Growth Mechanisms of TaN Thin Films Produced by DC Magnetron Sputtering on 304 Steel Substrates and Their Influence on the Corrosion Resistance

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

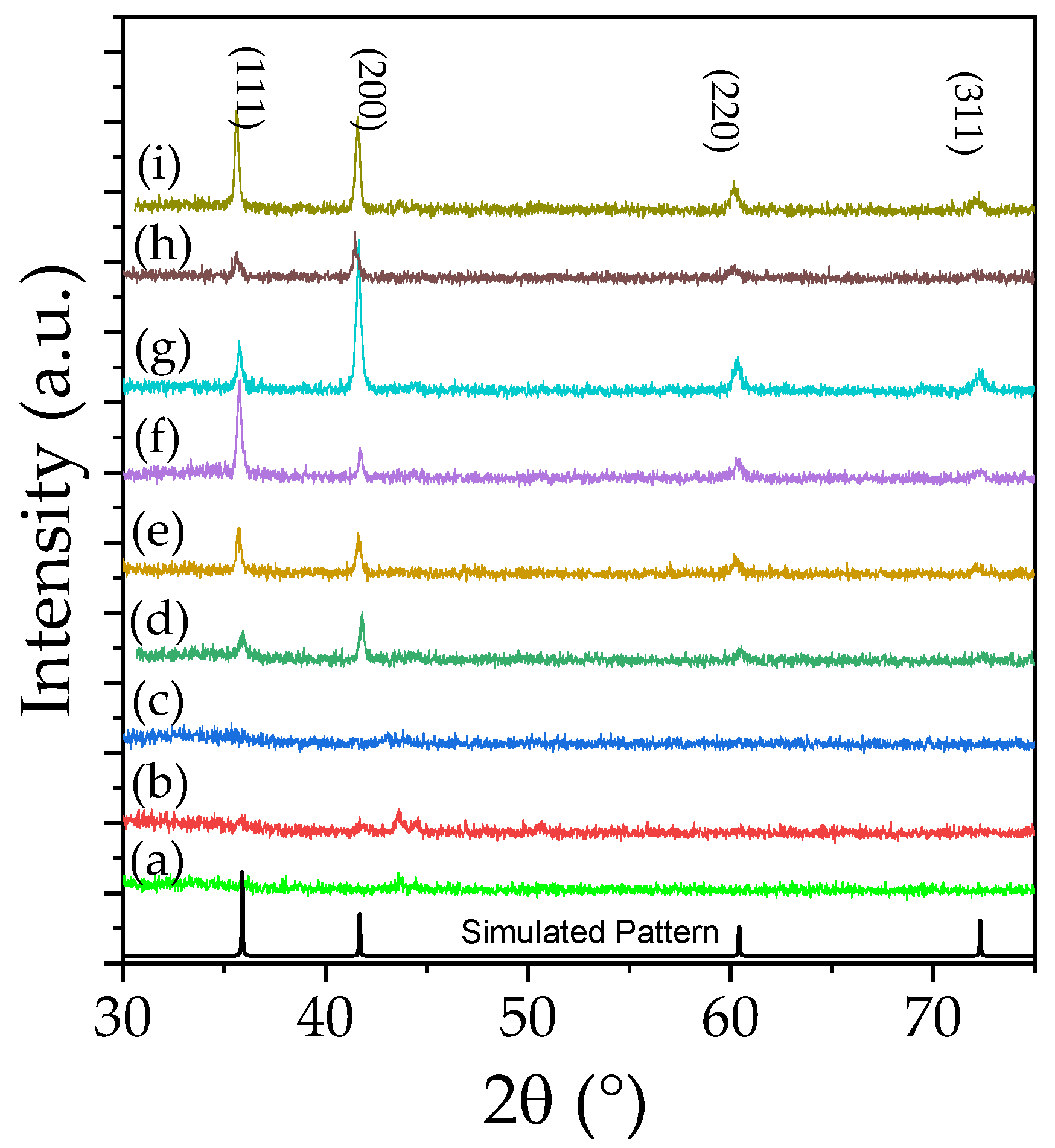

3.1. X-ray Diffraction Analysis

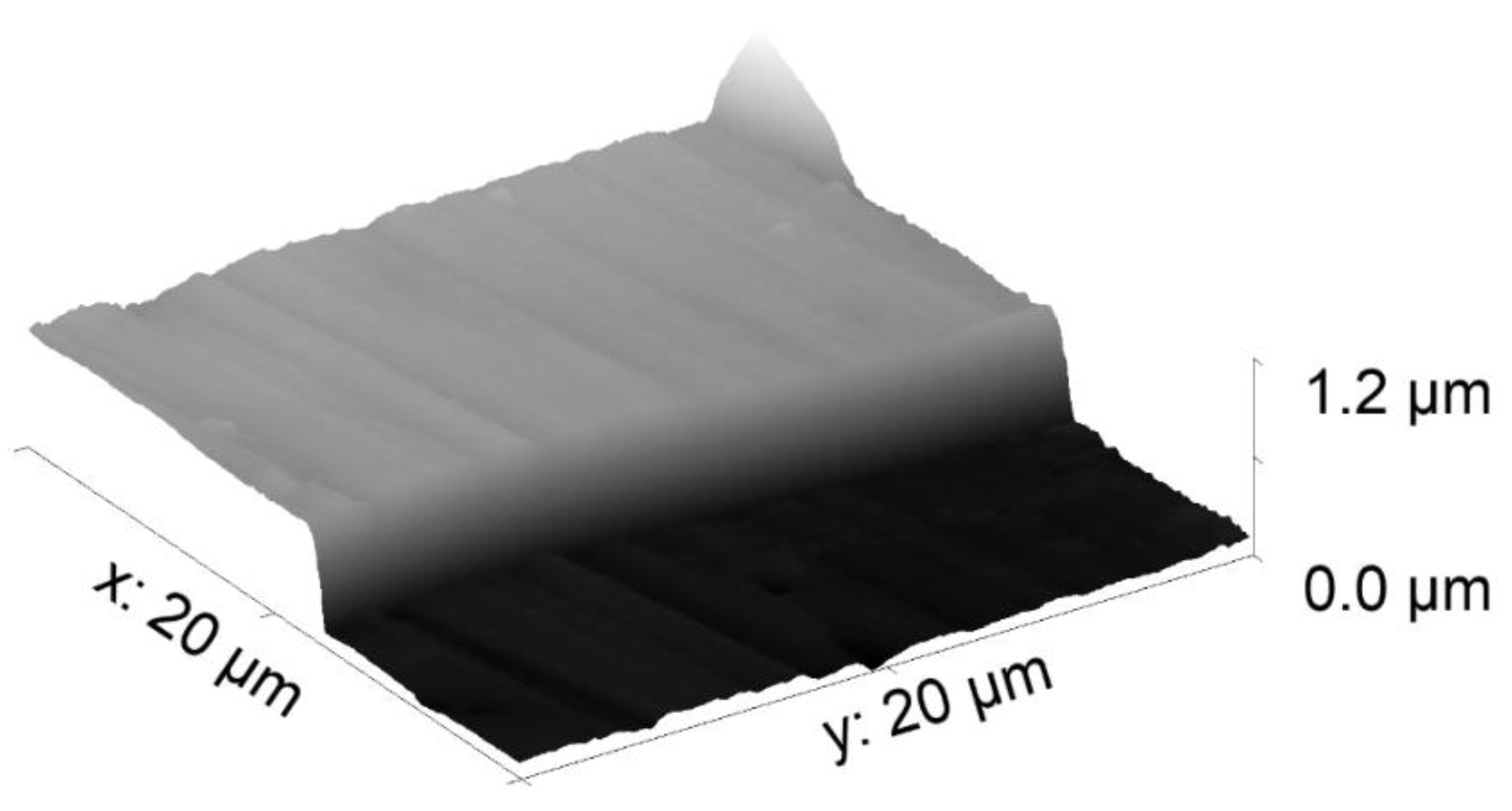

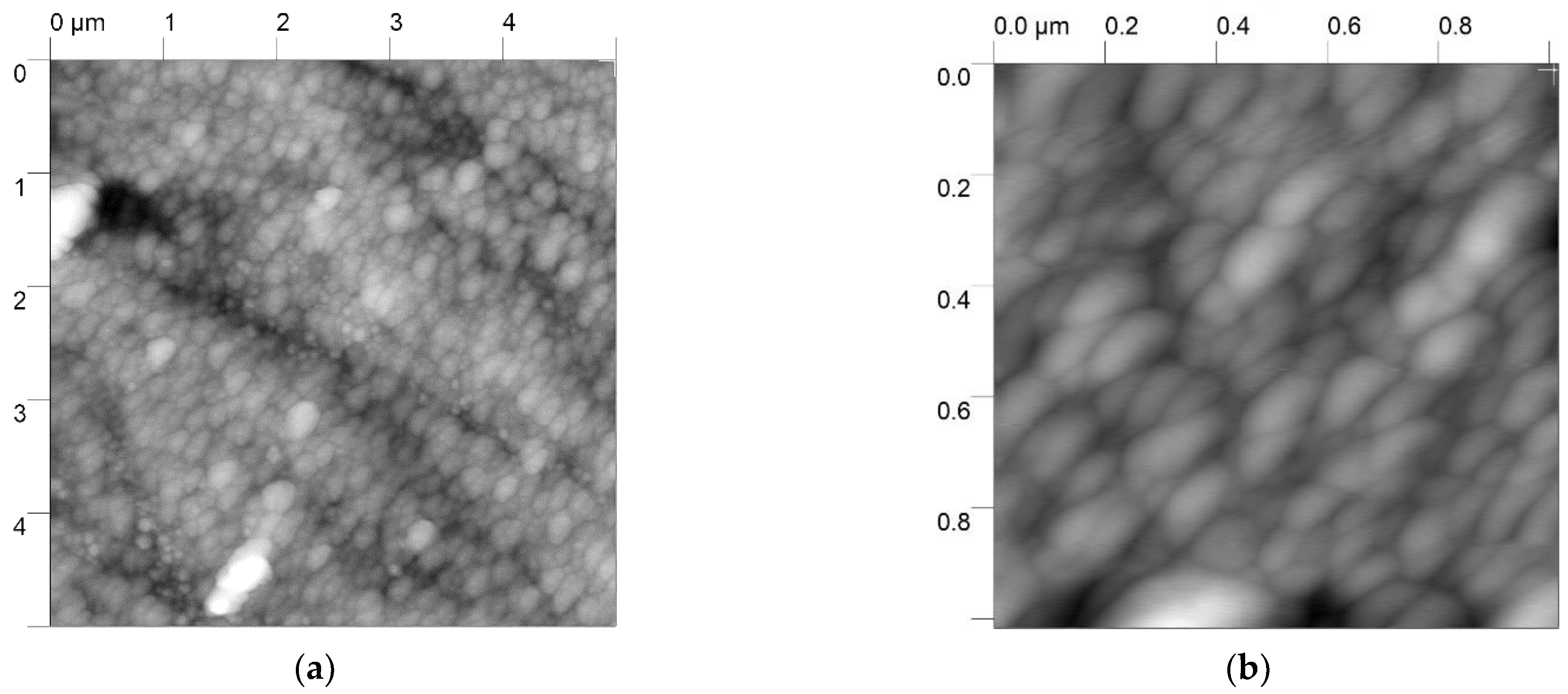

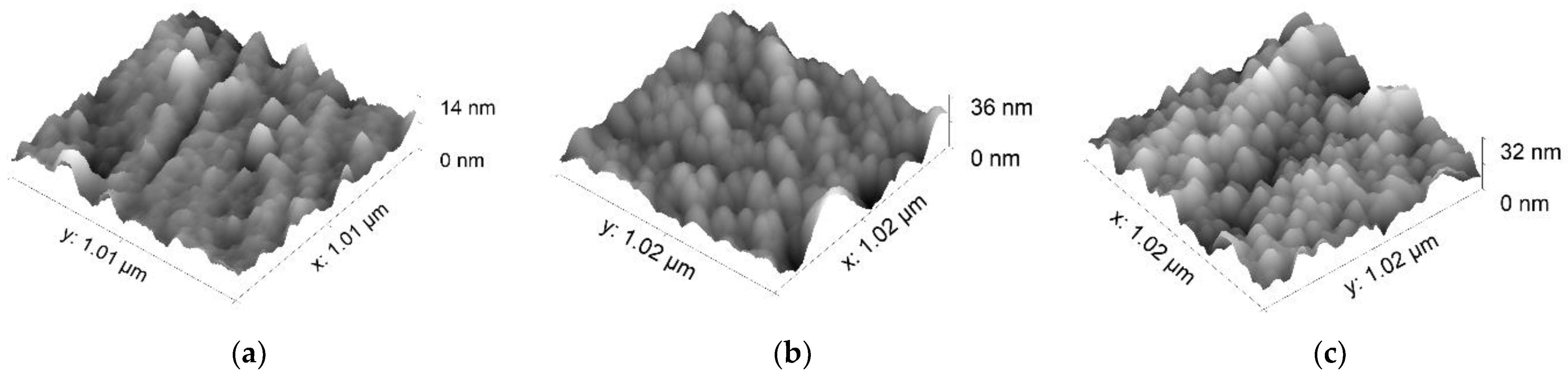

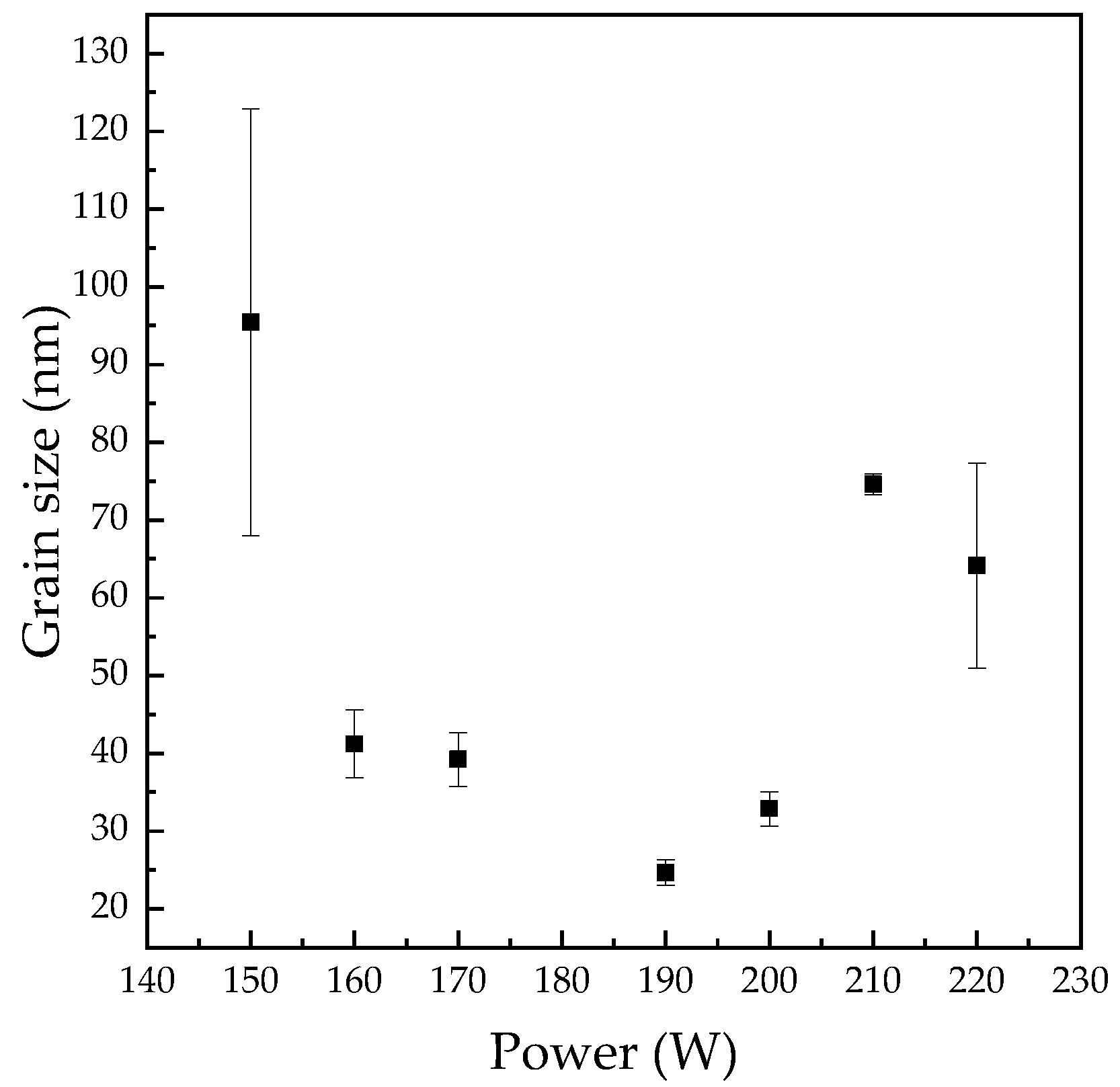

