Sequential Growth of Uniform β-NaYF4@β-NaLnF4 (Ln = Y, Lu, Yb) Microcrystals with Luminescent Properties of Multicolor Tuning and Dual-Mode Emission

Abstract

:1. Introduction

2. Results and Discussion

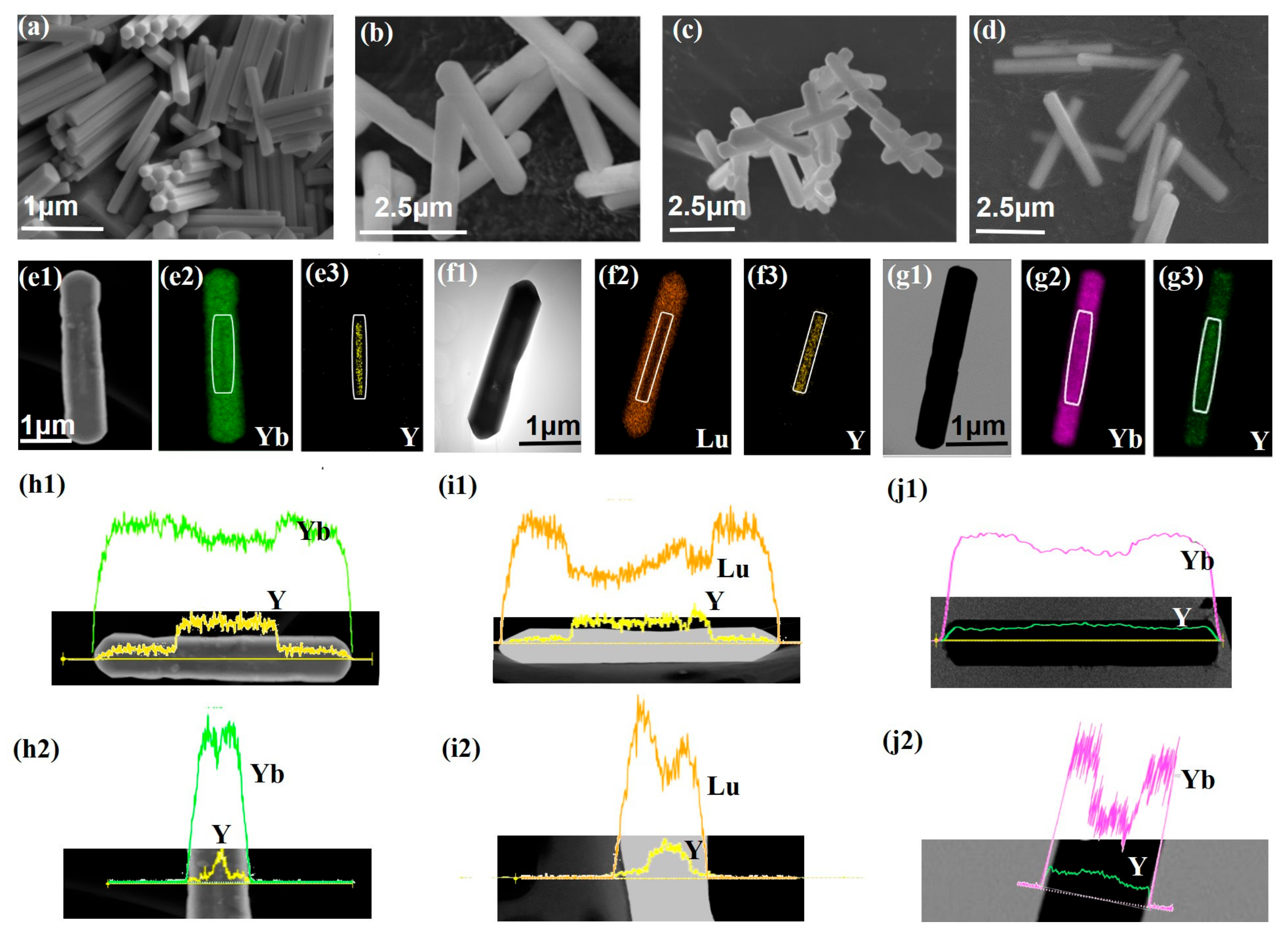

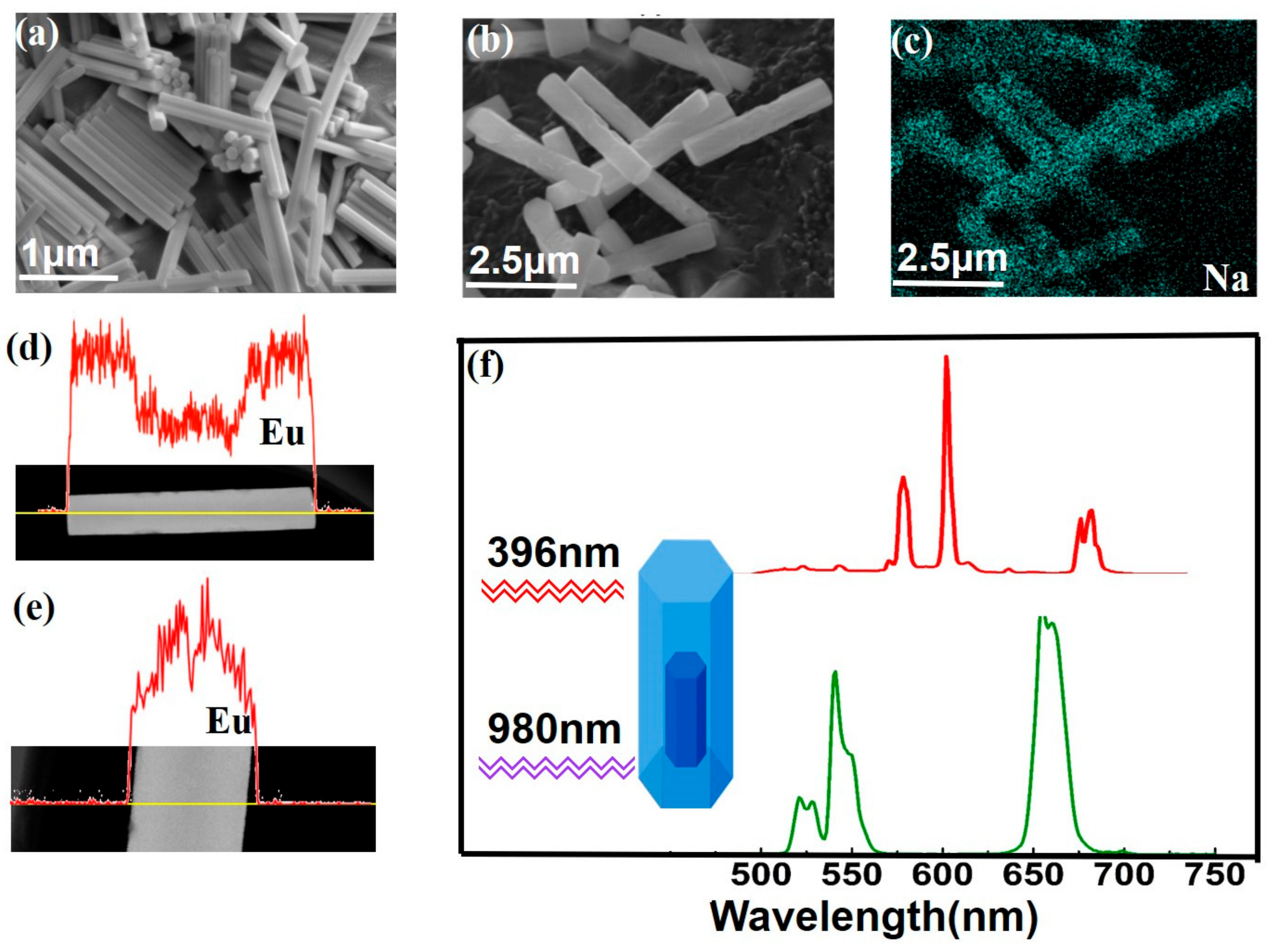

2.1. Confirmation of the Core-Shell Structure of Upconversion Microcrystals

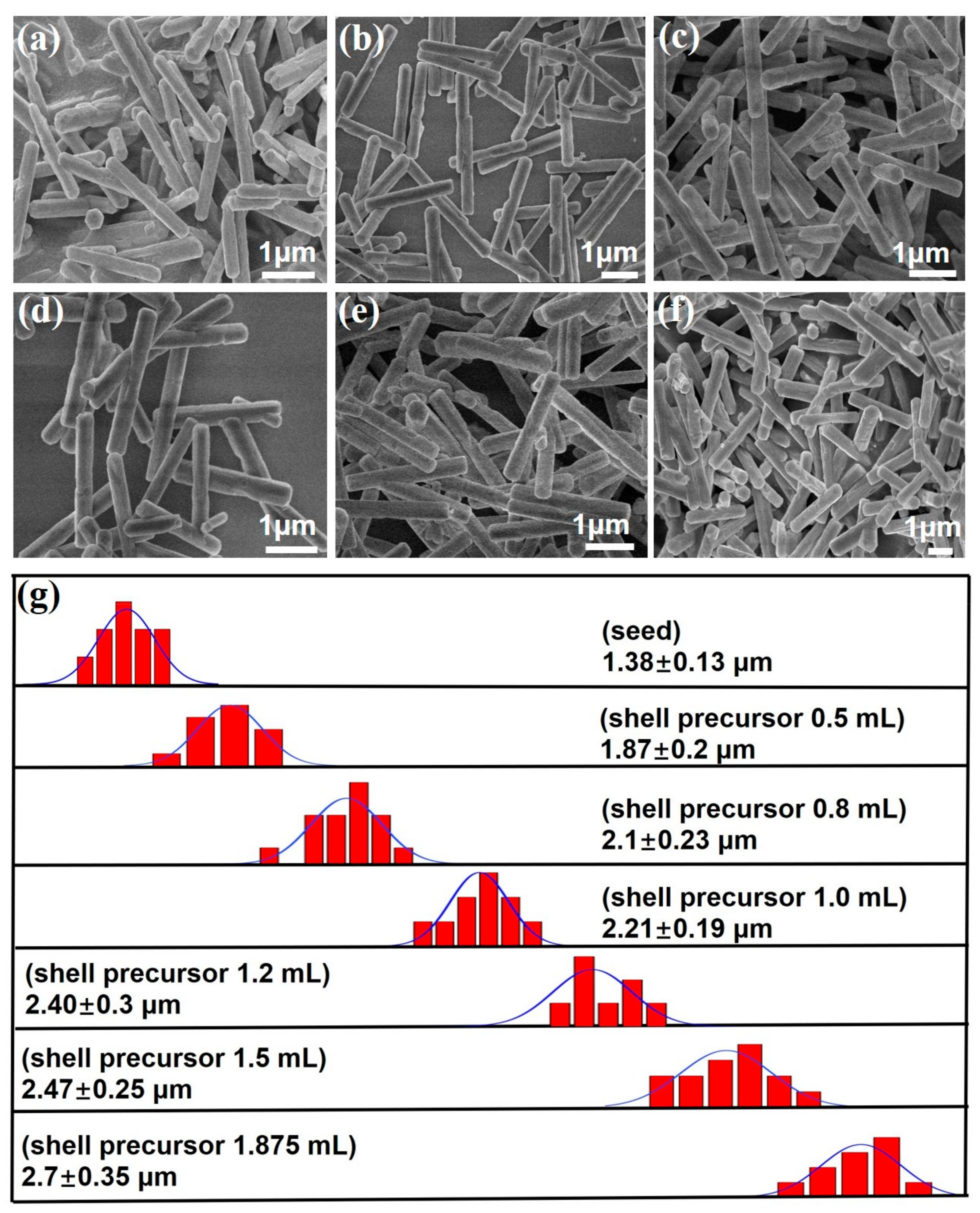

2.2. Core-Shell Microcrystals with Different Shell Thicknesses

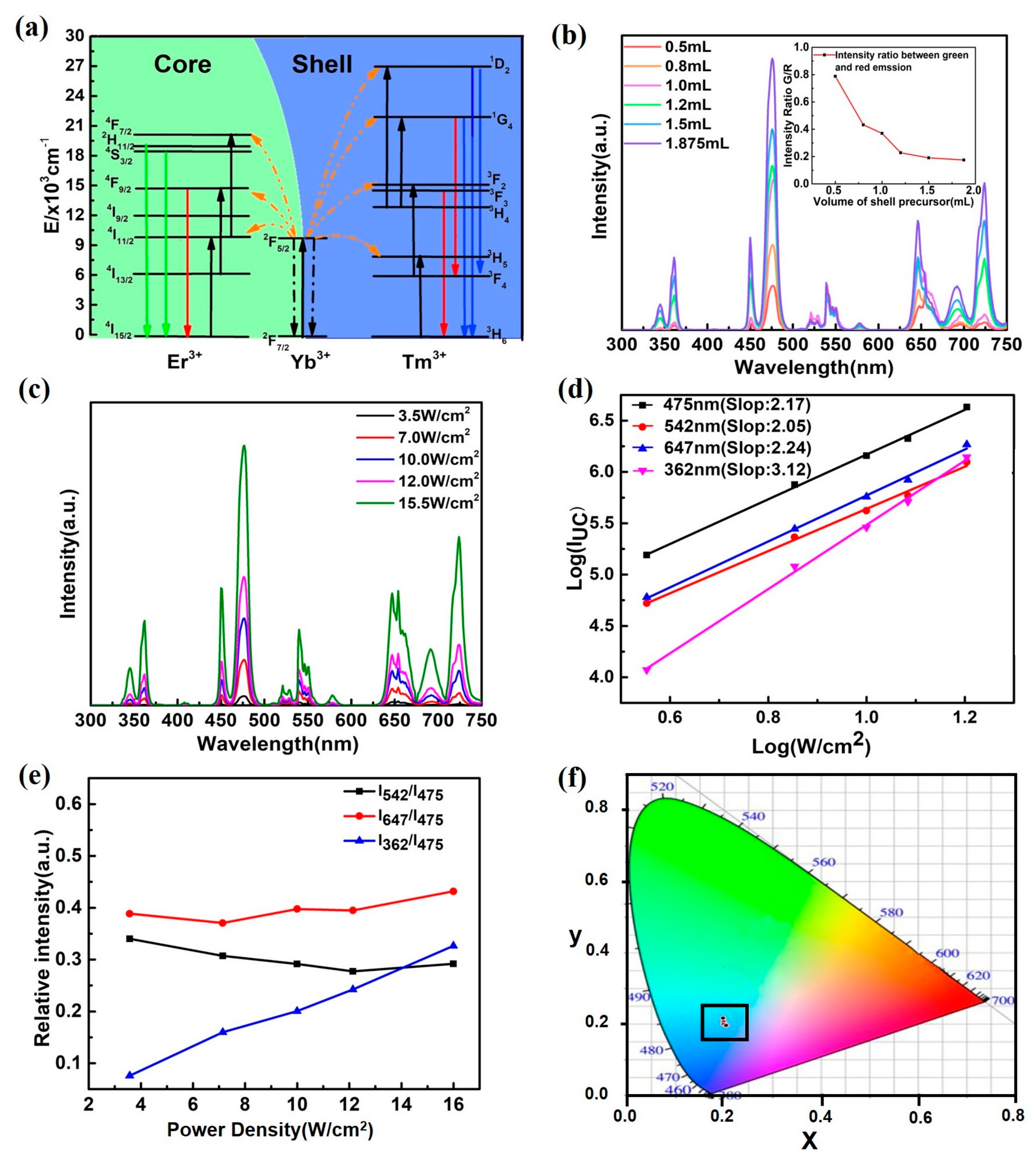

2.3. UC Luminescence Properties of Core-Shell Structured Microcrystals

