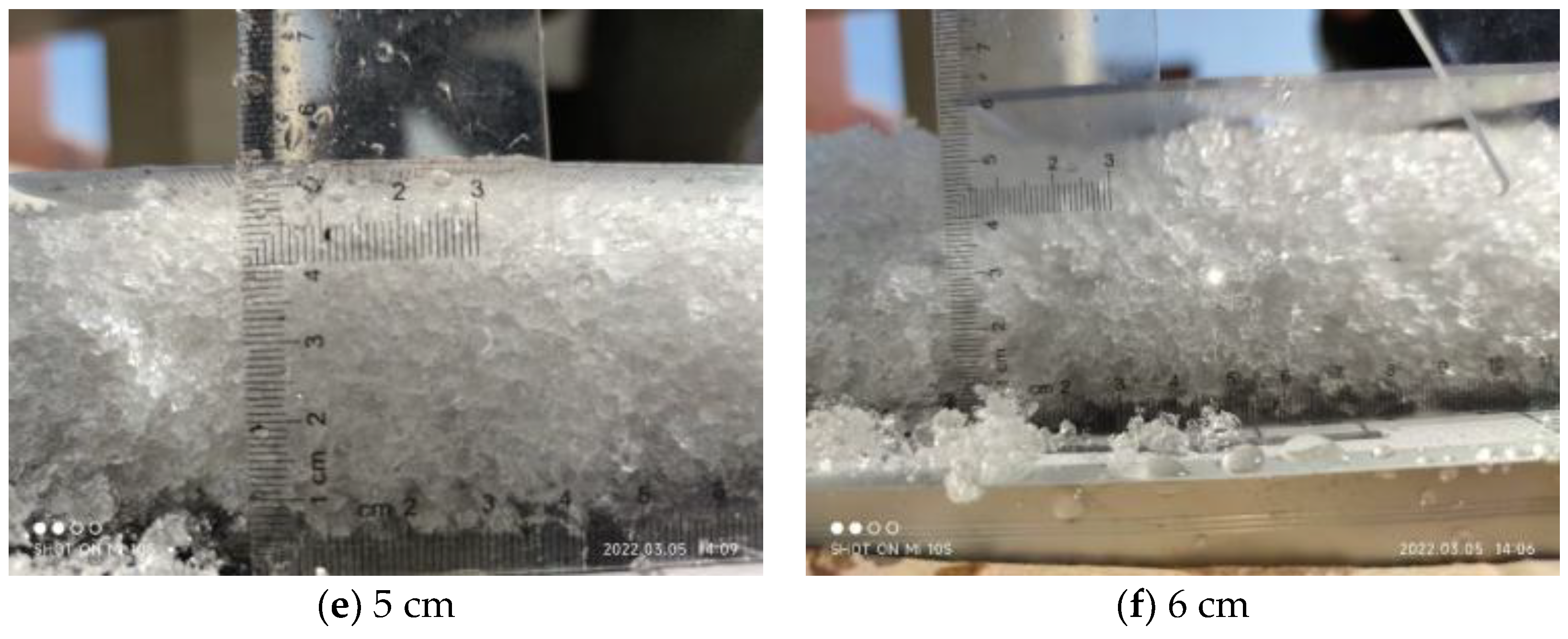

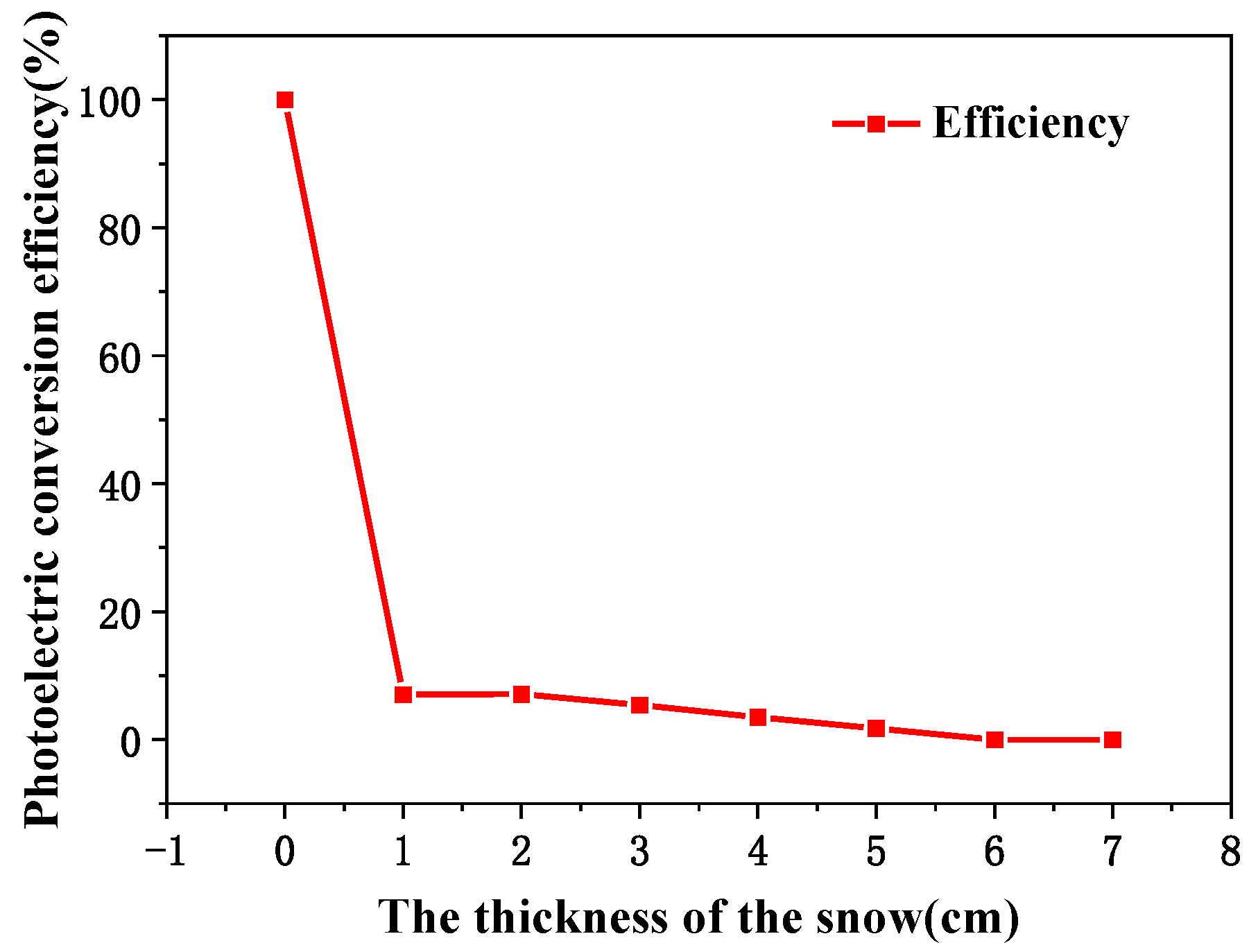

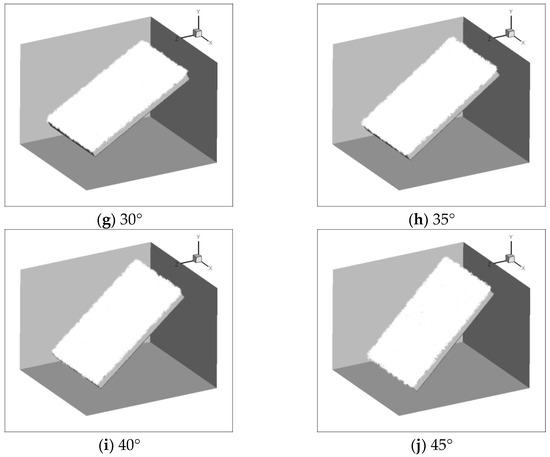

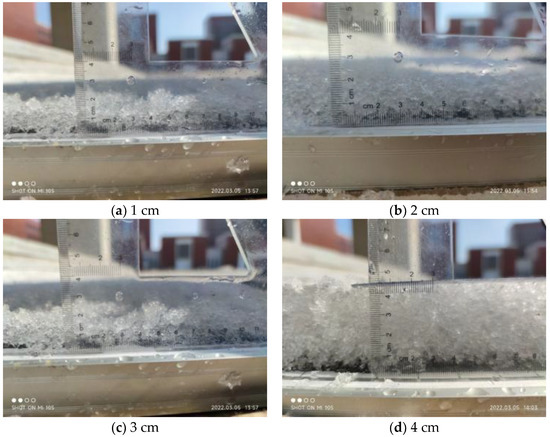

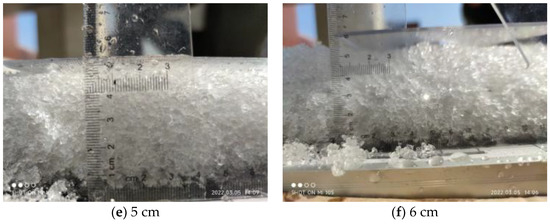

In order to study the effect of snow cover with different thicknesses on the photoelectric conversion efficiency of photovoltaic modules, the photovoltaic panels were placed horizontally outdoors in snowy weather to separately measure the output power of photovoltaic modules with a snow thickness ranging from 1 to 6 cm. Figure 7 shows the layout of the experimental measurement with a snow thickness of 1–6 cm. Figure 8 shows the impact of snow thickness on the efficiency of photovoltaic power generation. When there was no snow, the photoconversion efficiency of the photovoltaic battery was 100%. According to the experimental data, the power generation efficiency of the photovoltaic module reduced to 7.1% at a 1 cm snow thickness. When it increased from 1 cm to 6 cm, the power generation efficiency of the photovoltaic module continued a decreasing trend to zero. When the thickness of snow reached 2 cm and 3 cm, the power generation efficiency of the photovoltaic modules was unchanged, which is attributable to the impact of weather during the experiment or the insufficient accuracy of the solar controller involved. When the thickness of snow ranged between 3 cm and 6 cm, every 1 cm increase of snow thickness reduced the power generation efficiency of photovoltaic modules by about 2%, which basically conforms to a linear reduction. With the increase of snow thickness, the power generation efficiency of photovoltaic modules is sharply reduced, which has a significant impact on the power generation of photovoltaic power stations.

Figure 7.

Experimental measurements with snow thicknesses of 1–6 cm.

Figure 8.

Impact of snow thickness on photovoltaic power generation efficiency.

