3. Results and Discussion

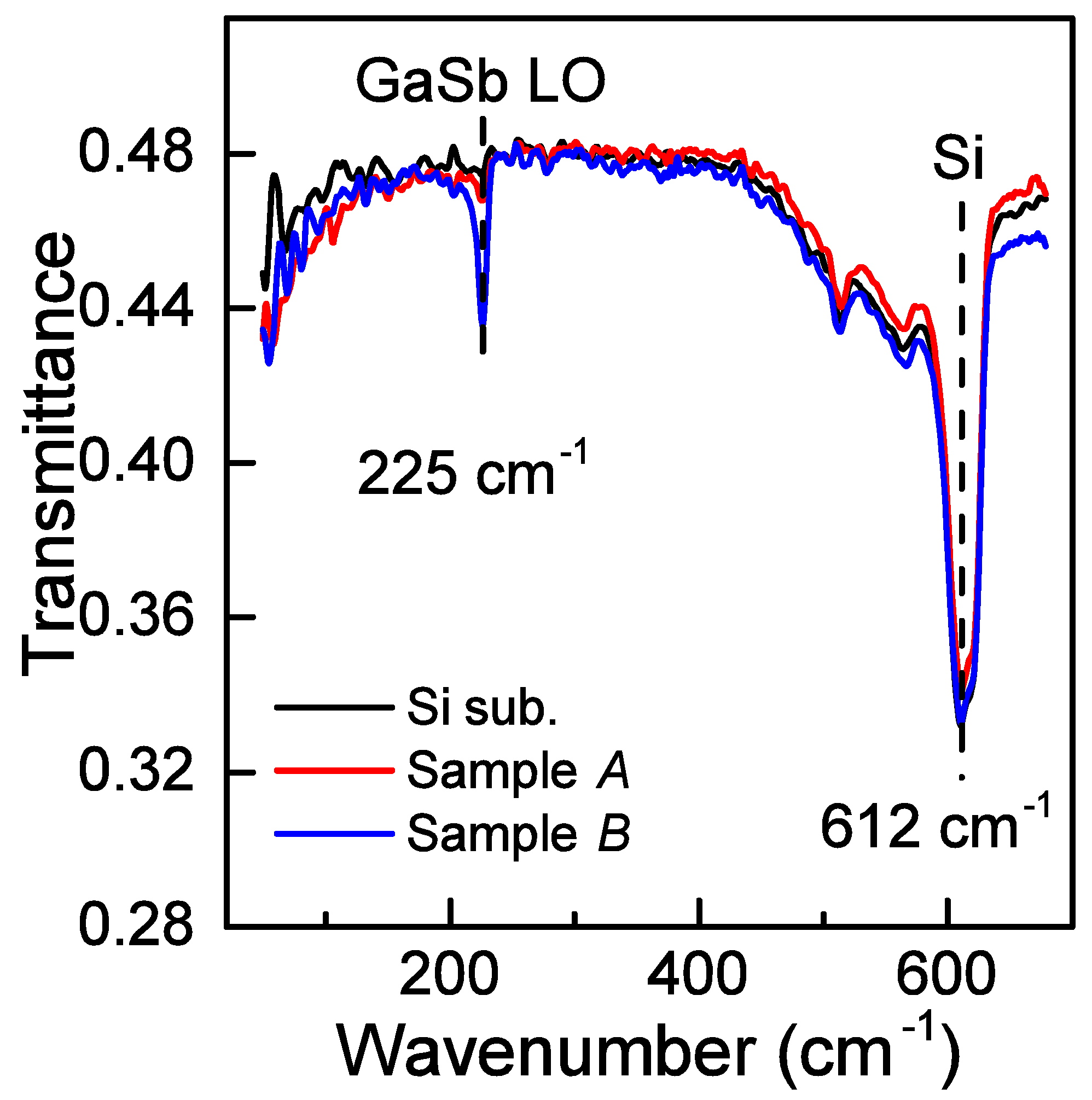

The formation of GaSb films by the SPE method was confirmed by the appearance of an absorption peak at 225 cm

−1 on the spectra in the far infrared (FIR) spectral region (

Figure 1). The observed peak corresponds to the longitudinal optical phonon (LO) [

19] in the GaSb cubic lattice (F-43m). The peak at 612 cm

−1 comes from the silicon substrate (

Figure 1). One can see that a decrease in the thickness of the GaSb film from 20 down to 14 nm resulted in a significant decrease (about four-fold) in the intensity of the 225 cm

−1 peak, which is due to the aggregation of the GaSb film on the sample

A surface during the annealing at 300–500 °C (see the discussion of the AES, LEED, and AFM data obtained for sample

A).

