1. Introduction

Tapping is a cutting operation, consisting of engraving the profile thread on a previously drilled surface where the diameter obtained is slightly smaller than the thread diameter. This operation is similar to broaching with the difference that in this operation, tool teeth describe a linear path whereas in tapping, the path is helical. The fact that, as in broaching, in tapping each active tooth has different geometry [

1] and besides the tool is immersed during cutting in the previous hole, practically without wobbly, makes this operation one of the most complex to analyze. On the other hand, tapping is usually carried out when the workpiece is practically finished and therefore, tapping is an operation of high added value.

As a consequence of the complexity of the operation and the high added value of the workpiece, tapping is a critical operation that should be taken into account. However, there are not many references to this process in the literature, as some authors have pointed out [

2]. The high complexity of the tapping operation is one of the main reasons for the relative absence of manuscripts on the topic. Models are not often successful due to this complexity.

Among the problems that can be achieved during the operation, the most important is the breakage of the tap inside the hole. This phenomenon sometimes implies workpiece rejection and then, the resulting increase of manufacturing costs. However, there are cases in which the workpiece can be recovered but in this case the broken tapping tool core must be removed and this operation increases manufacturing time and therefore manufacturing costs. In addition to the problem of tap tool breakage there are other problems such as; breakage of one or more teeth or the inevitable tool wear, which despite being less serious, must also be taken into account to not damage the operation quality.

Although for threading some materials such as abrasive castings, fiberglass, casting steels, austenitic steels and hardened steels, taps are usually carried out with carbide taps, the most commonly substrate used is high-speed steel (HSS) and in particular the obtained by powder metallurgy processes and therefore, the subject of this research.

On the other hand, with the progressive and successful introduction of anti-wear micro-coatings [

3,

4] most of the HSS tapping tools on the market are coated with very thin films of materials which improve extraordinarily their properties giving them a lower coefficient of friction, a lower capacity of chemical reaction with the workpiece material, a higher resistance to abrasion and a higher hot hardness. In this case, the HSS substrate purpose is to be a robust support and to facilitate a good adherence of the layers. Both properties are essential in the cutting process.

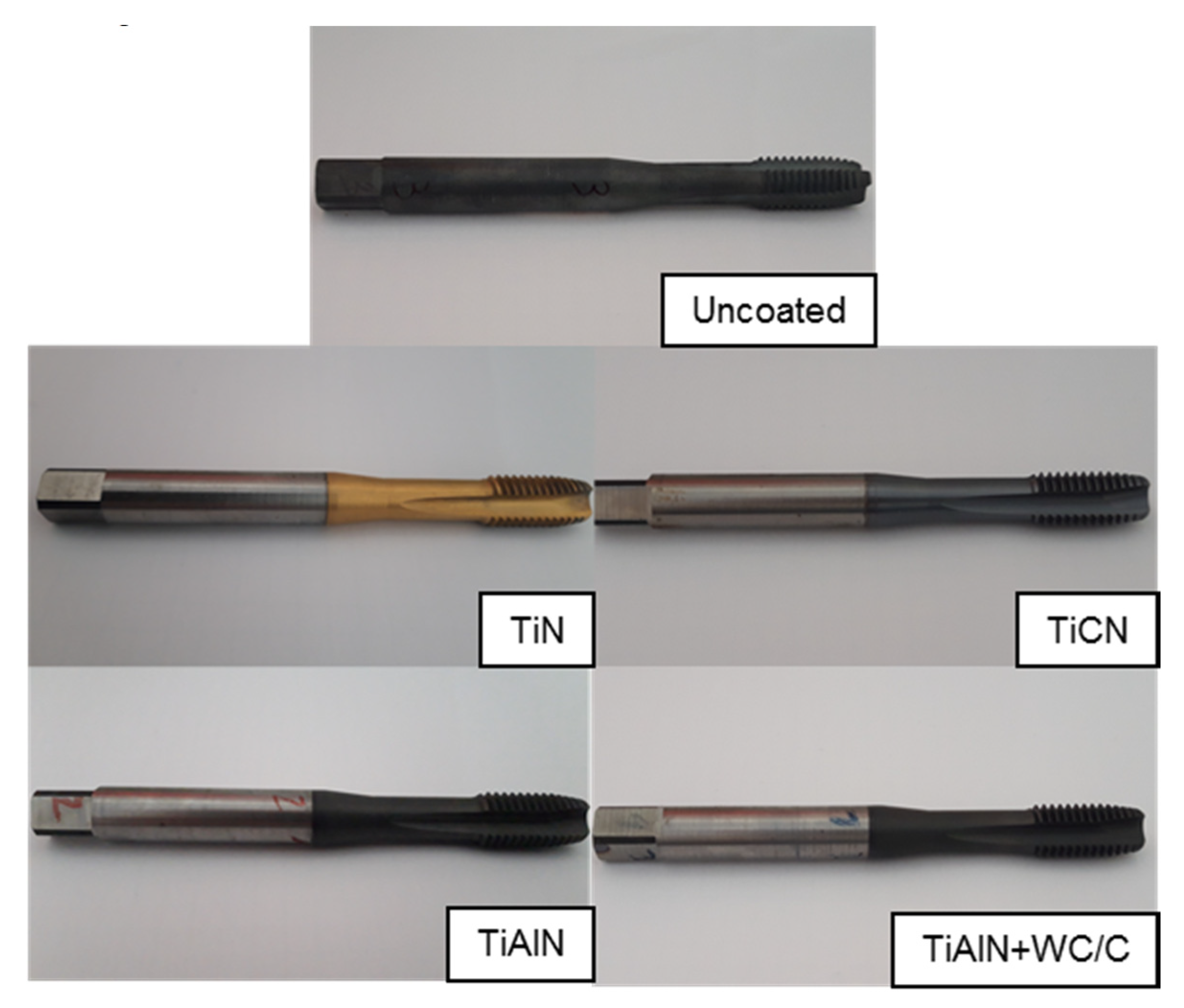

In this research a behavior analysis of three-channel M12 × 1.5 high-speed powdered steel taps is presented. The taps are the main current coatings, which are mentioned in order of appearance on the market—TiN, TiCN, TiAlN and TiAlN+WC/C and are compared with performance of the uncoated tap.

TiN was the first coating applied to cutting tools in the 1970s [

5]. This coating has a wide range of uses, being more expensive than the classic coatings (obtained by oxide deposition in a very hot atmosphere) but increasing considerably tap tool life and usually compensates its application. It is one of the first coatings tested on tools, initially on carbide tools and then on HSS ones. This coating is characterized by presenting low friction coefficient that reduces the heat generated during cutting and protects against adhesion and abrasion wear. In fact, after fifty years after its market introduction and despite existing more modern coatings, it is still applied nowadays due to it cheap application. In addition, its gold color reflects tool wear visually, which is useful for the operator with the aim of preventing uncontrolled tap breakage.

The next coating to be applied was TiCN, which has greater hardness and fracture toughness. This last property gives to tool edges resistance to dynamic loads, which makes it very suitable for high-speed and interrupted cutting conditions, where dynamics are always present. Recently, the change produced in the coating materials used and, in the techniques, should be highlighted. In particular, the development of coatings based on Ti, C, N and Al in their various combinations. The incorporation of Al and N gives the coatings better resistance to oxidation and greater hardness when tool is hot. It also reduces residual stresses, thus improving the adhesion of the layer to the core material. Among these new coating techniques, sputtering and “arc deposition” techniques stand out, which achieve “nano” size grain structures that allow graduate the layer composition along its thickness [

6]. The most commonly used representative of these new layers in cutting tools in general—and taps in particular—is TiAlN, a material with extraordinary resistance to high temperatures that works very well in the machining of cast iron parts [

7], which is the material that is going to be used in this research.

A more recent coating is the coating with lubricating capacity, which consists of depositing layers with a lubricating capacity [

8] on the hard layers mentioned above. The most common are CBCs (Carbon based coatings) and among them are DLCs (Diamond like Carbon), WC/Cs (Tungsten carbide/graphite) [

9,

10] and TiC/Cs. Another kind of lubricant coating is molybdenum sulphide (MoS

2), which has been used in space satellite workpieces, where low lubrication conditions are presented due to the vacuum environments, good results are achieved. Regarding CBCs, the WC/C is the one that will be used in this research on a TiAlN substrate.

Despite not being a high number of researches, which deals with tapping operations, several must be taken into account due to its utility. In particular, there are two researches in which Al-Si Alloys are tapped with HSS taps. In particular, in the first one 319 Al-Si alloy was tapped with HSS taps with diamond coatings and uncoated as reference. The use of this coating is due to the high abrasive performances that this kind of alloys. During the tests, MQL lubrication were used. The results shown that coatings are mandatory to achieve a suitable process. On the other hand, the use of MQL (Minimum Quantity Lubrication) was proved beneficial to avoid oil adhesions [

11]. Taking into account this last assertion, the other one analyzed the wear mechanisms. In this case, an uncoated HSS taps were used with the aim of enhancing wear on them. The conclusions obtained show that abrasion and adhesion wear caused a severe deterioration of lobes on the chamfered length of the tap [

12]. To avoid these wear mechanisms, other research focused on the influence of coating during the tapping process. In particular, tapping operations were carried out with several PVD (Physical Vapor Deposition) coatings on austempered ductile iron (ADI) in Elósegui et al. study [

13]. In particular, AlTiN, AlTiSiN and AlCrSiN were tested. The results show that employing drag grinding before coating the taps and better adhesion of the film to the substrate was achieved. On the other hand, forming and cutting taps were used in Pereira and da Silva [

14], respectively to tapping lamination carbon steel SAE 1045. In this case, TiCN and TiN coatings were tested. The results show that it is important to take into account the coating layer thickness but it was not discerned which kind of coating or which value thickness were the most robust. This last question was solved in 2019 by in Abdoos et al. [

15]. In this research the effect of coating thickness was tested on compacted graphite iron (CGI). In this work, coatings of ≈4 µm, ≈5.38 µm, ≈10 µm, ≈17 µm were tested. The results show that ≈10 µm of thickness is the optimum value to deal with this kind of material. Finally, several tests were carried out by Bezerra and Coelho [

16] on cast iron GG25 with taps coated with TiAlN and TiCN. The results show that the main wear mechanism was adhesion followed by abrasion as happened with Al-Si Alloys. Regarding coatings behaviors, at 30 m/min similar performance presented. However, when cutting speed was increased until 60 m/min, TiAlN was the best choice to deal with this cast iron, achieving an increase of tool life near to 60%. Other related works are given by Urbikaín et al. [

17] but for forming taps in this case. Other author also analyses the influence of the coatings on diverse tool geometries [

18,

19,

20] analyzing microstructure, mechanical, oxidation and corrosion properties of the Cr-Al-Si-N Coatings [

18], the Mo-Cu-V-N composite coatings [

19] and the tribological properties, oxidation resistance and turning performance of AlTiN/AlCrSiN multilayer coatings [

20].

