Chitosan Solution Containing Zein and Essential Oil as Bio Based Coating on Packaging Paper

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Coating Solutions and Procedures

2.2.1. Coating Solutions

2.2.2. The Coating Procedure

- (1)

- Uncoated paper (U);

- (2)

- Chitosan (first layer) and zein (second layer) in the layer-by-layer coating procedure (CZ) (ratio 1:1);

- (3)

- Blend of zein and rosemary oil coating on paper (one layer) (ZR);

- (4)

- Blend of chitosan and rosemary oil coting on paper (one layer) (CR);

- (5)

- Chitosan (first layer) and blend of zein and rosemary oil (second layer) in the layer-by-layer coating procedure (CZR) (ratio 1:1);

- (6)

- Paper with chitosan alone in one layer (C);

- (7)

- Paper with zein alone in one layer (Z).

2.3. Analysis of the Papers

2.3.1. Basic Properties

2.3.2. Moisture Content, Absorptiveness and Water Vapour Permeability

2.3.3. Grease Resistance

2.3.4. Mechanical Properties

2.3.5. Thermogravimetric Analysis (TGA)

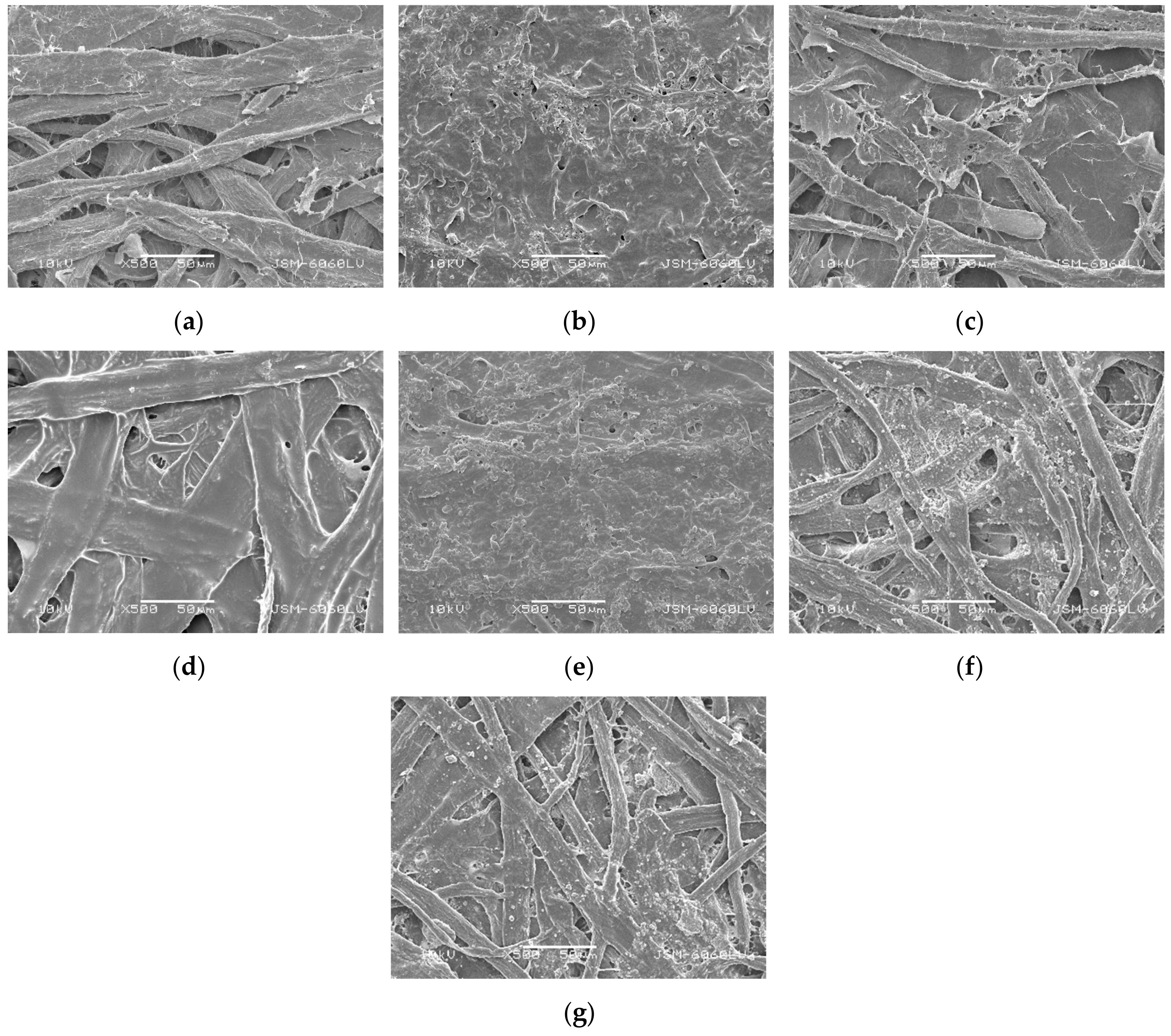

2.3.6. Surface Properties—Scanning Electron Microscope (SEM)

2.3.7. Statistics

3. Results and Discussion

3.1. Basic Properties

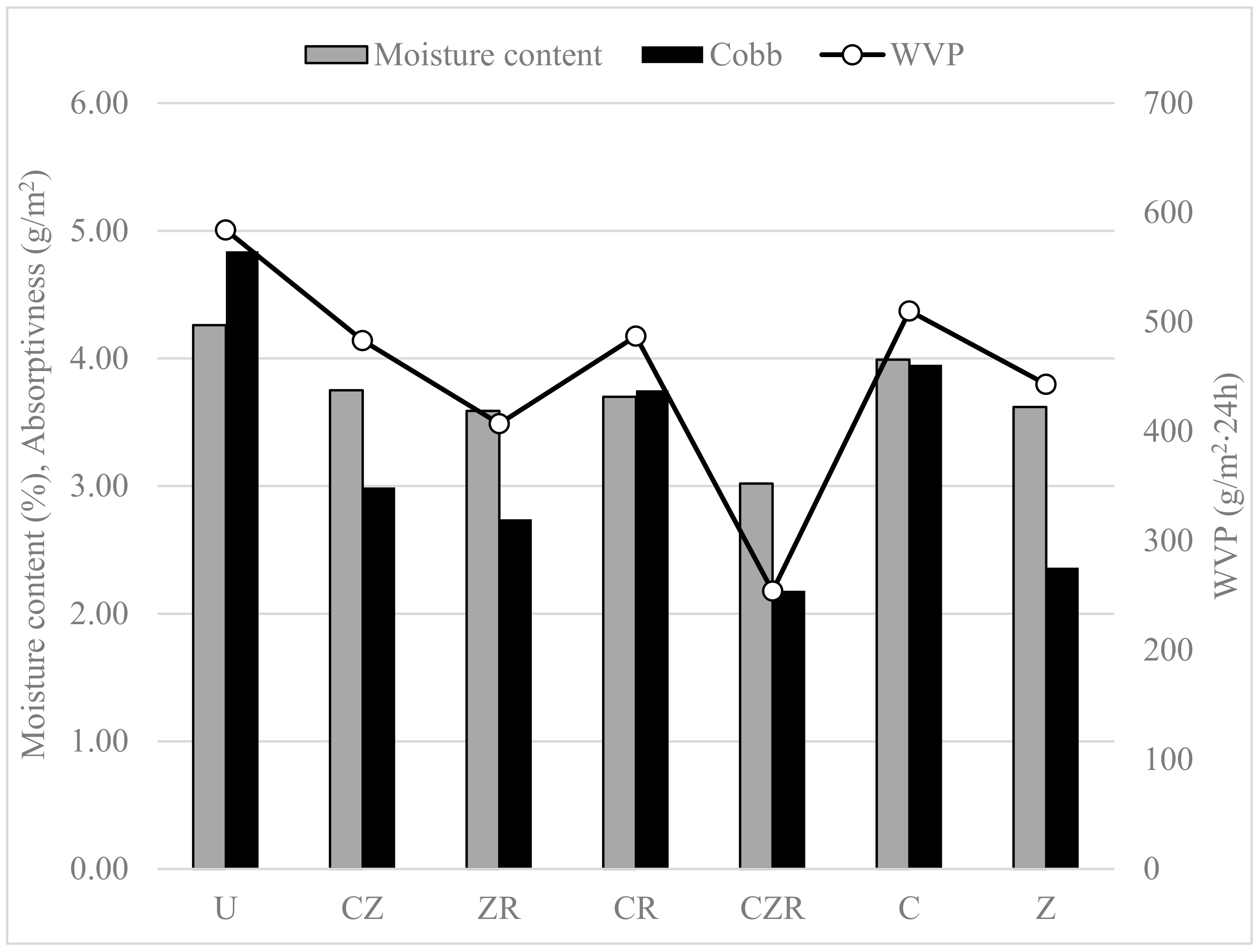

3.2. Moisture, Water and Grease Barrier Properties

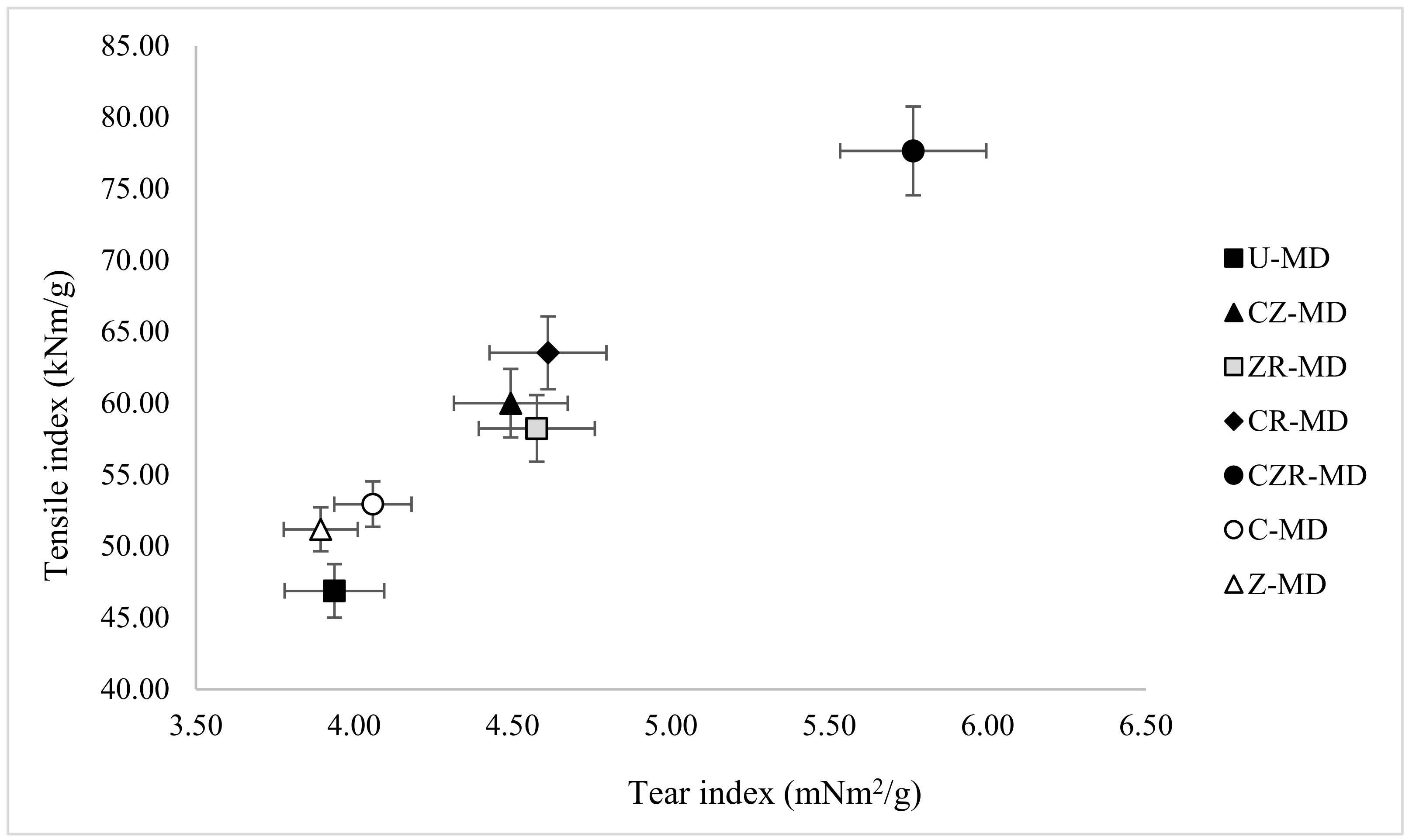

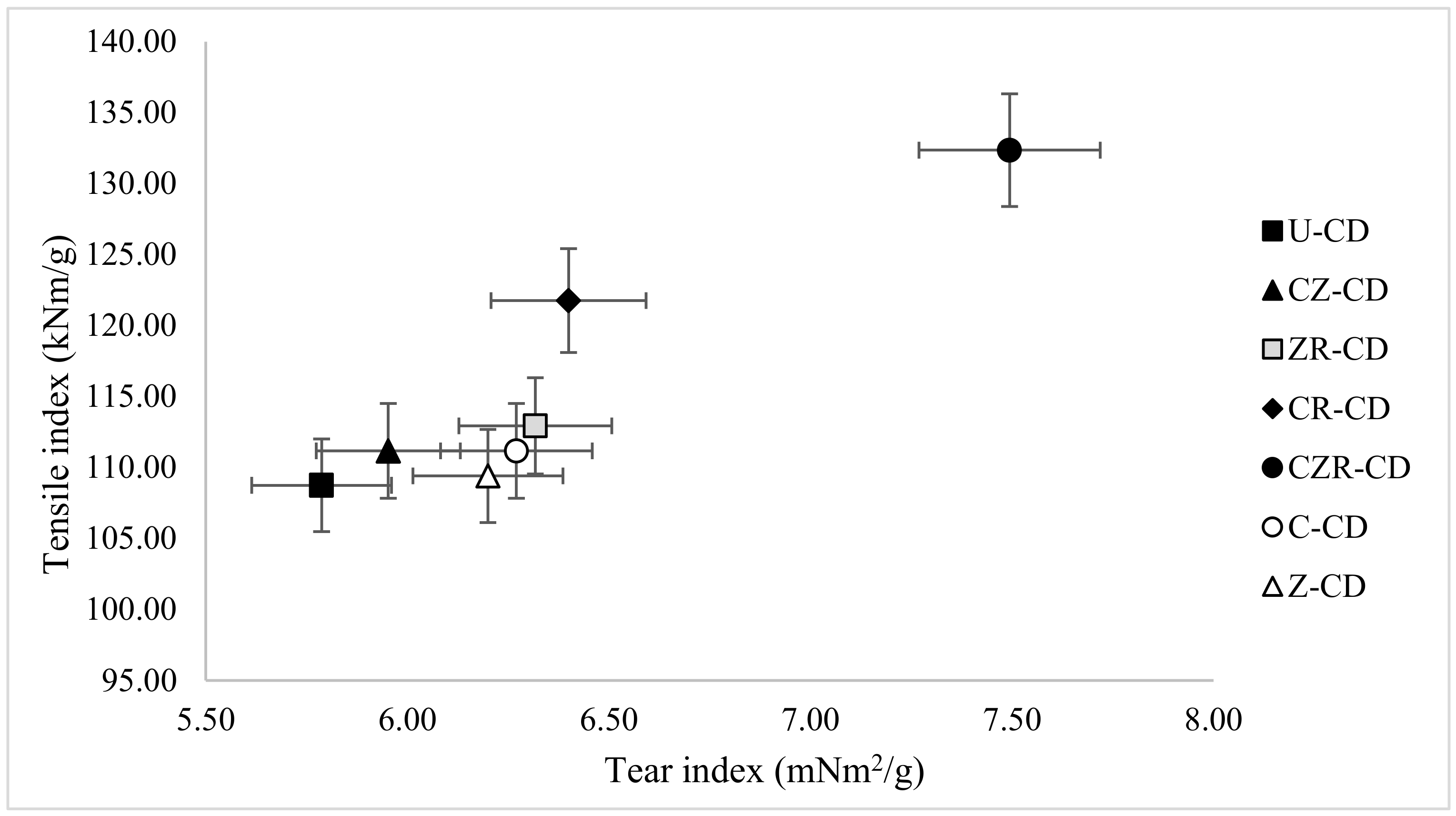

3.3. Mechanical Properties

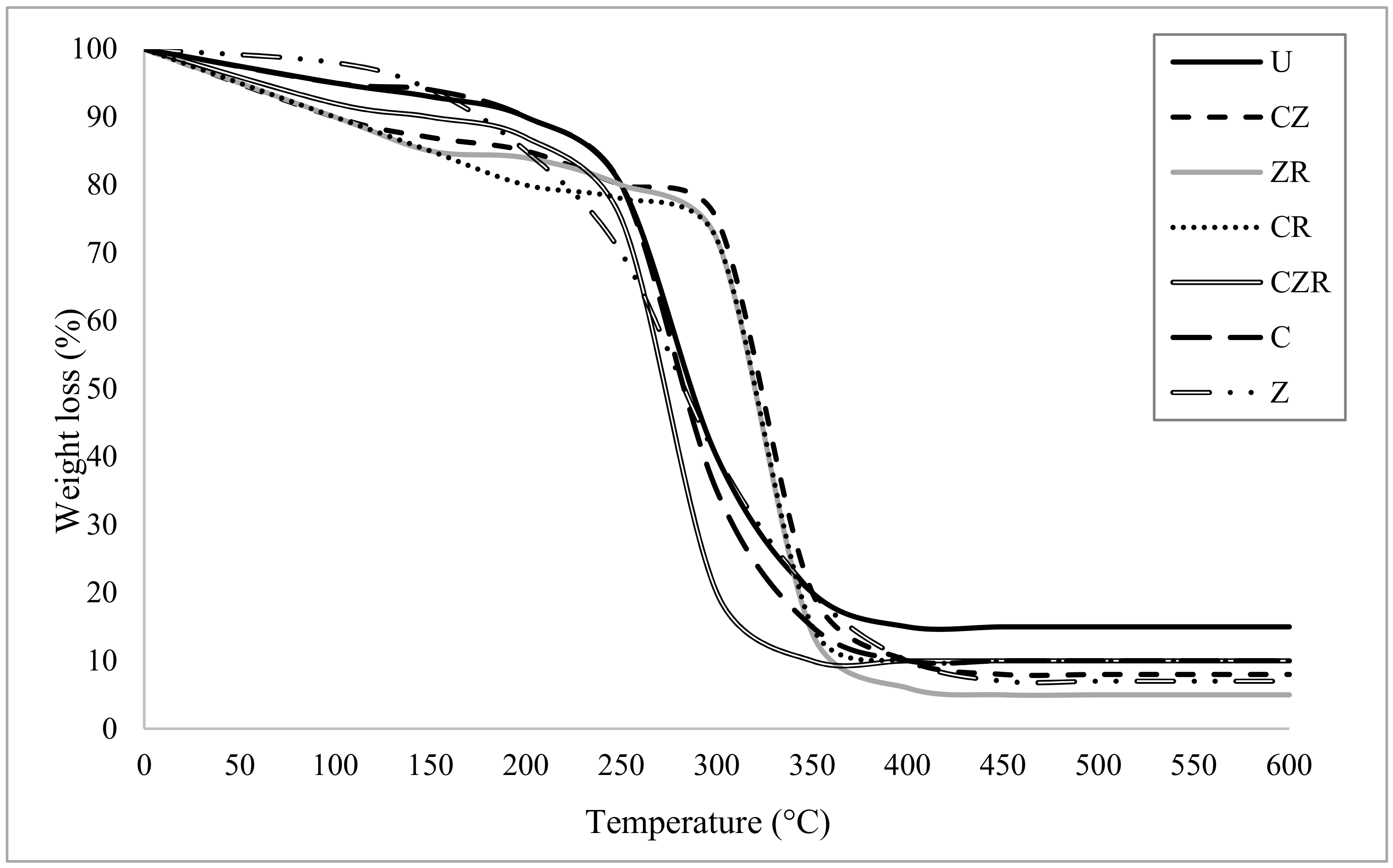

3.4. Thermogravimetric Analysis (TGA)

3.5. SEM

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Farhat, W.; Venditti, R.A.; Hubbe, M.; Taha, M.; Becquart, F.; Ayoub, A. A review of water-resistant hemicellulose-based materials: Processing and applications. ChemSusChem 2017, 10, 305–323. [Google Scholar] [CrossRef]

