Hydrodynamic Analysis of the Thickness Variation in a Solid Film Formed by a Spin Coating Process

Abstract

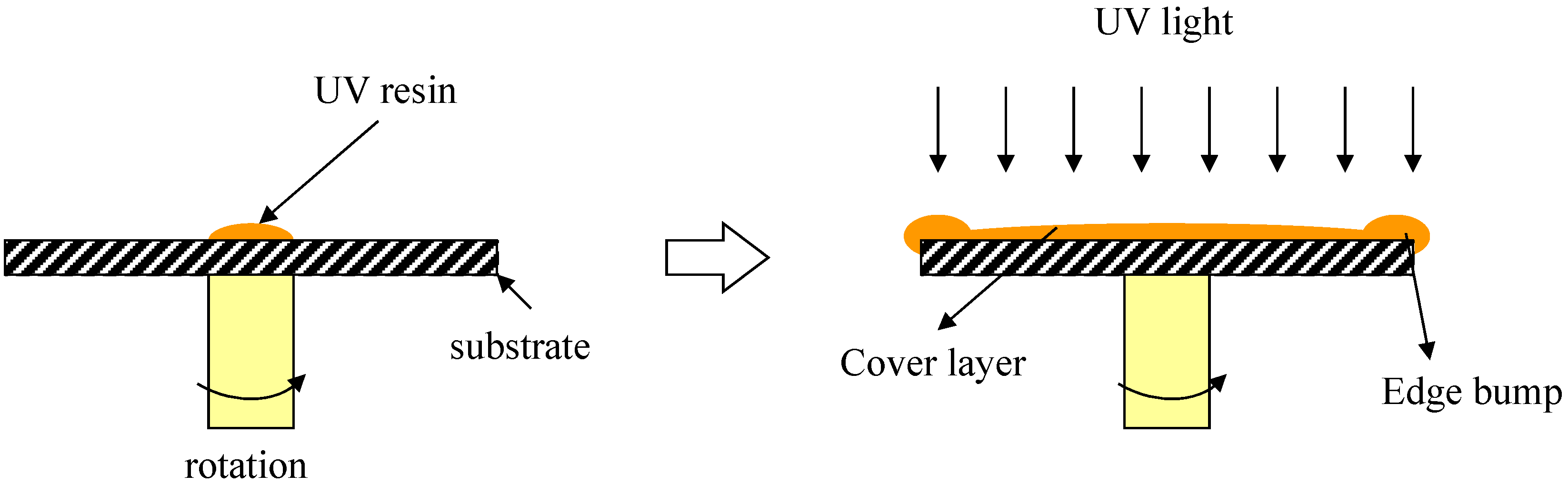

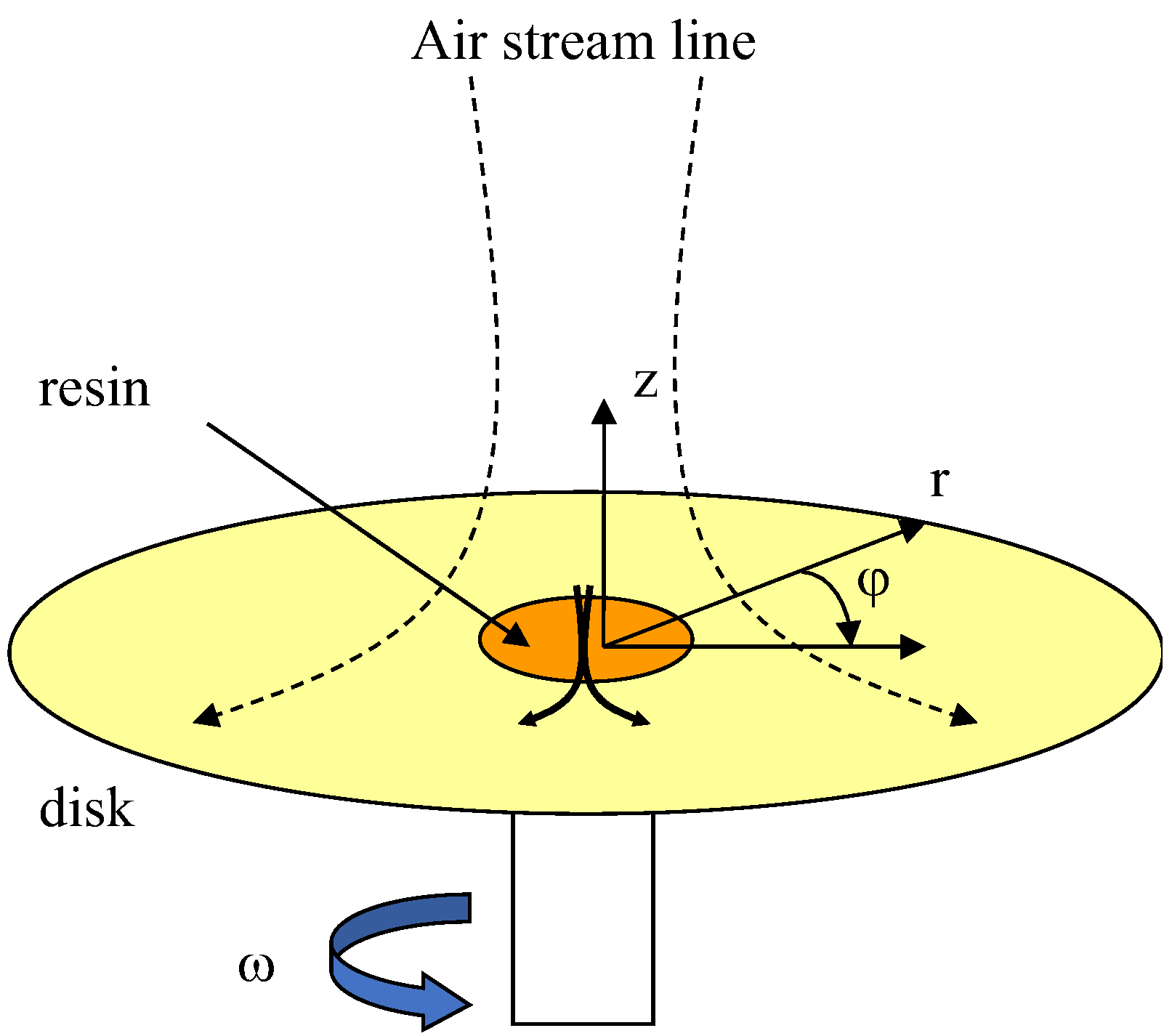