This work aims to have a better understanding of the tap performance comparing some of the existing coatings and it is motivated by the tool supplier NECO-Tivoly Group. Therefore, taking into account all these issues in this work four coatings behavior was analyzed during GG25 cast iron plates. In this case, dry tapping was used in order to enhance which coating presents better lubrication properties and at the same time avoiding the occurrence of adhesive wear. The manuscript was structured the following way—first, the machine setting up where the tapping process was developed, the tap geometry and coating properties are defined (

Section 2). Then, the test strategy, wear methodology and the end of life criteria chosen are described. Besides, the results of experimentation and wear analysis are presented (

Section 3). Subsequently, the discussion of the results is presented according to the wear, quantitatively evaluated, of the flank face of each of the teeth comparing the behaviors of the different coatings (

Section 4) and finally the conclusions are presented.

2. Materials and Methods

To carry out the tests, a vertical machining center and plates are used in which 2000 holes with a diameter of 10.5 mm were previously drilled by an HSS drill. All holes are inspected by H7 hole plain gauge with “go” & “no-go” checks (min. diam. 10.5 mm and max. diam. 10.518 mm).

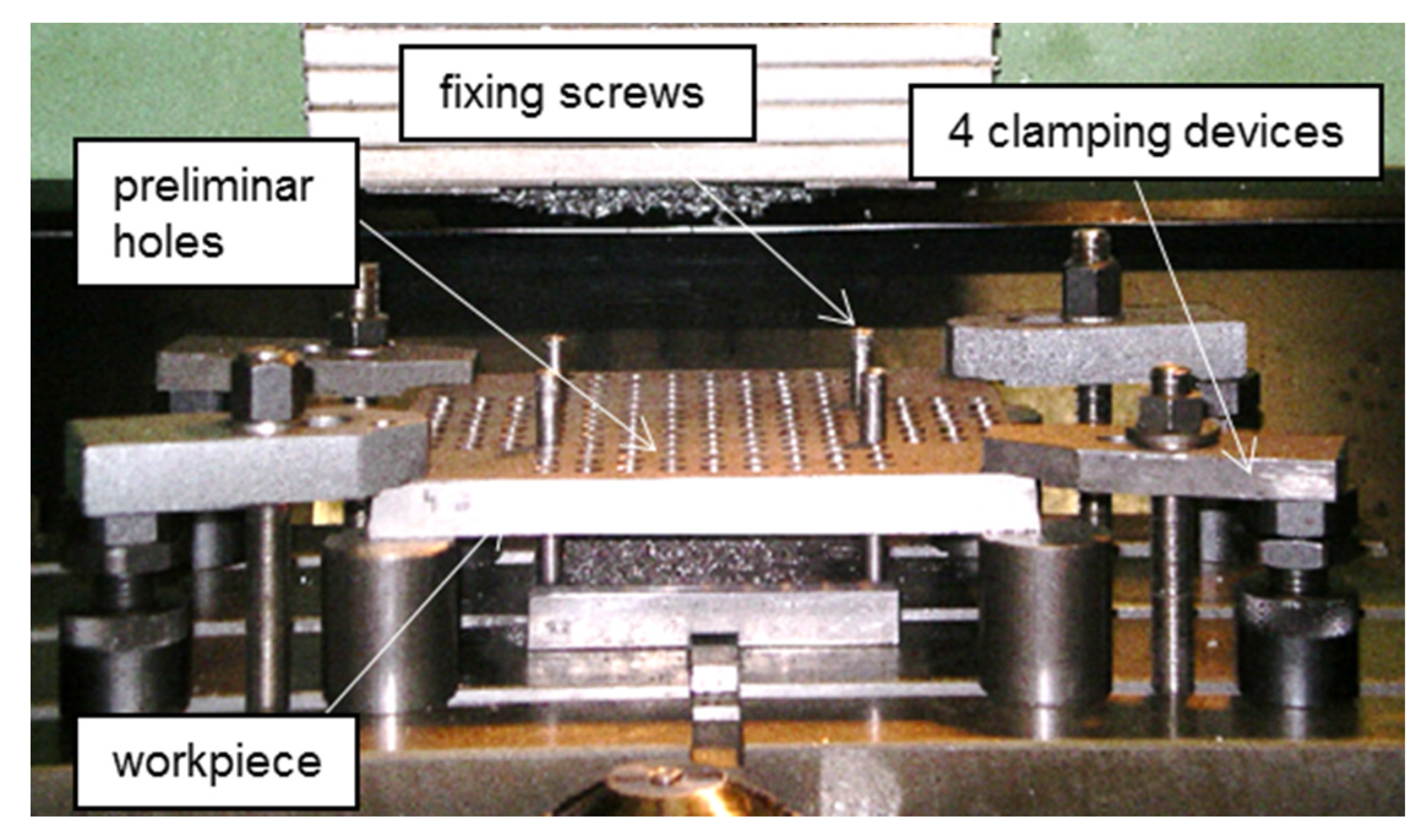

Figure 1 shows the detail of the tie used to fix and position the perforated plate to the table.

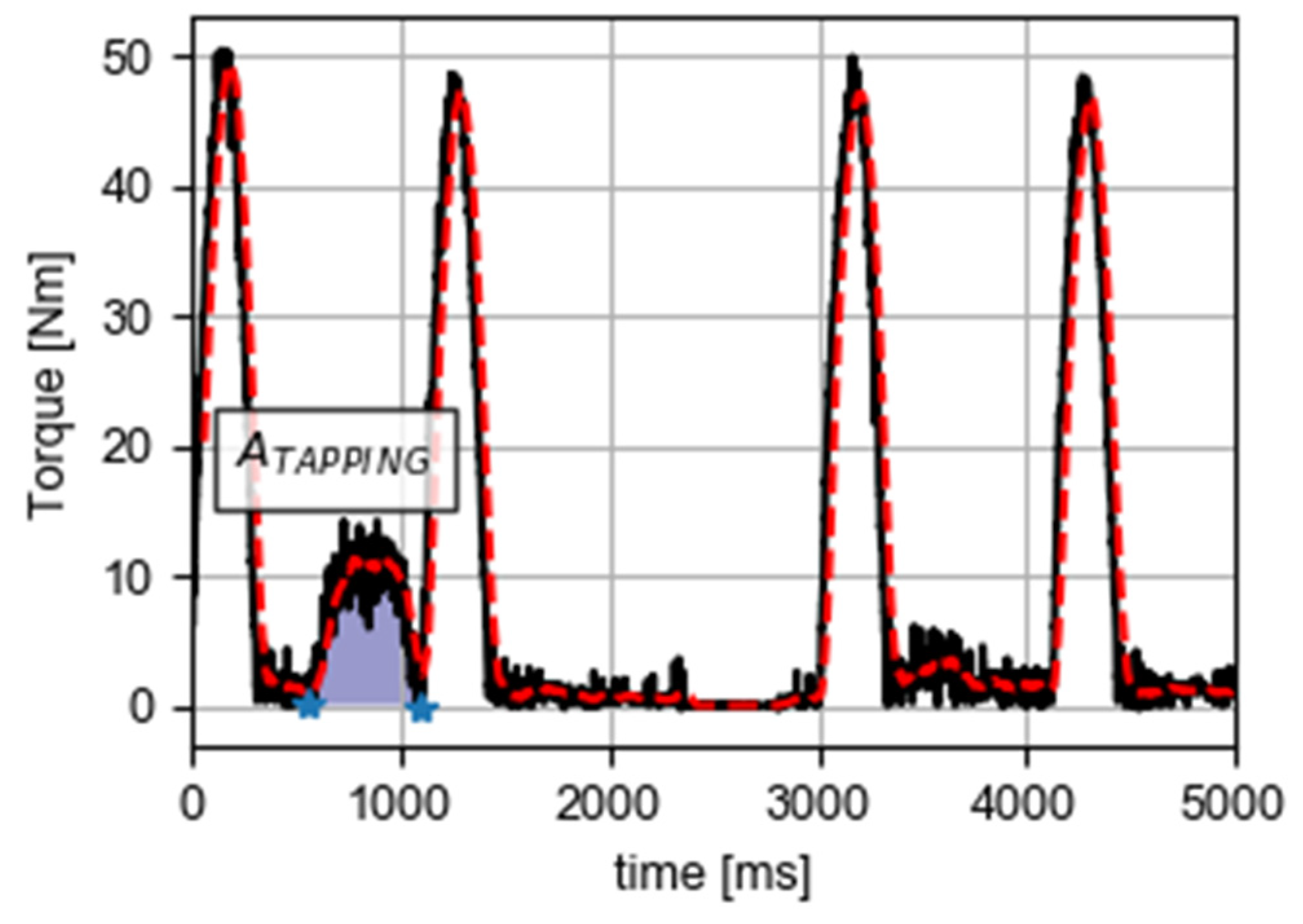

Tapping tools were fixed using a WIDAFLEX UTS tap holder (Fort Mill, SC, USA), Ref. UT40, the bushing was BILZ-M12 (Ostfildern, Germany). Before each test, the tap holder was fixed with a clutch torque of approximately 16 N-m as a safety measure to prevent tap tool breakage inside the hole.

