Selective Plasma Etching of Polymeric Substrates for Advanced Applications

Abstract

:1. Introduction

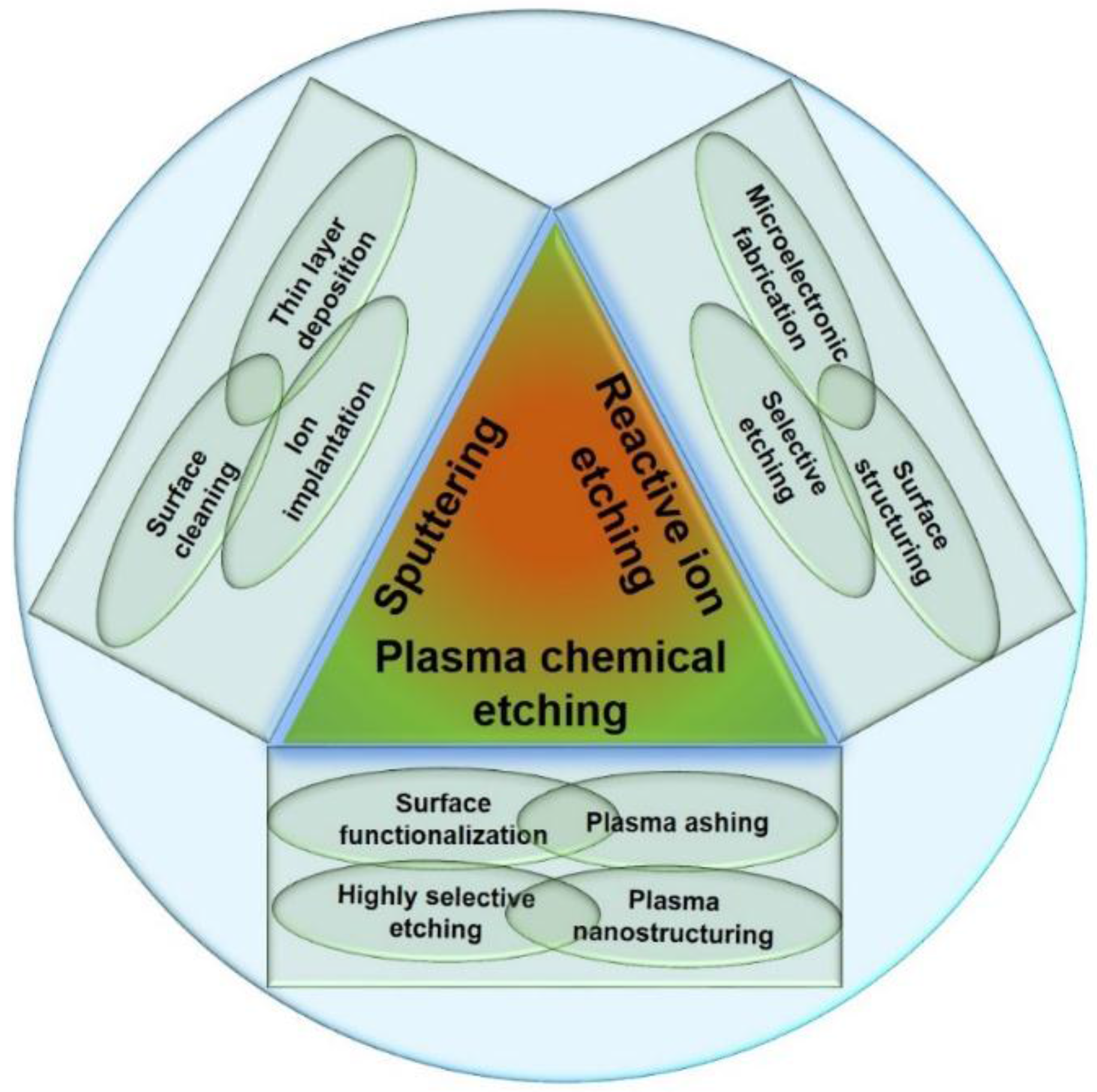

2. Plasma Processing

2.1. Sputtering

2.2. Reactive Ion Etching

2.3. Neutral Radical Plasma Chemical Etching

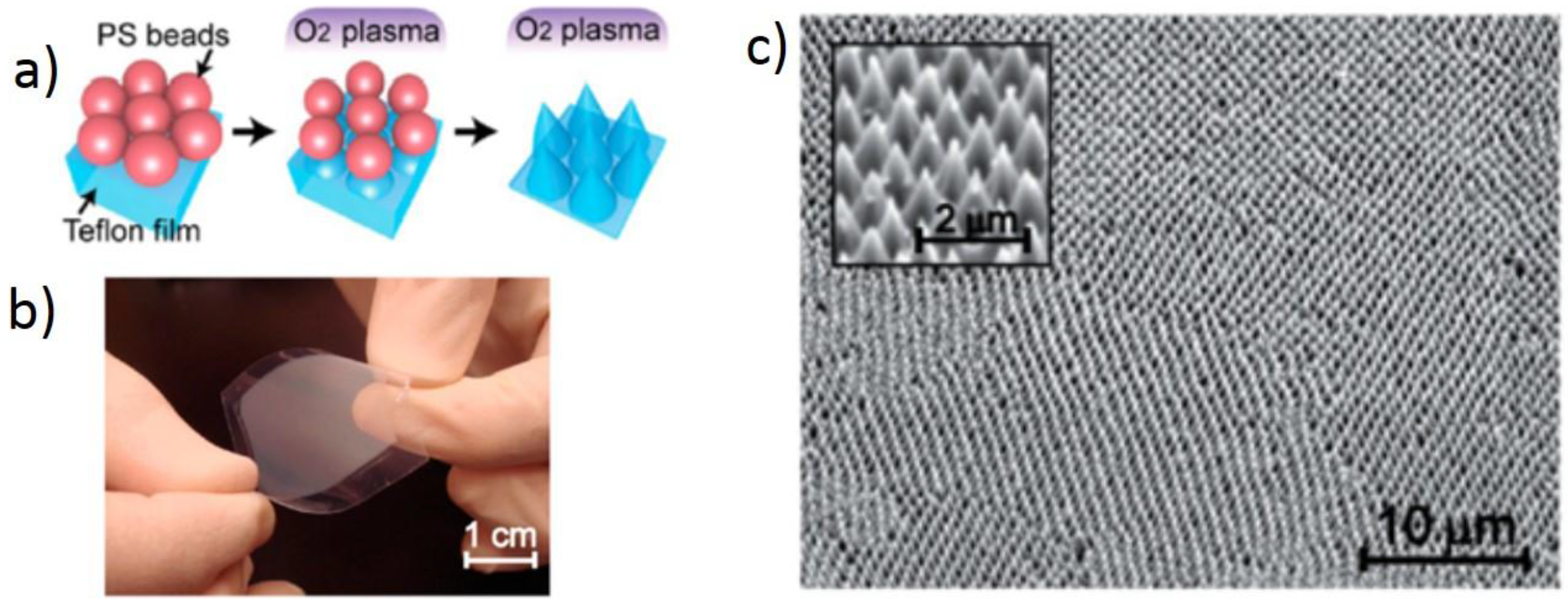

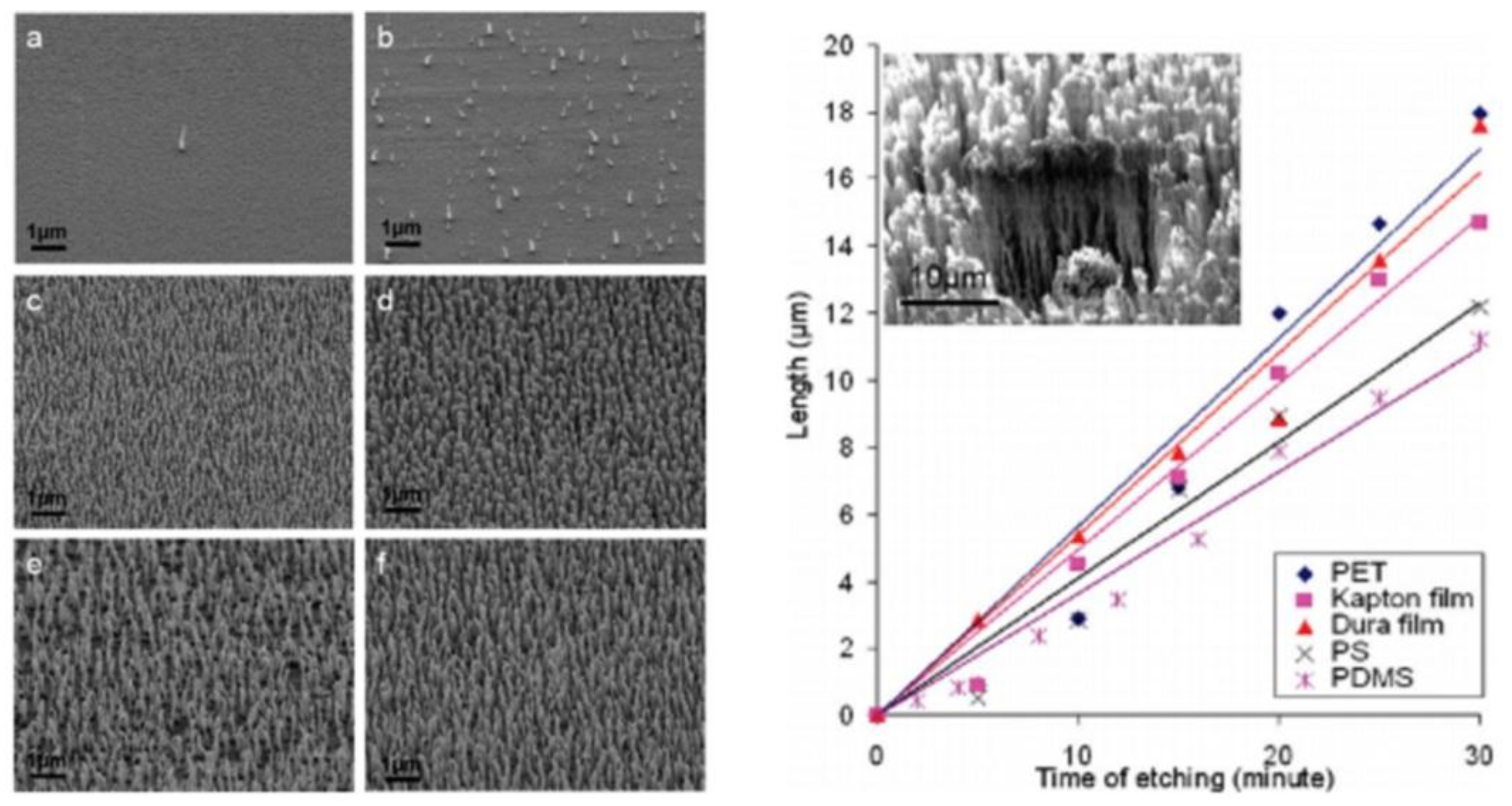

3. Applications of Plasma Functionalization and Etching of Polymers

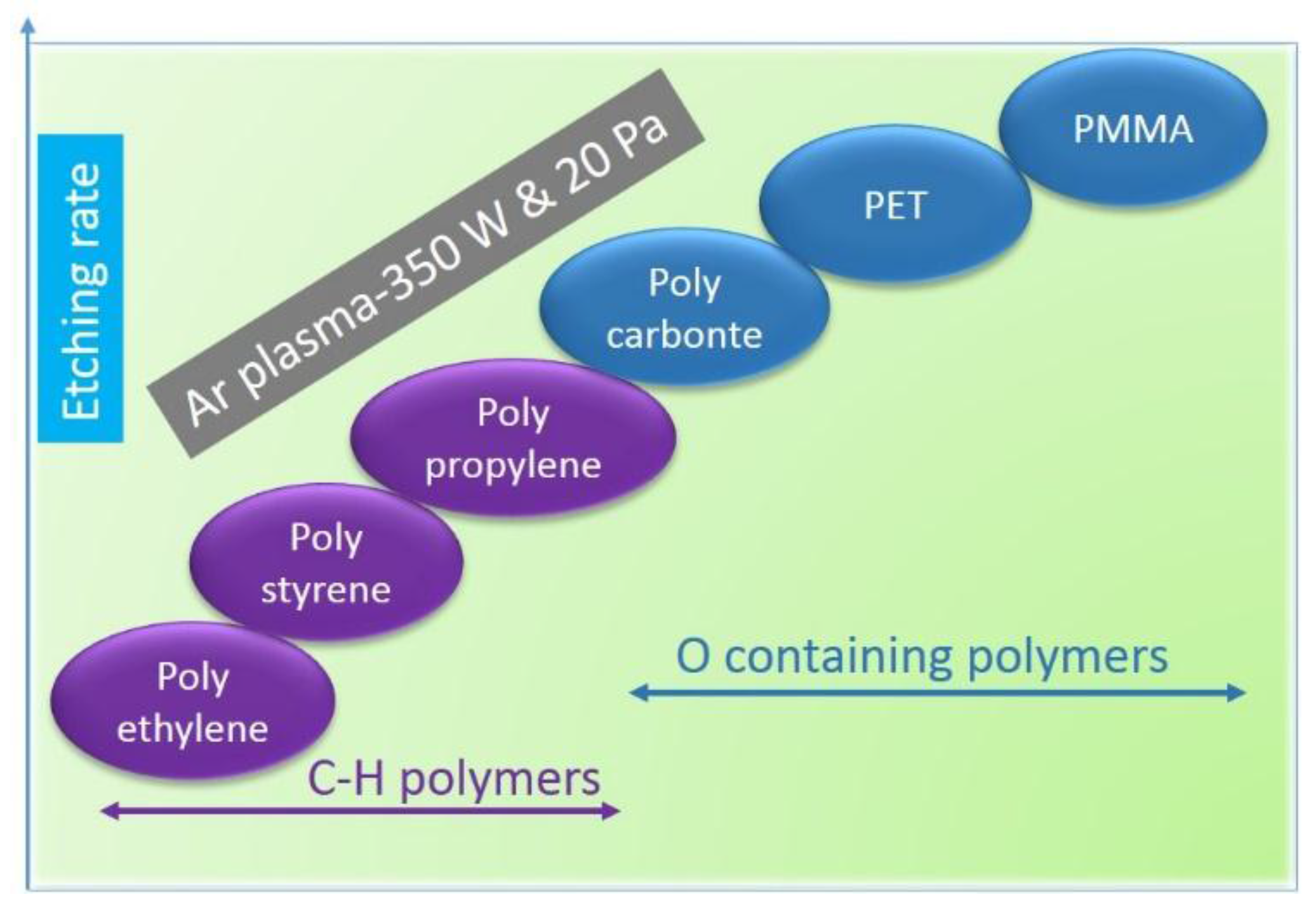

4. The Origin of Plasma Etching Selectivity

5. Applications of Plasma Selective Etching of Composite Materials

6. Conclusions and Research Challenges to Tackle

Acknowledgments

Conflicts of Interest

References

- Ostrikov, K.; Cvelbar, U.; Murphy, A.B. Plasma nanoscience: Setting directions, tackling grand challenges. J. Phys. D 2011, 44. [Google Scholar] [CrossRef]

- Zhang, Z.; Han, S.; Wang, C.; Li, J.; Xu, G. Single-walled carbon nanohorns for energy applications. Nanomaterials 2015, 5, 1732–1755. [Google Scholar] [CrossRef]

- Bo, Z.; Yang, Y.; Chen, J.; Yu, K.; Yan, J.; Cen, K. Plasma-enhanced chemical vapor deposition synthesis of vertically oriented graphene nanosheets. Nanoscale 2013, 5, 5180–5204. [Google Scholar] [CrossRef] [PubMed]

- Filipič, G.; Cvelbar, U. Copper oxide nanowires: A review of growth. Nanotechnology 2012, 23. [Google Scholar] [CrossRef] [PubMed]

