Electrochemical Behavior of Cu-MWCNT Nanocomposites Manufactured by Powder Technology

Abstract

:1. Introduction

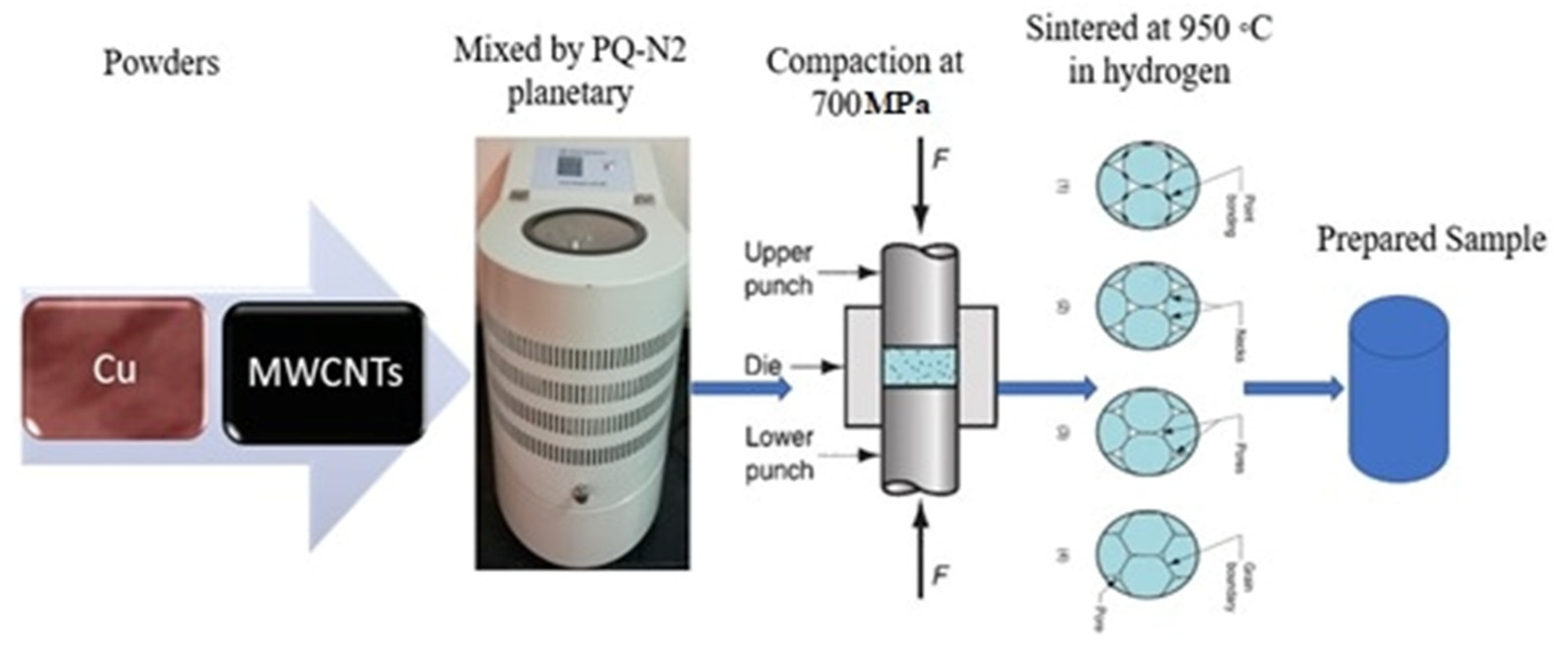

2. Materials and Methods

2.1. Materials

2.2. Powder Characterization

2.3. Relative Density Estimation

