Influence of Modeling Liquids and Universal Adhesives Used as Lubricants on Color Stability and Translucency of Resin-Based Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Color Measurements

2.2. Staining Procedure

2.3. Translucency

2.4. Color Differences

2.5. Statistical Analysis

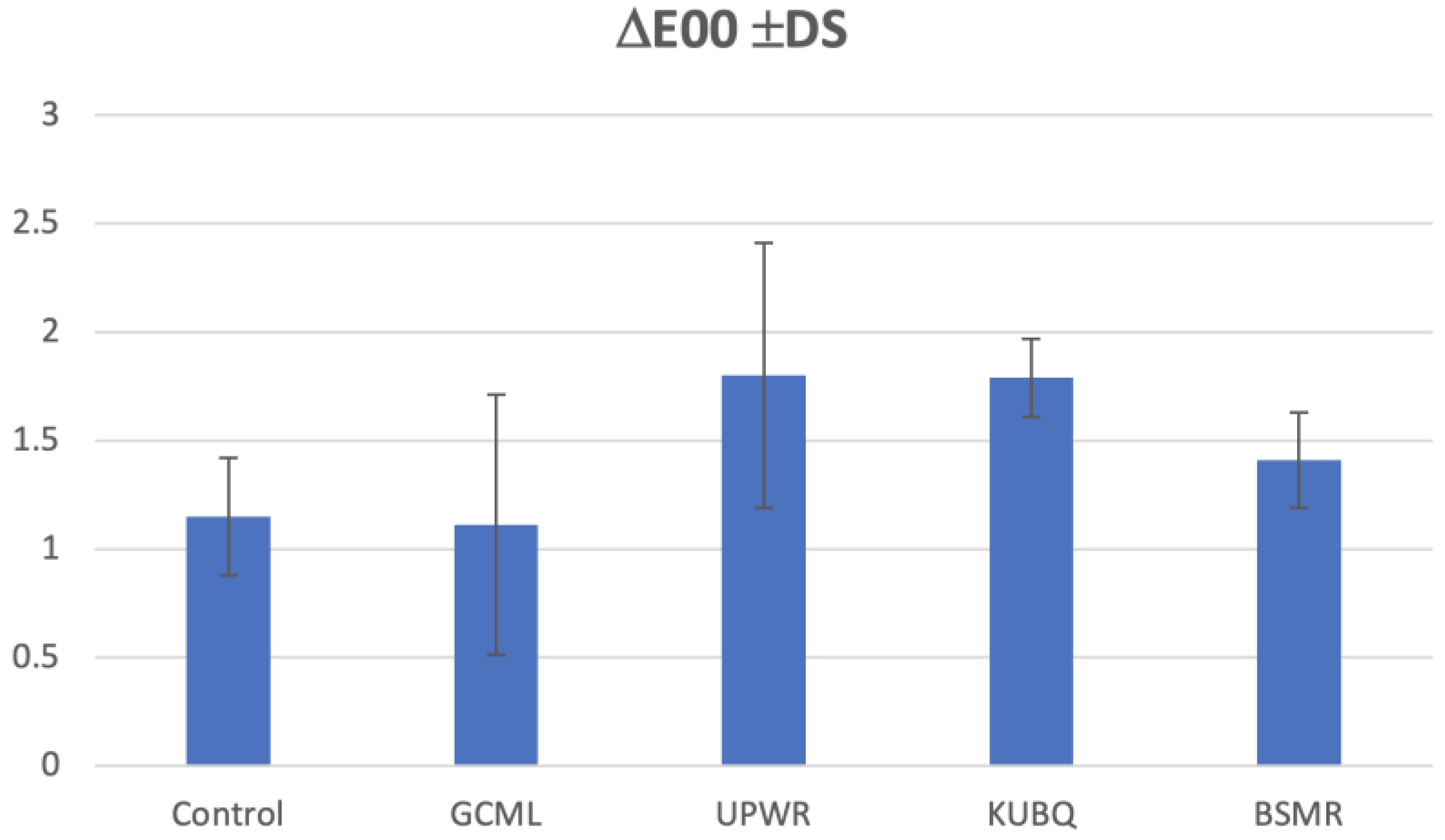

3. Results

4. Discussion

5. Conclusions

- The use of KUBQ significantly increases the a* color coordinate values (reddish) at baseline;