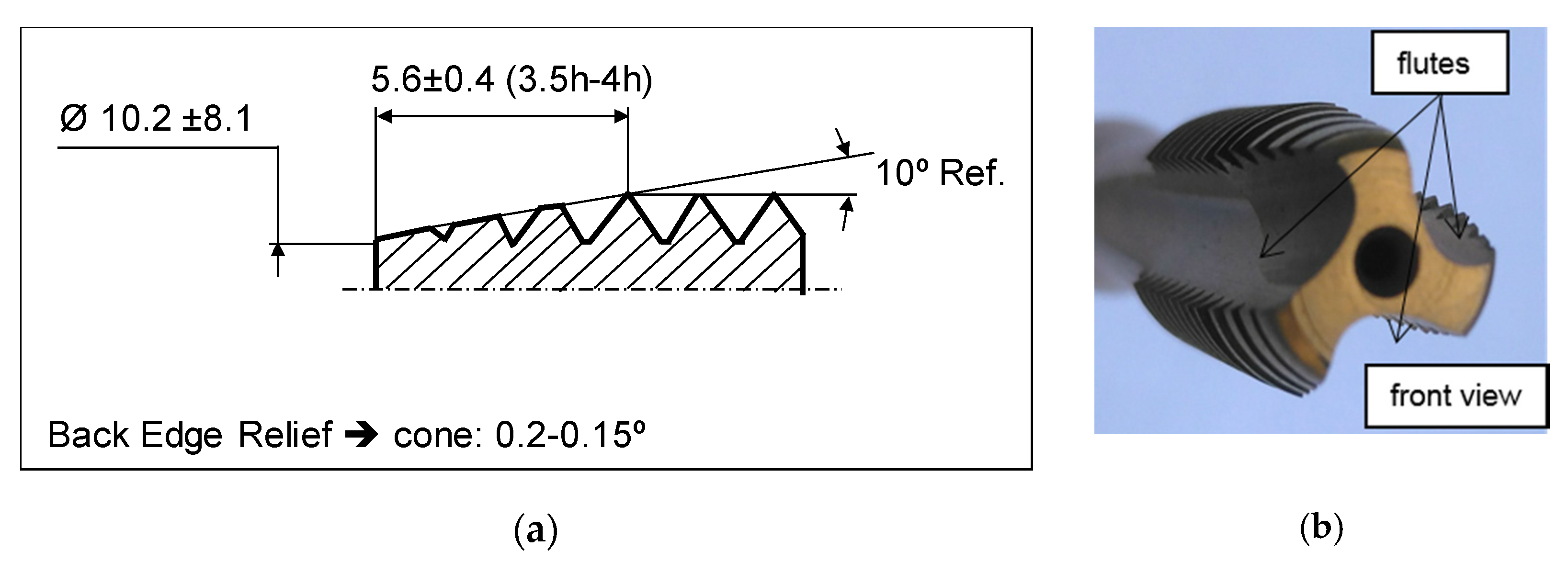

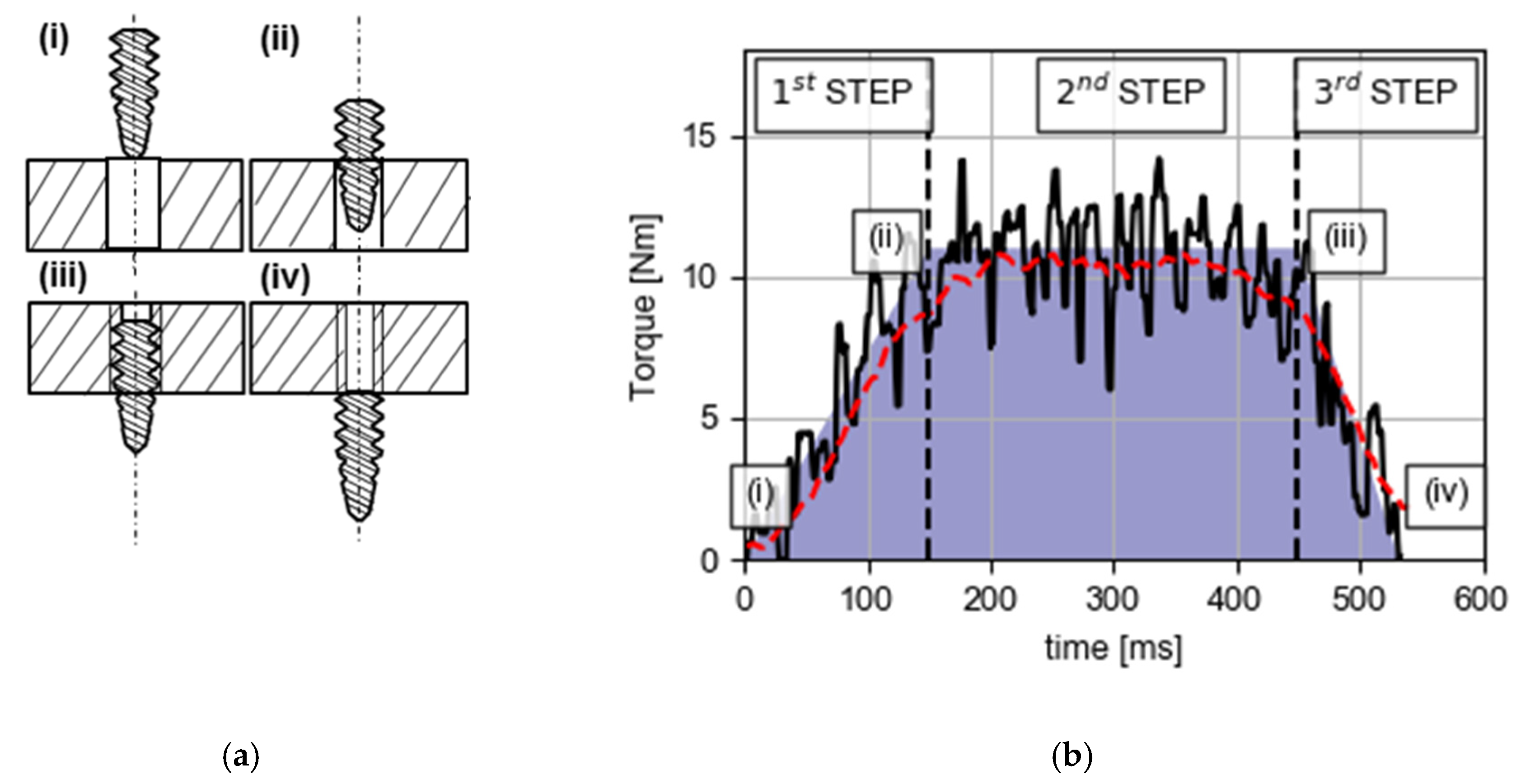

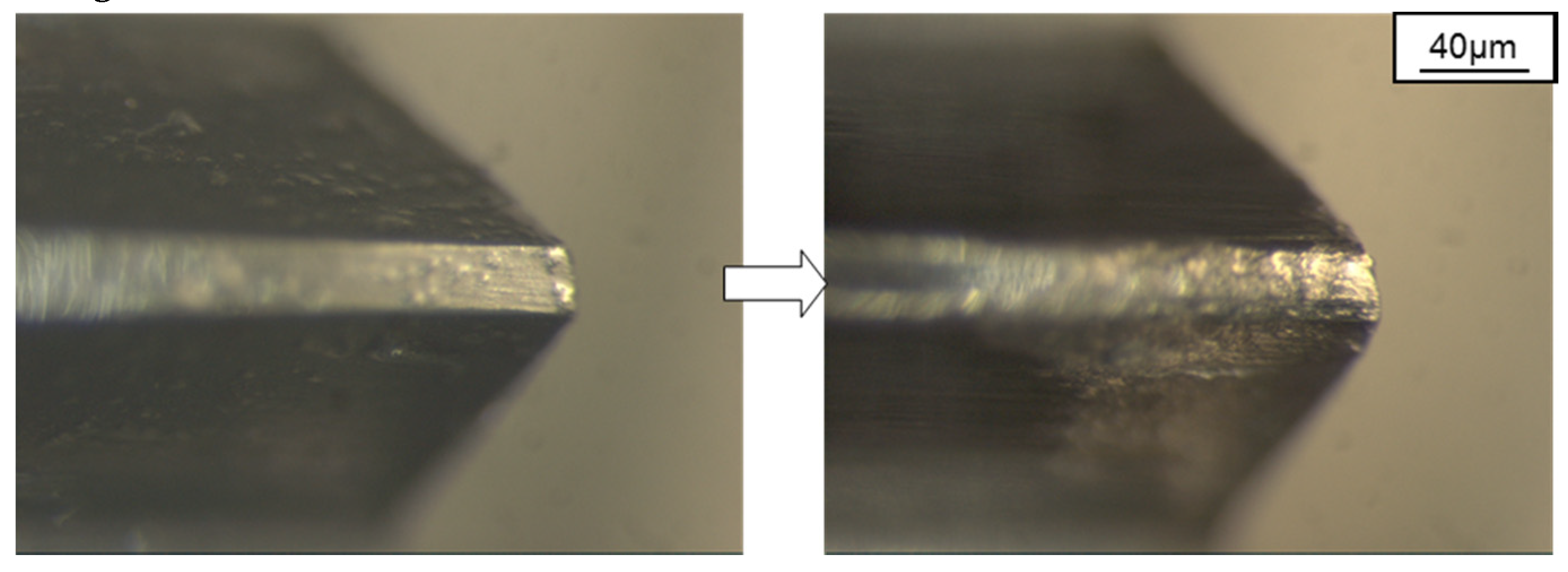

Part material was GG25 cast iron on plates of 250 mm × 225 mm and 20 mm thick on which, as was mentioned, holes with a diameter of 10.5 mm had been previously drilled. The type of tap used was M12×1.5 high speed steel (HSSEE) with a 10° inlet cone half angle and three channels (see

Figure 2a).

Figure 2b shows an axial view of the tap tool in which the three channels can be distinguished.