- Guo, S.; Dong, S. Graphene nanosheet: Synthesis, molecular engineering, thin film, hybrids, and energy and analytical applications. Chem. Soc. Rev. 2011, 40, 2644–2672. [Google Scholar] [CrossRef] [PubMed]

- Ashik, U.P.M.; Wan Daud, W.M.A.; Abbas, H.F. Production of greenhouse gas free hydrogen by thermocatalytic decomposition of methane—A review. Renew. Sustain. Energy Rev. 2015, 44, 221–256. [Google Scholar] [CrossRef]

- Mariotti, D.; Mitra, S.; Svrcek, V. Surface-engineered silicon nanocrystals. Nanoscale 2013, 5, 1385–1398. [Google Scholar] [CrossRef] [PubMed]

- Park, S.H.; Chae, J.; Cho, M.-H.; Kim, J.H.; Yoo, K.-H.; Cho, S.W.; Kim, T.G.; Kim, J.W. High concentration of nitrogen doped into graphene using N2 plasma with an aluminum oxide buffer layer. J. Mater. Chem. C 2014, 2, 933–939. [Google Scholar] [CrossRef]

- Meena, J.S.; Chu, M.-C.; Chang, Y.-C.; You, H.-C.; Singh, R.; Liu, P.-T.; Shieh, H.-P.D.; Chang, F.-C.; Ko, F.-H. Effect of oxygen plasma on the surface states of ZnO films used to produce thin-film transistors on soft plastic sheets. J. Mater. Chem. C 2013, 1, 6613–6622. [Google Scholar] [CrossRef]

- Pumera, M. Heteroatom modified graphenes: Electronic and electrochemical applications. J. Mater. Chem. C 2014, 2, 6454–6461. [Google Scholar] [CrossRef]

- Kumar, A.; Ann Lin, P.; Xue, A.; Hao, B.; Khin Yap, Y.; Sankaran, R.M. Formation of nanodiamonds at near-ambient conditions via microplasma dissociation of ethanol vapour. Nat. Commun. 2013, 4. [Google Scholar] [CrossRef] [PubMed]