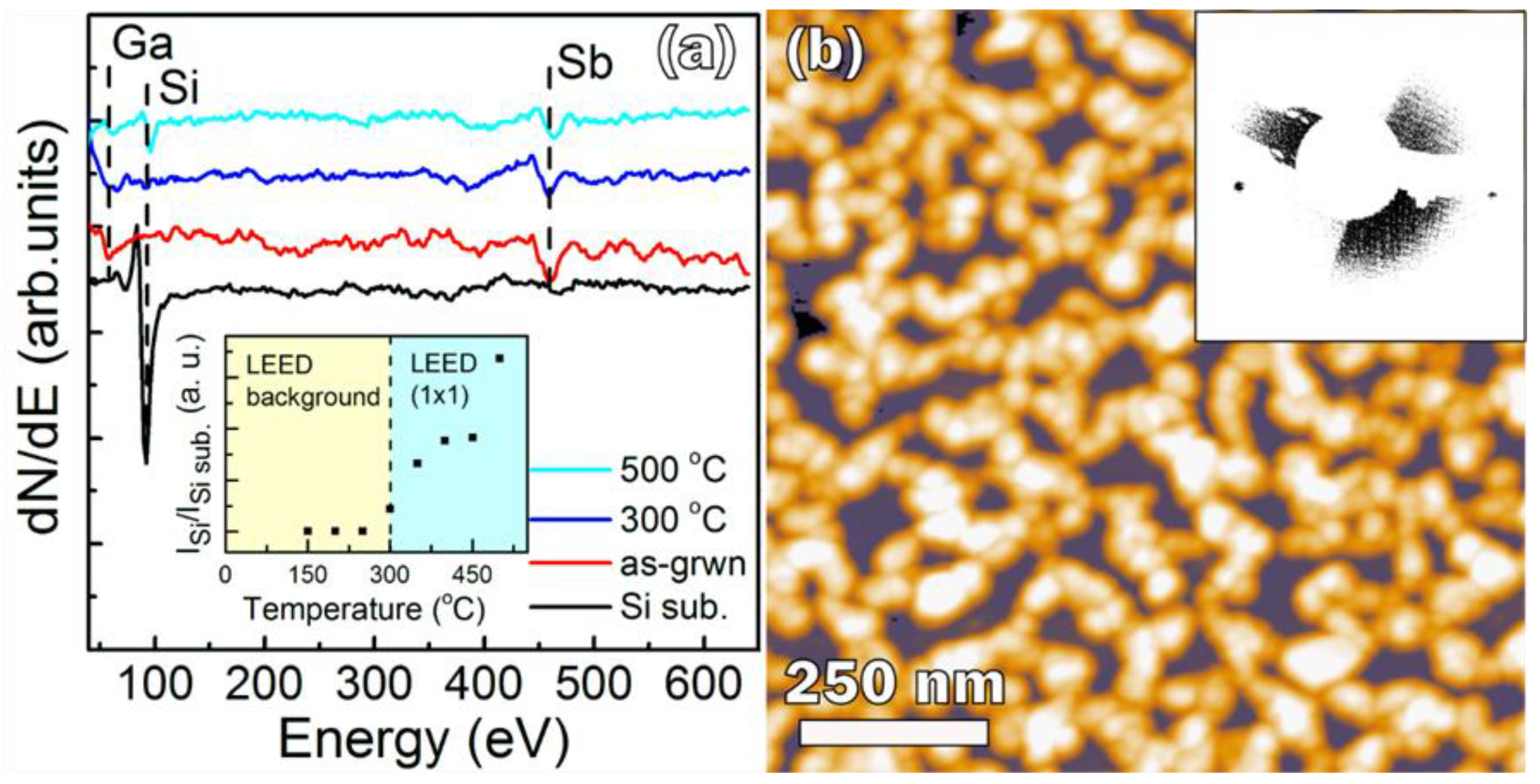

The as-deposited 14-nm-thick Ga–Sb stoichiometric mixture completely covers the substrate surface (sample

A), which is confirmed by the disappearance of the 92-eV silicon peak in the Auger spectrum and by the appearance of Ga (55 eV) and Sb (454 eV) peaks (