3.2. Scanning Probe Microscopy Analysis

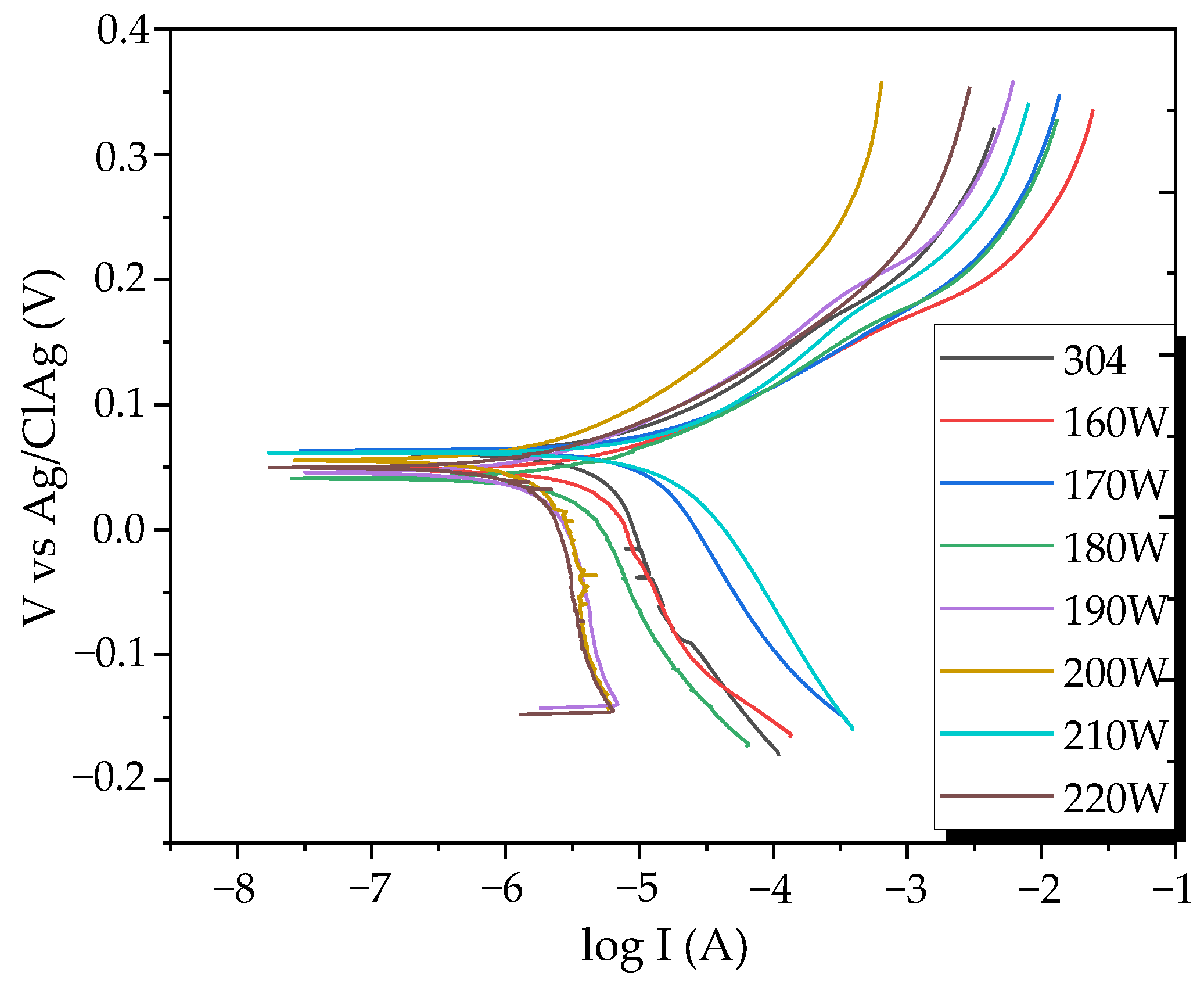

3.3. Corrosion Resistance Analysis

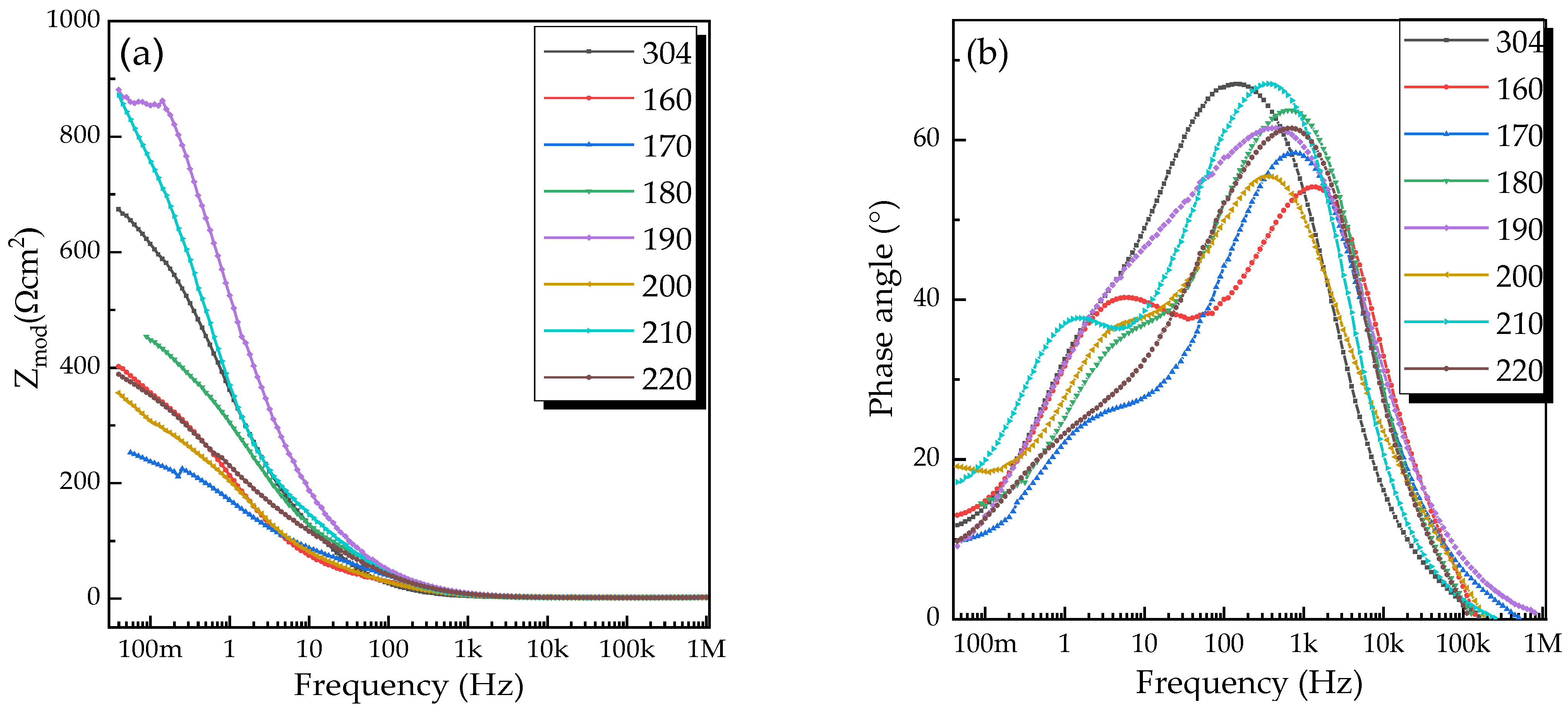

3.4. Electrochemical Impedance Spectroscopy (EIS)

4. Conclusions

- The successful synthesis of tantalum nitride has been achieved using the reactive DC sputtering technique and the effect of growth power on phase formation and microstructure has been investigated to reach an understanding of the growth mechanisms that predominate in the formation of the compound;

- Despite the fact that TaN is a material that is characterized by its great richness and coexistence of phases, with the parameter configuration used in this work, nanocrystalline films of the cubic δ-TaN structure were obtained for source power above 170 W, despite the low nitrogen content used, where it was then expected to obtain α-Ta or hexagonal ε-TaN; below this value, amorphous phases were obtained;

- Growth mechanisms were identified to be strongly related to the energy of ions reaching the substrate, where stress transition from compressive to tensile as applied power increases according to a variation in lattice parameter from 4.32 to 4.34 Å (free lattice parameter for δ-TaN is 4.34 Å), is related to energy decrement of nitrogen ions due to the collision frequency variations as a function of power;

