Research Progress of Water–Laser Compound Machining Technology

Abstract

:1. Introduction

2. Water Laser Compound Machining Interaction Mechanism

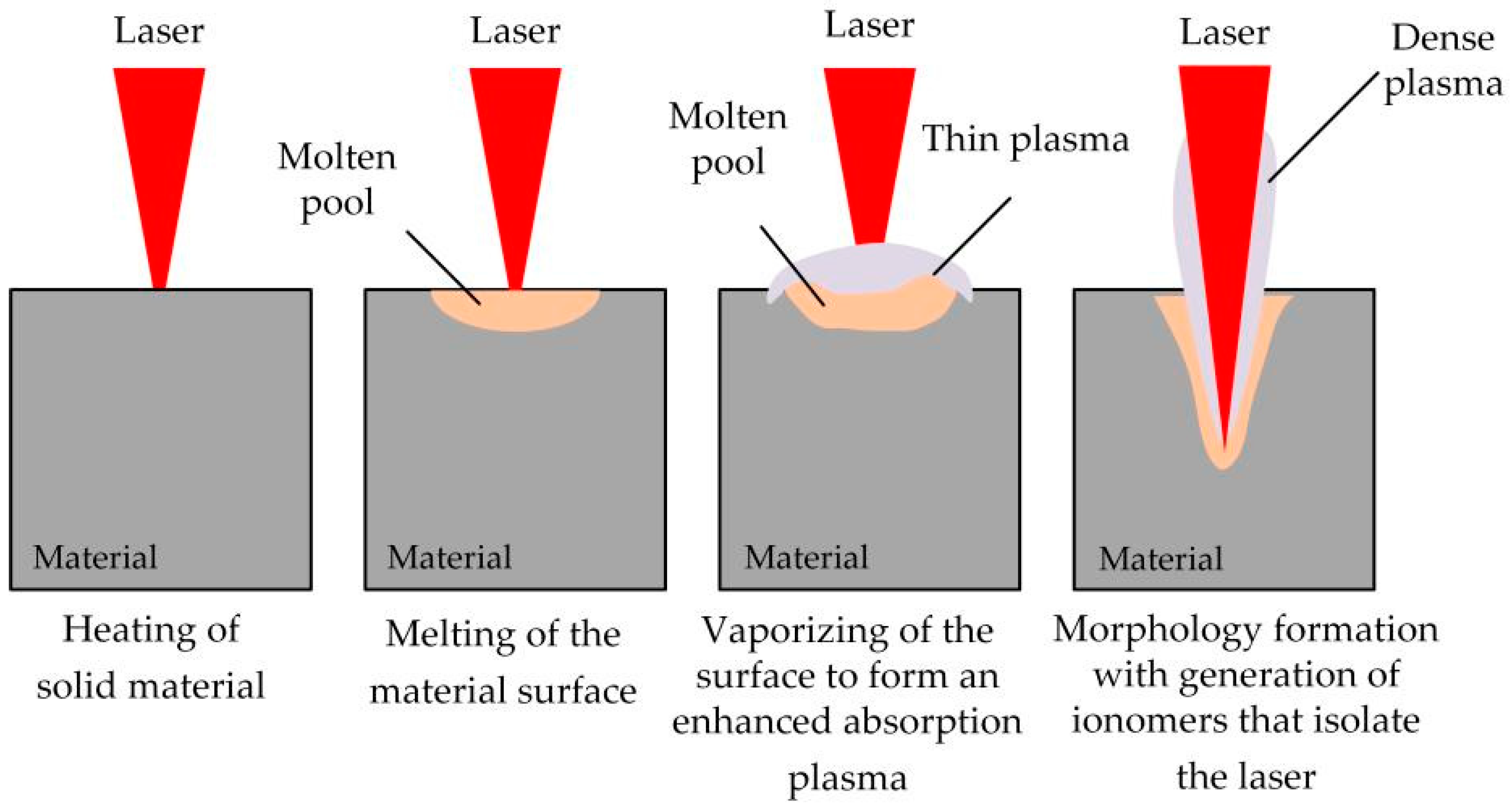

2.1. Laser–Material Interaction Mechanism

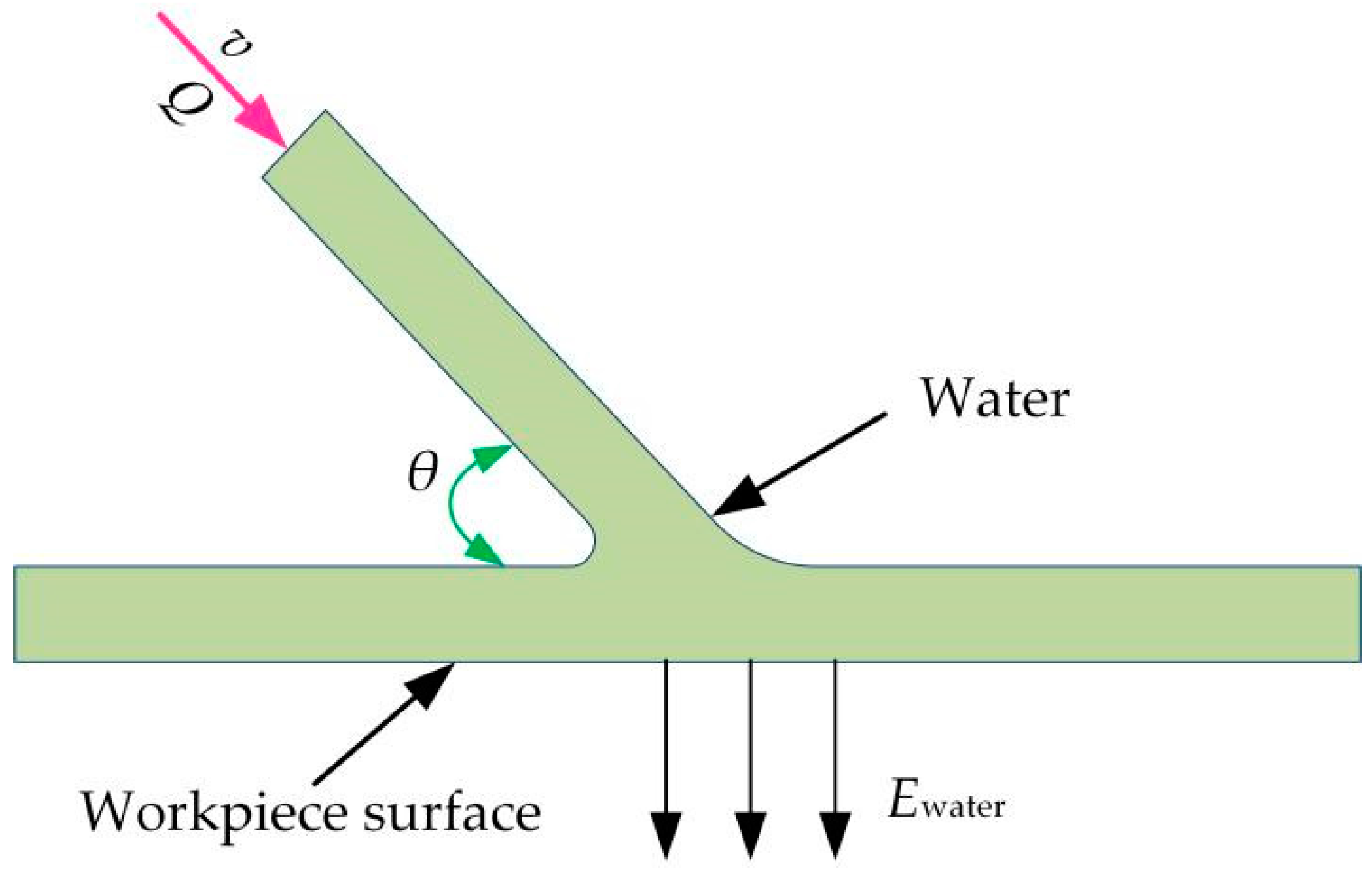

2.2. Water–Material Interaction Mechanism

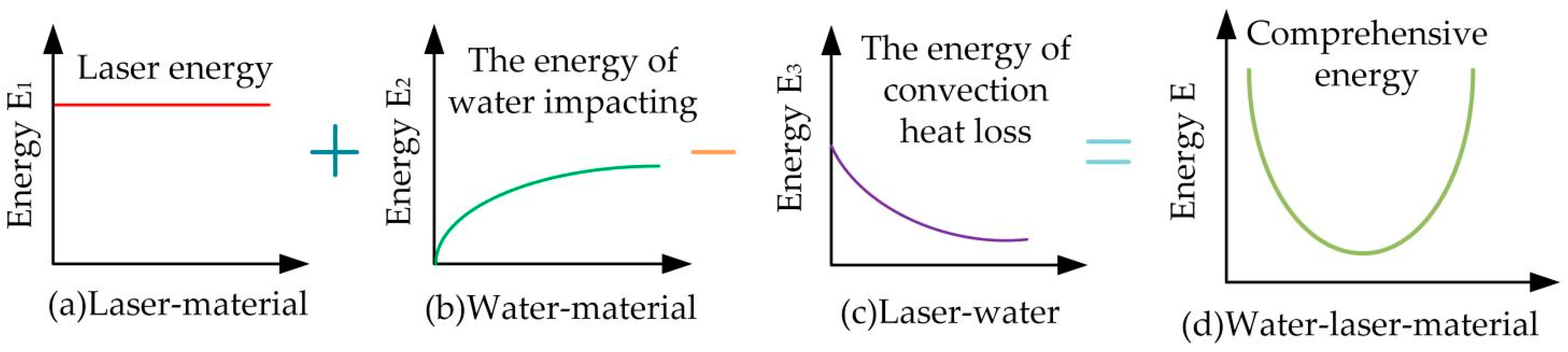

2.3. Water–Laser Interaction Mechanism

2.4. Water–Laser–Material Interaction Mechanism

