Insight on Incorporation of Essential Oils as Antimicrobial Substances in Biopolymer-Based Active Packaging

Abstract

:1. Introduction

2. Emergence of Microbiological Contamination in the Food Industry

2.1. Presence of Bacteria in Food

2.2. Presence of Yeasts and Fungi in Food

2.3. The Main Problem Related to the Presence of Microorganisms in Food

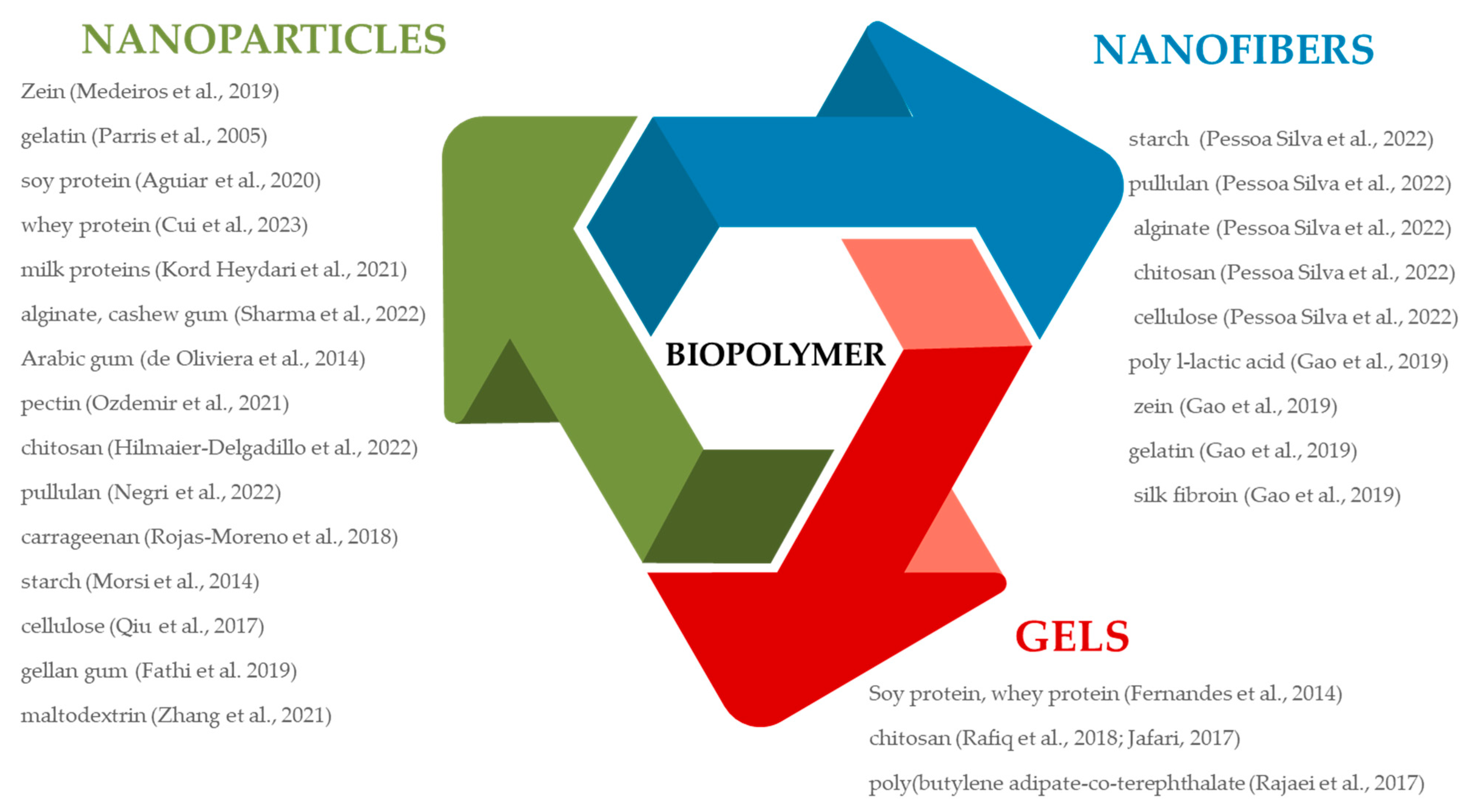

3. Biopolymer-Based Structures for Formation of Packaging Systems

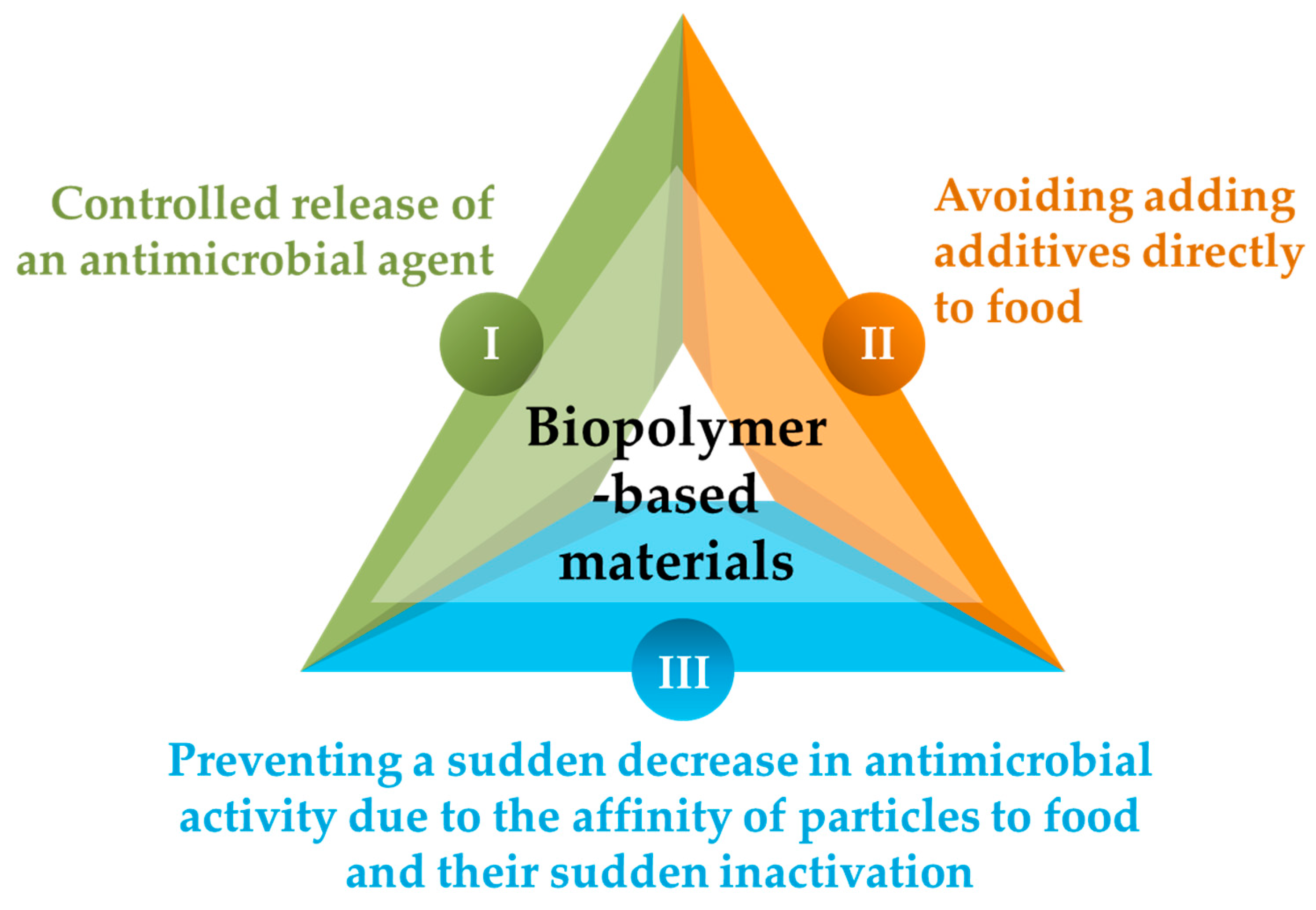

4. Antimicrobial Packaging as Control of Microbiological Activity in Food

5. Incorporation of Essential Oil as the Antimicrobial Substance in the Biopolymer Matrix

5.1. Direct Incorporation

5.2. Emulsification

5.3. Liposomes Formation

6. Migration of the Antimicrobial Substance into the Packaging System

- Diffusion of the substance from the packaging matrix;

- Desorption from the matrix surface;

- Sorption of the substance in the contact space;

- Desorption into food.

