A One-Step Method for Fabrication of Wear-Resistant Amphiphobic Microdimple Arrays Using Under-Liquid Laser Machining

Abstract

1. Introduction

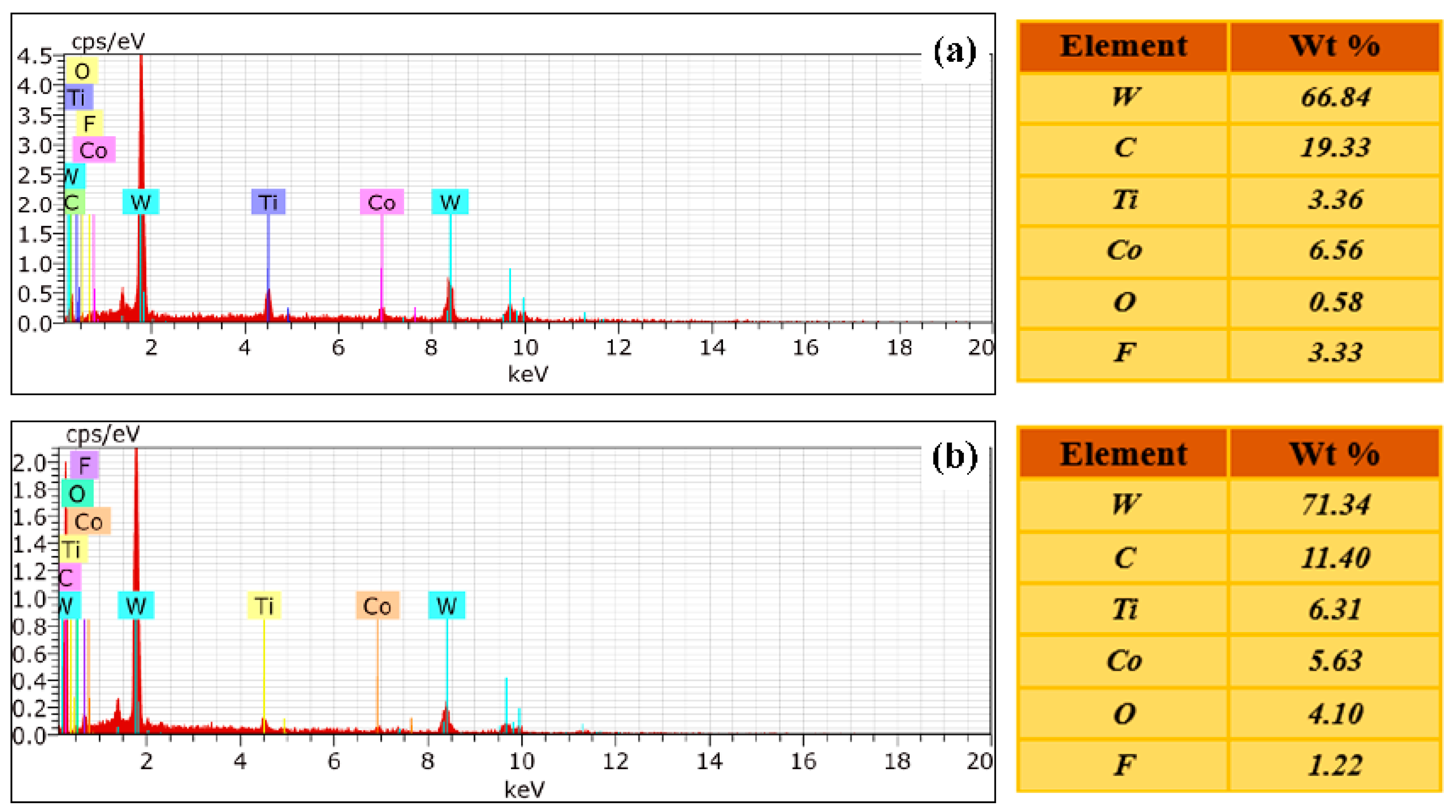

2. Materials and Methods

2.1. Materials and Reagents

2.2. Methods

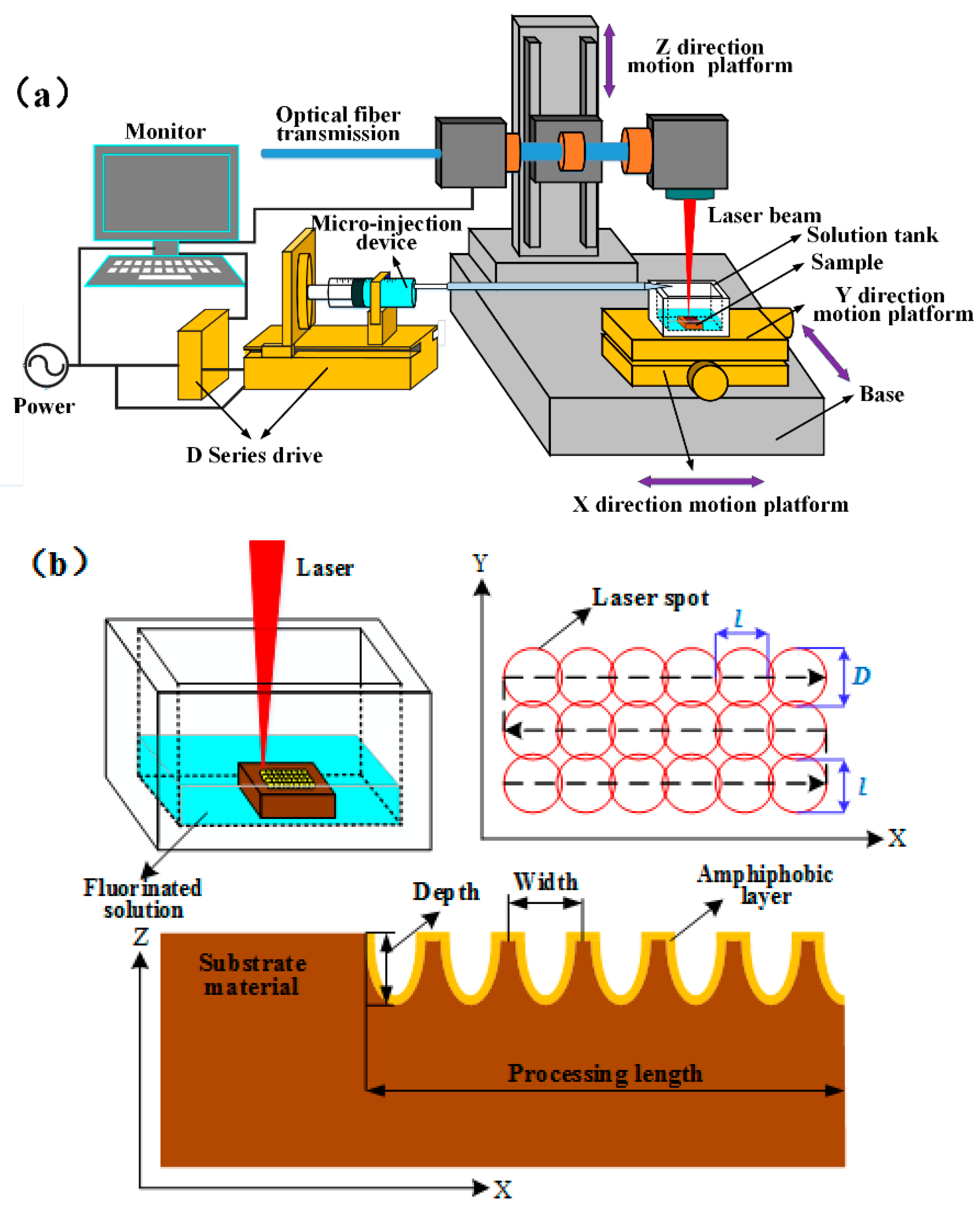

2.2.1. Experimental Setup

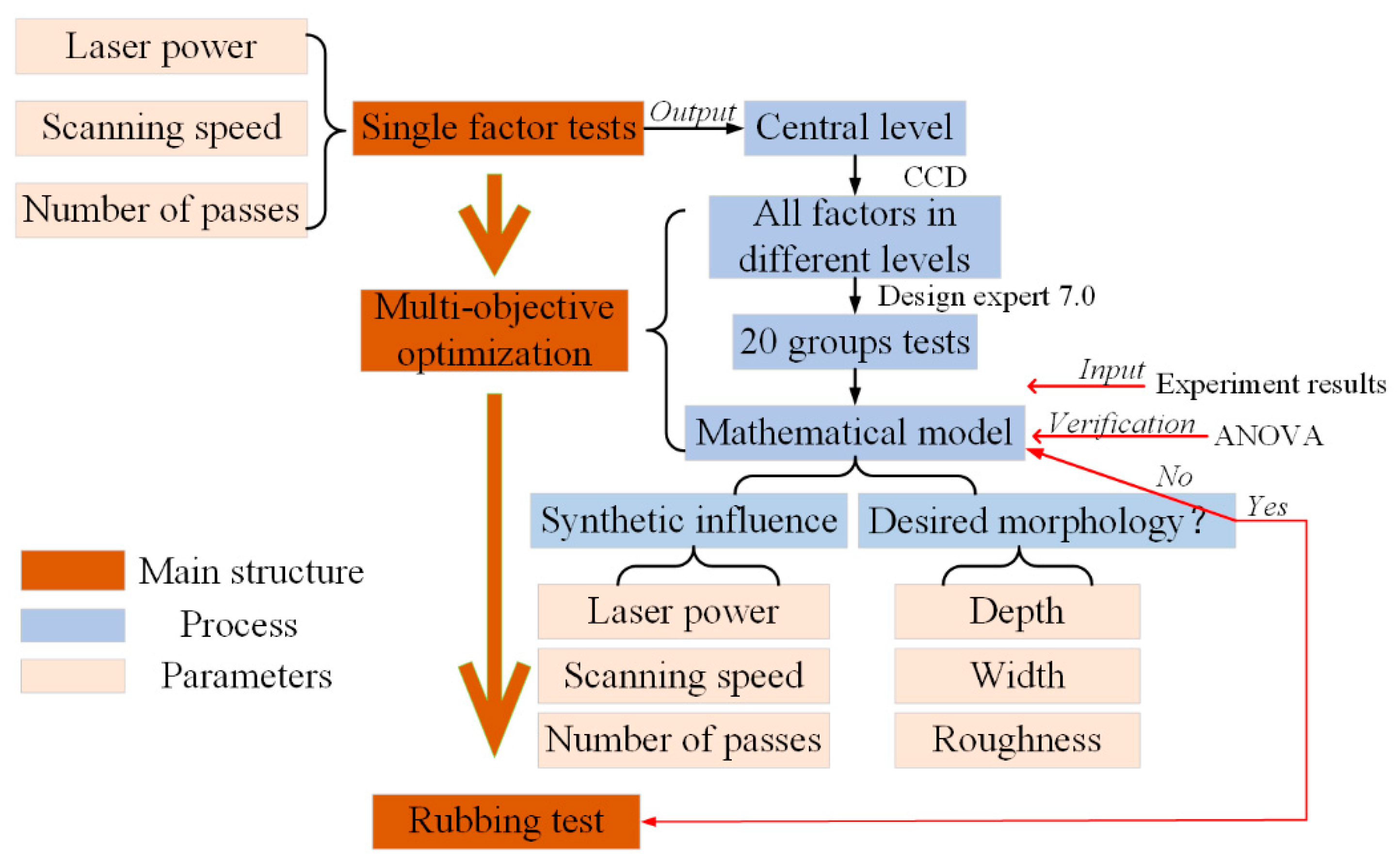