2.4. Electrical Resistivity and Thermal Conductivity Estimation

2.5. Electrochemical Behavior and Corrosion Resistance of Cu-MWCNT Nanocomposites

3. Results and Discussion

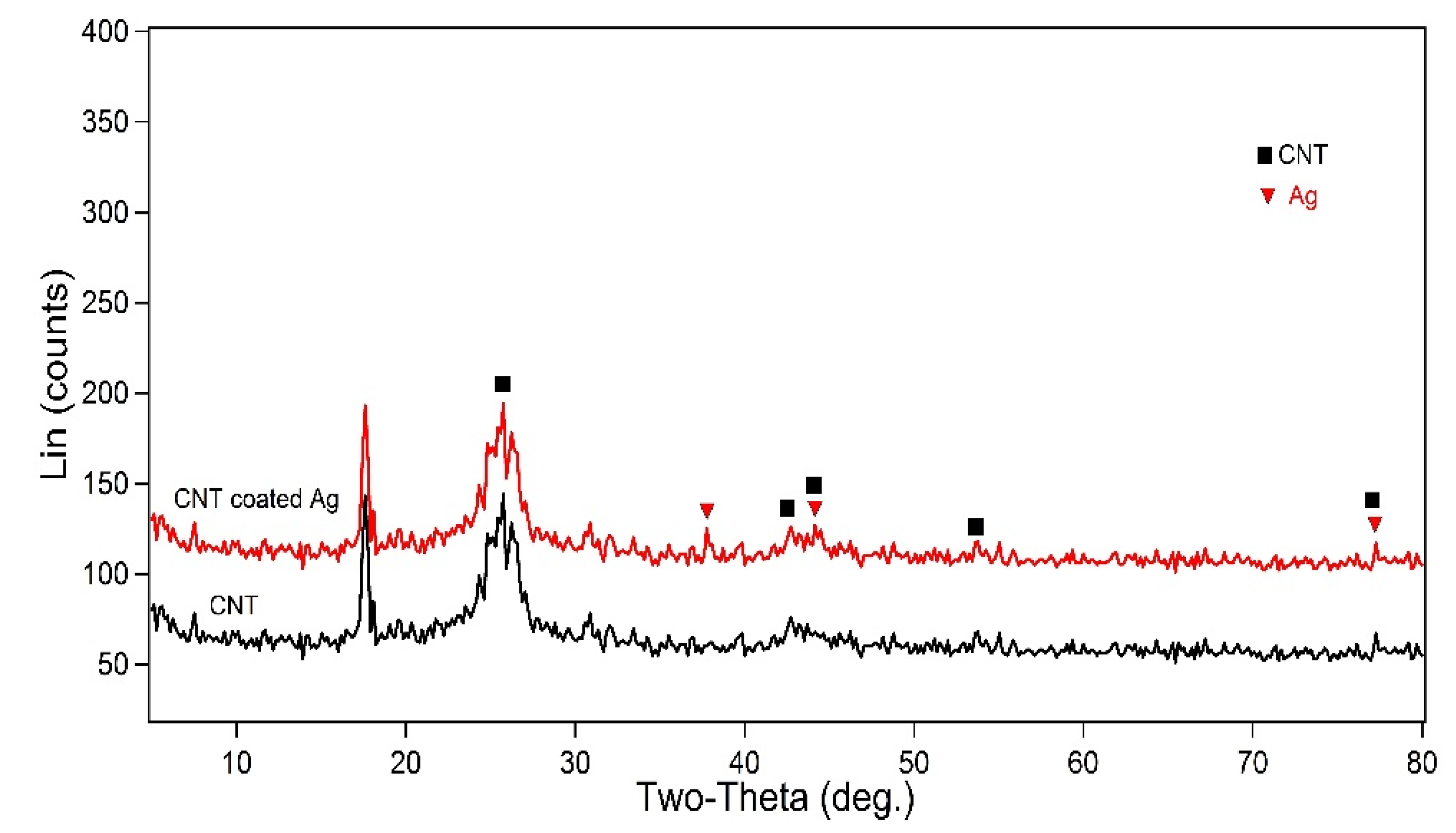

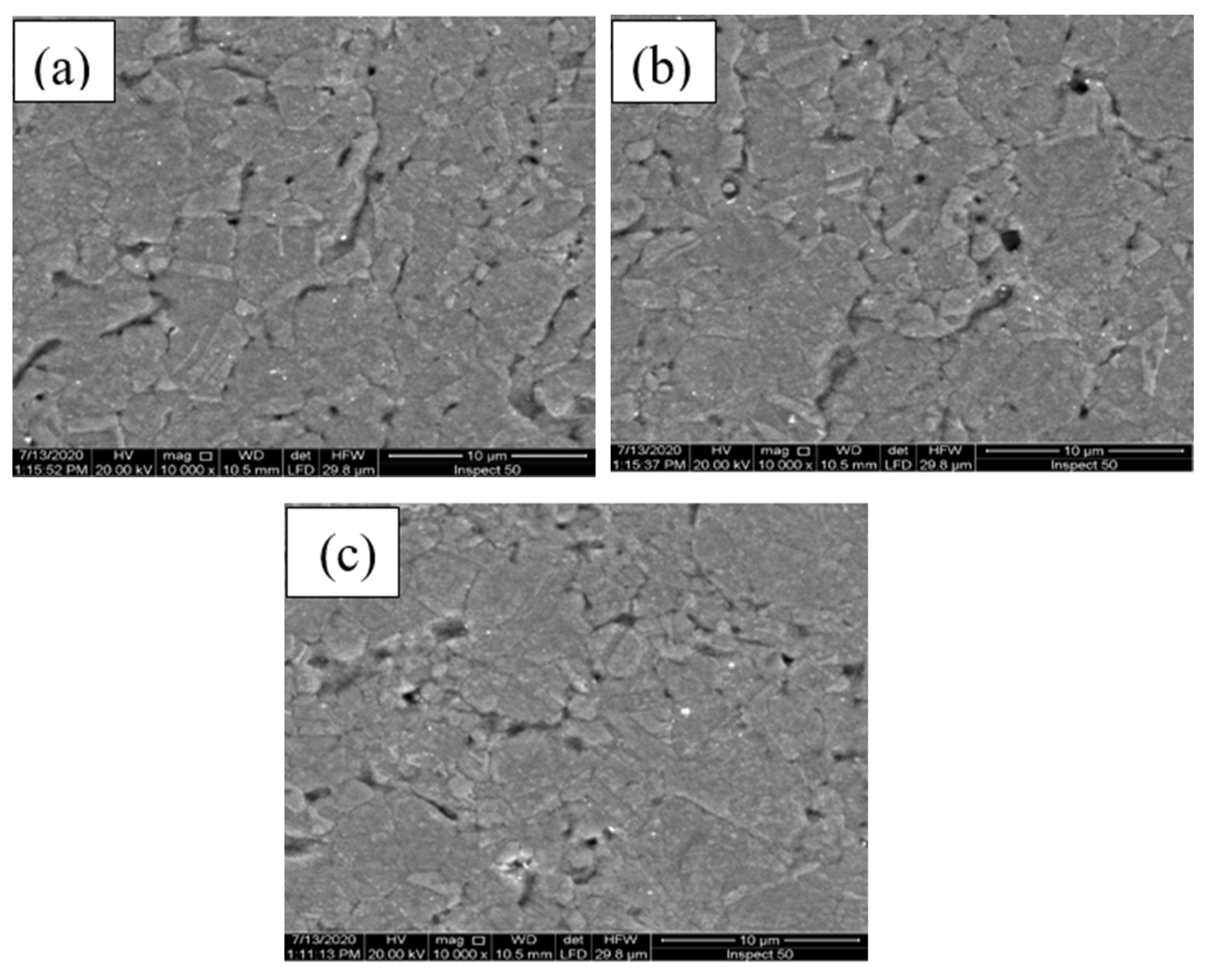