7. The Influence of the Packaging System on the Inactivation of Microbiological Contamination

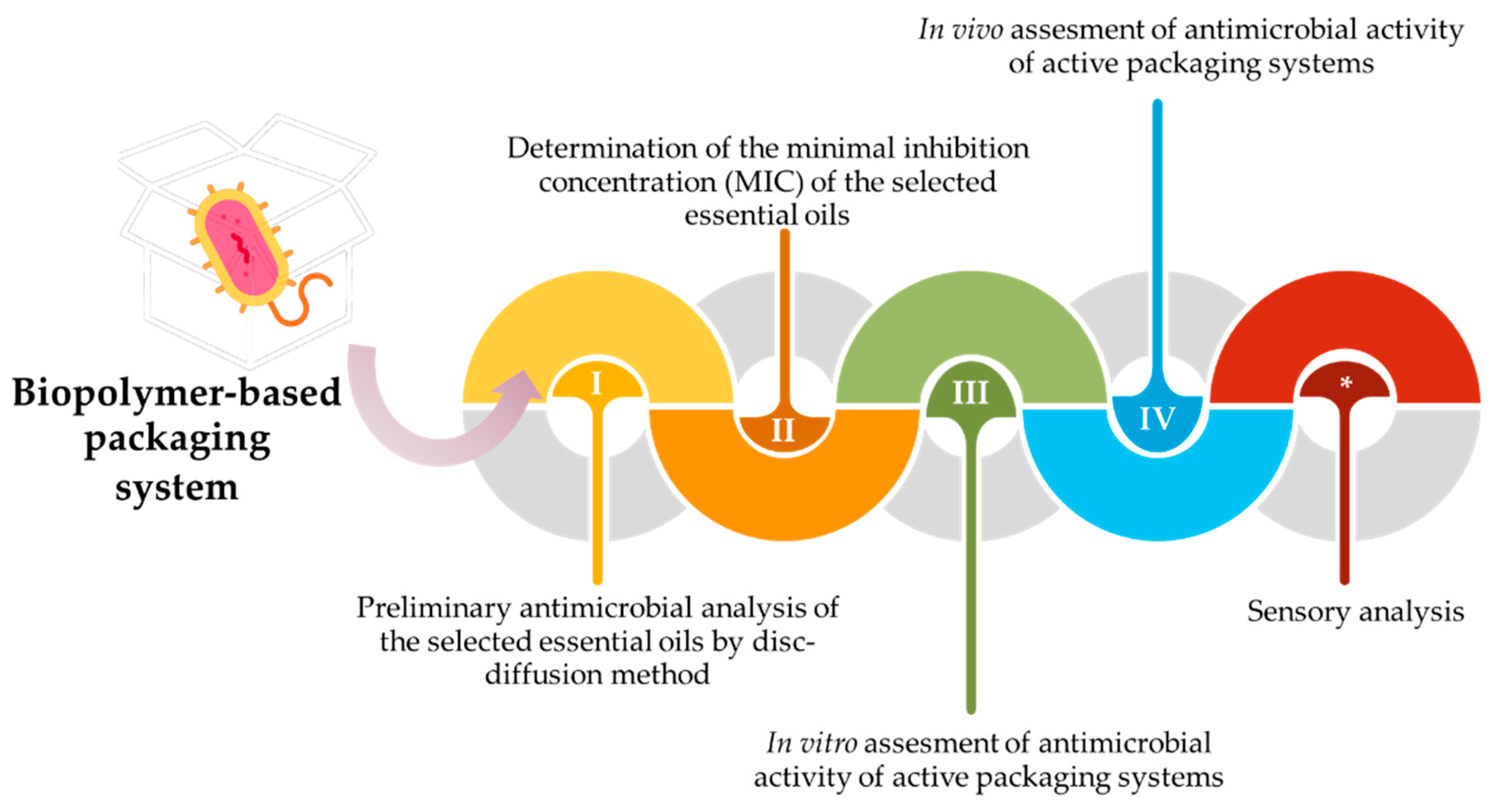

8. Proposal for Comprehensive Determination of Antimicrobial Potential of Biopolymer-Based Active Packaging with Incorporated Essential Oils

- Preliminary antimicrobial analysis of the selected essential oils by disc-diffusion method;

- Determination of the minimal inhibition concentration (MIC) of the selected essential oils;

- In vitro assessment of the antimicrobial activity of active packaging systems;

- In vivo assessment of the antimicrobial activity of active packaging systems;

- Sensory analysis.

- Difference Test—determine if there are detectable differences between food samples packaged with and without active ingredients;

- Descriptive Analysis—evaluate specific sensory attributes (e.g., taste, odor, texture) and quantify the intensity of these attributes using a trained panel;

- Consumer Acceptance Test—Assess consumer preferences and overall acceptance of the food products with active packaging systems compared to controls.

9. Conclusions and Future Perspectives for Real Application

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar, R.; Verma, A.; Shome, A.; Sinha, R.; Sinha, S.; Jha, P.K.; Kumar, R.; Kumar, P.; Shubham; Das, S.; et al. Impacts of Plastic Pollution on Ecosystem Services, Sustainable Development Goals, and Need to Focus on Circular Economy and Policy Interventions. Sustainability 2021, 13, 9963. [Google Scholar] [CrossRef]

- Nielsen, T.D.; Hasselbalch, J.; Holmberg, K.; Stripple, J. Politics and the plastic crisis: A review throughout the plastic life cycle. Wiley Interdiscip. Rev. Energy Environ. 2020, 9, e360. [Google Scholar] [CrossRef]

- Mangaraj, S.; Yadav, A.; Bal, L.M.; Dash, S.K.; Mahanti, N.K. Application of Biodegradable Polymers in Food Packaging Industry: A Comprehensive Review. J. Package Technol. Res. 2019, 3, 77–96. [Google Scholar] [CrossRef]

- Alizadeh-Sani, M.; Khezerlou, A.; Ehsani, A. Fabrication and characterization of the bionanocomposite film based on whey protein biopolymer loaded with TiO2 nanoparticles, cellulose nanofibers and rosemary essential oil. Ind. Crop. Prod. 2018, 124, 300–315. [Google Scholar] [CrossRef]

- Ishangulyyev, R.; Kim, S.; Lee, S.H. Understanding Food Loss and Waste—Why Are We Losing and Wasting Food? Foods 2019, 8, 297. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Yang, X.; Deng, H.; Guo, Y.; Xue, J. Gelatin films incorporated with thymol nanoemulsions: Physical properties and an-timicrobial activities. Int. J. Biol. Macromol. 2020, 150, 161–168. [Google Scholar] [CrossRef]

- Zubair, M.; Shahzad, S.; Hussain, A.; Pradhan, R.A.; Arshad, M.; Ullah, A. Current Trends in the Utilization of Essential Oils for Polysaccharide- and Protein-Derived Food Packaging Materials. Polymers 2022, 14, 1146. [Google Scholar] [CrossRef]

