Study of Co-Deposition of Tantalum and Titanium during the Formation of Layered Composite Materials by Magnetron Sputtering

Abstract

1. Introduction

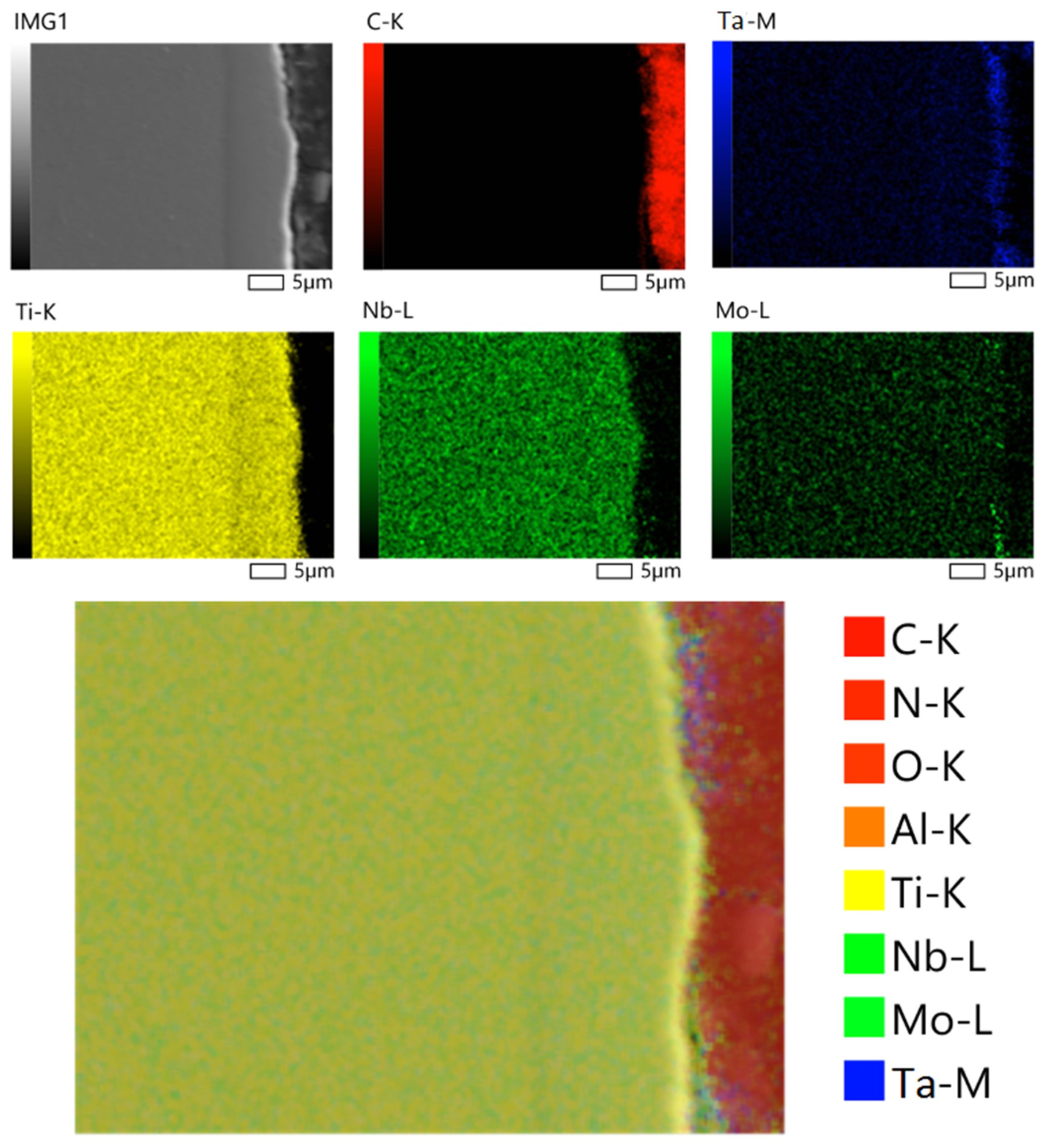

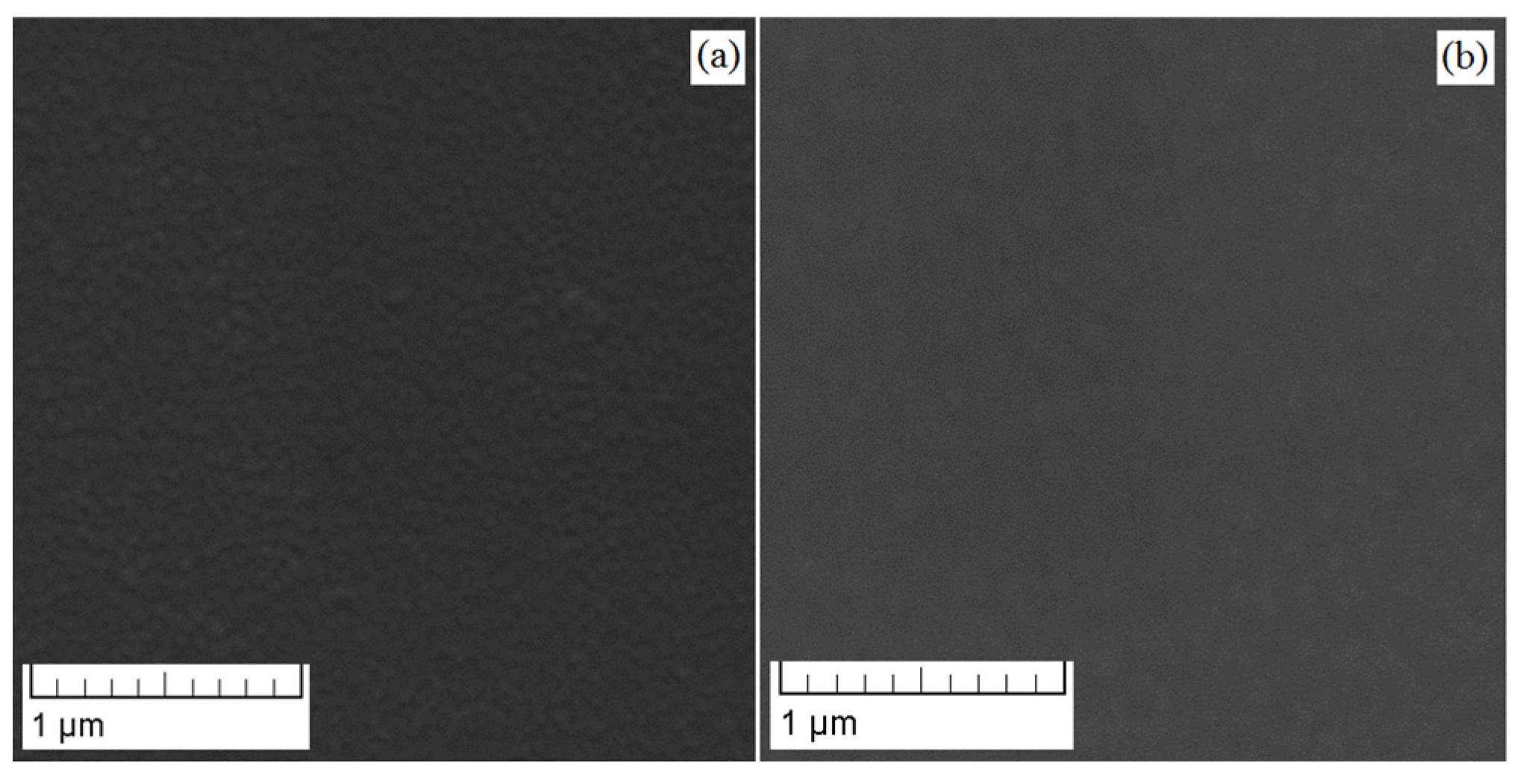

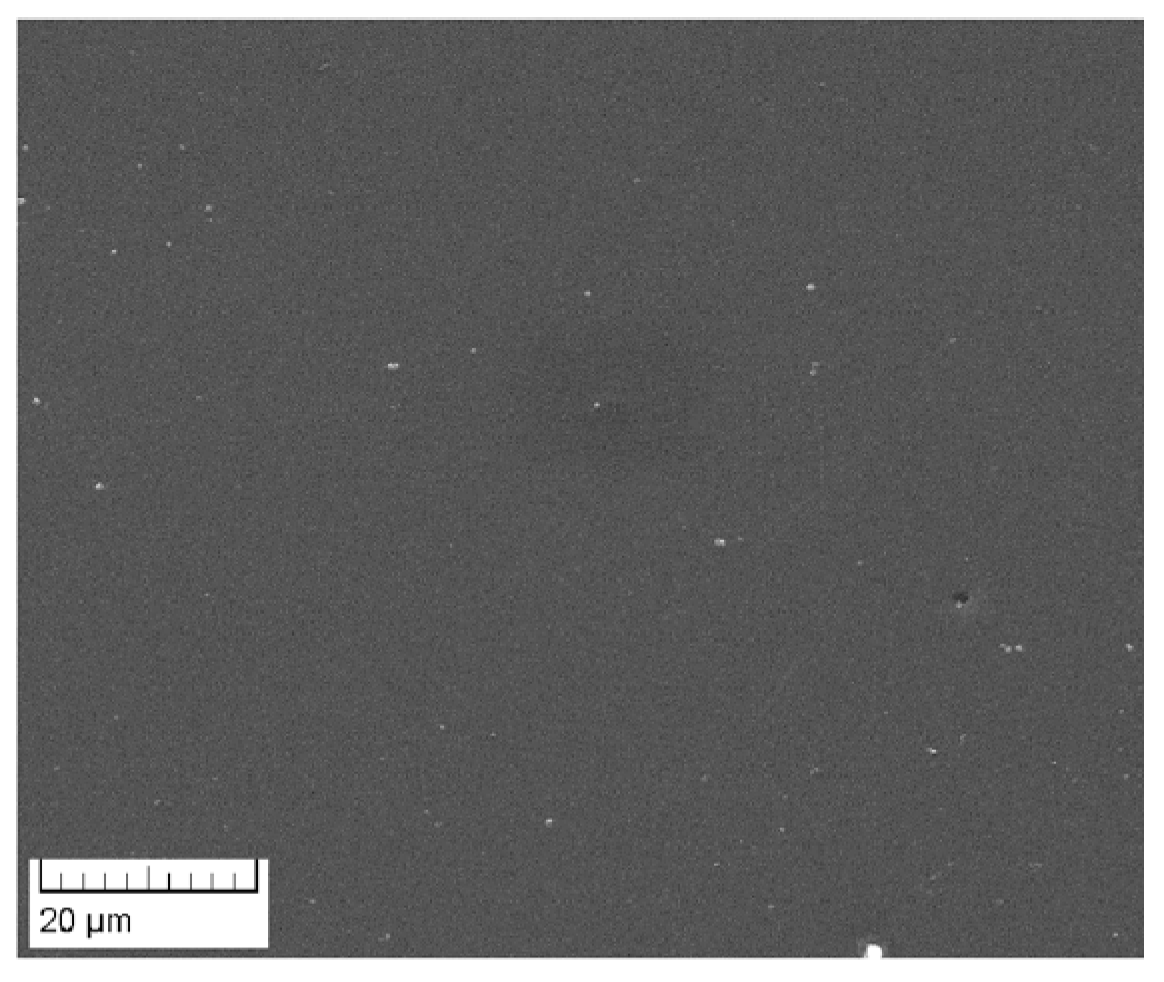

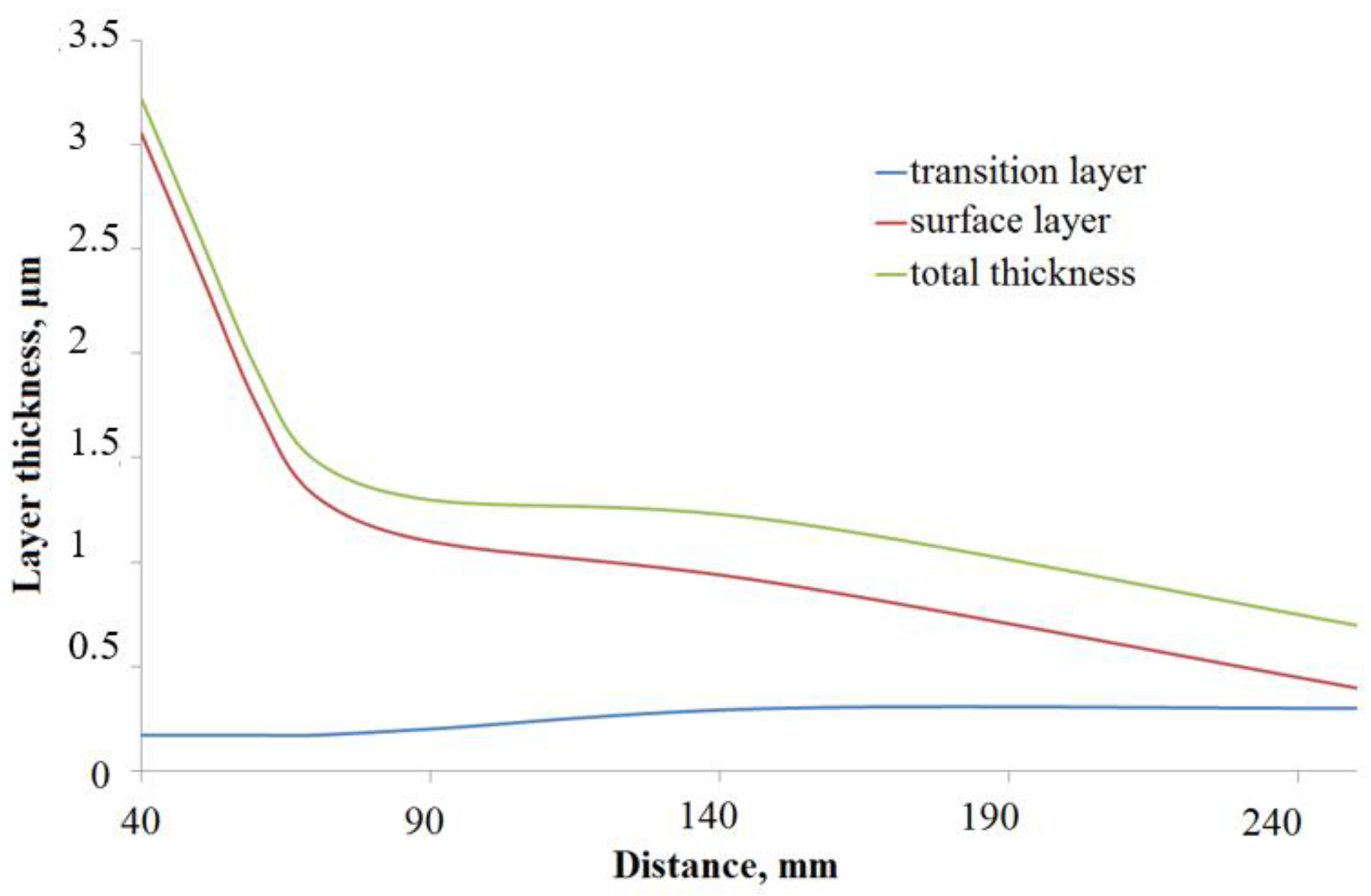

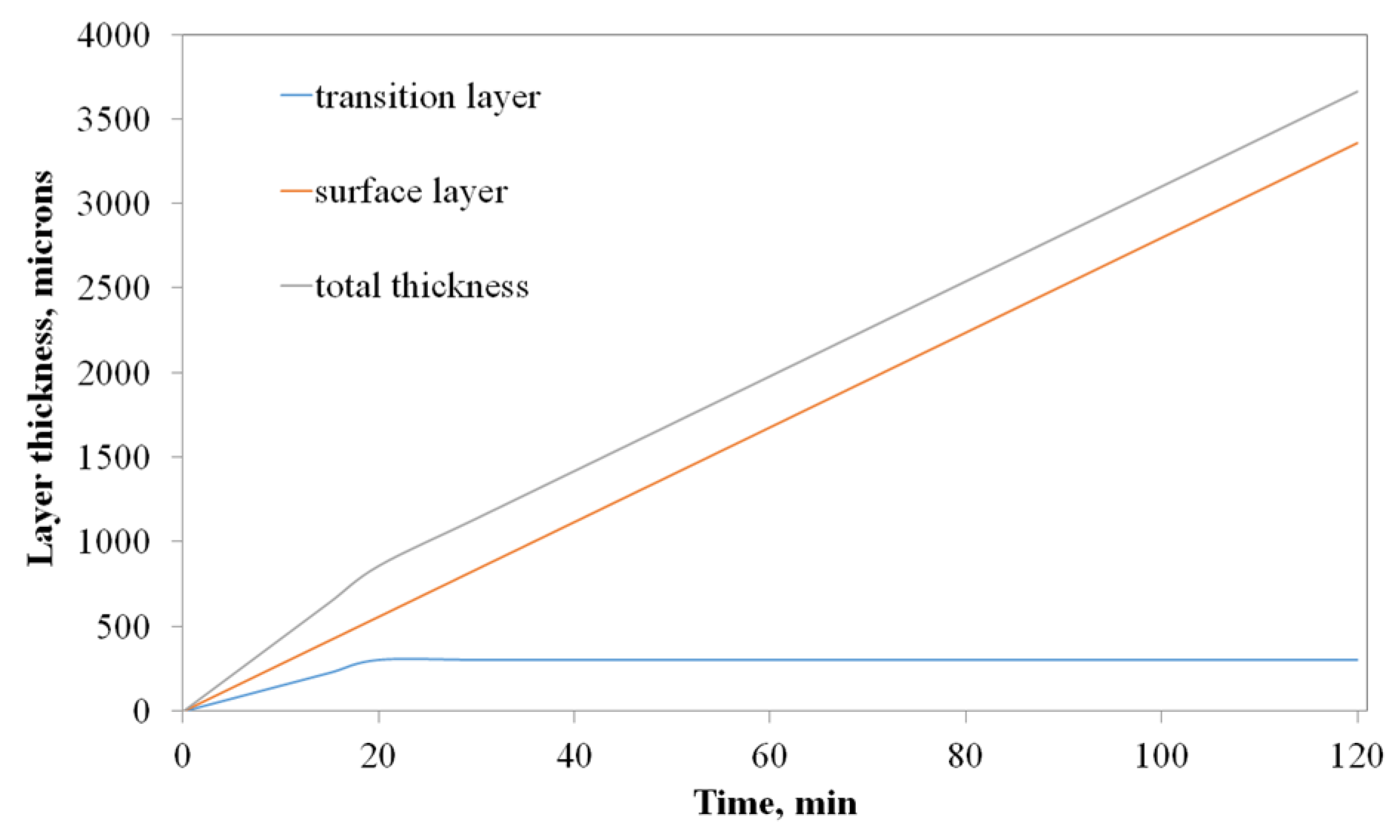

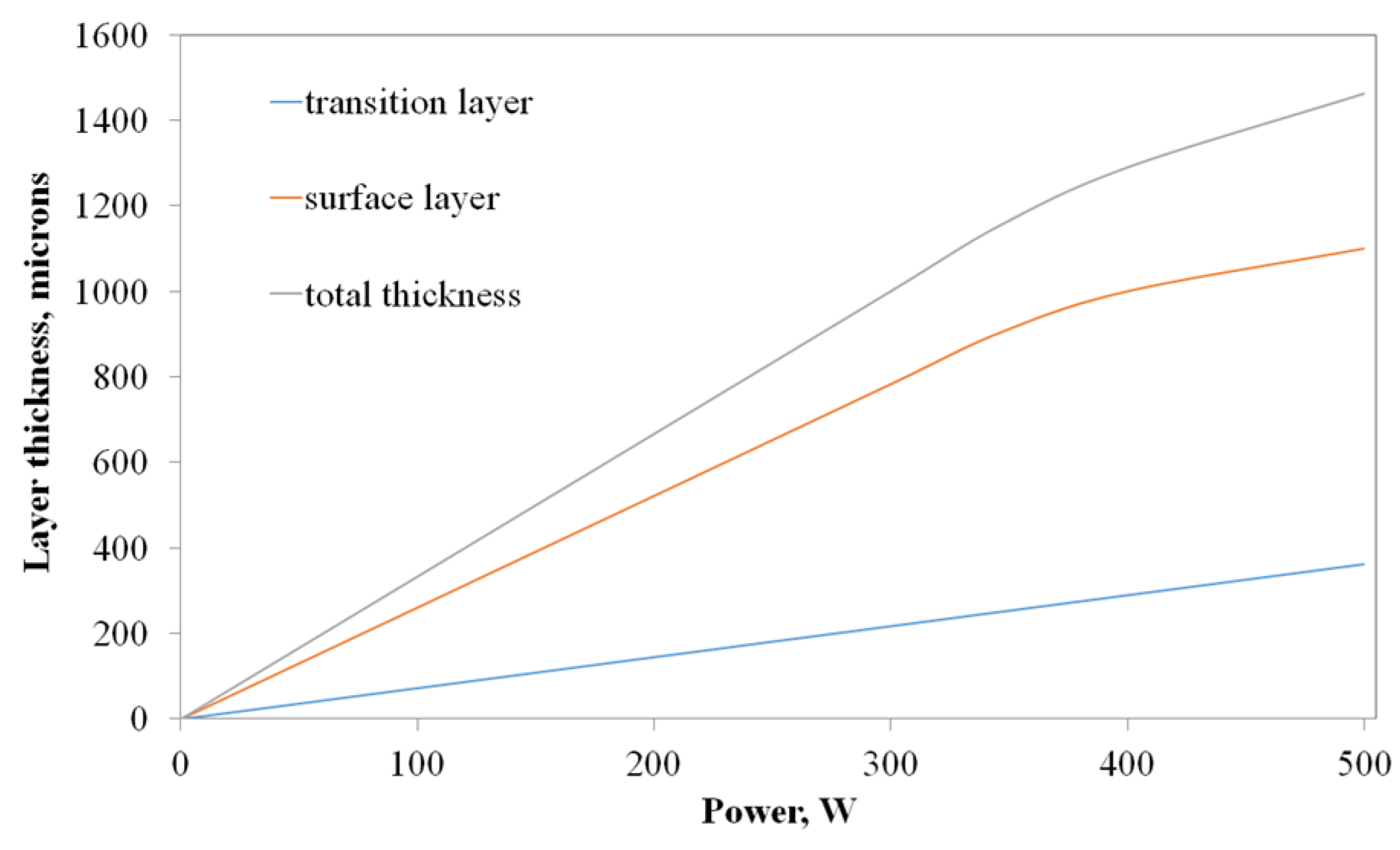

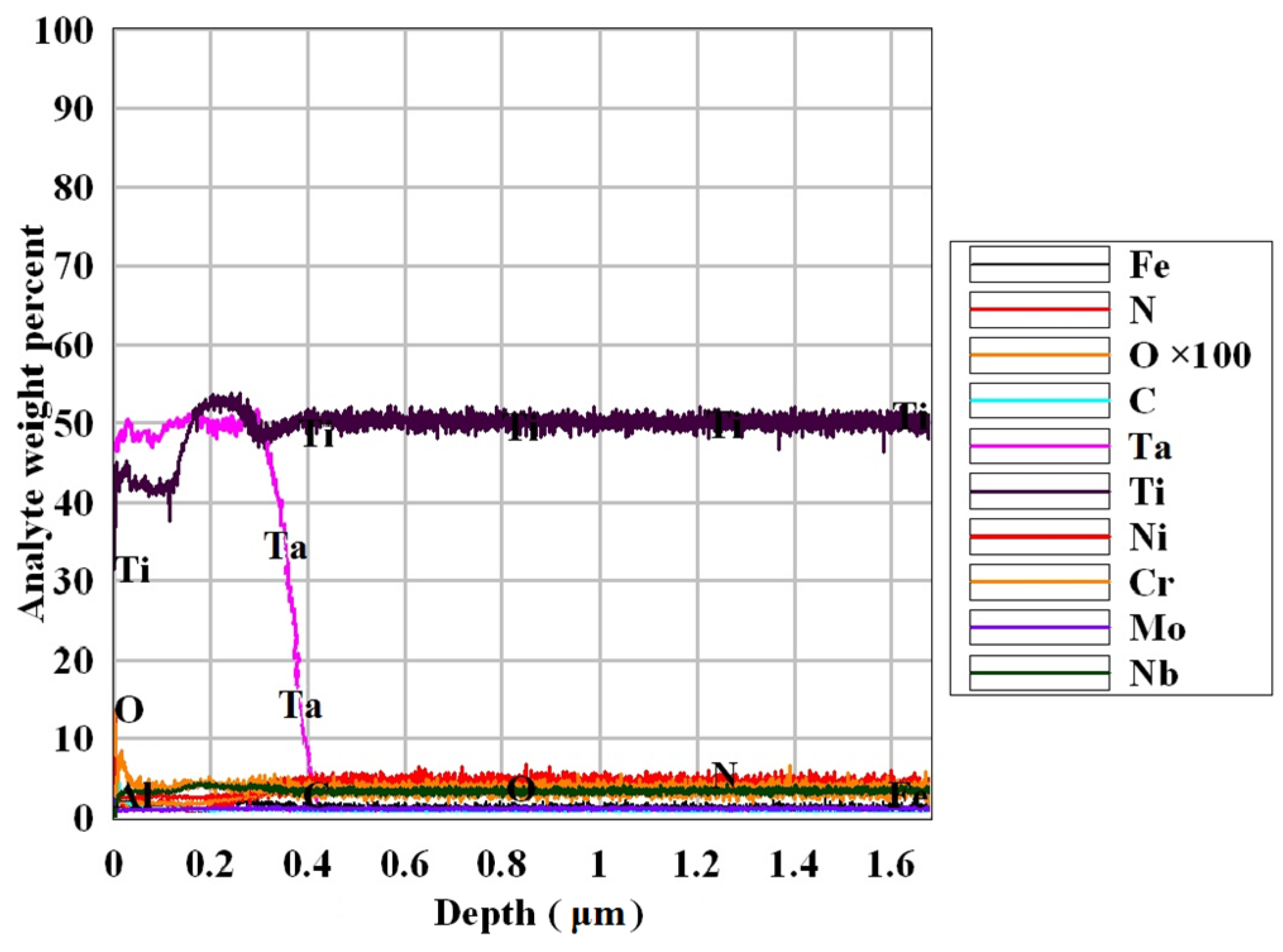

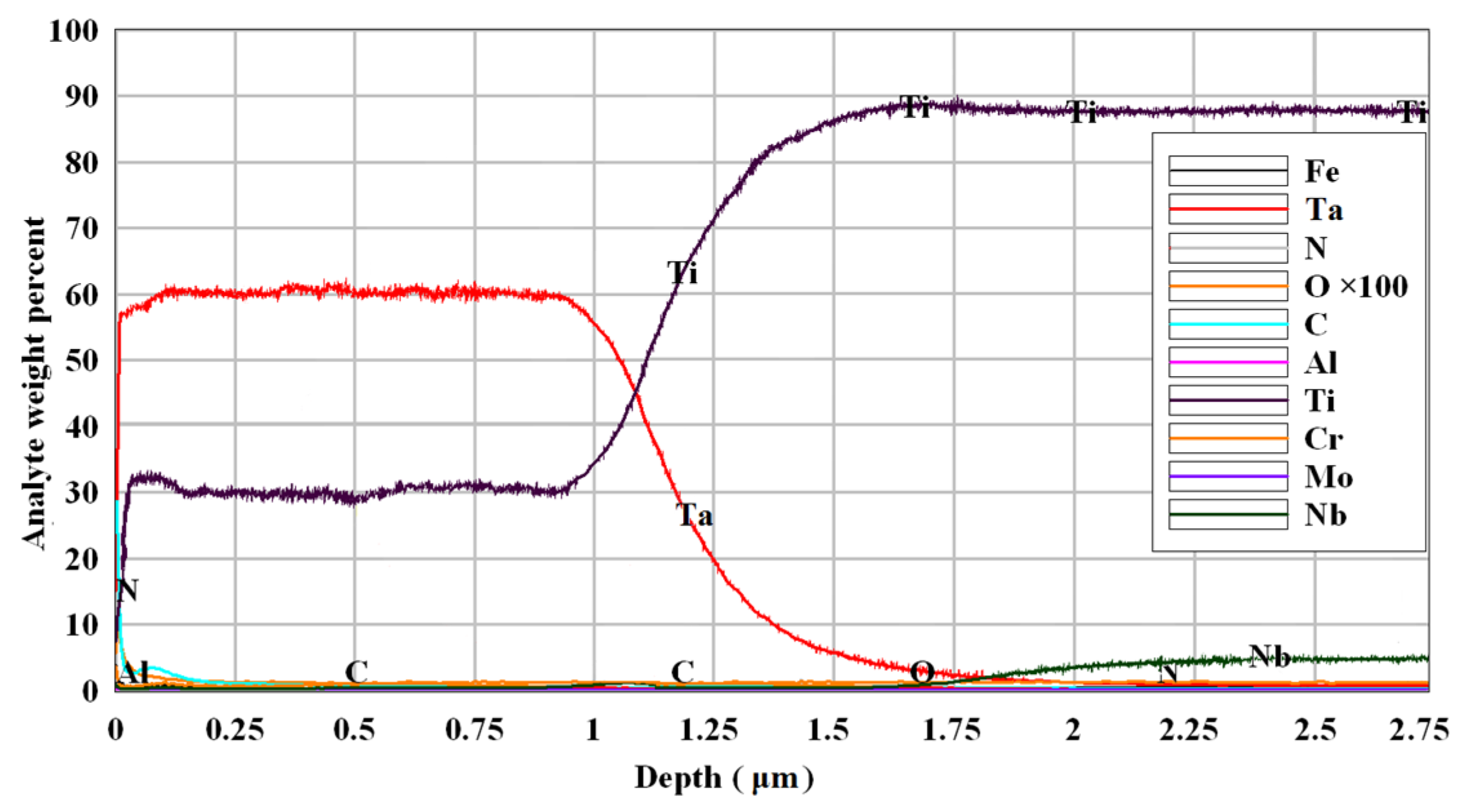

2. Materials and Methods

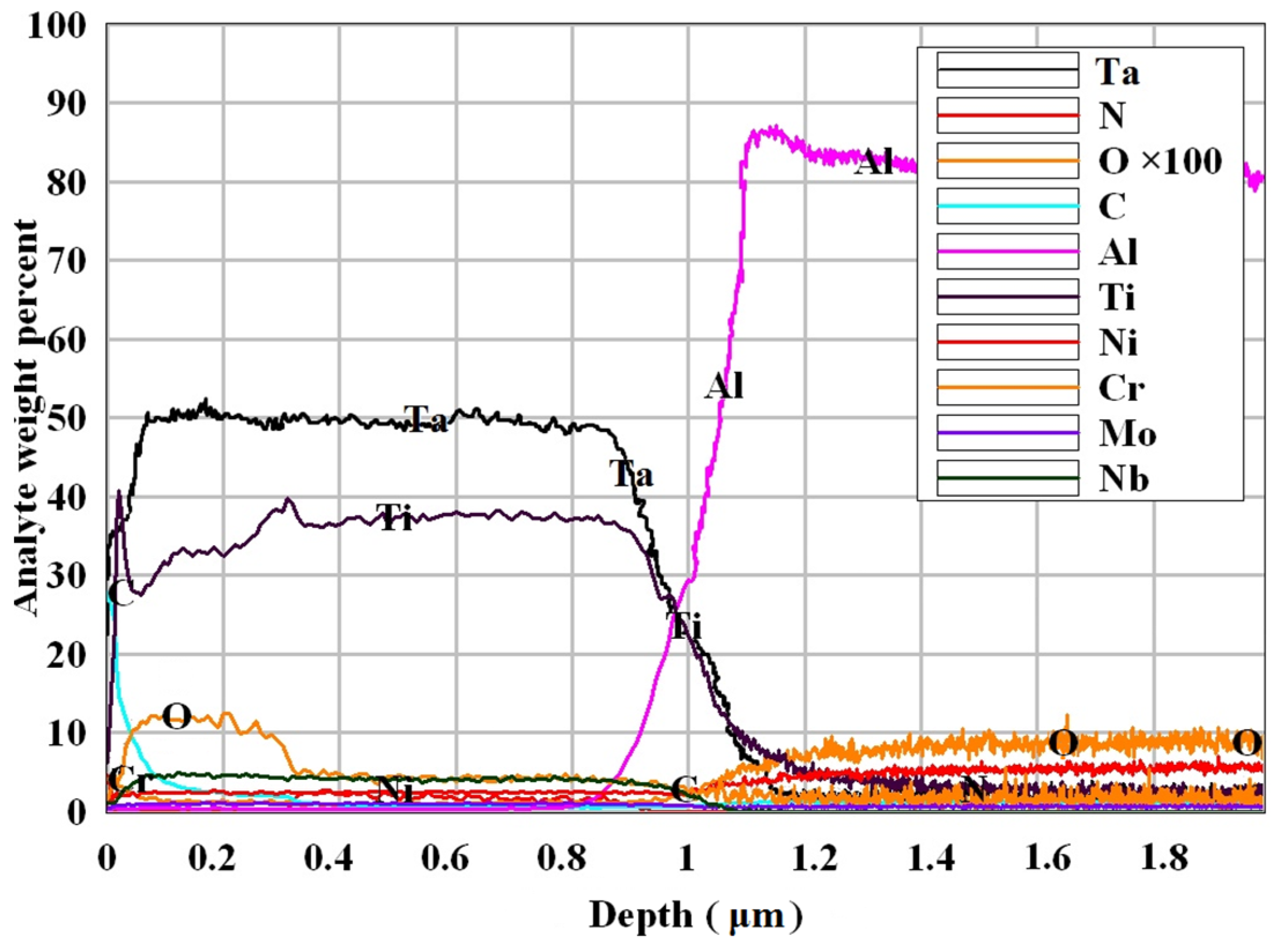

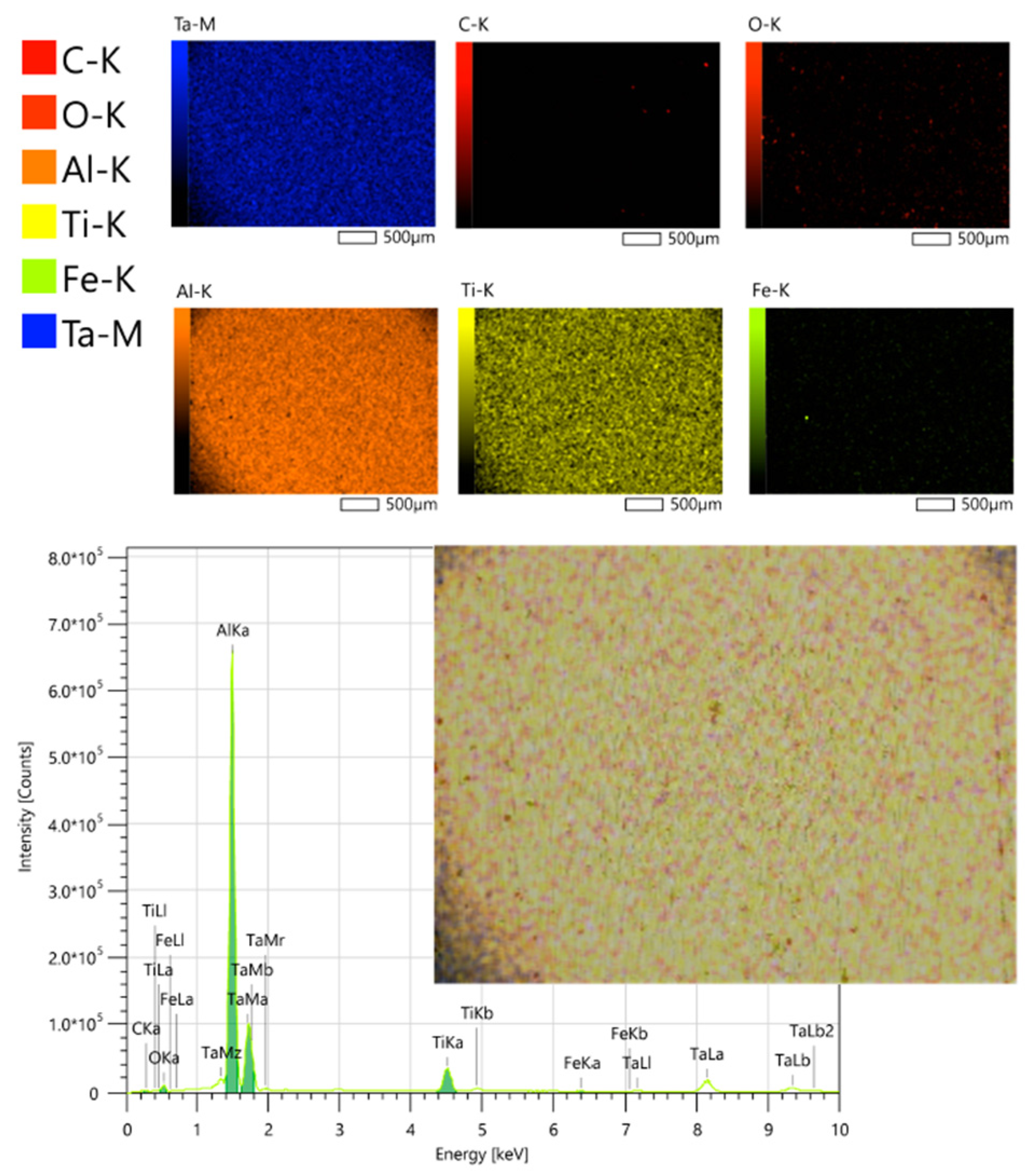

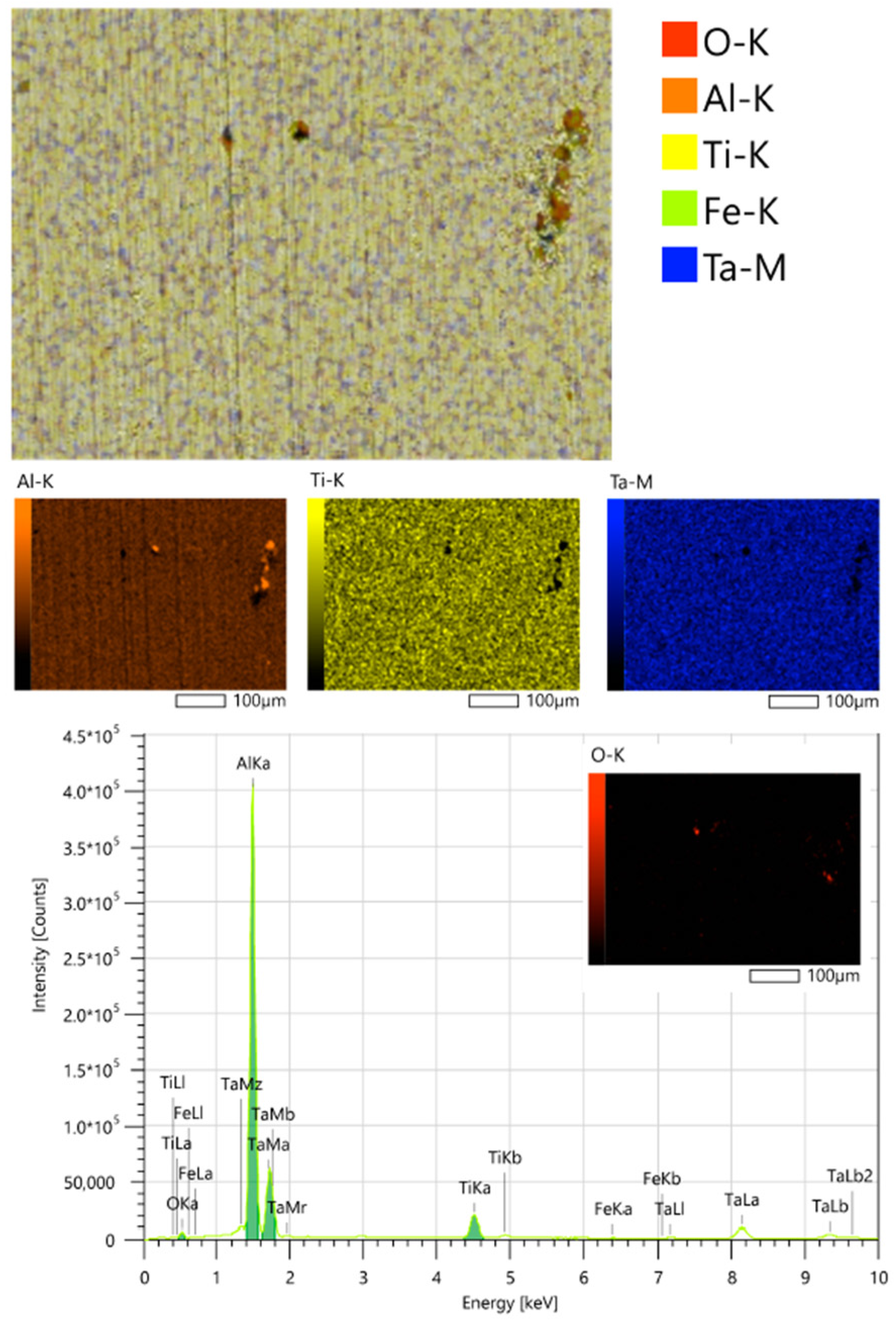

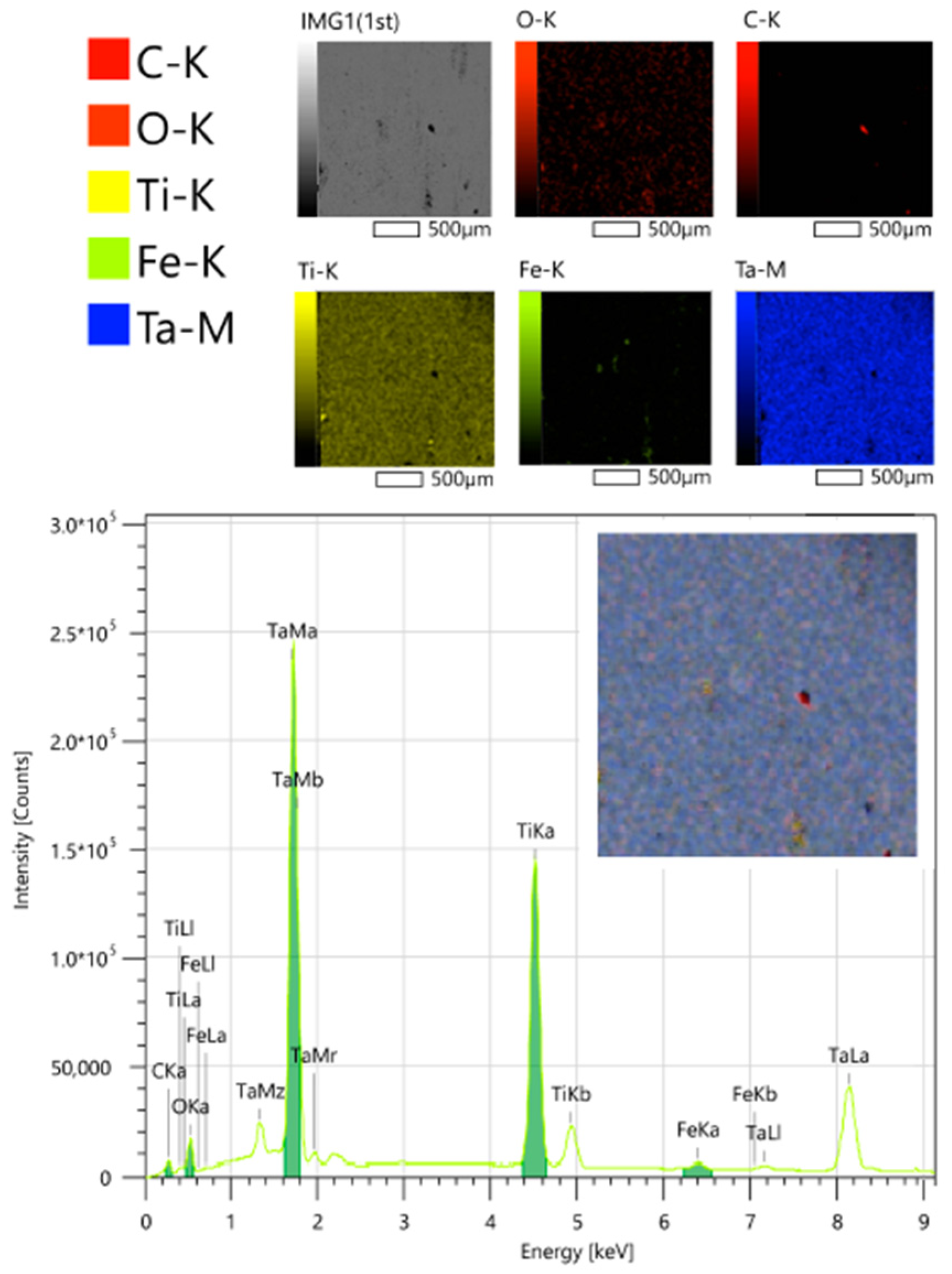

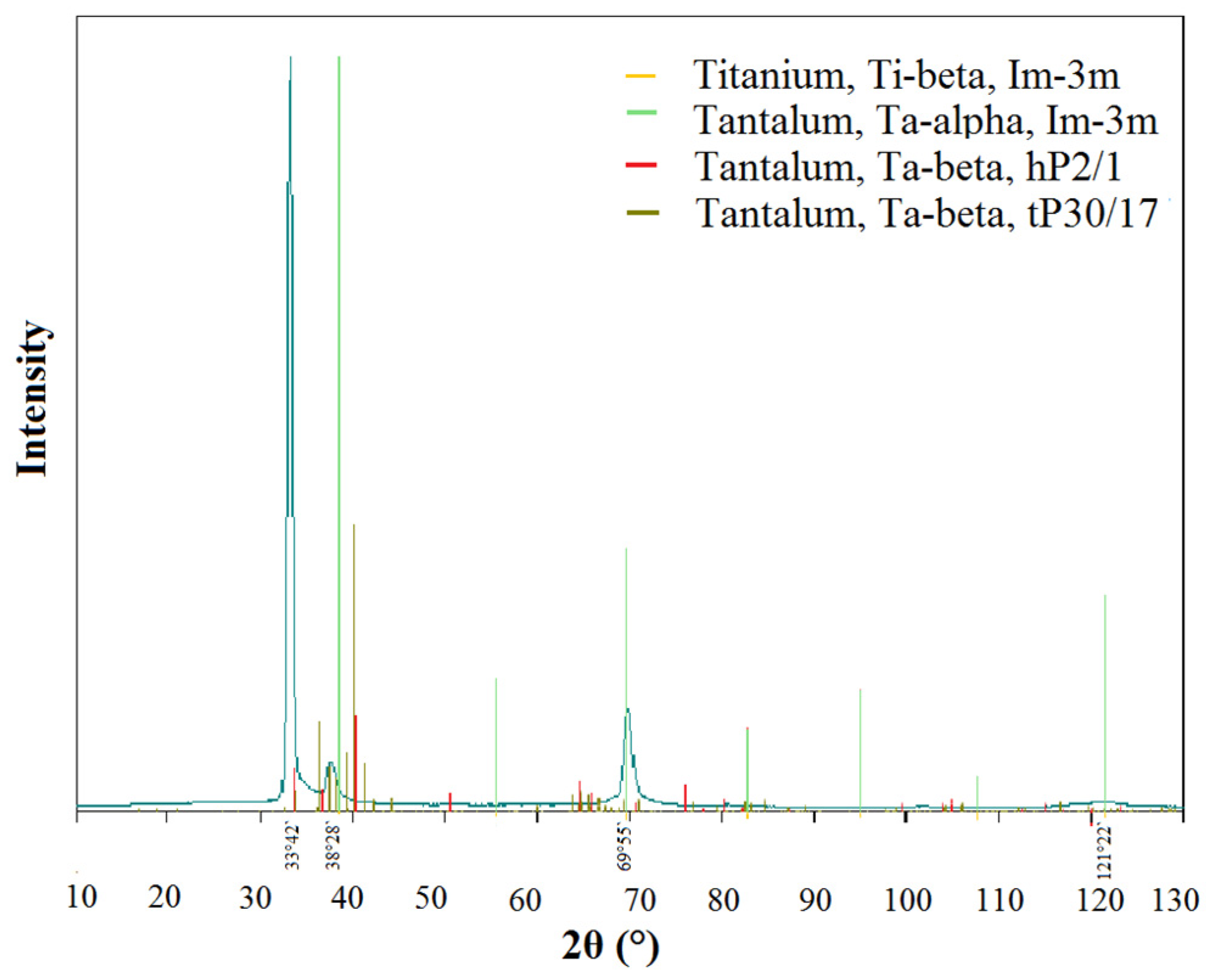

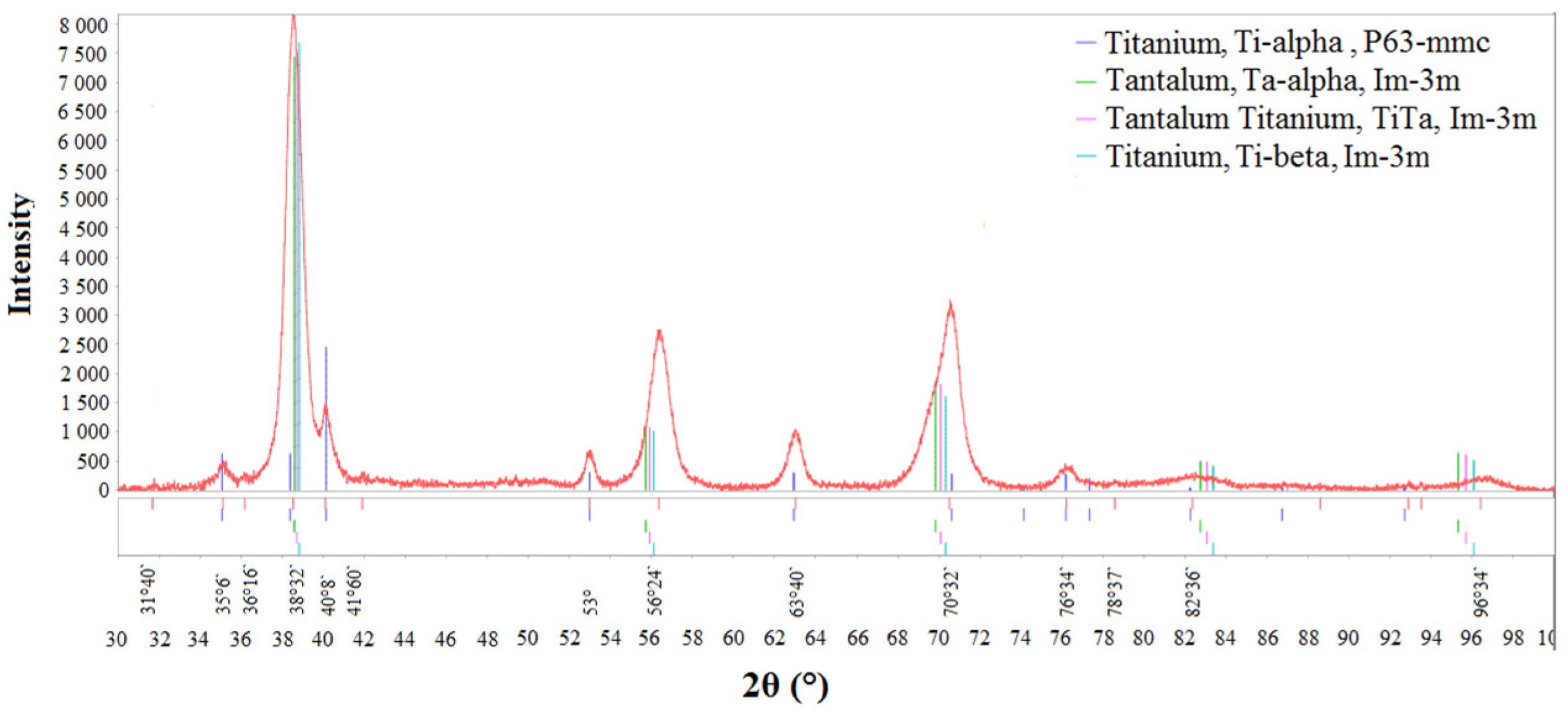

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wiatrowski, A.; Mazur, M.; Obstarczyk, A.; Wojcieszak, D.; Kaczmarek, D.; Morgiel, J.; Gibson, D. Comparison of the Physicochemical Properties of TiO2 Thin Films Obtained by Magnetron Sputtering with Continuous and Pulsed Gas Flow. Coatings 2018, 8, 412. [Google Scholar] [CrossRef]