:1. Introduction

2. Experiment

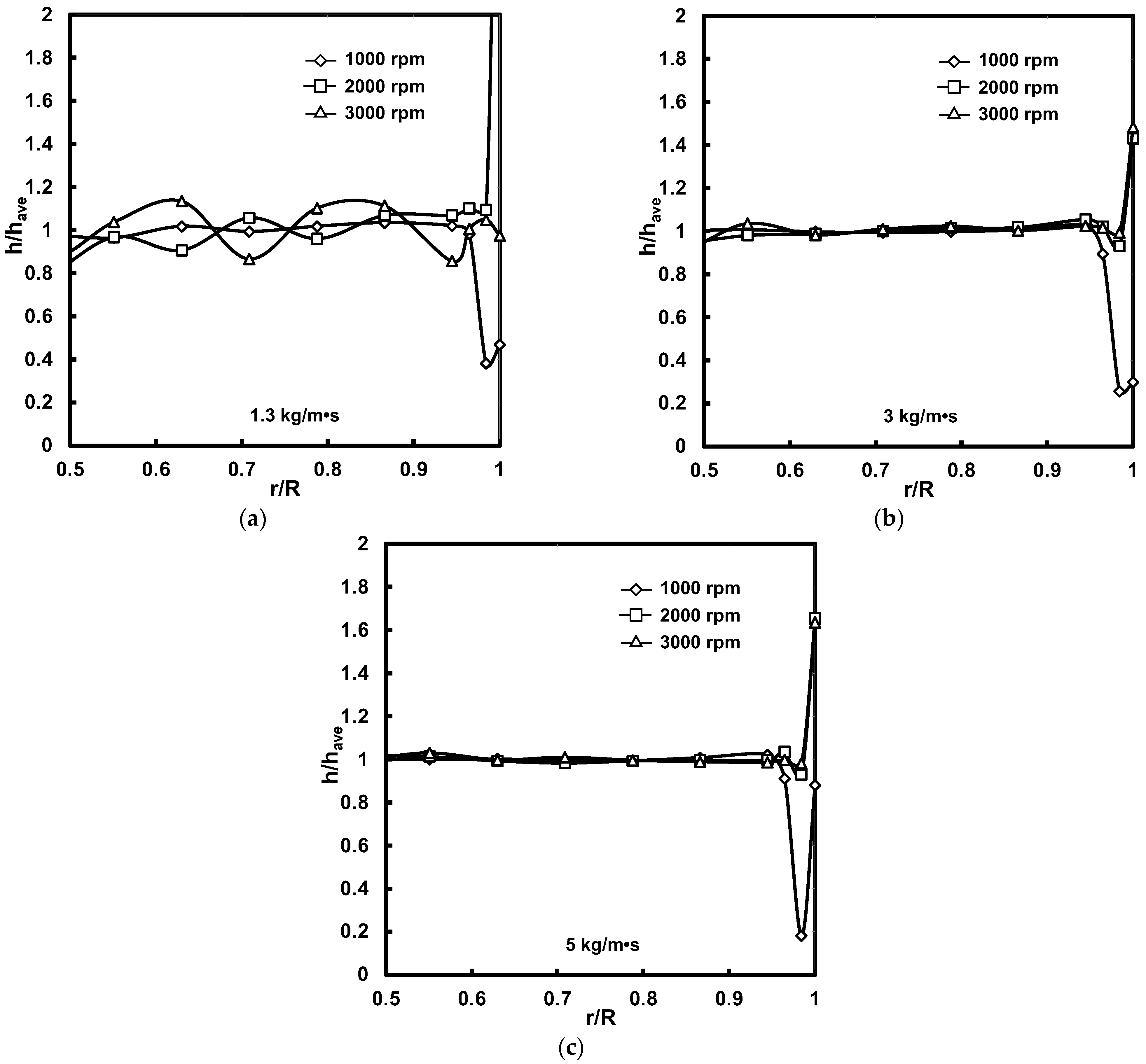

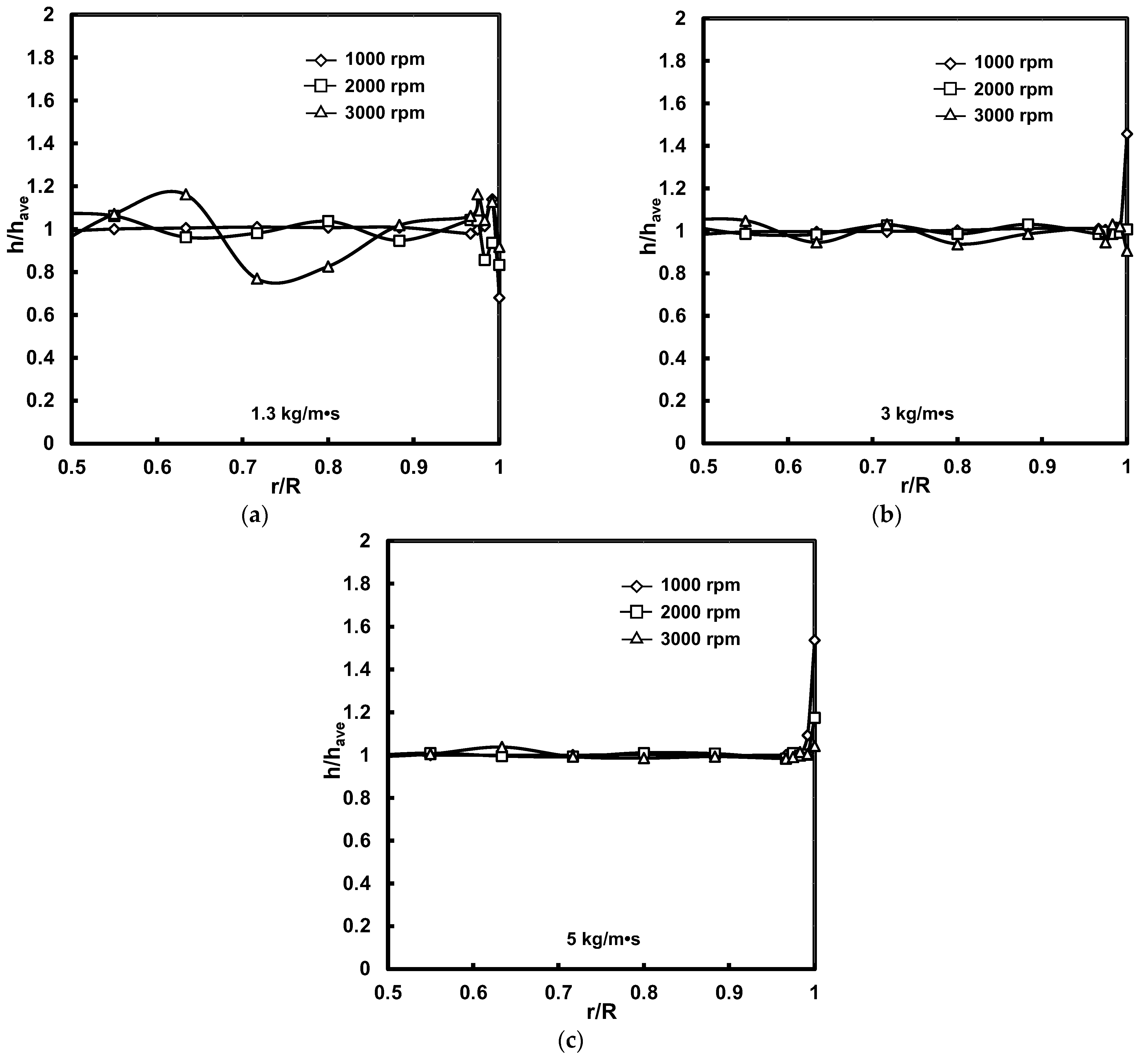

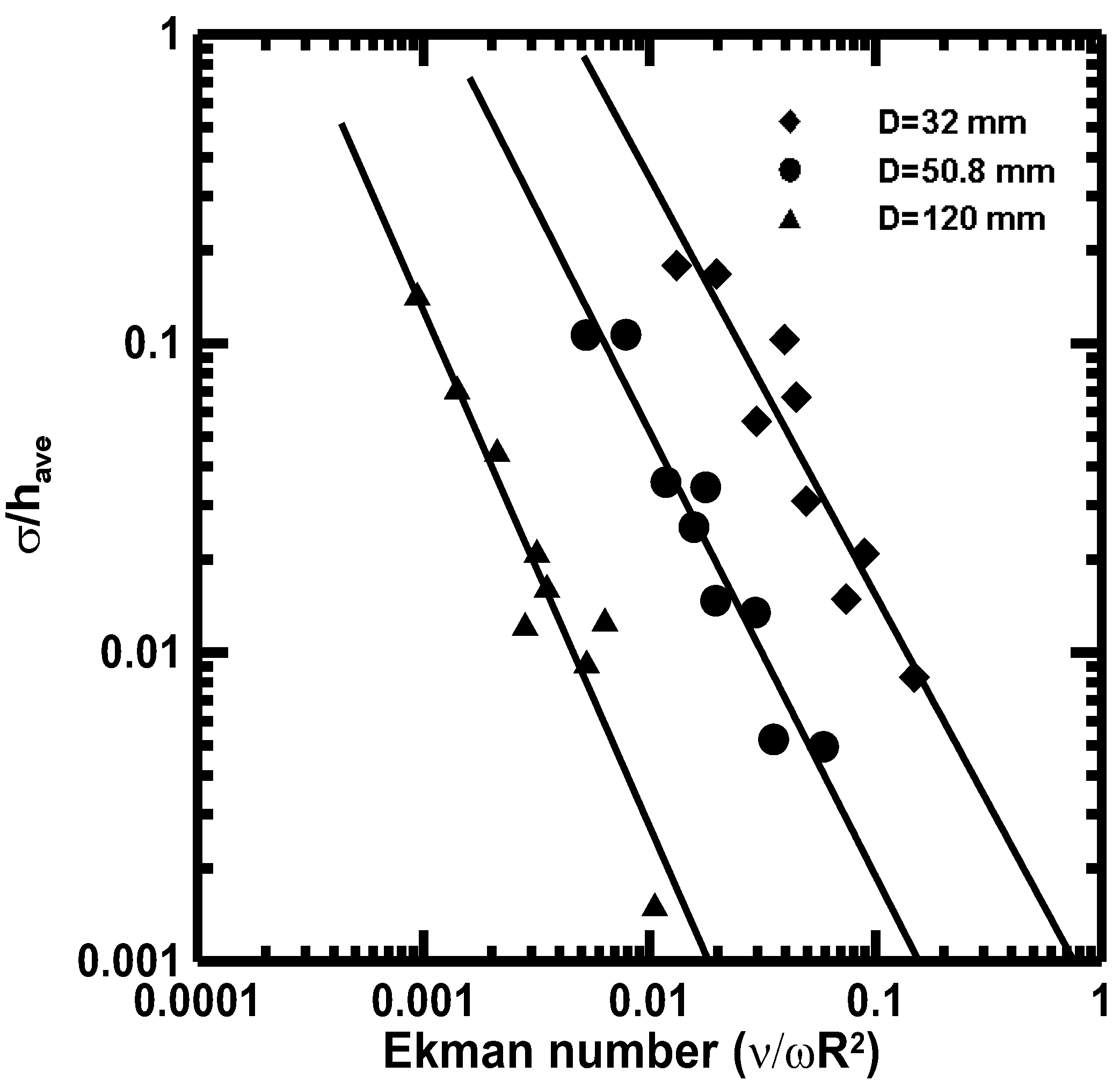

