Tailoring Mechanical Properties of a-C:H:Cr Coatings

Abstract

:1. Introduction

2. Materials and Methods

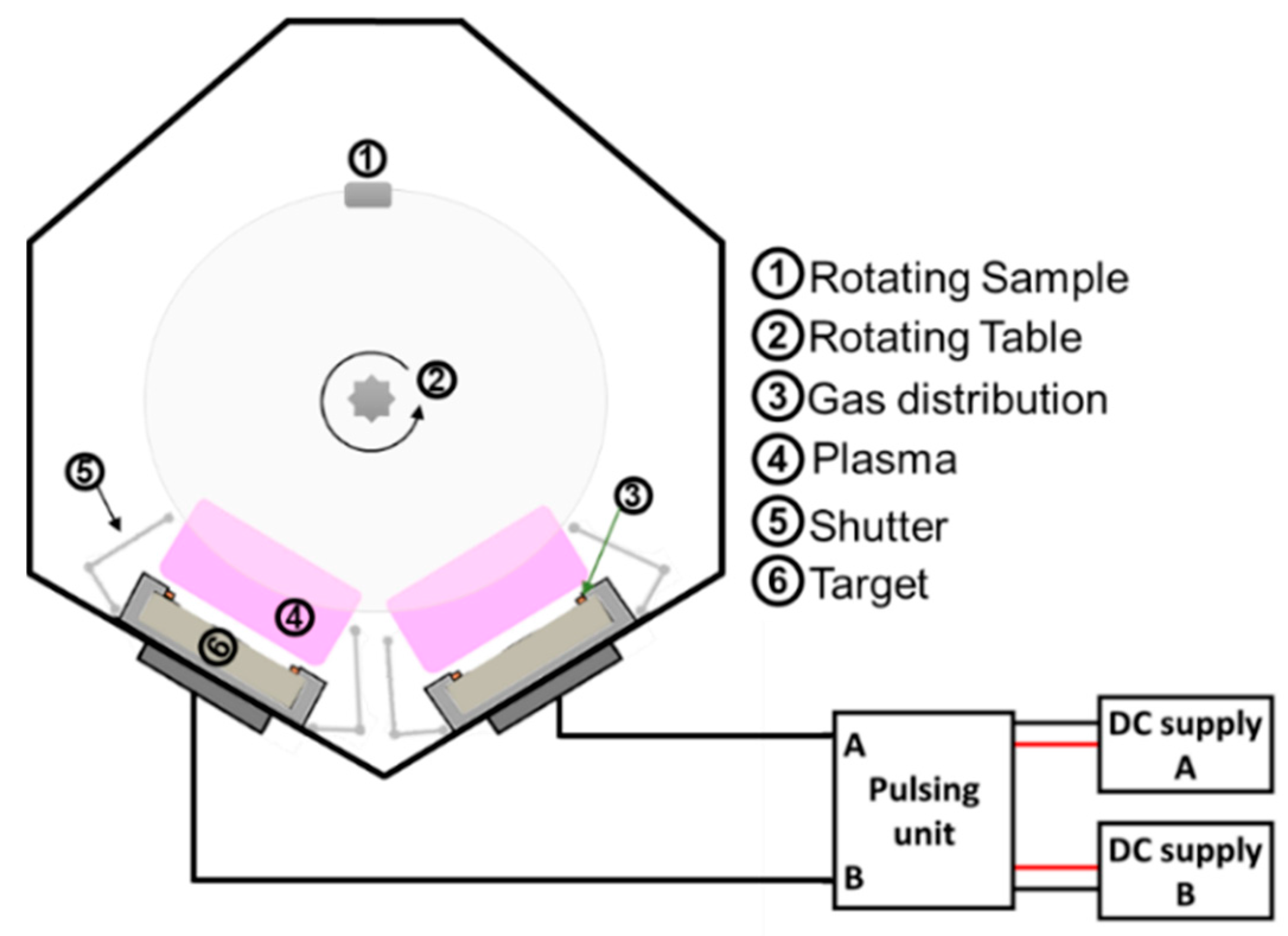

2.1. Coating Deposition

2.2. Characterization of the Coatings

2.2.1. Chemical and Structural Analysis

2.2.2. Nanoindentation and Micro-Scratch Tests

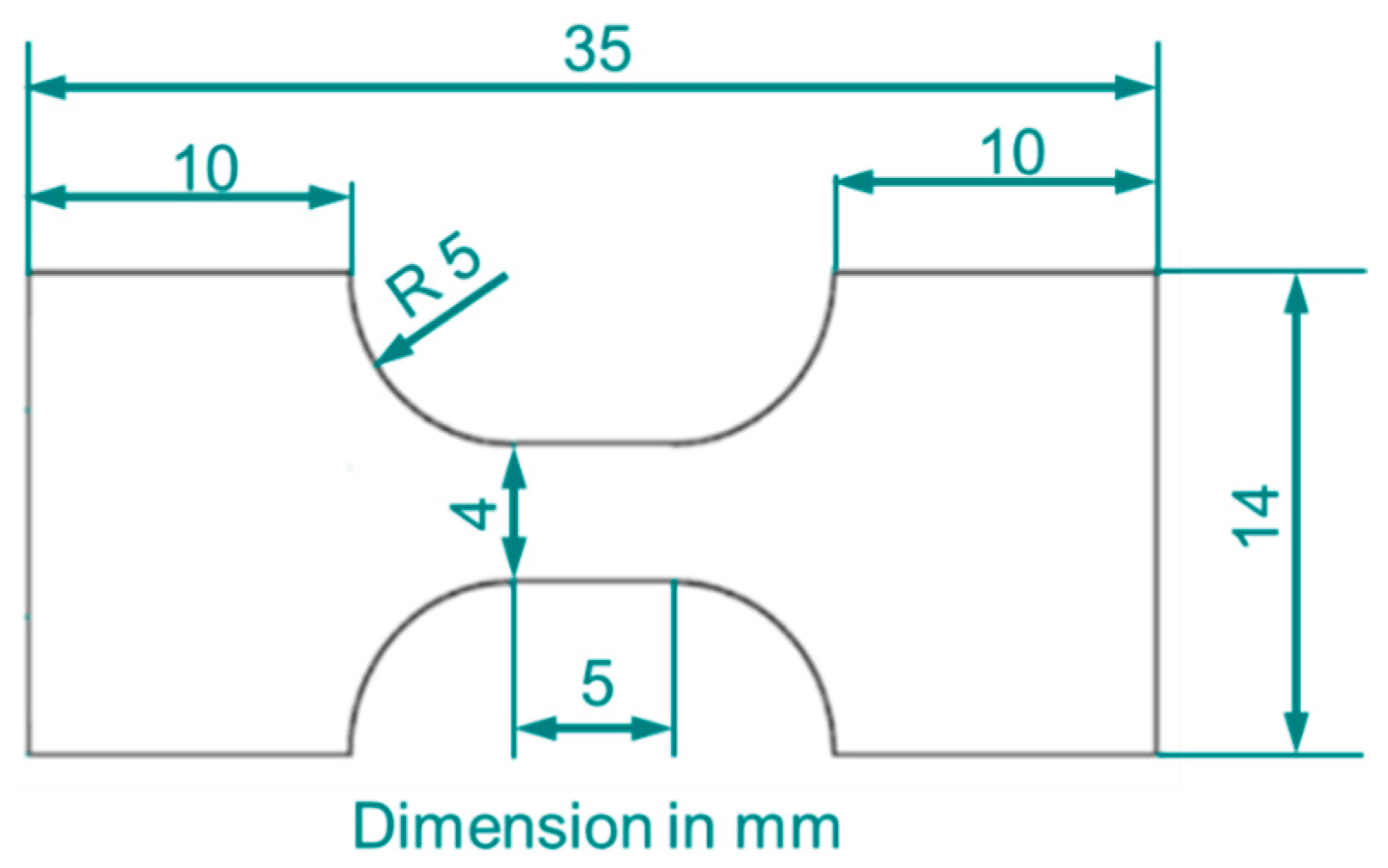

2.2.3. Tensile Test on Polymer Substrate

3. Results

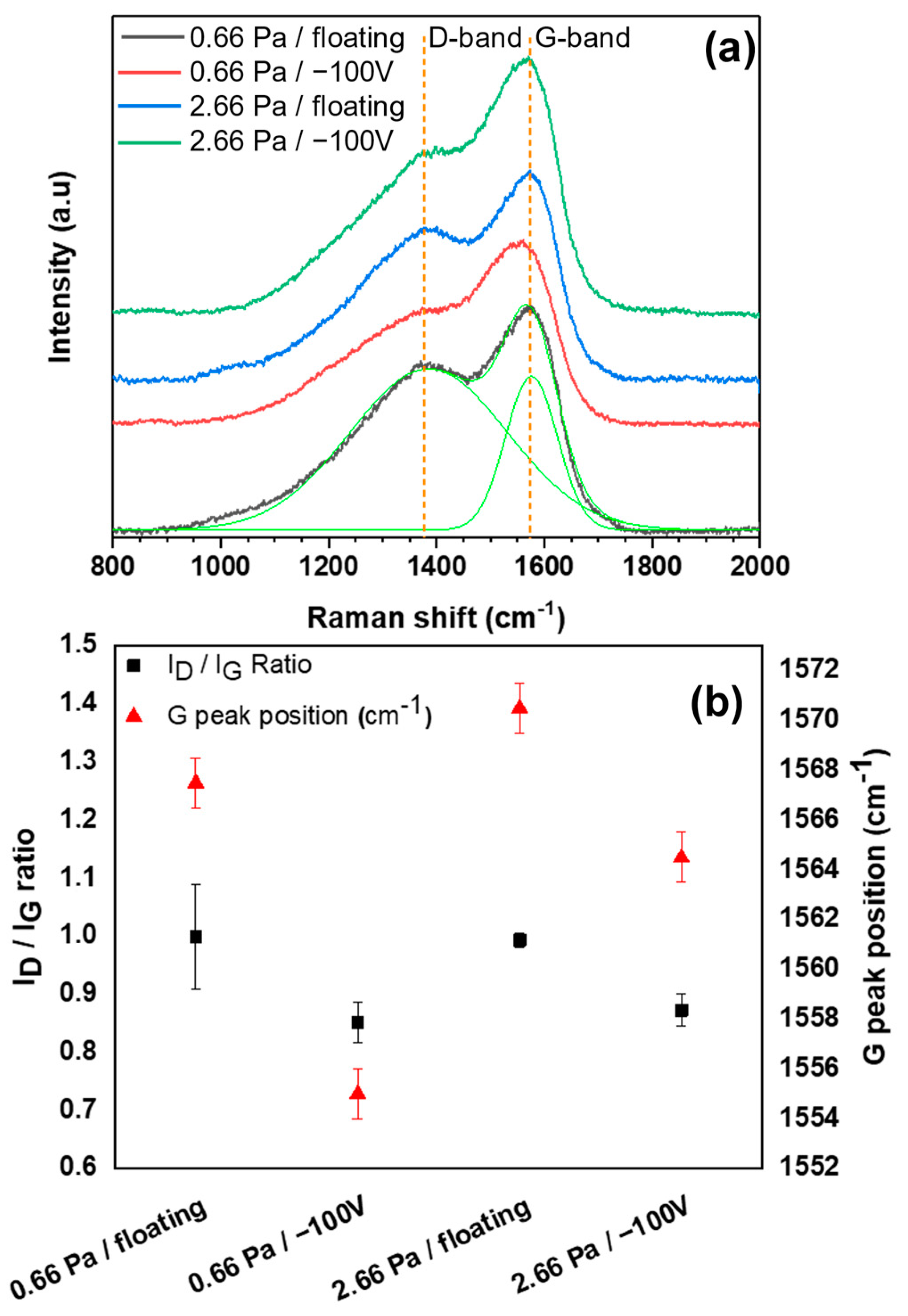

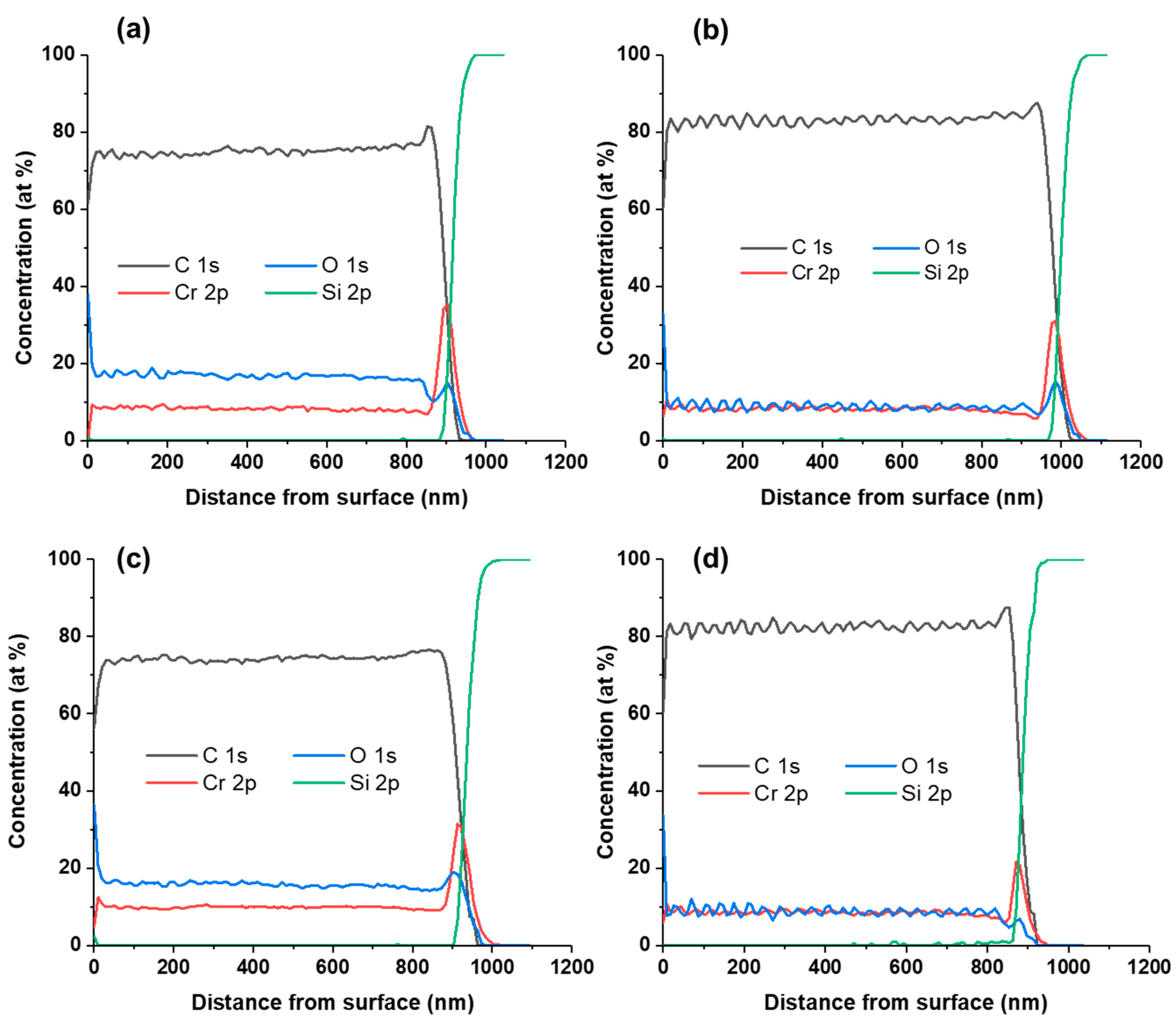

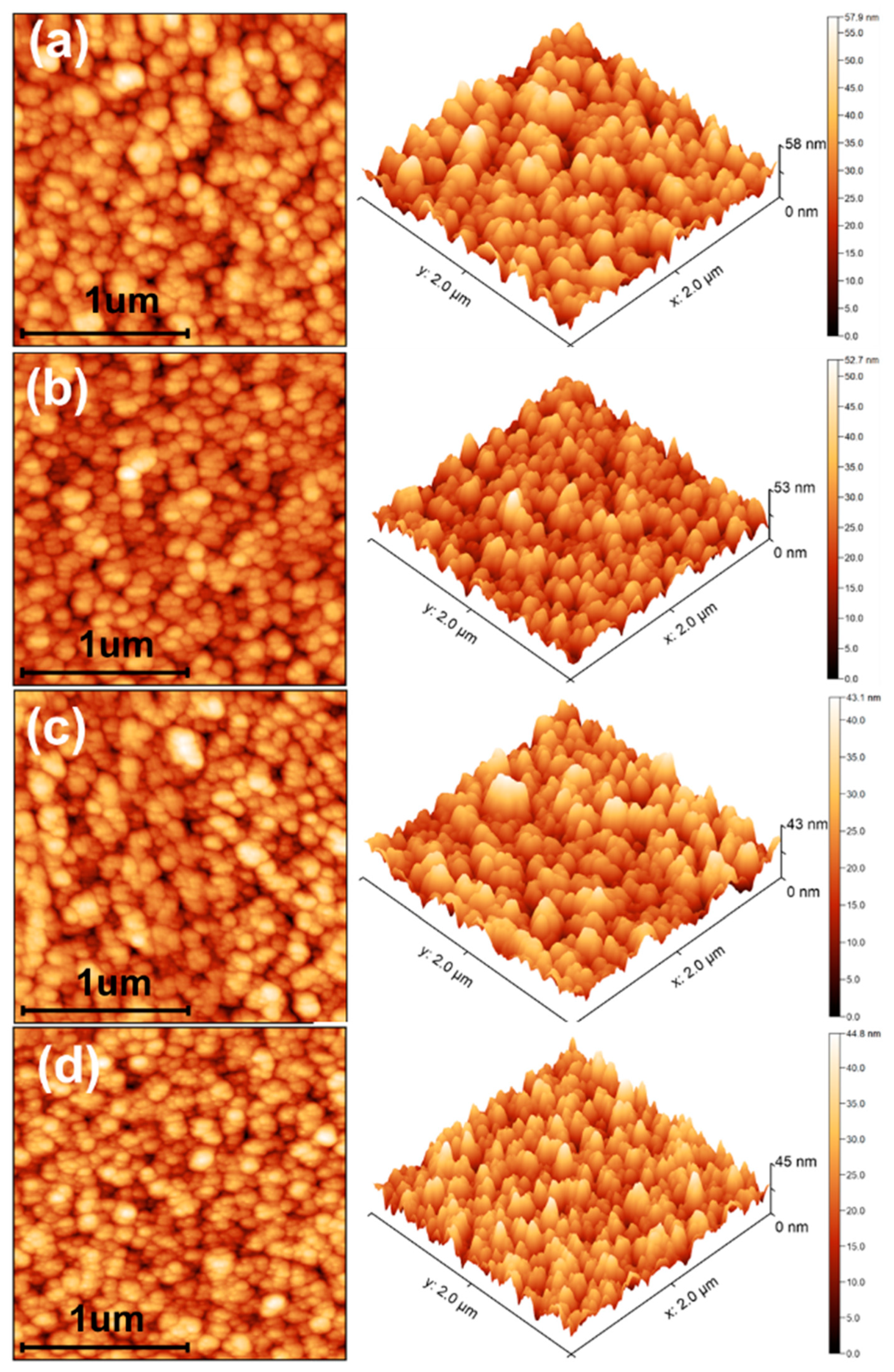

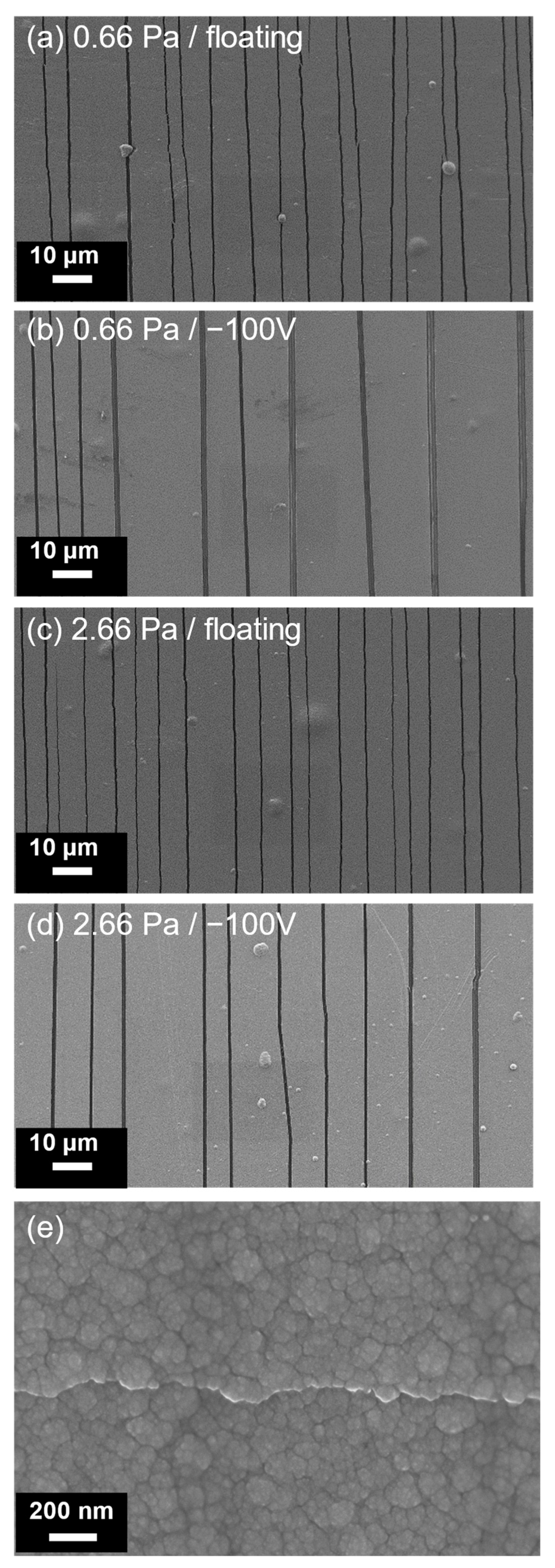

3.1. Structure, Composition and Surface Morphology

3.2. Mechanical and Tribological Properties

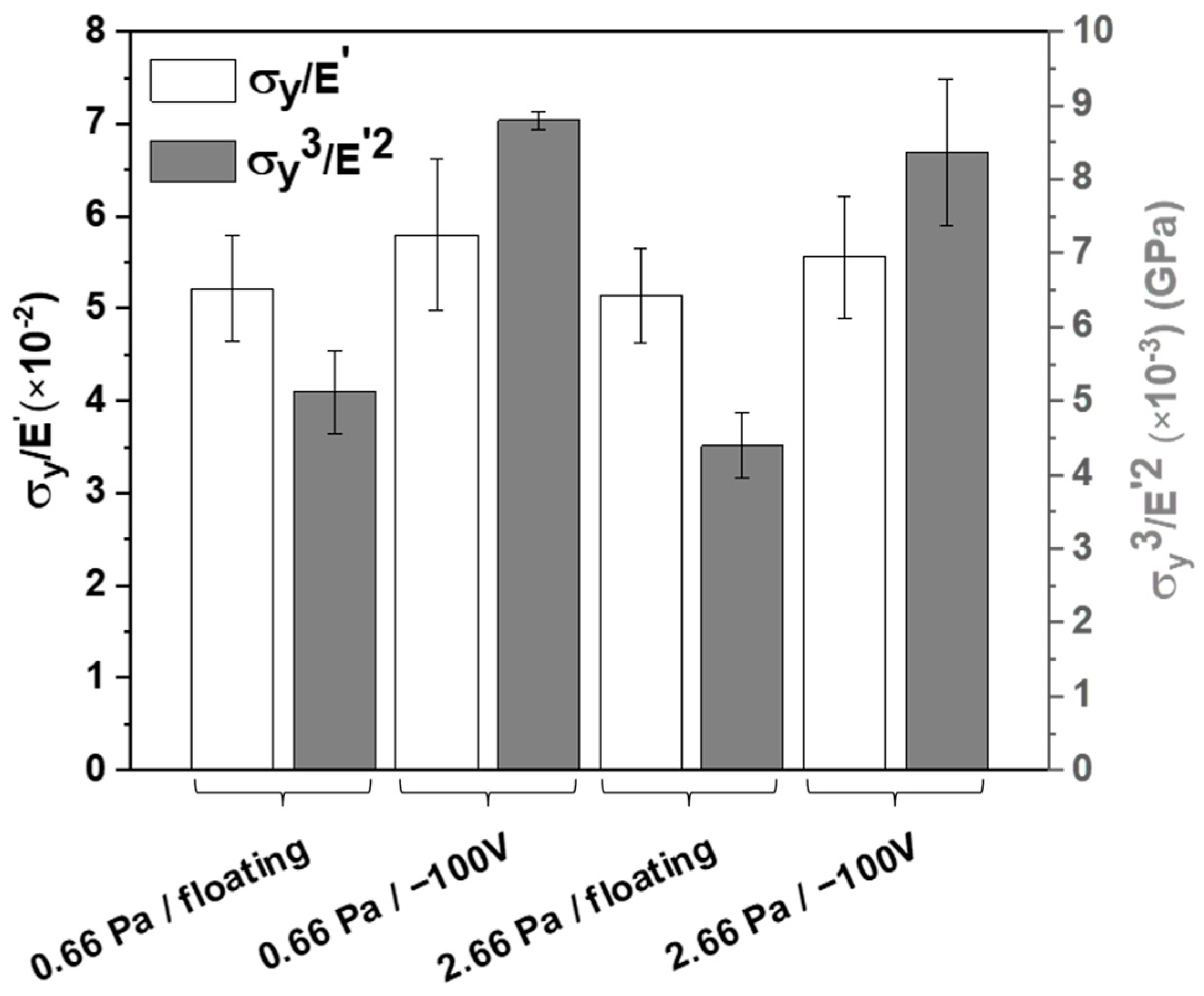

3.2.1. Nano-Indentation

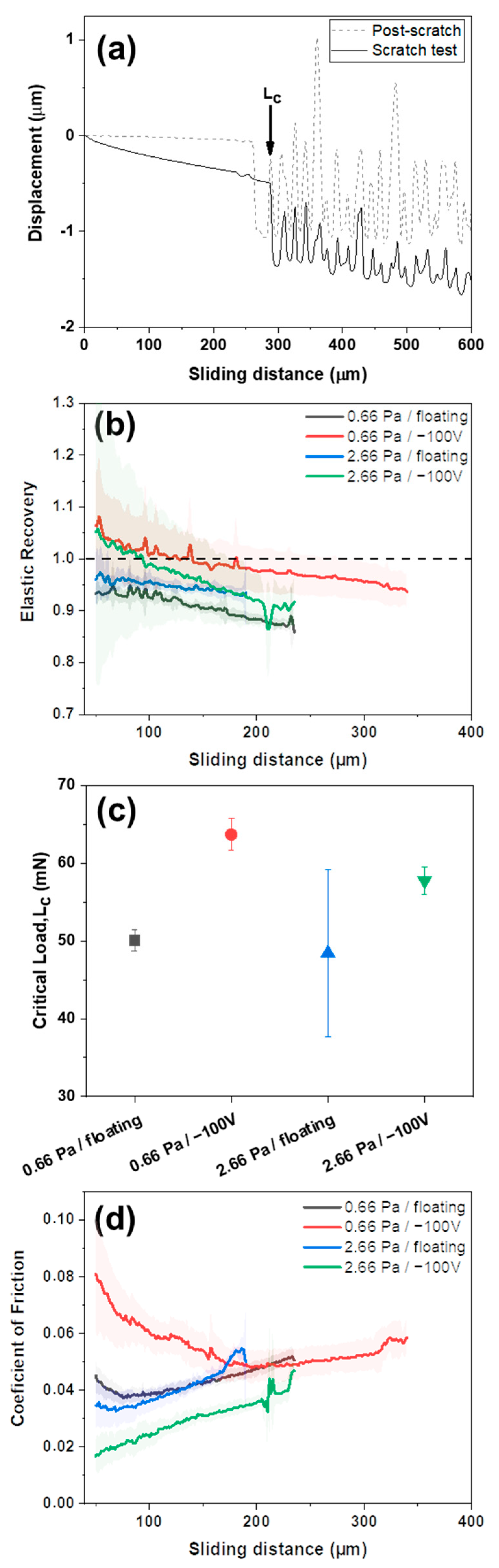

3.2.2. Wear Behavior

3.3. Uniaxial Tensile Tests

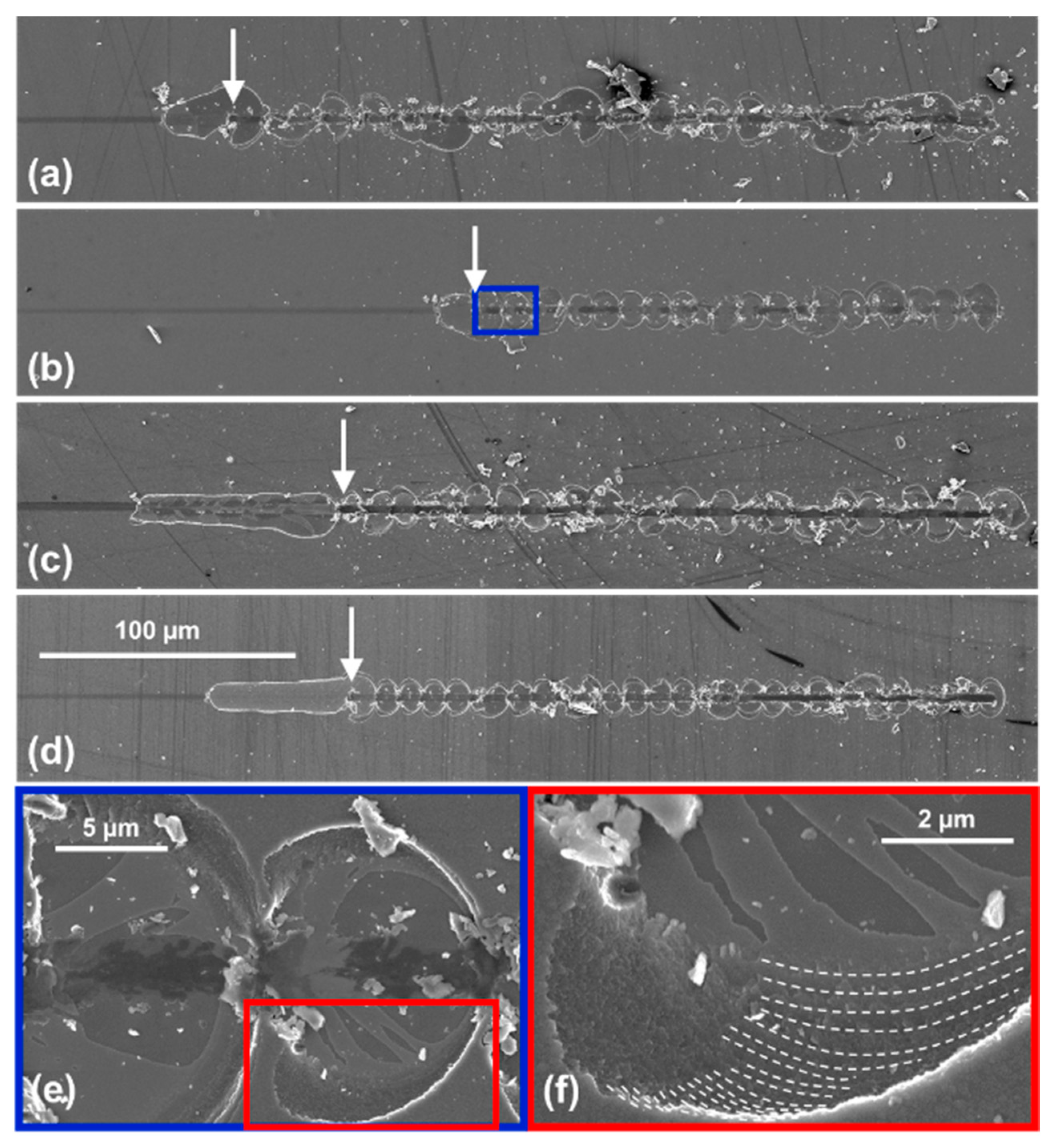

In-Situ SEM Tensile Tests

4. Discussion

4.1. Effect of Process Parameters on Hardness, Young’s Modulus, and Activation Volume