2.2.2. Experimental Design

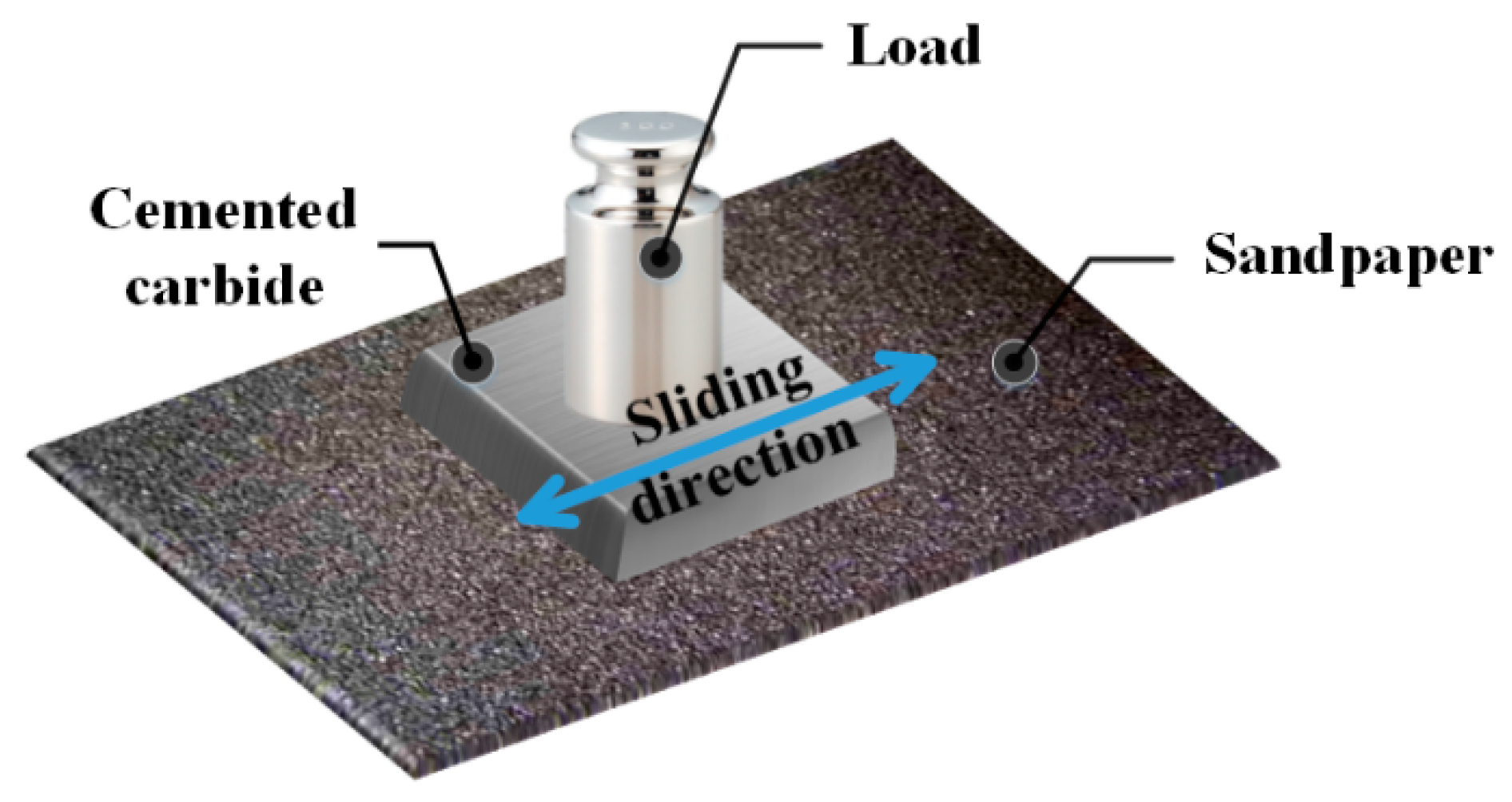

2.3. Wear-Resistance Tests

3. Results and Discussion

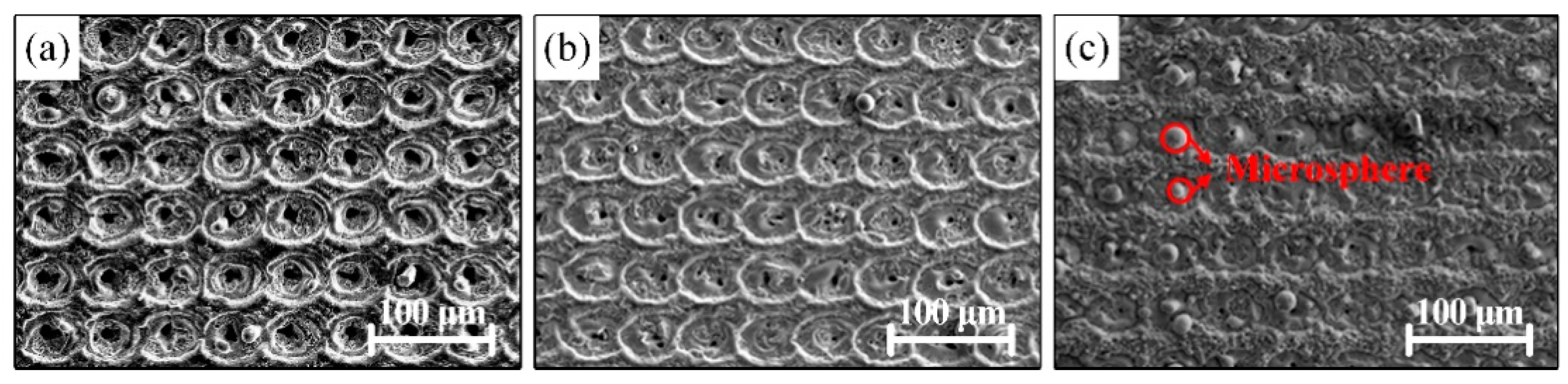

3.1. Single-Factor Tests for the Laser Parameters

3.1.1. Effect of Laser Power on Microdimple Structure

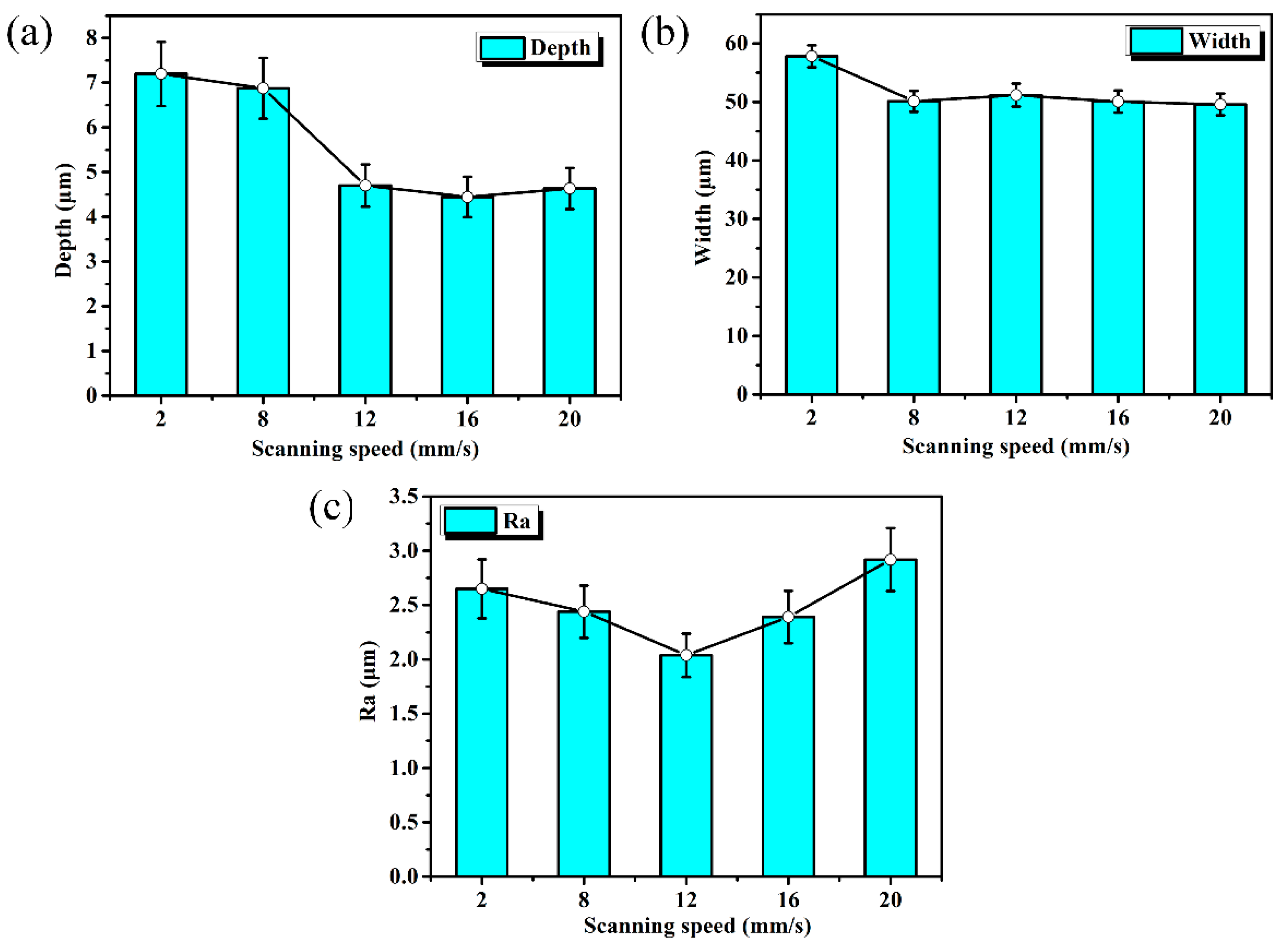

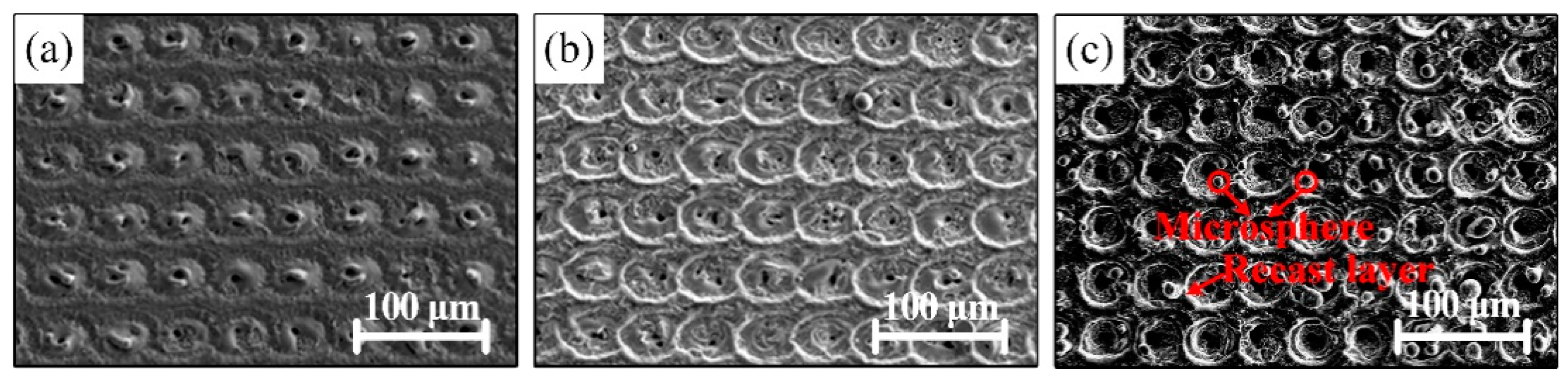