3.1. Microstructure Evolutions and PHASE structure

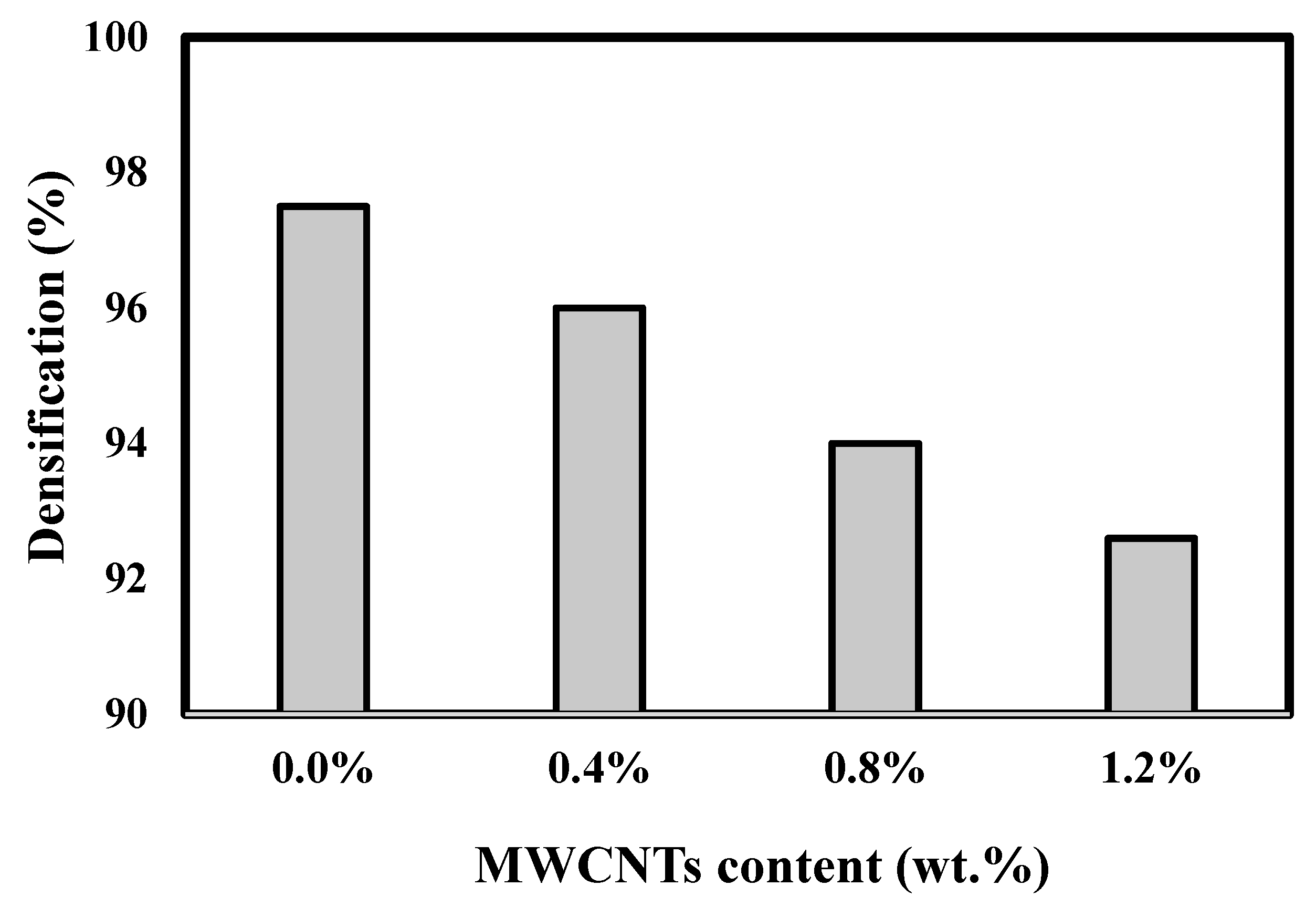

3.2. Relative Density Estimation

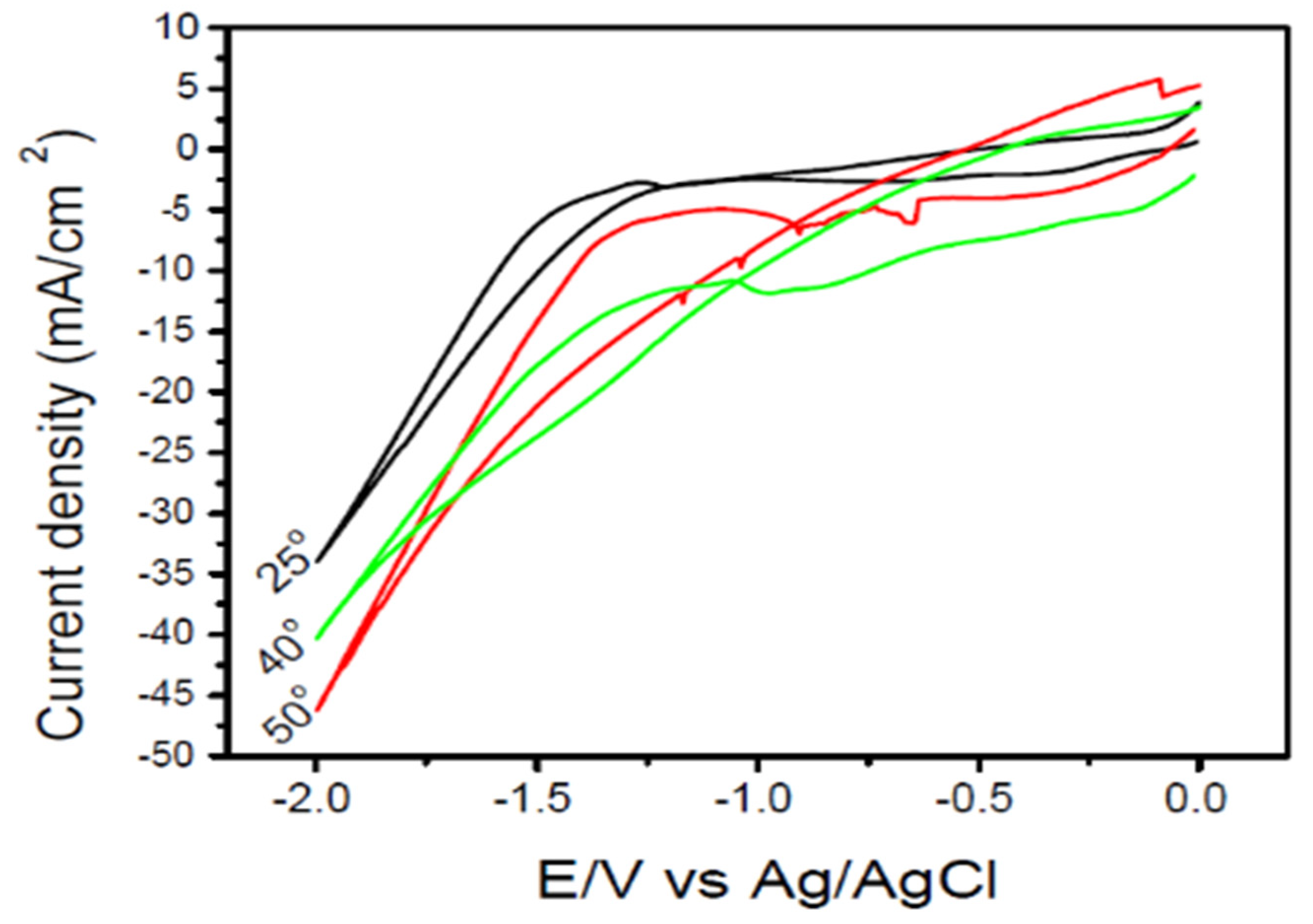

3.3. The Corrosion Resistance and Electrochemical Behavior of the Prepared Nanocomposites

4. Conclusions

- MWCNTs were coated with Ag nanoparticles by electroless deposition. The microstructure indicated that MWCNTs were distributed homogenously in the Cu matrix.

- The matrix density was reduced by raising the MWCNT nanocomposites’ content.