- El-Fattah, H.A.A.; El-Mahallawi, I.S.; Shazly, M.H.; Khalifa, W.A. Optical Properties and Microstructure of TiNxOy and TiN Thin Films before and after Annealing at Different Conditions. Coatings 2019, 9, 22. [Google Scholar] [CrossRef]

- Hu, Y.; Rasadujjaman, M.; Wang, Y.; Zhang, J.; Yan, J.; Baklanov, M. Study on the Electrical, Structural, Chemical and Optical Properties of PVD Ta(N) Films Deposited with Different N2 Flow Rates. Coatings 2021, 11, 937. [Google Scholar] [CrossRef]

- Dongquoc, V.; Seo, D.-B.; Anh, C.V.; Lee, J.-H.; Park, J.-H.; Kim, E.-T. Controlled Surface Morphology and Electrical Properties of Sputtered Titanium Nitride Thin Film for Metal–Insulator–Metal Structures. Appl. Sci. 2022, 12, 10415. [Google Scholar] [CrossRef]

- Korotkova, K.; Bainov, D.; Smirnov, S.; Yunusov, I.; Zhidik, Y. Electrical Conductivity and Optical Properties of Nanoscale Titanium Films on Sapphire for Localized Plasmon Resonance-Based Sensors. Coatings 2020, 10, 1165. [Google Scholar] [CrossRef]