Figure 2a). In addition, the Si(001)2 × 1 LEED pattern completely disappeared, indicating a disordered surface. Since the Si peak did not appear after annealing at 200–250 °C, the film was continuous at these temperatures. After annealing of the mixture film at 300 °C, the Si peak appears again (

Figure 2a, inset), as well as the Si(001)1 × 1 LEED pattern (

Figure 2b, inset). At 300 °C, the diffusion of Si atoms from the substrate into the GaSb film is small. Therefore, the observed Si peak and the LEED pattern originate from the Si substrate surface, which was uncovered because of the GaSb film agglomeration. Since the silicon peak intensity is very low at 300 °C, there is no significant GaSb film aggregation. The rapid increase of the Si peak with the increase of the annealing temperature (

Figure 2a, inset) resulted from intense GaSb film agglomeration, which is confirmed by the AFM data (

Figure 2b). The AFM image shows that after the final annealing (500 °C), an array of connected GaSb islands is formed, while about 30% of the substrate surface is free from GaSb. The islands’ concentration is rather high, at 4.3 × 10

10 cm

−2; their average lateral size is 50 nm and height is 21.3 nm. Because of agglomeration, the 14-nm-thick GaSb film became very rough, with

σrms = 7.05 nm. The discontinuity of the film is also confirmed by the FIR absorption spectroscopy data: a low intensity of the peak at 225 cm

−1 was caused by the decrease in GaSb film surface coverage (

Figure 1). Summarizing the results obtained for sample

A, we can state that: (i) the 14-nm-thick GaSb film was continuous after annealing at 200–250 °C, (ii) the GaSb film agglomeration took place during annealing at 300–500 °C, (iii) there is no significant GaSb film aggregation at 300 °C, and (iv) the GaSb film thickness of 14 nm is not sufficient to withstand annealing at temperatures of 300 °C and higher.