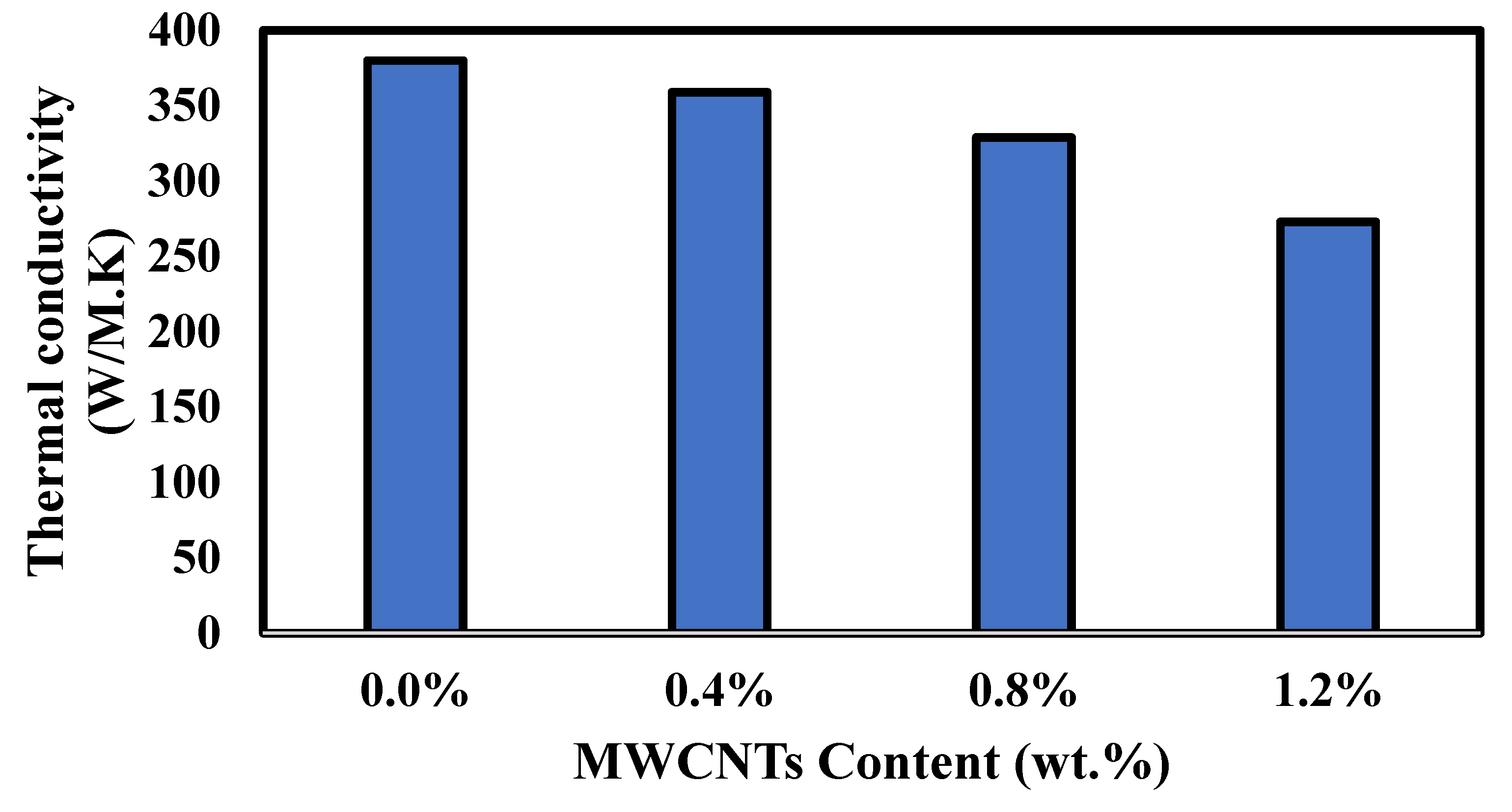

- Electrical resistivity gradually increased by adding MWCNTs to the Cu nanocomposite, while thermal conductivity decreased by increasing MWCNTs in the Cu nanocomposites.

- The maximum current density was 110 mA·cm−2 for the 1.2 wt.% MWCNTs.