Solar radiation is a form of electromagnetic wave, which is similar to visible light when projected onto the surface of an object. In this context, absorption, reflection, and penetration can occur. Comprising the total energy Q projected onto the snow surface of the photovoltaic module outside, part is absorbed by the snow; part is reflected on the snow surface; and the rest, denoted as penetrates the snow to the surface of the photovoltaic module. According to the law of conservation of energy, which is expressed as , the larger the thickness of snow, the more energy, indicated by gets absorbed. However, the surface for the total amount of solar radiation, denoted as Q, is finite, so it is inevitable that solar radiation infiltrates the snow to reach the surface. After receiving solar radiation, photovoltaic modules reduce the photovoltaic-module output power, as evidenced by the experimental data when the power generation efficiency of photovoltaic modules declines.

3.2. Test of the Influence of Snow Slip Distance on Photovoltaic Power Generation Efficiency

The current snow-removal technology relies on the heating of snow on the surface of the photovoltaic module to melt part of the snow. The snow water generated by the melting plays a role in lubrication between the photovoltaic module and the snow, thus reducing the friction coefficient between them. As a result, the snow gradually falls from the surface of the photovoltaic module. However, in winter, the temperature fluctuates around the freezing point most of the time, and there is often heavy wind blowing. The melted snow water tends to freeze rapidly due to the cooling effect of wind, thus making the snow attach tightly to the surface of the photovoltaic modules. Consequently, it is difficult to conduct snow-removal operations. Therefore, it is particularly important to slide the snow away from the surface of the photovoltaic modules in time. In order to faithfully simulate the impact of snow on photovoltaic power generation, especially when the snow falls from the photovoltaic panel, the impact of different sliding distances on power generation efficiency was studied. This experiment was mainly to simulate the sliding process of snow on the surface of photovoltaic modules. The snow was made manually, and the tilt angle of solar cells was 45°. This experiment was very important to explore the relationship between the sliding distance of the snow on the surface of the PV module and the power generation efficiency of the PV module and to analyze the change characteristics of the power generation efficiency of the PV module during the sliding process. On this basis, targeted suggestions are made on snow removal for photovoltaic modules in winter.