- Newell, D.G.; Koopmans, M.; Verhoef, L.; Duizer, E.; Aidara-Kane, A.; Sprong, H.; Opsteegh, M.; Langelaar, M.; Threfall, J.; Scheutz, F.; et al. Food-borne diseases—The challenges of 20 years ago still persist while new ones continue to emerge. Int. J. Food Microbiol. 2010, 139, S3–S15. [Google Scholar] [CrossRef]

- Cantas, L.; Suer, K. The Important Bacterial Zoonoses in “One Health” Concept. Front. Public Health 2014, 2, 144. [Google Scholar] [CrossRef]

- Rahman, M.T.; Sobur, M.A.; Islam, M.S.; Ievy, S.; Hossain, M.J.; El Zowalaty, M.E.; Rahman, A.T.; Ashour, H.M. Zoonotic Diseases: Etiology, Impact, and Control. Microorganisms 2020, 8, 1405. [Google Scholar] [CrossRef]

- Dowling, A.; O’Dwyer, J.; Adler, C. Alternatives to antibiotics-future trends. In Microbial Pathogens and Strategies for Combating then: Science, Technology and Education; Microbiology Book Series; Formatex Research Center: Badajoz, Spain, 2013; pp. 216–226. [Google Scholar]

- Bazy, M.B.; Hoffmann, S.; Moris, J.G. Ranking the Disease Burden of 14 Pathogens in Food Sources in the United States Using Attribution Data from Outbreak Investigations and Expert Elicitation. J. Food Prot. 2012, 75, 1278–1291. [Google Scholar]

- Johnson, N.B.; Hayes, L.D.; Brown, K.; Hoo, E.C.; Ethier, K.A. CDC National Health Report: Leading Causes of Morbidity and Mortality and Associated Behavioral Risk and Protective Factors—United States, 2005–2013; MMWR Suppl.; Centers for Disease Control and Prevention (CDC): Atlanta, GA, USA, 2014; Volume 63, pp. 3–27.

- FDA. Foodborne Illness-Causing Organisms in the U.S. Factsheet. 2015. Available online: http://www.fda.gov/downloads/Food/FoodborneIllnessContaminants/UCM187482.pdf (accessed on 25 December 2022).

- Karl, R.; Matthews, K.E.; Montville, T.J. Food Microbiology: An Introduction, 4th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Cvetković, D.; Markov, S.; Ranitović, A. Mikrobiološka Kontrola Bioprocesa, Praktikum ZA Studente Tehnološkog Fakulteta Novi Sad; Tehnološki fakultet Novi Sad, Univerzitet u Novom Sadu: Novi Sad, Srbija, 2017. [Google Scholar]

- Markov, S. Mikrobiologija, Udžbenik ZA Studente Tehnološkog Fakulteta Novi Sad; Tehnološki fakultet Novi Sad, Univerzitet u Novom Sadu: Novi Sad, Srbija, 2012. [Google Scholar]

- Caya, J.G. Clostridium botulinum and the Ophthalmologist: A Review of Botulism, Including Biological Warfare Ramifications of Botulinum Toxin. Surv. Ophthalmol. 2001, 46, 25–34. [Google Scholar] [CrossRef]

- Meloni, D.; Consolati, S.G.; Mazza, R.; Mureddu, A.; Fois, F.; Piras, F.; Mazzette, R. Presence and molecular characterization of the major serovars of Listeria monocytogenes in ten Sardinian fermented sausage processing plants. Meat Sci. 2014, 97, 443–450. [Google Scholar] [CrossRef] [PubMed]

- Deacon, J. Fungal Biology, 4th ed.; Blackwell Publishing: Malden, MA, USA, 2006; ISBN 10:1-4051-3066-0. [Google Scholar]

- Pitt, J.I.; Hocking, A.D. Fungi and Food Spoilage, 3rd ed.; Springer: Boston, MA, USA, 2009; ISBN 978-0-387-92206-5. [Google Scholar]

- Wyatt, T.T.; Wösten, H.A.; Dijksterhuis, J. Fungal Spores for Dispersion in Space and Time. Adv. Appl. Microbiol. 2013, 85, 43–91. [Google Scholar] [CrossRef] [PubMed]

- Sofi, S.; Singh, J.; Rafiq, S.; Ashraf, U.; Dar, B.; Nayik, G.A. A Comprehensive Review on Antimicrobial Packaging and its Use in Food Packaging. Curr. Nutr. Food Sci. 2018, 14, 305–312. [Google Scholar] [CrossRef]

- White, D.G.; Zhao, S.; Simjee, S.; Wagner, D.D.; McDermott, P.F. Antimicrobial resistance of foodborne pathogens. Microbes Infect. 2002, 4, 405–412. [Google Scholar] [CrossRef] [PubMed]

- Lynch, M.F.; Tauxe, R.V.; Hedberg, C.W. The growing burden of foodborne outbreaks due to contaminated fresh produce: Risks and opportunities. Epidemiol. Infect. 2009, 137, 307–315. [Google Scholar] [CrossRef] [PubMed]

- Karaman, R.; Jubeh, B.; Breijyeh, Z. Resistance of Gram-Positive Bacteria to Current Antibacterial Agents and Overcoming Approaches. Molecules 2020, 25, 2888. [Google Scholar] [CrossRef]

- Contreras, C.B.; Charles, G.; Toselli, R.; Strumia, M.C. Antimicrobial Active Packaging. In Biopackaging; CRC Press: Boca Raton, FL, USA, 2009; ISBN 9781315152349. [Google Scholar]

- Dybka-Stępień, K.; Antolak, H.; Kmiotek, M.; Piechota, D.; Koziróg, A. Disposable Food Packaging and Serving Materials—Trends and Biodegradability. Polymers 2021, 13, 3606. [Google Scholar] [CrossRef]

- Wang, X.; Ma, L.; Yan, S.; Chen, X.; Growe, A. Trade for Food Security: The Stability of Global Agricultural Trade Networks. Foods 2023, 12, 271. [Google Scholar] [CrossRef]

- Suvarna, V.; Nair, A.; Mallya, R.; Khan, T.; Omri, A. Antimicrobial Nanomaterials for Food Packaging. Antibiotics 2022, 11, 729. [Google Scholar] [CrossRef] [PubMed]

- Travičić, V.; Cvanić, T.; Cetković, G. Plant-Based Nano-Emulsions as Edible Coatings in the Extension of Fruits and Vegetables Shelf Life: A Patent Review. Foods 2023, 12, 2535. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Z.; Liu, W.; Zhu, G.; Zhou, R.; Niu, Y. Production and characterization of multinuclear microcapsules encapsulating lavender oil by complex coacervation. Flavour. Fragr. J. 2014, 29, 166–172. [Google Scholar] [CrossRef]

- Chen, M.; Hu, Y.; Zhou, J.; Xie, Y.; Wu, H.; Yuan, T.; Yang, Z. Facile fabrication of tea tree oil-loaded antibacterial microcapsules by complex coacervation of sodium alginate/quaternary ammonium salt of chitosan. RSC Adv. 2016, 6, 13032–13039. [Google Scholar] [CrossRef]

- de Matos, E.F.; Scopel, B.S.; Dettmer, A. Citronella essential oil microencapsulation by complex coacervation with leather waste gelatin and sodium alginate. J. Environ. Chem. Eng. 2018, 6, 1989–1994. [Google Scholar] [CrossRef]

- Koupantsis, T.; Paraskevopoulou, A. Flavor retention in sodium caseinate—Carboxymethylcellulose complex coacervates as a function of storage conditions. Food Hydrocoll. 2017, 69, 459–465. [Google Scholar] [CrossRef]

- Rojas-Moreno, S.; Osorio-Revilla, G.; Gallardo-Velázquez, T.; Cárdenas-Bailón, F.; Meza-Márquez, G. Effect of the cross-linking agent and drying method on encapsulation efficiency of orange essential oil by complex coacervation using whey protein isolate with different polysaccharides. J. Microencapsul. 2018, 35, 165–180. [Google Scholar] [CrossRef]