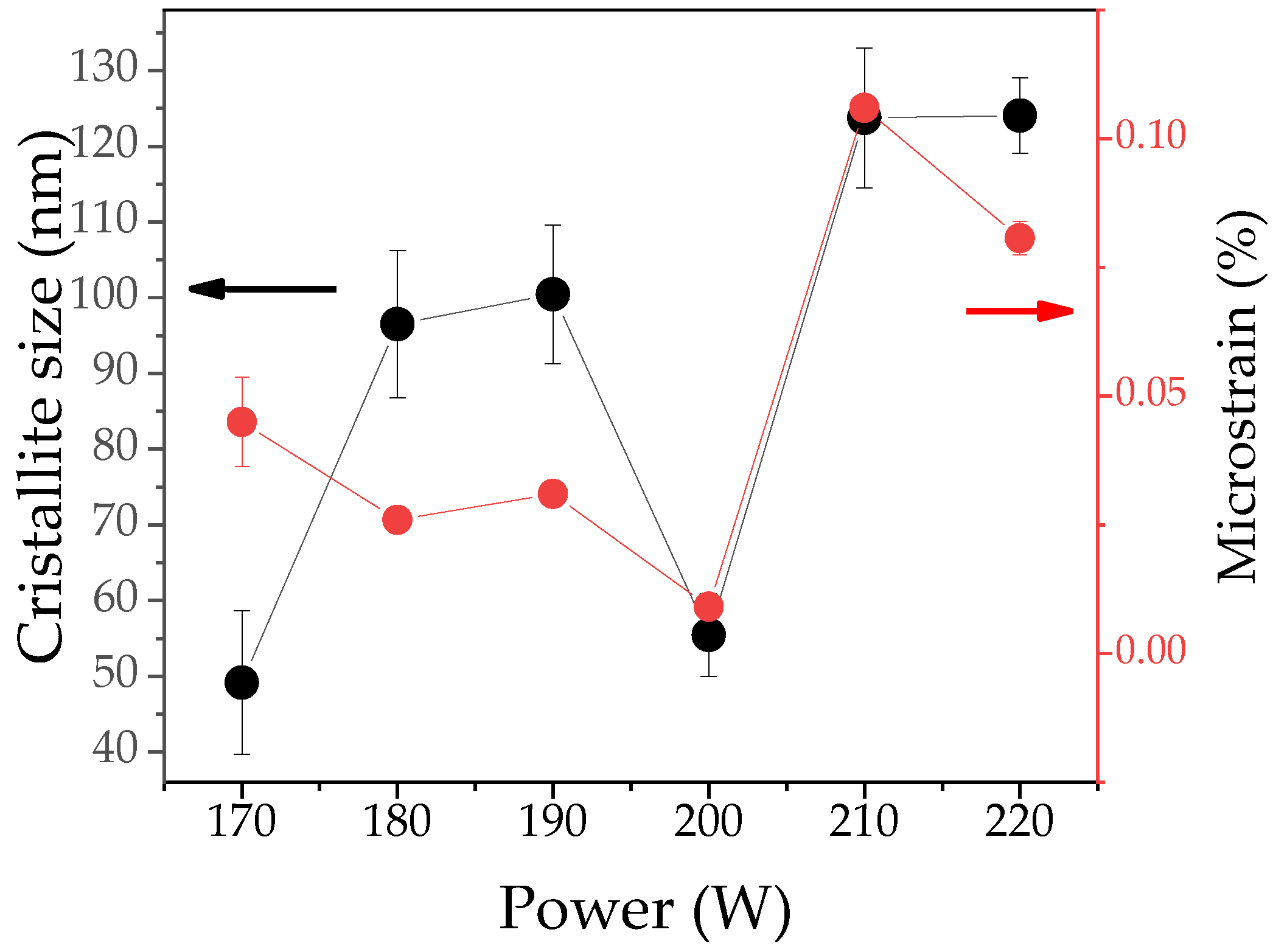

- Conventional diffusion increment of adatoms on the growing coating is favored as power goes from 170 W to 190 W, which is evidenced by the increment of crystallite size from 50 nm to 100 nm approximately. Subsequently, when power is increased to 200 W, an abnormal lowering in crystallite size is observed, implying an additional mechanism for diffusion, which consists of the collision frequency increment for Ta and N atoms, associated with adatom energy loss. Finally, higher power values lead to reactivation of diffusion processes due to the fact that energy loss due to collisions is recovered by the high potential applied to the deposition, implying a crystallite size growth above 100 nm;

- An additional mechanism is evident when microstrain increases simultaneously with crystallite size. This mechanism consists of the bombardment of reactive and neutral species against the growing coating when higher power is applied;

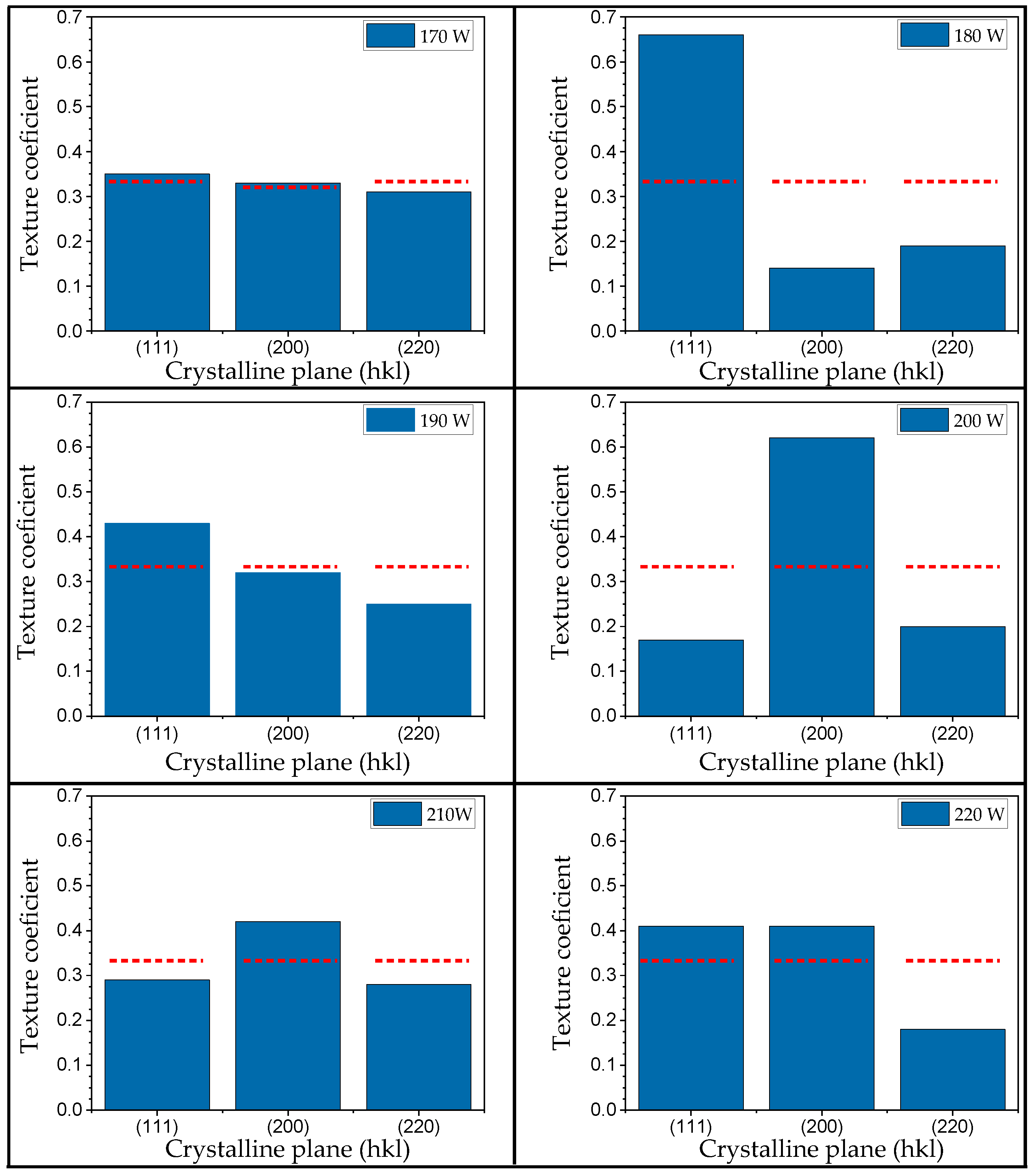

- From texture analysis, growth directions are influenced by the energy dissipation of adatoms in the substrate/growing coating surface. In addition to this, the high deposition rate and the low surface roughness of the samples is evidence of the high energy of the incident atoms. It was then possible to determine that excellent diffusion and homogeneous nucleation are the particular growth mechanisms that favor the formation of δ-TaN, for certain applied power values;

- The performance of the electrochemical tests allowed the determination that the increase in the grain size reduces the corrosion resistance of the coatings. However, it was also observed that the higher the deposition power, the better the corrosion resistance, achieving efficiencies of between 20 and 60%;

- Further work could be focused on the analysis of the cross-section of these coatings in order to correlate the specific mechanisms and lateral grain morphology (columnar and/or granular). Also, it would be very revealing to evaluate structural, microstructural, and morphological parameters with varying coating thickness in order to identify mechanisms at different stages of growth. It is important to note that knowing the mechanisms involved in the growth of this type of material by important techniques, such as magnetron sputtering will lead to the design and synthesis of coatings with specific desirable properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shostachenko, S.A.; Zakharchenko, R.V.; Ryzhuk, R.V.; Leshchev, S.V. Thermal Stability of Tantalum Nitride Based Thin Film Resistors. IOP Conf. Ser. Mater. Sci. Eng. 2019, 498, 012014. [Google Scholar] [CrossRef]

- Au, C.L.; Anderson, W.A.; Schmitz, D.A.; Flassayer, J.C.; Collins, F.M. Stability of Tantalum Nitride Thin Film Resistors. J. Mater. Res. 1990, 5, 1224–1232. [Google Scholar] [CrossRef]

- Kim, M.; Choi, M.; Lee, J.; Jin, W.; Choi, C. The Effective Work-Function of Atomic Layer Deposited TaN Thin Film Using TBTDET Precursor and NH3 Reactant Gas. Appl. Surf. Sci. 2022, 579, 152118. [Google Scholar] [CrossRef]