- Shankar, S.; Rhim, J.W. Effects of poly (butylene adipate-co-terephthalate) coating on the water resistant, mechanical, and antibacterial properties of Kraft paper. Prog. Org. Coat. 2018, 123, 153–159. [Google Scholar] [CrossRef]

- Gicquel, E.; Martin, C.; Yanez, J.G.; Bras, J. Cellulose nanocrystals as new bio-based coating layer for improving fiber-based mechanical and barrier properties. J. Mater. Sci. 2017, 52, 3048–3061. [Google Scholar] [CrossRef]

- Ma, S.; Li, T.; Liu, X.; Zhu, J. Research progress on bio-based thermosetting resins. Polym. Internat. 2016, 65, 164–173. [Google Scholar] [CrossRef]

- Helanto, K.E.; Matikainen, L.; Talja, R.; Rojas, O.J. Bio-based polymers for sustainable packaging and biobarriers: A critical review. BioResources 2019, 14, 4902–4951. [Google Scholar]

- Koppolu, R.; Lahti, J.; Abitbol, T.; Swerin, A.; Kuusipalo, J.; Toivakka, M. Continuous processing of nanocellulose and polylactic acid into multilayer barrier coatings. ACS Appl. Mater. Inter. 2019, 11, 11920–11927. [Google Scholar] [CrossRef] [PubMed]

- Vrabič Brodnjak, U. Influence of ultrasonic treatment on properties of bio-based coated paper. Prog. Org. Coat. 2017, 103, 93–100. [Google Scholar] [CrossRef]

- Bordenave, N.; Grelier, S.; Coma, V. Hydrophobization and antimicrobial activity of chitosan and paper-based packaging material. Biomacromolecules 2010, 11, 88–96. [Google Scholar] [CrossRef]

- Bordenave, N.; Grelier, S.; Pichavant, F.; Coma, V. Water and moisture susceptibility of chitosan and paper-based materials: Structure–property relationships. J. Agric. Food Chem. 2007, 55, 9479–9488. [Google Scholar] [CrossRef]

- Xu, Y.X.; Kim, K.M.; Hanna, M.A.; Nag, D. Chitosan–starch composite film: Preparation and characterization. Ind. Crop. Prod. 2005, 21, 185–192. [Google Scholar] [CrossRef]

- Wang, S.; Jing, Y. Effects of a chitosan coating layer on the surface properties and barrier properties of kraft paper. BioResources 2016, 11, 1868–1881. [Google Scholar] [CrossRef]

- Ham-Pichavant, F.; Sèbe, G.; Pardon, P.; Coma, V. Fat resistance properties of chitosan-based paper packaging for food applications. Carbohyd. Polym. 2005, 61, 259–265. [Google Scholar] [CrossRef]

- Rastogi, V.K.; Samyn, P. Bio-based coatings for paper applications. Coatings 2015, 5, 887–930. [Google Scholar] [CrossRef]

- Reis, A.B.; Yoshida, C.M.; Reis, A.P.C.; Franco, T.T. Application of chitosan emulsion as a coating on Kraft paper. Polym. Int. 2011, 60, 963–969. [Google Scholar] [CrossRef]

