Enhanced Tribological Performance of Micro-Beam Plasma-Cladded Ni60 Coatings with Addition of Mo and Ag Lubricants in a Wide Temperature Range

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

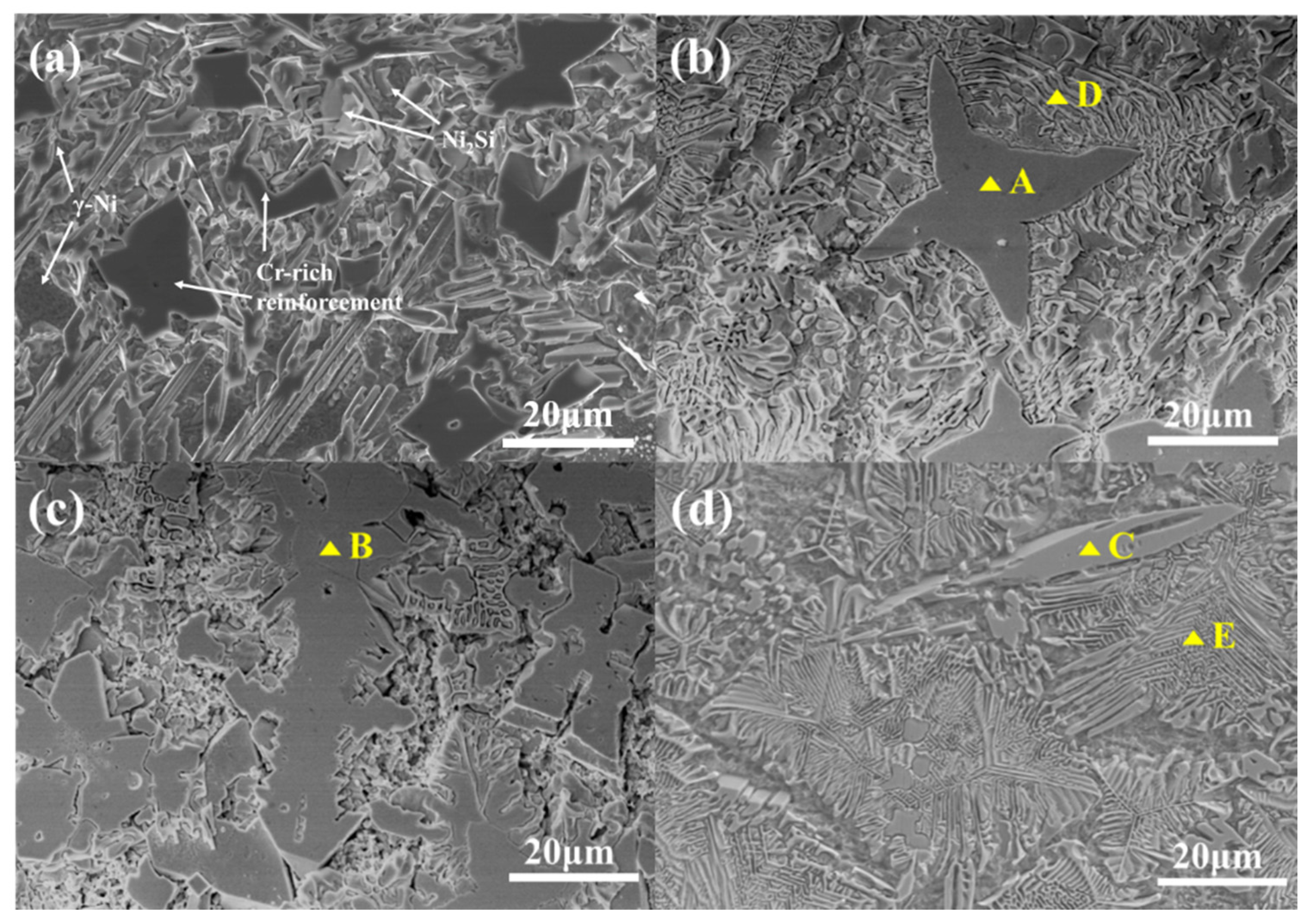

3.1. Microstructures

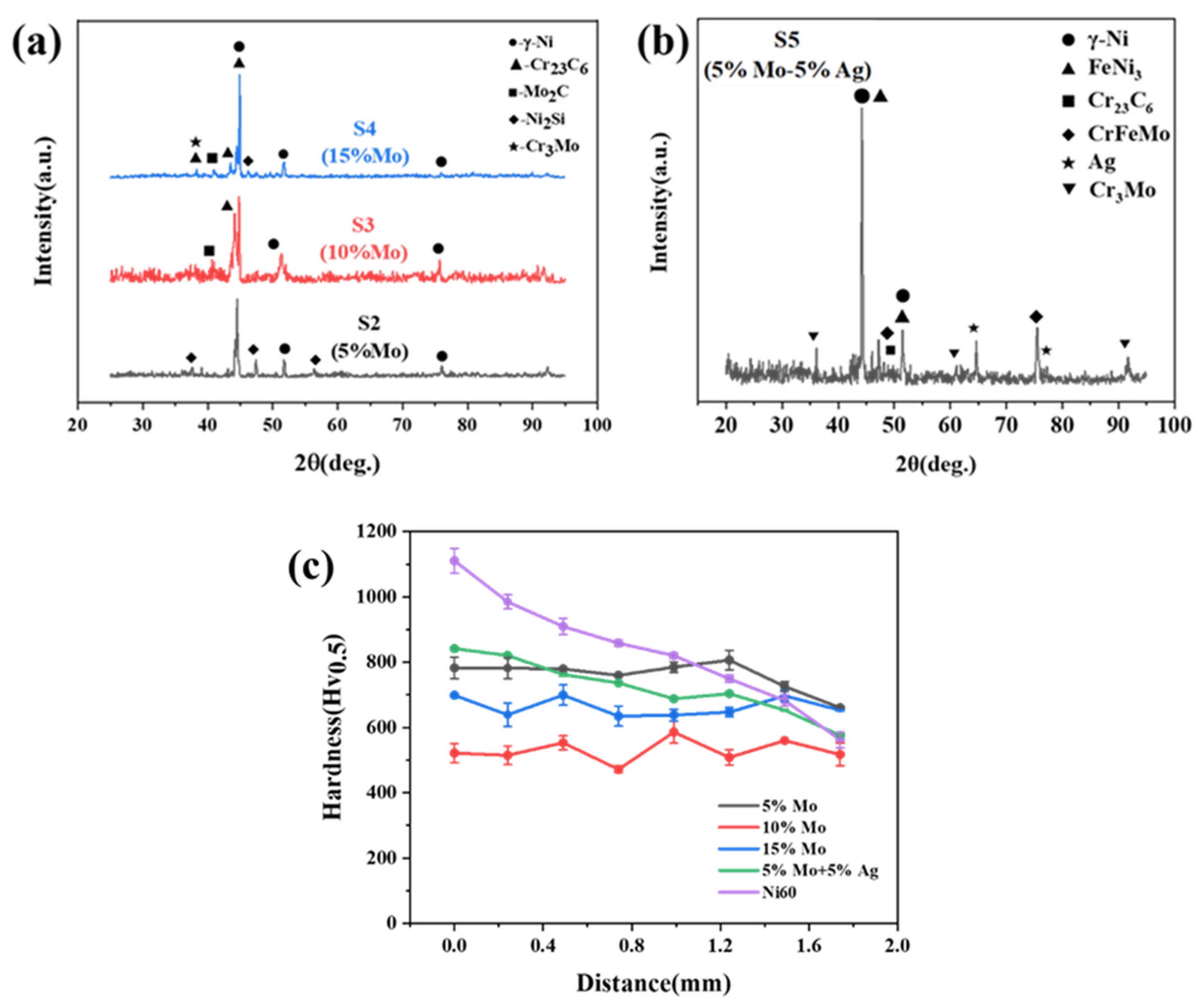

3.2. Hardness