4.2. Effect of Process Parameters on Wear Resistance

4.3. Effect of Process Parameters on Fracture Behavior

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tillmann, W.; Dias, N.F.L.; Stangier, D.; Schaak, C.; Höges, S. Heat treatment of binder jet printed 17–4 PH stainless steel for subsequent deposition of tribo-functional diamond-like carbon coatings. Mater. Des. 2022, 213, 110304. [Google Scholar] [CrossRef]

- Chodun, R.; Skowronski, L.; Trzcinski, M.; Nowakowska-Langier, K.; Kulikowski, K.; Naparty, M.; Radziszewski, M.; Zdunek, K. The Amorphous Carbon Thin Films Synthesized by Gas Injection Magnetron Sputtering Technique in Various Gas Atmospheres. Coatings 2023, 13, 827. [Google Scholar] [CrossRef]

- Neuville, S. New application perspective for tetrahedral amorphous carbon coatings. QScience Connect 2014, 2014, 8. [Google Scholar] [CrossRef]

- Fróis, A.; Aleixo, A.S.; Evaristo, M.; Santos, A.C.; Louro, C.S. Can a-C:H-Sputtered Coatings Be Extended to Orthodontics? Coatings 2021, 11, 832. [Google Scholar] [CrossRef]

- Sedlaček, M.; Podgornik, B.; Vižintin, J. Tribological properties of DLC coatings and comparison with test results: Development of a database. Mater. Charact. 2008, 59, 151–161. [Google Scholar] [CrossRef]

- Conde, F.F.; Diaz, J.A.Á.; Da Silva, G.F.; Tschiptschin, A.P. Dependence of wear and mechanical behavior of nitrocarburized/Crn/Dlc layer on film thickness. Mater. Res. 2019, 22. [Google Scholar] [CrossRef]

- Tamulevičius, S.; Meškinis, Š.; Tamulevičius, T.; Rubahn, H.-G. Diamond like carbon nanocomposites with embedded metallic nanoparticles. Rep. Prog. Phys. 2018, 81, 024501. [Google Scholar] [CrossRef]

- Popescu, A.C.; Stan, G.E.; Duta, L.; Nita, C.; Popescu, C.; Surdu, V.-A.; Husanu, M.-A.; Bita, B.; Ghisleni, R.; Himcinschi, C.; et al. The Role of Ambient Gas and Pressure on the Structuring of Hard Diamond-Like Carbon Films Synthesized by Pulsed Laser Deposition. Materials 2015, 8, 3284–3305. [Google Scholar] [CrossRef]

