Viscoelastic Simulation of Stress and Warpage for Memory Chip 3D-Stacked Package

Abstract

:1. Introduction

2. Finite Element Analysis

2.1. Geometric Model

2.2. Packaging Material Parameters

2.3. EMC Viscoelasticity

2.3.1. Experimental Instruments and Samples

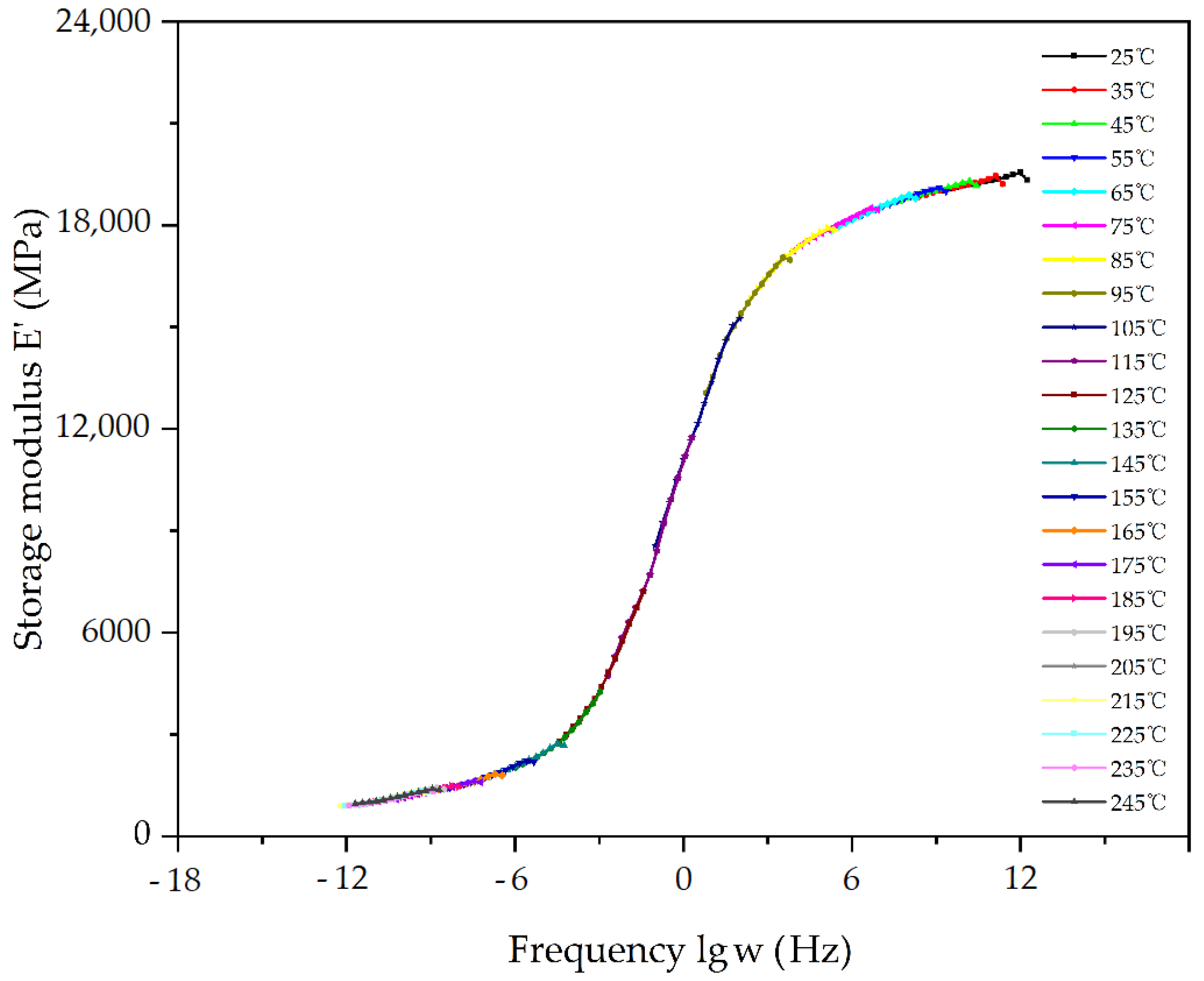

2.3.2. Experimental Data and Data Processing

2.3.3. Experimental Data

2.4. FE Mold

2.4.1. FE Mesh

2.4.2. Boundary Conditions and Load

3. Results and Discussion

3.1. Analysis of Stress Simulation Results

3.2. Analysis of Warpage Simulation Results

3.2.1. Influence of EMC Thickness on Warpage

3.2.2. Influence of Die Bond Material on Warpage

3.2.3. Influence of Die Thickness on Warpage

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tsai, M.Y.; Wang, C.T.; Hsu, C.H. The Effect of Epoxy Molding Compound on Thermal/Residual Deformations and Stresses in IC Packages During Manufacturing Process. Trans. Compon. Packag. Technol. 2006, 29, 625–635. [Google Scholar] [CrossRef]