- UPWR and KUBQ led to an unacceptable clinical color change after a 1-month artificial staining simulation;

- The use of the investigated lubricants did not influence translucency (TP and CR) at baseline or after the 1-month artificial staining simulation;

- Clinicians should take into consideration that color change may occur during the clinical service of the resin-based restorations; therefore, they should warn patients of this possible drawback.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Manauta, J.; Salat, A.; Putignano, A.; Devoto, W.; Paolone, G.; Hardan, L.S. Stratification in Anterior Teeth Using One Dentine Shade and a Predefined Thickness of Enamel: A New Concept in Composite Layering—Part I. Odonto-Stomatol. Trop. Trop. Dent. J. 2014, 37, 5–16. [Google Scholar]

- Manauta, J.; Salat, A.; Putignano, A.; Devoto, W.; Paolone, G.; Hardan, L.S. Stratification in Anterior Teeth Using One Dentine Shade and a Predefined Thickness of Enamel: A New Concept in Composite Layering—Part II. Odonto-Stomatol. Trop. Trop. Dent. J. 2014, 37, 5–13. [Google Scholar]

- Demarco, F.F.; Collares, K.; Coelho-de-Souza, F.H.; Correa, M.B.; Cenci, M.S.; Moraes, R.R.; Opdam, N.J.M. Anterior Composite Restorations: A Systematic Review on Long-Term Survival and Reasons for Failure. Dent. Mater. 2015, 31, 1214–1224. [Google Scholar] [CrossRef]

- Opdam, N.J.M.; van de Sande, F.H.; Bronkhorst, E.; Cenci, M.S.; Bottenberg, P.; Pallesen, U.; Gaengler, P.; Lindberg, A.; Huysmans, M.C.D.N.J.M.; van Dijken, J.W. Longevity of Posterior Composite Restorations: A Systematic Review and Meta-Analysis. J. Dent. Res. 2014, 93, 943–949. [Google Scholar] [CrossRef] [PubMed]

- Paolone, G. Direct Composite Restorations in Anterior Teeth. Managing Symmetry in Central Incisors. Int. J. Esthet. Dent. 2014, 9, 12–25. [Google Scholar] [PubMed]

- Paolone, G.; Mazzitelli, C.; Josic, U.; Scotti, N.; Gherlone, E.; Cantatore, G.; Breschi, L. Modeling Liquids and Resin-Based Dental Composite Materials—A Scoping Review. Materials 2022, 15, 3759. [Google Scholar] [CrossRef] [PubMed]

- Kutuk, Z.B.; Erden, E.; Aksahin, D.L.; Durak, Z.E.; Dulda, A.C. Influence of Modeling Agents on the Surface Properties of an Esthetic Nano-Hybrid Composite. Restor. Dent. Endod. 2020, 45, e13. [Google Scholar] [CrossRef]

- Araujo, F.S.; Barros, M.C.R.; Santana, M.L.C.; de Jesus Oliveira, L.S.; Silva, P.F.D.; Lima, G.D.S.; Faria-E-Silva, A.L. Effects of Adhesive Used as Modeling Liquid on the Stability of the Color and Opacity of Composites. J. Esthet. Restor. Dent. 2018, 30, 427–433. [Google Scholar] [CrossRef]

- Münchow, E.A.; Sedrez-Porto, J.A.; Piva, E.; Pereira-Cenci, T.; Cenci, M.S. Use of Dental Adhesives as Modeler Liquid of Resin Composites. Dent. Mater. 2016, 32, 570–577. [Google Scholar] [CrossRef] [PubMed]