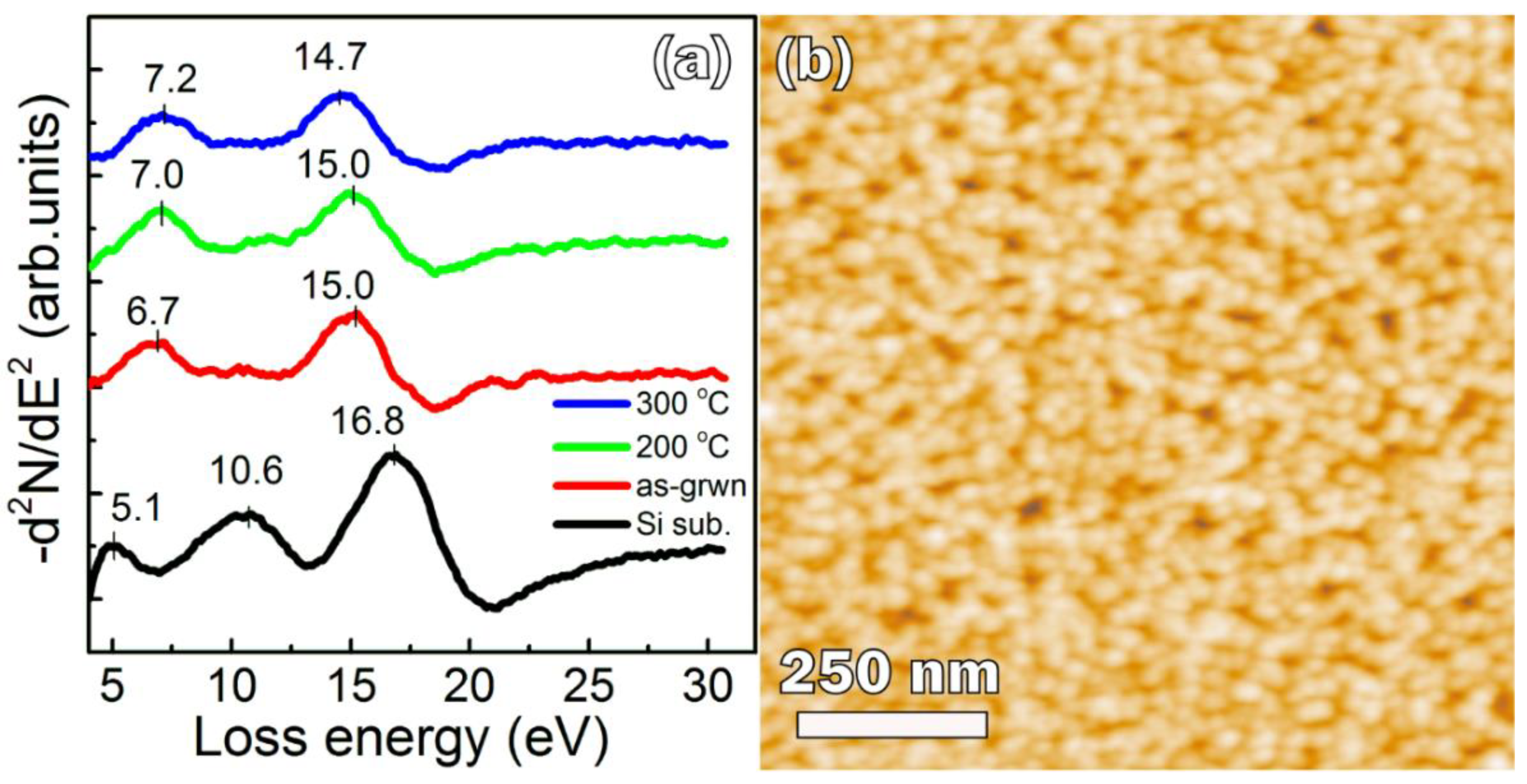

Therefore, for sample

B, we increased the film thickness by about 50%—up to 20 nm—and set the maximum annealing temperature at 300 °C because at this temperature, there is no significant film aggregation, but it is high enough for GaSb formation [

6]. After deposition of a 20-nm-thick Ga–Sb mixture, only GaSb peaks in the EELS spectrum were seen: at 6.7 and 15.0 eV [

17,

20] (

Figure 3a). The peak at 15.0 eV is closer to the bulk plasmon in crystalline cubic GaSb (14.7–14.8 eV [

17] and 14.7 [

20]) rather than in amorphous GaSb (14.3 eV [

21]), so we can state that a crystalline GaSb film with a cubic F-43 m lattice was formed.

According to the theory of plasma oscillations [

22], the value of the bulk plasmon energy

of GaSb is proportional to the square root of the valence electron concentration

in GaSb:

where

A is a constant which must be calculated for GaSb. To calculate this constant, we used the formula:

where

and

, respectively, are the energy of a bulk plasmon and the concentration of valence electrons for a relaxed GaSb single crystal. The valence electron concentration in relaxed single-crystal GaSb is

=

+

n −

p, where

= 32/(0.609593 nm)

3 = 1.41 × 10

23 cm

−3 is the valence electrons’ concentration in the ideal cubic GaSb, and

n and

p are the electron and hole concentrations in relaxed single-crystal GaSb, respectively. It was found that Czochralski-grown unintentionally

p-doped relaxed single-crystal GaSb has hole concentration

p ≈ 1.3 × 10

17 cm

−3 [

23]. Therefore, we can assume that for this

p-doped relaxed single-crystal GaSb,

n <<

p <<

, and hence

≈

= 1.41 × 10

23 cm

−3, while the energy of the bulk plasmon of the GaSb single crystal

= 14.7 eV [

17,

20]. We placed these values of

and

in Equation (2) and obtained

A = 3.91 × 10

‒11 eV·cm

3/2.

The high value of bulk plasmon energy of the as-grown GaSb film (e.g., 15 eV) in

Figure 3a results from the higher valence electron concentration (1.47 × 10

23 cm

−3—the value is calculated by Equation (1)) compared to the ideal GaSb structure. The change in the valence electron concentration

nv, and hence the shift energy of the bulk plasmon (e.g., 0.3 eV for plasmon energy of 15 eV), can originate from a change in the unit cell volume as a result of deformation.

Therefore, we consider the influence of GaSb lattice deformation

on the bulk plasmon energy

. Substituting Equation (2) into Equation (1), we obtain the equation for the calculation of the bulk plasmon energy of the real GaSb film:

The concentration of valence electrons depends on the deformation of the lattice by the formula

, where Δ

a is the change of the lattice constant of GaSb. The GaSb film grown in our conditions is

p-type, thus for this film

n <<

p, so we neglected contribution of electron concentration

n in the formula. According to our Hall measurements, the hole concentration in a continuous GaSb film (sample

B) is 1.6 × 10

18 cm

−3. It is higher than that in single crystal GaSb, but it is much less than the concentration of valence electrons of GaSb

= 1.41 × 10

23 cm

−3. Therefore, the contribution of the hole concentration

p to

is very small, so we ignored it. The number of valence electrons,

N, is obtained from the formula for an ideal crystal

; then

Substituting Equation (4) into Equation (3) and assuming

≈

, we obtain the equation for the estimation of the influence of deformation, Δ

a/

a, on the bulk plasmon energy,

:

