The first step of composite preparation was performed following compounding procedure with the direct mixing of filler and polymeric matrix as previously reported in [

14,

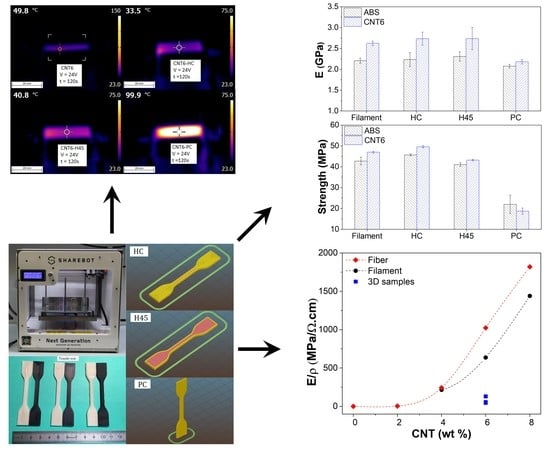

25]. For the purpose to increase the processing shear stresses during CNT dispersion, an ABS matrix with MFI of 14.8 ± 1.0 g/cm

3 (220 °C and 10 kg) was properly selected, with viscosity higher than ABS with MF of 23 g/cm

3 (220 °C and 10 kg) previously utilized for the production CNT composite from master-batch [

18]. Moreover, in the second step of filament extrusion, lower processing temperatures, 220 °C instead of 240 °C [

18], were set in order to furtherly improve dispersion under high shear stresses.

3.1. Filament Extrusion and Melt Flow Index

The filament of neat ABS and of ABS/CNT composites were extruded with an orientation factor of about 1.0 at 220 °C, as evaluated by the ratio between the cross-sectional area of the extruder die hole (

SDE) and the cross-sectional area of the obtained filament (

SF) according to Equation (6)

Moreover, the orientation factor of fiber produced by 3D-printer as the cross-sectional area of filament (

SF) and the cross-sectional area of the obtained fiber (

Sf), according to Equation (7)

The orientation factor is higher in the fiber (produced at 250 °C for ABS and at 280 °C for CNT6) than filament obtained at 220 °C due to the processing conditions. The higher the CNT content, the higher the orientation factor of fibers. Moreover, it is important to observe that linear density of fiber is progressively decreasing with CNT content, as shown in

Table 3.

This result could be explained by considering that the final diameter of fiber is decreasing with the nanofiller content (see detail in paragraph 3.6). Consequently, the free flow of the fibers from die of 3D-printer was used to evaluate the die-swelling (

DS), according to Equation (8), where

Sf is the cross-sectional area of fibers and

SDP is nozzle section of 3D-printer.

Table 3 shows that die-swelling of investigated composites is significantly reduced as the CNTs fraction increases; in particular, at 6 and 8 wt % of CNTs, die swelling in fiber is almost completely suppressed.

Moreover, the total orientation factor in fiber

OFT could be calculated combining Equations (6) and (7), as shown in Equation (9):

The total orientation factor in the fiber increased with CNT content in direct dependence on the first step of filament production at 220 °C and the subsequent extrusion from 3D printer at 250 °C (for ABS) or 280 °C (for nanocomposite), that is the most effective step. This cumulative effect could be a useful parameter for evaluating the processability of the various filaments.