- Dai, W.; Gao, X.; Liu, J.; Wang, Q. Microstructure, mechanical property and thermal stability of diamond-like carbon coatings with Al, Cr and Si multi-doping. Diam. Relat. Mater. 2016, 70, 98–104. [Google Scholar] [CrossRef]

- Zawischa, M.; Weihnacht, V.; Kaspar, J.; Zimmermann, M. Effect of doping elements to hydrogen-free amorphous carbon coatings on structure and mechanical properties with special focus on crack resistance. Mater. Sci. Eng. A 2022, 857, 144086. [Google Scholar] [CrossRef]

- Zia, A.W.; Zhou, Z.; Li, L.K.-Y. Structural, mechanical, and tribological characteristics of diamond-like carbon coatings. In Nanomaterials-Based Coatings; Elsevier: Amsterdam, The Netherlands, 2019; pp. 171–194. [Google Scholar] [CrossRef]

- Li, G.; Xu, Y.; Xia, Y. Effect of Cr Atom Plasma Emission Intensity on the Characteristics of Cr-DLC Films Deposited by Pulsed-DC Magnetron Sputtering. Coatings 2020, 10, 608. [Google Scholar] [CrossRef]

- Weicheng, K.; Kangmei, L.; Jun, H.; Structure, T.E.; Property, N. and Adhesive Force of Magnetron-Sputtered Cr-DLC Coating on a Nitrided Ti6Al4V Alloy. J. Phys. Chem. C 2021, 125, 16733–16745. [Google Scholar] [CrossRef]

- Cui, X.-J.; Ning, C.-M.; Shang, L.-L.; Zhang, G.-A.; Liu, X.-Q. Structure and Anticorrosion, Friction, and Wear Characteristics of Pure Diamond-Like Carbon (DLC), Cr-DLC, and Cr-H-DLC Films on AZ91D Mg Alloy. J. Mater. Eng. Perform. 2019, 28, 1213–1225. [Google Scholar] [CrossRef]

- Fauroux, A.; Vandenabeele, C.; Pflug, A.; Lucas, S. Experimental and theoretical study of a magnetron DC-PECVD acetylene discharge: Determination of the main species and reactions taking place in the plasma. Surf. Coat. Technol. 2020, 400, 126195. [Google Scholar] [CrossRef]

- Fauroux, A.; Pflug, A.; Lucas, S. Experimental and theoretical study of a magnetron DC-PECVD acetylene discharge: Identification of the deposition precursors and film growth mechanisms. Surf. Coat. Technol. 2021, 421, 127472. [Google Scholar] [CrossRef]

