Abstract

Relying on a cost-effective and green process that is technically and economically feasible on large scale is not enough to call a technology “sustainable”. We thus evaluate the sustainability of the production of the new “AquaSun” antifouling sol–gel coating with reference to each of the three main dimensions (economic, social, and environmental) of sustainable development. This study will hopefully assist in overcoming the “not invented here” syndrome that still affects many sol–gel technologies, including antifouling coatings derived via the sol–gel process.

1. Introduction

Named “AquaSun”, a new antifouling (AF) sol–gel coating comprised of organically modified silica (ORMOSIL) doped with flower-like microparticles of the visible-light photocatalyst Bi2WO6 was introduced in 2016 [1]. The AF activity of the new coating merges the solar-driven photocatalytic generation of powerful oxidizing species H2O2 and hydroxyl radicals (that readily degrade biomolecules and microbiological species) [2,3,4], with the foul release (FR) properties of conventional ORMOSIL xerogels [5].

Tested under real life situations irradiating a substrate coated with AquaSun immersed in the waters of Indian Ocean with (simulated) solar light for over 3 months, the coating retained its excellent original AF activity [2].

A typical AquaSun coating is made of a thin film (3 μm thick) of methylated silica sol–gel derived from a sol containing 50 mol% methyltriethoxysilane (MTES) and 50 mol% of tetraethyl orthosilicate (TEOS) [1]. Changes in the ORMOSIL composition further improved the mechanical properties of the AquaSun coating, eventually affording coatings whose high scratch resistance approaches levels previously obtainable only with physical vapor deposition and chemical vapor deposition techniques [6].

Recently indeed, alongside Visco and co-workers, we demonstrated the practical applicability of this new marine AF/FR coating reporting the excellent strength of adhesion of AquaSun enhanced coatings on real ship steel substrates [6]. The acute toxicity Microtox test, furthermore, showed evidence of the complete absence of ecotoxicity [6].

Silica-based sol–gel coatings share pronounced physical and chemical stability and a truly benign environmental profile [7]. Generally based on an FR mechanism due to the low surface energy of ORMOSIL-coated surface, sol–gel coatings have been widely investigated as FR coatings [5]. Their efficacy relies on the FR activity imparted to the hull by the thin hydrophobic ORMOSIL layer. Biofoulants sticking loosely to the hull are released even at low cruising speed [8]. Developed by Detty and Bright in the early 2000s [8], waterborne ORMOSIL xerogel coatings were first commercialized in the early 2010s [9].

Unfortunately, these biocide-free coatings do not exert antifouling action when the vessel remains idle, for example in port waters. Their efficacy, furthermore, is particularly low in warm and highly saline seawaters where biofouling proliferation is faster.

Should the durable and powerful AF activity of AquaSun coating be confirmed following testing on marine vessels and submerged structures, this eco-friendly multi-functional sol–gel coating would find widespread utilization to protect immersed surfaces of different nature, from vessels hull of different compositions (steel, resin, and wood) to submerged structures made of steel, concrete or wood [1,2,6].

How sustainable would be the production and use of the AquaSun coating?

Relying on a cost-effective and green process that is technically and economically feasible on large scale is not enough to call a technology “sustainable”. Rather than focusing only on the environmental dimension, we focus the analysis also on the other two main aspects (social and economic) of sustainable development. Indeed, most sustainability studies continue to pay limited attention to economy and society, while it is now increasingly clear that economic aspects have a significant effect on social aspects, while social aspects have a significant impact on environmental elements of sustainability [10].

2. Results and Discussion

2.1. Economic Insight

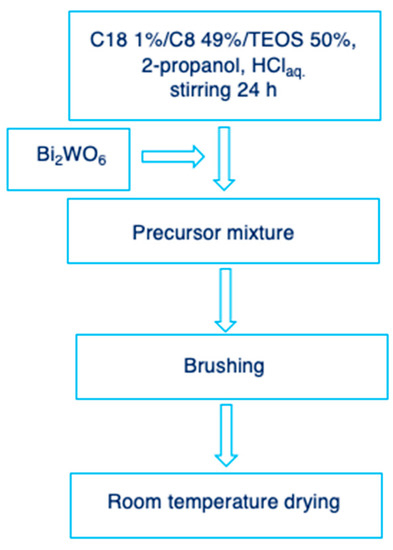

The preparation and application of the AquaSun coating take place via a three-step process (Scheme 1), described in detail elsewhere [1,6]. The coating can be deposited by brushing the waterborne paint on any (metal, wood, plastic) clean surface, followed by curing at room temperature and ambient pressure.

