Preparation of Healable Shellac Microcapsules and Color-Changing Microcapsules and Their Effect on Properties of Surface Coatings on Hard Broad-Leaved Wood Substrates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Preparation Methods

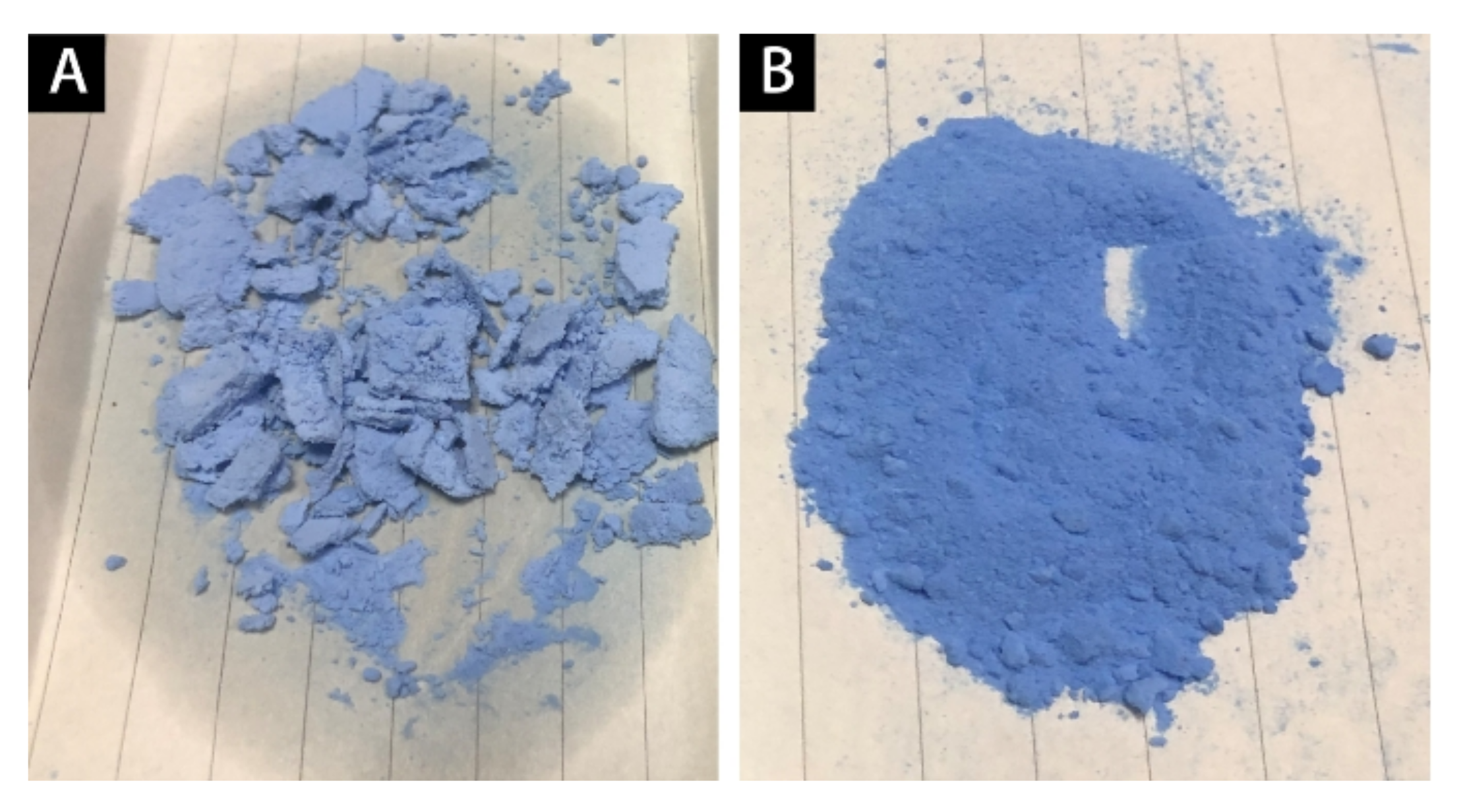

2.2.1. Preparation of Shellac Microcapsules

- (1)

- Preparation of wall material: 20.0 g of urea and 27.0 g of formaldehyde were added in a sealed beaker and stirred until completely dissolved. Triethanolamine was dripped into the mixed solution under stirring, the pH value was adjusted to 8.5–9.0, and the solution was stirred for 60 min to obtain the wall solution.