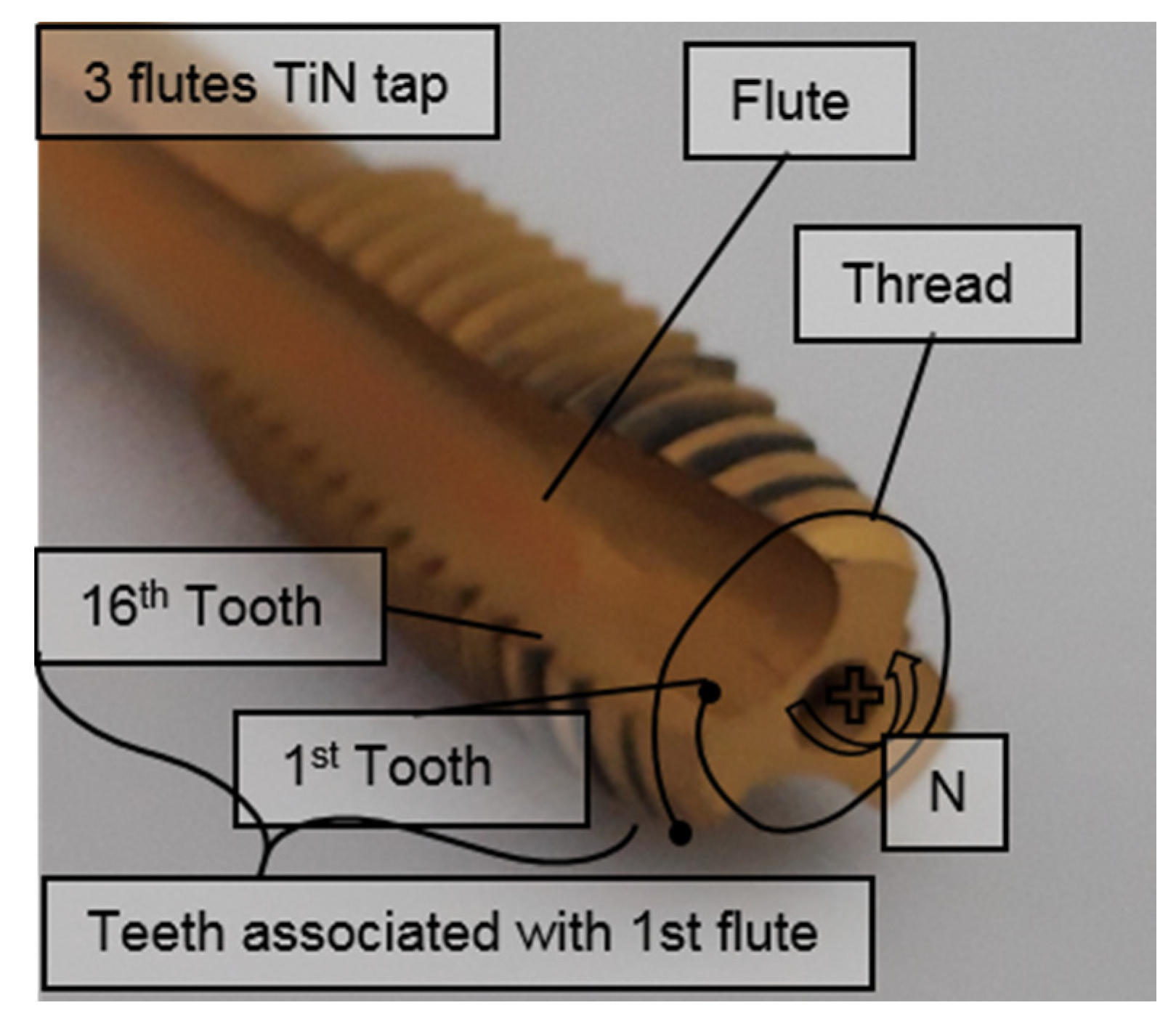

The nomenclature used to distinguish the different tap parts (flute, thread, tooth) are shown in

Figure 3.