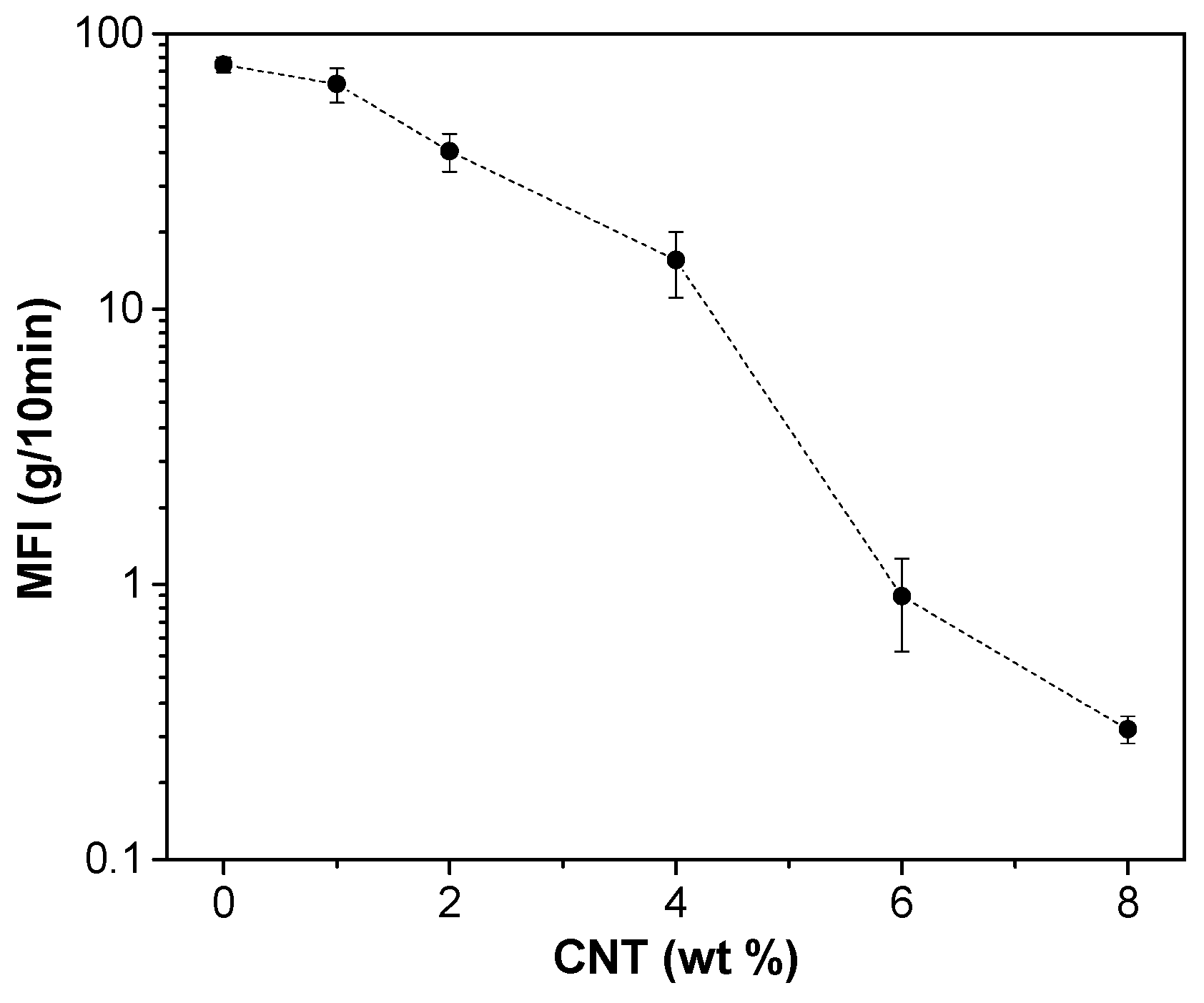

The effect of CNT on the melt flow index (MFI) of extruded ABS filaments was also investigated.

Figure 2 shows a strong decrease of MFI with the carbon nanotubes content, due to the increasing viscosity induced by the formation of a nanofiller network. This effect is also documented by a significant increase in the torque and internal pressure measured during the extrusion process after addition of CNT to ABS (see

Table 1). Even though the MFI of nanocomposites with CNT content higher than 4 wt % is extremely low, it has been possible to produce feedstock filaments by using twin screw extruder up to 8 wt % of CNT, reaching maximum values of internal pressure of about 46 bar and 120 Nm of torque.