3.1.2. Effect of Scanning Speed on Microdimple Structure

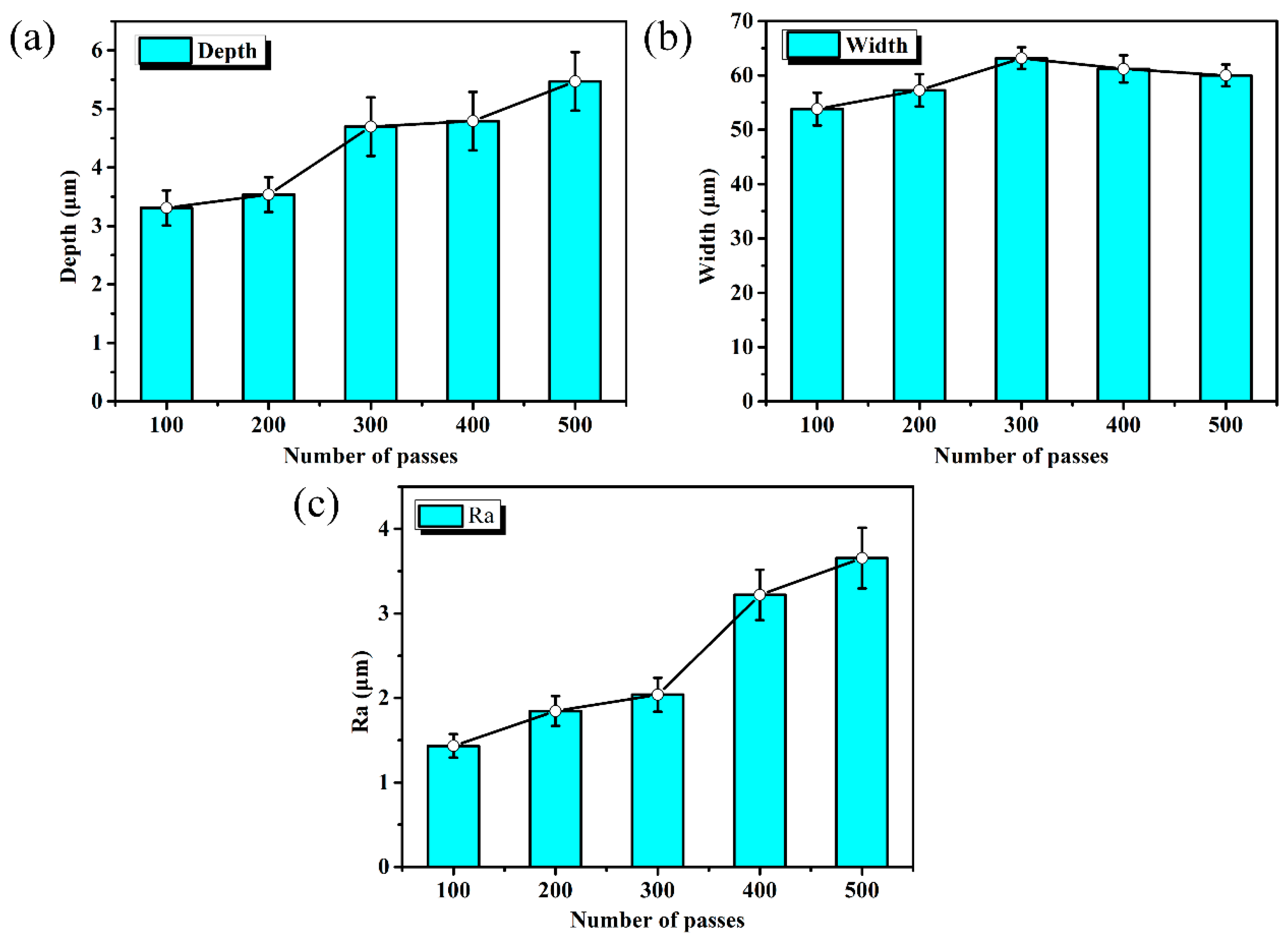

3.1.3. Effect of Number of Passes on Microdimple Structure

3.2. Multiobjective Optimization

3.2.1. Mathematical Models

- Depth = 6.14 + 4.77 A + 0.92 B − 0.044 C + 0.91 A × B − 0.49 A × C + 1.03 B × C + 0.40 A2 − 0.55 B2 + 0.20 C2 − 1.08 A × B × C + 1.14 A2 × B + 0.72 A2 × C − 0.41 A × B2 − 0.81 A3;

- Width = 53.11 − 2.41 A + 0.12 B − 0.67 C + 1.89 A × B − 1.98 A × C + 1.85 B × C − 1.45 A2 − 0.12 B2 + 0.30 C2 − 1.14 A × B × C + 0.23 A2 × B + 0.022 A2 × C + 4.95 A × B2 + 1.91 A3;

- Ra = 1.14 − 0.71 A + 0.18 B + 0.051 C + 0.072 A × B + 0.015 A × C + 0.061 B × C − 0.24 A2 − 0.13 B2 + 0.042 C2 − 0.077 A × B × C − 0.042 A2 × B − 0.027 A2 × C + 0.79 A × B2 + 0.34 A3;