- Rojas-Moreno, S.; Cardenas-Bailon, F.; Osorio-Revilla, G.; Gallardo Velazquez, T.; Proal-Najera, J. Effects of complex coacer-vation-spray drying and conventional spray drying on the quality of microencapsulated orange essential oil. J. Food Meas. Charact. 2018, 12, 650–660. [Google Scholar] [CrossRef]

- Dima, C.; Cotârlet, M.; Alexe, P.; Dima, S. Microencapsulation of essential oil of pimento [Pimenta dioica (L.) Merr.] by chitosan/k-carrageenan complex coacervation method. Innov. Food Sci. Emerg. Technol. 2014, 22, 203–211. [Google Scholar] [CrossRef]

- Shen, L.; Chen, J.; Bai, Y.; Ma, Z.; Huang, J.; Feng, W. Physical Properties and Stabilization of Microcapsules Containing Thyme Oil by Complex Coacervation. J. Food Sci. 2016, 81, N2258–N2262. [Google Scholar] [CrossRef]

- Ban, Z.; Zhang, J.; Li, L.; Luo, Z.; Wang, Y.; Yuan, Q.; Zhou, B.; Liu, H. Ginger essential oil-based microencapsulation as an efficient delivery system for the improvement of Jujube (Ziziphus jujuba Mill.) fruit quality. Food Chem. 2020, 306, 125628. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Peng, Z.; Li, J.; Li, S.; Kong, L.; Li, P.; Wang, Q. Development and evaluation of novel flavor microcapsules containing vanilla oil using a complex coacervation approach. Food Chem. 2014, 145, 272–277. [Google Scholar] [CrossRef]

- Lin, L.; Gu, Y.; Cui, H. Moringa oil/chitosan nanoparticles embedded gelatin nanofibers for food packaging against Listeria monocytogenes and Staphylococcus aureus on cheese. Food Packag. Shelf Life 2019, 19, 86–93. [Google Scholar] [CrossRef]

- Lin, L.; Mao, X.; Sun, Y.; Rajivgandhi, G.; Cui, H. Antibacterial properties of nanofibers containing chrysanthemum essential oil and their application as beef packaging. Int. J. Food Microbiol. 2019, 292, 21–30. [Google Scholar] [CrossRef] [PubMed]

- Vafania, B.; Fathi, M.; Soleimanian-Zad, S. Nanoencapsulation of thyme essential oil in chitosan-gelatin nanofibers by noz-zle-less electrospinning and their application to reduce nitrite in sausages. Food Bioprod. Process 2019, 116, 240–248. [Google Scholar] [CrossRef]

- Göksen, G.; Fabra, M.J.; Ekiz, H.I.; López-Rubio, A. Phytochemical-loaded electrospun nanofibers as novel active edible films: Characterization and antibacterial efficiency in cheese slices. Food Control. 2020, 112, 107133. [Google Scholar] [CrossRef]

- Ghayempour, S.; Montazer, M. A novel controlled release system based on Tragacanth nanofibers loaded Peppermint oil. Carbohydr. Polym. 2019, 205, 589–595. [Google Scholar] [CrossRef]

- Rafiq, M.; Hussain, T.; Abid, S.; Nazir, A.; Masood, R. Development of sodium alginate/PVA antibacterial nanofibers by the incorporation of essential oils. Mater. Res. Express 2018, 5, 035007. [Google Scholar] [CrossRef]

- Jafari, S.M. Nanoencapsulation Technologies for the Food and Nutraceutical Industries; Academic Press: Cambridge, MA, USA, 2017; pp. 1–34. [Google Scholar]

- Rajaei, A.; Hadian, M.; Mohsenifar, A.; Rahmani-Cherati, T.; Tabatabaei, M. A coating based on clove essential oils encapsu-lated by chitosan-myristic acid nanogel efficiently enhanced the shelf-life of beef cutlets. Food Packag. Shelf Life 2017, 14, 137–145. [Google Scholar] [CrossRef]

- Medeiros, J.; Blick, A.; Galindo, M.; Alvim, I.; Yamashita, F.; Ueno, C.; Shirai, M.; Grosso, C.; Corradini, E.; Sakanaka, L. In-corporation of Oregano Essential Oil Microcapsules in Starch-Poly (Butylene Adipate Co-Terephthalate) (PBAT) Films. Mac-Romol Symp. 2019, 383, 1800052. [Google Scholar] [CrossRef]

- Parris, N.; Cooke, P.H.; Hicks, K.B. Encapsulation of Essential Oils in Zein Nanospherical Particles. J. Agric. Food Chem. 2005, 53, 4788–4792. [Google Scholar] [CrossRef] [PubMed]

- Aguiar, M.C.S.; das Gracas Fernandes da Silva, M.F.; Fernandes, J.B.; Forim, M.R. Evaluation of the microencapsulation of orange essential oil in biopolymers by using a spray-drying process. Sci. Rep. 2020, 10, 11799. [Google Scholar] [CrossRef] [PubMed]

- Cui, H.; Xu, R.; Hu, W.; Li, C.; Abdel-Samie, M.A.; Lin, L. Effect of soy protein isolate nanoparticles loaded with litsea cubeba essential oil on performance of lentinan edible films. Int. J. Biol. Macromol. 2023, 242, 124686. [Google Scholar] [CrossRef] [PubMed]

- Kord Heydari, M.; Assadpour, E.; Jafari, S.M.; Javadian, H. Encapsulation of rose essential oil using whey protein concen-trate-pectin nanocomplexes: Optimization of the effective parameters. Food Chem. 2021, 356, 129731. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Mulrey, L.; Byrne, M.; Jaiswal, A.K.; Jaiswal, S. Encapsulation of Essential Oils in Nanocarriers for Active Food Packaging. Foods 2022, 11, 2337. [Google Scholar] [CrossRef]

- de Oliveira, E.F.; Paula, H.C.; de Paula, R.C. Alginate/cashew gum nanoparticles for essential oil encapsulation. Colloids Surf. B 2014, 113, 146–151. [Google Scholar] [CrossRef]

- Ozdemir, N.; Bayrak, A.; Tat, T.; Altay, F.; Kiralan, M.; Kurt, A. Microencapsulation of basil essential oil: Utilization of gum arabic/whey protein iso-late/maltodextrin combinations for encapsulation efficiency and in vitro release. Food Meas. 2021, 15, 1865–1876. [Google Scholar] [CrossRef]

- Hilmaier-Delgadillo, F.; Lara-Espinoza, C.L.; Félix-Arias, K.G.; Gomeztagle-Romero, M.Z.; Gomez-Rodriguez, G.H.; Sánchez-Villegas, J.A.; Rascón-Chu, A. Pectin nanoparticles: Fabrication and uses 2022. In Polysaccharide Nanoparticles; Venkatesan, J., Kim, S.-K., Anil, S., Sukumaran Anil, R.P.D., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 163–201. [Google Scholar]

- Negi, A.; Kesari, K.K. Chitosan Nanoparticle Encapsulation of Antibacterial Essential Oils. Micromachines 2022, 13, 1265. [Google Scholar] [CrossRef]

- Morsy, M.K.; Khalaf, H.H.; Sharoba, A.M.; El-Tanahi, H.H.; Cutter, C.N. Incorporation of Essential Oils and Nanoparticles in Pullulan Films to Control Foodborne Pathogens on Meat and Poultry Products. J. Food Sci. 2014, 79, M675–M684. [Google Scholar] [CrossRef]

- Qiu, C.; Chang, R.; Yang, J.; Ge, S.; Xiong, L.; Zhao, M.; Li, M.; Sun, Q. Preparation and characterization of essential oil-loaded starch nanoparticles formed by short glucan chains. Food Chem. 2017, 221, 1426–1433. [Google Scholar] [CrossRef]