- Mujtaba, M.; Morsi, R.E.; Kerch, G.; Elsabee, M.Z.; Kaya, M.; Labidi, J.; Khawar, K.M. Current advancements in chitosan-based film production for food technology; A review. Int. J. Biol. Macromol. 2019, 121, 889–904. [Google Scholar] [CrossRef]

- Cherpinski, A.; Torres-Giner, S.; Cabedo, L.; Méndez, J.A.; Lagaron, J.M. Multilayer structures based on annealed electrospun biopolymer coatings of interest in water and aroma barrier fiber-based food packaging applications. J. Appl. Polym. Sci. 2018, 135, 45501. [Google Scholar] [CrossRef]

- Kopacic, S.; Walzl, A.; Zankel, A.; Leitner, E.; Bauer, W. Alginate and chitosan as a functional barrier for paper-based packaging materials. Coatings 2018, 8, 235. [Google Scholar] [CrossRef]

- Hamdani, S.S.; Li, Z.; Rabnawaz, M.; Kamdem, D.P.; Khan, B.A. Chitosan-graft-polydimethylsiloxane/zein coatings for the fabrication of environmentally friendly oil-and water-resistant paper. ACS Sustain. Chem. Eng. 2020. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, R.; Ahmed, S.; Qin, W.; Liu, Y. Preparation and characterization of corn starch bio-active edible packaging films based on zein incorporated with orange-peel oil. Antioxidants 2019, 8, 391. [Google Scholar] [CrossRef]

- Kashiri, M.; Asadi, H.; Maghsoudlou, Y.; Mirzaei, H.; Alsoy Altinkaya, S. Characteristics of kraft papers coated with protein solutions containing tea extract powder with a layer-by-layer technique. Food Sci. Technol. 2019, 16, 85–197. [Google Scholar]

- Kashiri, M.; Cerisuelo, J.P.; Domínguez, I.; López-Carballo, G.; Muriel-Gallet, V.; Gavara, R.; Hernández-Muñoz, P. Zein films and coatings as carriers and release systems of Zataria multiflora Boiss. essential oil for antimicrobial food packaging. Food Hydrocolloid. 2017, 70, 260–268. [Google Scholar] [CrossRef]

- Li, Y.; Bai, Y.; Huang, J.; Yuan, C.; Ding, T.; Liu, D.; Hu, Y. Airglow discharge plasma treatment affects the surface structure and physical properties of zein films. J. Food Eng. 2020, 273, 109813. [Google Scholar] [CrossRef]

- Gagon, A.T.; Britt, D.W.; Bastarrachea, L.J. Zein-modified antimicrobial polypropylene: Characterization and reusability upon UV-A light exposure. LWT 2020, 121, 108983. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Z.; Wang, X.; Dong, S.; Sun, Y.; Zhao, Z. The properties of chitosan/zein blend film and effect of film on quality of mushroom (Agaricus bisporus). Postharvest Biol. Tec. 2019, 155, 47–56. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Z.; Han, X.; Sun, Y.; Wang, X. Effect of ethanol content on rheology of film-forming solutions and properties of zein/chitosan film. Int. J. Biol. Macromol. 2019, 134, 807–814. [Google Scholar] [CrossRef] [PubMed]

- Qu, L.; Chen, G.; Dong, S.; Huo, Y.; Yin, Z.; Li, S.; Chen, Y. Improved mechanical and antimicrobial properties of zein/chitosan films by adding highly dispersed nano-TiO2. Ind. Crops Prod. 2019, 130, 450–458. [Google Scholar] [CrossRef]

- Ortiz, C.M.; Salgado, P.R.; Dufresne, A.; Mauri, A.N. Microfibrillated cellulose addition improved the physicochemical and bioactive properties of biodegradable films based on soy protein and clove essential oil. Food Hydrocolloid. 2018, 79, 416–427. [Google Scholar] [CrossRef]

- Scartazzini, L.; Tosati, J.V.; Cortez, D.H.C.; Rossi, M.J.; Flôres, S.H.; Hubinger, M.D.; Monteiro, A.R. Gelatin edible coatings with mint essential oil (Mentha arvensis): Film characterization and antifungal properties. J. Food Sci. Technol. 2019, 56, 4045–4056. [Google Scholar] [CrossRef]

- Atarés, L.; Chiralt, A. Essential oils as additives in biodegradable films and coatings for active food packaging. Trends Food Sci. Technol. 2016, 48, 51–62. [Google Scholar] [CrossRef]

- Dashipour, A.; Razavilar, V.; Hosseini, H.; Shojaee-Aliabadi, S.; German, J.B.; Ghanati, K.; Khakpour, M.; Khaksar, R. Antioxidant and antimicrobial carboxymethyl cellulose films containing Zataria multiflora essential oil. Int. J. Biol. Macromol. 2015, 72, 606–613. [Google Scholar] [CrossRef]