- Barcellos, D.C.; Pucci, C.R.; Torres, C.R.G.; Goto, E.H.; Inocencio, A.C. Effects of Resinous Monomers Used in Restorative Dental Modeling on the Cohesive Strength of Composite Resin. J. Adhes. Dent. 2008, 10, 351–354. [Google Scholar]

- Tuncer, S.; Demirci, M.; Tiryaki, M.; Ünlü, N.; Uysal, O. The Effect of a Modeling Resin and Thermocycling on the Surface Hardness, Roughness, and Color of Different Resin Composites. J. Esthet. Restor. Dent. 2013, 25, 404–419. [Google Scholar] [CrossRef] [PubMed]

- De Paula, F.C.; Valentin, R.D.S.; Borges, B.C.D.; Medeiros, M.C.D.S.; De Oliveira, R.F.; Da Silva, A.O. Effect of Instrument Lubricants on the Surface Degree of Conversion and Crosslinking Density of Nanocomposites. J. Esthet. Restor. Dent. 2016, 28, 85–91. [Google Scholar] [CrossRef] [PubMed]

- Paolone, G.; Formiga, S.; De Palma, F.; Abbruzzese, L.; Chirico, L.; Scolavino, S.; Goracci, C.; Cantatore, G.; Vichi, A. Color Stability of Resin-Based Composites: Staining Procedures with Liquids-A Narrative Review. J. Esthet. Restor. Dent. 2022, 34, 865–887. [Google Scholar] [CrossRef]

- Zimmerli, B.; Koch, T.; Flury, S.; Lussi, A. The Influence of Toothbrushing and Coffee Staining on Different Composite Surface Coatings. Clin. Oral. Investig. 2012, 16, 469–479. [Google Scholar] [CrossRef]

- Ertaş, E.; Güler, A.U.; Yücel, A.C.; Köprülü, H.; Güler, E. Color Stability of Resin Composites after Immersion in Different Drinks. Dent. Mater. J. 2006, 25, 371–376. [Google Scholar] [CrossRef]

- Luo, M.R.; Cui, G.; Rigg, B. The Development of the CIE 2000 Colour-Difference Formula: CIEDE2000. Color Res. Appl. 2001, 26, 340–350. [Google Scholar] [CrossRef]

- CIE. CIE 015:2018 Colorimetry, 4th ed.; International Commission on Illumination (CIE): Vienna, Austria, 2018. [Google Scholar]

- Maske, T.T.; Hollanders, A.C.C.; Kuper, N.K.; Bronkhorst, E.M.; Cenci, M.S.; Huysmans, M.C.D.N.J.M. A Threshold Gap Size for in Situ Secondary Caries Lesion Development. J. Dent. 2019, 80, 36–40. [Google Scholar] [CrossRef] [PubMed]

- Paolone, G.; Scolavino, S.; Gherlone, E.; Spagnuolo, G.; Cantatore, G. The “Pre-Finishing” Approach in Direct Anterior Restorations. A Case Series. Dent. J. 2021, 9, 79. [Google Scholar] [CrossRef] [PubMed]

- Paolone, G.; Scolavino, S.; Gherlone, E.; Spagnuolo, G. Direct Esthetic Composite Restorations in Anterior Teeth: Managing Symmetry Strategies. Symmetry 2021, 13, 797. [Google Scholar] [CrossRef]

- Pereira, P.-L.; Pereira, R.; Silva, B.-G.; Lins, R.-B.-E.; Lima, D.-A.-N.-L.; Aguiar, F.-H.-B. Effect of Wetting Agent Coverage on the Surface Properties of Resin Composite Submitted to Brushing and Staining Cycles. J. Clini. Exp. Dent. 2021, 13, 795–801. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.-K.; Yu, B.; Zhao, G.-F.; Lim, J.I. Effects of Aging and HEMA Content on the Translucency, Fluorescence, and Opalescence Properties of Experimental HEMA-Added Glass Ionomers. Dent. Mater. J. 2010, 29, 9–14. [Google Scholar] [CrossRef] [PubMed]