- Fathi, M.; Karim, M.; Ahmadi, N. Nanostructures of cellulose for encapsulation of food ingredients. In Nanoencapsulation in the Food Industry: Biopolymer Nanostructures for Food Encapsulation Purposes; Jafari, S.M., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 493–519. [Google Scholar]

- Zhang, X.; Liu, D.; Jin, T.Z.; Chen, W.; He, Q.; Zou, Z.; Zhao, H.; Ye, X.; Guo, M. Preparation and characterization of gellan gum-chitosan polyelectrolyte complex films with the incorporation of thyme essential oil nanoemulsion. Food Hydrocoll. 2021, 114, 106570. [Google Scholar] [CrossRef]

- Fernandes, R.V.d.B.; Silva, E.K.; Borges, S.V.; de Oliveira, C.R.; Yoshida, M.I.; da Silva, Y.F.; do Carmo, E.L.; Azevedo, V.M.; Botrel, D.A. Proposing Novel Encapsulating Matrices for Spray-Dried Ginger Essential Oil from the Whey Protein Isolate-Inulin/Maltodextrin Blends. Food Bioprocess. Technol. 2017, 10, 115–130. [Google Scholar] [CrossRef]

- Pessoa Silva, M.; Fabi, J.P. Food biopolymers-derived nanogels for encapsulation and delivery of biologically active compounds: A perspective review. Food Hydrocoll. Health 2022, 2, 100079. [Google Scholar] [CrossRef]

- Gao, X.; Han, S.; Zhang, R.; Liu, G.; Wu, J. Progress in electrospun composite nanofibers: Composition, performance and applications for tissue engineering. J. Mater. Chem. B 2019, 7, 7075–7089. [Google Scholar] [CrossRef]

- Min, T.; Zhou, L.; Sun, X.; Du, H.; Zhu, Z.; Wen, Y. Electrospun functional polymeric nanofibers for active food packaging: A review. Food Chem. 2022, 391, 133239. [Google Scholar] [CrossRef]

- Nath, D.; Santhosh, R.; Pal, K.; Sarkar, P. Nanoclay-based active food packaging systems: A review. Food Packag. Shelf Life 2022, 31, 100803. [Google Scholar] [CrossRef]

- Bahrami, A.; Delshadi, R.; Assadpour, E.; Jafari, S.M.; Williams, L. Antimicrobial-loaded nanocarriers for food packaging applications. Adv. Colloid. Interface Sci. 2020, 278, 102140. [Google Scholar] [CrossRef]

- Adel, A.M.; Ibrahim, A.A.; El-Shafei, A.M.; Al-Shemy, M.T. Inclusion complex of clove oil with chitosan/β-cyclodextrin citrate/oxidized nanocellulose biocomposite for active food packaging. Food Packag. Shelf Life 2019, 20, 100307. [Google Scholar] [CrossRef]

- Erceg, T.; Šovljanski, O.; Stupar, A.; Ugarković, J.; Aćimović, M.; Pezo, L.; Tomić, A.; Todosijević, M. A comprehensive approach to chitosan-gelatine edible coating with β-cyclodextrin/lemongrass essential oil inclusion complex—Characterization and food application. Int. J. Biol. Macromol. 2022, 228, 400–410. [Google Scholar] [CrossRef]

- Celebioglu, A.; Yildiz, Z.I.; Uyar, T. Thymol/cyclodextrin inclusion complex nanofibrous webs: Enhanced water solubility, high thermal stability and antioxidant property of thymol. Food Res. Int. 2018, 106, 280–290. [Google Scholar] [CrossRef]

- Duda-Chodak, A.; Tarko, T.; Petka-Poniatowska, K. Antimicrobial Compounds in Food Packaging. Int J Mol Sci. 2023, 24, 2457. [Google Scholar] [CrossRef]

- Sung, S.-Y.; Sin, L.T.; Tee, T.-T.; Bee, S.-T.; Rahmat, A.; Rahman, W.; Tan, A.-C.; Vikhraman, M. Antimicrobial agents for food packaging applications. Trends Food Sci. Technol. 2013, 33, 110–123. [Google Scholar] [CrossRef]

- Siracusa, V. Packaging Material in the Food Industry. In Antimicrobial Food Packaging; Academic Press: Cambridge, MA, USA, 2016; pp. 95–106. [Google Scholar] [CrossRef]

- Tongnuanchan, P.; Benjakul, S. Essential Oils: Extraction, Bioactivities, and Their Uses for Food Preservation. J. Food Sci. 2014, 79, R1231–R1249. [Google Scholar] [CrossRef] [PubMed]

- Masango, P. Cleaner production of essential oils by steam distillation. J. Clean. Prod. 2005, 13, 833–839. [Google Scholar] [CrossRef]

- Dhifi, W.; Bellili, S.; Jazi, S.; Bahloul, N.; Mnif, W. Essential Oils’ Chemical Characterization and Investigation of Some Biological Activities: A Critical Review. Medicines 2016, 3, 25. [Google Scholar] [CrossRef]

- Krepker, M.; Shemesh, R.; Poleg, Y.D.; Kashi, Y.; Vaxman, A.; Segal, E. Active food packaging films with synergistic antimi-crobial activity. Food Control 2017, 76, 117–126. [Google Scholar] [CrossRef]

- Erceg, T.; Vukić, N.; Teofilović, V.; Baloš, S.; Stupar, A.; Šovljanski, O. Optimisation of the applicative properties of biodegradable cellulose acetate-based films using the principles of green chemistry. In Proceedings of the STED Conference, Trebinje, Bosnia and Herzegovina, 2–5 June 2022. [Google Scholar]

- Da Silva Dannenberg, G.; Funck, G.D.; dos Santos Cruxen, C.; Marques, J.D.L.; da Silva, W.P.; Fiorentini, M. Essential oil from pink pepper as an antimicrobial component in cellulose acetate film: Potential for application as active packaging for sliced cheese. LWT Food Sci. Technol. 2017, 81, 314–318. [Google Scholar] [CrossRef]

- Erceg, T.; Vukić, N.; Šovljanski, O.; Stupar, A.; Šergelj, V.; Aćimović, M.; Baloš, S.; Ugarković, J.; Šuput, D.; Popović, S.; et al. Characterization of Films Based on Cellulose Acetate/Poly(caprolactone diol) Intended for Active Packaging Prepared by Green Chemistry Principles. ACS Sustain. Chem. Eng. 2022, 10, 9141–9154. [Google Scholar] [CrossRef]

- Qin, Y.; Li, W.; Liu, D.; Yuan, M.; Li, L. Development of active packaging film made from poly (lactic acid) incorporated es-sential oil. Prog. Org. Coat. 2016, 103, 76–82. [Google Scholar] [CrossRef]

- Silveira, M.P.; Silva, H.C.; Pimentel, I.C.; Poitevin, C.G.; Stuart, A.K.d.C.; Carpiné, D.; Jorge, L.M.d.M.; Jorge, R.M.M. Development of active cassava starch cellulose nanofiber-based films incorporated with natural antimicrobial tea tree essential oil. J. Appl. Polym. Sci. 2020, 137, 48726. [Google Scholar] [CrossRef]

- Arezooa, E.; Mohammadrezaa, E.; Maryama, M.; Nafchi Abdorreza, M. The synergistic effects of cinnamon essential oil and nano TiO2 on antimicrobial and functional properties of sago starch films. Int. J. Biol. Macromol. 2020, 157, 743–751. [Google Scholar] [CrossRef] [PubMed]

- Perdana, M.I.; Ruamcharoen, J.; Panphon, S.; Leelakriangsak, M. Antimicrobial activity and physical properties of starch/chitosan film incorporated with lemongrass essential oil and its application. LWT 2021, 141, 110934. [Google Scholar] [CrossRef]

- Handayasari, F.; Suyatma, N.E.; Nurjanah, S. Physiochemical and antibacterial analysis of gelatin–chitosan edible film with the addition of nitrite and garlic essential oil by response surface methodology. J. Food Process. Preserv. 2019, 43, e14265. [Google Scholar] [CrossRef]