- Greczynski, G.; Hultman, L. Compromising Science by Ignorant Instrument Calibration—Need to Revisit Half a Century of Published XPS Data. Angew. Chem. 2020, 132, 5034–5038. [Google Scholar] [CrossRef]

- Greczynski, G.; Hultman, L. X-ray photoelectron spectroscopy: Towards reliable binding energy referencing. Prog. Mater. Sci. 2020, 107, 100591. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Hay, J.; Crawford, B. Measuring substrate-independent modulus of thin films. J. Mater. Res. 2011, 26, 727–738. [Google Scholar] [CrossRef]

- Gu, C.D.; Lian, J.S.; Jiang, Q.; Zheng, W.T. Experimental and modelling investigations on strain rate sensitivity of an electrodeposited 20 nm grain sized Ni. J. Phys. Appl. Phys. 2007, 40, 7440–7446. [Google Scholar] [CrossRef]

- Baral, P.; Orekhov, A.; Dohmen, R.; Coulombier, M.; Raskin, J.P.; Cordier, P.; Idrissi, H.; Pardoen, T. Rheology of amorphous olivine thin films characterized by nanoindentation. Acta Mater. 2021, 219, 117257. [Google Scholar] [CrossRef]

- Kim, K.; Luo, H.; Singh, A.K.; Zhu, T.; Graham, S.; Pierron, O.N. Environmentally Assisted Cracking in Silicon Nitride Barrier Films on Poly(ethylene terephthalate) Substrates. ACS Appl. Mater. Interfaces 2016, 8, 27169–27178. [Google Scholar] [CrossRef]

- Dundurs, J. Edge-bonded dissimilar orthogonal elastic wedges under normal and shear loading. J. Appl. Mech. Trans. ASME 1964, 36, 650–651. [Google Scholar] [CrossRef]

- Huang, R.; Prévost, J.H.; Huang, Z.Y.; Suo, Z. Channel-cracking of thin films with the extended finite element method. Eng. Fract. Mech. 2003, 70, 2513–2526. [Google Scholar] [CrossRef]

- Fu, K.; Chang, L.; Zheng, B.; Tang, Y.; Yin, Y. Analysis on cracking in hard thin films on a soft substrate under Berkovich indentation. Vacuum 2015, 112, 29–32. [Google Scholar] [CrossRef]

- Zhao, W.; Li, Y.; Wang, S.; He, X.; Shang, Y.; Peng, Q.; Wang, C.; Du, S.; Gui, X.; Yang, Y.; et al. Elastic improvement of carbon nanotube sponges by depositing amorphous carbon coating. Carbon 2014, 76, 19–26. [Google Scholar] [CrossRef]

- Ashby, M.F.; Greer, A.L. Metallic glasses as structural materials. Scr. Mater. 2006, 54, 321–326. [Google Scholar] [CrossRef]

- Wang, L.; Li, L.; Kuang, X. Effect of substrate bias on microstructure and mechanical properties of WC-DLC coatings deposited by HiPIMS. Surf. Coat. Technol. 2018, 352, 33–41. [Google Scholar] [CrossRef]

- Podgursky, V.; Alamgir, A.; Yashin, M.; Jõgiaas, T.; Viljus, M.; Raadik, T.; Danilson, M.; Sergejev, F.; Lümkemann, A.; Kluson, J.; et al. High-Temperature Tribological Performance of Al2O3/a-C:H:Si Coating in Ambient Air. Coatings 2021, 11, 495. [Google Scholar] [CrossRef]

- Bagherpour, A.; Haye, E.; Moskovkin, P.; Lucas, S. Vein pattern vs. columnar fracture shape in Cu-Zr thin film metallic glasses: Driving force and mechanism. Materialia 2023, 32, 101914. [Google Scholar] [CrossRef]

- Zhou, G.; Wang, L.; Wang, X.; Yu, Y.; Mutzke, A. Effect of bias voltage on microstructure and optical properties of Al2O3 thin films prepared by twin targets reactive high power impulse magnetron sputtering. Vacuum 2019, 166, 88–96. [Google Scholar] [CrossRef]

- Paul, A.; Lim, J.; Choi, K.; Lee, C. Effects of deposition parameters on the properties of chromium carbide coatings deposited onto steel by sputtering. Mater. Sci. Eng. A 2002, 332, 123–128. [Google Scholar] [CrossRef]

- Rohrbeck, M.; Körsten, S.; Fischer, C.B.; Wehner, S.; Kessler, B. Diamond-like carbon coating of a pure bioplastic foil. Thin Solid Films 2013, 545, 558–563. [Google Scholar] [CrossRef]

- Nix, W.D. Mechanical properties of thin films. Metall. Trans. A 1989, 20, 2217–2245. [Google Scholar] [CrossRef]

- Kermouche, G.; Loubet, J.L.; Bergheau, J.M. Extraction of stress–strain curves of elastic–viscoplastic solids using conical/pyramidal indentation testing with application to polymers. Mech. Mater. 2008, 40, 271–283. [Google Scholar] [CrossRef]

- van der Rest, A.; Idrissi, H.; Henry, F.; Favache, A.; Schryvers, D.; Proost, J.; Raskin, J.-P.; Van Overmeere, Q.; Pardoen, T. Mechanical behavior of ultrathin sputter deposited porous amorphous Al2O3 films. Acta Mater. 2017, 125, 27–37. [Google Scholar] [CrossRef]

- Argon, A.S. Inelastic behavior of non-polymeric glasses. Phys. Deform. Fract. Polym. 2013, 7, 174–227. [Google Scholar] [CrossRef]

- Geng, X.; Zhang, Z.; Barthel, E.; Dalmas, D. Mechanical behavior of stiff coating on glass under sliding contact. Wear 2010, 269, 351–361. [Google Scholar] [CrossRef]

- Freund, L.; Suresh, S. Thin Film Materials: Stress, Defect Formation and Surface Evolution. 2004. Available online: https://books.google.com/books?hl=en&lr=&id=9UNnzNYAkboC&oi=fnd&pg=PR16&dq=Freund+LB,+Suresh+S+(2003)+Thin+film+materials:+stress,+defect+formation,+and+surface+evolution.+Cambridge+University+Press,+Cambridge&ots=Ne0GJvVSvI&sig=j8MK9hv_e10_g9S6pWP0JchjwRc (accessed on 20 November 2023).

- Wei, X.; Chen, X.; Ren, X.; Lu, Q.; Zhang, L.; Wang, F. Polymeric amorphous carbon films with high hardness. Diam. Relat. Mater. 2017, 73, 253–259. [Google Scholar] [CrossRef]

- Kassavetis, S.N.; Logothetidis, S.; Matenoglou, G.M. Near-surface mechanical properties and surface morphology of hydrogenated amorphous carbon thin films. Surf. Coat. Technol. 2006, 200, 6400–6404. [Google Scholar] [CrossRef]

- Brande, P.V.; Lucas, S.; Winand, R.; Weymeersch, A.; Renard, L. Determination of the chemical and physical properties of hydrogenated carbon deposits produced by d.c. magnetron reactive sputtering. Surf. Coat. Technol. 1994, 68–69, 656–661. [Google Scholar] [CrossRef]

- De Vriendt, V.; Maseri, F.; Nonet, A.; Lucas, S. Study of Nanoparticles Formation in a Pulsed Magnetron Discharge in Acetylene. Plasma Process. Polym. 2009, 6, S6–S10. [Google Scholar] [CrossRef]

- Ji, M.; Jagodar, A.; Kovacevic, E.; Benyahia, L.; Poncin-Epaillard, F. Characterization of functionalized coatings prepared from pulsed plasma polymerization. Mater. Chem. Phys. 2021, 267, 124621. [Google Scholar] [CrossRef]