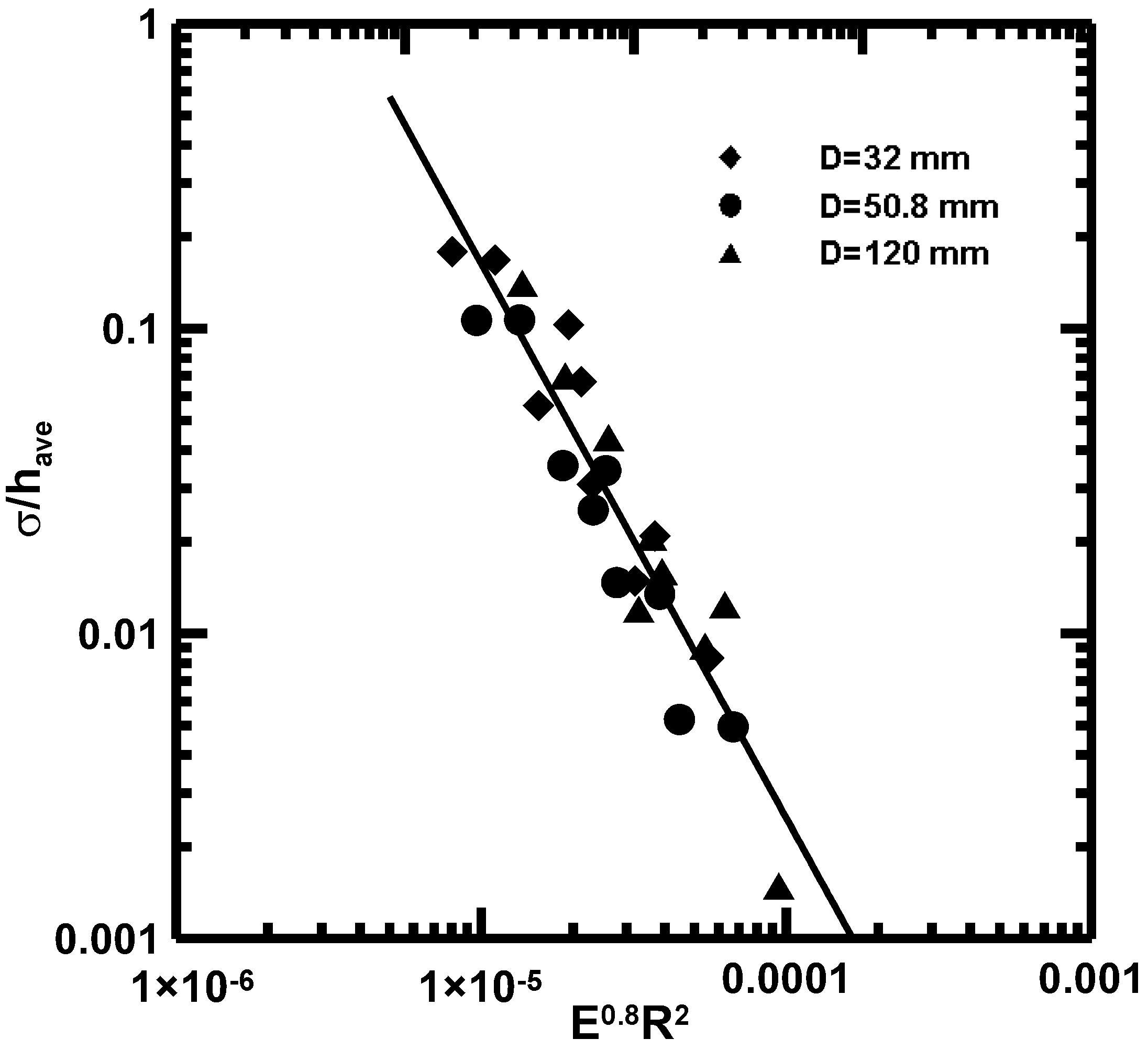

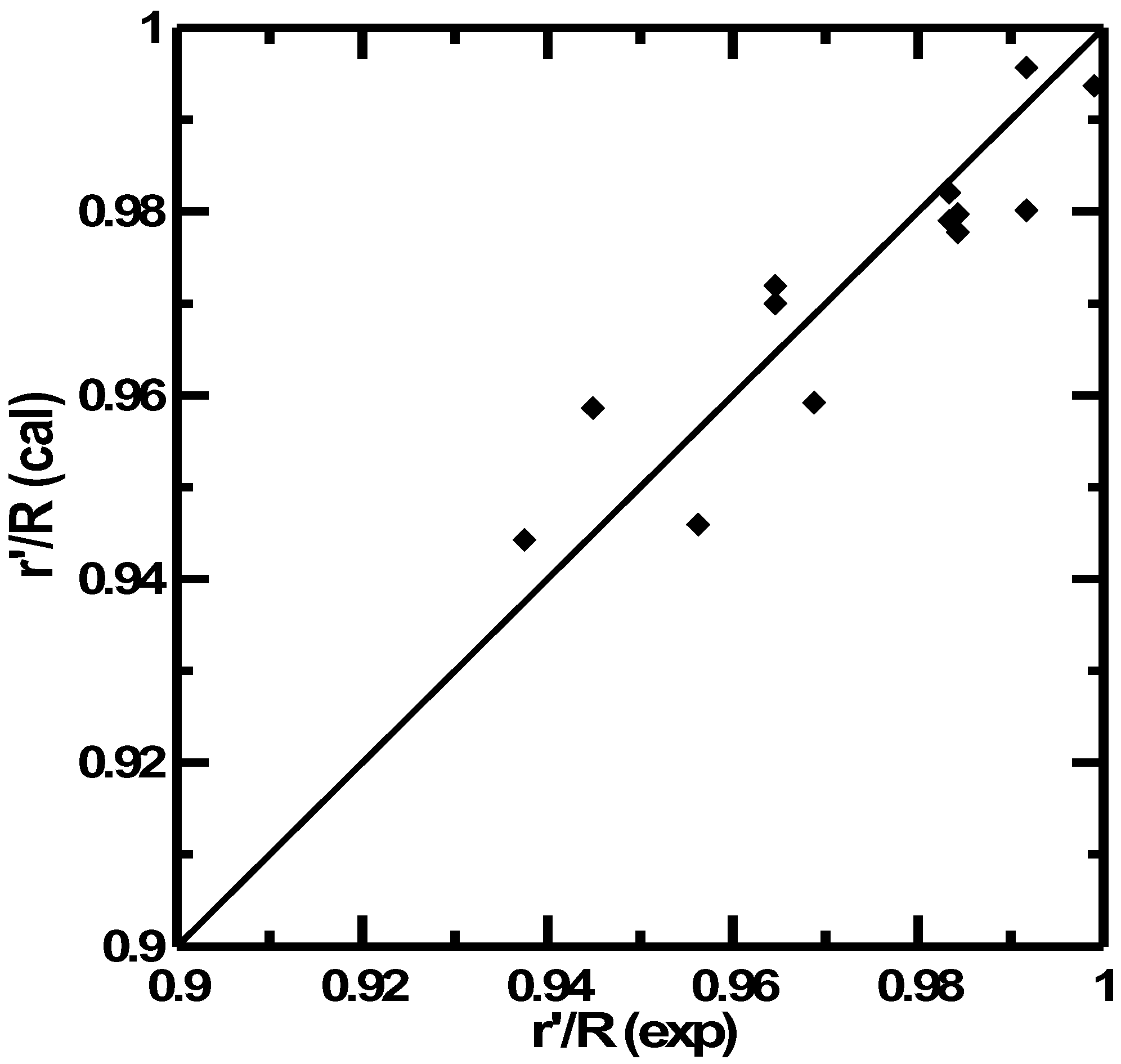

3. Results and Discussion

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kitamura, A.; Hasegawa, E.; Yoshizawa, M. Asymptotic analysis of the formation of thin liquid film in spin coating. Fluid Dyn. Res. 2022, 30, 107. [Google Scholar] [CrossRef]

- Elmansouri, A.; Outzourhit, A.; Oueriagli, A.; Lachkar, A.; Hadik, N.; Achour, M.E.; Abouelaoualim, A.; Malaoui, A.; Berrada, K.; Ameziane, E.L. Fabrication and characterization of Schottky diodes and thin films based on poly (o-toluidine) deposited by spincoating technique. Synth. Met. 2010, 160, 1487–1492. [Google Scholar] [CrossRef]