- Khokhar, Z.A.; Razzoog, M.E.; Yaman, P. Color Stability of Restorative Resins. Quintessence Int. 1991, 22, 733–737. [Google Scholar] [PubMed]

- Ruyter, I.E.; Nilner, K.; Moller, B. Color Stability of Dental Composite Resin Materials for Crown and Bridge Veneers. Dent. Mater. 1987, 3, 246–251. [Google Scholar] [CrossRef]

- ISO 4049:2019; Dentistry—Polymer-Based Restorative Materials. International Organization for Standardization: Geneva, Switzerland, 2019. Available online: https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/06/75/67596.html (accessed on 1 July 2021).

- Perez, M.D.M.; Ghinea, R.; Herrera, L.J.; Ionescu, A.M.; Pomares, H.; Pulgar, R.; Paravina, R.D. Dental Ceramics: A CIEDE2000 Acceptability Thresholds for Lightness, Chroma and Hue Differences. J. Dent. 2011, 39, e37–e44. [Google Scholar] [CrossRef] [PubMed]

- Paolone, G. Direct composites in anteriors: A matter of substrate. Int. J. Esthet. Dent. 2017, 12, 468–481. [Google Scholar] [PubMed]

- Bompolaki, D.; Lubisich, E.B.; Fugolin, A.P. Resin-Based Composites for Direct and Indirect Restorations: Clinical Applications, Recent Advances, and Future Trends. Dent. Clin. N. Am. 2022, 66, 517–536. [Google Scholar] [CrossRef] [PubMed]

- German, M.J. Developments in resin-based composites. Br. Dent. J. 2022, 232, 638–643. [Google Scholar] [CrossRef]

| Lubricants | |||

|---|---|---|---|

| Product | Manufacturer | Composition | Lot |

| GC Modeling liquid | GC Corp., Tokyo, Japan | Urethane dimethacrylate (UDMA), 2-hydroxy-1,3 dimethacryloxypropane 2-hydroxyethyl metacrylate and 2-hydroxy-1,3 dimethacryloxypropane | 2107071 |

| Composite Wetting Resin | Ultradent Products, South Jordan, USA | Triethylene, glycol dimethacrylate, diurethane dimethacrylate, silane and butylated hydroxytoluene | BH836 |

| Clearfil Universal Bond Quick | Kuraray, Noritake, Japan | MDP, bis-GMA, HEMA, hydrophilic amide monomers, colloidal silica, silane coupling agent, sodium fluoride, dl-camphorquinone, ethanol and water. | 220289 |

| Modeling Resin | BISCO, Schaumburg, USA | UDMA (20–40), amorphous silica (20–40), bis-EMA (10–30), TEGDMA (5–20) and bis-G- MA (1–10) | 2100000881 |

| Material | TPt0 | TPt1 | CRt0 | CRt1 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Control | 73.70 ± 1.20 A | 72.51 ± 1.09 A | 0.97 ± 0.34 A,B | 1.14 ± 0.35 A,B | 26.87 ± 1.47 A | 28.41 ± 1.23 A,B | 8.81 ± 1.27 A | 8.25 ± 1.07 A | 0.85 ± 0.02 A | 0.86 ± 0.02 A |

| GCML | 73.20 ± 1.28 A | 72.12 ± 1.37 A | 0.84 ± 0.29 A | 1.14 ± 0.27 A,B | 26.42 ± 0.87 A | 27.42 ± 0.85 A | 9.39 ± 1.56 A | 8.68 ± 1.71 A | 0.84 ± 0.03 A | 0.85 ± 0.03 A |