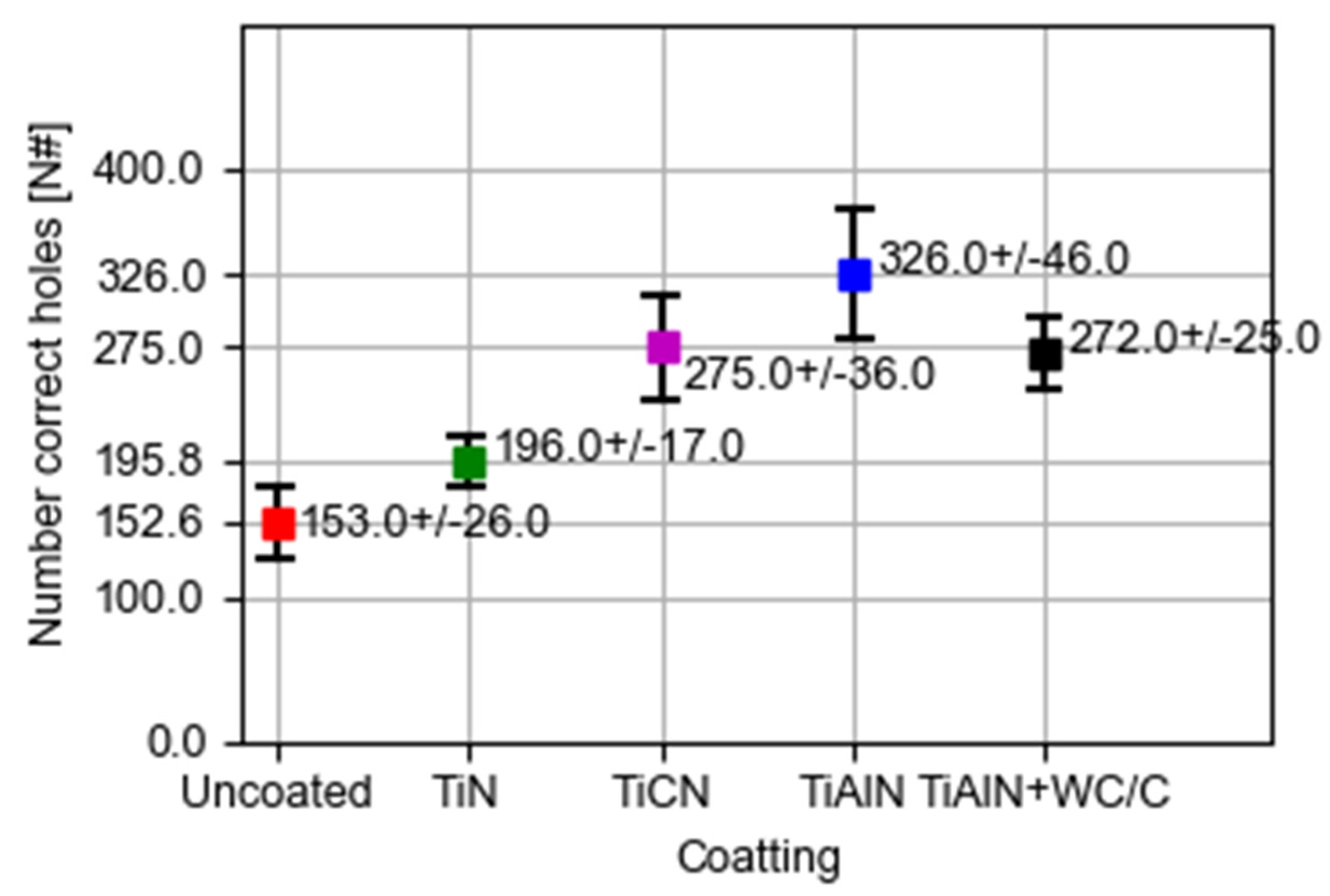

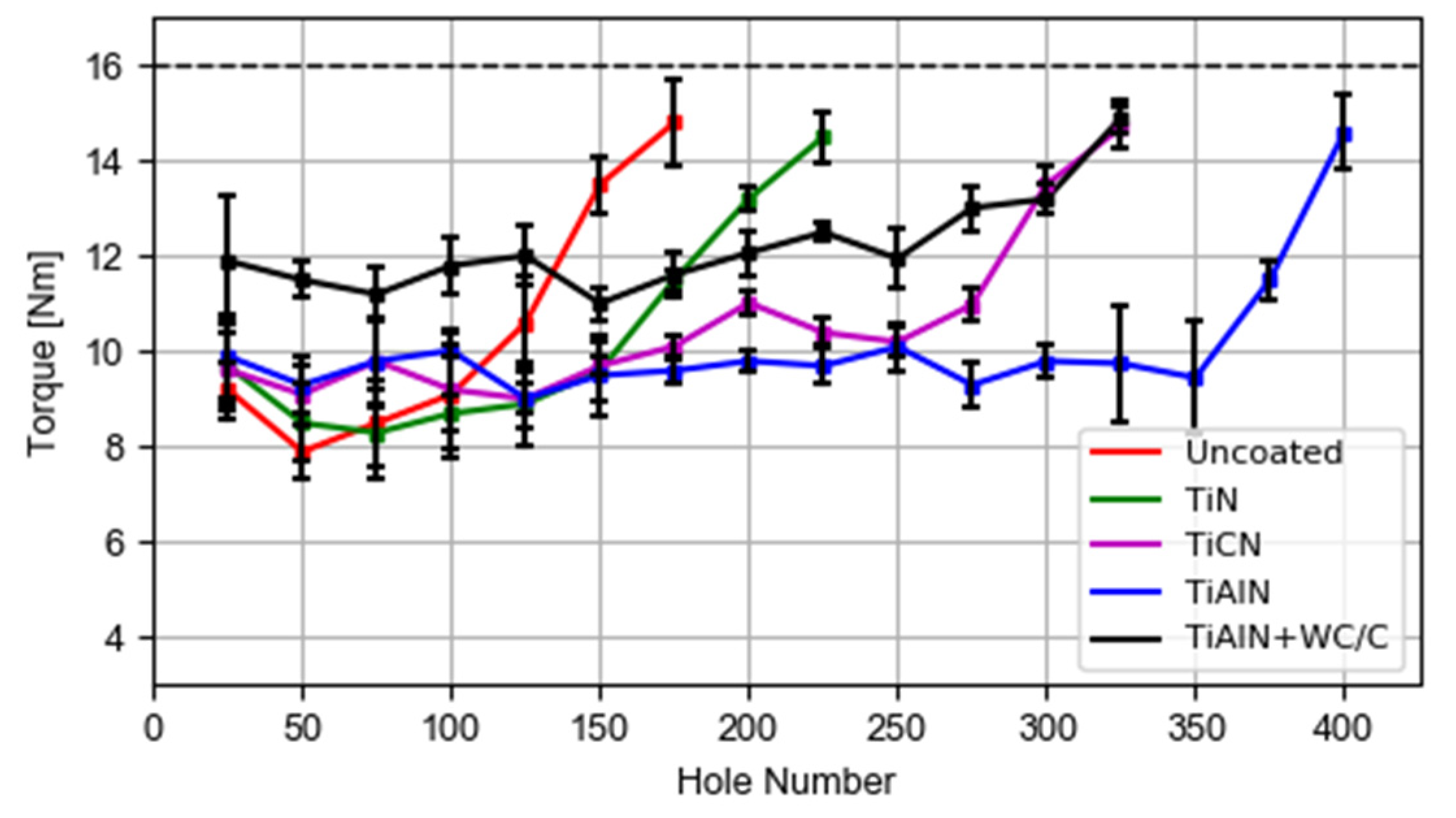

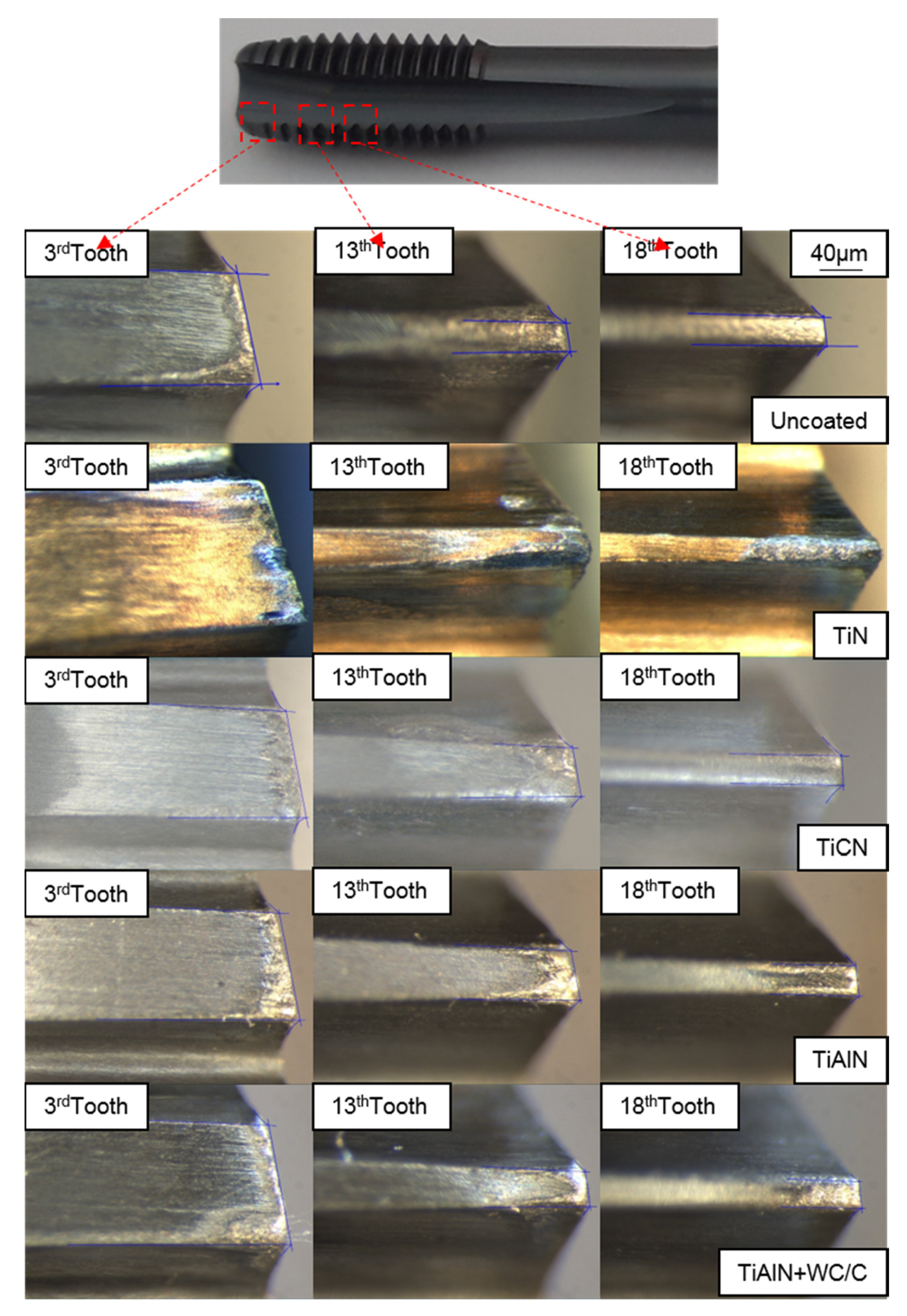

Four coating types (TiN, TiCN, TiAlN, TiAlN+WC/C), as it can be seen on

Figure 4, were tested with cutting conditions of

Vc = 50m/min and without the use of lubrication. Feed rate is derived from thread metric (M12 × 1.5), threading (tapping) is only one degree of freedom operation, so cutting speed is the master, feed the slave. These cutting conditions, which meet the requirements for productivity of the tool provider and industrial applications, can be considered demanding for this type of machining. This paper seeks to analyze the high-speed machining of iron. Five tap tools have been used for each coating.

Coatings were applied on taps by using PVD technology. The coating supplier used coupons for the Calo test in order to assess coating thickness, along with adhesion by scratch test. Droplets in coating were eliminated by drag grinding several minutes (using OTEC machine (Straubenhardt-Conweiler, Germany). Cutting Edge roundness was also checked, because it implies some variation in performance.

Table 1 illustrates the main parameters of coatings.

The coating supplier (Oerlikon Balzers, Antzuola, Spain) measures thickness and microhardness by X-ray fluorescence according to DIN ISO 3497 [

21] and ASTM B 568 standards [

22] and nanoindentation according to ISO 14577 [

23], respectively. Besides, the TiN coating provides a high wear resistance, prevents the cutting edges from being built up because of the cold scrap welding and obtains a higher surface quality of the thread. The TiCN coating has a higher abrasive resistance than previous one and is recommended for tough materials, casting and steels with hardnesses higher than 1000 N/mm

2. TiALN has ideal behavior for highly stressed components guarantying the best chip flow. Besides, it is developed to work in dry machining and at higher cutting speed conditions. Finally, the TiALN+WC/C has the same properties as the previous one plus additional lubricant layer to avoid the friction between thread profile and tap tooth.

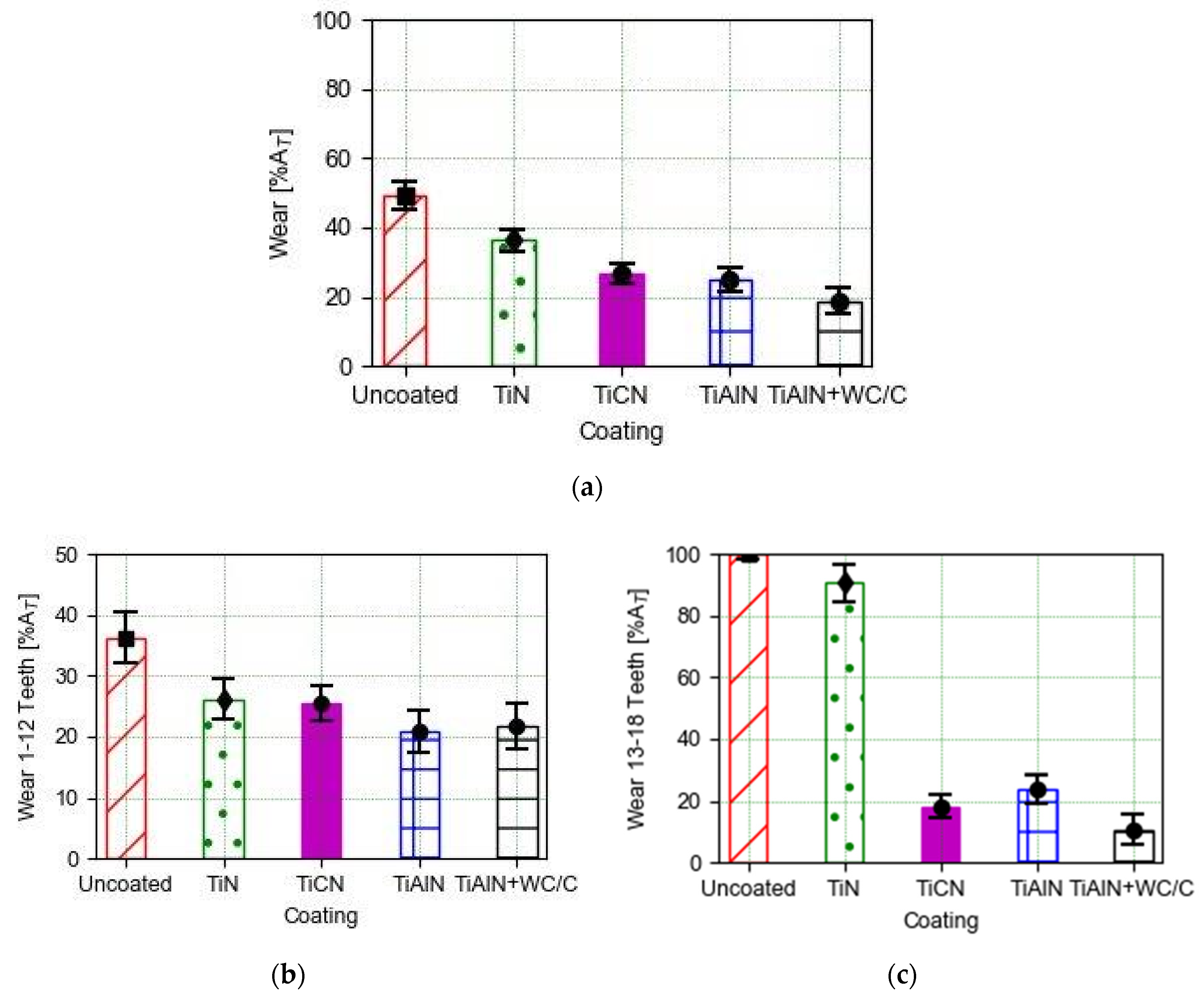

4. Discussion

Once experimental results were illustrated and analyzed and, also, the better performance of TiAlN y TiALN+WC/C coatings was observed, the following section—the Discussion—focuses on comparing the wear level of these coatings and without coating from the first tooth to the eighteenth one. Also, results on tool wear on each tooth on TiN and TiCN coatings are addressed. Before starting the discussion, the meaning of thread over the %

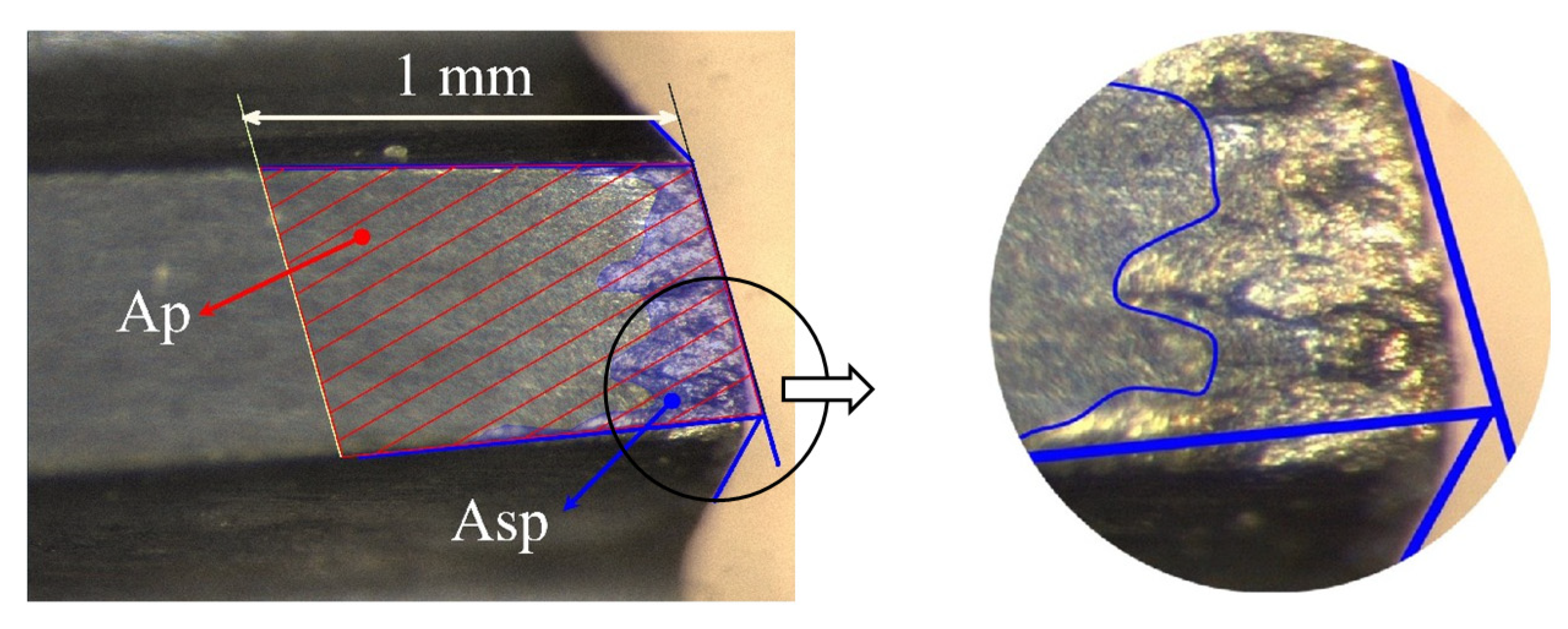

A profile is defined plastically in

Figure 3. However, the thread is the set of three teeth from the first flute to the same flute in a helicoidal movement.