- Tsurumi, N.; Tsuji, Y.; Masago, N.; Yoshizawa, K. Elucidation of Adhesive Interaction between the Epoxy Molding Compound and Cu Lead Frames. ACS Omega 2021, 6, 34173–34184. [Google Scholar] [CrossRef] [PubMed]

- Sumiya, Y.; Tsuji, Y.; Yoshizawa, K. Peel Adhesion Strength between Epoxy Resin and Hydrated Silica Surfaces: A Density Functional Theory Study. ACS Omega 2022, 7, 17393–17400. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.J.; Hwang, S.J.; Lee, H.H.; Huang, D.Y. Modeling of Viscoelastic Behavior of an Epoxy Molding Compound During and After Curing. Trans. Compon. Packag. Manuf. Technol. 2011, 1, 1755–1760. [Google Scholar] [CrossRef]

- Chao, R.; Fei, Q.; Wang, X. A Finite Element Simulation of PoP Assembly Processes. J. Beijing Univ. Technol. 2010, 38, 11556068. [Google Scholar]

- Cho, K.; Jeon, I. Numerical analysis of the warpage problem in TSOP. Microelectron. Reliab. 2004, 44, 621–626. [Google Scholar] [CrossRef]

- Kim, Y.K.; Park, I.S.; Choi, J. Warpage mechanism analyses of strip panel type PBGA chip packaging. Microelectron. Reliab. 2010, 50, 398–406. [Google Scholar] [CrossRef]

- Srikanth, N. Warpage analysis of epoxy molded packages using viscoelastic based model. J. Mater. Sci. 2006, 41, 3773–3780. [Google Scholar] [CrossRef]

- Kaija, K.; Pekkanen, V.; Maentysalo, M.; Mansikkamaeki, P. Controlling warpage of molded package for inkjet manufacturing. Microelectron. Eng. 2008, 85, 518–526. [Google Scholar] [CrossRef]

- Wu, R.W.; Chen, C.K.; Tsao, L.C. Prediction of package warpage combined experimental and simulation for four maps substrate. In Proceedings of the International Conference on Electronic Packaging Technology & High Density Packaging, Xi’an, China, 16–19 August 2010. [Google Scholar]

- Sadeghinia, M.; Jansen, K.; Ernst, L.J. Characterization and modeling the thermo-mechanical cure-dependent properties of epoxy molding compound. Int. J. Adhes. Adhes. 2012, 32, 82–88. [Google Scholar] [CrossRef]

- Ozturk, B.; Gromala, P.; Otto, C.; Fischer, A.; Ernst, L.J. Characterization of Adhesives and Interface Strength for Automotive Applications. In Proceedings of the International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems, Cascais, Portugal, 16–18 April 2012. [Google Scholar]

- Kiasat, M.S. Curing Shrinkage and Residual Stress in Viscoelastic Thermosetting Resins and Composites. Ph.D. Thesis, The Delft University of Technology, Delft, The Netherlands, 2000. [Google Scholar]

- Scott, T.F.; Cook, W.D.; Forsythe, J.S. Effect of the degree of cure on the viscoelastic properties of vinyl ester resins. Eur. Polym. J. 2008, 44, 3200–3212. [Google Scholar] [CrossRef]

- Driel, W.; Zhang, G.Q.; Janssen, J.; Ernst, L.J.; Su, F.; Chian, K.S.; Yi, S. Prediction and verification of process induced warpage of electronic packages. Microelectron. Reliab. 2003, 43, 765–774. [Google Scholar] [CrossRef]

- Williams, M.L.; Landel, R.F.; Ferry, J.D. The temperature dependence of relaxation mechanisms in amorphous polymers and other glass-forming liquids. J. Am. Chem. Soc. 1955, 77, 3701–3707. [Google Scholar] [CrossRef]

- Mess, L.E.; Brooks, J.M.; Corisis, D.J. Stacked Mass Storage Flash Memory Package. U.S. Patent 7375419, 2008. [Google Scholar]

- Duan, Y. Package Structure Design and Process Development for MOSFET Chip Based on Molded Interconnect System Technology. Master’s Thesis, Guilin University of Electronic Technology, Guilin, China, 2021. [Google Scholar]

- Lin, T.; Chen, C.; Li, J.; Cheng, X.; Qian, W.; Jian, C. Simulation and Validation of FBGA Package Warpage by Considering Viscoelastic Effect. Semicond. Technol. 2015, 40, 142–147. [Google Scholar]