- Lee, M.H.; Kim, S.Y.; Park, H.J. Effect of halloysite nanoclay on the physical, mechanical, and antioxidant properties of chitosan films incorporated with clove essential oil. Food Hydrocolloid. 2018, 84, 58–67. [Google Scholar] [CrossRef]

- Upadhyay, N.; Dwivedy, A.K.; Kumar, M.; Prakash, B.; Dubey, N.K. Essential oils as eco-friendly alternatives to synthetic pesticides for the control of Tribolium castaneum (Herbst) (Coleoptera: Tenebrionidae). J. Essent. Oil Bear. Plants 2018, 21, 282–297. [Google Scholar] [CrossRef]

- Tavares, M.; da Silva, M.R.M.; de Siqueira, L.B.D.O.; Rodrigues, R.A.S.; Bodjolle-d’Almeida, L.; Dos Santos, E.P.; Ricci-Júnior, E. Trends in insect repellent formulations: A review. Int. J. Pharm. 2018, 539, 190–209. [Google Scholar] [CrossRef] [PubMed]

- Turasan, H.; Sahin, S.; Sumnu, G. Encapsulation of rosemary essential oil. LWT-Food Sci. Technol. 2015, 64, 112–119. [Google Scholar] [CrossRef]

- Licciardello, F.; Muratore, G.; Suma, P.; Russo, A.; Nerín, C. Effectiveness of a novel insect-repellent food packaging incorporating essential oils against the red flour beetle (Tribolium castaneum). Innov. Food Sci. Emerg. 2013, 19, 173–180. [Google Scholar] [CrossRef]

- Abdollahi, M.; Rezaei, M.; Farzi, G. A novel active bionanocomposite film incorporating rosemary essential oil and nanoclay into chitosan. J. Food Eng. 2012, 111, 343–350. [Google Scholar] [CrossRef]

- Alizadeh-Sani, M.; Khezerlou, A.; Ehsani, A. Fabrication and characterization of the bionanocomposite film based on whey protein biopolymer loaded with TiO2 nanoparticles, cellulose nanofibers and rosemary essential oil. Ind. Crop Prod. 2018, 124, 300–315. [Google Scholar] [CrossRef]

- Sanuja, S.; Agalya, A.; Umapathy, M.J. Synthesis and characterization of zinc oxide–neem oil–chitosan bionanocomposite for food packaging application. Int. J. Biol. Macromol. 2015, 74, 76–84. [Google Scholar] [CrossRef]

- Abdollahi, M.; Rezaei, M.; Farzi, G. Improvement of active chitosan film properties with rosemary essential oil for food packaging. Int. J. Food Sci. Technol. 2012, 47, 847–853. [Google Scholar] [CrossRef]

- Siripatrawan, U.; Harte, B.R. Physical properties and antioxidant activity of an active film from chitosan incorporated with green tea extract. Food Hydrocoll. 2010, 24, 770–775. [Google Scholar] [CrossRef]

- Pires, J.R.A.; de Souza, V.G.L.; Fernando, A.L. Chitosan/montmorillonite bionanocomposites incorporated with rosemary and ginger essential oil as packaging for fresh poultry meat. Food Packag. Shelf Life. 2018, 17, 142–149. [Google Scholar] [CrossRef]

- Lee, B.H.; Lee, S.E.; Annis, P.C.; Pratt, S.J.; Park, B.S.; Tumaalii, F. Fumigant toxicity of essential oils and monoterpenes against the red flour beetle, Tribolium castaneum Herbst. J. Asia Pac. Entomol. 2002, 5, 237–240. [Google Scholar] [CrossRef]

- ISO 536–Paper and Board—Determination of Grammage; International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 534–Paper and Board—Determination of Thickness, Density and Specific Volume; International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 287–Paper and Board—Determination of Moisture Content of a Lot—Oven-Drying Method; International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 535–Paper and Board—Determination of Water Absorptiveness—Cobb Method; International Organization for Standardization: Geneva, Switzerland, 2014.

- ISO 2528–Sheet Materials—Determination of Water Vapour Transmission Rate (WVTR)—Gravimetric (Dish) Method; International Organization for Standardization: Geneva, Switzerland, 2017.

- TAPPI T511–Folding Endurance of Paper (MIT Tester); TAPPI organization: Peachtree Corners, GA, USA, 2006.

- EN ISO 13938/2:2019–Bursting Properties of Fabrics—Part 2: Pneumatic Method for Determination of Bursting Strength and Bursting Distension; International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 1974:2012 Paper—Determination of Tearing Resistance—Elmendorf Method; International Organization for Standardization: Geneva, Switzerland, 2019.