3.3. Morphological Analyses on Filaments and 3D-Printed Parts

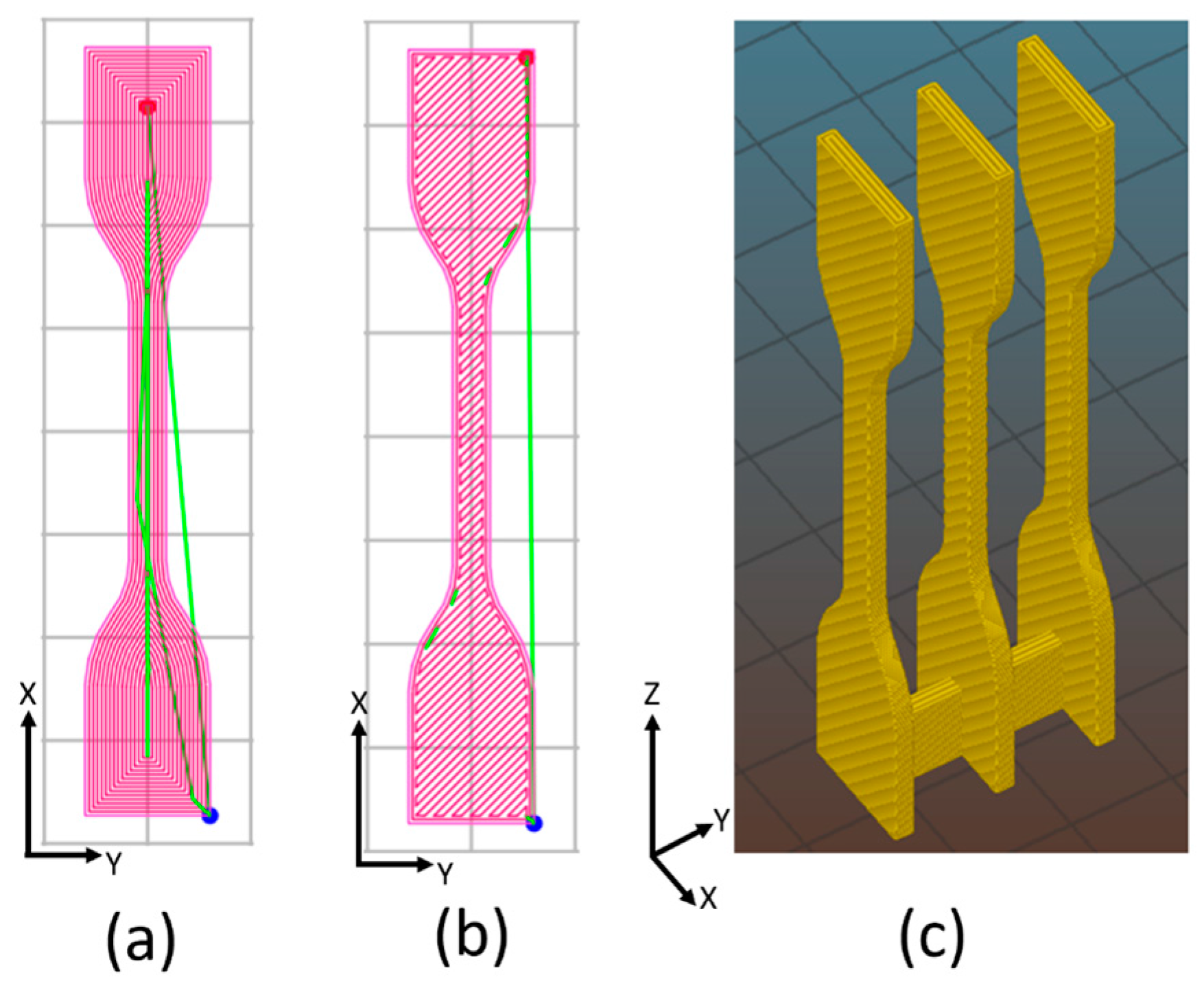

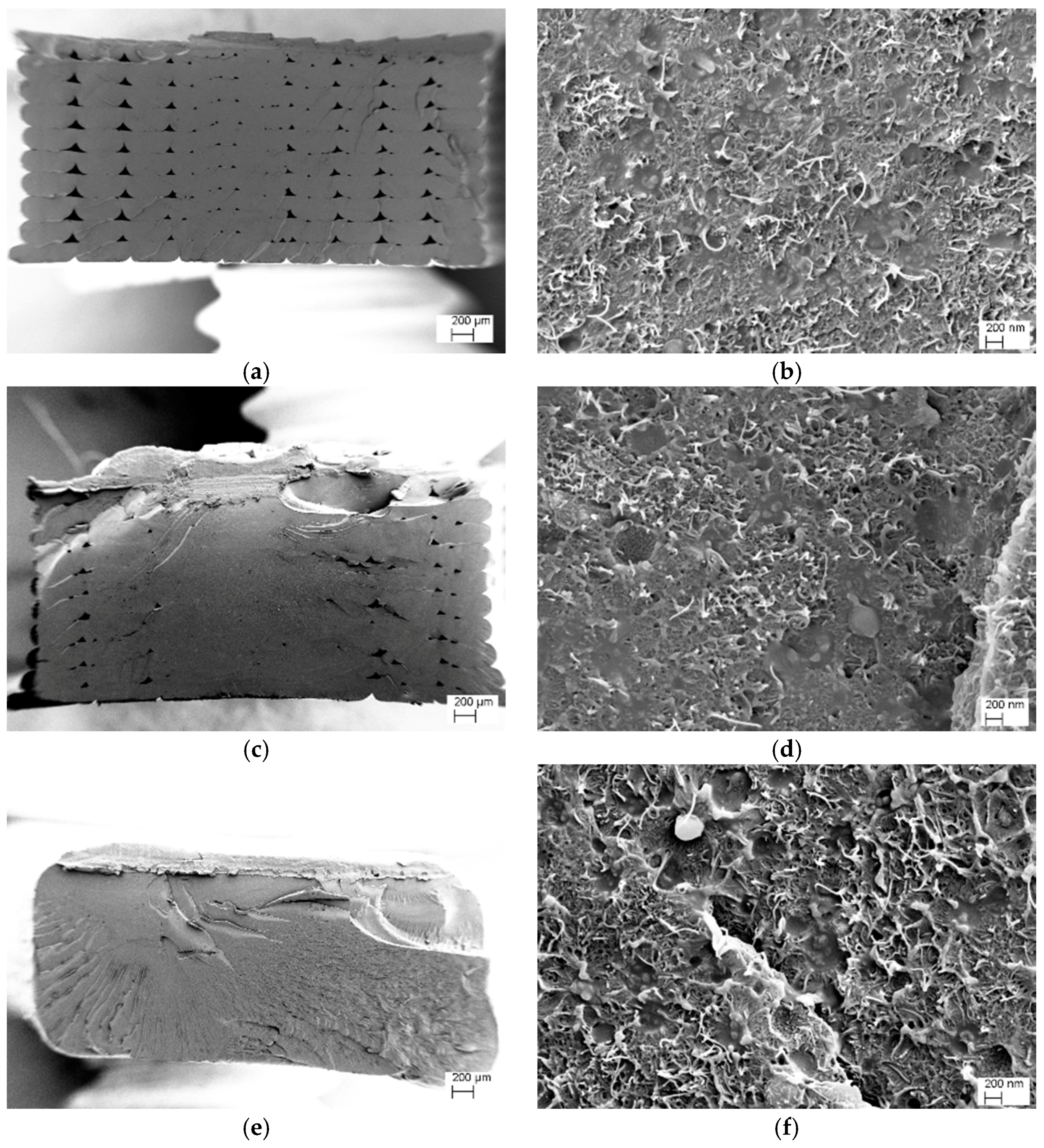

The fracture surface of cryogenically broken filaments and 3D-printed specimens were analyzed by electron microscopy.

Figure 4 illustrates the SEM images of ABS/CNT filaments with a CNTs content of 6 and 8 wt % at increasing magnification. Regarding the CNTs dispersion in both compositions, a homogenous distribution of single nanotubes in ABS matrix can be observed (no aggregates of nanotubes were detected). This means that the adopted two-steps process, consisting of mixing in an internal mixer followed by twin-screw extrusion, was capable to avoid the formation of nanofiller aggregates and to properly disperse CNTs in the ABS matrix. In addition, at high magnifications, a good adhesion level between CNT and ABS can be observed.

In

Figure 5a–f, the cross-sections of FDM nanocomposite specimens at low and high magnifications are visualized. Moreover, for FDM specimens the presence of voids (about 3 and 1 vol % as observed from

Figure 5a,c respectively) is documented. Also, uniform dispersion of nanofillers can be observed in

Figure 5b,d,f for all FDM specimens at different build orientations. By using the ImageJ software, the diameter of nanotubes was estimated to be about 33 ± 3 nm for all specimens (average of ten measurements).