- Peng, J.; Liao, J.; Zhang, G.; Huang, J.; Qiu, X. Microstructure evolution and mechanical performance of tetrahedral amorphous carbon coatings with dense droplets during annealing. Mater. Chem. Phys. 2023, 301, 127697. [Google Scholar] [CrossRef]

- Wang, J.P.; Tan, L.P.; Liew, T.Y.F.; Low, T.S.; Wong, H.L.; Lee, Y.K. Effects of DC Bias on the Thermal Stability of DC In-Line Sputtered CoCrTa/Cr Thin Film Media. MRS Proc. 1998, 517, 273. [Google Scholar] [CrossRef]

- Harrison, W.A. Electronic Structure and the Properties of Solids: The Physics of the Chemical Bond; Courier Corporation: Washington, DC, USA, 2012. [Google Scholar]

- Bhushan, B. Chemical, mechanical and tribological characterization of ultra-thin and hard amorphous carbon coatings as thin as 3.5 nm: Recent developments. Diam. Relat. Mater. 1999, 8, 1985–2015. [Google Scholar] [CrossRef]

- Dai, W.; Shi, Y. Effect of Bias Voltage on Microstructure and Properties of Tantalum Nitride Coatings Deposited by RF Magnetron Sputtering. Coatings 2021, 11, 911. [Google Scholar] [CrossRef]

- Bruno, P.; Cicala, G.; Losacco, A.M.; Decuzzi, P. Mechanical properties of PECVD hydrogenated amorphous carbon coatings via nanoindentation and nanoscratching techniques. Surf. Coat. Technol. 2004, 180–181, 259–264. [Google Scholar] [CrossRef]

- Lu, X.; Li, M.; Tang, X.; Lee, J. Micromechanical properties of hydrogenated diamond-like carbon multilayers. Surf. Coat. Technol. 2006, 201, 1679–1684. [Google Scholar] [CrossRef]

- Constantinou, M.; Nikolaou, P.; Koutsokeras, L.; Avgeropoulos, A.; Moschovas, D.; Varotsis, C.; Patsalas, P.; Kelires, P.; Constantinides, G. Metal (Ag/Ti)-Containing Hydrogenated Amorphous Carbon Nanocomposite Films with Enhanced Nanoscratch Resistance: Hybrid PECVD/PVD System and Microstructural Characteristics. Nanomaterials 2018, 8, 209. [Google Scholar] [CrossRef]

- Nißen, S.; Heeg, J.; Wienecke, M.; Behrend, D.; Warkentin, M. Enhancing adhesion strength of a-C:H:Cu composite coatings on Ti6Al4V by graded copper deposition in a rf-PVD/PECVD hybrid process. Surf. Coat. Technol. 2018, 350, 659–671. [Google Scholar] [CrossRef]

- Beake, B.D.; Liskiewicz, T.W.; Vishnyakov, V.M.; Davies, M.I. Development of DLC coating architectures for demanding functional surface applications through nano- and micro-mechanical testing. Surf. Coat. Technol. 2015, 284, 334–343. [Google Scholar] [CrossRef]

- Lemoine, P.; Quinn, J.P.; Maguire, P.; McLaughlin, J.A. Comparing hardness and wear data for tetrahedral amorphous carbon and hydrogenated amorphous carbon thin films. Wear 2004, 257, 509–522. [Google Scholar] [CrossRef]

- Chen, Q.; Zeng, C.; Xu, M.; Yuan, H.; Lv, H.; Wang, Z.; Wang, X. Effect of SiNx interlayer thickness on adhesion and friction properties of diamond-like carbon films. Diam. Relat. Mater. 2019, 94, 186–193. [Google Scholar] [CrossRef]

- Beake, B.D.; Lau, S.P. Nanotribological and nanomechanical properties of 5–80 nm tetrahedral amorphous carbon films on silicon. Diam. Relat. Mater. 2005, 14, 1535–1542. [Google Scholar] [CrossRef]

- Beake, B.D.; Goodes, S.R.; Shi, B. Nanomechanical and nanotribological testing of ultra-thin carbon-based and MoST films for increased MEMS durability. J. Phys. Appl. Phys. 2009, 42, 065301. [Google Scholar] [CrossRef]

- Idrissi, H.; Ghidelli, M.; Béché, A.; Turner, S.; Gravier, S.; Blandin, J.-J.; Raskin, J.-P.; Schryvers, D.; Pardoen, T. Atomic-scale viscoplasticity mechanisms revealed in high ductility metallic glass films. Sci. Rep. 2019, 9, 13426. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.X.; Zhang, S.; Lee, J.W.; Lew, W.S.; Li, B. Influence of bias voltage on the hardness and toughness of CrAlN coatings via magnetron sputtering. Surf. Coat. Technol. 2012, 206, 5103–5107. [Google Scholar] [CrossRef]

- Ghidelli, M.; Gravier, S.; Blandin, J.J.; Djemia, P.; Mompiou, F.; Abadias, G.; Raskin, J.P.; Pardoen, T. Extrinsic mechanical size effects in thin ZrNi metallic glass films. Acta Mater. 2015, 90, 232–241. [Google Scholar] [CrossRef]

- Treml, R.; Kozic, D.; Schöngrundner, R.; Kolednik, O.; Gänser, H.-P.; Brunner, R.; Kiener, D. Miniaturized fracture experiments to determine the toughness of individual films in a multilayer system. Extrem. Mech. Lett. 2016, 8, 235–244. [Google Scholar] [CrossRef]

- Yang, L.W.; Mayer, C.R.; Chawla, N.; LLorca, J.; Molina-Aldareguía, J.M. Nanomechanical characterization of the fracture toughness of Al/SiC nanolaminates. Extrem. Mech. Lett. 2020, 40, 100945. [Google Scholar] [CrossRef]

- Triani, G.; Campbell, J.A.; Evans, P.J.; Davis, J.; Latella, B.A.; Burford, R.P. Low temperature atomic layer deposition of titania thin films. Thin Solid Films. 2010, 518, 3182–3189. [Google Scholar] [CrossRef]

- Hirakata, H.; Nishijima, O.; Fukuhara, N.; Kondo, T.; Yonezu, A.; Minoshima, K. Size effect on fracture toughness of freestanding copper nano-films. Mater. Sci. Eng. A 2011, 528, 8120–8127. [Google Scholar] [CrossRef]

- Jungk, J.M.; Boyce, B.L.; Buchheit, T.E.; Friedmann, T.A.; Yang, D.; Gerberich, W.W. Indentation fracture toughness and acoustic energy release in tetrahedral amorphous carbon diamond-like thin films. Acta Mater. 2006, 54, 4043–4052. [Google Scholar] [CrossRef]

- Merle, B.; Göken, M. Fracture toughness of silicon nitride thin films of different thicknesses as measured by bulge tests. Acta Mater. 2011, 59, 1772–1779. [Google Scholar] [CrossRef]

- Jonnalagadda, K.; Cho, S.W.; Chasiotis, I.; Friedmann, T.; Sullivan, J. Effect of intrinsic stress gradient on the effective mode-I fracture toughness of amorphous diamond-like carbon films for MEMS. J. Mech. Phys. Solids. 2008, 56, 388–401. [Google Scholar] [CrossRef]

- Hu, Y.; Huang, J.-H.; Zuo, J.-M. In situ characterization of fracture toughness and dynamics of nanocrystalline titanium nitride films. J. Mater. Res. 2016, 31, 370–379. [Google Scholar] [CrossRef]

- Chasiotis, I.; Cho, S.W.; Jonnalagadda, K. Fracture Toughness and Subcritical Crack Growth in Polycrystalline Silicon. J. Appl. Mech. 2005, 73, 714–722. [Google Scholar] [CrossRef]