- Mikula, M.; Plašienka, D.; Roch, T.; Štyráková, K.; Satrapinskyy, L.; Drienovský, M.; Girman, V.; Grančič, B.; Pleceník, A.; Kúš, P. Structural Evolution of TaN-Alloyed Cr–Al–Y–N Coatings. Surf. Coat. Technol. 2016, 288, 203–210. [Google Scholar] [CrossRef]

- Kim, I.-S.; Cho, M.-Y.; Lee, D.-W.; Ko, P.-J.; Shin, W.H.; Park, C.; Oh, J.-M. Degradation Behaviors and Failure of Magnetron Sputter Deposited Tantalum Nitride. Thin Solid Films 2020, 697, 137821. [Google Scholar] [CrossRef]

- Wolf, S.; Breeden, M.; Kwak, I.; Park, J.H.; Kavrik, M.; Naik, M.; Alvarez, D.; Spiegelman, J.; Kummel, A.C. Low Temperature Thermal ALD TaNx and TiNx Films from Anhydrous N2H4. Appl. Surf. Sci. 2018, 462, 1029–1035. [Google Scholar] [CrossRef]

- Zhu, X.; Li, X.; Nistala, R.R.; Lim, J.D.; Seet, C.S.; Mo, Z.Q. Property Characterization of Tantalum Nitride Film Deposited with Different N2 Flow by X-ray Diffraction and X-ray Reflectivity. In Proceedings of the 2018 IEEE International Symposium on the Physical and Failure Analysis of Integrated Circuits (IPFA), Singapore, 16–19 July 2018; pp. 1–4. [Google Scholar]

- Schalk, N.; Tkadletz, M.; Mitterer, C. Hard Coatings for Cutting Applications: Physical vs. Chemical Vapor Deposition and Future Challenges for the Coatings Community. Surf. Coat. Technol. 2022, 429, 127949. [Google Scholar] [CrossRef]

- Ariharan, N.; Sriram, C.G.; Radhika, N.; Aswin, S.; Haridas, S. A Comprehensive Review of Vapour Deposited Coatings for Cutting Tools: Properties and Recent Advances. Trans. IMF 2022, in press. [Google Scholar] [CrossRef]

- Chen, Z.; Zheng, Y.; Huang, Y.; Gao, Z.; Sheng, H.; Bartosik, M.; Mayrhofer, P.H.; Zhang, Z. Atomic-Scale Understanding of the Structural Evolution of TiN/AlN Superlattice during Nanoindentation—Part 1: Deformation. Acta Mater. 2022, 234, 118008. [Google Scholar] [CrossRef]

- Hahn, R.; Koutná, N.; Wójcik, T.; Davydok, A.; Kolozsvári, S.; Krywka, C.; Holec, D.; Bartosik, M.; Mayrhofer, P.H. Mechanistic Study of Superlattice-Enabled High Toughness and Hardness in MoN/TaN Coatings. Commun. Mater. 2020, 1, 62. [Google Scholar] [CrossRef]

- Hernández-Navarro, C.; Rivera, L.P.; Flores-Martínez, M.; Camps, E.; Muhl, S.; García, E. Tribological Study of a Mono and Multilayer Coating of TaZrN/TaZr Produced by Magnetron Sputtering on AISI-316L Stainless Steel. Tribol. Int. 2019, 131, 288–298. [Google Scholar] [CrossRef]

- Stavrev, M.; Fischer, D.; Wenzel, C.; Drescher, K.; Mattern, N. Crystallographic and Morphological Characterization of Reactively Sputtered Ta, TaN and TaNO Thin Films. Thin Solid Films 1997, 307, 79–88. [Google Scholar] [CrossRef]

- Wehring, B.; Gerlich, L.; Uhlig, B. XPS Diffusion Analysis of Ta(N)/Ru Diffusion Barriers for Cobalt Interconnects. In Proceedings of the 2021 IEEE International Interconnect Technology Conference (IITC), Kyoto, Japan, 6–9 July 2021; pp. 1–3. [Google Scholar]

- Holloway, K.; Fryer, P.M.; Cabral, C.; Harper, J.M.E.; Bailey, P.J.; Kelleher, K.H. Tantalum as a Diffusion Barrier between Copper and Silicon: Failure Mechanism and Effect of Nitrogen Additions. J. Appl. Phys. 1992, 71, 5433–5444. [Google Scholar] [CrossRef]

- Soro, N.; Brodie, E.G.; Abdal-hay, A.; Alali, A.Q.; Kent, D.; Dargusch, M.S. Additive Manufacturing of Biomimetic Titanium-Tantalum Lattices for Biomedical Implant Applications. Mater. Des. 2022, 218, 110688. [Google Scholar] [CrossRef]

- Ji, P.; Liu, S.; Deng, H.; Ren, H.; Zhang, J.; Sun, T.; Xu, K.; Shi, C. Effect of Magnetron-Sputtered Monolayer Ta and Multilayer Ti-Zr-Ta and Zr-Ti-Ta Coatings on the Surface Properties of Biomedical Ti-6Al-4V Alloy. Mater. Lett. 2022, 322, 132464. [Google Scholar] [CrossRef]

- Stavrev, M.; Fischer, D.; Praessler, F.; Wenzel, C.; Drescher, K. Behavior of Thin Ta-Based Films in the Cu/Barrier/Si System. J. Vac. Sci. Technol. A Vac. Surf. Films 1999, 17, 993–1001. [Google Scholar] [CrossRef]

- Pfeiler, M.; Scheu, C.; Hutter, H.; Schnöller, J.; Michotte, C.; Mitterer, C.; Kathrein, M. On the Effect of Ta on Improved Oxidation Resistance of Ti–Al–Ta–N Coatings. J. Vac. Sci. Technol. A Vac. Surf. Films 2009, 27, 554–560. [Google Scholar] [CrossRef]

- Lozovoy, K.A.; Korotaev, A.G.; Kokhanenko, A.P.; Dirko, V.V.; Voitsekhovskii, A.V. Kinetics of Epitaxial Formation of Nanostructures by Frank–van Der Merwe, Volmer–Weber and Stranski–Krastanow Growth Modes. Surf. Coat. Technol. 2020, 384, 125289. [Google Scholar] [CrossRef]

- Engel, A.; Aeschbacher, A.; Inderbitzin, K.; Schilling, A.; Il’in, K.; Hofherr, M.; Siegel, M.; Semenov, A.; Hübers, H.-W. Tantalum Nitride Superconducting Single-Photon Detectors with Low Cut-off Energy. Appl. Phys. Lett. 2012, 100, 062601. [Google Scholar] [CrossRef]

- Samuel, J.J.; Kumar, P.K.; Kumar, D.D.; Kirubaharan, A.K.; Raj, T.A.; Aravind, P. Effect of Substrate Temperature and Preferred Orientation on the Tribological Properties of Tantalum Nitride Coatings. Mater. Today Proc. 2021, 44, 4404–4408. [Google Scholar] [CrossRef]

- Liu, E.; Jin, G.; Cui, X.; Xiao, Q.; Shao, T. Effect of Gas Pressure on the Mechanical Properties of Sputtered Tan Films. Phys. Procedia 2013, 50, 438–441. [Google Scholar] [CrossRef][Green Version]