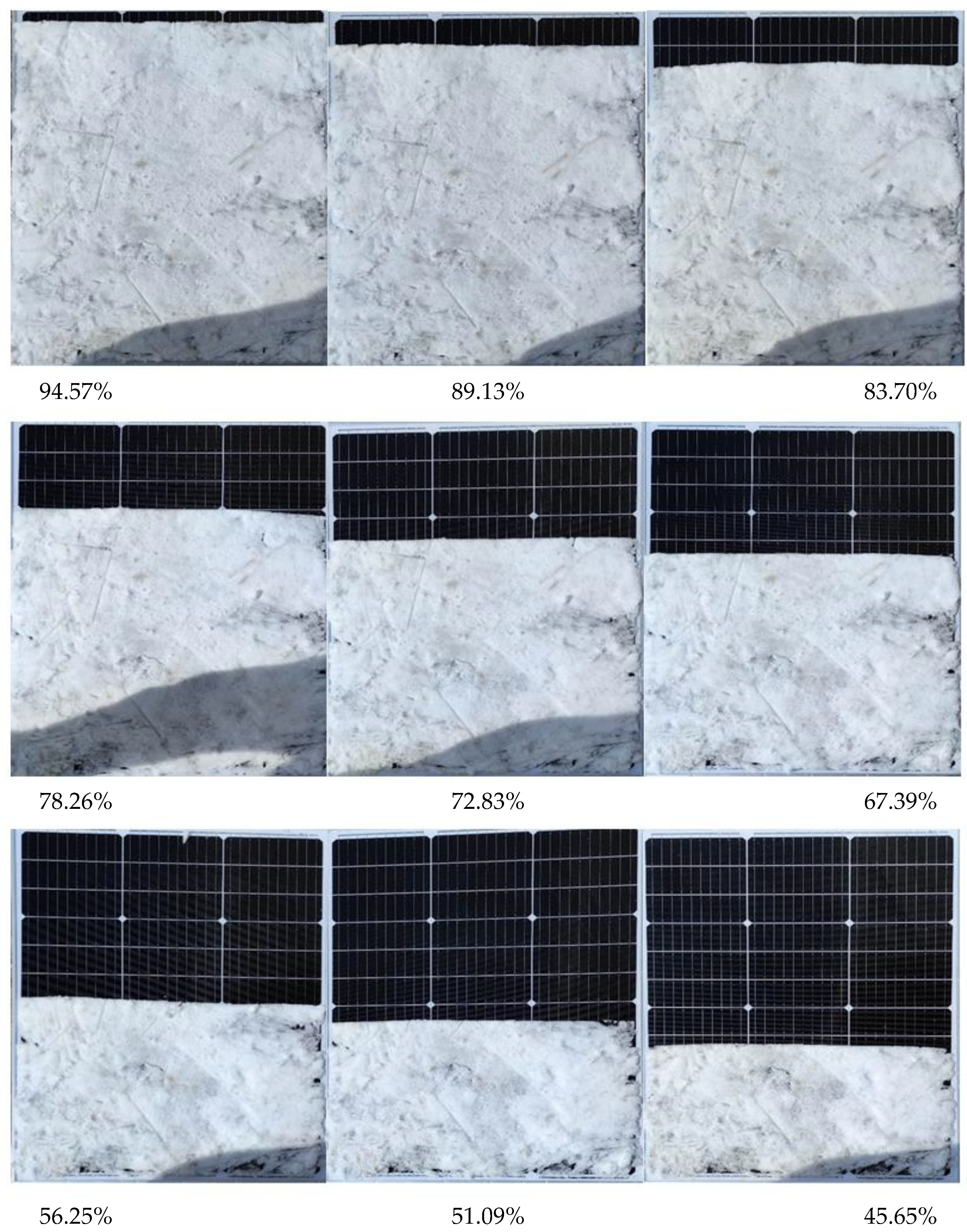

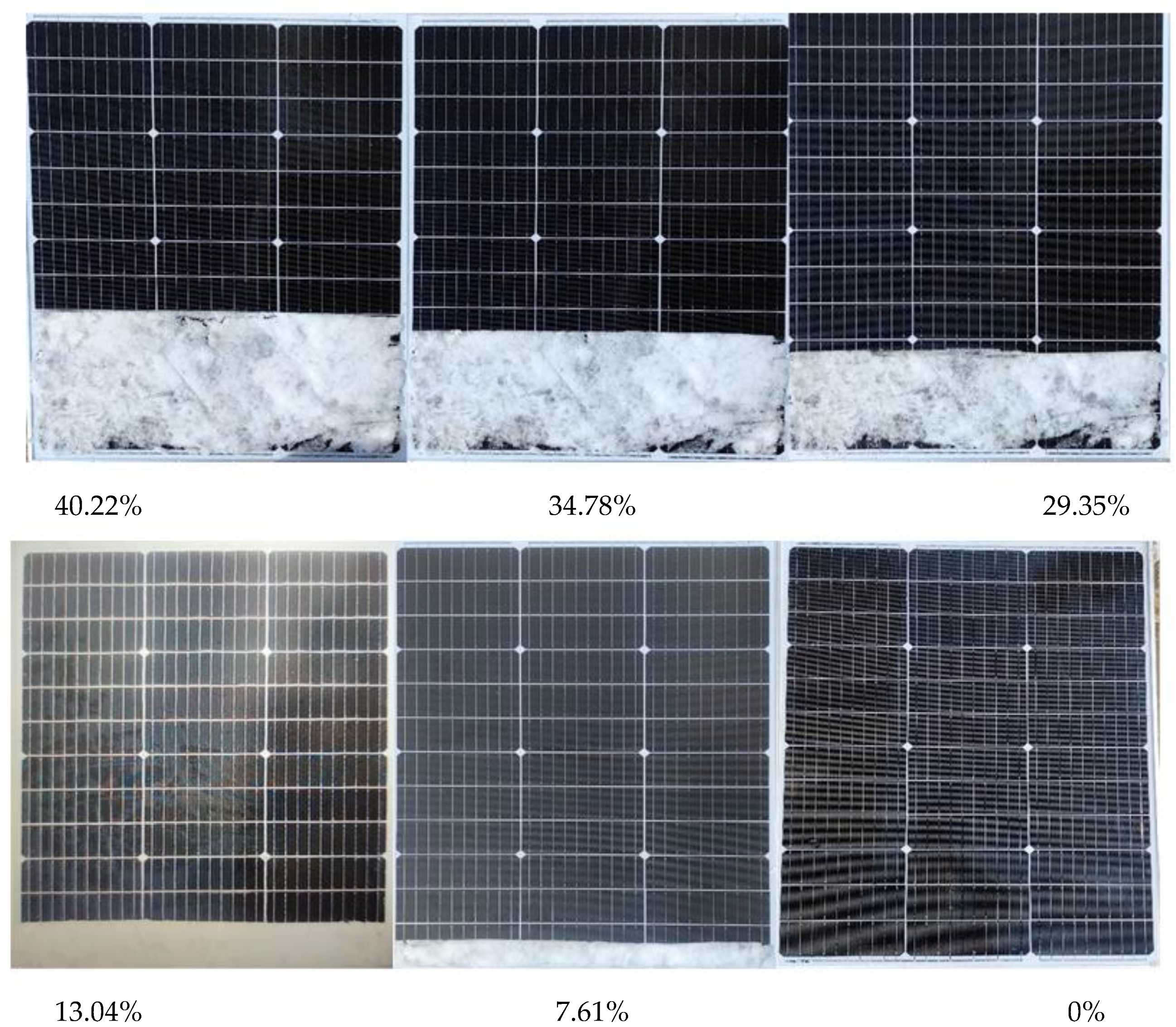

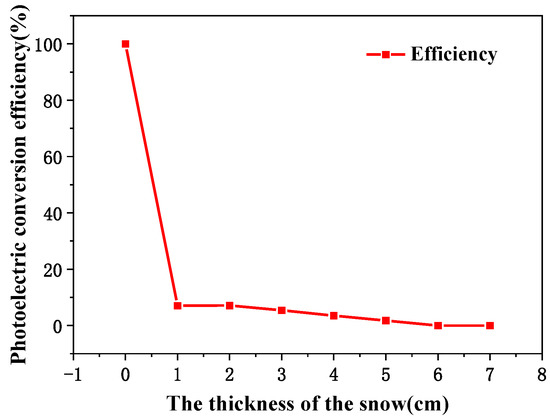

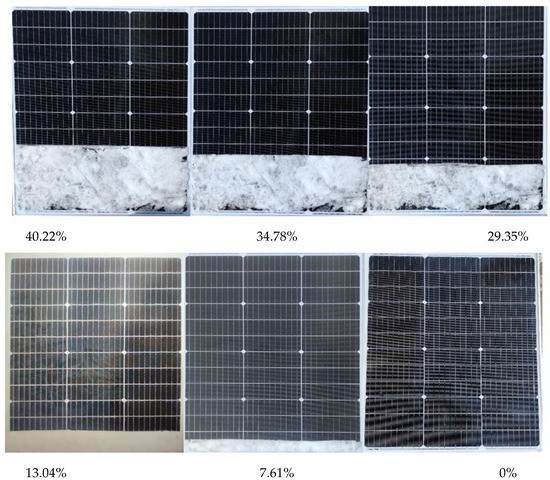

According to the influence of snow thickness on photovoltaic experimental efficiency, it is known that when the snow thickness reaches 1 cm, the photovoltaic-module power generation efficiency decreases to 4%. Therefore, it is considered that the photovoltaic panel cannot work normally under the condition of 1 cm of snow. Therefore, in order to facilitate the experiment and related operations, the snow thickness of the snow slip distance on the power generation efficiency of the photovoltaic module was set to 1 cm. Figure 9 illustrates the experimental process of snow-cover sliding on photovoltaic panels.

Figure 9.

Experimental process of snow-cover sliding on a photovoltaic panel.