Scheme 1.

Preparation and application of the AquaSun coating (C18: n-octadecyltrimethoxysilane, C8: n-octyltriethoxysilane).

Forthcoming practical applications, however, will use the spray-coating technique to further reduce the emission of volatile organic compounds (VOCs) and eliminate paint losses due to non-uniform layer application [11].

The process is largely cost-effective. The price of the starting materials needed to prepare the coating, after scaling up the lab-scale route 4000 times, allows for estimating the production cost of AquaSun. The raw materials (reagent grade) used for producing AquaSun and their current prices are listed in Table 1.

Table 1.

Raw materials needed to produce AquaSun, amount (×4000 lab-scale), and unit price.

In short, the AquaSun xerogel film is prepared to start from a formulation incorporating 12% w/w of Bi2WO6 suspended in a C18 1%/C8 49%/TEOS 50% silicon alkoxide solution in aqueous 2-propanol [6], wherein C18 stands for n-octadecyltrimethoxysilane and C8 for n-octyltriethoxysilane. The hydrolytic polycondensation of the silicon alkoxides is promoted by acidic conditions (HCl 0.1 N). As it generally happens with the sol–gel entrapment of bismuth tungstate micro- and submicron particles [12], the conversion rate for all chemicals employed is 100%, namely each compound in the AquaFast formulation is fully used, generating no waste or by-products.

We estimate the price of flower-like Bi2WO6 at USD 8/kg, based on the price of its raw materials (USD 1/kg for bismuth nitrate and USD 5/kg for sodium tungstate). The material can now be obtained by a low-temperature solvothermal process starting from Bi(NO3)3, NaWO4, ethylene glycol, and glacial acetic acid at only 120 °C for only 12 h [13], thereby significantly lowering the amount of energy required to produce the photocatalyst in previous synthetic processes.

In brief, the cost of the materials to produce 21.32 L of AquaSun would amount to USD 21.63 (USD 1.79 + USD 3.32 + USD 0.14 + USD 4.58 + USD 9 + USD 2.8), namely about USD 1.0/L. Obviously, the production cost is not limited to the cost of the raw materials, but includes also the cost of labor, utility (equipment and production plant), energy, money (discount rate), and taxation. Several methods can be used to carry out a complete economic evaluation, including the thorough economic life cycle assessment methodology [14]. What is relevant here is that the cost of equipment is that of the typical stainless steel agitated reactor used by specialty chemical companies to produce paints and coatings. The cost of energy, in its turn, would be limited to the small amount of power required to agitate the low viscous, waterborne AquaSun precursor formulation overnight.

In brief, the production cost of AquaSun is low and would not require changing the existing production equipment. Whether in catalysis for chemical manufacturing [15] or in formulating coatings, similar “drop-in” technologies are those ideally sought by the chemical industry when evaluating new “green chemistry” technology [16], because then no replacement for the expensive production unit/plant is required, and the new production can be carried out using existing equipment.

The payback time of the AquaSun manufacturing would be very short considering that a typical “green” antifouling paint based on the FR mechanism is sold at USD 393/gallon (USD 86/L) [17].

What it is also relevant from a broad economic evaluation viewpoint, is an insight into the availability of the active ingredients of the AquaSun coating. Driven by large and rapidly increasing demand, both bismuth nitrate [18] and sodium tungstate [19] (the Bi2WO6 precursors) are readily available in the chemical marketplace. Similarly, the price of TEOS and alkyl-modified silicon alkoxides has recently fallen to historic low levels. The alkoxides, whose high price exceeding USD 20/kg and in certain cases USD 100/kg has limited the market of sol–gel functional products for decades [20], are now chiefly manufactured and commercialized at low prices from China, also thanks to the large local availability of metal Si produced for the huge photovoltaic industry of the Asian country.

2.2. Environmental Insight

Plentiful research has been devoted to the development of eco-friendly AF coatings [21]. Though poorly known, these research efforts have been largely successful. From silicone hydrogels to paints incorporating microencapsulated biocide in 95% lesser amounts than conventional AF paints, several new generations of eco-friendly AF coatings have been commercialized [21]. In 2018, about 90% of commercial and recreational vessels were found to employ conventional AF paints using cuprous oxide (Cu2O) as the main biocide, often in combination with other biocides, formulated in copolymer paints [22]. This share was 95% in 2009 [5].