- (2)

- Preparation of core material: 22.5 g of shellac tablets and 112.5 g of anhydrous ethanol were dissolved and placed into a centrifuge to obtain clear liquid. Then, 1.76 g of sodium dodecyl benzene sulfonate white powder was added into 174 g of distilled water and stirred until in a transparent and granular state. The emulsifier and dissolved shellac were added into the rotor stirrer to emulsify for 30 min, and the core material solution was obtained.

- (3)

- Microencapsulation: The wall material of the urea–formaldehyde prepolymer was dropped into the core material solution. Next, 1.0 g of hydrated citric acid was added to water and dropped into the mixed solution of wall material and core material, and the pH was adjusted to 2.5–3.0. Then, the temperature of the water bath was raised to 70 °C and stirred for a reaction for 3 h. Afterward, the water bath was placed at room temperature for 48 h.

- (4)

- Suction filtration: After standing, the solution was stirred thoroughly using a glass rod. The liquid part was filtered and washed with distilled water and absolute ethanol. The final particle powder was dried in an oven at 40 °C for 48 h and naturally dried at room temperature to gain the microcapsule powder.

2.2.2. Preparation of Discoloration Microcapsules

- (1)

- Preparation of wall material: 3.00 g of urea and 4.05 g of formaldehyde were added in a sealed beaker and stirred until completely dissolved. Triethanolamine was dripped into the mixed solution under stirring, the pH value was adjusted to 8.5–9.0, and the solution was stirred for 60 min to obtain the wall solution.

- (2)

- Preparation of core material: 1.35 g of emulsifier (gum arabic powder) and 43.65 g of distilled water were mixed and stirred until completely dissolved to obtain the 3% solution. Then, 2.57 g of the color-changing compound made of crystal violet lactone, bisphenol A, and tetradecanol was added at the mass rate of 1: 3: 60 to the above solution. Then, it was placed in a magnetic stirrer, heated to 65 °C, and stirred for 60 min to obtain the core material solution.

- (3)

- Microencapsulation: The wall material solution was added to the core material solution, citric acid was added, and the pH was adjusted to 2.5~3.0. The mixture was stirred for 1 h, the temperature of the mixture was raised to 70 °C, and the mixture was stirred for 30 min. After stirring, the mixture was left to precipitate at room temperature for 48 h.

- (4)

- Suction filtration: After standing, the liquid part was filtered and washed with distilled water and absolute ethanol. The final granular powder was put into a 40 °C oven to dry for 48 h, and then it was allowed to dry at room temperature. Finally, the microcapsule powder was obtained.