- Attri, P.; Arora, B.; Choi, E.H. Utility of plasma: A new road from physics to chemistry. RSC Adv. 2013, 3, 12540–12567. [Google Scholar] [CrossRef]

- Meyyappan, M. A review of plasma enhanced chemical vapour deposition of carbon nanotubes. J. Phys. D 2009, 42. [Google Scholar] [CrossRef]

- Meyyappan, M. Plasma nanotechnology: Past, present and future. J. Phys. D 2011, 44. [Google Scholar] [CrossRef]

- Vasilev, K.; Griesser, S.S.; Griesser, H.J. Antibacterial surfaces and coatings produced by plasma techniques. Plasma Process. Polym. 2011, 8, 1010–1023. [Google Scholar] [CrossRef]

- Aria, A.I.; Lyon, B.J.; Gharib, M. Morphology engineering of hollow carbon nanotube pillars by oxygen plasma treatment. Carbon 2015, 81, 376–387. [Google Scholar] [CrossRef]

- Coburn, J.W.; Winters, H.F. Ion- and electron-assisted gas-surface chemistry—An important effect in plasma etching. J. Appl. Phys. 1979, 50, 3189–3196. [Google Scholar] [CrossRef]

- Denes, F.S.; Manolache, S. Macromolecular plasma-chemistry: An emerging field of polymer science. Prog. Polym. Sci. 2004, 29, 815–885. [Google Scholar] [CrossRef]

- Bohlmark, J.; Lattemann, M.; Gudmundsson, J.T.; Ehiasarian, A.P.; Aranda Gonzalvo, Y.; Brenning, N.; Helmersson, U. The ion energy distributions and ion flux composition from a high power impulse magnetron sputtering discharge. Thin Solid Films 2006, 515, 1522–1526. [Google Scholar] [CrossRef]