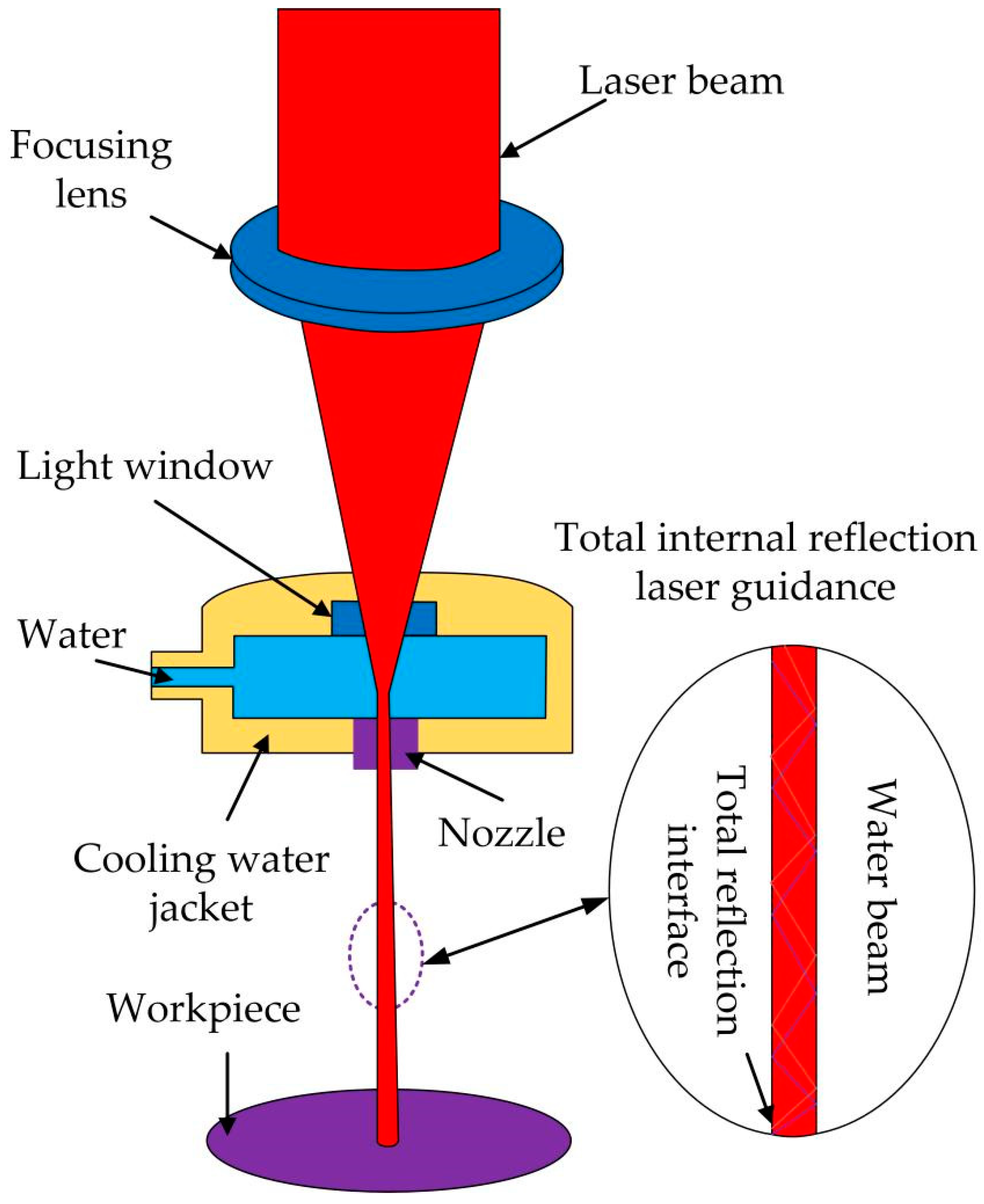

3. Water-Guided Laser Processing

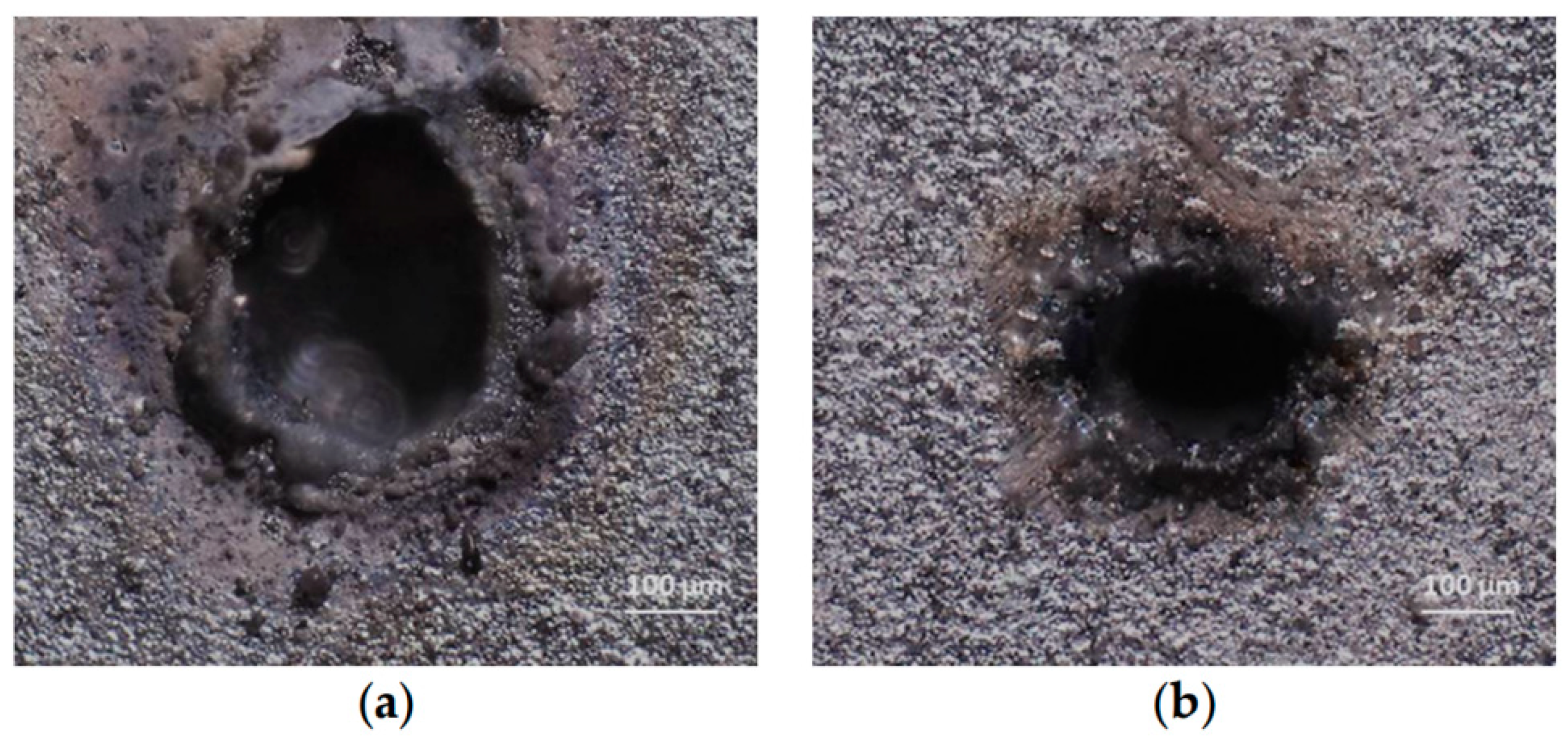

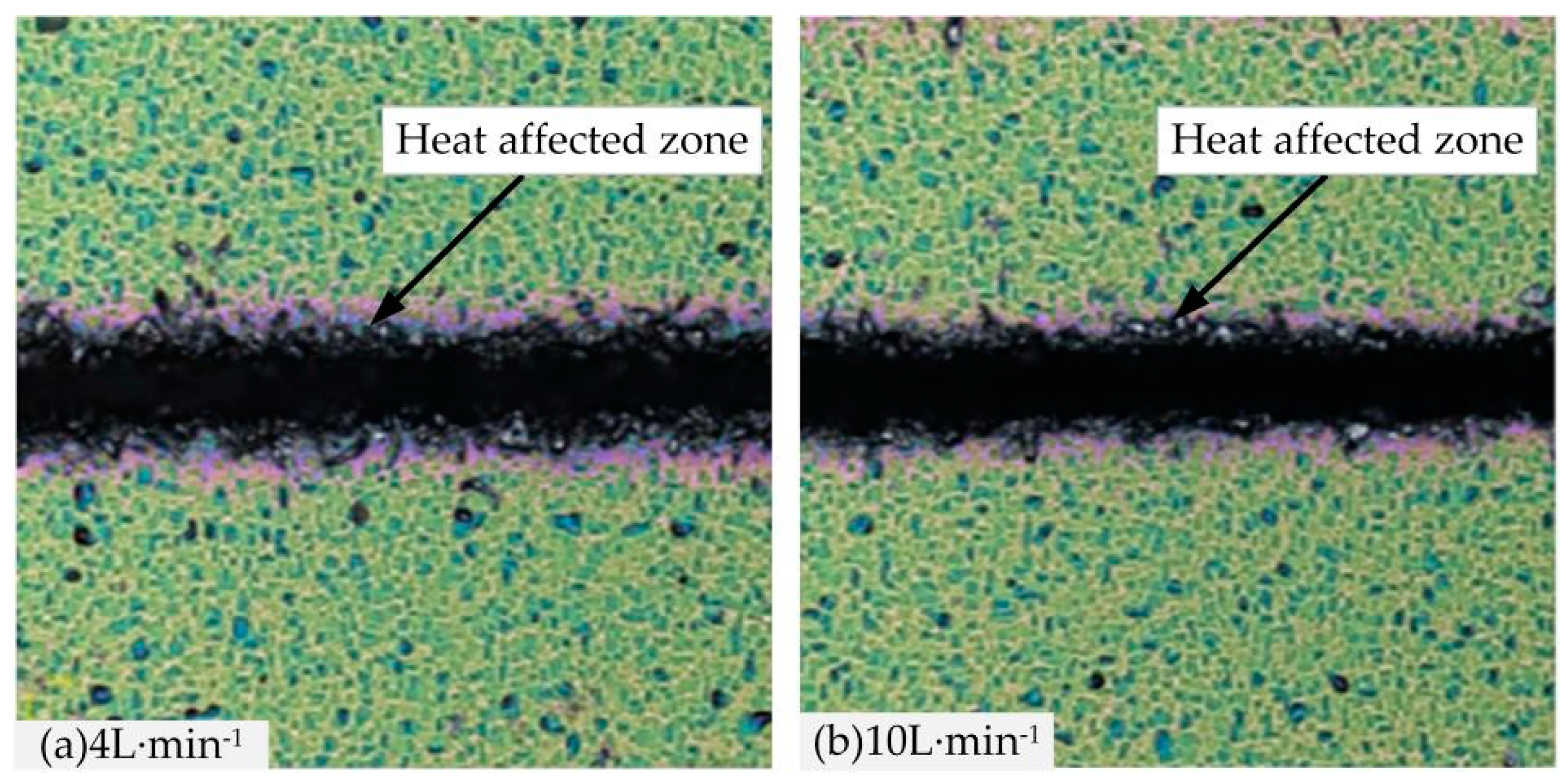

4. Underwater Laser Processing

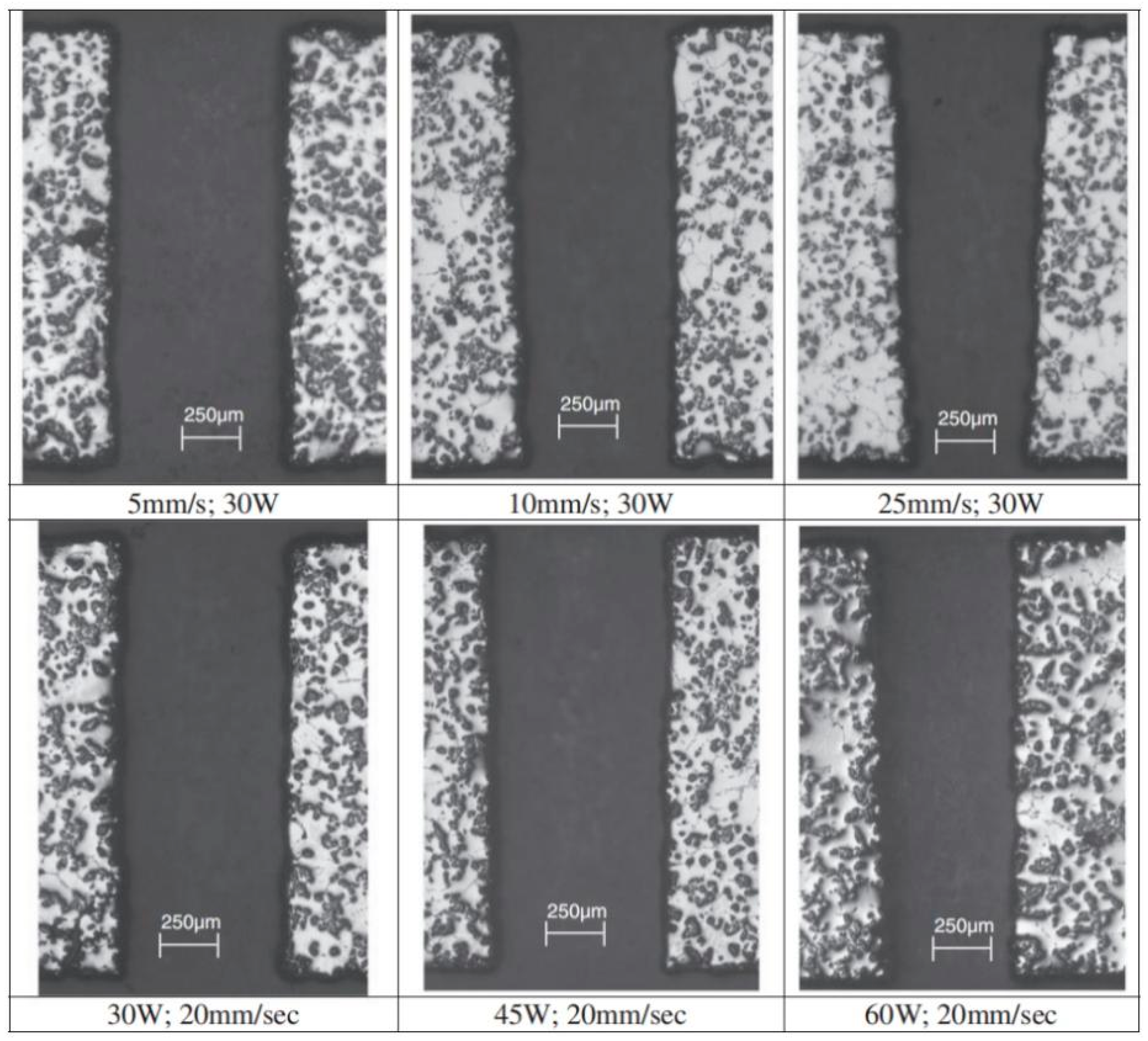

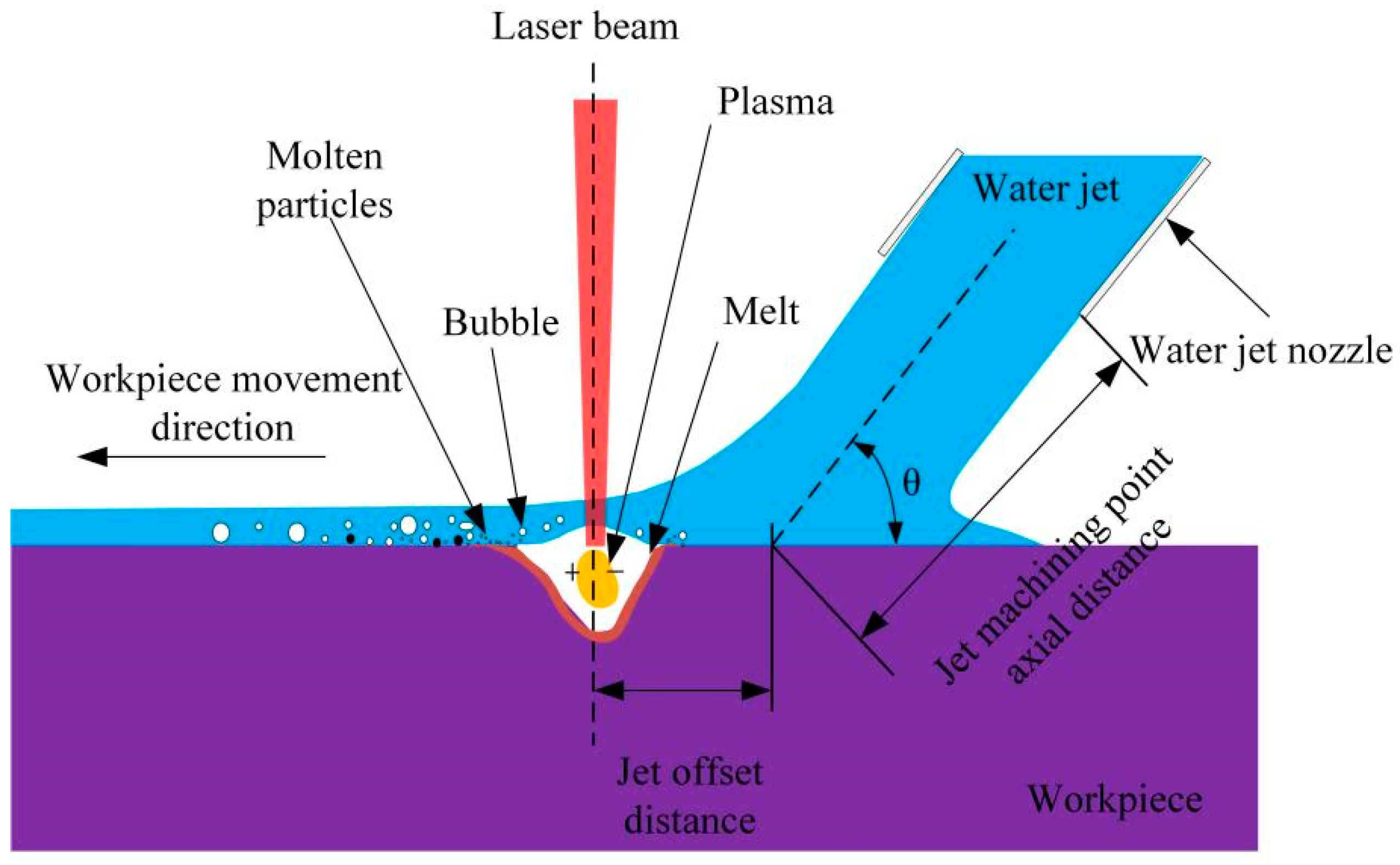

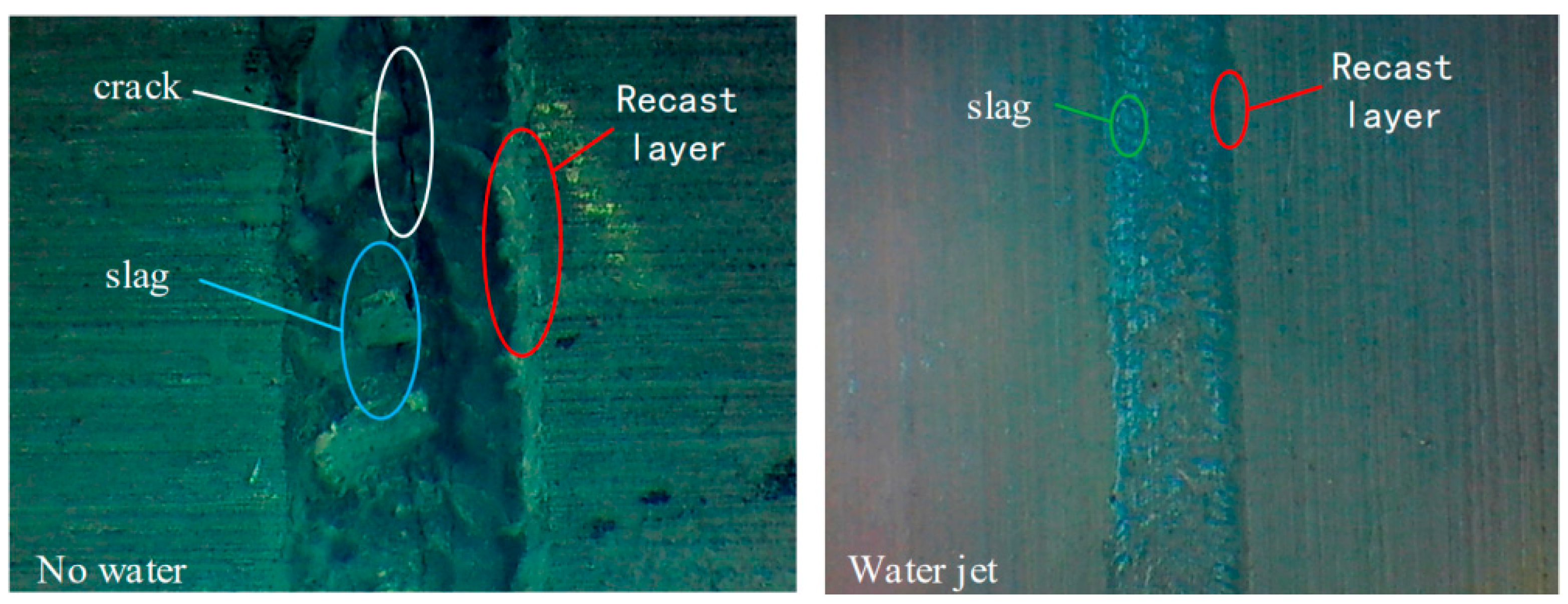

5. Water-Jet-Assisted Laser Processing

6. Technical Difficulties and Development Trends of Water Laser Compound Machining

- (1)

- Water-guided laser processing mainly realizes the perfect coupling of a water beam and a laser beam to reduce nozzle ablation problems; it improves the jetting stability of the water beam to reduce the laser scattering loss in the water beam; it reduces the coupling of the water-beam pulsation to improve the localization of the processing; and it reduces equipment maintenance costs.

- (2)

- The characteristics of the water layer have a greater impact on laser processing, whether in static or flowing water. Static underwater laser processing products scattered in the water and rising cavitation bubbles will affect the laser transmission. Therefore, the development trend of static underwater laser processing is to reduce the influence of processing products, cavitation bubbles on laser transmission and the disturbance of the water layer caused by bubble collapse. Flowing underwater laser processing needs to control the flow speed of the water layer to ensure that the processed products are taken away smoothly. In addition, the setting of the water inlet and outlet will increase the cost of the equipment and the reasonable thickness of the water layer can meet the processing requirements while reducing the laser loss in the water layer. Therefore, reasonable processing parameters and cost control are the development trend of flowing underwater laser processing.