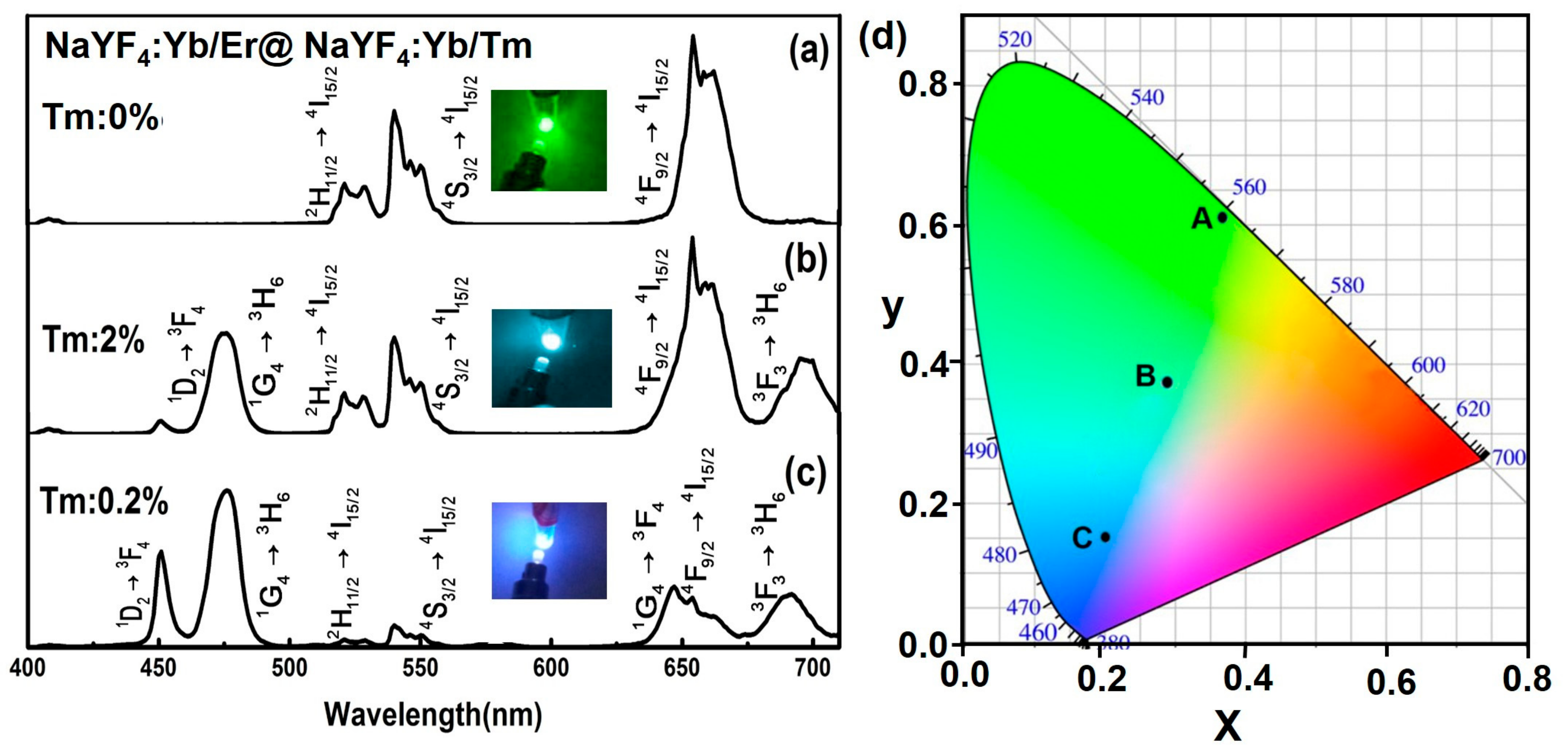

2.4. Upconversion Color Tuning

2.5. Dual-Mode Emission

3. Materials and Methods

3.1. Materials

3.2. Preparation of β-NaYF4:Er/Yb Microrods

3.3. Preparation of Seeding Microrods

3.4. Sequential Growth of Core-Shell Microrods

3.5. Characterization

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhou, B.; Shi, B.; Jin, D.; Liu, X. Controlling upconversion nanocrystals for emerging applications. Nat. Nanotechnol. 2015, 10, 924–936. [Google Scholar] [CrossRef] [PubMed]

