Implementation of the Homogenization Method in the Numerical Estimation of Wafer Warpage

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussions

3.1. Validation of the Loading Simplification

3.2. Validation of the Homogenization Approach

4. Conclusions

- -

- The replacement of the complete thermal cycle with the last cooling phase had virtually no effect on the numerical estimates of the warps.

- -

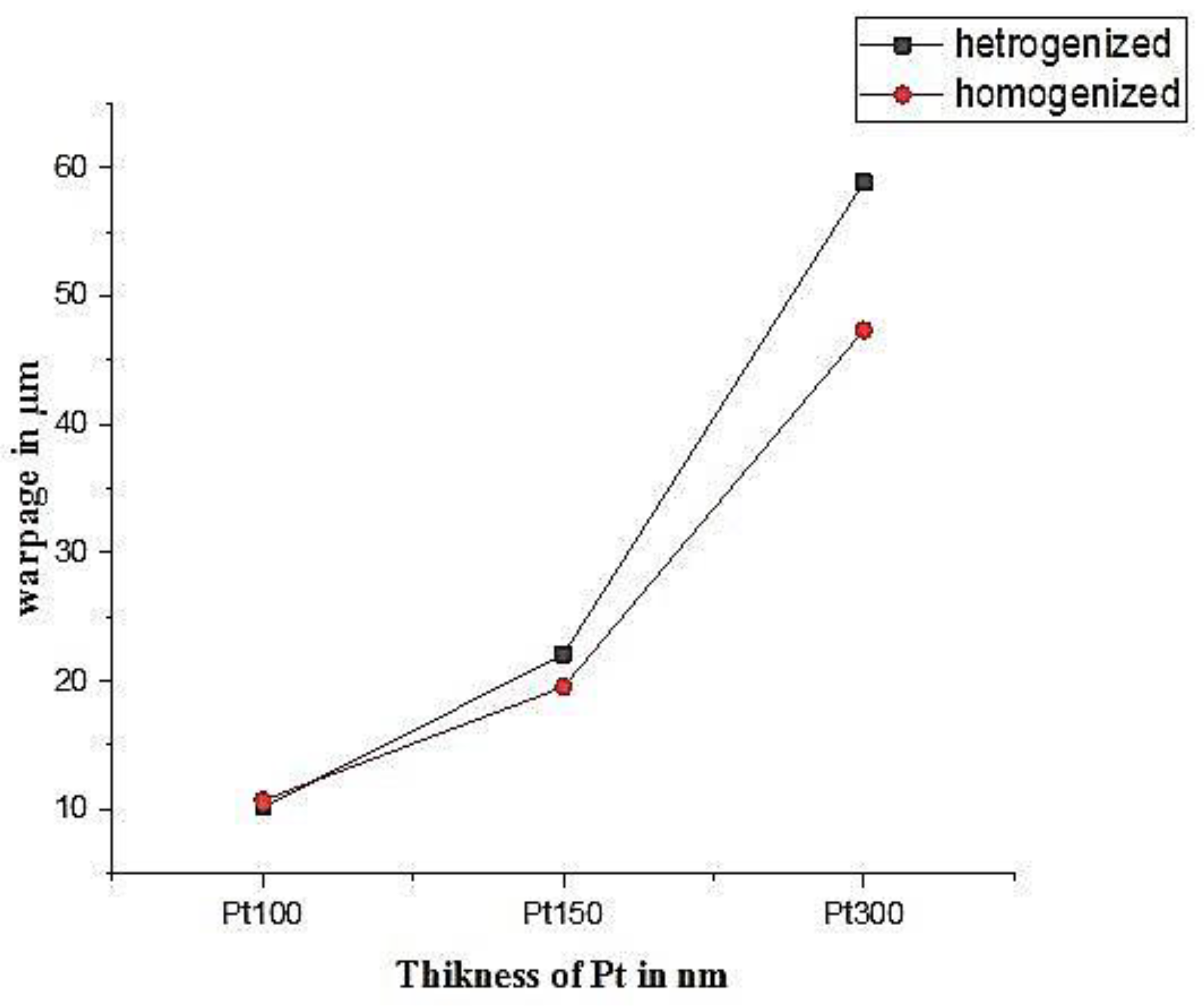

- The evolution of warping as a function of the thickness of Pt obtained numerically presents the same appearance as that measured experimentally.

- -

- Increasing the thickness of the metal film increased the warping.

- -

- The difference between the numerical and experimental results is mainly owing to the non-inclusion of intrinsic stresses in the numerical approaches.

- -

- The homogenization technique made it possible to reliably estimate the wafer warpage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ghellai, N.; Benmansour, A.; Chabane Sari, N.-E. Ellipsométrie spectroscopique. Photoniques 2011, 51, 22–27. [Google Scholar] [CrossRef]

- Lee, J.M.; Hong, S.K.; Hwang, C.S.; Kim, H.J.; Suk, C.G. Characterization of Pt electrodes for ferroelectric thin films prepared by metalloraganic chemical vapor deposition using Pt(CF3COCHCOCF3)2 and (CH3C5H4)Pt(CH3)3. J. Korean Phys. Soc. 1998, 33, S148–S151. [Google Scholar]

- Yao, W.Z.; Roqueta, F.; Craveur, J.C.; Belhenini, S.; Gardes, S.P.; Tougui, A. Modelling and analysis of the stress distribution in a multi-thin film system Pt/USG/Si. Mater. Res. Express 2018, 5, 046405. [Google Scholar] [CrossRef]

- Stoney, G.G. The Tension of Metallic Films Deposited by Electrolysis. Proc. R. Soc. Lond. Ser. A 1909, 82, 172–175. [Google Scholar] [CrossRef]