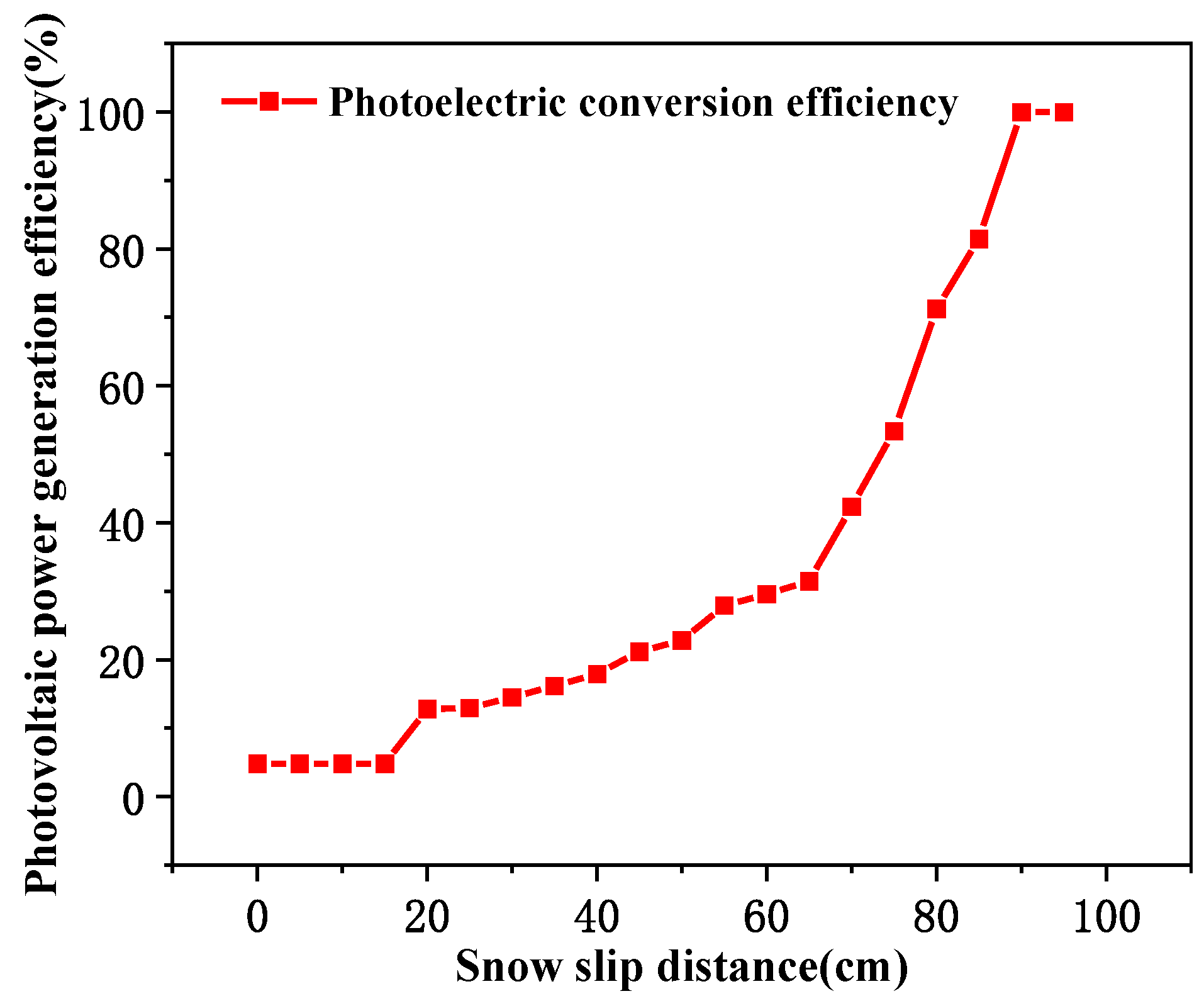

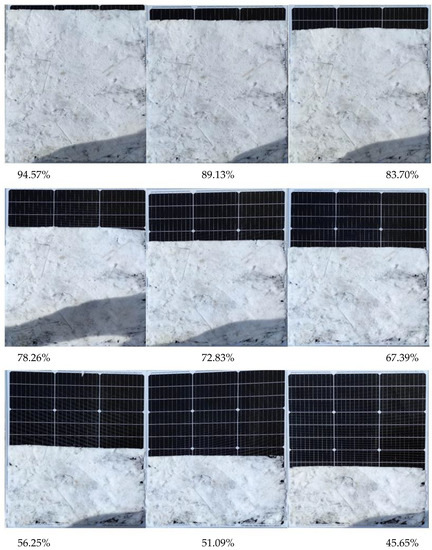

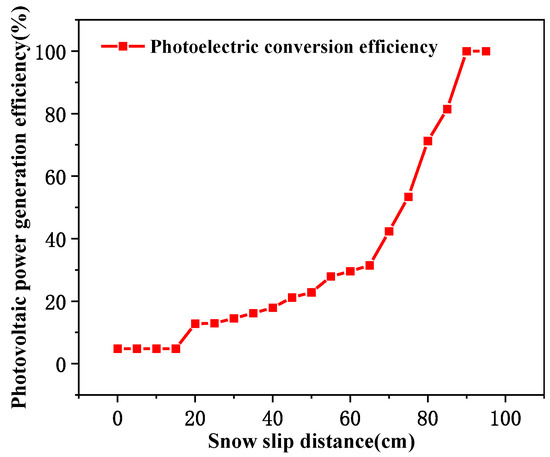

Figure 10 shows the curve of the relationship between the snow sliding distance and the light point conversion efficiency of photovoltaic panels. In the initial stage of snow sliding, covering the four data points of 0 cm, 5 cm, 10 cm, and 15 cm, the power generation efficiency of photovoltaic modules shows no significant change. Instead, it is maintained at about 4.8%. This was due to the snow covering the first group (the first longitudinal row) of photovoltaic modules not being completely removed and the photovoltaic module not being completely exposed to solar radiation. Consequently, the efficiency of power generation remained at the same level as the photovoltaic modules that were completely covered with snow. In the experiment, under the impact of snow thickness on the power generation efficiency of photovoltaic modules, the power generation efficiency achieved when the snow was less than 1 cm in thickness was about 7% of that as normal. By taking account of weather conditions and other factors, the data obtained from the two experiments are basically consistent.

Figure 10.

Relationship curve between snow slip distance and light point conversion efficiency of photovoltaic panel.

In the second stage of snow sliding, when the sliding distances were 20 cm, 25 cm, 30 cm, 35 cm, and 40 cm, the power generation efficiency of photovoltaic modules started to improve compared with the previous stage. Due to the full exposure of the top-end photovoltaic modules, the efficiency of power generation significantly increased from 4.8% to 12.8%. In the second stage, the efficiency of power generation also improved but to an insignificant degree, from 12.8% to 17.9%. This was due to the photovoltaic module being composed of multiple batteries in series and parallel. When a battery is partially blocked, its power generation efficiency is far less than that of the whole battery exposed to sunlight. When the snow sliding distance was 40 cm, half of the photovoltaic modules remained covered with snow. Therefore, the output power was extremely limited, only under less than 18% of the normal working condition of the power. Although the greater the sliding distance of snow on the panel, the higher the power generation efficiency of photovoltaic panels, the complete exposure of individual batteries within photovoltaic panels is an important factor affecting power generation efficiency.

In the third stage, when the sliding distances were 45 cm, 50 cm, 55 cm, 60 cm, and 65 cm, the power generation efficiency of the photovoltaic modules began to show significant improvement. When it increased from 40 cm to 45 cm, the efficiency of power generation increased from 17.9% to 21.2%, which is insignificant. This was due to when the snow sliding distance was 40 cm, both the first and second batteries were exposed to solar radiation and covered with the snow of a smaller thickness than 1 cm. Therefore, the improvement of power generation efficiency was limited. In the third stage, the power generation efficiency of the photovoltaic modules improved from 21.2% at the sliding distance of 45 cm to 31.4% at a sliding distance of 65 cm, which was twice the increase of power generation efficiency in the second stage. This was due to more than half of the photovoltaic modules being exposed to sunlight since the third stage. Meanwhile, the photovoltaic modules functioning as normal outnumbered those covered with snow. As a result, the resistance of the snow-covered PN junction to the current in the closed loop was reduced.

In the fourth stage of snow sliding, when the sliding distance reached 70 cm, 75 cm, 80 cm, 85 cm, and 90 cm, the power generation efficiency of photovoltaic modules improved significantly. When it increased from 65 cm to 70 cm, the power generation efficiency improved from 31.4% to 42.3%, which is basically consistent with that in the previous process from the second stage to the third stage. This was due to all the photovoltaic modules corresponding to this stage being basically exposed at the end of the previous stage. As a result, there was a slight increase in the efficiency of power generation when all the photovoltaic modules of this group were exposed. In this stage, the most significant improvement in power generation efficiency was achieved in the whole experimental process, with the power generation efficiency of photovoltaic modules enhanced from 42.3% at the sliding distance of 70 cm to 100% at the sliding distance of 90 cm.