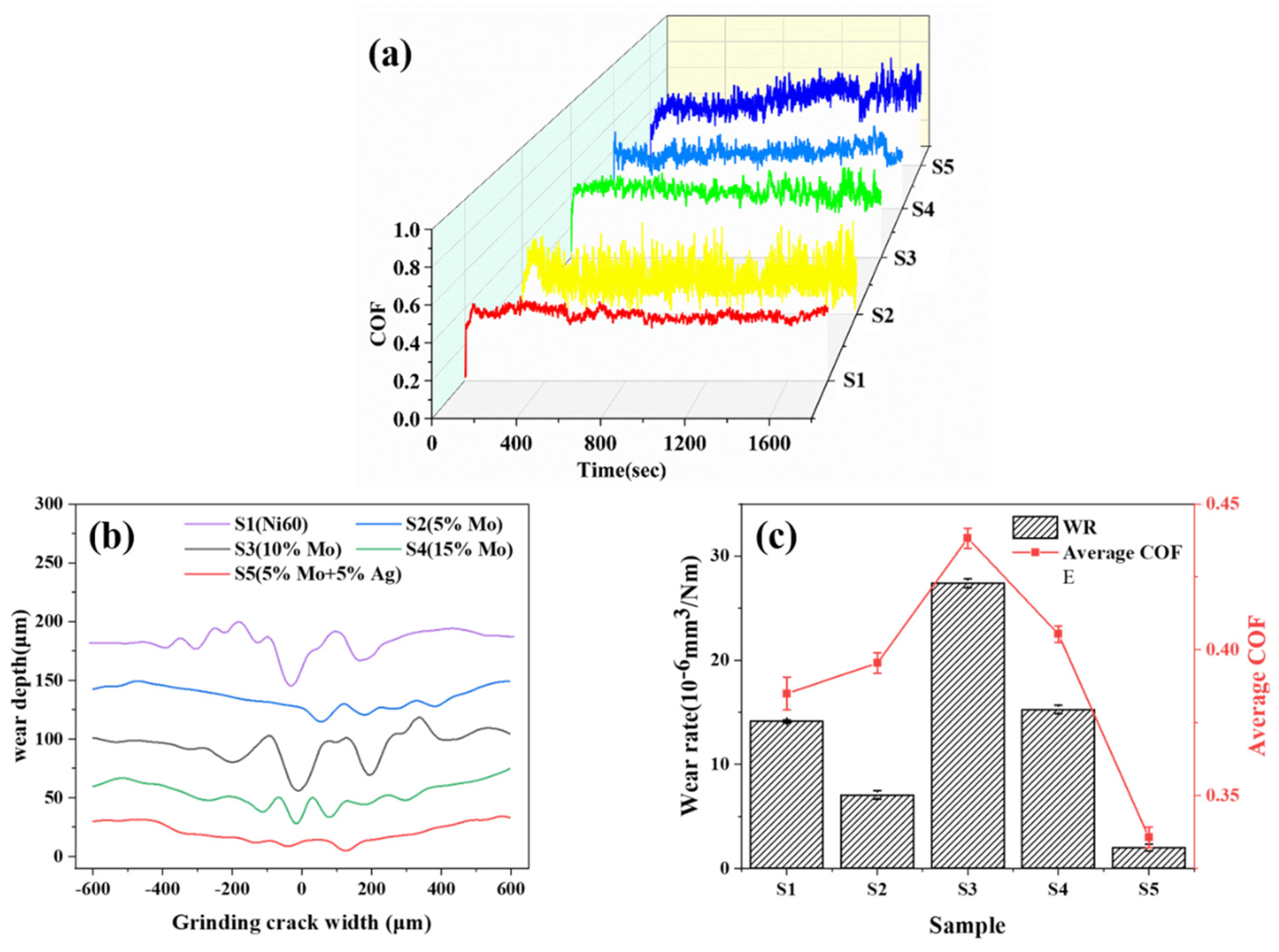

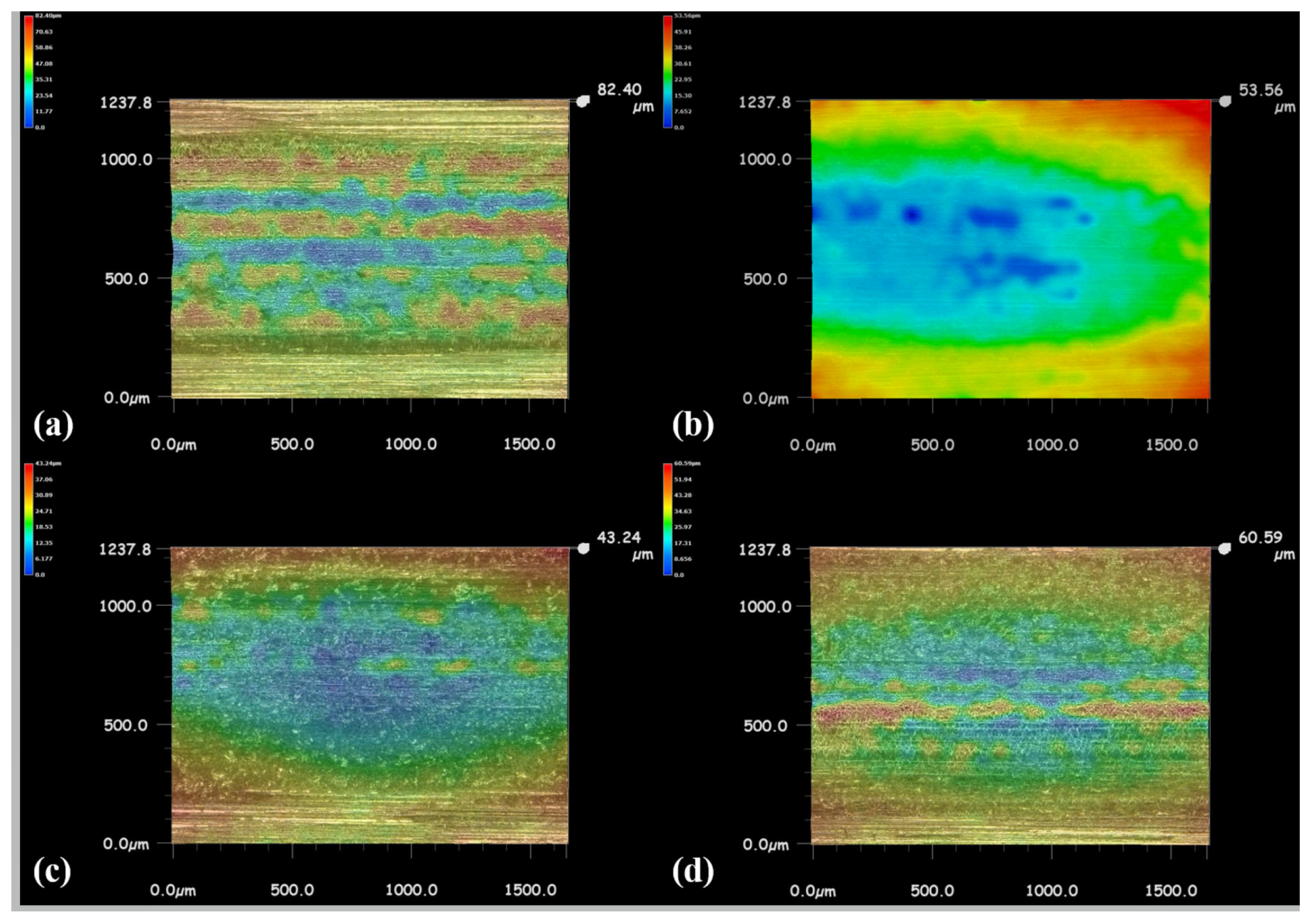

3.3. Tribological Properties

4. Conclusions

- Cladding layers prepared using the micro-beam plasma technique achieved metallurgical bonding with the substrate. This study has potential limitations. We did not take welding defects into full consideration, especially impurities, micro-cracks, and porosities. The presence of welding defects significantly affects the quality of the cladding layer. However, such defects are rarely observed in the cladding layers of micro-beam plasma welding, and the quality of the weld is partly ensured.