A recent comprehensive study on 1013 registered AF paints produced by 64 different manufacturers found that Cu2O with mean relative concentrations of 35.9% ± 12.8%, copper pyrithione, zinc pyrithione, zineb (zinc ethylenebis (dithiocarbamate)), DCOIT (4,5-dichloro-2-n-octyl-4-isothiazolin-3-one) and cuprous thiocyanate at 18.1% ± 8.0% (w/w) are the most frequently biocide species used by marine coating manufacturers [23].

In brief, the study showed evidence that the most commonly used AF coatings today are based on cuprous oxide and cuprous thiocyanate (CuSCN) typically formulated at 40 and 20 per cent concentrations, respectively, in combination with “booster” biocides [24]. The latter consist of copper or zinc pyrithione, and other synthetic antifungals, herbicide, and pesticide synthetic molecules originating from crop protection research in agriculture or in veterinary sciences, as in the case of medetomidine showing on barnacles a repellent, but not deadly, effect at very low concentrations [24].

Furthermore, the aforementioned study [23] of Fillmann and co-workers surprisingly unveiled that regardless of the worldwide ban of tributyltin in 2008, TBT was still registered for use in 5 out of 1013 commercial paint formulations either as tributyltin oxide or as tributyltin methacrylate.

Though far less harmful than TBT, copper and booster biocides leached by today’s AF paints are a significant source of marine pollution. One such paint is designed to last 3–5 years, gradually releasing all the incorporated biocides, causing a significant (and global) impact on marine life [25]. A recent experimental study on copper-based paints in the Venice lagoon, for example, revealed that copper released by selected commercial AF paints has potential disruptive effects on the biodiversity of coastal macrofouling communities, affecting both the settlement and growth of key species of macrofouling of hard-substrata [26].

Protection of commercial and recreational vessels from biofouling applying one such AF paint, however, is an unavoidable necessity to reduce fuel consumption due to additional dragging and friction originating from the foulant organisms on the unprotected hull. A ship with 10% barnacle fouling requires 36% more power to maintain the same speed [27].

One would therefore expect to find the hull of most ships, regularly treated with AF paints during dry-docking, free of hard foulants. Yet, a recent empirical study conducted on 249 vessels that dry-docked between 2015 and 2019, revealed that nearly every vessel presented hard fouling on the underwater hull, with 44% of vessels showing over 10% of the underwater hull surface covered with hard foulants [28]. Approximately 25% of the vessels displayed hard fouling coverage of between 10%–30%, and the remaining percentage of vessels suffered much higher levels. Assuming a 10% coverage of hard fouling on 40% of the fleet, this level of hard fouling would be responsible for at least an additional USD 6 billion spent on fuel per year for the global commercial fleet (at 2019 low fuel prices, today it would be much more) [28].

Such a high level of hard biofouling is due both to niche areas of the total underwater hull surface (accounting for as much as 10% of the overall hull surface area) [29], and to the ever longer periods of time during which ships remain idle in warm ocean waters, either waiting for a port or waiting for cargo. Niche areas of the hull experience either restricted water flow (limiting the action of biocidal coatings which require a flow of water to remove the top layer of coating) [29] or greater turbulence, compromising the AF coating’s efficacy.

Growing at >10% annual rate, the amount of AF paints globally consumed today exceeds the 100,000-tonne threshold [30], with overall revenues of USD 3 billion in 2019 [28].

The use of highly effective and environmentally friendly AF coatings such as AquaSun would therefore result in the prevention of sea, river and lake water contamination with toxic biocides. Bismuth tungstate is a completely insoluble inorganic salt not classified as hazardous and for which no exposure limit has been established. For example, the material is currently being evaluated to produce lead-free, personal protective articles for shielding low-energy gamma radiations [31].

Once entrapped in the inner porosity of the sol–gel organosilica coating, Bi2WO6 not only is not leached in solution but it is chemically and physically stabilized, improving its photocatalytic activity due to better charge (hole and electron) separation [12]. Perhaps not surprisingly, the acute toxicity (Microtox) test carried out on the AquaSun coating, has shown evidence of a complete absence of ecotoxicity [6].