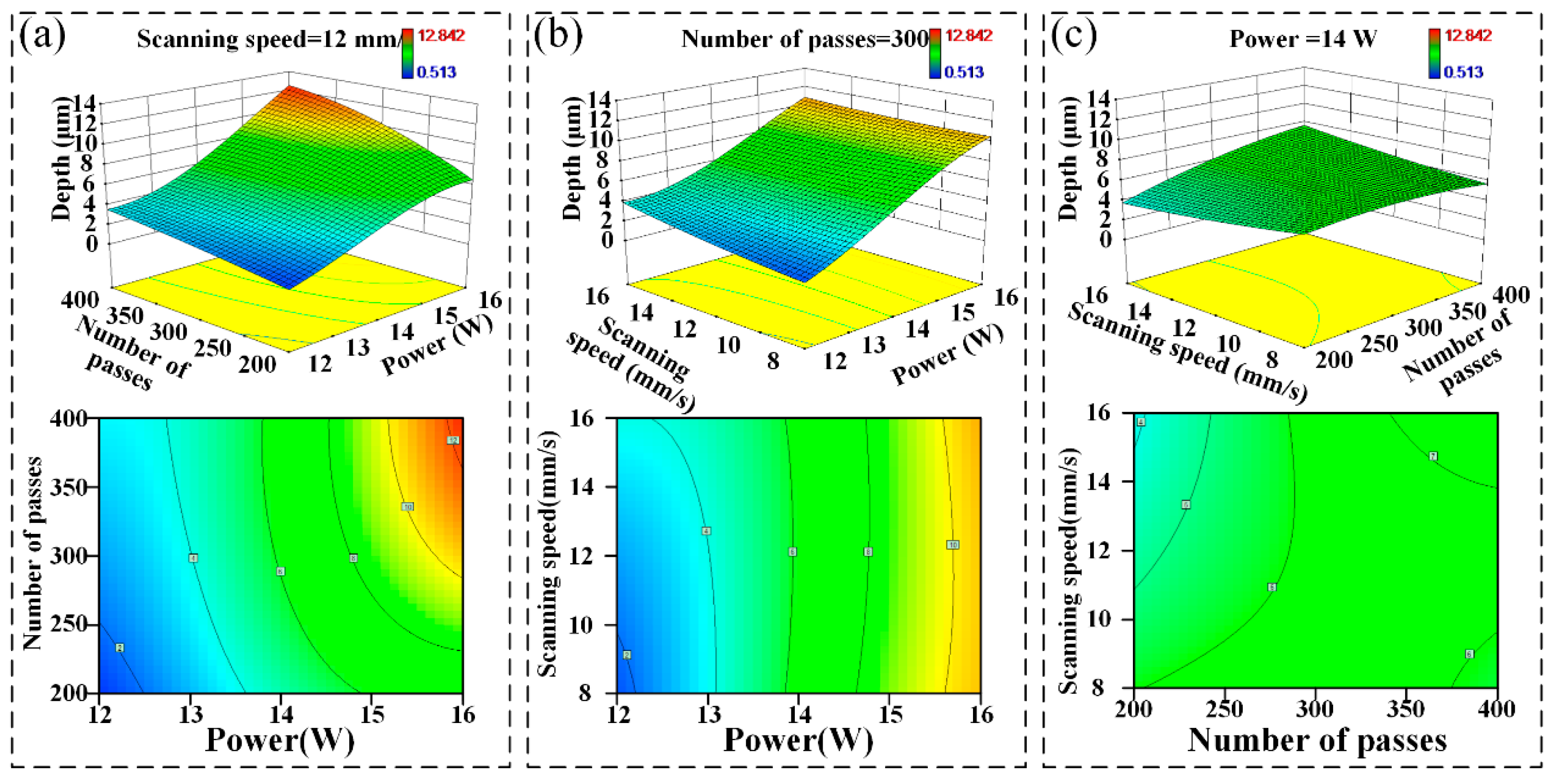

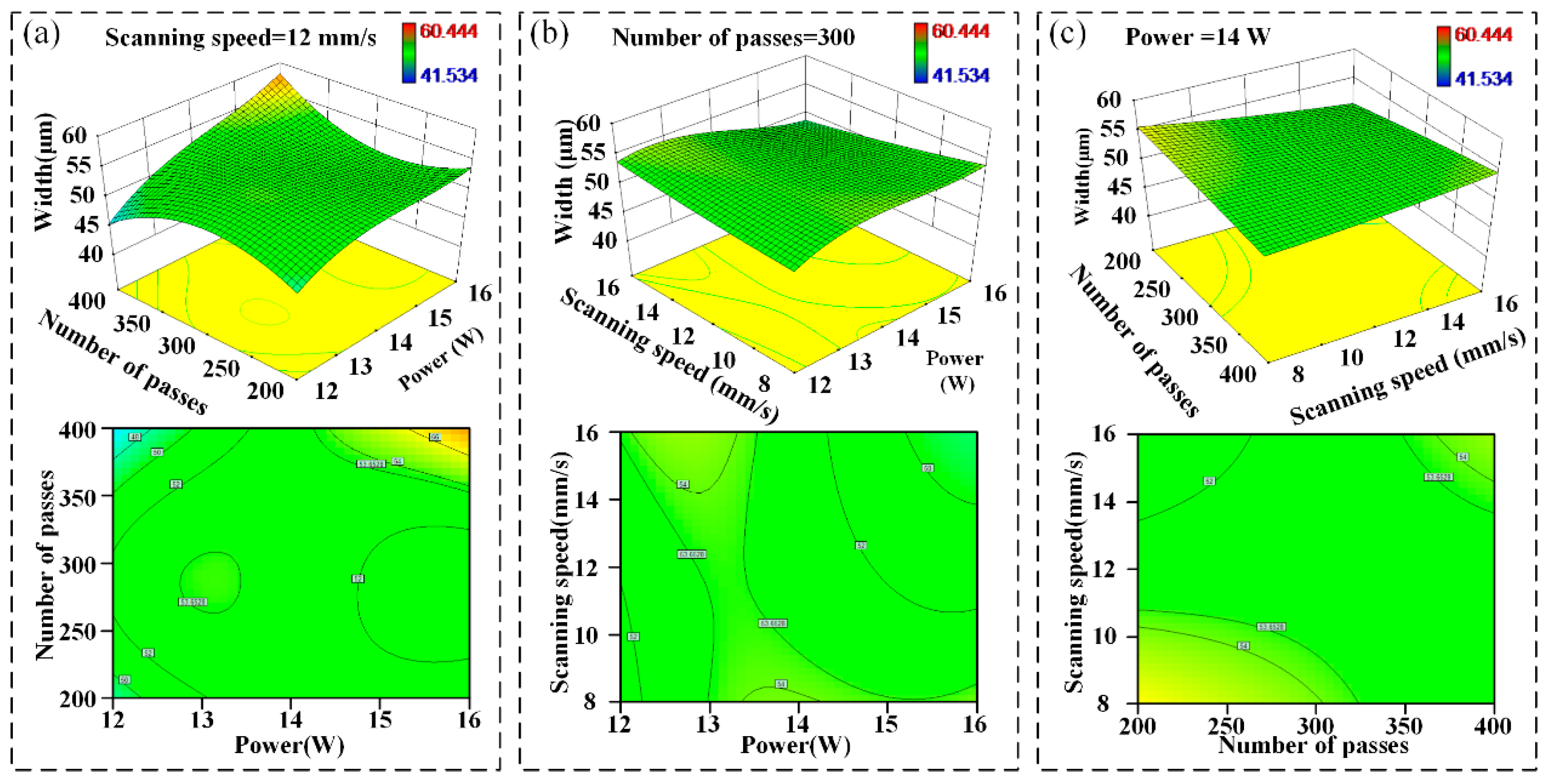

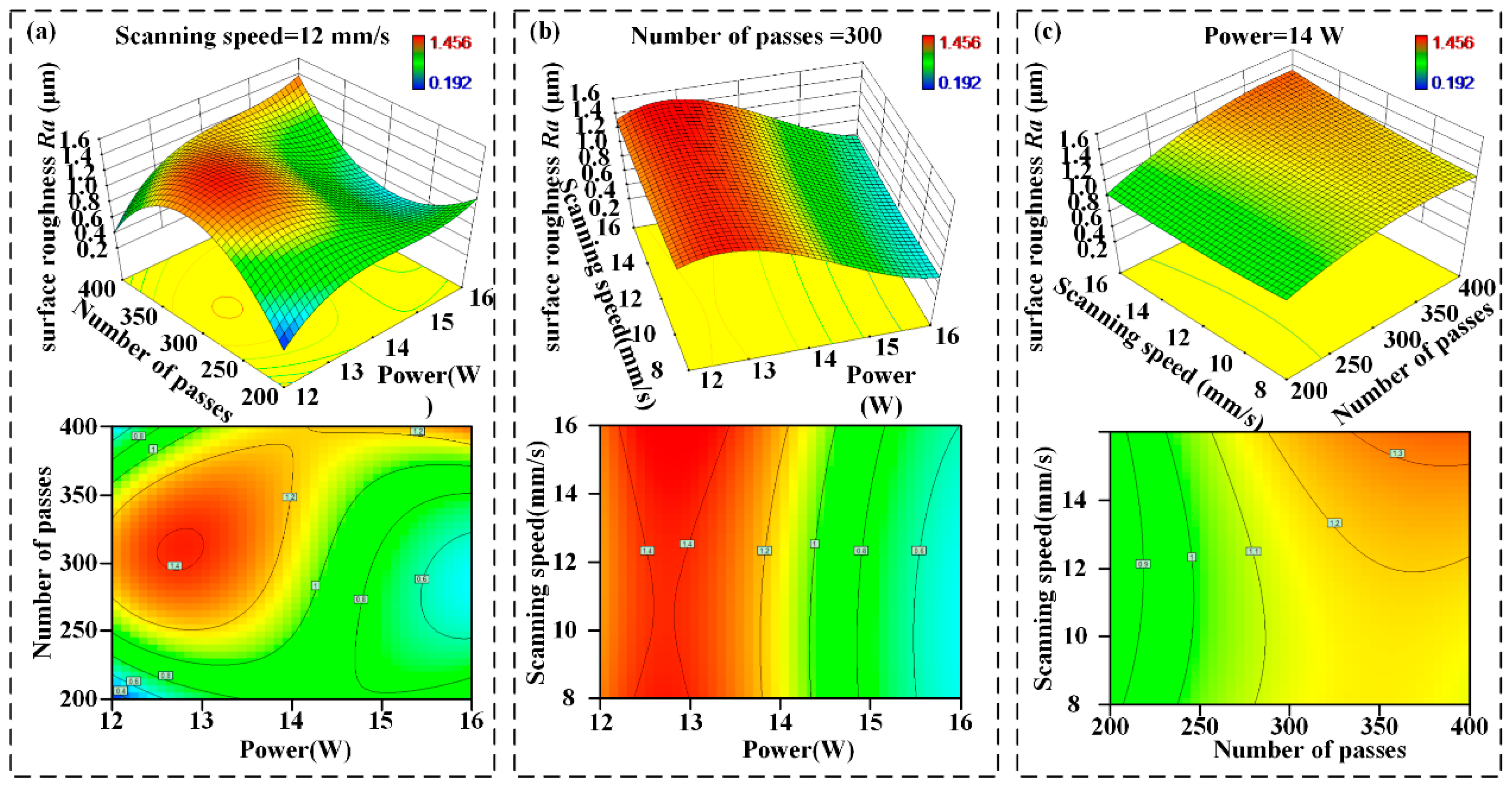

3.2.2. Influence of Laser Processing Parameters on the Responses

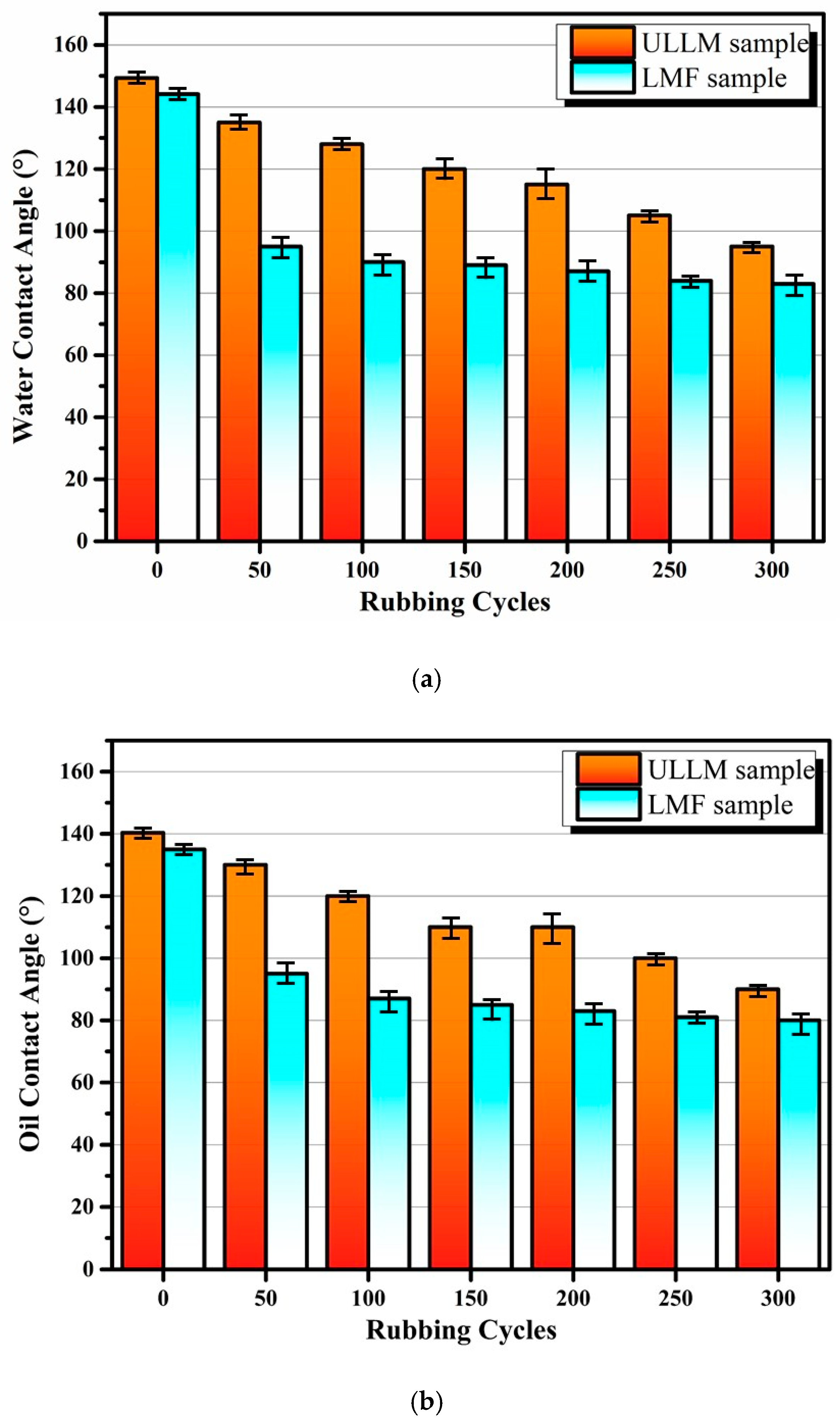

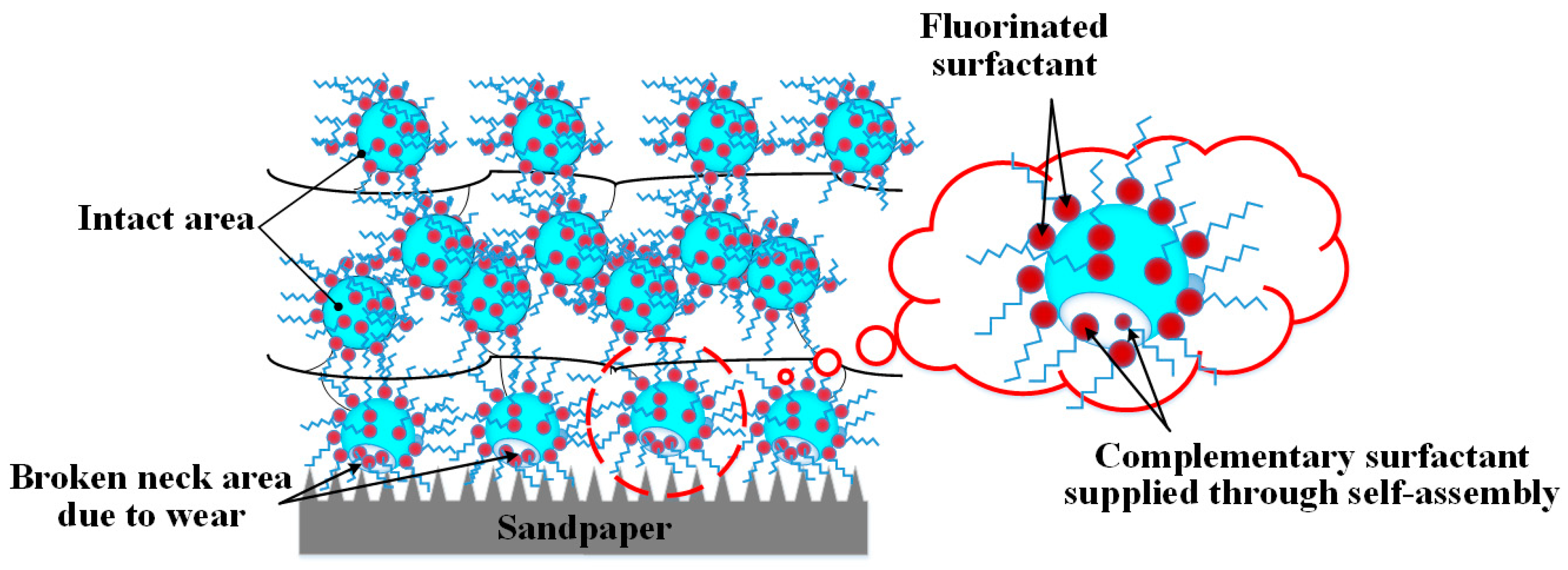

3.3. Wear-Resistance Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sun, M.; Ebner, C. Molecular dynamics study of flow at a fluid-wall interface. Phys. Rev. Lett. 1992, 69, 3491–3494. [Google Scholar] [CrossRef] [PubMed]

- Jabbarzadeh, A.; Atkinson, J.D.; Tanner, R.I. Wall slip in the molecular dynamics simulation of thin films of hexadecane. J. Chem. Phys. 1999, 110, 2612–2620. [Google Scholar] [CrossRef]

- Huang, J.Y.; Lai, Y.K.; Pan, F.; Yang, L.; Wang, H.; Zhang, K.Q.; Fuchs, H.; Chi, L.F. Multifunctional superamphiphobic TiO2 nanostructure surfaces with facile wettability and adhesion engineering. Small 2014, 10, 4865–4873. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Salazar, J.; Vahabi, H.; Joshi-Imre, A.; Voit, W.E.; Kota, A.K. Metamorphic superomniphobic surfaces. Adv. Mater. 2017, 29, 1700295. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Lai, H.; Cheng, Z.; Zhang, H.; Zhang, E.; Lv, T.; Liu, Y.; Jiang, L. Gecko toe pads inspired in situ switchable superhydrophobic shape memory adhesive film. Nanoscale 2019, 11, 8984–8993. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Lai, H.; Cheng, Z.; Zhang, H.; Liu, Y.; Jiang, L. Smart superhydrophobic shape memory adhesive surface toward selective capture/release of microdroplets. ACS Appl. Mater. Interfaces 2019, 11, 10988–10997. [Google Scholar] [CrossRef]

- Jin, H.; Kettunen, M.; Laiho, A.; Pynnönen, H.; Paltakari, J.; Marmur, A.; Ikkala, O.; Ras, R.H.A. Superhydrophobic and superoleophobic nanocellulose aerogel membranes as bioinspired cargo carriers on water and oil. Langmuir 2011, 27, 1930–1934. [Google Scholar] [CrossRef]