- Smith, T. Sputter cleaning and etching of crystal surfaces (Ti, W, Si) monitored by auger spectroscopy, ellipsometry and work function change. Surf. Sci. 1971, 27, 45–59. [Google Scholar] [CrossRef]

- Oehrlein, G.S. Reactive-ion etching. Phys. Today 1986, 39, 26–33. [Google Scholar] [CrossRef]

- Lee, H.; Oberman, D.B.; Harris, J.S. Reactive ion etching of GaN using CHF3/Ar and C2ClF5/Ar plasmas. Appl. Phys. Lett. 1995, 67, 1754–1756. [Google Scholar] [CrossRef]

- Levchenko, I.; Keidar, M.; Xu, S.; Kersten, H.; Ostrikov, K. Low-temperature plasmas in carbon nanostructure synthesis. J. Vac. Sci. Technol. B 2013, 31. [Google Scholar] [CrossRef]

- Ostrikov, K.; Levchenko, I.; Cvelbar, U.; Sunkara, M.; Mozetic, M. From nucleation to nanowires: A single-step process in reactive plasmas. Nanoscale 2010, 2, 2012–2027. [Google Scholar] [CrossRef] [PubMed]

- Tachi, S.; Tsujimoto, K.; Okudaira, S. Low-temperature reactive ion etching and microwave plasma etching of silicon. Appl. Phys. Lett. 1988, 52, 616–618. [Google Scholar] [CrossRef]

- Coburn, J.W.; Winters, H.F. Conductance considerations in the reactive ion etching of high aspect ratio features. Appl. Phys. Lett. 1989, 55, 2730–2732. [Google Scholar] [CrossRef]

- Cybart, S.A.; Roediger, P.; Ulin-Avila, E.; Wu, S.M.; Wong, T.J.; Dynes, R.C. Nanometer scale high-aspect-ratio trench etching at controllable angles using ballistic reactive ion etching. J. Vac. Sci. Technol. B 2013, 31. [Google Scholar] [CrossRef]

- Zeze, D.A.; Cox, D.C.; Weiss, B.L.; Silva, S.R.P. Lithography-free high aspect ratio submicron quartz columns by reactive ion etching. Appl. Phys. Lett. 2004, 84, 1362–1364. [Google Scholar] [CrossRef]

- Mozetič, M.; Vesel, A.; Monna, V.; Ricard, A. H density in a hydrogen plasma post-glow reactor. Vacuum 2003, 71, 201–205. [Google Scholar] [CrossRef]

- Filipič, G.; Baranov, O.; Mozetič, M.; Ostrikov, K.; Cvelbar, U. Uniform surface growth of copper oxide nanowires in radiofrequency plasma discharge and limiting factors. Phys. Plasmas (1994-Present) 2014, 21. [Google Scholar] [CrossRef]

- Wang, A.; Qin, M.; Guan, J.; Wang, L.; Guo, H.; Li, X.; Wang, Y.; Prins, R.; Hu, Y. The synthesis of metal phosphides: Reduction of oxide precursors in a hydrogen plasma. Angew. Chem. 2008, 120, 6141–6143. [Google Scholar] [CrossRef]

- Vratnica, Z.; Vujosevic, D.; Cvelbar, U.; Mozetic, M. Degradation of bacteria by weakly ionized highly dissociated radio-frequency oxygen plasma. IEEE Trans. Plasma Sci. 2008, 36, 1300–1301. [Google Scholar] [CrossRef]

- Vesel, A.; Mozetic, M. Surface functionalization of organic materials by weakly ionized highly dissociated oxygen plasma. J. Phys. Conf. Ser. 2009, 162. [Google Scholar] [CrossRef]

- Hartney, M.A.; Greene, W.M.; Soane, D.S.; Hess, D.W. Mechanistic studies of oxygen plasma etching. J. Vac. Sci. Technol. B 1988, 6, 1892–1895. [Google Scholar] [CrossRef]

- Pearton, S.J.; Norton, D.P. Dry etching of electronic oxides, polymers, and semiconductors. Plasma Process. Polym. 2005, 2, 16–37. [Google Scholar] [CrossRef]

- Filipič, G.; Baranov, O.; Mozetič, M.; Cvelbar, U. Growth dynamics of copper oxide nanowires in plasma at low pressures. J. Appl. Phys. 2015, 117. [Google Scholar] [CrossRef]

- Cvelbar, U. Interaction of non-equilibrium oxygen plasma with sintered graphite. Appl. Surf. Sci. 2013, 269, 33–36. [Google Scholar] [CrossRef]

- Cvelbar, U.; Mozetič, M.; Junkar, I.; Vesel, A.; Kovač, J.; Drenik, A.; Vrlinič, T.; Hauptman, N.; Klanjšek-Gunde, M.; Markoli, B.; et al. Oxygen plasma functionalization of poly(p-phenilene sulphide). Appl. Surf. Sci. 2007, 253, 8669–8673. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, X.; Zhang, X.; Yang, B.; Li, Z.; Zhang, Q.; Huang, Z.; Wei, Y. Fabrication of cross-linked fluorescent polymer nanoparticles and their cell imaging applications. J. Mater. Chem. C 2015, 3, 1854–1860. [Google Scholar] [CrossRef]

- Tsougeni, K.; Papageorgiou, D.; Tserepi, A.; Gogolides, E. “Smart” polymeric microfluidics fabricated by plasma processing: Controlled wetting, capillary filling and hydrophobic valving. Lab Chip 2010, 10, 462–469. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Zhou, G.; Wong, W.-Y. Recent design tactics for high performance white polymer light-emitting diodes. J. Mater. Chem. C 2014, 2, 1760–1778. [Google Scholar] [CrossRef]

- Uysal Unalan, I.; Cerri, G.; Marcuzzo, E.; Cozzolino, C.A.; Farris, S. Nanocomposite films and coatings using inorganic nanobuilding blocks (NBB): Current applications and future opportunities in the food packaging sector. RSC Adv. 2014, 4, 29393–29428. [Google Scholar] [CrossRef]

- Vlachopoulou, M.-E.; Kokkoris, G.; Cardinaud, C.; Gogolides, E.; Tserepi, A. Plasma etching of poly(dimethylsiloxane): Roughness formation, mechanism, control, and application in the fabrication of microfluidic structures. Plasma Process. Polym. 2013, 10, 29–40. [Google Scholar] [CrossRef]