3.4. Thermal Degradation Behavior

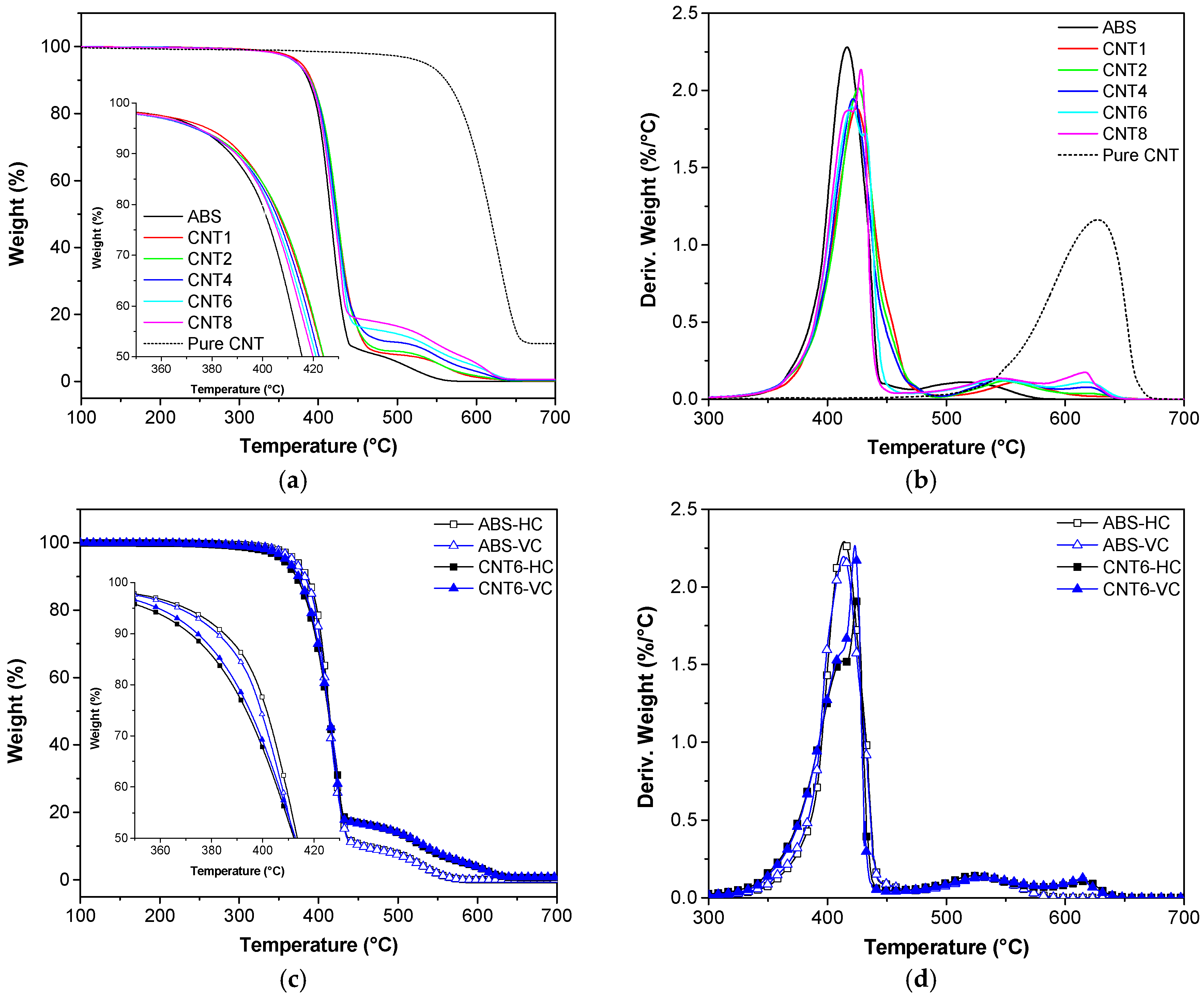

Thermal stability of ABS matrix and prepared composites was investigated by using thermal gravimetric analysis (TGA).

Figure 6a,b depicts the TGA thermogram of neat ABS and CNT-filled composite filaments, while the most important parameters are summarized in

Table 4. For the neat ABS in air environment two main degradation steps can be clearly observed at 416 °C and 514 °C, that could be attributed to the molecular chain scission and the oxidation of residual species, respectively [

26,

27]. On the other hand, neat CNTs showed one single decomposition step at around 627 °C. The onset temperature (

Tonset) and the maximum degradation temperature (

Td,max) of the composites slightly increase with rising CNTs fraction up to a maximum value for 2 wt % of CNTs; afterwards they decrease. Similar behavior was also observed for other systems, such as polylactic acid/CNT, where it was attributed to possible aggregation and breakage of CNTs at elevated concentrations [

28].

For CNT6 and CNT8 samples, it is possible to note that double peaks occurred between 420–430 °C. Moreover, an additional peak of nanocomposites with more than 4 wt % of CNT can be observed around 616–618 °C, which might be associated with the presence of CNT. The maximum mass loss rate (MMLR) in

Figure 6b is progressively reduced by the presence of CNT since the nanofiller can hinder the diffusion of volatile products generated by polymer decomposition [

27,

28,

29]. As reported in

Table 4, the residue of tested composites at 700 °C increases with the CNT fraction. However, the residual mass is lower than the nominal amount of CNT because of the oxidation of CNT in the air in the course of experiments.