- Zaman, A.; Meletis, E.I. Microstructure and Mechanical Properties of TaN Thin Films Prepared by Reactive Magnetron Sputtering. Coatings 2017, 7, 209. [Google Scholar] [CrossRef]

- Nevala, M.R.; Maasilta, I.J.; Senapati, K.; Budhani, R.C. Fabrication and Characterization of Epitaxial NbN/TaN/NbN Josephson Junctions Grown by Pulsed Laser Ablation. IEEE Trans. Appl. Supercond. 2009, 19, 253–256. [Google Scholar] [CrossRef]

- Williamson, G.; Hall, W. X-Ray Line Broadening from Filed Aluminium and Wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Harris, G.B.X. Quantitative Measurement of Preferred Orientation in Rolled Uranium Bars. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1952, 43, 113–123. [Google Scholar] [CrossRef]

- Mashimo, T.; Tashiro, S.; Toya, T.; Nishida, M.; Yamazaki, H.; Yamaya, S.; Oh-ishi, K.; Syono, Y. Synthesis of the Bl-type tantalum nitride by shock compression. J. Mater. Sci. 1993, 28, 3439–3443. [Google Scholar] [CrossRef]

- Nie, H.B.; Xu, S.Y.; Wang, S.J.; You, L.P.; Yang, Z.; Ong, C.K.; Li, J.; Liew, T.Y.F. Structural and Electrical Properties of Tantalum Nitride Thin Films Fabricated by Using Reactive Radio-Frequency Magnetron Sputtering. Appl. Phys. A Mater. Sci. Process. 2001, 73, 229–236. [Google Scholar] [CrossRef]

- Xu, S.; Munroe, P.; Xu, J.; Xie, Z.-H. The Microstructure and Mechanical Properties of Tantalum Nitride Coatings Deposited by a Plasma Assisted Bias Sputtering Deposition Process. Surf. Coat. Technol. 2016, 307, 470–475. [Google Scholar] [CrossRef]

- Petrunin, V.F.; Sorokin, N.I.; Borovinskaya, I.P.; Pityulin, A.N. Stability of Cubic Tantalum Nitrides during Heat Treatment. Poroshkovaya Metallurgiya 1980, 3, 62–64. [Google Scholar] [CrossRef]

- Baik, S.-I.; Kim, Y.-W. Microstructural Evolution of Tantalum Nitride Thin Films Synthesized by Inductively Coupled Plasma Sputtering. Appl. Microsc. 2020, 50, 7. [Google Scholar] [CrossRef]

- Olaya, J.J.; Marulanda, D.M.; Rodil, S. Preferential Orientation in Metal Nitride Deposited by the UBM System. Ing. Investig. 2010, 30, 125–129. [Google Scholar] [CrossRef]

- Chopra, K.L.; Randlett, M.R.; Duff, R.H. Face-Centred Cubic Modification in Sputtered Films of Tantalum, Molybdenum, Tungsten, Rhenium, Hafnium and Zirconium. Philos. Mag. 1967, 16, 261–273. [Google Scholar] [CrossRef]

- Al-masha’al, A.; Bunting, A.; Cheung, R. Evaluation of Residual Stress in Sputtered Tantalum Thin-Film. Appl. Surf. Sci. 2016, 371, 571–575. [Google Scholar] [CrossRef]

- Yoshihara, T. Variation of Internal Stresses in Sputtered Ta Films. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 1993, 11, 301. [Google Scholar] [CrossRef]

- Clevenger, L.A.; Mutscheller, A.; Harper, J.M.E.; Cabral, C.; Barmak, K. The Relationship between Deposition Conditions, the Beta to Alpha Phase Transformation, and Stress Relaxation in Tantalum Thin Films. J. Appl. Phys. 1992, 72, 4918–4924. [Google Scholar] [CrossRef]

- Caglioti, G.; Paoletti, A.; Ricci, F.P. On Resolution and Luminosity of a Neutron Diffraction Spectrometer for Single Crystal Analysis. Nucl. Instrum. Methods 1960, 9, 195–198. [Google Scholar] [CrossRef]

- Chan, K.-Y.; Teo, B.-S. Investigation into the Influence of Direct Current (DC) Power in the Magnetron Sputtering Process on the Copper Crystallite Size. Microelectron. J. 2007, 38, 60–62. [Google Scholar] [CrossRef]

- Ekpe, S.D.; Dew, S.K. Energy Deposition at the Substrate in a Magnetron Sputtering System. In Reactive Sputter Deposition; Springer: Berlin/Heidelberg, Germany, 2008; pp. 229–254. [Google Scholar]

- Le, M.-T.; Sohn, Y.-U.; Lim, J.-W.; Choi, G.-S. Effect of Sputtering Power on the Nucleation and Growth of Cu Films Deposited by Magnetron Sputtering. Mater. Trans. 2010, 51, 116–120. [Google Scholar] [CrossRef]

- Cogswell, D.A.; Bazant, M.Z. Coherency Strain and the Kinetics of Phase Separation in LiFePO4 Nanoparticles. ACS Nano 2012, 6, 2215–2225. [Google Scholar] [CrossRef]

- Shah, H.N.; Jayaganthan, R.; Kaur, D.; Chandra, R. Influence of Sputtering Parameters and Nitrogen on the Microstructure of Chromium Nitride Thin Films Deposited on Steel Substrate by Direct-Current Reactive Magnetron Sputtering. Thin Solid Films 2010, 518, 5762–5768. [Google Scholar] [CrossRef]

- Jaiswal, J.; Chauhan, S.; Chandra, R. Influence of Sputtering Parameters on Structural, Optical and Thermal Properties of Copper Nanoparticles Synthesized by DC Magnetron Sputtering. Int. J. Sci. Technol. Manag. 2015, 04, 678–688. [Google Scholar]

- Bin Rafiq, M.K.S.; Amin, N.; Alharbi, H.F.; Luqman, M.; Ayob, A.; Alharthi, Y.S.; Alharthi, N.H.; Bais, B.; Akhtaruzzaman, M. WS2: A New Window Layer Material for Solar Cell Application. Sci. Rep. 2020, 10, 771. [Google Scholar] [CrossRef] [PubMed]

- Hesse, D.; Zakharov, N.D.; Pignolet, A.; James, A.R.; Senz, S. TEM Cross-Section Investigations of Epitaxial Ba2Bi4Ti5O18 Thin Films on LaNiO3 Bottom Electrodes on CeO2/YSZ-Buffered Si(100). Cryst. Res. Technol. 2000, 35, 641–651. [Google Scholar] [CrossRef]

- Elangovan, T.; Murugeshan, S.; Mangalaraj, D.; Kuppusami, P.; Khan, S.; Sudha, C.; Ganesan, V.; Divakar, R.; Mohandas, E. Synthesis and High Temperature XRD Studies of Tantalum Nitride Thin Films Prepared by Reactive Pulsed Dc Magnetron Sputtering. J. Alloys Compd. 2011, 509, 6400–6407. [Google Scholar] [CrossRef]

- Ma, C.-H.; Huang, J.-H.; Chen, H. Texture Evolution of Transition-Metal Nitride Thin Films by Ion Beam Assisted Deposition. Thin Solid Films 2004, 446, 184–193. [Google Scholar] [CrossRef]