- Hatty, V.; Kahn, H.; Heuer, A.H. Fracture Toughness, Fracture Strength, and Stress Corrosion Cracking of Silicon Dioxide Thin Film. J. Microelectromechanical Syst. 2008, 17, 943–947. [Google Scholar] [CrossRef]

- Han, S.Z.; Kang, J.; Kim, S.-D.; Choi, S.-Y.; Kim, H.G.; Lee, J.; Kim, K.; Lim, S.H.; Han, B. Reliable and cost effective design of intermetallic Ni2Si nanowires and direct characterization of its mechanical properties. Sci. Rep. 2015, 5, 15050. [Google Scholar] [CrossRef]

- Karimi, A.; Wang, Y.; Cselle, T.; Morstein, M. Fracture mechanisms in nanoscale layered hard thin films, Thin Solid Films. Thin Solid Films 2002, 420–421, 275–280. [Google Scholar] [CrossRef]

- Massl, S.; Thomma, W.; Keckes, J.; Pippan, R. Investigation of fracture properties of magnetron-sputtered TiN films by means of a FIB-based cantilever bending technique. Acta Mater. 2009, 57, 1768–1776. [Google Scholar] [CrossRef]

- Frank, S.; Handge, U.A.; Olliges, S.; Spolenak, R. The relationship between thin film fragmentation and buckle formation: Synchrotron-based in situ studies and two-dimensional stress analysis. Acta Mater. 2009, 57, 1442–1453. [Google Scholar] [CrossRef]

- Nasim, M.; Li, Y.; Wen, C. Length-scale dependent deformation, strengthening, and ductility of fcc/fcc Ni/Al nanolaminates using micropillar compression testing. Acta Mater. 2020, 193, 318–328. [Google Scholar] [CrossRef]

- Liu, Z.; Monclús, M.A.; Yang, L.W.; Castillo-Rodríguez, M.; Molina-Aldareguía, J.M.; LLorca, J. Tensile deformation and fracture mechanisms of Cu/Nb nanolaminates studied by in situ TEM mechanical tests. Extrem. Mech. Lett. 2018, 25, 60–65. [Google Scholar] [CrossRef]

- Preiß, E. Fracture Toughness of Freestanding Metallic Thin Films Studied by Bulge Testing: = Charakterisierung der Bruchzähigkeit freistehender metallischer Dünnschichten mittels Bulge-Experimenten; FAU University Press: Erlangen, Germany, 2018. [Google Scholar]

- Keunecke, M.; Bewilogua, K.; Becker, J.; Gies, A.; Grischke, M. CrC/a-C:H coatings for highly loaded, low friction applications under formulated oil lubrication. Surf. Coat. Technol. 2012, 207, 270–278. [Google Scholar] [CrossRef]

- Ronkainen, H.; Varjus, S.; Holmberg, K. Friction and wear properties in dry, water- and oil-lubricated DLC against alumina and DLC against steel contacts. Wear 1998, 222, 120–128. [Google Scholar] [CrossRef]

- Meunier, C.; Alers, P.; Marot, L.; Stauffer, J.; Randall, N.; Mikhailov, S. Friction properties of ta-C and a-C:H coatings under high vacuum. Surf. Coat. Technol. 2005, 200, 1976–1981. [Google Scholar] [CrossRef]

| Sample | Column Diameter (nm) | Surface RMS Roughness (nm) |

|---|---|---|

| 0.66 Pa/floating | 31.5 ± 2.6 | 7.8 ± 0.16 |

| 0.66 Pa/−100 V | 24.7 ± 0.7 | 6.2 ± 0.01 |

| 2.66 Pa/floating | 31.7 ± 1.6 | 6.7 ± 0.81 |

| 2.66 Pa/−100 V | 29.1 ± 1.6 | 6.2 ± 0.14 |

| H (GPa) | (GPa) | (GPa) | (mN) | ||

|---|---|---|---|---|---|

| 0.66. Pa/floating | 3.5 ± 0.4 | 36.2 ± 2.8 | 5.21 ± 0.57 | 5.12 ± 0.56 | 50 ± 1.3 |

| 0.66 Pa/−100 V | 4.7 ± 0.8 | 45.1 ± 4.3 | 5.80 ± 0.81 | 8.80 ± 0.12 | 63.7 ± 2.0 |

| 2.66 Pa/floating | 3.1 ± 0.4 | 32.3 ± 1.9 | 5.15 ± 0.51 | 4.40 ± 0.43 | 48.4 ± 10.7 |

| 2.66 Pa/−100 V | 4.9 ± 0.7 | 48.7 ± 3.9 | 5.60 ± 0.65 | 8.37 ± 0.99 | 57.7 ± 1.2 |

(µm−1) | (J/m2) | (MPa·m1/2) | (nm) | |

|---|---|---|---|---|

| 0.66 Pa/floating | 0.128 ± 0.004 | 4.94 ± 0.04 | 0.42 ± 0.08 | 15.7 ± 0.82 |

| 0.66 Pa/−100 V | 0.049 ± 0.001 | 47.4 ± 0.83 | 1.46 ± 0.05 | 100.8 ± 1.08 |

| 2.66 Pa/floating | 0.173 ± 0.002 | 125 ± 5.63 | 2.01 ± 0.18 | 488.6 ± 2.68 |

| 2.66 Pa/−100 V | 0.1 ± 0.003 | 115 ± 2.95 | 2.37 ± 0.12 | 242.5 ± 1.55 |

| Sample | Precursor Gas/Source | Lc (mN) | |

|---|---|---|---|

| Ref. [51] | CH4 | 0.124–0.134 | 33–64 |

| Ref. [52] | CH4 | 0.11–0.16 | 43–120 |

| Ref. [53] | CH4 | - | 18.2–23.5 |

| Ref. [54] | C2H2 | 0.041–0.086 | 36–75 |

| Ref. [55] | C2H2 | 0.081 | 68 |

| Ref. [56] | C2H2 | 0.067 | 2.13 |

| Ref. [57] | Graphite | 0.14 | 6 |

| Ref. [58] | Graphite | ≈0.083 | 1.9–5 |

| Ref. [59] | Graphite | ≈0.081 | 40 |

| Our study | C2H2 | 0.09–0.1 | 48–64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bagherpour, A.; Baral, P.; Colla, M.-S.; Orekhov, A.; Idrissi, H.; Haye, E.; Pardoen, T.; Lucas, S. Tailoring Mechanical Properties of a-C:H:Cr Coatings. Coatings 2023, 13, 2084. https://doi.org/10.3390/coatings13122084

Bagherpour A, Baral P, Colla M-S, Orekhov A, Idrissi H, Haye E, Pardoen T, Lucas S. Tailoring Mechanical Properties of a-C:H:Cr Coatings. Coatings. 2023; 13(12):2084. https://doi.org/10.3390/coatings13122084

Chicago/Turabian StyleBagherpour, Alireza, Paul Baral, Marie-Stéphane Colla, Andrey Orekhov, Hosni Idrissi, Emile Haye, Thomas Pardoen, and Stéphane Lucas. 2023. "Tailoring Mechanical Properties of a-C:H:Cr Coatings" Coatings 13, no. 12: 2084. https://doi.org/10.3390/coatings13122084

APA StyleBagherpour, A., Baral, P., Colla, M.-S., Orekhov, A., Idrissi, H., Haye, E., Pardoen, T., & Lucas, S. (2023). Tailoring Mechanical Properties of a-C:H:Cr Coatings. Coatings, 13(12), 2084. https://doi.org/10.3390/coatings13122084