- Jacobs, T.; De Geyter, N.; Morent, R.; Desmet, T.; Dubruel, P.; Leys, C. Plasma treatment of polycaprolactone at medium pressure. Surf. Coat. Technol. 2011, 205, S543–S547. [Google Scholar] [CrossRef]

- Charbonnier, M.; Romand, M. Polymer pretreatments for enhanced adhesion of metals deposited by the electroless process. Int. J. Adhes. Adhes. 2003, 23, 277–285. [Google Scholar] [CrossRef]

- Yu, H.-D.; Regulacio, M.D.; Ye, E.; Han, M.-Y. Chemical routes to top-down nanofabrication. Chem. Soc. Rev. 2013, 42, 6006–6018. [Google Scholar] [CrossRef] [PubMed]

- Pochner, K.; Beil, S.; Horn, H.; Blömer, M. Treatment of polymers for subsequent metallization using intense UV radiation or plasma at atmospheric pressure. Surf. Coat. Technol. 1997, 97, 372–377. [Google Scholar] [CrossRef]

- Pascu, M.; Debarnot, D.; Durand, S.; Poncin-Epaillard, F. Surface modification of pvdf by microwave plasma treatment for electroless metallization. In Plasma Processes and Polymers; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2005; pp. 157–176. [Google Scholar]

- Macková, A.; Švorčík, V.; Strýhal, Z.; Pavlík, J. RBS and AFM study of Ag and Au diffusion into pet foils influenced by plasma treatment. Surf. Interface Anal. 2006, 38, 335–338. [Google Scholar] [CrossRef]

- Lin, Y.S.; Liu, H.M. Enhanced adhesion of plasma-sputtered copper films on polyimide substrates by oxygen glow discharge for microelectronics. Thin Solid Films 2008, 516, 1773–1780. [Google Scholar] [CrossRef]

- Li, W.T.; Charters, R.B.; Luther-Davies, B.; Mar, L. Significant improvement of adhesion between gold thin films and a polymer. Appl. Surf. Sci. 2004, 233, 227–233. [Google Scholar] [CrossRef]

- Zille, A.; Fernandes, M.M.; Francesko, A.; Tzanov, T.; Fernandes, M.; Oliveira, F.R.; Almeida, L.; Amorim, T.; Carneiro, N.; Esteves, M.F.; et al. Size and aging effects on antimicrobial efficiency of silver nanoparticles coated on polyamide fabrics activated by atmospheric DBD plasma. ACS Appl. Mater. Interfaces 2015, 7, 13731–13744. [Google Scholar] [CrossRef] [PubMed]

- Boyd, R.D.; Kenwright, A.M.; Badyal, J.P.S.; Briggs, D. Atmospheric nonequilibrium plasma treatment of biaxially oriented polypropylene. Macromolecules 1997, 30, 5429–5436. [Google Scholar] [CrossRef]

- Bazaka, K.; Jacob, M.V.; Crawford, R.J.; Ivanova, E.P. Plasma-assisted surface modification of organic biopolymers to prevent bacterial attachment. Acta Biomater. 2011, 7, 2015–2028. [Google Scholar] [CrossRef] [PubMed]

- Poncin-Epaillard, F.; Brosse, J.C.; Falher, T. Cold plasma treatment: Surface or bulk modification of polymer films? Macromolecules 1997, 30, 4415–4420. [Google Scholar] [CrossRef]

- Yasuda, H.; Gazicki, M. Biomedical applications of plasma polymerization and plasma treatment of polymer surfaces. Biomaterials 1982, 3, 68–77. [Google Scholar] [CrossRef]

- Inglis, W.; Sanders, G.H.W.; Williams, P.M.; Davies, M.C.; Roberts, C.J.; Tendler, S.J.B. A simple method for biocompatible polymer based spatially controlled adsorption of blood plasma proteins to a surface. Langmuir 2001, 17, 7402–7405. [Google Scholar] [CrossRef]

- Wang, H.; Kwok, D.T.K.; Wang, W.; Wu, Z.; Tong, L.; Zhang, Y.; Chu, P.K. Osteoblast behavior on polytetrafluoroethylene modified by long pulse, high frequency oxygen plasma immersion ion implantation. Biomaterials 2010, 31, 413–419. [Google Scholar] [CrossRef] [PubMed]

- Oehr, C. Plasma surface modification of polymers for biomedical use. Nucl. Instrum. Methods Phys. Res. Sect. B 2003, 208, 40–47. [Google Scholar] [CrossRef]

- Halfmann, H.; Bibinov, N.; Wunderlich, J.; Awakowicz, P. A double inductively coupled plasma for sterilization of medical devices. J. Phys. D 2007, 40. [Google Scholar] [CrossRef]

- Vesel, A.; Kolar, M.; Stana-Kleinschek, K.; Mozetic, M. Etching rates of blood proteins, blood plasma and polymer in oxygen afterglow of microwave plasma. Surf. Interface Anal. 2014, 46, 1115–1118. [Google Scholar] [CrossRef]

- Stoffels, E.; Flikweert, A.J.; Stoffels, W.W.; Kroesen, G.M.W. Plasma needle: A non-destructive atmospheric plasma source for fine surface treatment of (bio)materials. Plasma Sources Sci. Technol. 2002, 11. [Google Scholar] [CrossRef]

- Herrmann, H.W.; Henins, I.; Park, J.; Selwyn, G.S. Decontamination of chemical and biological warfare (CBW) agents using an atmospheric pressure plasma jet (APPJ). Phys. Plasmas 1999, 6, 2284–2289. [Google Scholar] [CrossRef]

- Lazović, S.; Puač, N.; Miletić, M.; Pavlica, D.; Jovanović, M.; Bugarski, D.; Mojsilović, S.; Maletić, D.; Malović, G.; Milenković, P.; et al. The effect of a plasma needle on bacteria in planktonic samples and on peripheral blood mesenchymal stem cells. New J. Phys. 2010, 12. [Google Scholar] [CrossRef]

- Feng, L.; Li, S.; Li, Y.; Li, H.; Zhang, L.; Zhai, J.; Song, Y.; Liu, B.; Jiang, L.; Zhu, D. Super-hydrophobic surfaces: From natural to artificial. Adv. Mater. 2002, 14, 1857–1860. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, F.; Niu, J.; Jiang, Y.; Wang, Z. Superhydrophobic surfaces: From structural control to functional application. J. Mater. Chem. 2008, 18, 621–633. [Google Scholar] [CrossRef]

- Erbil, H.Y.; Demirel, A.L.; Avcı, Y.; Mert, O. Transformation of a simple plastic into a superhydrophobic surface. Science 2003, 299, 1377–1380. [Google Scholar] [CrossRef] [PubMed]