2.2.3. Preparation of Coating

2.3. Testing and Characterization

3. Results and Discussion

3.1. Color Difference Analysis

3.2. Healable Analysis

3.3. Roughness Analysis

3.4. Hardness Analysis

3.5. Microstructure Analysis

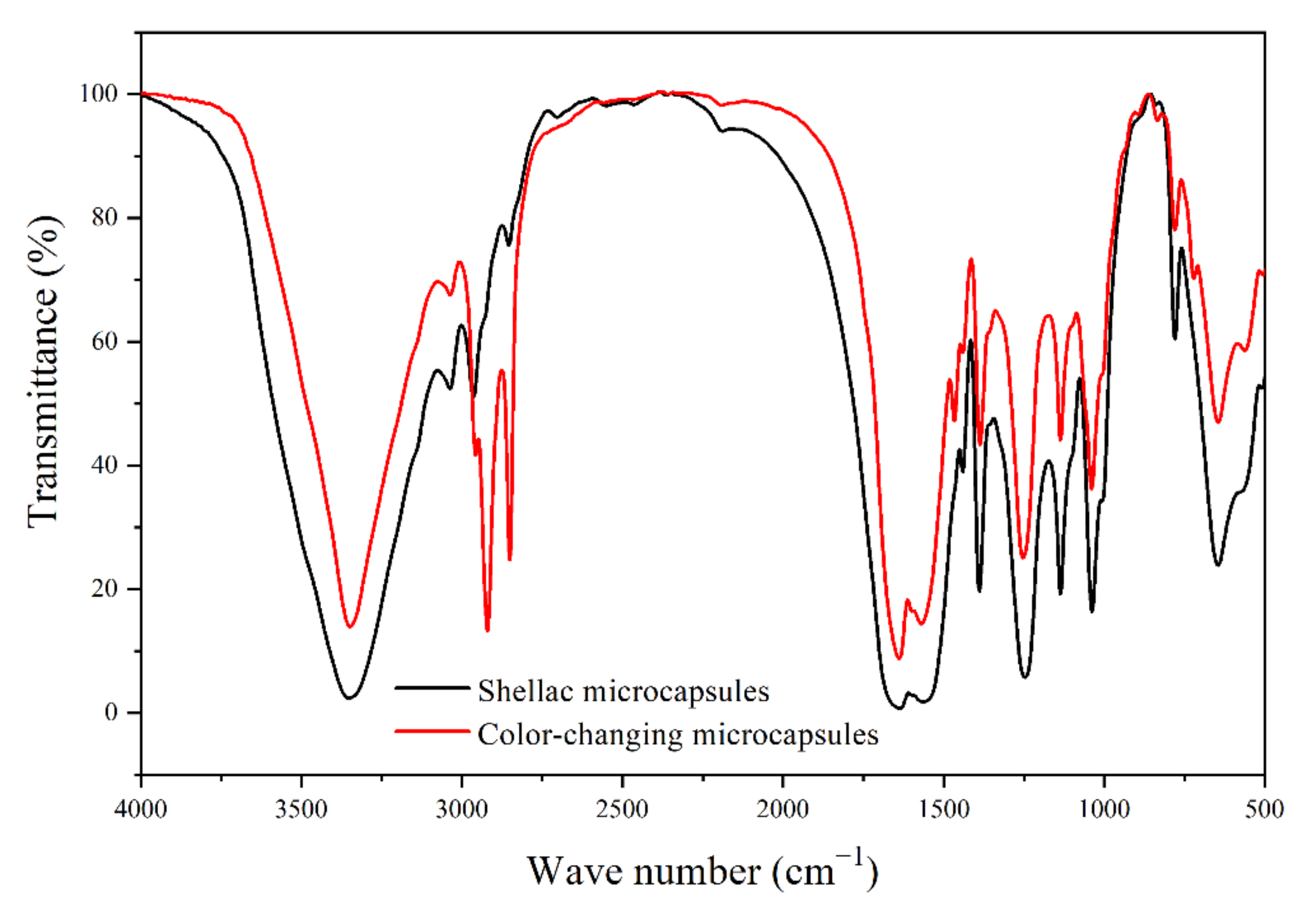

3.6. Infrared spectroscopy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Q.Q.; Gao, D.; Xu, W. Influence of the bottom color modification and material color modification process on the performance of modified Poplar. Coatings 2021, 11, 660. [Google Scholar] [CrossRef]

- Fu, R.Y.; Zhang, W.B.; Li, D.Q.; Zhang, H.J. Analyses on chemical composition of ancient wood structural component by using near infrared spectroscopy. J. For. Eng. 2021, 6, 114–119. [Google Scholar]