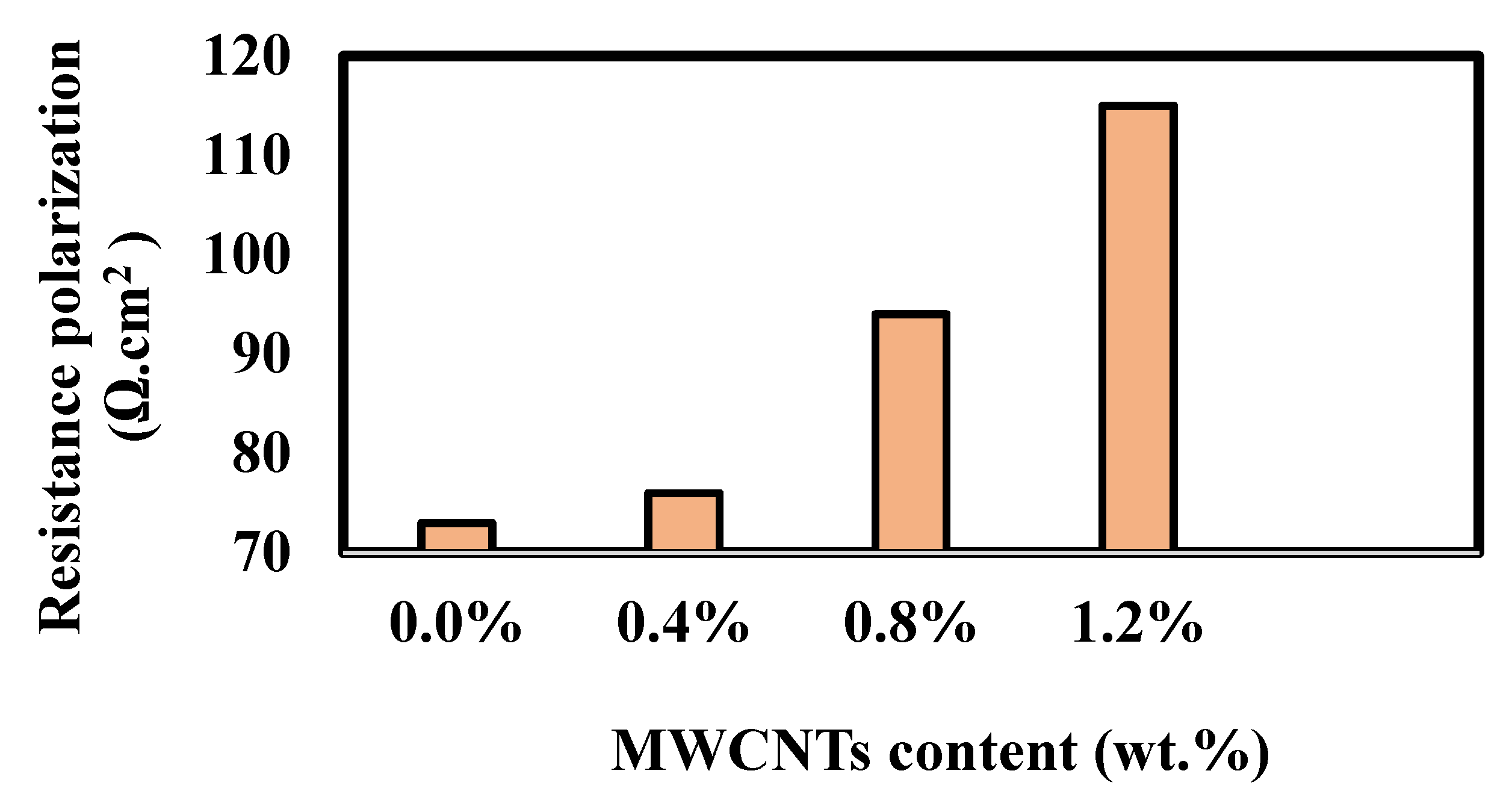

- The maximum resistance polarization was 115 Ω·cm2 for the 1.2 wt.% MWCNTs.

- The rate of corrosion declined for the 1.2 wt.% MWCNTs and reached its lowest value of 3.08 mm/year.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, H.; Wu, C.; Tang, D.Y.; Shi, X.; Xue, Y.; Huang, Q.; Zhang, J.; Elsheikh, A.H.; Ibrahim, A.M.M. Tribological Performance of Gradient Ag-Multilayer Graphene/TC4 Alloy Self-Lubricating Composites Prepared By Laser Additive Manufacturing. Tribol. Trans. 2021, 64, 819–829. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Abd Elaziz, M.; Ramesh, B.; Egiza, M.; Al-qaness, M.A.A. Modeling of drilling process of GFRP composite using a hybrid random vector functional link network/parasitism-predation algorithm. J. Mater. Res. Technol. 2021, 14, 298–311. [Google Scholar] [CrossRef]

- Thangaraj, M.; Ahmadein, M.; Alsaleh, N.A.; Elsheikh, A.H. Optimization of abrasive water jet machining of SiC reinforced aluminum alloy based metal matrix composites using Taguchi–DEAR technique. Materials 2021, 14, 6250. [Google Scholar] [CrossRef] [PubMed]

- Elsheikh, A.H.; Panchal, H.; Shanmugan, S.; Muthuramalingam, T.; El-Kassas, A.M.; Ramesh, B. Recent progresses in wood-plastic composites: Pre-processing treatments, manufacturing techniques, recyclability and eco-friendly assessment. Clean. Eng. Technol. 2022, 8, 100450. [Google Scholar] [CrossRef]

- Ahmadein, M.; El-Kady, O.A.; Mohammed, M.M.; Essa, F.A.; Alsaleh, N.A.; Djuansjah, J.; Elsheikh, A.H. Improving the mechanical properties and coefficient of thermal expansion of molybdenum-reinforced copper using powder metallurgy. Mater. Res. Express 2021, 8, 096502. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Yu, J.; Sathyamurthy, R.; Tawfik, M.M.; Shanmugan, S.; Essa, F.A. Improving the tribological properties of AISI M50 steel using Sns/Zno solid lubricants. J. Alloys Compd. 2020, 821, 153494. [Google Scholar] [CrossRef]