- Puliyalil, H.; Filipič, G.; Cvelbar, U. Recent advances in the methods for designing superhydrophobic surfaces. In Surface Energy; Aliofkhazraei, M., Ed.; InTech: Rijeka, Croatia, 2015; pp. 311–335. [Google Scholar]

- Toma, M.; Loget, G.; Corn, R.M. Flexible teflon nanocone array surfaces with tunable superhydrophobicity for self-cleaning and aqueous droplet patterning. ACS Appl. Mater. Interfaces 2014, 6, 11110–11117. [Google Scholar] [CrossRef] [PubMed]

- Tsougeni, K.; Vourdas, N.; Tserepi, A.; Gogolides, E.; Cardinaud, C. Mechanisms of oxygen plasma nanotexturing of organic polymer surfaces: From stable super hydrophilic to super hydrophobic surfaces. Langmuir 2009, 25, 11748–11759. [Google Scholar] [CrossRef] [PubMed]

- Korshak, V.V.; Svetlana, V.V. Dependence of thermal stability of polymers on their chemical structure. Russ. Chem. Rev. 1968, 37, 885. [Google Scholar] [CrossRef]

- Taylor, G.N.; Wolf, T.M. Oxygen plasma removal of thin polymer films. Polym. Eng. Sci. 1980, 20, 1087–1092. [Google Scholar] [CrossRef]

- Moss, S.J.; Jolly, A.M.; Tighe, B.J. Plasma oxidation of polymers. Plasma Chem. Plasma Process. 1986, 6, 401–416. [Google Scholar] [CrossRef]

- Zadok, E.; Sialom, B.; Mazur, Y. Oxygen atoms produced by microwave discharge: Reaction with arenes. Angew. Chem. Int. Ed. Engl. 1980, 19, 1004–1005. [Google Scholar] [CrossRef]

- Zadok, E.; Rubinraut, S.; Frolow, F.; Mazur, Y. Reactions of di-, tri-, and hexamethylbenzenes with oxygen(3P) atoms in liquid and on adsorbed phases. J. Am. Chem. Soc. 1985, 107, 2489–2494. [Google Scholar] [CrossRef]

- Xie, L.; Jiao, L.; Dai, H. Selective etching of graphene edges by hydrogen plasma. J. Am. Chem. Soc. 2010, 132, 14751–14753. [Google Scholar] [CrossRef] [PubMed]

- Xiang, H.; Kan, E.; Wei, S.-H.; Whangbo, M.-H.; Yang, J. “Narrow” graphene nanoribbons made easier by partial hydrogenation. Nano Lett. 2009, 9, 4025–4030. [Google Scholar] [CrossRef] [PubMed]

- Kerr, J.A. Handbook of Bimolecular and Termolecular Gas Reactions; Taylor & Francis: Boca Raton, FL, USA, 1987. [Google Scholar]

- Mogab, C.J.; Adams, A.C.; Flamm, D.L. Plasma etching of Si and SiO2—The effect of oxygen additions to CF4 plasmas. J. Appl. Phys. 1978, 49, 3796–3803. [Google Scholar] [CrossRef]

- Chun, I.; Efremov, A.; Yeom, G.Y.; Kwon, K.-H. A comparative study of CF4/O2/Ar and C4F8/O2/Ar plasmas for dry etching applications. Thin Solid Films 2015, 579, 136–143. [Google Scholar] [CrossRef]

- Hegemann, D.; Brunner, H.; Oehr, C. Plasma treatment of polymers for surface and adhesion improvement. Nucl. Instrum. Methods Phys. Res. Sect. B 2003, 208, 281–286. [Google Scholar] [CrossRef]

- Wohlfart, E.; Fernández-Blázquez, J.P.; Knoche, E.; Bello, A.; Pérez, E.; Arzt, E.; del Campo, A. Nanofibrillar patterns by plasma etching: The influence of polymer crystallinity and orientation in surface morphology. Macromolecules 2010, 43, 9908–9917. [Google Scholar] [CrossRef]

- Junkar, I.; Cvelbar, U.; Vesel, A.; Hauptman, N.; Mozetič, M. The role of crystallinity on polymer interaction with oxygen plasma. Plasma Process. Polym. 2009, 6, 667–675. [Google Scholar] [CrossRef]

- Chernomordik, B.D.; Russel, H.B.; Cvelbar, U.; Jasinski, J.B.; Kumar, V.; Deutsch, T.; Sunkara, M.K. Photoelectrochemical activity of as-grown, α-Fe2O3 nanowire array electrodes for water splitting. Nanotechnology 2012, 23. [Google Scholar] [CrossRef] [PubMed]

- Lazović, S.; Puač, N.; Spasić, K.; Malović, G.; Cvelbar, U.; Mozetič, M.; Radetić, M.; Petrović, Z.L. Plasma properties in a large-volume, cylindrical and asymmetric radio-frequency capacitively coupled industrial-prototype reactor. J. Phys. D Appl. Phys. 2013, 46. [Google Scholar] [CrossRef]

- Olde Riekerink, M.B.; Terlingen, J.G.A.; Engbers, G.H.M.; Feijen, J. Selective etching of semicrystalline polymers: CF4 gas plasma treatment of poly(ethylene). Langmuir 1999, 15, 4847–4856. [Google Scholar] [CrossRef]

- Nair, L.G.; Mahapatra, A.S.; Gomathi, N.; Joseph, K.; Neogi, S.; Nair, C.P.R. Radio frequency plasma mediated dry functionalization of multiwall carbon nanotube. Appl. Surf. Sci. 2015, 340, 64–71. [Google Scholar] [CrossRef]

- Black, C.T.; Guarini, K.W.; Milkove, K.R.; Baker, S.M.; Russell, T.P.; Tuominen, M.T. Integration of self-assembled diblock copolymers for semiconductor capacitor fabrication. Appl. Phys. Lett. 2001, 79, 409–411. [Google Scholar] [CrossRef]

- Chuang, V.P.; Ross, C.A.; Gwyther, J.; Manners, I. Self-assembled nanoscale ring arrays from a polystyrene-b-polyferrocenylsilane-b-poly(2-vinylpyridine)triblock terpolymer thin film. Adv. Mater. 2009, 21, 3789–3793. [Google Scholar] [CrossRef]

- Lammertink, R.G.H.; Hempenius, M.A.; van den Enk, J.E.; Chan, V.Z.H.; Thomas, E.L.; Vancso, G.J. Nanostructured thin films of organic–organometallic block copolymers: One-step lithography with poly(ferrocenylsilanes) by reactive ion etching. Adv. Mater. 2000, 12, 98–103. [Google Scholar]