- Saavedra, S.C.; Ventura-Aguilar, R.I.; Bautista-Baños, S.; Barrera-Necha, L.L. Biodegradable chitosan coating for improving quality and controlling Alternaria alternata growth in figs. World J. Adv. Res. Rev. 2020, 7, 115–125. [Google Scholar] [CrossRef]

- Socaciu, M.-I.; Fogarasi, M.; Semeniuc, C.A.; Socaci, S.A.; Rotar, M.A.; Mureşan, V.; Pop, O.L.; Vodnar, D.C. Formulation and Characterization of Antimicrobial Edible Films Based on Whey Protein Isolate and Tarragon Essential Oil. Polymers 2020, 12, 1748. [Google Scholar] [CrossRef]

- Donsì, F.; Ferrari, G. Essential oil nanoemulsions as antimicrobial agents in food. J. Biotechnol. 2016, 233, 106–120. [Google Scholar] [CrossRef] [PubMed]

- Ejaz, M.; Arfat, Y.A.; Mulla, M.; Ahmed, J. Zinc oxide nanorods/clove essential oil incorporated Type B gelatin composite films and its applicability for shrimp packaging. Food Packag. Shelf Life 2018, 15, 113–121. [Google Scholar] [CrossRef]

- Tongnuanchan, P.; Benjakul, S.; Prodpran, T. Structural, morphological and thermal behaviour characterisations of fish gelatin film incorporated with basil and citronella essential oils as affected by surfactants. Food Hydrocoll. 2014, 41, 33–43. [Google Scholar] [CrossRef]

- Wu, J.; Ge, S.; Liu, H.; Wang, S.; Chen, S.; Wang, J.; Li, J.; Zhang, Q. Properties and antimicrobial activity of silver carp (Hypophthalmichthys molitrix) skin gelatin-chitosan films incorporated with oregano essential oil for fish preservation. Food Packag. Shelf Life 2014, 2, 7–16. [Google Scholar] [CrossRef]

- Peng, Y.; Yin, L.; Li, Y. Combined effects of lemon essential oil and surfactants on physical and structural properties of chitosan films. Int. J. Food Sci. Technol. 2013, 48, 44–50. [Google Scholar] [CrossRef]

- Noshirvani, N.; Ghanbarzadeh, B.; Gardrat, C.; Rezaei, M.R.; Hashemi, M.; Le Coz, C.; Coma, V. Cinnamon and ginger essential oils to improve antifungal, physical and mechanical properties of chitosan-carboxymethyl cellulose films. Food Hydrocoll. 2017, 70, 36–45. [Google Scholar] [CrossRef]

- Biswas, A.; Furtado, R.F.; Bastos, M.d.S.R.; Benevides, S.D.; Oliveira, M.; Boddu, V.; Cheng, H. Preparation and characteri-zation of carboxymethyl cellulose films with embedded essential oils. J. Mater. Sci. Res. 2018, 7, 16–25. [Google Scholar]

- Han, Y.; Yu, M.; Wang, L. Physical and antimicrobial properties of sodium alginate/carboxymethyl cellulose films incorporated with cinnamon essential oil. Food Packag. Shelf Life 2018, 15, 35–42. [Google Scholar] [CrossRef]

- Otoni, C.G.; Pontes, S.F.O.; Medeiros, E.A.A.; Soares, N.d.F.F. Edible Films from Methylcellulose and Nanoemulsions of Clove Bud (Syzygium aromaticum) and Oregano (Origanum vulgare) Essential Oils as Shelf Life Extenders for Sliced Bread. J. Agric. Food Chem. 2014, 62, 5214–5219. [Google Scholar] [CrossRef]

- Kouravand, F.; Jooyandeh, H.; Barzegar, H.; Hojjati, M. Characterization of cross-linked whey protein isolate-based films containing Satureja Khuzistanica Jamzad essential oil. J. Food Process. Preserv. 2018, 42, e13557. [Google Scholar] [CrossRef]

- Mohammadi, M.; Mirabzadeh, S.; Shahvalizadeh, R.; Hamishehkar, H. Development of novel active packaging films based on whey protein isolate incorporated with chitosan nanofiber and nano-formulated cinnamon oil. Int. J. Biol. Macromol. 2020, 149, 11–20. [Google Scholar] [CrossRef]

- Sani, I.K.; Geshlaghi, S.P.; Pirsa, S.; Asdagh, A. Composite film based on potato starch/apple peel pectin/ZrO2 nanoparticles/ microencapsulated Zataria multiflora essential oil; investigation of physicochemical properties and use in quail meat packaging. Food Hydrocoll. 2021, 117, 106719. [Google Scholar] [CrossRef]

- Fenga, X.; Wanga, W.; Chua, Y.; Gao, C.; Liu, Q.; Tang, X. Effect of cinnamon essential oil nanoemulsion emulsified by OSA modified starch on the structure and properties of pullulan based films. LWT 2020, 134, 110123. [Google Scholar] [CrossRef]

- Sherry, M.; Charcosset, C.; Fessi, H.; Greige-Gerges, H. Essential oils encapsulated in liposomes: A review. J. Liposome Res. 2013, 23, 268–275. [Google Scholar] [CrossRef]

- Al-Moghazy, M.; El-Sayed, H.S.; Salama, H.H.; Nada, A.A. Edible packaging coating of encapsulated thyme essential oil in liposomal chitosan emulsions to improve the shelf life of Karish cheese. Food Biosci. 2021, 43, 101230. [Google Scholar] [CrossRef]

- Bastarrachea, L.; Dhawan, S.; Sablani, S.S. Engineering Properties of Polymeric-Based Antimicrobial Films for Food Packaging: A Review. Food Eng. Rev. 2011, 3, 79–93. [Google Scholar] [CrossRef]

- Quintavalla, S.; Vicini, L. Antimicrobial food packaging in meat industry. Meat Sci. 2002, 62, 373–380. [Google Scholar] [CrossRef] [PubMed]

- Arvanitoyannis, I.S.; Kotsanopoulos, K.V. Migration Phenomenon in Food Packaging. Food–Package Interactions, Mecha-nisms, Types of Migrants, Testing and Relative Legislation—A Review. Food Bioproc Techn 2013, 7, 21–36. [Google Scholar] [CrossRef]

- Motelica, L.; Ficai, D.; Ficai, A.; Oprea, O.C.; Kaya, D.A.; Andronescu, E. Biodegradable Antimicrobial Food Packaging: Trends and Perspectives. Foods 2020, 9, 1438. [Google Scholar] [CrossRef]

- Bhunia, K.; Sablani, S.S.; Tang, J.; Rasco, B. Migration of Chemical Compounds from Packaging Polymers during Microwave, Conventional Heat Treatment, and Storage. Compr. Rev. Food Sci. Food Saf. 2013, 12, 523–545. [Google Scholar] [CrossRef]

- Becerril, R.; Nerín, C.; Silva, F. Encapsulation Systems for Antimicrobial Food Packaging Components: An Update. Molecules 2020, 25, 1134. [Google Scholar] [CrossRef]

- Irkin, R.; Esmer, O.K. Novel food packaging systems with natural antimicrobial agents. J. Food Sci. Technol. 2015, 52, 6095–6111. [Google Scholar] [CrossRef]

- Cerisuelo, J.; Muriel-Galet, V.; Bermúdez, J.M.; Aucejo, S.; Catalá, R.; Gavara, R.; Hernández-Muñoz, P. Mathematical model to describe the release of an antimicrobial agent from an active package constituted by carvacrol in a hydrophilic EVOH coating on a PP film. J. Food Eng. 2012, 110, 26–37. [Google Scholar] [CrossRef]