- Zhao, Y.; Ren, J.; Zheng, X.X.; Pan, B.; Leng, W.Q. Effects of three kinds of fungi on color, chemical composition and route of infection of Picea sitchensis. J. For. Eng. 2021, 6, 88–93. [Google Scholar]

- Zhang, S.W.; Yu, A.X.; Song, X.Q.; Liu, X.Y. Synthesis and characterization of waterborne UV-curable polyurethane nanocomposites based on the macromonomer surface modification of colloidal silica. Prog. Org. Coat. 2013, 76, 1032–1039. [Google Scholar] [CrossRef]

- Feng, X.H.; Chen, J.Y.; Wu, Z.H.; Wu, Y.; Gan, J. The formation mechanism of “skin-tactile” coating and its application and trends in furniture. J. For. Eng. 2021, 6, 167–175. [Google Scholar]

- Xu, W.; Fang, X.Y.; Han, J.T.; Wu, Z.H.; Zhang, J.L. Effect of coating thickness on sound absorption property of four wood species commonly used for piano soundboards. Wood Fiber Sci. 2020, 52, 28–43. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y. Self-assembly of poly(styrene-methyl methacrylate-acrylic acid) (P(St-MMA-AA)) colloidal microspheres on wood surface by thermal-assisted gravity deposition. Wood Sci. Technol. 2021, 55, 403–417. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, J. Investigation of polystyrene-based microspheres from different copolymers and their structural color coatings on wood surface. Coatings 2021, 11, 14. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, J.; Wu, Z. Fabrication of coatings with structural color on a wood surface. Coatings 2020, 10, 32. [Google Scholar] [CrossRef] [Green Version]

- Agnol, L.D.; Dias, F.T.G.; Ornaghi, H.L.; Sangermano, M.; Bianchi, O. UV-curable waterborne polyurethane coatings: A state-ofthe-art and recent advances review. Prog. Org. Coat. 2021, 154, 106156. [Google Scholar] [CrossRef]

- Liu, Q.; Gao, D.; Xu, W. Effect of sanding processes on the surface properties of modified poplar coated by primer compared with mahogany. Coatings 2020, 10, 856. [Google Scholar] [CrossRef]

- Liu, Q.; Gao, D.; Xu, W. Effect of paint process on the performance of modified poplar wood antique. Coatings 2021, 11, 1174. [Google Scholar] [CrossRef]

- Xu, W.; Chen, P.; Yang, Y.; Wang, X.; Liu, X. Effects of freezing and steam treatments on the permeability of populus tomentosa. Materialwiss. Werkst. 2021, 52, 907–915. [Google Scholar] [CrossRef]

- Scheiner, M.; Dickens, T.J.; Okoli, O. Progress towards self-healing polymers for composite structural applications. Polymer 2016, 83, 260–282. [Google Scholar] [CrossRef]

- Lu, Z.; Hu, J.B.; Zhang, M.H.; Chang, S.S.; Liu, Y.; Zheng, L.; Li, X.J. Research on wettability of wood surface with waterborne-resin priming paint. J. For. Eng. 2021, 6, 178–183. [Google Scholar]

- Yan, X.X.; Peng, W.W. Preparation of microcapsules of urea formaldehyde resin coated waterborne coatings and their effect on properties of wood crackle coating. Coatings 2020, 10, 764. [Google Scholar] [CrossRef]

- Wu, S.; Tao, X.; Xu, W. Thermal conductivity of Poplar wood veneer impregnated with graphene/polyvinyl alcohol. Forests 2021, 12, 777. [Google Scholar] [CrossRef]

- Liu, Q.; Gu, Y.; Xu, W.; Lu, T.; Li, W.; Fan, H. Compressive properties of green velvet material used in mattress bedding. Appl. Sci. 2021, 11, 11159. [Google Scholar] [CrossRef]

- Chen, K.L.; Zhou, J.L.; Che, X.G.; Zhao, R.Y.; Gao, Q. One-step synthesis of core shell cellulose-silica/n-octadecane microcapsules and their application in waterborne self-healing multiple protective fabric coatings. J. Colloid Interface Sci. 2020, 566, 401–410. [Google Scholar] [CrossRef]