- Norajit, K.; Kim, K.M.; Ryu, G.H. Comparative studies on the characterization and antioxidant properties of biodegradable alginate films containing ginseng extract. J. Food Eng. 2010, 98, 377–384. [Google Scholar] [CrossRef]

- Gullichsen, J.; Paulapuro, H.; Lehtinen, E. Pigment coating and surface sizing of paper. Book 2000, 11, 2–61. [Google Scholar]

- Hong, P.Z.; Li, S.D.; Ou, C.Y.; Li, C.P.; Yang, L.; Zhang, C.H. Thermogravimetric analysis of chitosan. J. Appl. Polym. Sci. 2007, 105, 547–551. [Google Scholar] [CrossRef]

- Qin, Y.; Li, W.; Liu, D.; Yuan, M.; Li, L. Development of active packaging film made from poly (lactic acid) incorporated essential oil. Prog. Org. Coat. 2017, 103, 76–82. [Google Scholar] [CrossRef]

| Sample | Grammage (m/g2) | Thickness (µm) | Density (kg/m3) | Specific Surface Volume (m3/kg) |

|---|---|---|---|---|

| U | 80 ± 0.02 | 121 ± 0.5 a | 661.57 ± 0.4 | 0.00151 ± 0.0002 |

| CZ | 85 ± 0.03 | 124 ± 12 a | 685.48 ± 1.0 | 0.00146 ± 0.0003 |

| ZR | 85 ± 0.02 | 123 ± 1 a | 691.06 ± 0.5 | 0.00145 ± 0.0002 |

| CR | 85 ± 0.01 | 123 ± 0.5 a | 691.06 ± 0.7 | 0.00145 ± 0.0002 |

| CZR | 85 ± 0.03 | 124 ± 1 a | 685.48 ± 1.1 | 0.00146 ± 0.0001 |

| C | 85 ± 0.03 | 124 ± 2 a | 691.06 ± 1.0 | 0.0145 ± 0.0001 |

| Z | 85 ± 0.02 | 124 ± 1 a | 691.06 ± 0.9 | 0.0145 ± 0.0001 |

| Sample | TS (MPa) | E (%) | Bending Resistance (No. of Bendings) | Tear Resistance (mN) | Bursting Strength (kPa) | ||||

|---|---|---|---|---|---|---|---|---|---|

| MD | CD | MD | CD | MD | CD | MD | CD | ||

| U | 25 ± 0.5 | 58 ± 0.7 | 3.7 ± 0.2 | 2.0 ± 0.7 | 890 ± 9 | 1084 ± 0.5 | 315 ± 1 | 463 ± 1 | 307 ± 1 |

| CZ | 34 ± 1.1 | 63 ± 0.8 | 5.0 ± 0.3 | 3.8 ± 0.3 | 2097 ± 5 | 4314 ± 2 | 382 ± 2 | 506 ± 2 | 350 ± 1 |

| ZR | 33 ± 0.9 | 64 ± 1.1 | 5.2 ± 0.5 | 3.9 ± 0.4 | 2104 ± 3 | 5716 ± 5 | 389 ± 2 | 537 ± 0.5 | 353 ± 2 |

| CR | 36 ± 1.3 | 69 ± 0.6 | 5.4 ± 0.2 | 4.1 ± 0.6 | 2125 ± 7 | 5759 ± 8 | 392 ± 4 | 544 ± 6 | 362 ± 1 |

| CZR | 44 ± 1.2 | 75 ± 0.7 | 7.1 ± 0.6 | 6.0 ± 0.1 | 2517 ± 8 | 5843 ± 9 | 490 ± 3 | 637 ± 4 | 489 ± 3 |

| C | 31 ± 1.1 | 63 ± 0.5 | 4.0 ± 0.2 | 2.4 ± 0.3 | 3108 ± 8 | 5239 ± 7 | 345 ± 2 | 533 ± 4 | 362 ± 2 |

| Z | 30 ± 1.0 | 62 ± 0.4 | 3.9 ± 0.3 | 2.2 ± 0.3 | 2915 ± 4 | 4894 ± 4 | 331 ± 2 | 527 ± 1 | 358 ± 2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vrabič Brodnjak, U.; Tihole, K. Chitosan Solution Containing Zein and Essential Oil as Bio Based Coating on Packaging Paper. Coatings 2020, 10, 497. https://doi.org/10.3390/coatings10050497

Vrabič Brodnjak U, Tihole K. Chitosan Solution Containing Zein and Essential Oil as Bio Based Coating on Packaging Paper. Coatings. 2020; 10(5):497. https://doi.org/10.3390/coatings10050497

Chicago/Turabian StyleVrabič Brodnjak, Urška, and Katarina Tihole. 2020. "Chitosan Solution Containing Zein and Essential Oil as Bio Based Coating on Packaging Paper" Coatings 10, no. 5: 497. https://doi.org/10.3390/coatings10050497

APA StyleVrabič Brodnjak, U., & Tihole, K. (2020). Chitosan Solution Containing Zein and Essential Oil as Bio Based Coating on Packaging Paper. Coatings, 10(5), 497. https://doi.org/10.3390/coatings10050497