By applying Equation (5), we have found that the bulk plasmon energy

= 15 eV resulted from GaSb lattice compression of 1.33%. If we took into account the contribution of the hole concentration

p into the value of Δ

a/

a, then the obtained value would differ from that calculated from Equation (5) only by −3.6 × 10

−4%. It is very small value, so we neglected it. According to our assessment, during the GaSb mixture deposition, the substrate was gradually heated by Ga and Sb sources up to 170 °C at the end of the deposition process. This temperature is sufficient for the crystallization of the GaSb mixture [

24], therefore GaSb crystals appeared in the film during deposition. During the crystallization, noticeable compression of the GaSb lattice (1.33%) occurs. Further annealing at 200 °C did not change the bulk plasmon energy (

Figure 3a), and so it did not change the value of GaSb lattice deformation. We suppose that raising the temperature by 30 °C (up to 200 °C) cannot lead to remarkable recrystallization and reduce the deformation of the GaSb lattice. An increase in the annealing temperature up to 300 °C results in a decrease of the bulk plasmon energy (14.7 eV). This value of bulk plasmon energy corresponds to the relaxed GaSb film. Thus, the annealing at a temperature of 300 °C reduces the deformation in the GaSb film that was induced in the film during its crystallization.

The EELS peak at 6.7 eV, which appeared on the EELS spectra just after the deposition of the Ga–Sb mixture, is probably a superposition of the peaks originating from interband transitions (5.1–5.3 eV) and transitions from filled surface states to dangling bond levels (7.5–7.6 eV) [

17]. The presence of a single peak instead of two is most likely due to the insufficient resolution of our analyzer. In contrast to the bulk plasmon, with annealing, the 6.7 eV peak shifts to a higher energy (

Figure 3a). Since the intensity of the interband transitions depends on the volume of the material [

17], which does not change during the annealing, the shift of the 6.7 eV peak up to 7.2 eV should be assumed to be an increase of the contribution of transitions to dangling bond levels. This implies an increase of the contribution from the surface states, the number of which grows due to the increase of the GaSb film roughness during the annealing. Therefore, we assume that the observed high-energy shift of the EELS peak at 6.7 eV results from the increase of GaSb film roughness during the annealing.

The AFM image shows that the 20-nm-thick GaSb film covers the whole substrate (

Figure 3b) and consists of nanocrystals with sizes of some tens of nanometers. The maximum hole depth between nanocrystals is less than 10 nm. It has a roughness of

σrms = 1.74 nm (

Table 1), which is much lower than that obtained for GaSb films grown by MBE on clean silicon (

σrms ≈ 35 nm, at a film thickness of ≈20 nm) [

5] and an AlSb buffer layer (

σrms ≈ 5–6 nm) [

5]. The surface relief development during GaSb MBE growth arises from a large Ga surface diffusion coefficient, while in the case of SPE, Ga, and Sb atoms intermixed enough to form small crystalline grains at the very beginning of the annealing, at about 200 °C. The increase of the annealing temperature results in grain size growth, but without noticeable development of the film roughness.