- Nadort, A.; Zhao, J.; Goldys, E.M. Lanthanide upconversion luminescence at the nanoscale: Fundamentals and optical properties. Nanoscale 2016, 8, 13099–13130. [Google Scholar] [CrossRef] [PubMed]

- Fan, S.; Gao, G.; Busko, D.; Lin, Z.; Wang, S.; Wang, X.; Sun, S.; Turshatov, A.; Richards, B.S.; Sun, H.; et al. Monodisperse β-NaYF4:Yb3+, Tm3+ hexagonal microplates with efficient NIR-to-NIR up-conversion emission developed via ion exchange. J. Mater. Chem. C 2017, 5, 9770–9777. [Google Scholar] [CrossRef]

- Fischer, L.H.; Harms, G.S.; Wolfbeis, O.S. Upconverting nanoparticles for nanoscale thermometry. Angew. Chem. Int. Ed. 2011, 50, 4546–4551. [Google Scholar] [CrossRef] [PubMed]

- Goldys, E.M.; Tomsia, K.D.; Jinjun, S.; Dosev, D.; Kennedy, I.M.; Yatsunenko, S.; Godlewski, M. Optical characterization of Eu-doped and undoped Gd2O3 nanoparticles synthesized by the hydrogen flame pyrolysis method. J. Am. Chem. Soc. 2006, 128, 14498–14505. [Google Scholar] [CrossRef] [PubMed]

- Gai, S.; Li, C.; Yang, P.; Lin, J. Recent progress in rare earth micro/nanocrystals: Soft chemical synthesis, luminescent properties, and biomedical applications. Chem. Rev. 2014, 114, 2343–2389. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Tu, D.; Zhu, H.; Chen, X. Lanthanide-doped luminescent nanoprobes: Controlled synthesis, optical spectroscopy, and bioapplications. Chem. Soc. Rev. 2013, 42, 6924–6958. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Sun, Y.; Cao, T.; Peng, J.; Liu, Y.; Wu, Y.; Feng, W.; Zhang, Y.; Li, F. Hydrothermal synthesis of NaLuF4:153Sm,Yb,Tm nanoparticles and their application in dual-modality upconversion luminescence and SPECT bioimaging. Biomaterials 2013, 34, 774–783. [Google Scholar] [CrossRef] [PubMed]