- Zaman, A.; Meletis, E.I. Microstructure and Mechanical Properties of TaN Thin Films Prepared by Reactive Magnetron Sputtering. Coatings 2017, 7, 209. [Google Scholar] [CrossRef]

- Qiao, Z.; Li, X.; Lv, Y.; Xie, Y.; Hu, Y.; Wang, J.; Li, H.; Wang, S. Depositing a Titanium Coating on the Lithium Neutron Production Target by Magnetron Sputtering Technology. Materials 2021, 14, 1873. [Google Scholar] [CrossRef] [PubMed]

- Kaltschmidt, B.P.; Asghari, E.; Kiel, A.; Cremer, J.; Anselmetti, D.; Kaltschmidt, C.; Kaltschmidt, B.; Hütten, A. Magnetron Sputtering of Transition Metals as an Alternative Production Means for Antibacterial Surfaces. Microorganisms 2022, 10, 1843. [Google Scholar] [CrossRef]

- de Monteynard, A.; Luo, H.; Chehimi, M.; Ghanbaja, J.; Achache, S.; François, M.; Billard, A.; Sanchette, F. The Structure, Morphology, and Mechanical Properties of Ta-Hf-C Coatings Deposited by Pulsed Direct Current Reactive Magnetron Sputtering. Coatings 2020, 10, 212. [Google Scholar] [CrossRef]