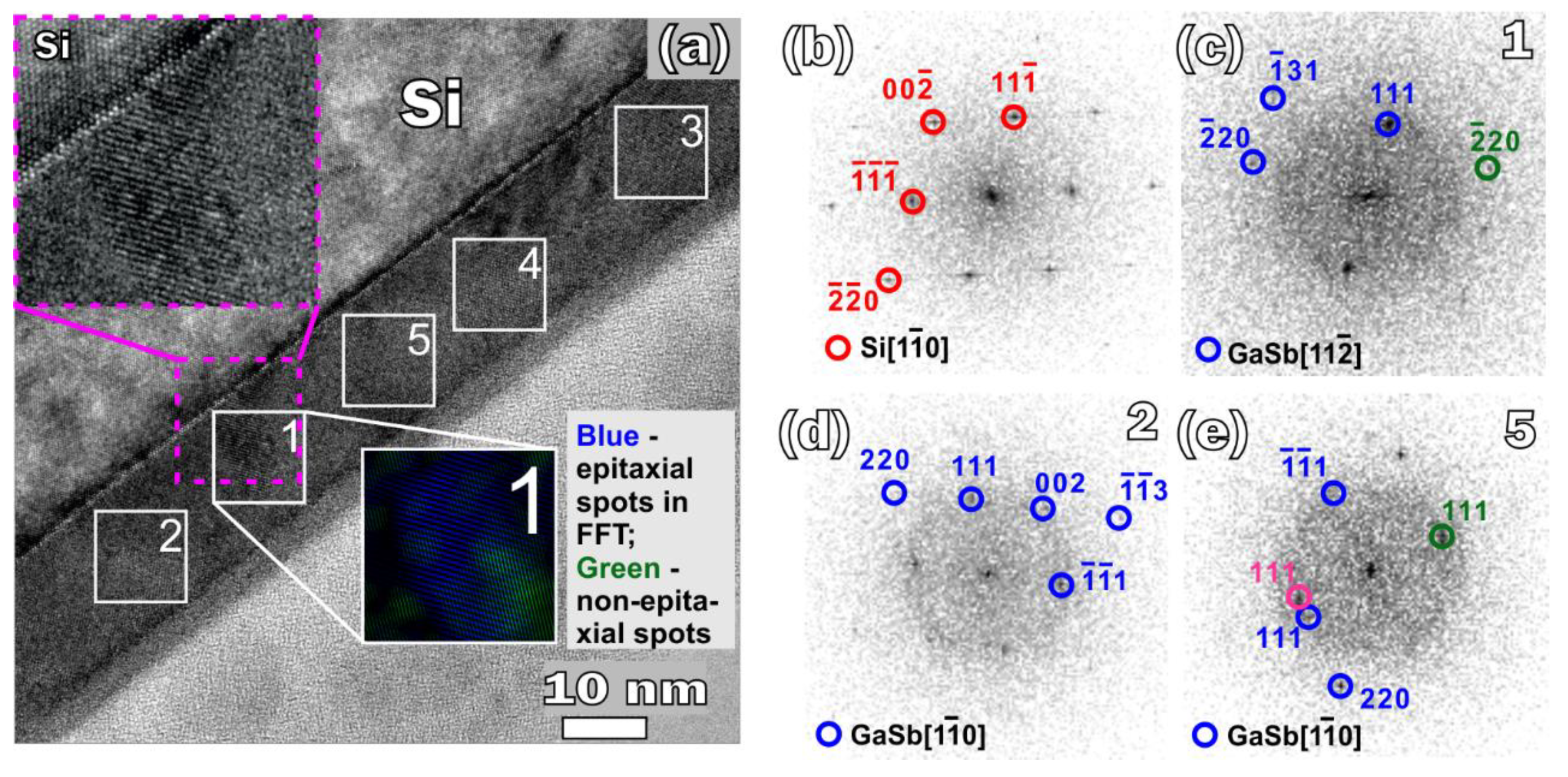

According to the results of TEM, the SPE-grown GaSb film is polycrystalline, consisting of grains with sizes of 9–16 nm (

Figure 4). The crystalline structure of the GaSb film was determined at several areas by analyzing the fast Fourier transform (FFT) patterns (

Figure 4c–e;

Table 2). The grains are characterized by both a compressive (up to −2.58%) and tensile stress (up to 0.9%) and they are disoriented relative to each other by an angle of 14–30°. To calculate the average deformation of GaSb film, the lattice deformation of 10 GaSb grains presented in the TEM image was determined. Among them five grains are not listed in

Table 2 as they have no interface with the substrate, thus no epitaxial relationship can be deduced for these grains. The average deformation of the GaSb film is −0.03%. The deformation value is slightly different from zero because of limited number of analyzed grains in the TEM image compared with those probed by electron beam of EELS, but it corresponds to the fully relaxed film. The epitaxial relationships (ERs) of the GaSb grains with the substrate are very diverse; most of them have not been previously described in the literature. The most frequently encountered ERs were: GaSb

||Si

and GaSb

||Si

(area 1), GaSb

||Si

and GaSb

||Si

(area 2), and GaSb

||Si

and GaSb

||Si

(area 3) (

Table 2,

Figure 4a,c,d).