- Jung, Y.S.; Ross, C.A. Orientation-controlled self-assembled nanolithography using a polystyrene—Polydimethylsiloxane block copolymer. Nano Lett. 2007, 7, 2046–2050. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.Y.; Nunns, A.; Gwyther, J.; Davis, R.L.; Manners, I.; Chaikin, P.M.; Register, R.A. Large-area nanosquare arrays from shear-aligned block copolymer thin films. Nano Lett. 2014, 14, 5698–5705. [Google Scholar] [CrossRef] [PubMed]

- Mozetič, M. Controlled oxidation of organic compounds in oxygen plasma. Vacuum 2003, 71, 237–240. [Google Scholar] [CrossRef]

- Panda, S.; Economou, D.J.; Meyyappan, M. Effect of metastable oxygen molecules in high density power-modulated oxygen discharges. J. Appl. Phys. 2000, 87, 8323–8333. [Google Scholar] [CrossRef]

- Dai, L.; Griesser, H.J.; Mau, A.W.H. Surface modification by plasma etching and plasma patterning. J. Phys. Chem. B 1997, 101, 9548–9554. [Google Scholar] [CrossRef]

- Chen, F.F.; Smith, M.D. Plasma. In Van Nostrand’s Scientific Encyclopedia; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005. [Google Scholar] [CrossRef]

- Donnelly, V.M.; Kornblit, A. Plasma etching: Yesterday, today, and tomorrow. J. Vac. Sci. Technol. A 2013, 31. [Google Scholar] [CrossRef]

- Mozetič, M.; Ostrikov, K.; Ruzic, D.N.; Curreli, D.; Cvelbar, U.; Vesel, A.; Primc, G.; Leisch, M.; Jousten, K.; Malyshev, O.B.; et al. Recent advances in vacuum sciences and applications. J. Phys. D 2014, 47. [Google Scholar] [CrossRef]

- Kontziampasis, D.; Constantoudis, V.; Gogolides, E. Plasma directed organization of nanodots on polymers: Effects of polymer type and etching time on morphology and order. Plasma Process. Polym. 2012, 9, 866–872. [Google Scholar] [CrossRef]

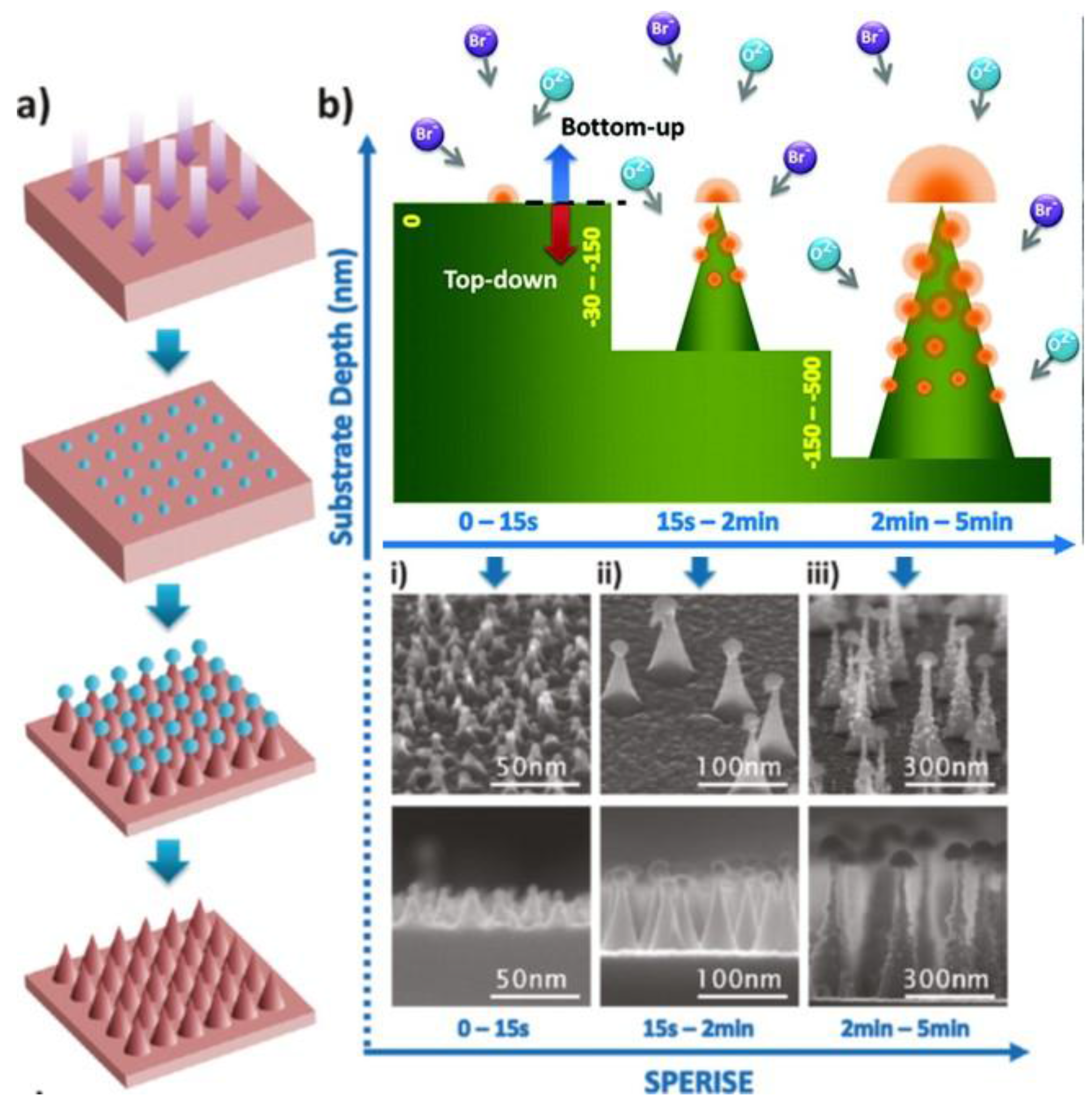

- Vourdas, N.; Kontziampasis, D.; Kokkoris, G.; Constantoudis, V.; Goodyear, A.; Tserepi, A.; Cooke, M.; Gogolides, E. Plasma directed assembly and organization: Bottom-up nanopatterning using top-down technology. Nanotechnology 2010, 21. [Google Scholar] [CrossRef] [PubMed]