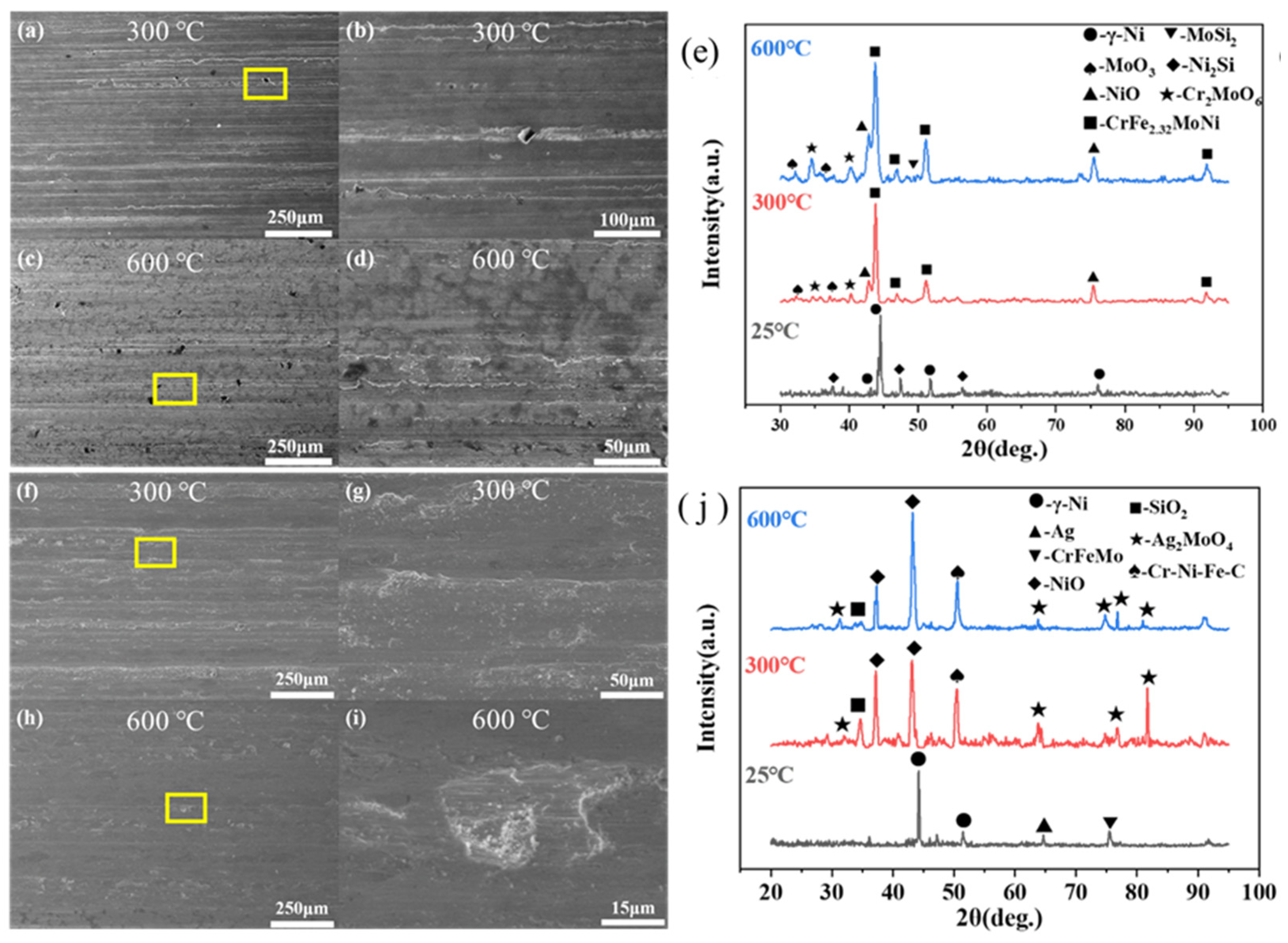

- The coefficient of friction of the coating layer exhibited regular variations at elevated temperatures upon the moderate addition of Mo. At 300 °C, MoO3 and Cr2MoO6 were formed in S2 as solid lubricants, contributing to high-temperature self-lubrication. However, the generation of MoSi2 leads to an increase in adhesion wear at 600 °C. The cladding layers exhibited lower COF and wear rate after adding an additional Ag element. The newly formed composite cladding layer underwent a transformation at elevated temperatures, resulting in the development of a layered cubic spinel structure composed of Ag2MoO4. The preferential break of low-energy Ag-O bonded during the friction process enables excellent lubrication performance through sliding between these layers.

- Modern aerospace, weapons, and other manufacturing industries have a great demand for mechanical moving parts in a wide temperature range while having good lubricity and wear resistance of the material and its preparation technology. The Ni-based coatings with excellent friction properties and lubrication performance in the study have great potential in these fields, such as high-temperature air bearings, gas turbine seals, low heat dissipation diesel engine piston rings, and cylinder wall lubrication.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, N.; Liu, Q.; Li, Z.; Bai, Y.; Sun, Y.W.; Li, Z.D. Tribological behavior of plasma-sprayed metal based solid self-lubricating coatings under heavy load. Wear 2021, 486–487, 204108. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar Banga, H.; Singh, H.; Kundal, S. An outline on modern day applications of solid lubricants. Mater. Today Proc. 2020, 28, 1962–1967. [Google Scholar] [CrossRef]

- Nguyen, C.; Tieu, A.K.; Deng, G.; Wexler, D.; Vo, T.D.; Wang, L. Tribological performance of a cost-effective CrFeNiAl0.3Ti0.3 high entropy alloy based self-lubricating composite in a wide temperature range. Tribol. Int. 2022, 174, 107743. [Google Scholar] [CrossRef]

- Bian, S.; Yu, L.; Xu, J.; Xu, J. Impact of Ag on the microstructure and tribological behaviors of adaptive ZrMoN–Ag composite lubricating films. J. Mater. Res. Technol. 2022, 19, 2346–2355. [Google Scholar] [CrossRef]

- Geng, Y.; Tan, H.; Cheng, J.; Chen, J.; Sun, Q.; Zhu, S. Microstructure, mechanical and vacuum high temperature tribological properties of AlCoCrFeNi high entropy alloy based solid-lubricating composites. Tribol. Int. 2020, 151, 106444. [Google Scholar] [CrossRef]

- Geng, Y.; Chen, J.; Tan, H.; Cheng, J.; Zhu, S.; Yang, J. Tribological performances of CoCrFeNiAl high entropy alloy matrix solid-lubricating composites over a wide temperature range. Tribol. Int. 2021, 151, 106912. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, J.; Yu, Y.; Guo, C.; Chen, J. Effect of powders refinement on the tribological behavior of Ni-based composite coatings by laser cladding. Appl. Surf. Sci. 2012, 258, 6697–6704. [Google Scholar] [CrossRef]

- Liu, J.; Yu, H.; Chen, C.; Weng, F.; Dai, J. Research and development status of laser cladding on magnesium alloys: A review. Opt. Lasers Eng. 2017, 93, 195–210. [Google Scholar] [CrossRef]