The ERs of GaSb

||Si

and GaSb

||Si

(area 4) and GaSb

||Si

and GaSb

||Si

(area 5) completely coincide with the relations obtained for GaSb grown by MBE [

7,

11]. Besides, the ER for area 5 is rarely observed. In our paper [

25] devoted to GaSb nanocrystals SPE-grown on Si(001) and embedded in a silicon matrix, we obtained only one ER for all the nanocrystals: GaSb

||Si

and GaSb

||Si

. The ER looks differ from the ER obtained for GaSb nanocrystals formed by high-dose ion implantation followed by GaSb crystallization inside the silicon lattice: GaSb

||Si

and GaSb

||Si

[

26]. However, due to the symmetry of the Si and GaSb crystals, if one observes ER GaSb

||Si

and GaSb

||Si

, the following relationships for the matching planes should also be observed: GaSb

||Si

and GaSb

||Si

. So, we can state that the ERs observed for GaSb nanocrystals grown both by SPE and by ion-beam synthesis are identical. This means that when GaSb crystallizes directly from a Si crystal lattice during MBE [

7,

11], ion-beam synthesis [

26], or SPE of a thin layer of GaSb (less 5 nm) [

25], the only ER is GaSb

||Si

and GaSb

||Si

. In this case, the matching direction relationship is GaSb

||Si

, which leads to a mismatch of 12.2% in this direction. On the contrary, when SPE films are formed from the Ga–Sb mixture, many different ERs are observed (

Table 2). A variety of ERs indicates that GaSb crystallization begins at not only the Si/GaSb interface, but also all over the film bulk. A different characteristic of the film crystallization is explained by the fact that during the deposition of the Ga–Sb mixture, the substrate temperature gradually increased from room temperature up to ~170 °C, due to the heating of the substrate caused by the Ga and Sb sources. Since the diffusion of Ga atoms over the surface and in the bulk of the Ga–Sb mixture film is significantly hampered compared to its diffusion over crystalline Si or GaSb surfaces, and since a temperature of 170 °C is sufficient for the GaSb crystallization [

24], crystal nucleation takes place all over the Ga–Sb film. If a GaSb grain has no interface with the substrate (isolated grain), it can be arbitrarily oriented relative to the substrate, as one can see in

Figure 4a (FFT filtration inset, green grain) and

Figure 4c. A disorientation angle calculated for planes GaSb

and GaSb

of isolated grains – namely, angle between GaSb

and Si

planes, and angle between GaSb

and Si

planes – was in the range of −14–26°; only in one case was the value about 0.1°. On the contrary, all the GaSb grains in areas 1–5 had a sharp interface with the substrate (

Figure 4a, magenta frame inset) and epitaxial orientation (see disorientation angle in

Table 2). Being most likely, their crystallization began from the substrate, while the new ERs could form under the influence of a GaSb_grain/Ga–Sb_mixture interface and the neighboring isolated grains, because when only the Si substrate influences crystallization, the only ERs that can be observed is GaSb

||Si

and GaSb

||Si

. Thus, during SPE growth of a GaSb film, crystallization begins both in the film bulk and at the film/substrate interface.