- (3)

- Water-jet-assisted laser processing is a relatively economical processing technology. It does not require expensive laser–water coupling devices, only the stability of the water jet. The stability of the water jet is a prerequisite for ensuring the quality of water-jet-assisted laser processing. Therefore, an excellent nozzle structure and a stable and reliable liquid supply system are the prerequisites for ensuring the quality of water-jet-assisted laser processing. Furthermore, reasonable setting of the process parameters is the guarantee of good processing quality.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Legall, H.; Bonse, J.; Krüger, J. Review of X-ray exposure and safety issues arising from ultra-short pulse laser material processing. J. Radiol. Prot. 2021, 41, R28. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Jiang, T.; Yu, Y.; Bai, Y.; Song, M.; Miao, Q.; Ma, Y.; Liu, J. Water-jet assisted nanosecond laser microcutting of northeast china ash wood: Experimental study. BioResources 2019, 14, 128–138. [Google Scholar] [CrossRef]

- Park, C.; Shin, B.S.; Kang, M.S.; Ma, Y.W.; Oh, J.Y.; Hong, S.M. Experimental study on micro-porous patterning using UV pulse laser hybrid process with chemical foaming agent. Int. J. Precis. Eng. Manuf. 2015, 16, 1385–1390. [Google Scholar] [CrossRef]

- Boyu, S.; Hongchao, Q.; Jibin, Z.; Ying, L.; Yuebin, G. Current status of water-jet guided laser cutting technology. Opto-Electron. Eng. 2017, 44, 1039–1044. [Google Scholar]

- Desbiens, J.-P.; Masson, P. Arf excimer laser micromachining of pyrex, SiC and PZT for rapid prototyping of mems components. Sens. Actuators A Phys. 2007, 136, 546–563. [Google Scholar] [CrossRef]

- Li, X.; Chen, Y.; Si, X.; Li, H.; Chen, X. Laser and laser-liquid composite etching of Si wafers. Lasers Eng. 2022, 52, 233–245. [Google Scholar]

- Li, X.; Chen, X.H.; Li, H.G.; Xu, X.; Liu, W. Comparative study of laser and water jet-assisted laser surface processing of SiC. Lasers Eng. 2021, 50, 221–233. [Google Scholar]

- Cui, X.; Sun, J. High Pressure Water Jet Technology; Coal Industry Press: Beijing, China, 1993. [Google Scholar]

- Li, X.; Huang, S.; Tang, J.P.; Mu, W.H.; Xu, X.; Chen, X.H. Effects of laser machining aluminum alloy in different media. Micromachines 2022, 13, 1130. [Google Scholar] [CrossRef]

- Gao, Y.B.; Guo, X.Y.; Xiang, X.; Han, P.Z.; Tang, Y.B. Analysis on flow field and shape structure of circular nozzle water jet. China Saf. Sci. J. 2021, 31, 82–88. [Google Scholar]

- Chen, Y.L.; Li, X.; Chen, X.H.; Li, H.G.; Xu, X. Effects of the laser-water-jet processing of silicon carbide. J. Appl. Mech. Tech. Phys. 2022, 63, 11–16. [Google Scholar] [CrossRef]

- Sun, D.; Han, F.Z.; Ying, W.S. Numerical simulation of water jet-guided laser cutting of carbon fiber-reinforced plastics. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 233, 2023–2032. [Google Scholar] [CrossRef]

- Chen, X.H.; Li, X.; Song, W.; Wu, C.; Zhang, Y. Effects of a low-pressure water jet assisting the laser etching of polycrystalline silicon. Appl. Phys. A Mater. Sci. Process. 2018, 124, 556. [Google Scholar] [CrossRef]

- Hopman, S.; Mayer, K.; Fell, A.; Mesec, M.; Granek, F. Laser cutting of silicon with the liquid jet guided laser using a chlorine-containing jet media. Appl. Phys. A Mater. Sci. Process. 2011, 102, 621–627. [Google Scholar] [CrossRef]

- Liao, Z.R.; Xu, D.D.; Axinte, D.; Diboine, J.; Wretland, A. Surface formation mechanism in waterjet guided laser cutting of a Ni-based superalloy. CIRP Ann. Manuf. Technol. 2021, 70, 155–158. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiao, H.; Zhao, J.; Cao, Z. Research on water jet-guided laser micro-hole machining of 6061 aluminum alloy. Int. J. Adv. Manuf. Technol. 2022, 118, 1–13. [Google Scholar] [CrossRef]

- Huang, Y.; Liang, E.; Zhang, G.; Zhou, L.; Huang, P.; Jiao, H.; Zhou, J.; Zhong, Z.; Shi, T.; Long, Y. Research on laser beams focusing and coupling technology of water jet guided laser with high adjustment tolerance. Opt. Commun. 2022, 508, 127677. [Google Scholar] [CrossRef]

- Liu, Q.; Zhao, Y.; Meng, J.; Zhao, G.; Li, L.; Zhou, H.; Wang, K.; Liu, G.; Cao, C.; Zheng, Z. Research on the influence of water-laser coupling cavity and nozzle structure on the flow characteristics of water beam fiber. Iran. J. Sci. Technol. Trans. Mech. Eng. 2022, 1–18. [Google Scholar] [CrossRef]

- Liu, Y.; Wei, M.; Zhang, T.; Qiao, H.; Li, H. Overview on the development and critical issues of water jet guided laser machining technology. Opt. Laser Technol. 2021, 137, 106820. [Google Scholar] [CrossRef]

- Tabie, V.M.; Koranteng, M.O.; Yunus, A.; Kuuyine, F. Water-Jet Guided Laser Cutting Technology-an Overview. Lasers Manuf. Mater. Process. 2019, 6, 189–203. [Google Scholar] [CrossRef]

- Ikeda, T.; Ozawa, K.; Kutsuna, M.; Okada, H. Water-jet-guided laser processing for wafer. Weld. World 2003, 47, 3–6. [Google Scholar] [CrossRef]

- Li, C.-F.; Johnson, D.B.; Kovacevic, R. Modeling of waterjet guided laser grooving of silicon. Int. J. Mach. Tools Manuf. 2003, 43, 925–936. [Google Scholar] [CrossRef]

- Li, C.-F.; Johnson, D.B.; Kovacevic, R. Modelling of heat transfer in waterjet guided laser drilling of silicon. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2003, 217, 583–600. [Google Scholar] [CrossRef]

- Rashed, C.A.A.; Romoli, L.; Tantussi, F.; Fuso, F.; Burgener, M.; Cusanelli, G.; Allegrini, M.; Dini, G. Water jet guided laser as an alternative to EDM for micro-drilling of fuel injector nozzles: A comparison of machined surfaces. J. Manuf. Process. 2013, 15, 524–532. [Google Scholar] [CrossRef]

- Huang, Y.X.; Zhao, Y.W.; Yang, L.F.; Zhou, J.; Jiao, H.; Long, Y.H. Theoretical study of water jet guided laser technology based on non-uniform electric field deflection water jet. Opt. Commun. 2019, 442, 31–39. [Google Scholar] [CrossRef]

- Shi, Y.; Jiang, Z.L.; Cao, J.; Ehmann, K.F. Texturing of metallic surfaces for superhydrophobicity by water jet guided laser micro-machining. Appl. Surf. Sci. 2020, 500, 144286. [Google Scholar] [CrossRef]