- Rivera-Tello, C.D.; Broitman, E.; Flores-Ruiz, F.J.; Perez-Alvarez, J.; Flores-Jiménez, M.; Jiménez, O.; Flores, M. Micro and Macro-Tribology Behavior of a Hierarchical Architecture of a Multilayer TaN/Ta Hard Coating. Coatings 2020, 10, 263. [Google Scholar] [CrossRef]

- Farahani, N.; Kelly, P.J.; West, G.; Hill, C.; Vishnyakov, V. Photocatalytic Activity of Reactively Sputtered Titania Coatings Deposited Using a Full Face Erosion Magnetron. Coatings 2013, 3, 177–193. [Google Scholar] [CrossRef]

- Wang, Y.-H.; Rahman, K.H.; Wu, C.-C.; Chen, K.-C. A Review on the Pathways of the Improved Structural Characteristics and Photocatalytic Performance of Titanium Dioxide (TiO2) Thin Films Fabricated by the Magnetron-Sputtering Technique. Catalysts 2020, 10, 598. [Google Scholar] [CrossRef]

- Kelly, P.J.; West, G.T.; Ratova, M.; Fisher, L.; Ostovarpour, S.; Verran, J. Structural Formation and Photocatalytic Activity of Magnetron Sputtered Titania and Doped-Titania Coatings. Molecules 2014, 19, 16327–16348. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-Y.; Park, J.-B. Various Coated Barrier Membranes for Better Guided Bone Regeneration: A Review. Coatings 2022, 12, 1059. [Google Scholar] [CrossRef]