- Huang, J.; Lai, Y.; Wang, L.; Li, S.; Ge, M.; Zhang, K.; Fuchs, H.; Chi, L. Controllable wettability and adhesion on bioinspired multifunctional tio2 nanostructure surfaces for liquid manipulation. J. Mater. Chem. A 2014, 2, 18531–18538. [Google Scholar] [CrossRef]

- Ma, J.; Duong, H.; Lian, Y.; Lei, S. Assessment of microgrooved cutting tool in dry machining of AISI 1045 steel. J. Manuf. Sci. Eng. 2005, 137, 031001. [Google Scholar] [CrossRef]

- Ryk, G.; Etsion, I. Testing piston rings with partial laser surface texturing for friction reduction. Wear 2006, 261, 792–796. [Google Scholar] [CrossRef]

- Hu, J.; Xu, H. Friction and wear behavior analysis of the stainless steel surface fabricated by laser texturing underwater. Tribol. Int. 2016, 102, 371–377. [Google Scholar] [CrossRef]

- Tala-Ighil, N.; Fillon, M. A numerical investigation of both thermal and texturing surface effects on the journal bearings static characteristics. Tribol. Int. 2015, 90, 228–239. [Google Scholar] [CrossRef]

- Rapoport, L.; Moshkovich, A.; Perfilyev, V.; Lapsker, I.; Halperin, G.; Itovich, Y.; Etsion, I. Friction and wear of MoS2 films on laser textured steel surfaces. Surf. Coat. Technol. 2008, 202, 3332–3340. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, M.; Wang, X. Effect of surface texture on wear behavior and wear mechanism of metal-polyformaldehyde friction pair. Surf. Technol. 2017, 46, 9–14. [Google Scholar]

- Lu, Y. Superior lubrication properties of biomimetic surfaces with hierarchical structure. Tribol. Int. 2018, 119, 131–142. [Google Scholar] [CrossRef]

- Liu, S.; Liu, X.; Latthe, S.; Gao, L.; An, S.; Yoon, S.; Liu, B.; Xing, R. Self-cleaning transparent superhydrophobic coatings through simple sol–gel processing of fluoroalkylsilane. Appl. Surf. Sci. 2015, 351, 897–903. [Google Scholar] [CrossRef]