- Yu, C.L.; Sakthinathan, S.; Lu, M.T.; Yu, S.T.; Kuo, C.Y.; You, Y.F.; Chiu, T.W. CuAlO2/AIN double-layer thin film prepared by the spin coating approach. Thin Solid Film. 2022, 753, 139260. [Google Scholar] [CrossRef]

- Muhammad, S.; Nomaan, A.T.; Idris, M.I.; Rashid, M. Structural, optical and electrical investigation of low-temperature processed zinc oxide quantum dots based thin films using precipitation-spin coating on flexible substrates. Phys. B Phys. Condens. Matter 2022, 635, 413806. [Google Scholar] [CrossRef]

- Dehghan, M.; Behjat, A. Deposition of zinc oxide as an electron transport layer in planar perovskite solar cells by spray and SILAR methods comparable with spin coating. RSD Adv. 2019, 9, 20917–20924. [Google Scholar] [CrossRef] [Green Version]

- Lang, J.; Wang, J.; Zhang, Q.; Li, X.; Han, Q.; Wei, M.; Sui, Y.; Wang, D.; Yang, J. Chemical precipitation synthesis and significant enhancement in photocatalytic activity of Ce-doped ZnO nanoparticles. Ceram. Int. 2016, 42, 14175–14181. [Google Scholar] [CrossRef]

- Ziti, A.; Hartiti, B.; Labrim, H.; Doubi, Y.; Nkuissi, H.J.T.; Nouria, Y.; Fadili, S.; Batan, A.; Tahri, M.; Ridah, A.; et al. Investigation of CZTS absorber layer deposited by spin coating technique for photovoltaic applications. Mater. Today Proc. 2022, 53, 355–360. [Google Scholar] [CrossRef]

- Tchognia, J.H.N.; Arba, Y.; Hartiti, B.; Ridah, A.; Ndjaka, J.M.; Thevenin, P. Effect of sulfurization time on properties of Cu2ZnSnS4 thin films obtained by sol-gel deposited precursors. Opt. Quant. Electron. 2016, 48, 134. [Google Scholar] [CrossRef]

- Tchognia, J.H.N.; Arba, Y.; Hartiti, B.; Ridah, A.; Ndjaka, J.M.; Ridah, A.; Thevenin, P. Solution-based deposition of wurzite copper zinc tin sulfide nanocrystals as a novel absorber in thin film solar cells. Opt. Quant. Electron. 2016, 48, 255. [Google Scholar] [CrossRef]

- Tanaka, K.; Moritake, N.; Uchiki, H. Preparation of Cu2ZnSnS4 thin film by sulfurizing sol-gel deposited precursors. Energy Mater. Sol. Cells 2007, 91, 1199–1201. [Google Scholar] [CrossRef]

- Heinz, B.; Eisenhammer, T.; Dubs, M.; Yavaser, C.; Pfaff, T. Blu-ray disc cover layer production using spin coating technology. Opt. Data Storage Top. Meet. 2006, 117–119. [Google Scholar]

- Decre, M.M.J.; Vromans, P.H.H.G.M. Cover layer technology for the high-numerical-aperture digital video recording system. Jpn. J. Appl. Phys. 2000, 39, 775. [Google Scholar] [CrossRef]

- Get, R.; Islam, S.M.; Singh, S.; Mahala, P. Organic polymer bilayer structures for applications in flexible solar cell T devices. Microelectron. Eng. 2020, 222, 111200. [Google Scholar] [CrossRef]

- Zheng, Q.; Wang, C.; Ma, G.; Jin, M.; Chen, S.; Lai, Y.; Yu, J. Annealing temperature impact on Sb2S3 solar cells prepared by spin-coating method. Mater. Lett. 2019, 243, 104–107. [Google Scholar] [CrossRef]

- Kim, W.; Park, J.; Kim, H.; Pak, Y.; Lee, H.; Jung, G.Y. Sequential dip-spin coating method: Fully infiltration of MAPbI3-xClx into mesoporous TiO2 for stable hybrid perovskite solar cells. Electrochim. Acta 2017, 245, 734–741. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.H.; Jung, K.; Lee, M.J. Influence of spin-coating methods on properties of planar solar cells based on ambient-air-processed triple-cation mixed-halide perovskites. J. Alloys Compd. 2021, 879, 160373. [Google Scholar] [CrossRef]

- Jiang, J.; Tao, H.J.; Chen, S.; Tan, B.; Zhou, N.; Zhu, L.; Zhao, Y.; Wang, Y.; Tao, J. Efficiency enhancement of perovskite solar cells by fabricating as-prepared film before sequential spin-coating procedure. Appl. Surf. Sci. 2016, 371, 289–295. [Google Scholar] [CrossRef] [Green Version]