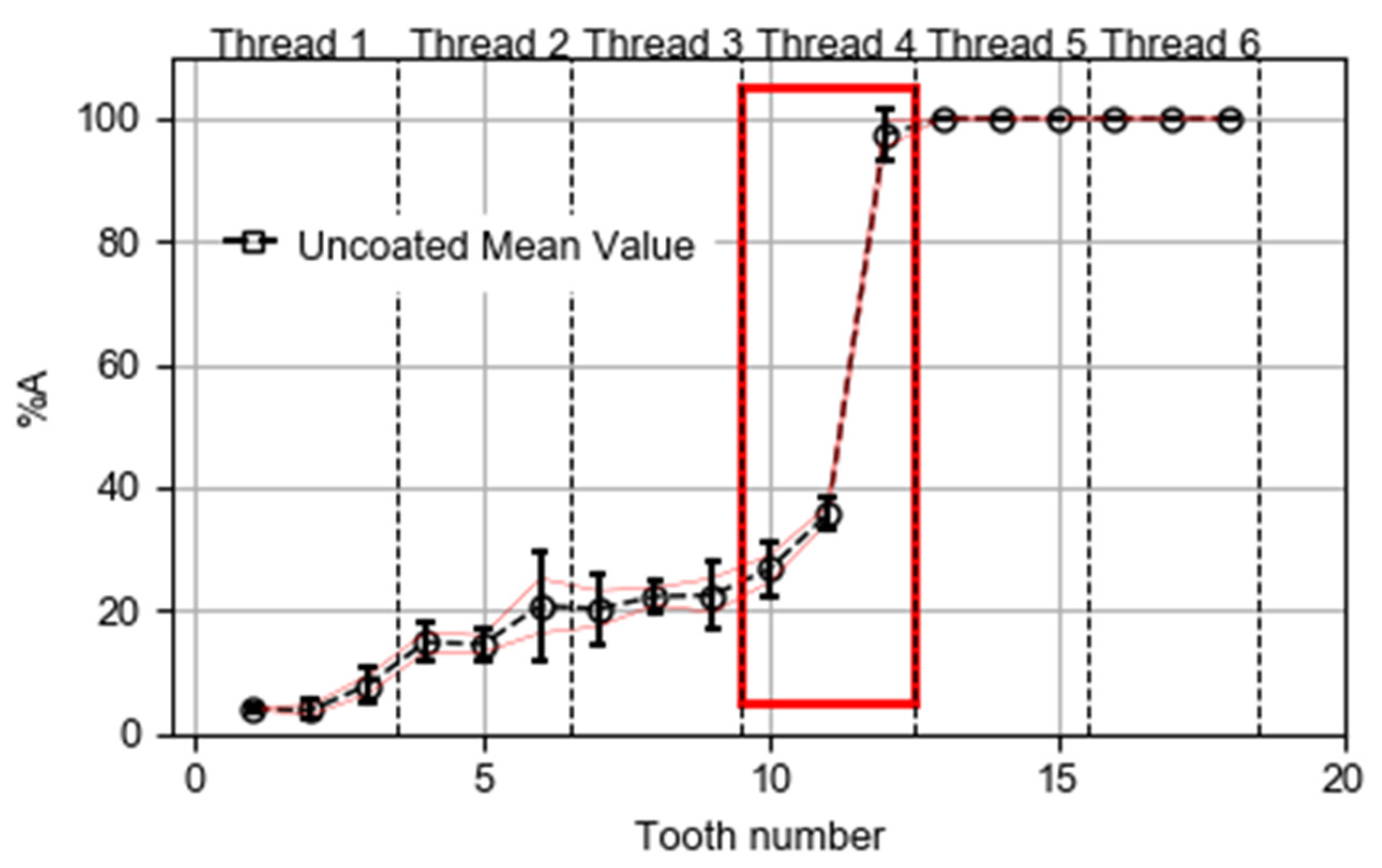

4.1. Discussion of Results on Uncoated Taps

In all taps tested, the cutting teeth are from tooth 1 to tooth 10. From 13, they are in the cylindrical part and therefore are finishing teeth. Regarding tooth numbers 11 and 12, there are three possibilities—(a) teeth 11 and 12 can be cutting tooth and fishing one, respectively, (b) they can be both cutting ones or (c) they can be both finishing. Logically, the probability of being cutting tooth is higher in edge 11 than in tooth 12.

Figure 14 shows the evolution of parameter %

A for each tooth from the first one to the eighteenth tooth of the five uncoated taps studied. The behaviors of %

A profiles are similar among uncoated taps.

Therefore and to simplify the analysis,

Figure 15 illustrates the mean value of %

A of these five specimens with a 95% confidence interval.

Focusing on

Figure 15, the value of %

A remains below 10% in teeth 1, 2 and 3 and it suddenly changes to a value less than 20% in teeth 4 and 5 and it increases up to 20% and remains in the next six teeth (5 to 10). Tooth 11 exhibits slightly more wear than 30% and tooth 12 rises to a value of 100%. Assuming, as it seems logical, that in the five uncoated taps tested, tooth 11 is a cutting one (since it maintains the wear values of the previous ones). Taking into account the finishing thread profile of tooth 12, an explanation of the high wear value of the tooth 12 can be a consequence of the wear on the flank face suffered by tooth number 11, which leaves the thread profile unfinished and, therefore, tooth 12 removes the uncut material. This one, like the rest of the friction teeth, suffers heavy wear at its two corners and as its main edge is very small (1/8 of the step, that is, 0.18 mm), the wear of both corners (see

Figure 11) overlap generating a high relative wear value on the clearance face. As tooth 12 wears out, it leaves the thread profile unfinished and, consequently, tooth 13 becomes cutting edge. This wear is propagated along the friction teeth being responsible for calibrating the thread.

Despite the 100% wear value of teeth 12–18, the threads generated by the uncoated taps were inspected by the “GO/NO-GO” thread gauge and all threads are in tolerances. Although the wear parameter %A is 100%, the amount of material without removing it from the thread profile is small enough not to prevent the threaded hole from allowing the thread gauge to enter. Consequently, teeth 12–18 clearance faces of uncoated taps have higher wear levels than the other coated ones. However, the wear is shallow and, consequently, the threads are correct.

This mean wear profile of uncoated taps is the basis wear profile for comparing with the other coated ones. Besides, and as mentioned before, the TiAlN and TiAlN+WC/C were selected to discuss the wear results because they have the minimum wear levels as it was described in

Section 3.