- García, E.; Flores, M.; Rodríguez, E.; Rivera, L.P.; Camps, E.; Muhl, S. Tribological, Tribocorrosion and Wear Mechanism Studies of TaZrN Coatings Deposited by Magnetron Sputtering on TiAlV Alloy. Coatings 2018, 8, 295. [Google Scholar] [CrossRef]

- Alvarez, R.; Muñoz-Piña, S.; González, M.U.; Izquierdo-Barba, I.; Fernández-Martínez, I.; Rico, V.; Arcos, D.; García-Valenzuela, A.; Palmero, A.; Vallet-Regi, M.; et al. Antibacterial Nanostructured Ti Coatings by Magnetron Sputtering: From Laboratory Scales to Industrial Reactors. Nanomaterials 2019, 9, 1217. [Google Scholar] [CrossRef]

- Yelkarasi, C.; Recek, N.; Kazmanli, K.; Kovač, J.; Mozetič, M.; Urgen, M.; Junkar, I. Biocompatibility and Mechanical Stability of Nanopatterned Titanium Films on Stainless Steel Vascular Stents. Int. J. Mol. Sci. 2022, 23, 4595. [Google Scholar] [CrossRef] [PubMed]

- Mina-Aponzá, S.; Castro-Narváez, S.; Caicedo-Bejarano, L.; Bermeo-Acosta, F. Study of Titanium–Silver Monolayer and Multilayer Films for Protective Applications in Biomedical Devices. Molecules 2021, 26, 4813. [Google Scholar] [CrossRef] [PubMed]

- Ding, Z.; Zhou, Q.; Wang, Y.; Ding, Z.; Tang, Y.; He, Q. Microstructure and properties of monolayer, bilayer and multilayer Ta2O5-based coatings on biomedical Ti-6Al-4V alloy by magnetron sputtering. Ceram. Int. 2020, 47, 1133–1144. [Google Scholar] [CrossRef]

- Zhang, M.; Ma, Y.; Gao, J.; Hei, H.; Jia, W.; Bai, J.; Liu, Z.; Huang, X.; Xue, Y.; Yu, S.; et al. Mechanical, Electrochemical, and Osteoblastic Properties of Gradient Tantalum Coatings on Ti6Al4V Prepared by Plasma Alloying Technique. Coatings 2021, 11, 631. [Google Scholar] [CrossRef]

- Rodrigues, M.M.; Fontoura, C.P.; Maddalozzo, A.E.D.; Leidens, L.M.; Quevedo, H.G.; Souza, K.D.S.; Crespo, J.D.S.; Michels, A.F.; Figueroa, C.A.; Aguzzoli, C. Ti, Zr and Ta coated UHMWPE aiming surface improvement for biomedical purposes. Compos. Part B: Eng. 2020, 189, 107909. [Google Scholar] [CrossRef]