Finally, it is also remarkable in light of the emerging circular bioeconomy, that silicon alkoxides can now be sourced directly by reacting biogenic SiO2 abundant, for example, in rice bran (the rice’s main co-product) with ethanol [32], thereby avoiding deriving the alkoxides from SiCl4 sourced from ultrapure silicon obtained via the carbothermal reduction of quartz SiO2 at 1900 °C.

2.3. Social Insight

The development and large-scale utilization of new antifouling technology developed starting from a preventative approach will have social consequences of global relevance. Marine pollution, including that from AF paints, disrupts coastal ecosystems where usually plentiful economic activity takes place. A recent meta-study on the environmental impact of leisure vessels in Mediterranean coastal areas included antifouling paints (alongside anchoring and engine noise disturbance) amid the three most impactful (“high-risk”) pollution typologies strongly affecting fragile organisms and habitats [33].

The fact that Cu+ released by copper-based paints in the Venice lagoon has potentially disruptive effects on the biodiversity of coastal macrofouling communities might soon alter the native structure of the benthic communities (those in the lowest level of a body of water) [26]. The Venice lagoon, for example, hosts a broad mussel farming activity. For comparison, significant concentrations of butyltin, dibutyltin, and tributyltin as well as of diuron (1-[3,4-dichlorophenyl]-3,3 dimethylurea) were found in mussels from Thailand’s coastal areas already in 2005, with an even higher concentration of TBT in areas where aquaculture practice was common [34].

The low production cost of the AquaSun sol–gel glassy coating (see above) has the potential to make the green technology affordable for all, and not only for those who can purchase 1 L of a “green” AF paint at prices that for fluoropolymer silicon exceed USD 100/L [9].

Furthermore, the low thickness of the hard (102–104 MPa elastic modulus) and thin (10–60 μm) ORMOSIL xerogel coatings [5] implies that a far lower amount of paint would be needed to functionalize the hull of a vessel when compared to conventional green silicone-based AF paints based on foul release mechanism (a typical silicone coating has >150 μm thickness).

Relying on a cost-effective and green process that is technically and economically feasible on large scale, however, is not enough to call a technology “sustainable”. To be truly sustainable, a technology must combine its positive effects on the environment with affordable costs for all, including fishermen and ship owners in economically developing nations. For example, today’s low-cost, efficient, and durable photovoltaic modules based on crystalline silicon solar cells are a truly sustainable technology providing largely positive environmental, social, and economic benefits to their users in both economically developing and developed nations [35].

Renewing and expanding the production of antifouling paints based on the eco-friendly and simple sol–gel process, offers numerous benefits also from the job creation viewpoint. This can be indirectly verified, for instance, with the case of a Greek manufacturer of functional paints chiefly based on the sol–gel process. In only 15 years since its foundation in 2005, the company reached a staff of 35 people [36].

From the social viewpoint, it is also relevant that the coating will be independently produced by numerous manufacturers similar to what happens with the production of “generic drugs”, namely medicines whose patent is expired, whose low cost and large availability benefit populations across the world [37].

3. Conclusions

A sustainability analysis aimed to investigate whether the new class of organosilica-based photocatalytic “AquaSun” coating is suitable for industrial production, taking into account the usually neglected economic and social dimensions of sustainability, shows numerous relevant results.

First, from an economic viewpoint, the production of the AquaSun coating merging the foul release properties of sol–gel foul release coatings [5,9] and the visible-light photocatalytic activity of Bi2WO6 [38], would be technically and economically viable. The raw material cost of one L of the coating based on the cost of the raw materials alone is approximately USD 1. The production process, furthermore, has the “drop-in” characteristics of the green chemistry technologies sought by the chemical industry in its ongoing transition driven by sustainability [15,16]. Its industrial uptake, indeed, would not require changing the existing equipment used to manufacture paints and coatings.

Second, the use of AquaSun coating would offer several environmental benefits. No toxic species are present in the coating or are generated during its function, translating into the lack of ecotoxicity [6]. The active H2O2 biocidal species generated in situ under the action of solar light readily decomposes into O2 and H2O [1,2]. Production of the coating would take place via a zero-waste process affording no by-products, whereas application of the waterborne sol–gel coating via spray-coating would minimize VOC emissions [11] and maximize the material efficiency of the coating deposition process. Finally, production of the new sol–gel AF paint would soon benefit from the ongoing shift in silicon alkoxides manufacturing from SiCl4 and thus silicon obtained via the carbothermal reduction of quartz SiO2, to Si alkoxides directly derived from reacting biogenic SiO2 with ethanol in a new, low energy synthetic process [32].