4. Discussion

Based on the numerical simulation and experimental and analytical results, some suggestions for improving the power generation efficiency of PV panels under snow cover are proposed. When the thickness of snow exceeds 1 cm, it is necessary to carry out snow removal immediately from the surface of the photovoltaic modules, thus ensuring the normal operation of the photovoltaic power station during the day. When the snow thickness reaches 6 cm, the power generation efficiency is reduced to zero for the photovoltaic power station, which means the operation of the station is stopped. This has a massive impact on the normal functioning of the power grid. At this time, manual snow removal should be considered. For large photovoltaic power stations, manual snow removal is a laborious and costly process. Therefore, in those areas with heavy snowfall, the selection of photovoltaic modules for use in photovoltaic power stations is of much importance. When a photovoltaic power station is under construction, the photovoltaic modules should be installed at a certain height from the ground. This is due to when the snow is falling, there is not enough space allowed to pile up the snow falling from the photovoltaic modules, which hinders the snow from sliding. When it is not possible to completely clear the snow from the photovoltaic panels, we recommend that the snow cover of the individual battery be completely cleared.

5. Conclusions

In this paper, the effect of snow thickness on photovoltaic-module power generation efficiency is discussed by numerical simulation. Additionally, the effect of photovoltaic-module snow on photoelectric conversion efficiency was studied by building a test bed. Based on the numerical simulation and experimental and analytical results, some suggestions for improving the power generation efficiency of PV panels under snow cover are proposed. On this basis, the following conclusions can be drawn:

By simulating the process of snow covering the photovoltaic modules, it is found that the tilt angle of the photovoltaic modules affects whether the photovoltaic modules can be easily cleared of snow. The smaller the tilt angle, the more likely the photovoltaic module is to be covered with snow, hence the greater the amount of snow accumulation and the larger the snow thickness.

Through the experiment on how snow thickness impacts on the power generation efficiency of photovoltaic modules, it is discovered that the thickness of snow directly affects the power generation efficiency of photovoltaic modules. This is due to the reflection-of-snow-to-solar-radiation being only related to the reflectivity of the surface of snow. When the thickness of snow increases, the amount of snow staying on the photovoltaic module increases. In this case, the absorbed solar radiation increases, thus reducing the amount of radiation reaching the surface of the photovoltaic module. When the snow thickness reaches 1 cm, the power generation efficiency of the entire photovoltaic module reduces to 7.1% of that as normal. When the snow thickness reaches 6 cm, the power generation capacity of the photovoltaic module is zeroed, which means it does not function at all. The sliding of snow on the photovoltaic panel is beneficial to enhance the efficiency of photoelectric conversion. Although the greater the sliding distance of snow on the panel, the higher the power generation efficiency of photovoltaic panels, the complete exposure of the individual battery within photovoltaic panels is an important factor affecting power generation efficiency.

In this paper, the characteristics of photovoltaic cells are not fully considered when studying the snow accumulation process of solar photovoltaic cells, and the variable of sliding angle is not considered when studying the snow removal on the surface of solar cells. Therefore, in the next study, we will test the energy generation and solar radiation of solar cells to further evaluate the efficiency of solar cells. We will compare and study the I–V curve of solar cells under normal conditions and coverage conditions. In addition, for the snow-removal phenomenon on the surface of solar cells, we will add the solar-cell tilt angle as a variable to illustrate the impact of different angles on the sliding speed and power generation.

Author Contributions

Conceptualization, Z.Q., C.Z. and W.Z.; methodology, Z.Q.; software, C.Z.; validation, H.L. and W.Z.; formal analysis, Z.Q. and F.A.; investigation, W.Z.; resources, Z.Q. and F.A.; data curation, H.L.; writing—original draft preparation, Z.Q., C.Z. and W.Z.; writing—review and editing, C.Z., Y.X. and J.Q.; visualization, C.Z.; supervision, H.L.; project administration, H.L.; funding acquisition, H.L. All authors have read and agreed to the published version of the manuscript.

Funding

The authors appreciate the financial supports provided by the National Oversea High-level Talents Program of China, the National Natural Science Foundation of China (No. 52266017), and the Major Project of the National Social Science Foundation of China (No. 21&ZD133). This study was also supported by the Xinjiang Natural Science Fund for Distinguished Young Scholars (No. 2021D01E08), the Xinjiang Regional Coordination Special Project-International Science and Technology Cooperation Program (No. 2022E01026), the Xinjiang Major Science and Technology Special Project (No. 2022401002-2,2022A01007-1,2022A01007-4), the Xinjiang Key Research and development Project (No. 2022B03028-2, No. 2022B01033-2, and No. 2022B01022-1), the Central Guidance on Local Science and Technology Development Project (No. ZYYD2022C16), the Innovation Team Project of Xinjiang University (No. 500122006021), the High-level Talents Project of Xinjiang University (No. 100521001), the Outstanding doctoral student research innovation Project of Xinjiang University (No. XJU2022BS100).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kannan, N.; Vakeesan, D. Solar energy for future world: A review. Renew. Sustain. Energy Rev. 2016, 62, 1092–1105. [Google Scholar] [CrossRef]

- Mehrtash, M.; Quesada, G.; Dutil, Y.; Rousse, D. Performance evaluation of sun tracking photovoltaic systems in Canada. In Proceedings of the 20th Annual International Confernece on Mechanical Engineering–ISME, Shiraz, Iran, 16–18 May 2012. [Google Scholar]