- Hu, J.; Liu, Y.; Wu, Z.H.; Pang, X.R. Construction of bionic structural color coating on wood surface based on polystyrene microspheres. J. For. Eng. 2021, 6, 35–42. [Google Scholar]

- Revuelta, M.V.; Bogdan, S.; Gamez-Espinosa, E.; Deya, M.C.; Romagnoli, R. Green antifungal waterborne coating based on essential oil microcapsules. Prog. Org. Coat. 2020, 151, 106101. [Google Scholar] [CrossRef]

- Busch, L.; Avlasevich, Y.; Zwicker, P.; Thiede, G. Release of the model drug SR101 from polyurethane nanocapsules in porcine hair follicles triggered by LED-derived low dose UVA light. Int. J. Pharm. 2021, 597, 120339. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.D.; Liu, Y.; Li, Z.; Wang, W.C. Thermochromic microcapsules with highly transparent shells obtained through in-situ polymerization of urea formaldehyde around thermochromic cores for smart wood coatings. Sci. Rep. 2018, 8, 4015. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pedaballi, S.; Li, C.C.; Song, Y.J. Dispersion of microcapsules for the improved thermochromic performance of smart coatings. RSC Adv. 2019, 9, 24175–24183. [Google Scholar] [CrossRef] [Green Version]

- Park, S.; Cho, Y.A.; Park, S.; Oh, M.; Kim, D.; Lim, G.; Park, J.J. Polyurea microcapsules with different phase change material for thermochromic smart displays. Chem. Lett. 2019, 48, 1343–1346. [Google Scholar] [CrossRef]

- GB/T 6739-2006; Paint and Varnishes-Determination of Film Hardness by Pencil Test. Standardization Administration of the People’s Republic of China: Beijing, China, 1998.

| Sample | Content of Color-Changing Microcapsules (%) | Shellac Microcapsule Content (%) | Adding Situation of Microcapsule |

|---|---|---|---|

| 1# | 10.0 | 5.0 | primer with color-changing microcapsules and topcoat with shellac microcapsules |

| 2# | 10.0 | 15.0 | topcoat with color-changing microcapsules and primer with shellac microcapsules |

| 3# | 20.0 | 5.0 | topcoat with color-changing microcapsules and primer with shellac microcapsules |

| 4# | 20.0 | 15.0 | primer with color-changing microcapsules and topcoat with shellac microcapsules |

| Sample | Content of Color-Changing Microcapsules (%) | Shellac Microcapsule Content (%) | Adding Situation of Microcapsule |

|---|---|---|---|

| 5# | 10.0 | 15.0 | primer with color-changing microcapsules and topcoat with shellac microcapsules |

| 6# | 0 | 0 | no microcapsules |

| 7# | 10.0 | 0 | primer with color-changing microcapsules |

| 8# | 0 | 15.0 | topcoat with shellac microcapsules |

| Sample | L | a | b | c | h | L’ | a’ | b’ | c’ | h’ | △L* | △a* | △b* | △E* |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1# | 55.3 | 16.2 | 18.4 | 24.5 | 48.6 | 52.7 | 16.8 | 16.0 | 23.2 | 43.5 | −2.6 | 0.6 | −2.4 | 3.6 |

| 2# | 58.8 | 13.1 | 16.6 | 21.2 | 51.7 | 59.9 | 12.8 | 14.7 | 19.5 | 48.8 | 1.1 | −0.3 | −.9 | 2.2 |

| 3# | 56.9 | 15.7 | 17.7 | 23.7 | 48.4 | 57.2 | 14.5 | 16.3 | 21.8 | 48.4 | 0.3 | −1.2 | −1.4 | 1.9 |

| 4# | 60.1 | 10.9 | 11.3 | 15.7 | 46 | 57.7 | 13.4 | 11.0 | 17.4 | 39.5 | −2.4 | 2.5 | −0.3 | 3.5 |