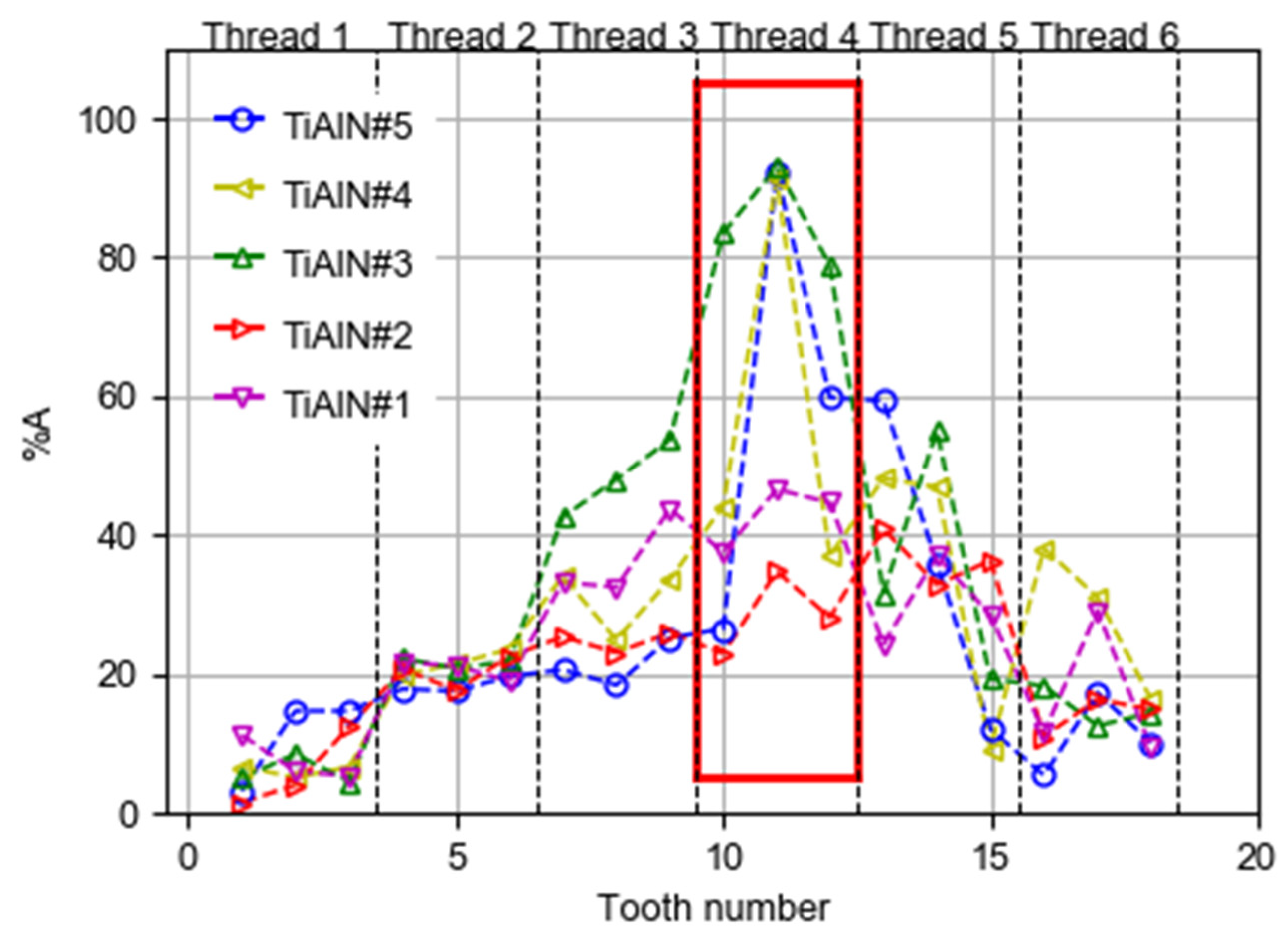

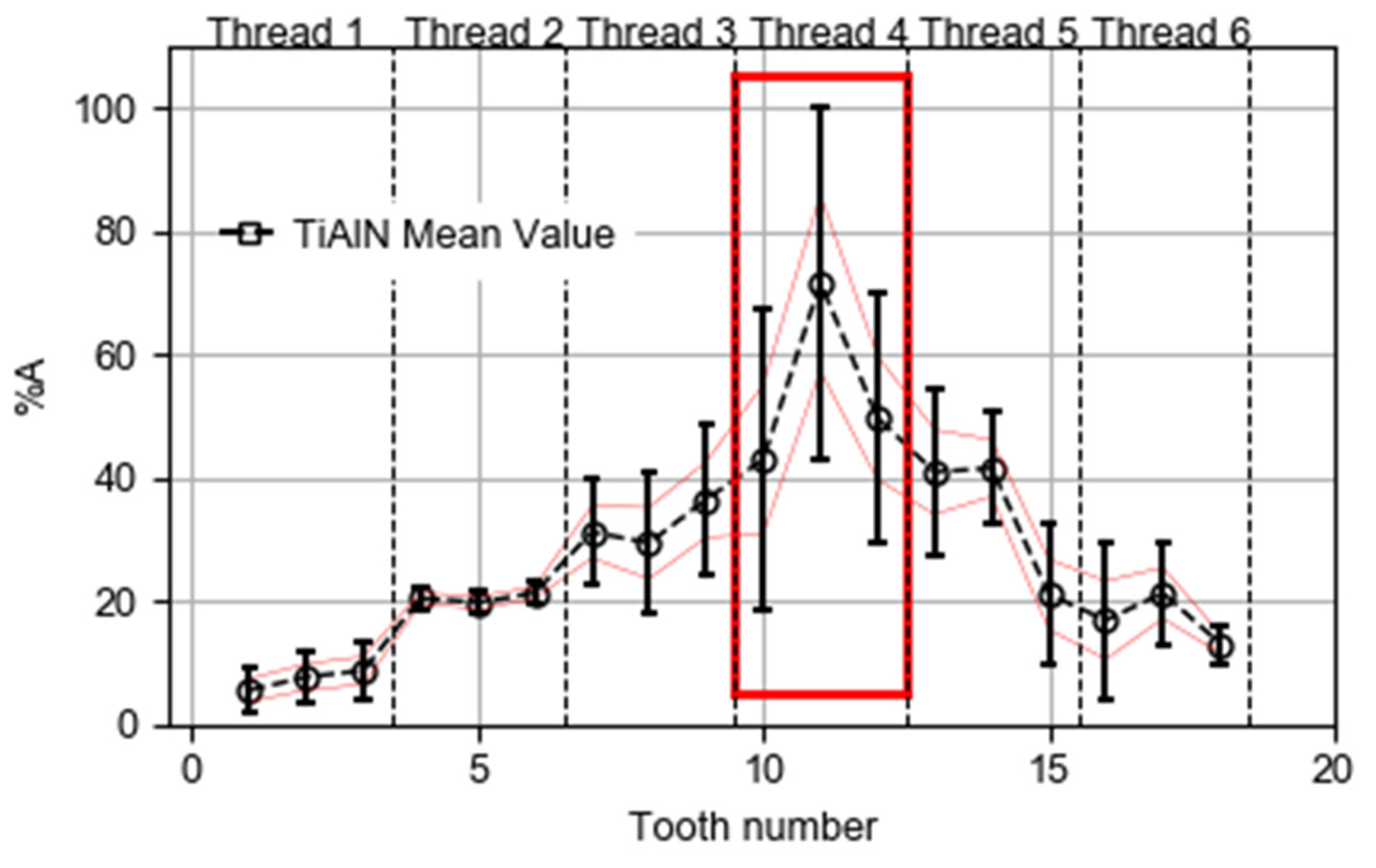

4.2. Discussion of Results on TiAlN Coated Taps

Figure 16 illustrates the different behaviors of %

A parameter for each tooth. Observing the similar wear shapes of all taps, the average wear profile is calculated to simplify the results.

Therefore,

Figure 10 shows the average %

A values of five taps with a 95% confidence interval.

Taking into account the wear profile values of uncoated taps in

Figure 15,

Figure 17 shows a similar behavior till the sixth tooth comparing with

Figure 15 because the average wear levels of teeth 1, 2, and 3 are close to the 10%, then the wear level increases up to 20% in tooth 4 and, finally, this value is maintained in teeth 5 and 6. Therefore, this behavior is similar in both taps. The same does not happen with the dispersion values that are clearly lower than those of the uncoated ones, observed in

Figure 15, especially those corresponding to thread 2. Continuing with the analysis, it is observed that between tooth 6 and 7 another increase happens until reaching a value greater than 30% and this value is maintained in tooth 8. In teeth 9 and 10, the values reach 35% and 40%, respectively. Therefore, the conical part of tap has roughly the same wear level independent of coating as can be seen in

Figure 13b.

In the conical-cylindrical part, the wear percentage reaches 40%, more than 50% and a maximum value of 65% in teeth 10, 11, and 12, respectively. Therefore, the increases are 30% and 25% from teeth 9 to 12 and from teeth 10 to 12, respectively. For these same uncoated teeth, the same parameter soared the value of 20%, 25%, and 100% in teeth 9, 10, and 12, respectively (see

Figure 15). That is, in the same interval of teeth, it presented increases of 80% and 75%, respectively, values much higher than those of 30% and 25% of TiAlN. Consequently, the TiAlN coating prevents the development of strong wear gradients detected in the uncoated taps.

On the other hand, this coating prevention on the finishing teeth is maintained along the cylindrical part of the tool because wear begins to decrease, more or less with the same slope with which it had been increasing and dispersions also decrease with respect to those of teeth 10, 11, and 12. In all uncoated teeth show a wear percentage of 100% and their dispersions are null because the Asp wear areas on these teeth are always higher than the Ap control area. It does not make sense therefore compare both coatings from edge 12 onwards.

However, the dispersion corresponding to the uncoating is much less than TiAlN coated taps (as can be seen by comparing

Figure 15 and

Figure 17). This strong dispersion implies a low reliability of the TiAlN coating, a problem well known to manufacturers of coated tools. This worse reliability is due to the high dispersion of the life values of the taps (

Table 2), to the influence through the decrease of %

A values from teeth 12 to 18 and to the gradients in the tap border teeth. Finally, there is also a striking low correlation between the number of threaded holes at the end of life and the overall wear area (

At) of the taps (area under the curve %

A-number of teeth), in other words, equal taps (of the same coatings) present, at the end of life, some quite different overall wear levels(see 1.3 versus 4.3 in

Table 2 and

Figure 15 and

Figure 17, respectively).