- Qu, M.; Ma, X.; He, J.; Feng, J.; Liu, S.; Yao, Y.; Hou, L.; Liu, X. Facile selective and diverse fabrication of superhydrophobic, superoleophobic-superhydrophilic and superamphiphobic materials from kaolin. ACS Appl. Mater. Interfaces 2017, 9, 1011–1020. [Google Scholar] [CrossRef]

- Chen, F.; Song, J.; Lu, Y.; Huang, S.; Liu, X.; Sun, J.; Carmalt, C.J.; Parkin, I.P.; Xu, W. Creating robust superamphiphobic coatings for both hard and soft materials. J. Mater. Chem. 2015, 3, 20999–21008. [Google Scholar] [CrossRef]

- Li, J.; Zhou, X.; Li, J.; Che, L.; Yao, J.; McHale, G.; Chaudhury, M.K.; Wang, Z. Topological liquid diode. Sci. Adv. 2017, 3, eaao3530. [Google Scholar] [CrossRef]

- Li, N.; Wu, L.; Yu, C.; Dai, H.; Wang, T.; Dong, Z.; Jiang, L. Ballistic jumping drops on superhydrophobic surfaces via electrostatic manipulation. Adv. Mater. 2018, 30, 201703838. [Google Scholar] [CrossRef]

- Tahmassebi, N.; Moradian, S.; Ramezanzadeh, B.; Khosravi, A.; Behdad, S. Effect of addition of hydrophobic nano silica on viscoelastic properties and scratch resistance of an acrylic/melamine automotive clearcoat. Tribol. Int. 2010, 43, 685–693. [Google Scholar] [CrossRef]

- Song, Y.; Nair, R.; Zou, M.; Wang, Y. Adhesion and friction properties of micro/nano-engineered superhydrophobic/hydrophobic surfaces. Thin Solid Film. 2010, 518, 3801–3807. [Google Scholar] [CrossRef]

- Kim, H.; Noh, K.; Choi, C.; Khamwannah, J.; Villwock, D. Extreme superomniphobicity of multiwalled 8 nm TiO2 nanotubes. Langmuir 2011, 27, 10191–10196. [Google Scholar] [CrossRef]

- Tadanaga, K.; Kitamuro, K.; Matsuda, A.; Minami, T. Formation of superhydrophobic alumina coating films with high transparency on polymer substrates by the sol-gel method. J. Sol-Gel Sci. Techn. 2003, 26, 705–708. [Google Scholar]