- Deng, R.; Qin, F.; Chen, R.; Huang, W.; Hong, M.; Liu, X. Temporal full-colour tuning through non-steady-state upconversion. Nat. Nanotechnol. 2015, 10, 237–242. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wei, T.; Li, X.; Zhang, B.; Wang, J.; Huang, C.; Yuan, Q. Near-Infrared-Light-Mediated Imaging of Latent Fingerprints based on Molecular Recognition. Angew. Chem. Int. Ed. 2014, 53, 1616–1620. [Google Scholar] [CrossRef] [PubMed]

- Meruga, J.M.; Baride, A.; Cross, W.; Kellar, J.J.; May, P.S. Red-green-blue printing using luminescence-upconversion inks. J. Mater. Chem. C 2014, 2, 2221–2227. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L.; Deng, R.; Tian, J.; Zong, Y.; Jin, D.; Liu, X. Multicolor barcoding in a single upconversion crystal. J. Am. Chem. Soc. 2014, 136, 4893–4896. [Google Scholar] [CrossRef] [PubMed]

- Du, P.; Lim, J.H.; Leem, J.W.; Cha, S.M.; Yu, J.S. Enhanced Photovoltaic Performance of Dye-Sensitized Solar Cells by Efficient Near-Infrared Sunlight Harvesting using Upconverting Y2O3:Er3+/Yb3+ Phosphor Nanoparticles. Nanoscale Res. Lett. 2015, 10, 321. [Google Scholar] [CrossRef] [PubMed]

- De Wildn, J.; Rath, J.K.; Meijerink, A.; van Sark, W.G.J.H.M.; Schropp, R.E.I. Enhanced near-infrared response of a-Si:H solar cells with β-NaYF4:Yb3+ (18%), Er3+ (2%) upconversion phosphors. Sol. Energy Mater. Sol. Cells 2010, 94, 2395–2398. [Google Scholar] [CrossRef]

- Luoshan, M.; Bai, L.; Bu, C.; Liu, X.; Zhu, Y.; Guo, K.; Jiang, R.; Li, M.; Zhao, X. Surface plasmon resonance enhanced multi-shell-modified upconversion NaYF4:Yb3+, Er3+@SiO2@Au@TiO2 crystallites for dye-sensitized solar cells. J. Power Sources 2016, 307, 468–473. [Google Scholar] [CrossRef]

- Gao, G.; Turshatov, A.; Howard, I.A.; Busko, D.; Hudry, D.; Richards, B.S. Up-conversion fluorescent labels for plastic recycling: A review. Adv. Sustain. Syst. 2017, 1, 1600033. [Google Scholar] [CrossRef]

- Xia, A.; Gao, Y.; Zhou, J.; Li, C.; Yang, T.; Wu, D.; Wu, L.; Li, F. Core-shell NaYF4:Yb3+,Tm3+@FexOy nanocrystals for dual-modality T2-enhanced magnetic resonance and NIR-to-NIR upconversion luminescent imaging of small-animal lymphatic node. Biomaterials 2011, 32, 7200–7208. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Zheng, M.; Kong, X.; Zhang, Y.; Zeng, Q.; Sun, Z.; Buma, W.J.; Zhang, H. Separately doped upconversion-C60 nanoplatform for NIR imaging-guided photodynamic therapy of cancer cells. Chem. Commun. 2013, 49, 3224–3226. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Deng, K.; Wei, X.; Jiang, G.; Duan, C.; Chen, Y.; Yin, M. Upconversion luminescence of NaYF4: Yb3+, Er3+ for temperature sensing. Opt. Commun. 2013, 291, 138–142. [Google Scholar] [CrossRef]

- Chen, G.; Agren, H.; Ohulchanskyy, T.Y.; Prasad, P.N. Light upconverting core-shell nanostructures: Nanophotonic control for emerging applications. Chem. Soc. Rev. 2015, 44, 1680–1713. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Liu, X. Multicolor tuning of lanthanide-doped nanoparticles by single wavelength excitation. Acc. Chem. Res. 2014, 47, 1378–1385. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Wang, L.; Wang, Z.; Liu, X.; Xiong, Y. Modification of NaYF4:Yb,Er@SiO2 nanoparticles with gold nanocrystals for tunable green-to-red upconversion emissions. J. Phys. Chem. C 2011, 115, 3291–3296. [Google Scholar] [CrossRef]

- Fan, S.; Wang, S.; Yu, L.; Sun, H.; Gao, G.; Hu, L. Ion-redistribution induced efficient upconversion in β-NaYF4:20%Yb3+,2%Er3+ microcrystals with well controlled morphology and size. Opt. Express 2017, 25, 180–190. [Google Scholar] [CrossRef] [PubMed]