- Essa, F.A.; Yu, J.; Elsheikh, A.H.; Tawfik, M.M. A new M50 matrix composite sintered with a hybrid Sns/Zno nanoscale solid lubricants: An experimental investigation. Mater. Res. Express 2019, 6, 116523. [Google Scholar] [CrossRef]

- Miracle, D. Metal matrix composites–from science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Dorri Moghadam, A.; Schultz, B.F.; Ferguson, J.; Omrani, E.; Rohatgi, P.K.; Gupta, N. Functional metal matrix composites: Self-lubricating, self-healing, and nanocomposites-an outlook. Jom 2014, 66, 872–881. [Google Scholar] [CrossRef]

- Khoshaim, A.B.; Moustafa, E.B.; Bafakeeh, O.T.; Elsheikh, A.H. An Optimized Multilayer Perceptrons Model Using Grey Wolf Optimizer to Predict Mechanical and Microstructural Properties of Friction Stir Processed Aluminum Alloy Reinforced by Nanoparticles. Coatings 2021, 11, 1476. [Google Scholar] [CrossRef]

- Chen, L.; Hou, Z.; Liu, Y.; Luan, C.; Zhu, L.; Li, W. High strength and high ductility copper matrix composite reinforced by graded distribution of carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2020, 138, 106063. [Google Scholar] [CrossRef]

- Zhang, L.; He, X.; Qu, X.; Duan, B.; Lu, X.; Qin, M. Dry sliding wear properties of high volume fraction SiCp/Cu composites produced by pressureless infiltration. Wear 2008, 265, 1848–1856. [Google Scholar] [CrossRef]

- Maji, P.; Dube, R.; Basu, B. Enhancement of wear resistance of copper with tungsten addition (≤20 wt%) by powder metallurgy route. J. Tribol. 2009, 131, 041602. [Google Scholar] [CrossRef]

- Oseli, A.; Vesel, A.; Mozetič, M.; Žagar, E.; Huskić, M.; Slemenik Perše, L. Nano-mesh superstructure in single-walled carbon nanotube/polyethylene nanocomposites, and its impact on rheological, thermal and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2020, 136, 105972. [Google Scholar] [CrossRef]

- Zheng, Z.; Yang, A.; Tao, J.; Li, J.; Zhang, W.; Li, X.; Xue, H. Mechanical and Conductive Properties of Cu Matrix Composites Reinforced by Oriented Carbon Nanotubes with Different Coatings. Nanomaterials 2022, 12, 266. [Google Scholar] [CrossRef]

- Kang, D.; Hwang, S.; Jung, B.; Shim, J. Characterizations of polypropylene/single-walled carbon nanotube nanocomposites prepared by the novel melt processing technique with a controlled residence time. Processes 2021, 9, 1395. [Google Scholar] [CrossRef]

- Lozovyi, F.; Ivanenko, K.; Nedilko, S.; Revo, S.; Hamamda, S. Thermal analysis of polyethylene + X% carbon nanotubes. Nanoscale Res. Lett. 2016, 11, 97. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Arai, S.; Osaki, T. Fabrication of copper/multiwalled carbon nanotube composites containing different sized nanotubes by electroless deposition. J. Electrochem. Soc. 2014, 162, D68. [Google Scholar] [CrossRef] [Green Version]

- Chu, K.; Jia, C.-c.; Li, W.-s. Thermal conductivity enhancement in carbon nanotube/Cu–Ti composites. Appl. Phys. A 2013, 110, 269–273. [Google Scholar] [CrossRef]

- Chu, K.; Jia, C.; Guo, H.; Li, W. On the thermal conductivity of Cu–Zr/diamond composites. Mater. Des. 2013, 45, 36–42. [Google Scholar] [CrossRef]

- Cho, S.; Kikuchi, K.; Kawasaki, A. On the role of amorphous intergranular and interfacial layers in the thermal conductivity of a multi-walled carbon nanotube–copper matrix composite. Acta Mater. 2012, 60, 726–736. [Google Scholar] [CrossRef]

- Firkowska, I.; Boden, A.; Vogt, A.-M.; Reich, S. Effect of carbon nanotube surface modification on thermal properties of copper–CNT composites. J. Mater. Chem. 2011, 21, 17541–17546. [Google Scholar] [CrossRef]

- Fathy, A.; Sadoun, A.; Abdelhameed, M. Effect of matrix/reinforcement particle size ratio (PSR) on the mechanical properties of extruded Al–SiC composites. Int. J. Adv. Manuf. Technol. 2014, 73, 1049–1056. [Google Scholar] [CrossRef]

- Shehata, F.; Fathy, A.; Abdelhameed, M.; Moustafa, S. Preparation and properties of Al2O3 nanoparticle reinforced copper matrix composites by in situ processing. Mater. Des. 2009, 30, 2756–2762. [Google Scholar] [CrossRef]

- ASTM, D. 1217. Standard Test Method for Density and Relative Density (Specific Gravity) of Liquids by Bingham Pycnometer; Annual Book of ASTM Standards: West Conshohocken, PA, USA, 2007; ASTM-D1217-20. [Google Scholar]