- Ji, P.; Liu, S.; Deng, H.; Ren, H.; Zhang, J.; Sun, T.; Xu, K.; Shi, C. Effect of magnetron-sputtered monolayer Ta and multilayer Ti-Zr-Ta and Zr-Ti-Ta coatings on the surface properties of biomedical Ti-6Al-4V alloy. Mater. Lett. 2022, 322. [Google Scholar] [CrossRef]

- Baigonakova, G.; Marchenko, E.; Yasenchuk, Y.; Kokorev, O.; Vorozhtsov, A.; Kulbakin, D. Microstructural characterization, wettability and cytocompatibility of gradient coatings synthesized by gas nitriding of three-layer Ti/Ni/Ti nanolaminates magnetron sputtered on the TiNi substrate. Surf. Coatings Technol. 2022, 436. [Google Scholar] [CrossRef]

- Lenis, J.; Rico, P.; Ribelles, J.G.; Pacha-Olivenza, M.; González-Martín, M.; Bolívar, F. Structure, morphology, adhesion and in vitro biological evaluation of antibacterial multi-layer HA-Ag/SiO2/TiN/Ti coatings obtained by RF magnetron sputtering for biomedical applications. Mater. Sci. Eng. C 2020, 116, 111268. [Google Scholar] [CrossRef] [PubMed]

- Lenis, J.; Bejarano, G.; Rico, P.; Ribelles, J.G.; Bolívar, F. Development of multilayer Hydroxyapatite - Ag/TiN-Ti coatings deposited by radio frequency magnetron sputtering with potential application in the biomedical field. Surf. Coatings Technol. 2019, 377, 124856. [Google Scholar] [CrossRef]

- López-Huerta, F.; Cervantes, B.; González, O.; Hernández-Torres, J.; García-González, L.; Vega, R.; Herrera-May, A.L.; Soto, E. Biocompatibility and Surface Properties of TiO2 Thin Films Deposited by DC Magnetron Sputtering. Materials 2014, 7, 4105–4117. [Google Scholar] [CrossRef] [PubMed]

- Marchenko, E.; Baigonakova, G.; Kokorev, O.; Yasenchuk, Y.; Vorozhtsov, A. Biocompatibility Assessment of Coatings Obtained in Argon and Nitrogen Atmospheres for TiNi Materials. Metals 2022, 12, 1603. [Google Scholar] [CrossRef]

- Domínguez-Crespo, M.; Torres-Huerta, A.; Rodríguez, E.; González-Hernández, A.; Brachetti-Sibaja, S.; Dorantes-Rosales, H.; López-Oyama, A. Effect of deposition parameters on structural, mechanical and electrochemical properties in Ti/TiN thin films on AISI 316L substrates produced by r. f. magnetron sputtering. J. Alloy. Compd. 2018, 746, 688–698. [Google Scholar] [CrossRef]

- Akimchenko, I.O.; Rutkowski, S.; Tran, T.-H.; Dubinenko, G.E.; Petrov, V.I.; Kozelskaya, A.I.; Tverdokhlebov, S.I. Polyether Ether Ketone Coated with Ultra-Thin Films of Titanium Oxide and Zirconium Oxide Fabricated by DC Magnetron Sputtering for Biomedical Application. Materials 2022, 15, 8029. [Google Scholar] [CrossRef] [PubMed]

- Subramanian, B.; Muraleedharan, C.; Ananthakumar, R.; Jayachandran, M. A comparative study of titanium nitride (TiN), titanium oxy nitride (TiON) and titanium aluminum nitride (TiAlN), as surface coatings for bio implants. Surf. Coatings Technol. 2011, 205, 5014–5020. [Google Scholar] [CrossRef]

- González-Hernández, A.; Aperador, W.; Flores, M.; Onofre-Bustamante, E.; Bermea, J.E.; Bautista-García, R.; Gamboa-Soto, F. Influence of Deposition Parameters on Structural and Electrochemical Properties of Ti/Ti2N Films Deposited by RF-Magnetron Sputtering. Metals 2022, 12, 1237. [Google Scholar] [CrossRef]

- Stolin, A.M.; Bazhin, P. Manufacture of multipurpose composite and ceramic materials in the combustion regime and high-temperature deformation (SHS extrusion). Theor. Found. Chem. Eng. 2014, 48, 751–763. [Google Scholar] [CrossRef]

- Bazhin, P.; Stolin, A.M.; Alymov, M.I. Preparation of nanostructured composite ceramic materials and products under conditions of a combination of combustion and high-temperature deformation (SHS extrusion). Nanotechnologies Russ. 2014, 9, 583–600. [Google Scholar] [CrossRef]

- Krivoshapkin, P.; Mikhaylov, V.; Krivoshapkina, E.; Zaikovskii, V.; Melgunov, M.; Stalugin, V. Mesoporous Fe–alumina films prepared via sol–gel route. Microporous Mesoporous Mater. 2015, 204, 276–281. [Google Scholar] [CrossRef]

- Kononova, S.V.; Korytkova, E.N.; Maslennikova, T.; Romashkova, K.A.; Kruchinina, E.V.; Potokin, I.L.; Gusarov, V. Polymer-inorganic nanocomposites based on aromatic polyamidoimides effective in the processes of liquids separation. Russ. J. Gen. Chem. 2010, 80, 1136–1142. [Google Scholar] [CrossRef]

- Fattah-Alhosseini, A.; Elmkhah, H.; Ansari, G.; Attarzadeh, F.; Imantalab, O. A comparison of electrochemical behavior of coated nanostructured Ta on Ti substrate with pure uncoated Ta in Ringer’s physiological solution. J. Alloy. Compd. 2018, 739, 918–925. [Google Scholar] [CrossRef]

- Seidl, W.; Bartosik, M.; Kolozsvári, S.; Bolvardi, H.; Mayrhofer, P. Improved mechanical properties, thermal stabilities, and oxidation resistance of arc evaporated Ti-Al-N coatings through alloying with Ta. Surf. Coatings Technol. 2018, 344, 244–249. [Google Scholar] [CrossRef]

- Sevost’Yanov, M.A.; Nasakina, E.O.; Baikin, A.S.; Sergienko, K.V.; Konushkin, S.V.; Kaplan, M.A.; Seregin, A.V.; Leonov, A.V.; Kozlov, V.A.; Shkirin, A.V.; et al. Biocompatibility of new materials based on nano-structured nitinol with titanium and tantalum composite surface layers: Experimental analysis in vitro and in vivo. J. Mater. Sci. Mater. Med. 2018, 29, 33. [Google Scholar] [CrossRef]

- Li, P.; Zhang, X.; Xu, R.; Wang, W.; Liu, X.; Yeung, K.W.K.; Chu, P.K. Electrochemically deposited chitosan/Ag complex coatings on biomedical NiTi alloy for antibacterial application. Surf. Coat. Technol. 2013, 232, 370–375. [Google Scholar] [CrossRef]

- Cheng, Y.; Cai, W.; Li, H.T.; Zheng, Y.F. Surface modification of NiTi alloy with tantalum to improve its biocompatibility and radiopacity. J. Mater. Sci. 2006, 41, 4961–4964. [Google Scholar] [CrossRef]

- Lee, D.-W.; Kim, Y.-N.; Cho, M.-Y.; Ko, P.-J.; Lee, D.; Koo, S.-M.; Moon, K.-S.; Oh, J.-M. Reliability and characteristics of magnetron sputter deposited tantalum nitride for thin film resistors. Thin Solid Films 2018, 660, 688–694. [Google Scholar] [CrossRef]

- Siddiqui, J.; Hussain, T.; Ahmad, R.; Umar, Z.A. On the structural, morphological and electrical properties of tantalum oxy nitride thin films by varying oxygen percentage in reactive gases plasma. Chin. J. Phys. 2017, 55, 1412–1422. [Google Scholar] [CrossRef]

- Kumar, M.; Kumari, N.; Kumar, V.P.; Karar, V.; Sharma, A.L. Determination of optical constants of tantalum oxide thin film deposited by electron beam evaporation. Mater. Today: Proc. 2018, 5, 3764–3769. [Google Scholar] [CrossRef]

- Cristea, D.; Velicu, I.-L.; Cunha, L.; Barradas, N.; Alves, E.; Craciun, V. Tantalum-Titanium Oxynitride Thin Films Deposited by DC Reactive Magnetron Co-Sputtering: Mechanical, Optical, and Electrical Characterization. Coatings 2021, 12, 36. [Google Scholar] [CrossRef]

- Ormanova, M.; Dechev, D.; Ivanov, N.; Mihai, G.; Gospodinov, M.; Valkov, S.; Enachescu, M. Synthesis and Characterization of Ti-Ta-Shape Memory Surface Alloys Formed by the Electron-Beam Additive Technique. Coatings 2022, 12, 678. [Google Scholar] [CrossRef]

- Tu, R.; Min, R.; Yang, M.; Yuan, Y.; Zheng, L.; Li, Q.; Ji, B.; Zhang, S.; Yang, M.; Shi, J. Overcoming the Dilemma between Low Electrical Resistance and High Corrosion Resistance Using a Ta/(Ta,Ti)N/TiN/Ti Multilayer for Proton Exchange Membrane Fuel Cells. Coatings 2022, 12, 689. [Google Scholar] [CrossRef]

- Guo, D.; Zhang, S.; Huang, T.; Wu, S.; Ma, X.; Guo, F. Corrosion Properties of DLC Film in Weak Acid and Alkali Solutions. Coatings 2022, 12, 1776. [Google Scholar] [CrossRef]

- Bunshah, R.F. Deposition Technologies for Films and Coating; Noyes Publikations: Park Ridge, IL, USA, 1982; p. 489 p. [Google Scholar]

- Kulczyk-Malecka, J.; Kelly, P.J.; West, G.; Clarke, G.C.; Ridealgh, J.A. Characterisation Studies of the Structure and Properties of As-Deposited and Annealed Pulsed Magnetron Sputtered Titania Coatings. Coatings 2013, 3, 166–176. [Google Scholar] [CrossRef]