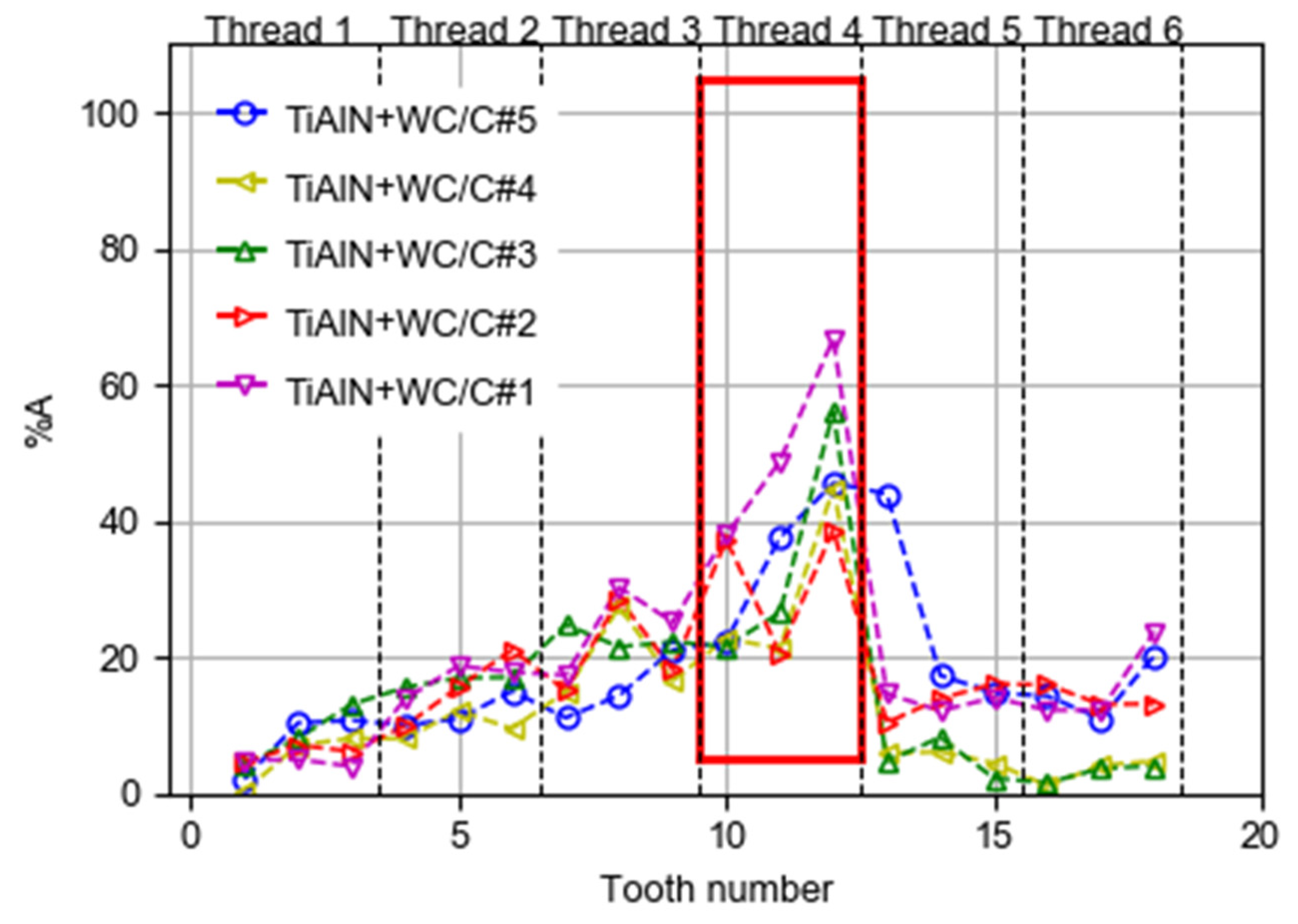

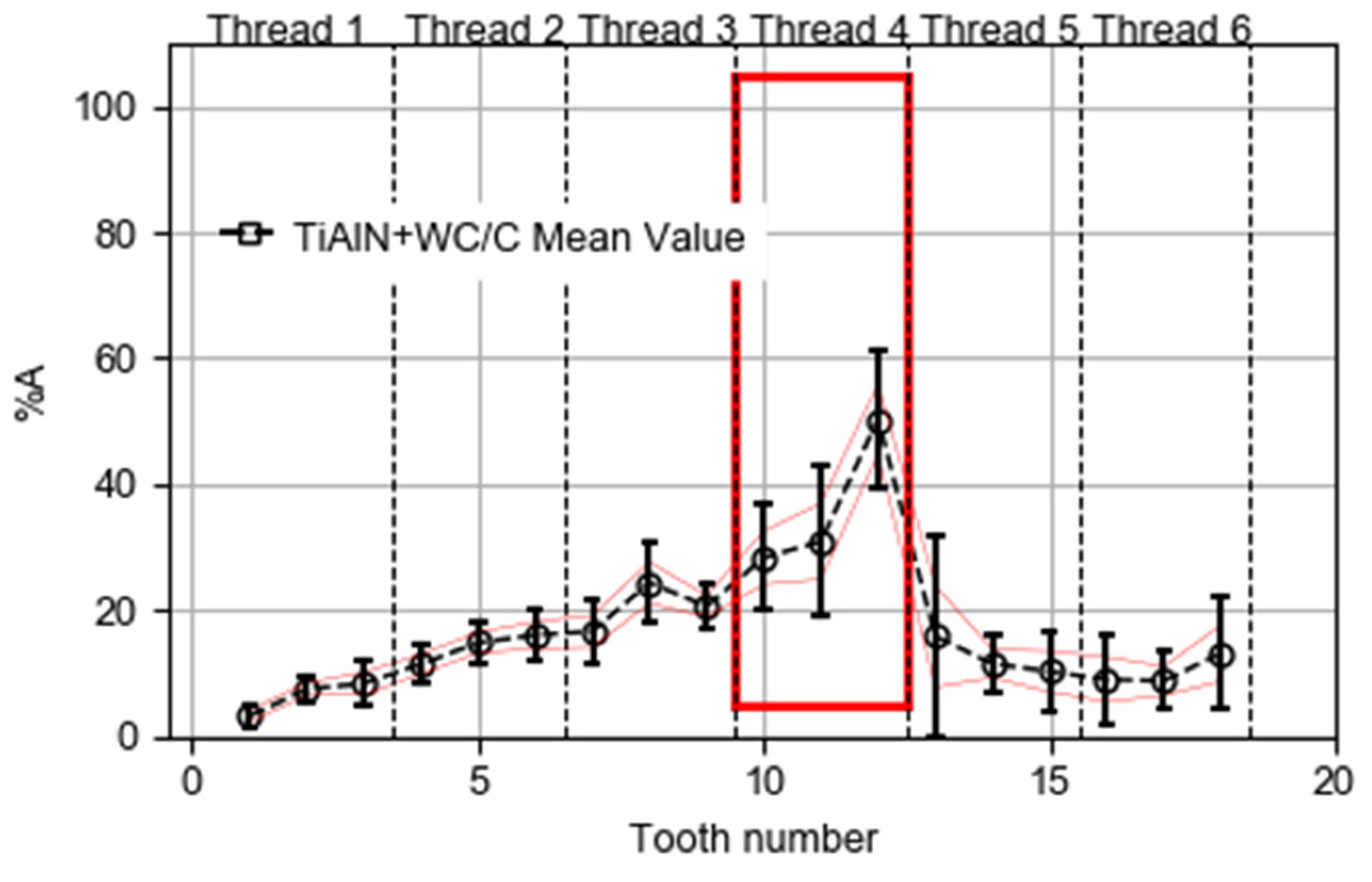

4.3. Discussion of Results on TiAlN+WC/C Coated Taps

Figure 11 illustrates the %

A parameter evolution for each tooth from the first tooth to the eighteenth one of the five taps studied.

Before starting the discussion of TiAlN+WC/C taps, the wear profiles of this coating are like previous ones. Therefore, the discussion is reasonably equal to the previous section when comparing this coating tap with uncoated one. This part focuses the study on comparing this coating with the previous one being the best tap tool according to the tool life and wear level.

To simplify the analysis,

Figure 18 shows the %

A average value of five tools with a 95% confidence interval.

As seen previously, the TiAlN+WC/C coating is, a priori, superior to the TiAlN, due to the addition of a WC/C layer that acts as a lubricant and to assess this superiority [

10], both will be compared below.

Firstly, an impressive difference is observed in behavior observing

Table 2, consequently, both types of taps reach the end of life defined by the torque value of 16 N-m having made a very different number of holes 272 and 326 coated with TiAlN+WC/C and TiAlN, respectively. This result states the addition of a layer of solid WC/C lubricant not only does not improve but also worsens the life of the tap and, consequently, this result contradicts the purpose that is sought with the contribution of the layer.

However, from the observation of

Figure 17 and

Figure 19, it is concluded that the average and dispersion of the %

A values of the TiAlN coating are much higher than TiAlN+WC/C one because the first one presents has not got the lubricant layer. This wear decrement is lower at edges seven through thirteen and, specially, at finishing teeth (cylindrical part).

Finally, the WC/C moves the maximum one tooth reduces the maximum peak of wear in 30%. Besides, the wear propagation is less in this coating along the finishing teeth.

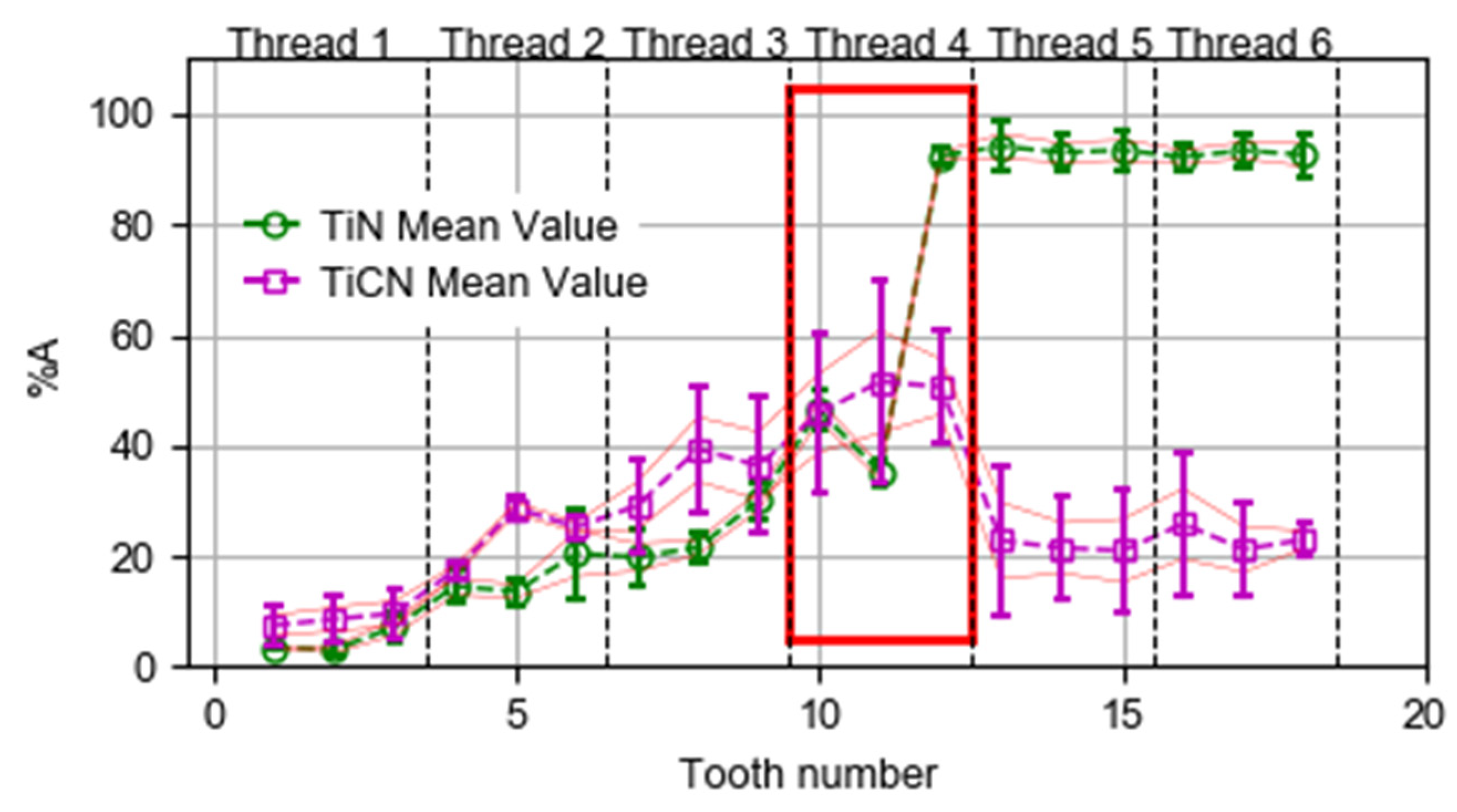

4.4. Discussion of Results on TiN and TiCN Coated Taps

In this subchapter a review of the results of mean wear area percentage %

A on TiCN and TiN coating taps is address.

Figure 20 shows the wear of the different tap tooth at the end of the tool life one it reaches the end of life criterion. The mean value of the 5 taps on TiCN and the 5 taps on TiN is shown. The wear behavior on the TiN taps is similar to the one observed on the uncoated tools (

Figure 15) but the 100% of wear is not observed at the cylindrical teeth. On the other hand, TiCN tools shown values closer to the ones observed at the TiAlN and TiAlN+WC/C as it can be concluded comparing

Figure 17 and

Figure 19 and

Figure 20.