- Gao, G.; Busko, D.; Kauffmann-Weiss, S.; Turshatov, A.; Howard, I.A.; Richards, B.S. Finely-tuned NIR-to-visible up-conversion in La2O3:Yb3+,Er3+ microcrystals with high quantum yield. J. Mater. Chem. C 2017, 5, 11010–11017. [Google Scholar] [CrossRef]

- Fan, S.; Wang, S.; Sun, H.; Sun, S.; Gao, G.; Hu, L. Efficient dual-mode up-conversion and down-shifting emission in β-NaYF4:Yb3+,Er3+ microcrystals via ion exchange. J. Am. Ceram. Soc. 2017, 100, 3061–3069. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y. Monodisperse silica-coated polyvinylpyrrolidone/NaYF4 nanocrystals with multicolor upconversion fluorescence emission. Angew. Chem. 2006, 118, 7896–7899. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.; Jiang, S. Multicolor core/shell-structured upconversion fluorescent nanoparticles. Adv. Mater. 2008, 20, 4765–4769. [Google Scholar] [CrossRef]

- Zhou, B.; Tao, L.; Tsang, Y.H.; Jin, W. Core–shell nanoarchitecture: A strategy to significantly enhance white-light upconversion of lanthanide-doped nanoparticles. J. Mater. Chem. C 2013, 1, 4313–4318. [Google Scholar] [CrossRef]

- Tian, Q.; Tao, K.; Sun, K. β-NaYF4:Yb, Er at β-NaYF4 core/shell nanocrystals with significantly enhanced upconversion fluorescence by a successive two-step hot-injection approach. Micro Nano Lett. 2013, 8, 731–734. [Google Scholar] [CrossRef]

- Ouyang, J.; Yin, D.; Cao, X.; Wang, C.; Song, K.; Liu, B.; Zhang, L.; Han, Y.; Wu, M. Synthesis of NaLuF4-based nanocrystals and large enhancement of upconversion luminescence of NaLuF4:Gd, Yb, Er by coating an active shell for bioimaging. Dalton Trans. 2014, 43, 14001–14008. [Google Scholar] [CrossRef] [PubMed]

- Shao, W.; Chen, G.; Kuzmin, A.; Kutscher, H.L.; Pliss, A.; Ohulchanskyy, T.Y.; Prasad, P.N. Tunable Narrow Band Emissions from Dye-Sensitized Core/Shell/Shell Nanocrystals in the Second Near-Infrared Biological Window. J. Am. Chem. Soc. 2016, 138, 16192–16195. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Guo, Z.; Zhao, T.; Lu, Y.; Zhou, L.; Zhao, D.; Zhang, F.; Li, X. Filtration Shell Mediated Power Density Independent Orthogonal Excitations-Emissions Upconversion Luminescence. Angew. Chem. Int. Ed. 2016, 55, 2464–2469. [Google Scholar] [CrossRef] [PubMed]

- Liang, L.; Liu, Y.; Bu, C.; Guo, K.; Sun, W.; Huang, N.; Peng, T.; Sebo, B.; Pan, M.; Liu, W.; et al. Highly uniform, bifunctional core/double-shell-structured beta-NaYF4:Er3+, Yb3+@SiO2@TiO2 hexagonal sub-microprisms for high-performance dye sensitized solar cells. Adv. Mater. 2013, 25, 2174–2180. [Google Scholar] [CrossRef] [PubMed]

- Liang, L.; Liu, Y.; Zhao, X. Double-shell β-NaYF4:Yb3+,Er3+/SiO2/TiO2 submicroplates as a scattering and upconverting layer for dye-sensitized solar cells. Chem. Commun. 2013, 49, 3958–3960. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Huang, L.; Liu, X. Unraveling epitaxial habits in the NaLnF4 system for color multiplexing at the single-particle level. Angew. Chem. Int. Ed. 2016, 55, 5718–5722. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Xu, X.; Du, Y.; Qin, X.; Zhang, Y.; Ma, C.; Wen, S.; Ren, W.; Goldys, E.M.; Piper, J.A.; et al. Three-dimensional controlled growth of monodisperse sub-50 nm heterogeneous nanocrystals. Nat. Commun. 2016, 7, 10254. [Google Scholar] [CrossRef] [PubMed]