Third, production and use of the AquaSun coating would provide significant social benefits. The elimination of marine pollution deriving from release of toxic biocides and “booster” species from conventional AF paints would directly translate in improved economic activities, such as aquaculture, in coastal areas. The production of the coating would also result in the creation of numerous new jobs in numerous countries where production would start.

The present sustainability study, likely the first in the field of new generation sol–gel antifouling coatings, will hopefully contribute to overcoming the “not invented here” syndrome [39] that still affects many sol–gel technologies [20], including AF coatings derived via the sol–gel process [5]. Future investigations will address the main limitations of the study: the economic viability investigation is preliminary. Subsequent studies will employ analytical tools such as commercial software packages for a detailed manufacturing cost analysis including sensitivity analysis for the main process parameters. Similarly, a life-cycle analysis will be useful to assess the environmental impacts of producing and using AquaSun.

Author Contributions

Conceptualization, R.C. and M.P.; data curation, A.S.; funding acquisition, R.C.; investigation, A.S.; methodology, R.C., A.S. and M.P.; writing—original draft, R.C.; writing—review and editing, M.P. All authors have read and agreed to the published version of the manuscript.

Funding

NAVTEC (Consorzio di Ricerca per l’Innovazione tecnologica, Sicilia, Trasporti navali, commerciali e da diporto s.c.a.r.l). Research project “TecHnology and materials for safe Low consumption and low life cycle cost veSSels and crafts (Thalassa)”, grant number ARS01_00293 PON2014-2020.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This study is dedicated to Annamaria Visco, University of Messina, on the occasion of her recent Habilitation (November 2021) to Full Professor of materials engineering. We thank NAVTEC (Consorzio di Ricerca per l’Innovazione tecnologica, Sicilia, Trasporti navali, commerciali e da diporto s.c.a.r.l) for funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Scandura, G.; Ciriminna, R.; Xu, Y.-J.; Pagliaro, M.; Palmisano, G. Nanoflower-like Bi2WO6 encapsulated in ORMOSIL as a novel photocatalytic antifouling and foul-release coating. Chem. Eur. J. 2016, 22, 7063–7067. [Google Scholar] [CrossRef]

- Scandura, G.; Ciriminna, R.; Ozer, L.Y.; Meneguzzo, F.; Palmisano, G.; Pagliaro, M. Antifouling and photocatalytic antibacterial activity of the AquaSun coating in seawater and related media. ACS Omega 2017, 2, 7568–7575. [Google Scholar] [CrossRef] [PubMed]

- Olsen, S.M.; Kristensen, J.B.; Laursen, B.S.; Pedersen, L.T.; Dam-Johansen, K.; Kiil, S. Antifouling effect of hydrogen peroxide release from enzymatic marine coatings: Exposure testing under equatorial and Mediterranean conditions. Prog. Org. Coat. 2010, 68, 248–252. [Google Scholar] [CrossRef]

- Elzanowska, H.; Wolcott, R.G.; Hannum, D.M.; Hurst, J.K. Bactericidal properties of hydrogen peroxide and copper or iron-containing complex ions in relation to leukocyte function. Free Radic. Biol. Med. 1995, 18, 437–449. [Google Scholar] [CrossRef]

- Detty, M.R.; Ciriminna, R.; Bright, F.V.; Pagliaro, M. Environmentally benign sol–gel antifouling and foul-releasing coatings. Acc. Chem. Res. 2014, 47, 678–687. [Google Scholar]

- Scurria, A.; Scolaro, C.; Sfameni, S.; di Carlo, G.; Pagliaro, M.; Visco, A.M.; Ciriminna, R. Towards AquaSun practical utilization: Strong adhesion and lack of ecotoxicity of solar-driven antifouling sol-gel coating. Prog. Org. Coat. 2022, 165, 106771. [Google Scholar] [CrossRef]

- Ciriminna, R.; Fidalgo, A.; Palmisano, G.; Ilharco, L.M.; Pagliaro, M. Silica-based sol-gel coatings: A critical perspective from a practical viewpoint. In Bio-Based and Environmentally Benign Coatings; Tiwari, A., Soucek, M.D., Eds.; John Wiley & Sons and Scrivener Publishing: Beverly, MA, USA, 2016; pp. 149–158. [Google Scholar]