| Sample | Content of Color-Changing Microcapsules (%) | Shellac Microcapsule Content (%) | Adding Situation of Microcapsule | Chromatic Aberration |

|---|---|---|---|---|

| 1# | 10.0 | 5.0 | primer with color-changing microcapsules and topcoat with shellac microcapsules | 3.6 |

| 2# | 10.0 | 15.0 | topcoat with color-changing microcapsules and primer with shellac microcapsules | 2.2 |

| 3# | 20.0 | 5.0 | topcoat with color-changing microcapsules and primer with shellac microcapsules | 1.9 |

| 4# | 20.0 | 15.0 | primer with color-changing microcapsules and topcoat with shellac microcapsules | 3.5 |

| Mean 1 | 2.900 | 2.750 | 3.550 | - |

| Mean 2 | 2.700 | 2.850 | 2.050 | - |

| Range | 0.200 | 0.100 | 1.500 | - |

| Sample | L | a | b | c | h | L’ | a’ | b’ | c’ | h’ | △L | △a | △b | △E |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5# | 63.2 | 10.5 | 11.7 | 15.8 | 48.1 | 58.9 | 10.0 | 10.4 | 14.5 | 46.2 | −4.3 | −0.5 | −1.3 | 4.5 |

| 6# | 51.4 | 16.6 | 29.4 | 33.8 | 60.5 | 50.5 | 15.5 | 29.1 | 35.1 | 56 | −0.9 | −1.1 | −0.3 | 1.5 |

| 7# | 58.3 | 15.2 | 22.9 | 27.4 | 56.3 | 54.7 | 16.4 | 19.8 | 25.8 | 50.3 | −3.6 | 1.2 | −3.1 | 4.9 |

| 8# | 59.1 | 13.3 | 13.3 | 18.8 | 45.0 | 58.0 | 12.0 | 14.1 | 18.6 | 49.6 | −1.1 | −1.3 | 0.8 | 1.9 |

| Sample | Before Repairing (μm) | After Repairing (μm) | Difference (μm) |

|---|---|---|---|

| 5# | 14.21 | 8.81 | 5.40 |

| 6# | 15.39 | 15.27 | 0.12 |

| 7# | 14.81 | 14.81 | 0 |

| 8# | 10.88 | 7.99 | 2.89 |

| Sample | 5# | 6# | 7# | 8# |

|---|---|---|---|---|

| Roughness (μm) | 2.808 | 0.294 | 2.075 | 3.858 |

| Sample | 5# | 6# | 7# | 8# |

|---|---|---|---|---|

| Hardness | 6 H | 5 H | 4 H | 5 H |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, Y.; Yan, X. Preparation of Healable Shellac Microcapsules and Color-Changing Microcapsules and Their Effect on Properties of Surface Coatings on Hard Broad-Leaved Wood Substrates. Coatings 2022, 12, 991. https://doi.org/10.3390/coatings12070991

Qin Y, Yan X. Preparation of Healable Shellac Microcapsules and Color-Changing Microcapsules and Their Effect on Properties of Surface Coatings on Hard Broad-Leaved Wood Substrates. Coatings. 2022; 12(7):991. https://doi.org/10.3390/coatings12070991

Chicago/Turabian StyleQin, Yanzhao, and Xiaoxing Yan. 2022. "Preparation of Healable Shellac Microcapsules and Color-Changing Microcapsules and Their Effect on Properties of Surface Coatings on Hard Broad-Leaved Wood Substrates" Coatings 12, no. 7: 991. https://doi.org/10.3390/coatings12070991

APA StyleQin, Y., & Yan, X. (2022). Preparation of Healable Shellac Microcapsules and Color-Changing Microcapsules and Their Effect on Properties of Surface Coatings on Hard Broad-Leaved Wood Substrates. Coatings, 12(7), 991. https://doi.org/10.3390/coatings12070991