- Abel, K.A.; Boyer, J.C.; Andrei, C.M.; van Veggel, F.C.J.M. Analysis of the Shell Thickness Distribution on NaYF4/NaGdF4 Core/Shell Nanocrystals by EELS and EDS. J. Phys. Chem. Lett. 2011, 2, 185–189. [Google Scholar] [CrossRef]

- Wen, H.Q.; Peng, H.Y.; Liu, K.; Bian, M.H.; Xu, Y.J.; Dong, L.; Yan, X.; Xu, W.P.; Tao, W.; Shen, J.L.; et al. Sequential Growth of NaYF4:Yb/Er@NaGdF4 Nanodumbbells for Dual-Modality Fluorescence and Magnetic Resonance Imaging. ACS Appl. Mater. Interfaces 2017, 9, 9226–9232. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Shen, D.; Yang, J.; Yao, C.; Che, R.; Zhang, F.; Zhao, D. Successive Layer-by-Layer Strategy for Multi-Shell Epitaxial Growth: Shell Thickness and Doping Position Dependence in Upconverting Optical Properties. Chem. Mater. 2013, 25, 106–112. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, G.; Wu, E.; Bi, G.; Wu, B.; Teng, Y.; Zhou, S.; Qiu, J. Ultrasensitive polarized up-conversion of Tm3+–Yb3+ doped β-NaYF4 single nanorod. Nano Lett. 2013, 13, 2241–2246. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.; Song, M.; Wu, E.; Wu, B.; Zhou, J.; Zeng, H.; Liu, X.; Qiu, J. Polarization modulated upconversion luminescence: Single particle vs. few-particle aggregates. Nanoscale 2015, 7, 6462–6466. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Qin, W.; Wang, L.; Wei, G.; Zhu, P.; Kim, R. Intense ultraviolet upconversion luminescence from hexagonal NaYF4:Yb3+/Tm3+ microcrystals. Opt. Express 2008, 16, 11907–11914. [Google Scholar] [CrossRef] [PubMed]

- Zheng, K.; Wang, L.; Zhang, D.; Zhao, D.; Qin, W. Power switched multiphoton upconversion emissions of Er3+ in Yb3+/Er3+ codoped β-NaYF4 microcrystals induced by 980 nm excitation. Opt. Express 2010, 18, 2934–2939. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Deng, R.; Wang, J.; Wang, Q.; Han, Y.; Zhu, H.; Chen, X.; Liu, X. Tuning upconversion through energy migration in core-shell nanoparticles. Nat. Mater. 2011, 10, 968–973. [Google Scholar] [CrossRef] [PubMed]

- Shao, W.; Chen, G.; Ohulchanskyy, T.Y.; Yang, C.; Agren, H.; Prasad, P.N. A core–multiple shell nanostructure enabling concurrent upconversion and quantum cutting for photon management. Nanoscale 2017, 9, 1934–1941. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ju, D.; Song, F.; Han, Y.; Cui, W.; Zhou, A.; Liu, S.; Wang, X.; Feng, M.; Ming, C. Sequential Growth of Uniform β-NaYF4@β-NaLnF4 (Ln = Y, Lu, Yb) Microcrystals with Luminescent Properties of Multicolor Tuning and Dual-Mode Emission. Nanomaterials 2017, 7, 448. https://doi.org/10.3390/nano7120448

Ju D, Song F, Han Y, Cui W, Zhou A, Liu S, Wang X, Feng M, Ming C. Sequential Growth of Uniform β-NaYF4@β-NaLnF4 (Ln = Y, Lu, Yb) Microcrystals with Luminescent Properties of Multicolor Tuning and Dual-Mode Emission. Nanomaterials. 2017; 7(12):448. https://doi.org/10.3390/nano7120448

Chicago/Turabian StyleJu, Dandan, Feng Song, Yingdong Han, Wenjing Cui, Aihua Zhou, Shujing Liu, Xueqin Wang, Ming Feng, and Chengguo Ming. 2017. "Sequential Growth of Uniform β-NaYF4@β-NaLnF4 (Ln = Y, Lu, Yb) Microcrystals with Luminescent Properties of Multicolor Tuning and Dual-Mode Emission" Nanomaterials 7, no. 12: 448. https://doi.org/10.3390/nano7120448

APA StyleJu, D., Song, F., Han, Y., Cui, W., Zhou, A., Liu, S., Wang, X., Feng, M., & Ming, C. (2017). Sequential Growth of Uniform β-NaYF4@β-NaLnF4 (Ln = Y, Lu, Yb) Microcrystals with Luminescent Properties of Multicolor Tuning and Dual-Mode Emission. Nanomaterials, 7(12), 448. https://doi.org/10.3390/nano7120448