| UPWR | 73.44 ± 1.15 A | 72.21 ± 0.88 A | 1.10 ± 0.35 A,B | 1.49 ± 0.28 B,C | 27.20 ± 0.94 A | 30.48 ± 1.10 C | 8.84 ± 0.82 A | 8.37 ± 0.86 A | 0.85 ± 0.02 A | 0.86 ± 0.02 A |

| KUBQ | 73.83 ± 0.57 A | 72.11 ± 0.76 A | 1.35 ± 0.44 B | 1.57 ± 0.40 C | 27.21 ± 0.90 A | 29.98 ± 0.89 C | 8.38 ± 1.09 A | 7.83 ± 0.88 A | 0.86 ± 0.02 A | 0.87 ± 0.02 A |

| BSMR | 72.78 ± 0.92 A | 71.38 ± 0.87 A | 0.80 ± 0.25 A | 0.93 ± 0.24 A | 26.69 ± 0.90 A | 28.69 ± 0.95 B | 8.79 ± 0.81 A | 8.19 ± 0.70 A | 0.85 ± 0.02 A | 0.86 ± 0.01 A |

| Material | ||||||

|---|---|---|---|---|---|---|

| Control | 1.19 ± 0.27 A | −0.17 ± 0.11 B | −1.54 ± 0.66 C,D | 1.15 ± 0.27 A | −0.56 ± 0.35 A | 0.01 ± 0.01 A |

| GCML | 1.08 ± 0.97 A | −0.30 ± 0.23 A,B | −1.00 ± 0.72 D | 1.11 ± 0.60 A | −0.70 ± 0.50 A | 0.01 ± 0.01 A |

| UPWR | 1.23 ± 0.97 A | −0.39 ± 0.20 A | −3.28 ± 0.87 A | 1.80 ± 0.61 B | −0.47 ± 0.32 A | 0.01 ± 0.01 A |

| KUBQ | 1.73 ± 0.34 A | −0.22 ± 0.12 A,B | −2.76 ± 0.27 A,B | 1.79 ± 0.18 B | −0.55 ± 0.35 A | 0.01 ± 0.01 A |

| BSMR | 1.39 ± 0.30 A | −0.13 ± 0.09 B | −2.01 ± 0.61 B,C | 1.41 ± 0.22 A,B | −0.60 ± 0.37 | 0.01 ± 0.01 A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paolone, G.; Mazzitelli, C.; Zechini, G.; Scolavino, S.; Goracci, C.; Scotti, N.; Cantatore, G.; Gherlone, E.; Vichi, A. Influence of Modeling Liquids and Universal Adhesives Used as Lubricants on Color Stability and Translucency of Resin-Based Composites. Coatings 2023, 13, 143. https://doi.org/10.3390/coatings13010143

Paolone G, Mazzitelli C, Zechini G, Scolavino S, Goracci C, Scotti N, Cantatore G, Gherlone E, Vichi A. Influence of Modeling Liquids and Universal Adhesives Used as Lubricants on Color Stability and Translucency of Resin-Based Composites. Coatings. 2023; 13(1):143. https://doi.org/10.3390/coatings13010143

Chicago/Turabian StylePaolone, Gaetano, Claudia Mazzitelli, Giacomo Zechini, Salvatore Scolavino, Cecilia Goracci, Nicola Scotti, Giuseppe Cantatore, Enrico Gherlone, and Alessandro Vichi. 2023. "Influence of Modeling Liquids and Universal Adhesives Used as Lubricants on Color Stability and Translucency of Resin-Based Composites" Coatings 13, no. 1: 143. https://doi.org/10.3390/coatings13010143

APA StylePaolone, G., Mazzitelli, C., Zechini, G., Scolavino, S., Goracci, C., Scotti, N., Cantatore, G., Gherlone, E., & Vichi, A. (2023). Influence of Modeling Liquids and Universal Adhesives Used as Lubricants on Color Stability and Translucency of Resin-Based Composites. Coatings, 13(1), 143. https://doi.org/10.3390/coatings13010143