- Zhou, S.H.; Wang, Y.; Jiang, C.; Zhu, J.Z.; Chen, L.Q.; Liu, Z.K. First-principles calculations and thermodynamic modeling of the Ni–Mo system. Mater. Sci. Eng. A 2005, 397, 288–296. [Google Scholar] [CrossRef]

- Li, F.; Cheng, J.; Zhu, S.; Hao, J.; Yang, J.; Liu, W. Microstructure and mechanical properties of Ni-based high temperature solid-lubricating composites. Mater. Sci. Eng. A 2017, 682, 475–481. [Google Scholar] [CrossRef]

- Liu, X.B.; Liu, H.Q.; Liu, Y.F.; He, X.M.; Sun, C.F.; Wang, M.-D. Effects of temperature and normal load on tribological behavior of nickel-based high temperature self-lubricating wear-resistant composite coating. Compos. Part B Eng. 2013, 53, 347–354. [Google Scholar] [CrossRef]

- Li, F.; Cheng, J.; Qiao, Z.; Ma, J.; Zhu, S.; Fu, L. A Nickel-Alloy-Based High-Temperature Self-Lubricating Composite with Simultaneously Superior Lubricity and High Strength. Tribol. Lett. 2013, 49, 573–577. [Google Scholar] [CrossRef]

- Pinate, S.; Leisner, P.; Zanella, C. Wear resistance and self-lubrication of electrodeposited Ni-SiC: MoS2 mixed particles composite coatings. Surf. Coat. Technol. 2021, 421, 127400. [Google Scholar] [CrossRef]

- Liu, F.; Jia, J. Tribological Properties and Wear Mechanisms of NiCr–Al2O3–SrSO4–Ag Self-Lubricating Composites at Elevated Temperatures. Tribol. Lett. 2013, 49, 281–290. [Google Scholar] [CrossRef]

- Li, J.; Xiong, D.; Wu, H.; Dai, J.; Cui, T. Tribological properties of molybdenized silver-containing nickel base alloy at elevated temperatures. Tribol. Int. 2009, 42, 1722–1729. [Google Scholar] [CrossRef]

- Huang, X.Y.; Wang, J.H.; Zhang, H.Q.; Ren, J.; Zan, Q.F.; Gong, Q.M.; Wu, B. WC-Ni-Cr-based self-lubricating composites fabricated by pulsed electric current sintering with addition of WS2 solid lubricant. Int. J. Refract. Met. Hard Mater. 2017, 66, 158–162. [Google Scholar] [CrossRef]

- Ouyang, J.-H.; Liang, X.-S.; Liu, Z.-G.; Yang, Z.-L.; Wang, Y.-J. Friction and wear properties of hot-pressed NiCr–BaCr2O4 high temperature self-lubricating composites. Wear 2013, 301, 820–827. [Google Scholar] [CrossRef]

- Feng, S.; Zhou, X.; Zhang, Q. Tribological Behavior of Ni-based Self-lubricating Composites with the Addition of Ti3SiC2 and Ag2W2O7. J. Wuhan Univ. Technol.—Mater. Sci. Ed. 2019, 34, 698–706. [Google Scholar] [CrossRef]

- Yang, M.S.; Liu, X.B.; Fan, J.W.; He, X.M.; Shi, S.H.; Fu, G.Y. Microstructure and wear behaviors of laser clad NiCr/Cr3C2–WS2 high temperature self-lubricating wear-resistant composite coating. Appl. Surf. Sci. 2013, 258, 3757–3762. [Google Scholar] [CrossRef]

- Cheng, J.; Zhen, J.; Zhu, S.; Yang, J.; Ma, J.; Li, W. Friction and wear behavior of Ni-based solid-lubricating composites at high temperature in a vacuum environment. Mater. Des. 2017, 122, 405–413. [Google Scholar] [CrossRef]

- Morisada, Y.; Miyamoto, Y.; Takaura, Y.; Hirota, K.; Tamari, N. Mechanical properties of SiC composites incorporating SiC-coated multi-walled carbon nanotubes. Int. J. Refract. Met. Hard Mater. 2007, 25, 322–327. [Google Scholar] [CrossRef]

- Hareharen, K.; Pradeep Kumar, S.; Panneerselvam, T.; Dinesh Babu, P.; Sriraman, N. Investigating the effect of laser shock peening on the wear behaviour of selective laser melted 316L stainless steel. Opt. Laser Technol. 2023, 162, 1–13. [Google Scholar] [CrossRef]

- Fan, X.; Li, W.; Yang, J.; Zhu, S.; Cui, S.; Chen, B.; Zhai, H. Effect of MoO3 Content on Ni3Al-Ag-MoO3 Composite Coating Microstructure and Tribological Properties. Coatings 2023, 13, 624. [Google Scholar] [CrossRef]