- Balaguer, M.P.; Lopez-Carballo, G.; Catala, R.; Gavara, R.; Hernandez-Munoz, P. Antifungal properties of gliadin films in-corporating cinnamaldehyde and application in active food packaging of bread and cheese spread foodstuffs. Int. J. Food Microbiol. 2013, 166, 369–377. [Google Scholar] [CrossRef]

- Robertson, G. Food Packaging—Principles and Practice, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2006; ISBN 978-1-4398-6242-1. [Google Scholar]

- Feigenbaum, A.E.; Riquet, A.M.; Scholler, D. Fatty Food Simulants: Solvents to Mimic the Behavior of Fats in Contact with Packaging Plastics. In Food Packaging Testing Methods and Applications; Sara, J.R., Ed.; American Chemical Society: Washington, DC, USA, 2000. [Google Scholar]

- Appendini, P.; Hotchkiss, J.H. Review of antimicrobial food packaging. Innov. Food Sci. Emerg. Technol. 2002, 3, 113–126. [Google Scholar] [CrossRef]

- Miranda, J.M.; Jorge, F.; Dominguez, L.; Cepeda, A.; Franco, C.M. In vitro Growth Inhibition of Food-borne Pathogens and Food Spoilage Microorganism by Vitamin K5. Food Bioprocess. Technol. 2010, 4, 1060–1065. [Google Scholar] [CrossRef]

- Muriel-Galet, V.; Cerisuelo, J.P.; López-Carballo, G.; Lara, M.; Gavara, R.; Hernández-Muñoz, P. Development of antimicrobial films for microbiological control of packaged salad. Int. J. Food Microbiol. 2012, 157, 195–201. [Google Scholar] [CrossRef] [PubMed]

- Radusin, T.; Ristic, I.; Pilic, B.; Novakovic, A. Antimicrobial nanomaterials for food packaging applications. Food Feed. Res. 2013, 43, 119–126. [Google Scholar] [CrossRef]

- de Azeredo, H.M.C. Antimicrobial nanostructures in food packaging. Trends Food Sci. Technol. 2013, 30, 56–69. [Google Scholar] [CrossRef]

- Malhotra, B.; Keshwani, A.; Kharkwal, H. Antimicrobial food packaging: Potential and pitfalls. Front. Microbiol. 2015, 6, 611. [Google Scholar] [CrossRef] [PubMed]

- Zahra, S.A.; Butt, Y.N.; Nasar, S.; Akram, S.; Fatima, Q.; Ikram, J. Food Packaging in Perspective of Microbial Activity: A Review. J. Microbiol. Biotechnol. Food Sci. 2016, 6, 752–757. [Google Scholar] [CrossRef]

- Li, M.; Noriega-Trevino, M.E.; Nino-Martinez, N.; Marambio-Jones, C.; Wang, J.; Damoiseaux, R.; Ruiz, F.; Hoek, E.M. Synergistic Bactericidal Activity of Ag-TiO2 Nanoparticles in Both Light and Dark Conditions. Environ. Sci. Technol. 2011, 45, 8989–8995. [Google Scholar] [CrossRef]

- Rhim, J.-W.; Park, H.-M.; Ha, C.-S. Bio-nanocomposites for food packaging applications. Prog. Polym. Sci. 2013, 38, 1629–1652. [Google Scholar] [CrossRef]

- Aminlari, L.; Hashemi, M.M.; Aminlari, M. Modified Lysozymes as Novel Broad Spectrum Natural Antimicrobial Agents in Foods. J. Food Sci. 2014, 79, R1077–R1090. [Google Scholar] [CrossRef]

- Meira, S.M.M.; Zehetmeyer, G.; Jardim, A.I.; Scheibel, J.M.; de Oliveira, R.V.B.; Brandelli, A. Polypropylene/Montmorillonite Nanocomposites Containing Nisin as Antimicrobial Food Packaging. Food Bioprocess. Technol. 2014, 7, 3349–3357. [Google Scholar] [CrossRef]

- Resa, C.P.O.; Gerschenson, L.N.; Jagus, R.J. Natamycin and nisin supported on starch edible films for controlling mixed culture growth on model systems and Port Salut cheese. Food Control 2014, 44, 146–151. [Google Scholar] [CrossRef]

- Lantano, C.; Alfieri, I.; Cavazza, A.; Corradini, C.; Lorenzi, A.; Zucchetto, N.; Montenero, A. Natamycin based sol–gel anti-microbial coatings on polylactic acid films for food packaging. Food Chem. 2014, 165, 342–347. [Google Scholar] [CrossRef] [PubMed]

- Otoni, C.G.; de Moura, M.R.; Aouada, F.A.; Camilloto, G.P.; Cruz, R.S.; Lorevice, M.V.; de, F.F. Soares, N.; Mattoso, L.H.C. Antimicrobial and physical-mechanical properties of pectin/papaya puree/cinnamaldehyde nanoemulsion edible composite films. Food Hydrocoll. 2014, 41, 188–194. [Google Scholar] [CrossRef]

- Hill, L.E.; Gomes, C.; Taylor, T.M. Characterization of beta-cyclodextrin inclusion complexes containing essential oils (trans-cinnamaldehyde, eugenol, cinnamon bark, and clove bud extracts) for antimicrobial delivery applications. LWT 2013, 51, 86–93. [Google Scholar] [CrossRef]

- Mith, H.; Duré, R.; Delcenserie, V.; Zhiri, A.; Daube, G.; Clinquart, A. Antimicrobial activities of commercial essential oils and their components against food-borne pathogens and food spoilage bacteria. Food Sci. Nutr. 2014, 2, 403–416. [Google Scholar] [CrossRef]

- Micić, D.; Đurović, S.; Riabov, P.; Tomić, A.; Šovljanski, O.; Filip, S.; Tosti, T.; Dojčinović, B.; Božović, R.; Jovanović, D.; et al. Rosemary essential oils as a promising source of bioactive compounds: Chemical composition, thermal properties, biological activity and gastronomical perspectives. Foods 2021, 10, 2734. [Google Scholar] [CrossRef]

- Aćimović, M.; Šovljanski, O.; Šeregelj, V.; Pezo, L.; Zheljazkov, V.D.; Ljujić, J.; Tomić, A.; Ćetković, G.; Čanadanović-Brunet, J.; Miljković, A.; et al. Chemical composition, antioxidant and antimicrobial activity of Dracocephalum moldavica L. essential oil and hydrolate. Plants 2022, 11, 941. [Google Scholar] [CrossRef]

- Šovljanski, O.; Saveljić, A.; Aćimović, M.; Šeregelj, V.; Pezo, L.; Tomić, A.; Ćetković, G.; Tešević, V. Biological profiling of essential oils and hydrolates of Ocimum basilicum var. genovese and var. minimum originated from Serbia. Processes 2022, 10, 1893. [Google Scholar] [CrossRef]

- Pavlić, B.; Teslić, N.; Vidaković, A.; Vidović, S.; Velićanski, A.; Versari, A.; Radosavljević, R.; Zeković, Z. Sage processing from by-product to high quality powder: I. Bioact. Potential. Ind. Crop. Prod. 2017, 107, 81–89. [Google Scholar] [CrossRef]

- Riabov, P.A.; Micić, D.; Božović, R.B.; Jovanović, D.V.; Tomić, A.; Šovljanski, O.; Filip, S.; Tosti, T.; Ostojić, S.; Blagojević, S.; et al. The chemical, biological and thermal characteristics and gastronomical perspectives of Laurus nobilis essential oil from different geograohical origin. Ind. Crop Prod. 2020, 151, 112498. [Google Scholar] [CrossRef]

- Hulankova, R. The Influence of Liquid Medium Choice in Determination of Minimum Inhibitory Concentration of Essential Oils against Pathogenic Bacteria. Antibiotics 2022, 11, 150. [Google Scholar] [CrossRef] [PubMed]