- Harper, B.D.; Chih-Ping, W. A geometrically nonlinear model for predicting the intrinsic film stress by the bending-plate method. Int. J. Solids Struct. 1990, 26, 511–525. [Google Scholar] [CrossRef]

- Thakur, R.P.S.; Chhabra, N.; Ditali, A. Effects of wafer bow and warpage on the integrity of thin gate oxides. Appl. Phys. Lett. 1994, 64, 3428–3430. [Google Scholar] [CrossRef]

- Zhang, H.-W.; Wu, J.-K.; Lü, J.; Fu, Z.-D. Extended multiscale finite element method for mechanical analysis of heterogeneous materials. Acta Mech. Sin. 2010, 26, 899–920. [Google Scholar] [CrossRef]

- Kanouté, P.; Boso, D.; Chaboche, J.; Schrefler, B. Multiscale Methods for Composites: A Review. Arch. Comput. Methods Eng. 2009, 16, 31–75. [Google Scholar] [CrossRef]

- Eshelby, J.D.; Peierls, R.E. The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc. R. Soc. Lond. Ser. Math. Phys. Sci. 1957, 241, 376–396. [Google Scholar] [CrossRef]

- Mori, T.; Tanaka, K. Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall. 1973, 21, 571–574. [Google Scholar] [CrossRef]

- Hashin, Z.; Shtrikman, S. A variational approach to the theory of the elastic behaviour of multiphase materials. J. Mech. Phys. Solids 1963, 11, 127–140. [Google Scholar] [CrossRef]

- Hill, R. A self-consistent mechanics of composite materials. J. Mech. Phys. Solids 1965, 13, 213–222. [Google Scholar] [CrossRef]

- Xia, Z.; Zhou, C.; Yong, Q.; Wang, X. On selection of repeated unit cell model and application of unified periodic boundary conditions in micro-mechanical analysis of composites. Int. J. Solids Struct. 2006, 43, 266–278. [Google Scholar] [CrossRef]

- Li, X.; Liu, Q.; Zhang, J. A micro–macro homogenization approach for discrete particle assembly—Cosserat continuum modeling of granular materials. Int. J. Solids Struct. 2010, 47, 291–303. [Google Scholar] [CrossRef]

- Babuška, I. Homogenization Approach In Engineering. In Computing Methods in Applied Sciences and Engineering; Beckmann, M., Künzi, H.P., Eds.; Lecture Notes in Economics and Mathematical Systems; Springer: Berlin/Heidelberg, Germany, 1976; Volume 134, pp. 137–153. [Google Scholar] [CrossRef]

- Miled, H.F.; Roqueta, F.; Craveur, J.C.; Le Bourhis, E.; Gardes, P.; Tougui, A. Analytical multi-step homogenization methodology for a stack of thin films in microelectronics. In Proceedings of the 21st International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Cracow, Poland, 5–8 July 2020; pp. 1–7. [Google Scholar] [CrossRef]

- Cheng, Z.; Ding, Y.; Zhang, Z.; Zhou, M.; Chen, Z. Coupled Thermo-Mechanical Analysis of 3D ICs Based on an Equivalent Modeling Methodology with Sub-Modeling. IEEE Access 2020, 8, 14146–14154. [Google Scholar] [CrossRef]

- Berthelot, J.M. Composite Materials, Mechanical Behaviour and Structural Analysis; Springer: New York, NY, USA, 1999. [Google Scholar] [CrossRef]

- Schapery, R.A. Thermal Expansion Coefficients of Composite Materials Based on Energy Principles. J. Compos. Mater. 1968, 2, 380–404. [Google Scholar] [CrossRef]

| USG | Pt | Si | |

|---|---|---|---|

| E (GPa) | 94 | 177 | 169 |

| υ | 0.17 | 0.39 | 0.063 |

| α ( | 0.5 | 9 | 2.8 |

| Pt (100 nm) | Pt (150 nm) | Pt (300 nm) | |

|---|---|---|---|

| (GPa) | 110.600 | 116.660 | 129.430 |

| (GPa) | 103.740 | 107.800 | 117.924 |

| v12, v13 | 0.214 | 0.23 | 0.26 |

| 0.2 | 0.212 | 0.23 | |

| (GPa) | 45.551 | 47.430 | 51.360 |

| (GPa) | 43.225 | 44.472 | 47.930 |

| (10−6/ °C) | 3.22 | 4.02 | 5.47 |

| (10−6/ °C) | 4.31 | 4.96 | 6.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belhenini, S.; El Fatmi, I.; Richard, C.; Tougui, A.; Roqueta, F. Implementation of the Homogenization Method in the Numerical Estimation of Wafer Warpage. Coatings 2023, 13, 318. https://doi.org/10.3390/coatings13020318

Belhenini S, El Fatmi I, Richard C, Tougui A, Roqueta F. Implementation of the Homogenization Method in the Numerical Estimation of Wafer Warpage. Coatings. 2023; 13(2):318. https://doi.org/10.3390/coatings13020318

Chicago/Turabian StyleBelhenini, Soufyane, Imad El Fatmi, Caroline Richard, Abdellah Tougui, and Fabrice Roqueta. 2023. "Implementation of the Homogenization Method in the Numerical Estimation of Wafer Warpage" Coatings 13, no. 2: 318. https://doi.org/10.3390/coatings13020318

APA StyleBelhenini, S., El Fatmi, I., Richard, C., Tougui, A., & Roqueta, F. (2023). Implementation of the Homogenization Method in the Numerical Estimation of Wafer Warpage. Coatings, 13(2), 318. https://doi.org/10.3390/coatings13020318