TGA thermograms reported in

Figure 6c,d prove that 3D-printed specimens prepared at the different built orientations (HC and VC) exhibited a behavior similar to that observed for neat ABS filaments. However, as reported in

Table 4, 3D-printed nanocomposite samples, i.e., CNT6-HC and CNT6-VC, showed a slightly lower

Tonset than the corresponding neat ABS samples. The residue at 475 °C and 575 °C was considered to evaluate the CNTs content. In particular, the relative residue obtained after subtraction of ABS contribute fit quite well with the nominal CNT wt %.

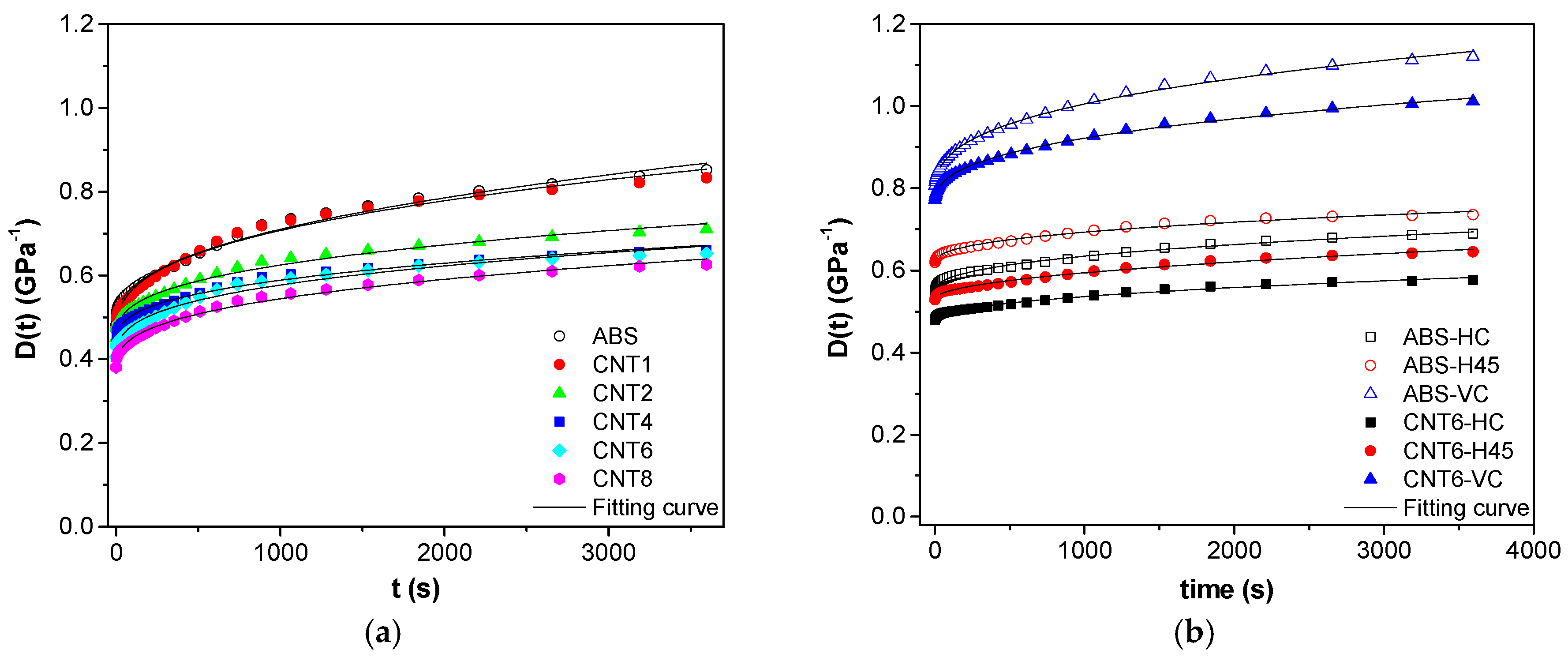

3.7. Creep Stability

Figure 9a,b shows the creep compliance at 30 °C of neat ABS and composites found for (a) filaments and for (b) FDM samples. If no plastic deformation occurs, compliance of isothermal tensile creep,

Dtot(

t), consists two components: elastic (instantaneous)

Del and viscoelastic (time-dependent)

Dve, as defined in Equation (10).

Incorporation of CNTs in ABS accounts for a pronounced reduction of both compliance components, as reported in

Table 7.

Del is characterized by an almost linear decrease with CNTs fraction, which is in conformity with the inverse trend of tensile modulus (

Table 5 and

Table 6). For example, the composite with 8 wt % of the nanofiller showed

Del or

Dtot,3600s by 21% or 26% lower than the neat matrix. For FDM samples, a similar effect of CNT on both elastic and viscoelastic creep compliance was observed: 6 wt % of the nanofiller in ABS matrix reduced the total compliance of nanocomposite by 16%, 12% and 10% for HC, H45 and VC respectively.

The empirical Findley’s model (power law), summarized in Equation (11) was used to describe the viscoelastic creep response [

30,

31,

32]:

where

De is the elastic (instantaneous) creep compliance,

k is a coefficient related to the magnitude of the underlying retardation process and

n is an exponent related to the time dependence of the creep process. The fitting parameters for experimental creep data are summarized in

Table 7. The fitting model was satisfactory, as

R2 around 0.99 was found for all samples value. The addition of CNT reduced the creep compliance of composites; in particular, the value of parameter

De, for both filaments and 3D-parts are in good agreement with the values of

Del. from Equation (10). The coefficient

n reflects the kinetics of displacements of the segments of macromolecules in the viscous medium in the course of the creep and it was found to slightly decrease with the presence of CNT in ABS filaments.