- Gonela, K.K.; Vijayavarman, C.; Palanivel, M.; Mariappan, L.; Ramasubramanian, L.N.; Kannan, A.R. Effect of robotic weaving motion on mechanical and microstructural characteristics of wire arc additively manufactured NiTi shape memory alloy. Int. J. Mater. Res. 2022, 114, 10–11. [Google Scholar] [CrossRef]

- Wang, D.; Tan, H.; Chen, W.; Zhu, S.; Cheng, J.; Yang, J. Tribological behavior of Ni3Al–Ag based self-lubricating alloy with Ag2MoO4 formed by high temperature tribo-chemical reaction. Tribol. Int. 2021, 153, 106659. [Google Scholar] [CrossRef]

- Ye, F.; Lou, Z.; Wang, Y.; Liu, W. Wear mechanism of Ag as solid lubricant for wide range temperature application in micro-beam plasma cladded Ni60 coatings. Tribol. Int. 2022, 167, 107402. [Google Scholar] [CrossRef]

| Element | C | Cr | B | Si | Fe | Ni |

|---|---|---|---|---|---|---|

| Composition | 0.78 | 15.90 | 1.90 | 4.55 | 5.00 | balance |

| No. | Mo | Ni60 | Ag |

|---|---|---|---|

| S1 | - | 100 | - |

| S2 | 5 | 95 | - |

| S3 | 10 | 90 | - |

| S4 | 15 | 85 | - |

| S5 | 5 | 90 | 5 |

| Welding Velocity v/(mm·s−1) | Current I/A | Shielding Gas Flow F/(L·min−1) | Plasma Gas Pressure P/(MPa) |

|---|---|---|---|

| 0.6 | 30 | 15 | 0.4 |

| Temperature (°C) | Applied Load (N) | Frequency (Hz) | Stroke Length (mm) | Testing Time (min) |