- Kakoi, Y.; Tsutsui, Y.; Ono, N.; Umezawa, K.; Kondo, N. SAE Technical Paper. Emission Reduction Technologies Applied to High-Speed Direct Injection Diesel Engine; SAE International: Warrendale, PA, USA, 1998. [Google Scholar]

- Park, W.; Choi, S.; Chung, S.; Ha, J. A study on exhaust characteristics in HIDI diesel engine applied EGR cooler. In Proceedings of the KSAE 2003 Fall Conference, Seoul, Republic of Korea, 1 May 2003; pp. 393–397. [Google Scholar]

- Jayakumar, P. Resource Assessment Handbook; Asia and Pacific Center for Transfer of Technology of the United Nations, ESCAP: Bangkok, Thailand, 2009. [Google Scholar]

- International Renewable Energy Agency. Installed Capacity Trends [EB/OL]. 2022. Available online: https://www.irena.org/solar (accessed on 1 April 2022).

- Paudyal, B.R.; Shakya, S.R. Dust accumulation effects on efficiency of solar PV modules for off grid purpose: A case study of Kathmandu. Sol. Energy 2016, 135, 103–110. [Google Scholar] [CrossRef]

- Stridh, B. Evaluation of economical benefit of cleaning of soiling and snow in PV plants at three European locations. In Proceedings of the 2012 38th IEEE Photovoltaic Specialists Conference, Austin, TX, USA, 3–8 June 2012; pp. 001448–001451. [Google Scholar]

- Hashemi, B.; Cretu, A.M.; Taheri, S. Snow loss prediction for photovoltaic farms using computational intelligence techniques. IEEE J. Photovolt. 2020, 10, 1044–1052. [Google Scholar] [CrossRef]

- Jelle, B.P. The challenge of removing snow downfall on photovoltaic solar cell roofs in order to maximize solar energy efficiency—Research opportunities for the future. Energy Build. 2013, 67, 334–351. [Google Scholar] [CrossRef]

- Marion, B.; Schaefer, R.; Caine, H.; Sanchez, G. Measured and modeled photovoltaic system energy losses from snow for Colorado and Wisconsin locations. Sol. Energy 2013, 97, 112–121. [Google Scholar] [CrossRef]

- Powers, L.; Newmiller, J.; Townsend, T. Measuring and modeling the effect of snow on photovoltaic system performance. In Proceedings of the 2010 35th IEEE Photovoltaic Specialists Conference, Honolulu, HI, USA, 20–25 June 2010; pp. 000973–000978. [Google Scholar]

- Sugiura, T.; Yamada, T.; Nakamura, H.; Umeya, M.; Sakuta, K.; Kurokawa, K. Measurements, analyses and evaluation of residential PV systems by Japanese monitoring program. Sol. Energy Mater. Sol. Cells 2003, 75, 767–779. [Google Scholar] [CrossRef]

- Heidari, N.; Gwamuri, J.; Townsend, T.; Pearce, J.M. Impact of snow and ground interference on photovoltaic electric system performance. IEEE J. Photovolt. 2015, 5, 1680–1685. [Google Scholar] [CrossRef]

- Wang, Y.; Yao, X.; Chen, J.; He, Z.; Liu, J.; Li, Q.; Wang, J.; Jiang, L. Organogel as durable anti-icing coatings. Sci. China Mater. 2015, 58, 559–565. [Google Scholar] [CrossRef]

- Beemer, D.L.; Wang, W.; Kota, A.K. Durable gels with ultra-low adhesion to ice. J. Mater. Chem. A 2016, 4, 18253–18258. [Google Scholar] [CrossRef]

- Rahmatmand, A.; Harrison, S.J.; Oosthuizen, P.H. An experimental investigation of snow removal from photovoltaic solar panels by electrical heating. Sol. Energy 2018, 171, 811–826. [Google Scholar] [CrossRef]

- Yan, C.; Qu, M.; Chen, Y.; Feng, M. Snow removal method for self-heating of photovoltaic panels and its feasibility study. Sol. Energy 2020, 206, 374–380. [Google Scholar] [CrossRef]

- Anadol, M.A. Snow melting on photovoltaic module surface heated with transparent resistive wires embedded in polyvinyl butyral interlayer. Sol. Energy 2020, 212, 101–112. [Google Scholar] [CrossRef]

- Aldawoud, A.; Aldawoud, A.; Aryanfar, Y.; Assad, M.E.H.; Sharma, S.; Alayi, R. Reducing PV soiling and condensation using hydrophobic coating with brush and controllable curtains. Int. J. Low-Carbon Technol. 2022, 17, 919–930. [Google Scholar] [CrossRef]

- Fries, L.; Antonyuk, S.; Heinrich, S.; Palzer, S. DEM–CFD modeling of a fluidized bed spray granulator. Chem. Eng. Sci. 2011, 66, 2340–2355. [Google Scholar] [CrossRef]

- Lu, H.; Zhang, L.Z. Influences of dust deposition on ground-mounted solar photovoltaic arrays: A CFD simulation study. Renew. Energy 2019, 135, 21–31. [Google Scholar] [CrossRef]

- Pruitt, W.O. Why and How to Study a Snowcover. Can. Field Nat. 2005, 119, 118–128. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).