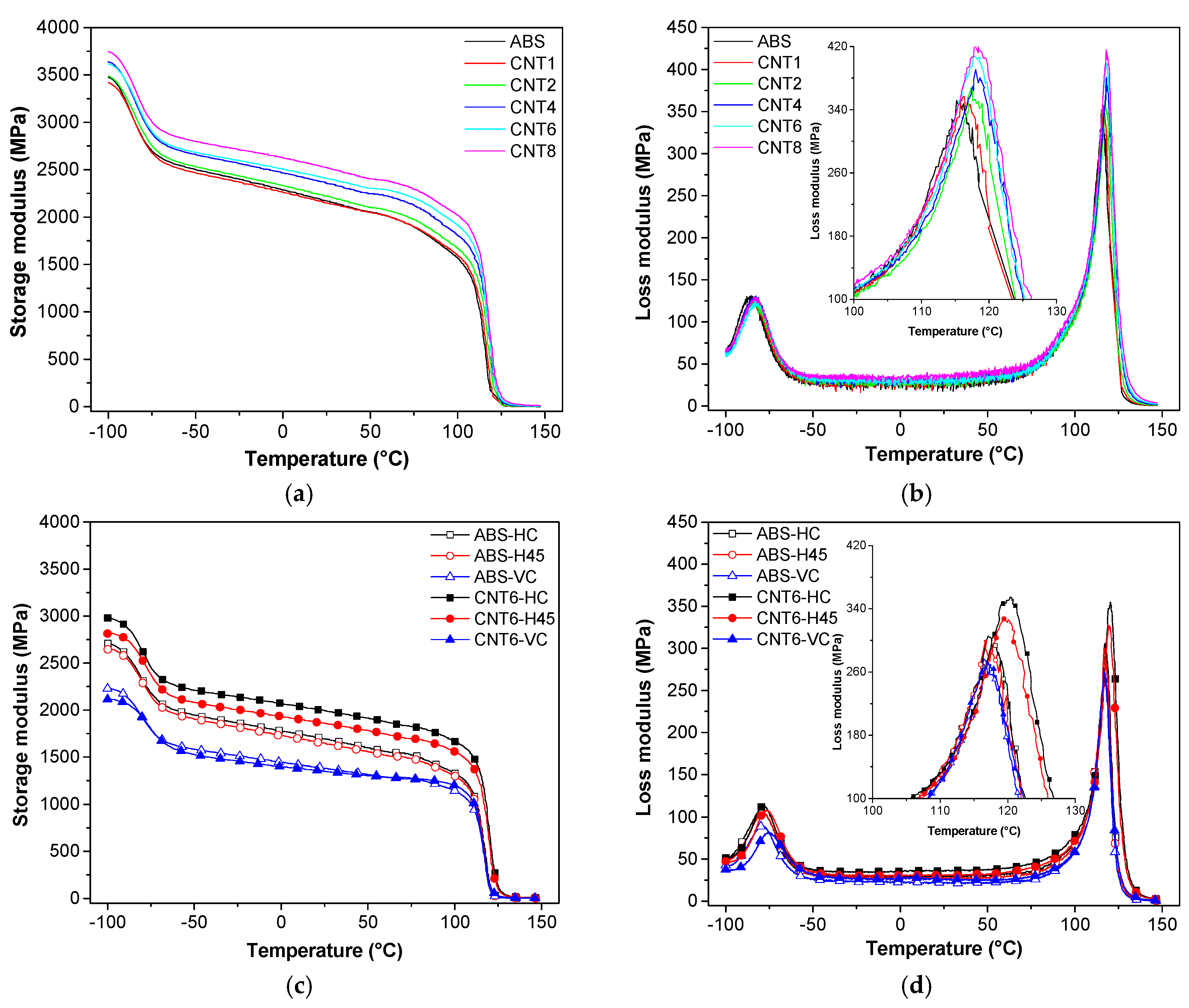

3.8. Dynamic Mechanical Response and Coefficient of Thermal Expansion

Figure 10 documents that ABS matrix and all composites show two transitions which can be identified with the glass transition of butadiene phase (B-phase;

Tg1 = −84 °C) and the glass transition of styrene–acrylonitrile phase (SAN phase;

Tg2 = 125 °C). Incorporation of CNT accounts for enhancement of the storage modulus of composites above that of ABS matrix, which becomes more pronounced at higher temperatures. For instance, at the highest concentration of CNT (8 wt %), the storage modulus of composite filament exceeds that of ABS by about 16% at 30 °C and by 897% at 130 °C.

Incorporated CNT also contributes to enhancing the dissipation of mechanical energy, as represented by the dynamic loss modulus. Moreover, the nanofiller also increases the glass transition temperatures of both butadiene and styrene–acrylonitrile phases by about 3 °C due to the hindering of segmental motions at the interface. Similar observations were also reported in prior papers [

23,

33].

As expected, the storage modulus of 3D-printed specimens at build parallel and ±45° orientations (HC and H45) is higher than that measured on samples with the VC orientation. The behavior observed for HC and H45 samples is related to the direction of the deposited filaments preferentially aligned and isotropic materials inclined at ±45° along the tensile applied load respectively, while the deposited layers in VC specimens are mostly oriented transversally to the tensile force. In general, the 3D-printed samples show storage modulus lower than original filaments due to the presence of voids and specific orientation of extruded microfilaments in 3D-printed samples (HC and VC).