- Samal, P.; Newkirk, J. Materials Standards and Test Method Standards for Powder Metallurgy. ASM Handb. 2015, 7, 45–51. [Google Scholar]

- Fathy, A.; El-Kady, O. Thermal expansion and thermal conductivity characteristics of Cu–Al2O3 nanocomposites. Mater. Des. 2013, 46, 355–359. [Google Scholar] [CrossRef]

- Lee, D.; Kim, B. Nanostructured Cu–Al2O3 composite produced by thermochemical process for electrode application. Mater. Lett. 2004, 58, 378–383. [Google Scholar] [CrossRef]

- Barakat, W.; Wagih, A.; Elkady, O.A.; Abu-Oqail, A.; Fathy, A.; El-Nikhaily, A. Effect of Al2O3 nanoparticles content and compaction temperature on properties of Al–Al2O3 coated Cu nanocomposites. Compos. Part B Eng. 2019, 175, 107140. [Google Scholar] [CrossRef]

- Ling, G.; Li, Y. Influencing factors on the uniformity of copper coated nano-Al2O3 powders prepared by electroless plating. Mater. Lett. 2005, 59, 1610–1613. [Google Scholar] [CrossRef]

- Rajkovic, V.; Bozic, D.; Jovanovic, M.T. Effects of copper and Al2O3 particles on characteristics of Cu–Al2O3 composites. Mater. Des. 2010, 31, 1962–1970. [Google Scholar] [CrossRef]

- Elsayed, E.; Harraz, F.; Saba, A. Nanocrystalline zinc oxide thin films prepared by electrochemical technique for advanced applications. Int. J. Nanoparticles 2012, 5, 136–148. [Google Scholar] [CrossRef]

| Powder | Purity % | Particle Size (nm) | Particle Shape | Density (g/cm3) |

|---|---|---|---|---|

| Cu | 99.99 | ~50 | Spherical | 8.94 |

| MWCNTs | 99.97 | ~50 | Tube | 0.7~1.7 |

| Sample | Percent (wt.%) | Relative Density |

|---|---|---|

| Cu pure | 100 | 97.5 |

| MWCNTs | 0.4 | 96 |

| MWCNTs | 0.8 | 94 |

| MWCNTs | 1.2 | 92.6 |

| Sample | Percent (wt.%) | Resistance R (Ω) | Height (mm) | Area = T.W (mm2) | Electrical Resistivity ρ = (µΩ·cm) | Thermal Conductivity K = σ.L.T (W.m−1/K) |

|---|---|---|---|---|---|---|

| Cu Pure | 100 | 0.00000069 | 4.06 | 113 | 1.92 | 380 |

| MWCNTs | 0.4 | 0.0000009 | 5 | 113 | 2.01 | 359 |

| MWCNTs | 0.8 | 0.0000011 | 5.6 | 113 | 2.2 | 329 |

| MWCNTs | 1.2 | 0.0000013 | 5.5 | 113 | 2.6 | 273 |

| Sample | Percent (wt.%) | Resistance Polarization (Ω·cm2) | Corrosion Rate (mm/y) |

|---|---|---|---|

| Cu Pure | 100 | 73 | 4.5 |

| MWCNTs | 0.4 | 76 | 4 |

| MWCNTs | 0.8 | 94 | 3.328 |

| MWCNTs | 1.2 | 115 | 3.08 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammed, M.M.; Elsayed, E.M.; El-Kady, O.A.; A. Alsaleh, N.; Elsheikh, A.H.; Essa, F.A.; Ahmadein, M.; Djuansjah, J. Electrochemical Behavior of Cu-MWCNT Nanocomposites Manufactured by Powder Technology. Coatings 2022, 12, 409. https://doi.org/10.3390/coatings12030409

Mohammed MM, Elsayed EM, El-Kady OA, A. Alsaleh N, Elsheikh AH, Essa FA, Ahmadein M, Djuansjah J. Electrochemical Behavior of Cu-MWCNT Nanocomposites Manufactured by Powder Technology. Coatings. 2022; 12(3):409. https://doi.org/10.3390/coatings12030409

Chicago/Turabian StyleMohammed, Moustafa M., Elsayed M. Elsayed, Omyma A. El-Kady, Naser A. Alsaleh, Ammar H. Elsheikh, Fadl A. Essa, Mahmoud Ahmadein, and Joy Djuansjah. 2022. "Electrochemical Behavior of Cu-MWCNT Nanocomposites Manufactured by Powder Technology" Coatings 12, no. 3: 409. https://doi.org/10.3390/coatings12030409

APA StyleMohammed, M. M., Elsayed, E. M., El-Kady, O. A., A. Alsaleh, N., Elsheikh, A. H., Essa, F. A., Ahmadein, M., & Djuansjah, J. (2022). Electrochemical Behavior of Cu-MWCNT Nanocomposites Manufactured by Powder Technology. Coatings, 12(3), 409. https://doi.org/10.3390/coatings12030409