|---|---|---|---|---|

| 25, 300, 600 | 20 | 5 | 10 | 30 |

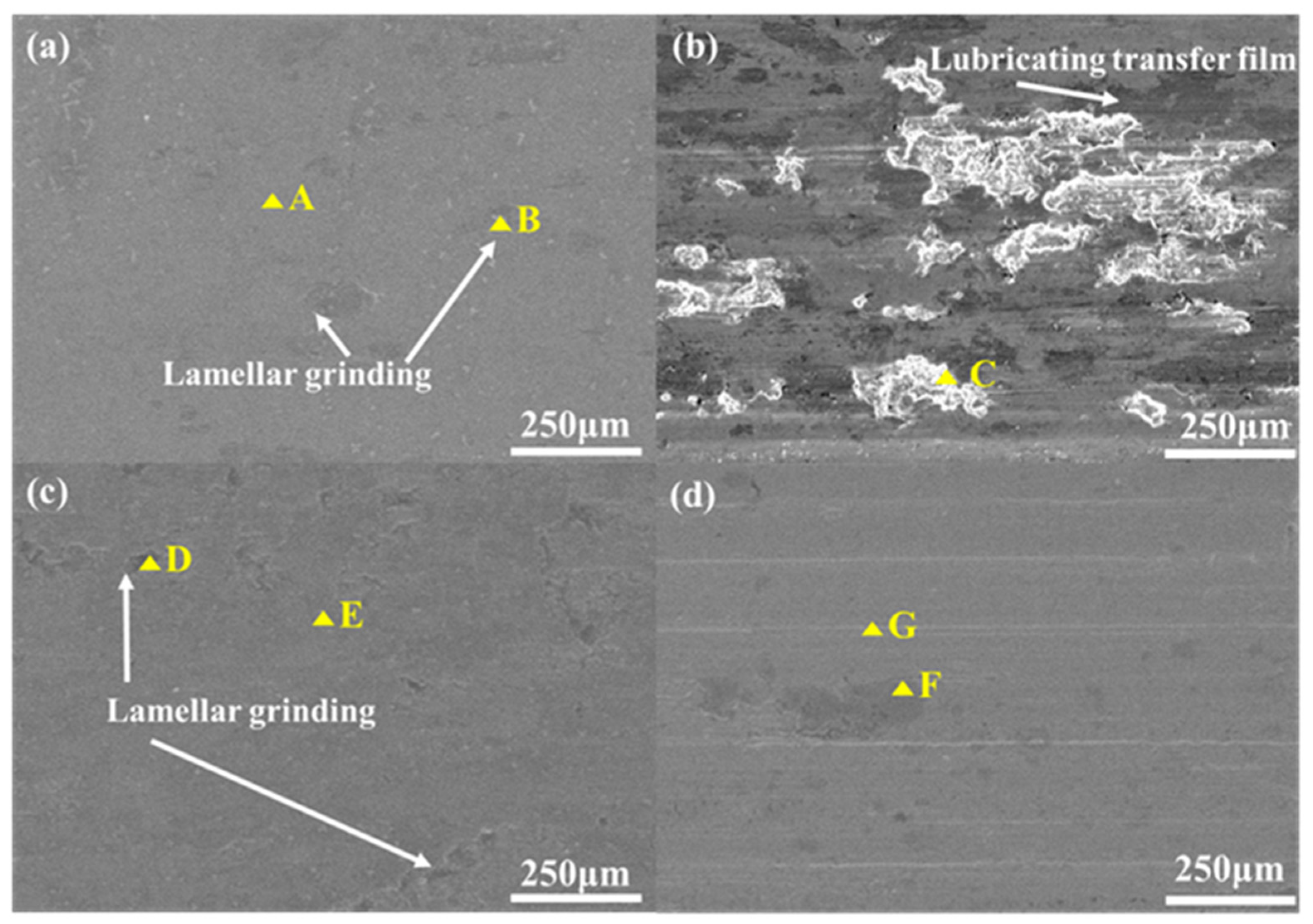

| Position | Ni | Cr | Fe | Mo | Si | C |

|---|---|---|---|---|---|---|

| A | 6.94 | 36.35 | 9.34 | 28.69 | - | 18.68 |

| B | 8.78 | 32.03 | 2.63 | 34.18 | - | 22.39 |

| C | 4.27 | 41.23 | 15.87 | 3.95 | - | 33.10 |

| D | 57.20 | 4.93 | 18.28 | - | 6.92 | 12.67 |

| E | 44.42 | 16.73 | 30.35 | 4.90 | 3.70 | - |

| No. | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|

| Average COF | 0.3850 | 0.4008 | 0.4355 | 0.4004 | 0.3410 |

| Wear rate | 14.13 | 7.060 | 27.39 | 15.27 | 2.080 |

| Position | Ni | Cr | O | Mo | Ag | Al | C | Fe |

|---|---|---|---|---|---|---|---|---|

| A | 14.851 | 5.609 | 17.415 | 0.581 | - | 0.358 | 44.775 | 16.411 |

| B | 24.645 | 27.201 | 16.119 | 1.936 | - | 1.793 | - | 28.306 |

| C | 50.548 | 9.215 | 17.172 | 1.566 | - | 0.413 | 8.565 | 12.521 |

| D | 27.658 | 13.453 | 27.825 | 19.306 | - | 1.613 | - | 10.145 |

| E | 56.196 | 17.899 | 8.037 | 3.005 | - | 4.109 | - | 10.754 |

| F | 50.795 | 9.445 | 10.701 | 3.621 | 4.709 | 5.102 | - | 15.629 |

| G | - | 7.980 | - | 2.769 | 82.615 | 2.247 | - | 4.389 |

| No. | 300 °C | 600 °C | ||

|---|---|---|---|---|