- Jansen, K.M.B. Thermomechanical modeling and characterization of Polymers. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2005. [Google Scholar]

- Ma, D.; He, P.; Xu, Z.; Zhou, Y. Structure and Properties of Polymers, 2nd ed.; Science Press: Beijing, China, 1995; pp. 253–267. [Google Scholar]

- Yen, F.; Chen, E.; Lai, J.Y.; Wang, Y.P. The Improvement Guidelines of BGA Warpage within SMT Temperature Profile Using Shadow Moiré Technique. In Proceedings of the 8th International Conference on Electronic Packaging Technology, Shanghai, China, 14–17 August 2007. [Google Scholar]

- Song, S.N.; Tan, H.H.; Ong, P.L. Die attach film application in multi die stack package. In Proceedings of the Electronic Packaging Technology Conference, Singapore, 7–9 December 2005. [Google Scholar]

- Yauw, O.; Jie, W.; Tan, A.; Qin, I.; Schulze, G. Leading edge die stacking and wire bonding technologies for advanced 3D memory packages. In Proceedings of the 19th Electronics Packaging Technology Conference, Singapore, 6–9 December 2017. [Google Scholar]

| Item | Material | Size (mm) | E (MPa) | v | A (ppm/°C) |

|---|---|---|---|---|---|

| EMC | EMC | 12 × 10 × 0.9 | Test | 0.3 | 9.38, T < Tg 38.68, T > Tg |

| Chip | Si | 10 × 8.0 × 0.1 | 131,000 | 0.3 | 2.8 |

| 10 × 7.8 × 0.1 | |||||

| 10 × 7.6 × 0.1 | |||||

| 10 × 7.4 × 0.1 | |||||

| 4 × 1.0 × 0.1 | |||||

| DA | DAF | 10 × 8.0 × 0.02 | 640@25 °C 140@150 °C | 0.4 | 48.00 |

| 10 × 7.8 × 0.02 | |||||

| 10 × 7.6 × 0.02 | |||||

| 10 × 7.4 × 0.02 | |||||

| 4 × 1.0 × 0.02 | |||||

| substrate | BT | 12 × 10 × 0.2 | X, Y: 26,000 Z: 11,000 | XZ, YZ: 0.39 XY: 0.11 | X, Y: 15 Z: 50 |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Frequency (Hz) | 0.1 | 0.18 | 0.32 | 0.56 | 1 | 1.8 | 3.2 | 5.6 | 10 | 17.8 | 31.6 | 56 | 100 |

| No. | Relaxation Time τi (s) | Shear Relaxation Coefficient Gi | Volume Relaxation Coefficient Ki |

|---|---|---|---|

| τ1 | 1.00 × 10−8 | 239.32 | 518.54 |

| τ2 | 1.00 × 10−6 | 272.59 | 590.62 |

| τ3 | 1.00 × 10−4 | 354.33 | 767.71 |

| τ4 | 1.00 × 10−3 | 349.54 | 757.34 |

| τ5 | 1.00 × 10−2 | 513.60 | 1112.8 |

| τ6 | 1.00 × 10−1 | 966.29 | 2093.6 |

| τ7 | 1.00 × 100 | 853.56 | 1849.4 |

| τ8 | 1.00 × 101 | 1106.5 | 2397.4 |

| τ9 | 1.00 × 102 | 726.77 | 1574.6 |

| τ10 | 1.00 × 103 | 560.19 | 1213.8 |

| τ11 | 1.00 × 104 | 475.34 | 1029.7 |

| τ12 | 1.00 × 106 | 305.22 | 662.19 |

| τ13 | 1.00 × 108 | 87.513 | 183.44 |

| τ14 | 1.00 × 109 | 150.87 | 342.30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Cao, S.; Lu, G.; Yang, D. Viscoelastic Simulation of Stress and Warpage for Memory Chip 3D-Stacked Package. Coatings 2022, 12, 1976. https://doi.org/10.3390/coatings12121976

Wang X, Cao S, Lu G, Yang D. Viscoelastic Simulation of Stress and Warpage for Memory Chip 3D-Stacked Package. Coatings. 2022; 12(12):1976. https://doi.org/10.3390/coatings12121976

Chicago/Turabian StyleWang, Xiyou, Sicheng Cao, Guangsheng Lu, and Daoguo Yang. 2022. "Viscoelastic Simulation of Stress and Warpage for Memory Chip 3D-Stacked Package" Coatings 12, no. 12: 1976. https://doi.org/10.3390/coatings12121976

APA StyleWang, X., Cao, S., Lu, G., & Yang, D. (2022). Viscoelastic Simulation of Stress and Warpage for Memory Chip 3D-Stacked Package. Coatings, 12(12), 1976. https://doi.org/10.3390/coatings12121976