- Adelmann, B.; Ngo, C.; Hellmann, R. High aspect ratio cutting of metals using water jet guided laser. Int. J. Adv. Manuf. Technol. 2015, 80, 2053–2060. [Google Scholar] [CrossRef]

- Qiao, H.; Zhihe, C.; Jianfeng, C.; Zhao, J. Experimental study on water jet guided laser micro-machining of mono-crystalline silicon. Opt. Laser Technol. 2021, 140, 107057. [Google Scholar] [CrossRef]

- Qiao, H.C.; Cao, Z.H.; Zhao, J.B. Micromorphology of metallic surfaces for hydrophobicity by waterjet-guided laser processing. Int. J. Adv. Manuf. Technol. 2021, 114, 2159–2167. [Google Scholar] [CrossRef]

- Cao, Z.H.; Qiao, H.C.; Zhao, J.B. Research of process parameter optimization on laser water-jet machining of 6061 aluminum. Laser Infrared 2021, 51, 567–574. [Google Scholar]

- Zhang, Y.N.; Qiao, H.C.; Zhao, J.B.; Cao, Z.H.; Yu, Y.F. Numerical simulation of water jet-guided laser micromachining of CFRP. Mater. Today Commun. 2020, 25, 101456. [Google Scholar] [CrossRef]

- Marimuthu, S.; Dunleavey, J.; Liu, Y.; Smith, B.; Kiely, A.; Antar, M. Water-jet guided laser drilling of SiC reinforced aluminium metal matrix composites. J. Compos. Mater. 2019, 53, 3787–3796. [Google Scholar] [CrossRef]

- Tangwarodomnukun, V.; Likhitangsuwat, P.; Tevinpibanphan, O.; Dumkum, C. Laser ablation of titanium alloy under a thin and flowing water layer. Int. J. Mach. Tools Manuf. 2015, 89, 14–28. [Google Scholar] [CrossRef]

- Patel, D.N.; Singh, R.P.; Thareja, R.K. Craters and nanostructures with laser ablation of metal/metal alloy in air and liquid. Appl. Surf. Sci. 2014, 288, 550–557. [Google Scholar] [CrossRef]

- Wee, L.M.; Ng, E.Y.K.; Prathama, A.H.; Zheng, H. Micro-machining of silicon wafer in air and under water. Opt. Laser Technol. 2010, 43, 62–71. [Google Scholar] [CrossRef]

- Choo, K.L.; Ogawa, Y.; Kanbargi, G.; Otra, V.; Raff, L.M.; Komanduri, R. Micromachining of silicon by short-pulse laser ablation in air and under water. Mater. Sci. Eng. A 2003, 372, 145–162. [Google Scholar] [CrossRef]

- Iwatani, N.; Doan, H.D.; Fushinobu, K. Optimization of near-infrared laser drilling of silicon carbide under water. Int. J. Heat Mass Transf. 2014, 71, 515–520. [Google Scholar] [CrossRef]

- Lu, J.; Xu, R.Q.; Chen, X.; Shen, Z.H.; Ni, X.W.; Zhang, S.Y.; Gao, C.M. Mechanisms of laser drilling of metal plates underwater. J. Appl. Phys. 2004, 95, 3890–3894. [Google Scholar] [CrossRef]

- Long, J.Y.; Matthew, H.E.; Ouyang, Y.X.; Zhang, Y.K.; Xie, X.Z.; Costas, P.G. Effects of immersion depth on the dynamics of cavitation bubbles generated during ns laser ablation of submerged targets. Opt. Lasers Eng. 2021, 137, 106334. [Google Scholar] [CrossRef]

- Tangwarodomnukun, V.; Wang, J.; Mathew, P. A comparison of dry and underwater laser micromachining of silicon substrates. In Key Engineering Materials; Trans Tech Publications Ltd.: Zürich, Switzerland, 2010; Volume 934, pp. 693–698. [Google Scholar]

- Das, A.K.; Saha, P. Micromachining of silicon with excimer laser in air and water medium. Int. J. Manuf. Technol. Manag. 2010, 21, 42–53. [Google Scholar] [CrossRef]

- Parmar, M.; James, S. Experimental and modeling study of liquid-assisted–laser beam micromachining of smart ceramic materials. J. Manuf. Mater. Process. 2018, 2, 28. [Google Scholar] [CrossRef] [Green Version]

- Krstulović, N.; Shannon, S.; Stefanuik, R.; Fanara, C. Underwater-laser drilling of aluminum. Int. J. Adv. Manuf. Technol. 2013, 69, 1765–1773. [Google Scholar] [CrossRef]

- Zhu, G.Z.; Zhu, C.H.; Yuan, X.; Lu, P.X. UV Laser Assisted Processing of Ceramics in Air and in Water. In Lasers in Material Processing and Manufacturing II; SPIE: Beijing, China, 2004; Volume 5629, pp. 309–313. [Google Scholar]

- Choubey, A.; Jain, R.K.; Ali, S.; Singh, R.; Vishwakarma, S.C.; Agrawal, D.K.; Arya, R.; Kaul, R.; Upadhyaya, B.N.; Oak, S.M. Studies on pulsed Nd:YAG laser cutting of thick stainless steel in dry air and underwater environment for dismantling applications. Opt. Laser Technol. 2015, 71, 6–15. [Google Scholar] [CrossRef]

- Muhammad, N.; Li, L. Underwater femtosecond laser micromachining of thin nitinol tubes for medical coronary stent manufacture. Appl. Phys. A Mater. Sci. Process. 2012, 107, 849–861. [Google Scholar] [CrossRef]

- Lv, J.; Dong, X.; Wang, K.D.; Duan, W.Q.; Fan, Z.J.; Mei, X.S. Study on process and mechanism of laser drilling in water and air. Int. J. Adv. Manuf. Technol. 2016, 86, 1443–1451. [Google Scholar] [CrossRef]

- Charee, W.; Tangwarodomnukun, V. Surface Morphology of Silicon Induced by Laser Ablation in Flowing Water. In Materials Science Forum; Trans Tech Publications Ltd.: Zürich, Switzerland, 2016; Volume 816, pp. 115–120. [Google Scholar]

- Wee, L.M.; Khoong, L.E.; Tan, C.W.; Lim, G.C. Solvent-Assisted Laser Drilling of Silicon Carbide. Int. J. Appl. Ceram. Technol. 2011, 8, 1263–1276. [Google Scholar] [CrossRef]

- Alahmari, A.M.; Ahmed, N.; Darwish, S. Laser beam micro-machining under water immersion. Int. J. Adv. Manuf. Technol. 2016, 83, 1671–1681. [Google Scholar] [CrossRef]