| COF | Wear Rate | COF | Wear Rate | |

| S2 | 0.3970 | 8.13 | 0.4921 | 12.21 |

| S5 | 0.2464 | 3.50 | 0.3319 | 4.86 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, F.; Zhang, Y.; Lou, Z.; Wang, Y. Enhanced Tribological Performance of Micro-Beam Plasma-Cladded Ni60 Coatings with Addition of Mo and Ag Lubricants in a Wide Temperature Range. Coatings 2023, 13, 1996. https://doi.org/10.3390/coatings13121996

Ye F, Zhang Y, Lou Z, Wang Y. Enhanced Tribological Performance of Micro-Beam Plasma-Cladded Ni60 Coatings with Addition of Mo and Ag Lubricants in a Wide Temperature Range. Coatings. 2023; 13(12):1996. https://doi.org/10.3390/coatings13121996

Chicago/Turabian StyleYe, Fuxing, Yufeng Zhang, Zhi Lou, and Yingfan Wang. 2023. "Enhanced Tribological Performance of Micro-Beam Plasma-Cladded Ni60 Coatings with Addition of Mo and Ag Lubricants in a Wide Temperature Range" Coatings 13, no. 12: 1996. https://doi.org/10.3390/coatings13121996

APA StyleYe, F., Zhang, Y., Lou, Z., & Wang, Y. (2023). Enhanced Tribological Performance of Micro-Beam Plasma-Cladded Ni60 Coatings with Addition of Mo and Ag Lubricants in a Wide Temperature Range. Coatings, 13(12), 1996. https://doi.org/10.3390/coatings13121996