- Shin, C.-S.; Gall, D.; Kim, Y.-W.; Hellgren, N.; Petrov, I.; Greene, J.E. Development of Preferred Orientation in Polycrystalline NaCl-Structure δ-TaN Layers Grown by Reactive Magnetron Sputtering: Role of Low-Energy Ion Surface Interactions. J. Appl. Phys. 2002, 92, 5084–5093. [Google Scholar] [CrossRef]

- Chawla, V.; Jayaganthan, R.; Chawla, A.K.; Chandra, R. Microstructural Characterizations of Magnetron Sputtered Ti Films on Glass Substrate. J. Mater. Process. Technol. 2009, 209, 3444–3451. [Google Scholar] [CrossRef]

- Jin, Y.; Wu, W.; Li, L.; Chen, J.; Zhang, J.; Zuo, Y.; Fu, J. Effect of Sputtering Power on Surface Topography of Dc Magnetron Sputtered Ti Thin Films Observed by AFM. Appl. Surf. Sci. 2009, 255, 4673–4679. [Google Scholar] [CrossRef]

- Escobar, D. Microstructure, Residual Stress and Hardness of Titanium-Zirconium Nitride Thin Films. Master’s Thesis, Universidad Nacional de Colombia sede Manizales, Bogota, Colombia, 2012. [Google Scholar]

- Hernández, D.A.P.; Parra, E.R.; Arango, P.J.A.; Giraldo, B.S.; Medina, C.D.A. Innovative Method for Coating of Natural Corrosion Inhibitor Based on Artemisia Vulgaris. Materials 2021, 14, 2234. [Google Scholar] [CrossRef]

- Firouzabadi, S.S.; Naderi, M.; Dehghani, K.; Mahboubi, F. Effect of Nitrogen Flow Ratio on Nano-Mechanical Properties of Tantalum Nitride Thin Film. J. Alloys Compd. 2017, 719, 63–70. [Google Scholar] [CrossRef]

- Gramberg, U.; Renner, M.; Diekmann, H. Tantalum as a Material of Construction for the Chemical Processing Industry—A Critical Survey. Mater. Corros. 1995, 46, 689–700. [Google Scholar] [CrossRef]

- Ralston, K.D.; Birbilis, N. Effect of Grain Size on Corrosion: A Review. Corrosion 2010, 66, 075005. [Google Scholar] [CrossRef]

- Ramírez-Jerez, J.A.; Valero-Alvarado, M.; Peña-Ballesteros, D.Y.; Torres-Ramírez, J.E. Influence of Crystal Size of Galvanized Zinc Sheets in Environments with Sulfates and Clorides. Rev. Fac. Ing. 2015, 24, 99. [Google Scholar] [CrossRef]

- Espinosa, J.P.N. Corrosion Resistance Evaluation of TiZrN Thin Films through Electrochemical Techniques. In Proceedings of the 2018 IEEE International Symposium on the Physical and Failure Analysis of Integrated Circuits (IPFA), Singapore, 16–19 July 2019; pp. 1–4. [Google Scholar]

- Lu, Y.; Weng, R.; Hwang, W.; Yang, Y. Study of Phase Transition and Electrical Resistivity of Tantalum Nitride Films Prepared by DC Magnetron Sputtering with OES Detection System. Thin Solid Films 2001, 398–399, 356–360. [Google Scholar] [CrossRef]

| Power of the Sample (W) | Thickness (nm) | Error (nm) |

|---|---|---|

| 120 | 467.08 | ±3.4 |

| 150 | 424.02 | ±1.4 |

| 160 | 697.91 | ±3.5 |

| 170 | 579.26 | ±1.7 |

| 180 | 707.16 | ±3.5 |

| 190 | 560.33 | ±3.5 |

| 200 | 524.4 | ±6.1 |

| 210 | 588.37 | ±1.1 |

| 220 | 645.96 | ±3.2 |

| Power of the Sample | Roughness Rq (Rms) (nm) | Error (nm) |

|---|---|---|

| 120 | 4.6 | 1.4 |

| 150 | 10.7 | 3.7 |

| 160 | 22.6 | 9.9 |

| 170 | 7.9 | 1.3 |

| 180 | 17.9 | 3.7 |

| 190 | 13.5 | 3.1 |

| 200 | 6.7 | 1.6 |

| 210 | 11.2 | 2.9 |

| 220 | 8.2 | 2.7 |

| Sample | Icorr (u.A) | Ecorr (mV) | Rp (kΩ∙cm2) | Corrosion Rate (mmpy) | P (%) |

|---|---|---|---|---|---|

| 304 | 6.55 | 44.69 | 3.24 | 1.55 × 10−3 | - |

| 160 | 4.88 | 45.78 | 3.40 | 1.15 × 10−3 | 25.49 |

| 170 | 12.49 | 57.56 | 1.40 | 2.95 × 10−3 | 0 |

| 180 | 4.29 | 26.17 | 4.41 | 1.01 × 10−3 | 34.50 |

| 190 | 2.71 | 34.25 | 7.83 | 6.41 × 10−4 | 58.62 |

| 200 | 2.44 | 40.07 | 7.97 | 5.72 × 10−4 | 62.74 |

| 210 | 21.12 | 59.77 | 1.16 | 5.00 × 10−3 | 0 |

| 220 | 2.35 | 33.92 | 8.27 | 5.51 × 10−4 | 64.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serna-Manrique, M.D.; Escobar-Rincón, D.; Ospina-Arroyave, S.; Pineda-Hernández, D.A.; García-Gallego, Y.P.; Restrepo-Parra, E. Growth Mechanisms of TaN Thin Films Produced by DC Magnetron Sputtering on 304 Steel Substrates and Their Influence on the Corrosion Resistance. Coatings 2022, 12, 979. https://doi.org/10.3390/coatings12070979

Serna-Manrique MD, Escobar-Rincón D, Ospina-Arroyave S, Pineda-Hernández DA, García-Gallego YP, Restrepo-Parra E. Growth Mechanisms of TaN Thin Films Produced by DC Magnetron Sputtering on 304 Steel Substrates and Their Influence on the Corrosion Resistance. Coatings. 2022; 12(7):979. https://doi.org/10.3390/coatings12070979

Chicago/Turabian StyleSerna-Manrique, Milton David, Daniel Escobar-Rincón, Santiago Ospina-Arroyave, Daniel Alejandro Pineda-Hernández, Yury Paola García-Gallego, and Elisabeth Restrepo-Parra. 2022. "Growth Mechanisms of TaN Thin Films Produced by DC Magnetron Sputtering on 304 Steel Substrates and Their Influence on the Corrosion Resistance" Coatings 12, no. 7: 979. https://doi.org/10.3390/coatings12070979

APA StyleSerna-Manrique, M. D., Escobar-Rincón, D., Ospina-Arroyave, S., Pineda-Hernández, D. A., García-Gallego, Y. P., & Restrepo-Parra, E. (2022). Growth Mechanisms of TaN Thin Films Produced by DC Magnetron Sputtering on 304 Steel Substrates and Their Influence on the Corrosion Resistance. Coatings, 12(7), 979. https://doi.org/10.3390/coatings12070979