- Dong, C.; Gu, Y.; Zhong, M.; Li, L.; Sezer, K.; Ma, M.; Liu, W. Fabrication of superhydrophobic cu surfaces with tunable regular micro and random nano-scale structures by hybrid laser texture and chemical etching. J. Mater. Process. Technol. 2011, 211, 1234–1240. [Google Scholar] [CrossRef]

- Marco, C.; Eaton, S.; Levi, M.; Cerullo, G.; Turri, S. High-fidelity solvent-resistant replica molding of hydrophobic polymer surfaces produced by femtosecond laser nanofabrication. Langmuir 2011, 13, 8391–8395. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Lin, C. Robust superhydrophobic transparent coatings fabricated by a low-temperature sol-gel process. Appl. Surf. Sci. 2014, 305, 702–709. [Google Scholar] [CrossRef]

- Geng, Z.; He, J. An effective method to significantly enhance the robustness and adhesion-to-substrate of high transmittance superamphiphobic silica thin films. J. Mater. Chem. 2014, 2, 16601–16607. [Google Scholar] [CrossRef]

- Barthwal, S.; Kim, Y.; Lim, S. Mechanically robust superamphiphobic aluminum surface with nanopore-embedded microtexture. Langmuir 2013, 29, 11966–11974. [Google Scholar] [CrossRef]

- Liu, X.; Gu, H.; Wang, M.; Du, X.; Gao, B.; Elbaz, A.; Sun, L.; Liao, J.; Xiao, P.; Gu, Z. 3D printing of bioinspired liquid superrepellent structures. Adv. Mater. 2018, 30, 1800103. [Google Scholar] [CrossRef]

- Dong, Z.; Schumann, M.F.; Hokkanen, M.J.; Chang, B.; Welle, A.; Zhou, Q.; Ras, R.H.A.; Xu, Z.; Wegener, M.; Levkin, P.A. Superoleophobic slippery lubricant-infused surfaces: combining two extremes in the same surface. Adv. Mater. 2018, 30, 1803890. [Google Scholar] [CrossRef] [PubMed]

- Cairns, D.R.; Kessman, A.J.; Richter, P.J.; Bottari, F.J.; Randall, N.X. Mechanical and tribological investigations of sol–gel derived SiO2 optical coatings. Wear 2008, 265, 411–416. [Google Scholar] [CrossRef]

- Xu, L.; Karunakaran, R.; Guo, J.; Yang, S. Transparent, superhydrophobic surfaces from one-step spin coating of hydrophobic nanoparticles. ACS Appl. Mater. Interfaces 2012, 4, 1118–1125. [Google Scholar] [CrossRef] [PubMed]

- Guo, F.; Li, X.M.; Wong, P.L. A novel approach to measure slip-length of thin lubricant films under high pressures. Tribol. Int. 2012, 46, 22–29. [Google Scholar] [CrossRef]

- Hong, M.H.; Koh, M.L.; Zhu, S.; Lu, Y.F.; Chong, T.C. Steam-assisted laser ablation and its signal diagnostics. Appl. Surf. Sci. 2002, 911, 197–198. [Google Scholar] [CrossRef]

- You; Donghyun; Moin; Parviz. Effects of hydrophobic surfaces on the drag and lift of a circular cylinder. Phys. Fluids 2007, 8, 081701. [Google Scholar]

- Hao, X.Q.; Sun, P.C.; Xiao, S.N.; Yang, Y.F.; Li, L. Tribological performance of surface with different wettability under ball-on-disc test. Appl. Surf. Sci. 2020, 501, 144228. [Google Scholar] [CrossRef]

- Konovalenko, I.V.; Maruschak, P.O. Application of the properties of fuzzy sets in the computer analysis of the shapes and sizes of tear pits. Mater. Sci. 2018, 53, 548–559. [Google Scholar] [CrossRef]

- Lytvynenko, I.V.; Maruschak, P.O.; Lupenko, S.A. Processing and modeling of ordered relief at the surface of heat-resistant steels after laser irradiation as a cyclic random process. Autom. Control Comp. Sci. 2014, 48, 1–9. [Google Scholar] [CrossRef]

| Factors | Symbol | Unit | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|---|---|

| Power | A | W | 10 | 12 | 14 | 16 | 18 |

| Number of passes | B | 1 | 100 | 200 | 300 | 400 | 500 |

| Scanning speed | C | mm/s | 5 | 8 | 12 | 16 | 18 |

| Test Number | A (W) | B (1) | C (mm/s) | Depth (μm) | Width (μm) | Ra (μm) |

|---|---|---|---|---|---|---|

| 1 | 12 | 200 | 8 | 2.436 | 50.583 | 0.450 |

| 2 | 16 | 200 | 8 | 6.550 | 57.395 | 0.948 |

| 3 | 12 | 400 | 8 | 0.513 | 41.534 | 0.316 |

| 4 | 16 | 400 | 8 | 12.594 | 60.444 | 1.411 |

| 5 | 12 | 200 | 16 | 0.551 | 47.272 | 0.192 |

| 6 | 16 | 200 | 16 | 7.012 | 50.710 | 1.058 |

| 7 | 12 | 400 | 16 | 7.058 | 50.169 | 0.610 |

| 8 | 16 | 400 | 16 | 12.842 | 56.596 | 1.456 |

| 9 | 10 | 300 | 12 | 2.625 | 47.014 | 0.534 |

| 10 | 18 | 300 | 12 | 10.787 | 57.756 | 1.424 |

| 11 | 14 | 100 | 12 | 3.267 | 52.615 | 0.501 |

| 12 | 14 | 500 | 12 | 5.778 | 52.887 | 0.974 |

| 13 | 14 | 300 | 5 | 6.839 | 55.198 | 1.178 |

| 14 | 14 | 300 | 18 | 6.531 | 52.768 | 1.310 |

| 15 | 14 | 300 | 12 | 6.174 | 52.412 | 1.173 |

| 16 | 14 | 300 | 12 | 6.283 | 53.625 | 1.072 |

| 17 | 14 | 300 | 12 | 6.039 | 53.305 | 1.122 |

| 18 | 14 | 300 | 12 | 6.356 | 53.534 | 1.303 |

| 19 | 14 | 300 | 12 | 5.932 | 53.240 | 1.066 |

| 20 | 14 | 300 | 12 | 6.079 | 52.527 | 1.094 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, P.; Hao, X.; Xiao, S.; Niu, Y.; Li, L.; Qi, H. A One-Step Method for Fabrication of Wear-Resistant Amphiphobic Microdimple Arrays Using Under-Liquid Laser Machining. Coatings 2020, 10, 559. https://doi.org/10.3390/coatings10060559

Sun P, Hao X, Xiao S, Niu Y, Li L, Qi H. A One-Step Method for Fabrication of Wear-Resistant Amphiphobic Microdimple Arrays Using Under-Liquid Laser Machining. Coatings. 2020; 10(6):559. https://doi.org/10.3390/coatings10060559

Chicago/Turabian StyleSun, Pengcheng, Xiuqing Hao, Sinong Xiao, Yusheng Niu, Liang Li, and Huan Qi. 2020. "A One-Step Method for Fabrication of Wear-Resistant Amphiphobic Microdimple Arrays Using Under-Liquid Laser Machining" Coatings 10, no. 6: 559. https://doi.org/10.3390/coatings10060559

APA StyleSun, P., Hao, X., Xiao, S., Niu, Y., Li, L., & Qi, H. (2020). A One-Step Method for Fabrication of Wear-Resistant Amphiphobic Microdimple Arrays Using Under-Liquid Laser Machining. Coatings, 10(6), 559. https://doi.org/10.3390/coatings10060559