The data summarized in

Table 8, clearly show that the storage modulus of HC or H45 at 30 °C is enhanced by about 15% or 12% due to the addition of carbon nanotubes. The observed effect is even more pronounced at higher temperatures: at 130 °C the storage modulus of CNT6-HC or CNT6-H45 is 5 times higher than that of neat ABS-HC and ABS-H45. On the other hand, CNT do not exhibit any stiffening effect on storage modulus along VC orientation in the temperature range −50 to 30 °C, while a three-fold increase in the storage modulus can be observed at 130 °C.

The presence of carbon nanotubes also increases the glass temperature of CNT6-HC and CNT6-H45 by about 3 °C, which is identical with previously reported an increase in

Tg for nanocomposite filaments (see

Supplementary Materials Table S2).

The stiffness loss (

SLTg) at the glass transition temperature could be evaluated from the reduction of storage modulus before and after the transition (Δ

E’), according to Equation (12) as a function of storage modulus at 30 °C.

where Δ

E’ represents the modulus variation from −100 °C to −50 °C, or from 90 °C to 130 °C, in the case of transition of butadiene or SAN phase, respectively (see data in

Table 8).

In the zone of butadiene transition, the parameter SL was found to progressively decrease from about 0.45 (ABS matrix) up to 0.38 for CNT8, in dependence on the content of CNT for all nanocomposite samples (both filaments and 3D-printed parts) as indication of the role of nanofiller in the relative stiffening at room temperature. On the other hand, the stiffness loss at the main glass transition (Tg of SAN phase) is almost linearly increasing with CNT content, from 0.80 (ABS filament) to about 0.84 for CNT8 filaments and it depends on the stiffening of rubbery phase above Tg.

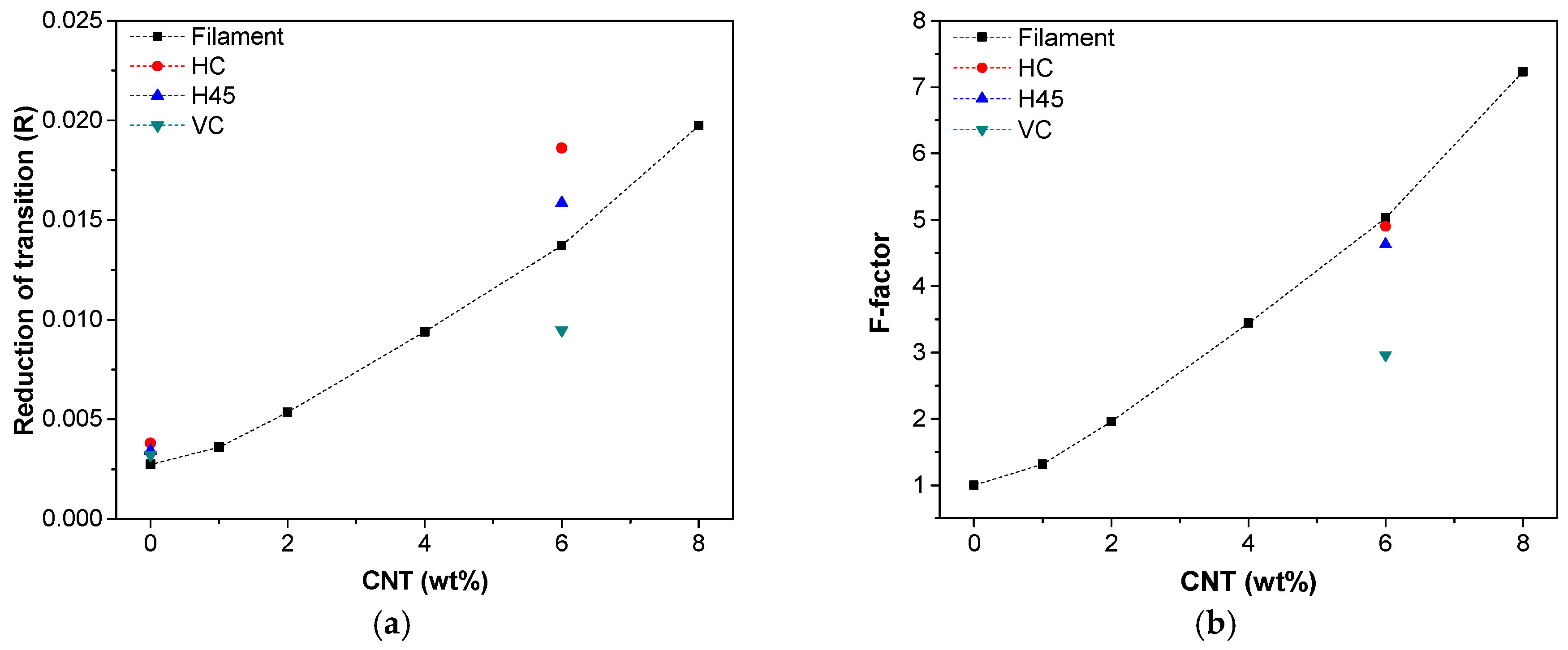

Figure 11a,b shows the reduction of the main transition of storage modulus (

R) and

F-factor [

23,

24] which are plotted as functions of the CTN fraction. In

Figure 11a, the stiffening effect of CNTs in the rubbery phase above

Tg of SAN is well documented. In particular, this effect seems to be more pronounced for FDM samples (HC and H45) with respect to filaments CNT6, probably owing to the higher orientation and adhesion/dispersion of carbon nanotubes in FDM process.