- Padilla, J.U.; Graells, M.; Valle, J.S.; Serrano, J.L. A viscosity-mediated model for relating gloss and film thickness of coatings. Prog. Org. Coat. 2019, 136, 10595. [Google Scholar]

- Emslie, A.G.; Bonner, F.T.; Peck, L.G. Flow of a viscous liquid on a rotating disk. J. Appl. Phys. 1958, 29, 858. [Google Scholar] [CrossRef]

- Jenekhe, S.A.; Schuldt, S.B. Coating flow of non-Newtonian fluids on a flat rotating disk. Ind. Eng. Chem. Fundam. 1984, 23, 432. [Google Scholar] [CrossRef]

- Tu, Y.O. Contact line slippage of fluid flow on a rotating disk. J. Colloid Interface Sci. 1986, 29, 237. [Google Scholar] [CrossRef]

- Meyerhofer, D. Characteristics of resist films produced by spinning. J. Appl. Phys. 1978, 49, 3993. [Google Scholar] [CrossRef] [Green Version]

- Lin, M.C.; Chen, C.K. Finite amplitude long-wave instability of a thin viscoelastic fluid during spin coating. Appl. Mathmatical Model. 2012, 36, 2536–2549. [Google Scholar] [CrossRef]

- Sisoev, G.M.; Matar, O.K.; Lawrence, C.J. Axisymmetric wave regimes in viscous liquid film flow over a spinning disk. J. Fluid Mech. 2003, 495, 385. [Google Scholar] [CrossRef]

- Matar, O.K.; Sisoev, G.M.; Lawrence, C.J. Evolution scales for wave regimes in liquid film flow over a spinning disk. Phys. Fluids 2004, 16, 1532. [Google Scholar] [CrossRef]

- Leneweit, G.; Roesner, K.G.; Koehler, R. Effect of surfactants on the stability of thin liquid film flow on a rotating disk. J. Colloid Interface Sci. 2003, 260, 349. [Google Scholar] [CrossRef]

- Tomas, S.; Faghri, A.; Hankey, W. Experimental analysis and flow visualization of a thin liquid film on a stationary and rotating disk. J. Fluids Eng. 1991, 113, 73. [Google Scholar] [CrossRef]

- Leshev, I.; Peev, G. Film flow on a horizontal rotating disk. Chem. Eng. Proc. 2003, 42, 925. [Google Scholar] [CrossRef]

- Charwat, A.F.; Kelly, R.E.; Gazley, C. The flow and stability of thin liquid films on a rotating disk. J. Fluid Mech. 1972, 53, 227. [Google Scholar]

- Espig, H.; Hoyle, R. Waves in a thin liquid layer on a rotating disk. J. Fluid Mech. 1965, 22, 671. [Google Scholar] [CrossRef]

- Yokoi, K.; Xiao, F. Mechanism of structure formation in circular hydraulic jumps: Numerical studies of strongly deformed free-surface shallow flows. Physica D 2002, 161, 202. [Google Scholar] [CrossRef]

| Disk Diameter (mm) | Rotation Speed (rpm) | Resin | ||||

|---|---|---|---|---|---|---|

| Viscosity (kg/m·s) | Surface Tension (N/m) | Density (kg/m3) | Mass Applied (g) | |||

| D = 32, 50.8 | D = 120 | |||||

| 32 | 1000 | 1.3 | 0.0382 | 1230 | 2 | 6.3 |

| 50.8 | 2000 | 3 | 0.0398 | 1230 | 1.8 | 6 |

| 120 | 3000 | 5 | 0.037 | 1260 | 1 | 5.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, H. Hydrodynamic Analysis of the Thickness Variation in a Solid Film Formed by a Spin Coating Process. Coatings 2022, 12, 698. https://doi.org/10.3390/coatings12050698

Park H. Hydrodynamic Analysis of the Thickness Variation in a Solid Film Formed by a Spin Coating Process. Coatings. 2022; 12(5):698. https://doi.org/10.3390/coatings12050698

Chicago/Turabian StylePark, Heesung. 2022. "Hydrodynamic Analysis of the Thickness Variation in a Solid Film Formed by a Spin Coating Process" Coatings 12, no. 5: 698. https://doi.org/10.3390/coatings12050698

APA StylePark, H. (2022). Hydrodynamic Analysis of the Thickness Variation in a Solid Film Formed by a Spin Coating Process. Coatings, 12(5), 698. https://doi.org/10.3390/coatings12050698