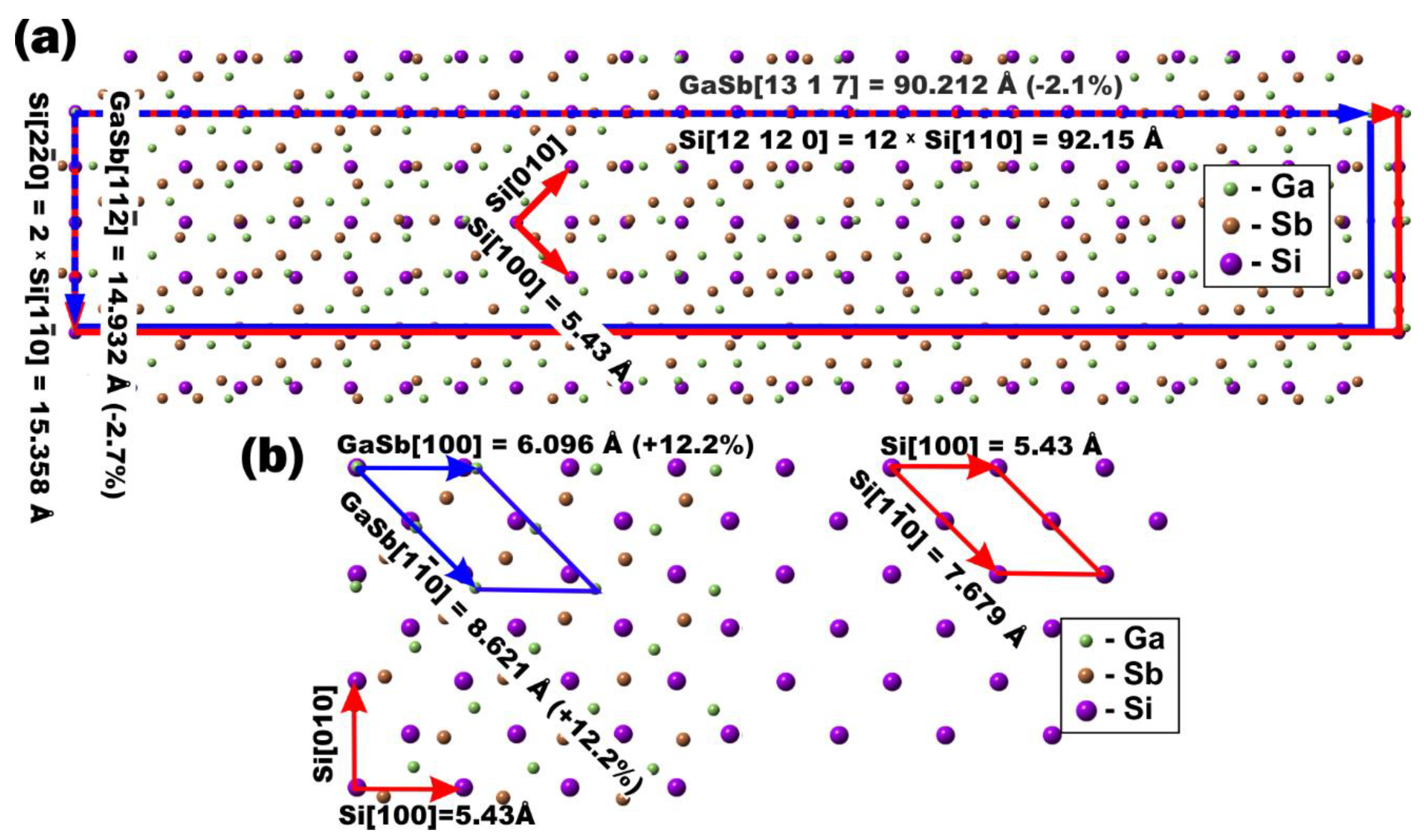

To estimate the deformation of the GaSb unit cell on the Si(001) surface, we calculated the mismatch between the GaSb and Si lattices in selected directions on the Si(001) surface for the ERs corresponding to the areas 1 and 4 (

Figure 5a,b). The lattice mismatch

M for lattice vectors GaSb[

U1V1W1] and Si[

UVW] of 2D cells of GaSb and Si, was calculated by the following equation:

where

is the length of vector [

U1V1W1] of the 2D GaSb lattice;

is the length of vector [

UVW] of the 2D Si lattice;

aGaSb and

aSi are the lattice constants of GaSb and Si, respectively. The

b values are shown in

Figure 5a,b. The ER for area 4, GaSb

||Si

and GaSb

||Si

, is common for MBE-grown GaSb, while the ER for area 1, GaSb

||Si

and GaSb

||Si

, was observed only for SPE-grown GaSb; below, we will refer to this ER as

GS. It attracted our attention because of a small discrepancy between the GaSb and Si (−2.7%) lattices in the direction of GaSb

(lattice vectors GaSb

and Si

in

Figure 5a).

While for GaSb

||Si

and GaSb

||Si

in the direction of GaSb

, the mismatch is 12.2% (

Figure 5b), for

GS ER on the Si(001) surface, together with the GaSb

||Si

epitaxial direction, there is another possible direction with a mismatch of −2.1%: GaSb

||Si

(lattice vectors GaSb[13 1 7] and Si[12 12 0] in

Figure 5a). Although

GS ER is incommensurate (

Figure 5a), the difference in the mismatch along GaSb

and GaSb

is only 0.6%. The maximum mismatch value of

GS ER is about four times smaller than that for the GaSb

||Si

direction (12.2%), which coexists with GaSb

||Si

on the Si(001) surface for the ER of GaSb

||Si

and GaSb

||Si

(

Figure 5b). The arrangement of atoms shown in

Figure 5b is realized at MBE and leads to significant deformation of the GaSb crystal, which is relaxed by dislocations localized at the GaSb/Si(001) interface [

25]. In the case of embedding into the Si matrix, the edge dislocations give rise to threading dislocations in the Si cap layer [

25]. The new arrangement of atoms found for SPE-grown GaSb and shown in

Figure 5a induced a smaller deformation in the GaSb crystal, and hence could cause a lower dislocation density at the GaSb/Si(001) interface. Thus, the

GS ER is very suitable for GaSb embedding into the Si matrix. Determining the growth conditions that allow the formation of a GaSb film with the only ER being

GS will be the task of our future work.