- Tang, Y.; Finlay, J.A.; Kowalke, G.L.; Meyer, A.E.; Bright, F.V.; Callow, M.E.; Callow, J.A.; Wendt, D.E.; Detty, M.R. Hybrid xerogel films as novel coatings for antifouling and fouling release. Biofouling 2005, 21, 59–71. [Google Scholar] [CrossRef] [Green Version]

- Detty, M.R.; Ciriminna, R.; Bright, F.V.; Pagliaro, M. Xerogel coatings produced by the sol–gel process as anti-fouling, fouling-release surfaces: From lab bench to commercial reality. ChemNanoMat 2015, 1, 148–154. [Google Scholar]

- Svensson, G.; Ferro, C.; Høgevold, N.; Padin, C.; Varela, J.C.S.; Sarstedt, M. Framing the triple bottom line approach: Direct and mediation effects between economic, social and environmental elements. J. Clean. Prod. 2018, 197, 972–991. [Google Scholar] [CrossRef]

- Parkhill, R.L.; Knobbe, E.T.; Donley, M.S. Application and evaluation of environmentally compliant spray-coated ormosil films as corrosion resistant treatments for aluminum 2024-T3. Prog. Org. Coat. 2001, 41, 261–265. [Google Scholar] [CrossRef]

- Zhang, Y.; Ciriminna, R.; Palmisano, G.; Xu, Y.-J.; Pagliaro, M. Sol-gel entrapped visible light photocatalysts for selective conversions. RSC Adv. 2014, 4, 18341–18346. [Google Scholar] [CrossRef]

- Yao, B.; Wang, L.; Li, Z.; Xing, X.; Ma, Z.; Wang, Y.; Liu, Y.; He, J.; Zheng, G.; Zhang, F. Cost-effective Bi2WO6 for the efficient degradation rhodamine B and tetracycline. SSRN Pap. 2022. [Google Scholar] [CrossRef]

- Garrido, R.; Silvestre, J.D.; Flores-Colen, I.; de Fátima Júlio, M.; Pedroso, M. Economic assessment of the production of subcritically dried silica-based aerogels. J. Non-Cryst. Sol. 2019, 516, 26–34. [Google Scholar] [CrossRef]

- Ciriminna, R.; della Pina, C.; Falletta, E.; Teles, J.H.; Pagliaro, M. Industrial applications of gold catalysis. Angew. Chem. Int. Ed. 2016, 55, 14210–14217. [Google Scholar] [CrossRef]

- Pagliaro, M. An industry in transition: The chemical industry and the megatrends driving its forthcoming transformation. Angew. Chem. Int. Ed. 2019, 58, 11154–11159. [Google Scholar] [CrossRef]

- See, for Example, the SS-5000A Silicone Slip Clean Hull and Anti-Fouling Coating. Available online: https://siliconesolutions.com/catalog/product/view/_ignore_category/1/id/1366/s/ss-5000a/ (accessed on 15 June 2022).

- Prescient Strategic Intelligence, Bismuth Nitrate Market Research Report, Delhi. 2020. Available online: https://www.psmarketresearch.com/market-analysis/bismuth-nitrate-market-report (accessed on 19 July 2022).

- IndustryARC. Sodium Tungstate Market—Forecast (2021–2026), Hyderabad. 2022. Available online: https://www.industryarc.com/Research/Sodium-Tungstate-Market-Research-501533 (accessed on 19 July 2022).

- Ciriminna, R.; Pagliaro, M. Open challenges in sol-gel science and technology. J. Sol.-Gel. Sci. Technol. 2022, 191, 29–36. [Google Scholar] [CrossRef]

- Ciriminna, R.; Bright, F.V.; Pagliaro, M. Ecofriendly antifouling marine coatings. ACS Sust. Chem. Eng. 2015, 3, 559–565. [Google Scholar] [CrossRef]

- Blossom, N.; Szafranski, F.; Lotz, A. Use of copper-based antifouling paint: A US regulatory update. CoatingsTech 2018, 15, 63–68. [Google Scholar]

- Paz-Villarraga, C.A.; Castro, Í.B.; Fillmann, G. Biocides in antifouling paint formulations currently registered for use. Environ. Sci. Pollut. Res. 2022, 29, 30090–30101. [Google Scholar] [CrossRef]