- Nguyen, T.T.P.; Tanabe, R.; Ito, Y. Effects of an absorptive coating on the dynamics of underwater laser-induced shock process. Appl. Phys. A 2014, 116, 1109–1117. [Google Scholar] [CrossRef]

- Mullick, S.; Madhukar, Y.K.; Roy, S.; Kumar, S.; Shukla, D.K.; Nath, A.K. Development and parametric study of a water-jet assisted underwater laser cutting process. Int. J. Mach. Tools Manuf. 2013, 68, 48–55. [Google Scholar] [CrossRef]

- Tangwarodomnukun, V.; Wang, J.; Huang, C.Z.; Zhu, H.T. An investigation of hybrid laser-waterjet ablation of silicon substrates. Int. J. Mach. Tools Manuf. 2012, 56, 39–49. [Google Scholar] [CrossRef]

- Chen, X.H.; Li, X.; Wu, C.; Zhang, Y. Influence of Water Jet Assisted Laser Processing Silicon Carbide. Laser Optoelectron. Prog. 2019, 56, 26264–26280. (In Chinese) [Google Scholar]

- Wang, L.; Huang, C.Z.; Wang, J.; Zhu, H.T.; Liang, X.G. An experimental investigation on laser assisted waterjet micro-milling of silicon nitride ceramics. Ceram. Int. 2018, 44, 5636–5645. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, J.; Yao, P.; Huang, C.Z. Heat transfer and material ablation in hybrid laser-waterjet microgrooving of single crystalline germanium. Int. J. Mach. Tools Manuf. 2017, 116, 25–39. [Google Scholar] [CrossRef]

- Ng, E.Y.K.; Guannan, D. The stability of 305μm-diameter water jet for jet-guided laser machining. Int. J. Adv. Manuf. Technol. 2015, 78, 939–946. [Google Scholar] [CrossRef]

- Zhou, J.; Huang, Y.-X.; Zhao, Y.-W.; Jiao, H.; Liu, Q.-Y.; Long, Y.-H. Study on water-assisted laser ablation mechanism based on water layer characteristics. Opt. Commun. 2019, 450, 112–121. [Google Scholar] [CrossRef]

- Annoni, M.; Arleo, F.; Malmassari, C. CFD aided design and experimental validation of an innovative air assisted pure water jet cutting system. J. Mater. Process. Technol. 2014, 214, 1647–1657. [Google Scholar] [CrossRef] [Green Version]

- Jiang, T.; Yang, C.M.; Yu, Y.Q.; Lou, Y.X.; Liu, J.Q.; Ma, Y. Water-Jet Assisted Laser Cutting of Korean Pine (Pinus koraiensis): Process and Parameters Optimization. Bioresources 2020, 15, 2540–2549. [Google Scholar] [CrossRef]

- Guo, B.; Zhang, J.; Wu, M.T.; Zhao, Q.L.; Liu, H.; Monier, A.; Wang, J.H. Water assisted pulsed laser machining of micro-structured surface on CVD diamond coating tools. J. Manuf. Process. 2020, 56, 591–601. [Google Scholar] [CrossRef]

- Tangwarodomnukun, V.; Wang, J.; Huang, C.Z.; Zhu, H.T. Heating and material removal process in hybrid laser-waterjet ablation of silicon substrates. Int. J. Mach. Tools Manuf. 2014, 79, 1–16. [Google Scholar] [CrossRef]

- Yang, C.; Jiang, T.; Yu, Y.; Dun, G.; Ma, Y.; Liu, J. Study on surface quality of wood processed by water-jet assisted nanosecond laser. Bioresources 2018, 13, 3125–3134. [Google Scholar] [CrossRef]

- Brecher, C.; Janssen, H.; Eckert, M.; Schmidt, F. Thermal Investigation of Interaction between High-power CW-laser Radiation and a Water-jet. Phys. Procedia 2016, 83, 317–327. [Google Scholar] [CrossRef]

- Kalyanasundaram, D.; Shehata, G.; Neumann, C.; Shrotriya, P.; Molian, P. Design and validation of a hybrid laser/water-jet machining system for brittle materials. J. Laser Appl. 2008, 20, 127–134. [Google Scholar] [CrossRef]

- Chryssolouris, G.; Sheng, P.; Anastasia, N. Laser Grooving of Composite Materials with the Aid of a Water Jet. J. Eng. Ind. 1993, 115, 62–72. [Google Scholar] [CrossRef]

- Chen, X.H.; Xu, X.; Liu, W.; Huang, L.; Li, H.; Wu, C.; Mu, W.H.; Li, X. Study on the Influence of Surface Temperature Field of Aluminum Alloy Etched by Laser Water Jet Composite Machining. Materials 2020, 13, 3206. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.C.; Huang, C.Z.; Wang, J.; Zhu, H.T.; Yao, P.; Liu, Z.Q. An analytical model for the prediction of temperature distribution and evolution in hybrid laser-waterjet micro-machining. Precis. Eng. 2017, 47, 33–45. [Google Scholar] [CrossRef]

- Bao, J.D.; Long, Y.H.; Tong, Y.Q.; Yang, X.Q.; Zhang, B.; Zhou, Z.Q. Experiment and simulation study of laser dicing silicon with water-jet. Appl. Surf. Sci. 2016, 387, 491–496. [Google Scholar] [CrossRef]

- Chen, X.H.; Li, X.; Wu, C.; Ma, Y.P.; Zhang, Y.; Huang, L.; Liu, W. Optimization of Processing Parameters for Water-Jet-Assisted Laser Etching of Polycrystalline Silicon. Appl. Sci. 2019, 9, 1882. [Google Scholar] [CrossRef]

- Wang, X.S.; Huang, Y.K.; Wang, X.W.; Xu, B.; Feng, J.; Shen, B. Experimental investigation and optimization of laser induced plasma micromachining using flowing water. Opt. Laser Technol. 2020, 126, 106067. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, K.; Zhou, Q.; Chen, Q.; Liu, Y.; Wang, C.; Li, X. Research Progress of Water–Laser Compound Machining Technology. Coatings 2022, 12, 1887. https://doi.org/10.3390/coatings12121887

Shao K, Zhou Q, Chen Q, Liu Y, Wang C, Li X. Research Progress of Water–Laser Compound Machining Technology. Coatings. 2022; 12(12):1887. https://doi.org/10.3390/coatings12121887

Chicago/Turabian StyleShao, Kun, Qunlin Zhou, Qingshan Chen, Yi Liu, Chenfang Wang, and Xiang Li. 2022. "Research Progress of Water–Laser Compound Machining Technology" Coatings 12, no. 12: 1887. https://doi.org/10.3390/coatings12121887

APA StyleShao, K., Zhou, Q., Chen, Q., Liu, Y., Wang, C., & Li, X. (2022). Research Progress of Water–Laser Compound Machining Technology. Coatings, 12(12), 1887. https://doi.org/10.3390/coatings12121887