- Havelt, T.; Brettschneider, S.; Schmitz, M. Evaluation of practical applicability and synergistic effects of bio-based food pack-aging materials combined with plant-based stabilisers. Processes 2021, 9, 1838. [Google Scholar] [CrossRef]

- Karbowiak, M.; Szymanski, P.; Zielinska, D. Synergistic effect of combination of various microbial hurdles in the biopreserva-tion of meat and meat products—Systematic review. Foods 2023, 12, 1430. [Google Scholar] [CrossRef] [PubMed]

- Nur Hanani, Z.A.; Reich, F.; Tolksdorf, T.; Siemen, H.; Bandick, N. Monitoring the effect of active packaging films with sil-ver-kaolinite using different packaging systems on the quality of the beef meat. Heliyon 2022, 8, e11019. [Google Scholar] [CrossRef]

- Vizzini, P.; Beltrame, E.; Zanet, V.; Vidić, J.; Manzano, M. Development and evaluation of qPCR detection method and Zn-MgO/alginate active packaging for controlling Listeria monocytogenes contamination in cold-smoked salmon. Foods 2020, 9, 1353. [Google Scholar] [CrossRef]

- Pateiro, M.; Domínguez, R.; Bermúdez, R.; Munekata, P.E.; Zhang, W.; Gagaoua, M.; Lorenzo, J.M. Antioxidant active packaging systems to extend the shelf life of sliced cooked ham. Curr. Res. Food Sci. 2019, 1, 24–30. [Google Scholar] [CrossRef]

- Ruskova, M.; Šiškova, A.O.; Mosnackova, K.; Gago, C.; Guerreiro, A.; Bučkova, M.; Puškarova, A.; Pangallo, D.; Antunes, M.D. Biodegradable active packaging enriched with essential oils for enhacing the shelf life of strawberries. Antioxidants 2023, 12, 755. [Google Scholar] [CrossRef]

- Sipos, L.; Nyitrai, A.; Hitka, G.; Friedrich, L.F.; Kokai, Z. Sensory Panel Performance Evaluation—Comprehensive Review of Practical Approaches. Appl. Sci. 2021, 11, 11977. [Google Scholar] [CrossRef]

| Bacteria | Food Sources | Health Risks |

|---|---|---|

| Salmonella | Raw poultry, eggs | Gastroenteritis, fever |

| Escherichia coli | Undercooked beef, raw vegetables | Diarrhea, kidney failure |

| Listeria monocytogenes | Deli meats, soft cheeses | Listeriosis (severe illness) |

| Campylobacter | Raw or undercooked poultry | Diarrhea, cramps |

| Clostridium botulinum | Canned and low-acid foods | Botulism (paralysis) |

| Microorganism | Food Sources | Health Risks |

|---|---|---|

| Yeasts | ||

| Saccharomyces cerevisiae | Bread, beer, wine | Generally non-pathogenic |

| Candida spp. | Found in milk products | Opportunistic infections |

| Zygosaccharomyces spp. | Found in fermented foods | Generally non-pathogenic |

| Debaryomyces spp. | Dairy products, fermented foods | Generally non-pathogenic |

| Fungi | ||

| Aspergillus spp. | Nuts, grains, dried fruits | Aflatoxin production |

| Penicillium spp. | Cheese, spoilage of various foods | Some species used in cheese production, allergenic spores |

| Fusarium spp. | Grains, cereals | Mycotoxin production |

| Botrytis cinerea | Fruits, vegetables | Allergenic spores |

| Rhizopus spp. | Fruits, vegetables, baked goods | Allergenic spores |

| Comparation of Packaging Type | |||

|---|---|---|---|

| Classical Food Packaging | Biodegradable Food Packaging | ||

| Used materials | Metal Glass Paper Conventional plastic | Based on synthetic polymers | Based on biopolymers obtained from plants, animals, and microorganisms |

| Properties | Non-biodegradable persists in environment—degrades very slow good barrier and mechanical properties low levels of interaction with packaged food | Biodegradable in nature possesses worse mechanical and barrier properties low weight and ability to be easily handled | |

| Advantages | Strong and durable, excellent food protection longer shelf life of food product widely available and versatile; some of them can be low weight (plastic, paper) low levels of interaction with packaged food | Environmentally friendly, reduces plastic pollution can be produced from renewable resources nontoxic reduces carbon emissions and amount of plastic waste low weight and ability to be easily handled; can be edible can be designed to prolong food product shelf-life [29] | |

| Limitations | Non-environmentally friendly; production leads to great energy consumption, fossil fuel depletion, and emissions of volatile organic compounds (VOC) limited recyclability for some materials; long-time of decomposition; increase the amount of solid waste generation production of microplastic (conventional plastic) | Poor barrier and mechanical properties; may require specific disposal conditions to biodegrade properly (polylactide, polyhydroxyalkanoate) | |

| Method | Direct Incorporation | Emulsification | Liposomes Formation |

|---|---|---|---|

| The main characteristics of method | Using low energy if biopolymers possess hydrophobic character [63,64,65,66]; using a high-sheared homogenizer for hydrocolloids [67,68,69,70,71] | Using high-speed stirring and emulsifying agent intended for the formation of oil in water emulsion [73,74,75,76,77,78,79,80,81,82] | Dissolution of phospholipids and EOs in an organic solvent to create a lipid solution; evaporation of solvent and formation of a lipid dispersion in distilled water; size adjustment by ultrasonication. |

| Advantages | Shorter time for the preparation of active packaging; no additional steps –simpler procedure; can be more cost-effective | Stabilization and protection of EOs; improve their solubility in aqueous environments, provide their uniform distribution and controlled release. Nanoemulsions ensure better bioavailability of antimicrobial compounds and improved optical properties of packaging. In comparison to emulsions, nanoemulsions provide better stability to environmental conditions such as pH, temperature, and shear forces. | Targeted delivery and improved bioavailability, along with protection of ingredients and reduced undesirable reactions. |

| Limitations | Possible accumulation of essential oil on the surface of the film; deterioration of EO properties (oxidation, thermal degradation); | Specialized equipment and careful formulation to obtain stable formulation; Use of synthetic surfactants that can be irritable. | Complex production, difficulties in achieving consistent and desired liposome sizes, as well as the potential impact on texture, appearance, and flavor of food. |

| Method | Biopolymer–Based Nanostructures | Cyclodextrins | Nanoclays |

| The main characteristics of method |

| Mixing of EO and cyclodextrins in distilled water, stirring, filtration, and drying. | Preparation of EO and nano clay solution in an appropriate solvent. Mixing the solutions and stirring |

| Advantages |

| Odor and flavor control; help to maintain the sensory quality of the packaged food; they ensure protection of Eos’ degradation and their slow release over time. | Improvement of mechanical and barrier properties of packaging material. |

| Limitations |

| High price and limited solubility in water. | Can cause reduced transparency and migration into packaged food. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomić, A.; Šovljanski, O.; Erceg, T. Insight on Incorporation of Essential Oils as Antimicrobial Substances in Biopolymer-Based Active Packaging. Antibiotics 2023, 12, 1473. https://doi.org/10.3390/antibiotics12091473

Tomić A, Šovljanski O, Erceg T. Insight on Incorporation of Essential Oils as Antimicrobial Substances in Biopolymer-Based Active Packaging. Antibiotics. 2023; 12(9):1473. https://doi.org/10.3390/antibiotics12091473

Chicago/Turabian StyleTomić, Ana, Olja Šovljanski, and Tamara Erceg. 2023. "Insight on Incorporation of Essential Oils as Antimicrobial Substances in Biopolymer-Based Active Packaging" Antibiotics 12, no. 9: 1473. https://doi.org/10.3390/antibiotics12091473

APA StyleTomić, A., Šovljanski, O., & Erceg, T. (2023). Insight on Incorporation of Essential Oils as Antimicrobial Substances in Biopolymer-Based Active Packaging. Antibiotics, 12(9), 1473. https://doi.org/10.3390/antibiotics12091473