- Howell, D.; Berhends, B. Consequences of antifouling coatings—The chemist’s perspective. In Biofouling; Dürr, S., Thomason, J.C., Eds.; Blackwell Publishing: Oxford, UK, 2009; pp. 226–242. [Google Scholar] [CrossRef]

- Amara, I.; Miled, W.; Slama, R.B.; Ladhari, N. Antifouling processes and toxicity effects of antifouling paints on marine environment. A review. Environ. Toxicol. Pharmacol. 2018, 57, 115–130. [Google Scholar] [CrossRef]

- Cima, F.; Varello, R. Potential disruptive effects of copper-based antifouling paints on the biodiversity of coastal macrofouling communities. Environ. Sci. Pollut. Res. 2022. [Google Scholar] [CrossRef] [PubMed]

- Schultz, M.P.; Bendick, J.A.; Holm, E.R.; Hertel, W.M. Economic impact of biofouling on a naval surface ship. Biofouling 2010, 27, 87–98. [Google Scholar] [CrossRef] [PubMed]

- Williams, D. (Safinah Group). Quantifying the Scale of the Barnacle Fouling Problem on the Global Shipping Fleet, Gateshead (GB). 2020. Available online: https://www.rivieramm.com/whitepapers/whitepapers/quantifying-the-scale-of-the-barnacle-fouling-problem-on-the-global-shipping-fleet (accessed on 19 July 2022).

- Moser, C.S.; Wier, T.P.; First, M.R.; Grant, J.F.; Riley, S.C.; Robbins-Wamsley, S.H.; Tamburri, M.N.; Ruiz, G.M.; Miller, A.W.; Drake, L.A. Quantifying the extent of niche areas in the global fleet of commercial ships: The potential for “super-hot spots” of biofouling. Biol. Invasions 2017, 19, 1745–1759. [Google Scholar] [CrossRef]

- Global Industry Analysts. Antifouling Coatings—Global Market Trajectory & Analytics; Global Industry Analysts: San Francisco, CA, USA, 2021. [Google Scholar]

- Liu, J.-H.; Zhang, Q.-P.; Sun, N.; Zhao, Y.; Shi, R.; Zhou, Y.-L.; Zheng, J. Elevated gamma-rays shielding property in lead-free bismuth tungstate by nanofabricating structures. J. Phys. Chem. Solids 2018, 112, 185–189. [Google Scholar] [CrossRef]

- Laine, R.M.; Furgal, J.C.; Doan, P.; Pan, D.; Popova, V.; Zhang, X. Avoiding carbothermal reduction: Distillation of alkoxysilanes from biogenic, green, and sustainable sources. Angew. Chem. Int. Ed. 2016, 55, 1065–1069. [Google Scholar] [CrossRef]

- Carreño, A.; Lloret, J. Environmental impacts of increasing leisure boating activity in Mediterranean coastal waters. Ocean Coast. Manag. 2021, 209, 105693. [Google Scholar] [CrossRef]

- Harino, H.; Ohji, M.; Wattayakorn, G.; Arai, T.; Rungsupa, S.; Miyazaki, N. Occurrence of antifouling biocides in sediment and green mussels from Thailand. Arch. Environ. Contam. Toxicol. 2006, 51, 400–407. [Google Scholar] [CrossRef]

- Fang, H.; Wang, X.; Song, W. Technology selection for photovoltaic cell from sustainability perspective: An integrated approach. Renew. Energy 2020, 153, 1029–1041. [Google Scholar] [CrossRef]

- NanoPhos SA. Available online: https://ec.europa.eu/futurium/en/tech-society-2020/nanophos-sa.html (accessed on 19 July 2022).

- Lewek, P.; Karda, P. Generic drugs: The benefits and risks of making the switch. J. Fam. Pract. 2010, 59, 634–640. [Google Scholar]

- Zhang, N.; Ciriminna, R.; Pagliaro, M.; Xu, Y.-J. Nanochemistry-derived Bi2WO6 nanostructures: Towards sustainable chemicals and fuels production induced by visible light. Chem. Soc. Rev. 2014, 43, 5276–5287. [Google Scholar] [CrossRef]

- Hannen, J.; Antons, D.; Piller, F.; Salge, T.O.; Coltman, T.; Devinney, T.M. Containing the not-invented-here syndrome in external knowledge absorption and open innovation: The role of indirect countermeasures. Res. Policy 2019, 48, 103822. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).