- Al-Masha’Al, A.; Bunting, A.; Cheung, R. Evaluation of residual stress in sputtered tantalum thin-film. Appl. Surf. Sci. 2016, 371, 571–575. [Google Scholar] [CrossRef]

- Zhou, Y.M.; Xie, Z.; Xiao, H.N.; Hu, P.F.; He, J. Effects of deposition parameters on tantalum films deposited by direct current magnetron sputtering. J. Vac. Sci. Technol. A: Vacuum, Surfaces, Films 2009, 27, 109–113. [Google Scholar] [CrossRef]

- Bernoulli, D.; Müller, U.; Schwarzenberger, M.; Hauert, R.; Spolenak, R. Magnetron sputter deposited tantalum and tantalum nitride thin films: An analysis of phase, hardness and composition. Thin Solid Films 2013, 548, 157–161. [Google Scholar] [CrossRef]

- Zhou, Y.; Xie, Z.; Xiao, H.; Hu, P.; He, J. Effects of deposition parameters on tantalum films deposited by direct current magnetron sputtering in Ar–O2 mixture. Appl. Surf. Sci. 2011, 258, 1699–1703. [Google Scholar] [CrossRef]

- Zhou, Y.; Xie, Z.; Ma, Y.; Xia, F.; Feng, S. Growth and characterization of Ta/Ti bi-layer films on glass and Si (111) substrates by direct current magnetron sputtering. Appl. Surf. Sci. 2012, 258, 7314–7321. [Google Scholar] [CrossRef]

- Navid, A.; Chason, E.; Hodge, A. Evaluation of stress during and after sputter deposition of Cu and Ta films. Surf. Coatings Technol. 2010, 205, 2355–2361. [Google Scholar] [CrossRef]

- Myers, S.; Lin, J.; Souza, R.; Sproul, W.D.; Moore, J.J. The β to α phase transition of tantalum coatings deposited by modulated pulsed power magnetron sputtering. Surf. Coatings Technol. 2012, 214, 38–45. [Google Scholar] [CrossRef]

- Cacucci, A.; Loffredo, S.; Potin, V.; Imhoff, L.; Martin, N. Interdependence of structural and electrical properties in tantalum/tantalum oxide multilayers. Surf. Coatings Technol. 2012, 227, 38–41. [Google Scholar] [CrossRef]

- Navid, A.; Hodge, A. Nanostructured alpha and beta tantalum formation—Relationship between plasma parameters and microstructure. Mater. Sci. Eng. A 2012, 536, 49–56. [Google Scholar] [CrossRef]

- Navid, A.; Hodge, A. Controllable residual stresses in sputtered nanostructured alpha-tantalum. Scr. Mater. 2010, 63, 867–870. [Google Scholar] [CrossRef]

- Zabolotnyi, V.T. Ion Intermixing in Solids; MGIEM (TU): Moscow, Russian, 1997; p. 62 p. [Google Scholar]

- Kuz’michev, A.I. Magnetron Spattering Systems. Book 1. Introduction Into Physics And Technique Of Magnetron Scattering; Avers: Kiev, Ukraine, 2008; p. 244 p. [Google Scholar]

- Poate, J.M.; Foti, G.; Jacobson, D.C. Surface Modification and Alloying by Laser; Ion and Electron Beams: Plenum, NY, USA, 1983; p. 424 p. [Google Scholar]

- Dorranian, D.; Solati, E.; Hantezadeh, M.; Ghoranneviss, M.; Sari, A. Effects of low temperature on the characteristics of tantalum thin films. Vacuum 2011, 86, 51–55. [Google Scholar] [CrossRef]

- Maeng, S.; Axe, L.; Tyson, T.; Gladczuk, L.; Sosnowski, M. Corrosion behaviour of magnetron sputtered α- and β-Ta coatings on AISI 4340 steel as a function of coating thickness. Corros. Sci. 2006, 48, 2154–2171. [Google Scholar] [CrossRef]

- Su, Y.; Huang, W.; Zhang, T.; Shi, C.; Hu, R.; Wang, Z.; Cai, L. Tribological properties and microstructure of monolayer and multilayer Ta coatings prepared by magnetron sputtering. Vacuum 2021, 189, 110250. [Google Scholar] [CrossRef]

- Niu, Y.; Chen, M.; Wang, J.; Yang, L.; Guo, C.; Zhu, S.; Wang, F. Preparation and thermal shock performance of thick α-Ta coatings by direct current magnetron sputtering (DCMS). Surf. Coatings Technol. 2017, 321, 19–25. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, B.; Chu, J.; Nieh, T. Hardness enhancement in nanocrystalline tantalum thin films. Scr. Mater. 2006, 54, 1227–1230. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, Q.; Niu, H.; Li, Y.; Chen, C.; Yu, Z.; Bai, X.; Zhang, P. Formation of nanocrystalline structure in tantalum by sliding friction treatment. Int. J. Refract. Met. Hard Mater. 2014, 45, 71–75. [Google Scholar] [CrossRef]

- Shankar, V.; Mariappan, K.; Nagesha, A.; Reddy, G.P.; Sandhya, R.; Mathew, M.; Jayakumar, T. Effect of tungsten and tantalum on the low cycle fatigue behavior of reduced activation ferritic/martensitic steels. Fusion Eng. Des. 2012, 87, 318–324. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.; Wang, G.; Bai, X.; Tan, P.; Li, Z.; Yu, Z. High strength bulk tantalum with novel gradient structure within a particle fabricated by spark plasma sintering. Mater. Sci. Eng. A 2011, 528, 8332–8336. [Google Scholar] [CrossRef]

- Silva, R.A.; Silva, I.P.; Rondot, B. Effect of Surface Treatments on Anodic Oxide Film Growth and Electrochemical Properties of Tantalum used for Biomedical Applications. J. Biomater. Appl. 2006, 21, 93–103. [Google Scholar] [CrossRef]

- Chakraborty, B.; Halder, S.; Maurya, K.; Srivastava, A.; Toutam, V.; Dalai, M.; Sehgal, G.; Singh, S. Evaluation of depth distribution and characterization of nanoscale Ta/Si multilayer thin film structures. Thin Solid Films 2012, 520, 6409–6414. [Google Scholar] [CrossRef]

- Colin, J.J.; Abadias, G.; Michel, A.; Jaouen, C. On the origin of the metastable β-Ta phase stabilization in tantalum sputtered thin films. Acta Mater. 2017, 126, 481–493. [Google Scholar] [CrossRef]

- Nasakina, E.O.; Sevost’Yanov, M.A.; Mikhailova, A.B.; Gol’Dberg, M.A.; Demin, K.Y.; Kolmakov, A.G.; Zabolotnyi, V.T. Preparation of a nanostructured shape-memory composite material for biomedical applications. Inorg. Mater. 2015, 51, 400–404. [Google Scholar] [CrossRef]

- Nasakina, E.; A Sevostyanov, M.; Mikhaylova, A.B.; Baikin, A.S.; Sergienko, K.V.; Leonov, A.V.; Kolmakov, A.G. Formation of alpha and beta tantalum at the variation of magnetron sputtering conditions. IOP Conf. Series: Mater. Sci. Eng. 2016, 110, 012042. [Google Scholar] [CrossRef]

| No. | Sample | Rel. ext. | Yield Strength (MPa) | Tensile Strength (MPa) | Load (kgf) | Young’s Modulus (GPa) |

|---|---|---|---|---|---|---|

| 1 | Ti-Nb-Zr | 3.05 | 583.68 | 671.58 | 44.58 | 27.571 |

| 2 | Ti-Nb-Zr–Ti, 30 min | 3.21 | 419.79 | 579.43 | 47.19 | 25.675 |

| 3 | Ti-Nb-Zr–Ti–Ta, 30 min | 3.65 | 448.75 | 619.67 | 45.42 | 23.278 |

| 4 | Ti-Nb-Zr–Ta/Ti, 30 min | 3.67 | 451.24 | 618.72 | 47.12 | 22.589 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nasakina, E.O.; Sudarchikova, M.A.; Demin, K.Y.; Mikhailova, A.B.; Sergienko, K.V.; Konushkin, S.V.; Kaplan, M.A.; Baikin, A.S.; Sevostyanov, M.A.; Kolmakov, A.G. Study of Co-Deposition of Tantalum and Titanium during the Formation of Layered Composite Materials by Magnetron Sputtering. Coatings 2023, 13, 114. https://doi.org/10.3390/coatings13010114

Nasakina EO, Sudarchikova MA, Demin KY, Mikhailova AB, Sergienko KV, Konushkin SV, Kaplan MA, Baikin AS, Sevostyanov MA, Kolmakov AG. Study of Co-Deposition of Tantalum and Titanium during the Formation of Layered Composite Materials by Magnetron Sputtering. Coatings. 2023; 13(1):114. https://doi.org/10.3390/coatings13010114

Chicago/Turabian StyleNasakina, Elena Olegovna, Maria Andreevna Sudarchikova, Konstantin Yurievich Demin, Alexandra Borisovna Mikhailova, Konstantin Vladimirovich Sergienko, Sergey Viktorovich Konushkin, Mikhail Alexandrovich Kaplan, Alexander Sergeevich Baikin, Mikhail Anatolyevich Sevostyanov, and Alexei Georgievich Kolmakov. 2023. "Study of Co-Deposition of Tantalum and Titanium during the Formation of Layered Composite Materials by Magnetron Sputtering" Coatings 13, no. 1: 114. https://doi.org/10.3390/coatings13010114

APA StyleNasakina, E. O., Sudarchikova, M. A., Demin, K. Y., Mikhailova, A. B., Sergienko, K. V., Konushkin, S. V., Kaplan, M. A., Baikin, A. S., Sevostyanov, M. A., & Kolmakov, A. G. (2023). Study of Co-Deposition of Tantalum and Titanium during the Formation of Layered Composite Materials by Magnetron Sputtering. Coatings, 13(1), 114. https://doi.org/10.3390/coatings13010114