Moreover, the

F-factor represents a relative measure of modulus in the temperature interval of the glass transition, assuming that modulus at glassy state is dominated by the strength of intermolecular forces when polymer chains and nanofillers are packed [

23]. Thus, the higher

F-factor, the higher the effectiveness of the filler.

Figure 11b presents the increase in the

F-factor of filaments with the fraction of CNT and it confirms the relative effectiveness of CNT nanofiller with its fraction in composites in the rubbery phase.

For FDM sample (HC and H45), the reinforcing efficiency is slightly lower than filament at 6 wt % of CNT, maintaining almost the same adhesion level of nanofiller and matrix during FDM process. On the other hand, VC sample shows a different effect since the properties of these specimens are mainly dependent on the inter-layer matrix adhesion and mostly independent on the compatibility of the polymer chains and nanofiller.

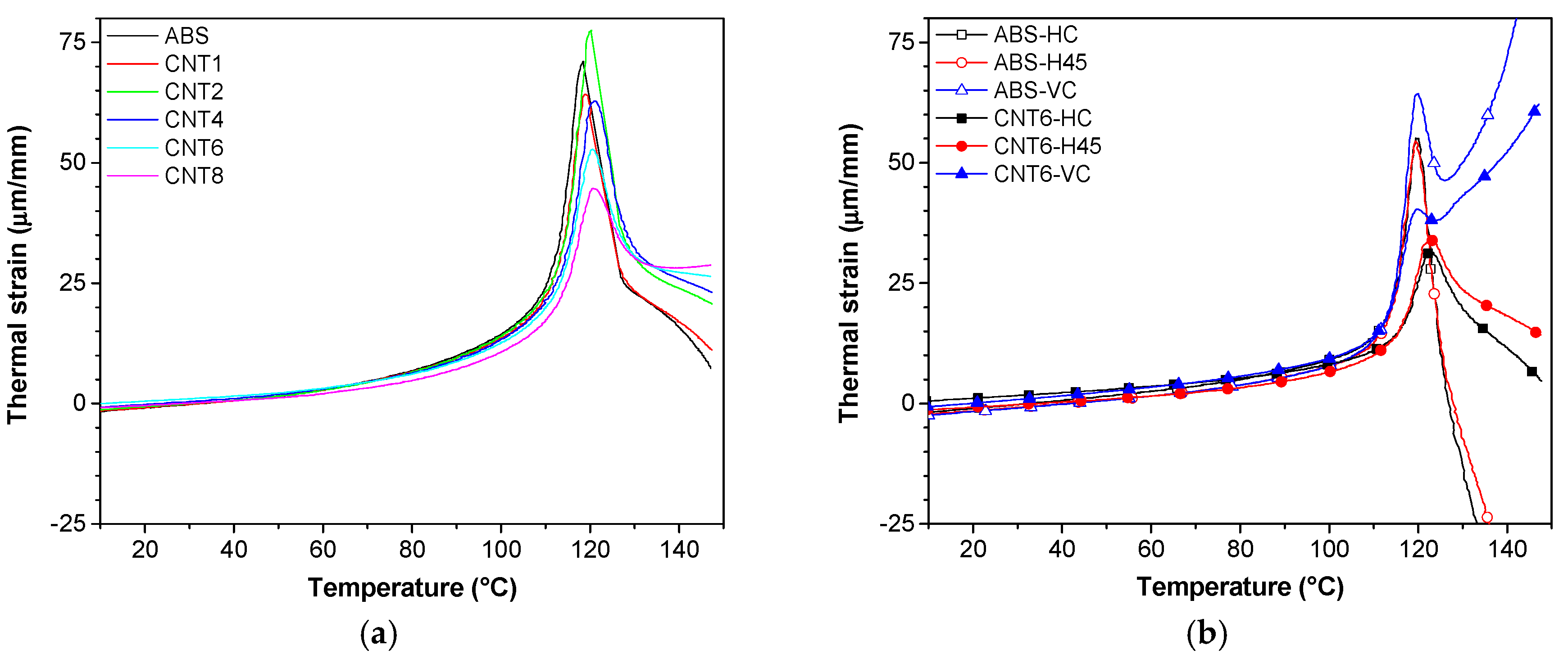

Thermal strain of ABS/CNT filaments is plotted in

Figure 12a and the coefficient of thermal expansion of all samples is reported in

Table 9. The thermal strain of composite filaments exhibited the linear trend up to 100 °C, i.e., approximately to the glass transition temperature. The steep increment of thermal strain indicates the transition from the glassy state to the rubbery state with the much higher mobility of polymer chains. Above 120 °C, the thermal strain showed negative slope with respect to the temperature scale due to some shrinkage of the polymer chains orientated during extrusion. Incorporated CNT markedly reduced the coefficient of thermal expansion (see

Table 9). As expected, the composite with the highest concentration of CNT shows the largest drop of the coefficient of thermal expansion, i.e., 79.6 for ABS to 52.3 × 10

−6/K for CNT8 at the room temperature (20~50 °C) and from −891 for ABS to −51 × 10

−6/K for CNT8 at the temperature (130~150 °C).

In the temperature interval 20/50 °C, FDM specimens (HC, H45 and VC) printed from neat ABS, exhibit CLTE values of 85.8, 74.5 and 79.1 × 10

−6/K, respectively (see

Table 9). The presence of CNTs accounts for a reduction of the CLTE of FDM specimens by 31% or 27% for HC or H45 but no effect was observed for VC build orientation.