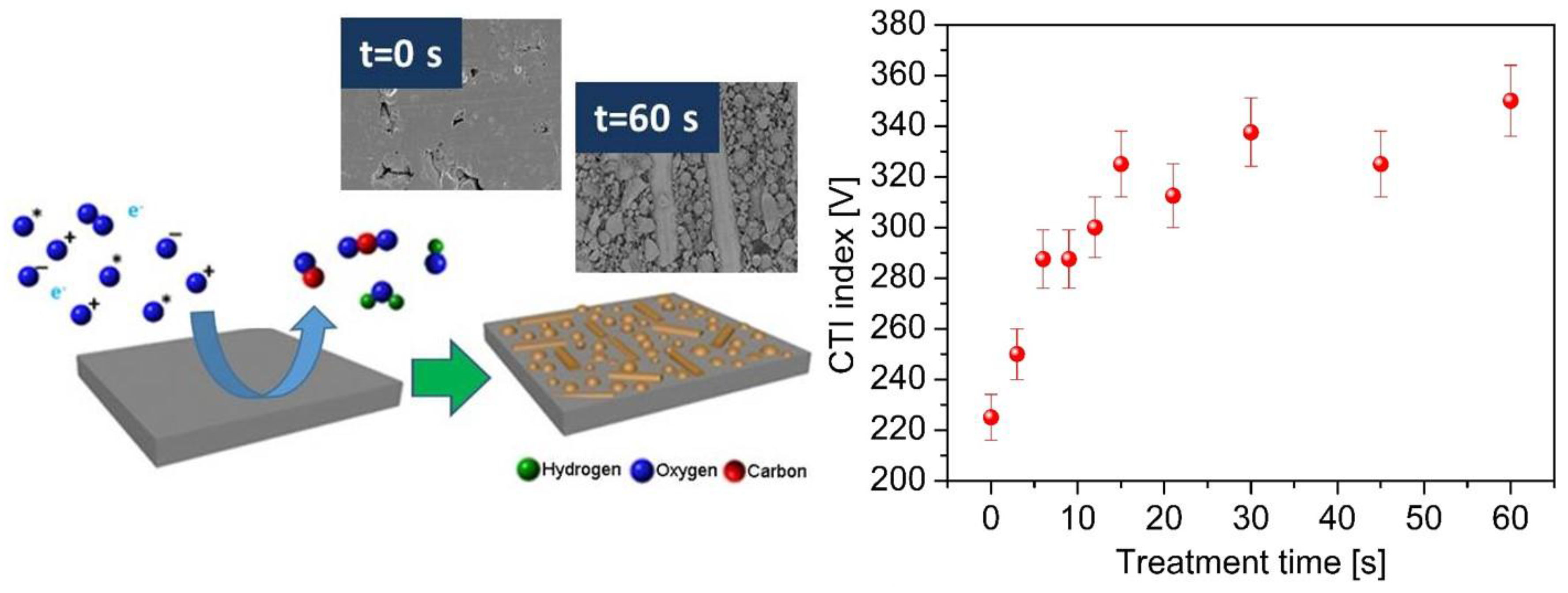

- Puliyalil, H.; Cvelbar, U.; Filipic, G.; Petric, A.D.; Zaplotnik, R.; Recek, N.; Mozetic, M.; Thomas, S. Plasma as a tool for enhancing insulation properties of polymer composites. RSC Adv. 2015, 5, 37853–37858. [Google Scholar] [CrossRef]

- El-Aguizy, T.A.; Jeong, J.-H.; Jeon, Y.-B.; Li, W.Z.; Ren, Z.F.; Kim, S.-G. Transplanting carbon nanotubes. Appl. Phys. Lett. 2004, 85, 5995–5997. [Google Scholar] [CrossRef]

- Che, Y.; Wang, C.; Liu, J.; Liu, B.; Lin, X.; Parker, J.; Beasley, C.; Wong, H.S.P.; Zhou, C. Selective synthesis and device applications of semiconducting single-walled carbon nanotubes using isopropyl alcohol as feedstock. ACS Nano 2012, 6, 7454–7462. [Google Scholar] [CrossRef] [PubMed]

- Hou, P.-X.; Li, W.-S.; Zhao, S.-Y.; Li, G.-X.; Shi, C.; Liu, C.; Cheng, H.-M. Preparation of metallic single-wall carbon nanotubes by selective etching. ACS Nano 2014, 8, 7156–7162. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Qi, P.; Wang, X.; Lu, Y.; Li, X.; Tu, R.; Bangsaruntip, S.; Mann, D.; Zhang, L.; Dai, H. Selective etching of metallic carbon nanotubes by gas-phase reaction. Science 2006, 314, 974–977. [Google Scholar] [CrossRef] [PubMed]

- Di, C.-A.; Wei, D.; Yu, G.; Liu, Y.; Guo, Y.; Zhu, D. Patterned graphene as source/drain electrodes for bottom-contact organic field-effect transistors. Adv. Mater. 2008, 20, 3289–3293. [Google Scholar] [CrossRef]

- Liao, Z.; Wan, Q.; Liu, H.; Tang, Q. Realization of size controllable graphene micro/nanogap with a micro/nanowire mask method for organic field-effect transistors. Appl. Phys. Lett. 2011, 99. [Google Scholar] [CrossRef]

- Jiang, L.; Fan, Z. Design of advanced porous graphene materials: From graphene nanomesh to 3d architectures. Nanoscale 2014, 6, 1922–1945. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; Hu, J.; Zeng, H. Two-dimensional semiconductors: Recent progress and future perspectives. J. Mater. Chem. C 2013, 1, 2952–2969. [Google Scholar] [CrossRef]

- Zang, J.; Ryu, S.; Pugno, N.; Wang, Q.; Tu, Q.; Buehler, M.J.; Zhao, X. Multifunctionality and control of the crumpling and unfolding of large-area graphene. Nat. Mater. 2013, 12, 321–325. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Z.; Huang, X.; Yin, Z.; Li, H.; Chen, Y.; Li, H.; Zhang, Q.; Ma, J.; Boey, F.; Zhang, H. Fabrication of graphene nanomesh by using an anodic aluminum oxide membrane as a template. Adv. Mater. 2012, 24, 4138–4142. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.; Safron, N.S.; Han, E.; Arnold, M.S.; Gopalan, P. Fabrication and characterization of large-area, semiconducting nanoperforated graphene materials. Nano Lett. 2010, 10, 1125–1131. [Google Scholar] [CrossRef] [PubMed]

- Ding, J.; Du, K.; Wathuthanthri, I.; Choi, C.-H.; Fisher, F.T.; Yang, E.-H. Transfer patterning of large-area graphene nanomesh via holographic lithography and plasma etching. J. Vac. Sci. Technol. Technol. B 2014, 32. [Google Scholar] [CrossRef]

- Sinitskii, A.; Tour, J.M. Patterning graphene through the self-assembled templates: Toward periodic two-dimensional graphene nanostructures with semiconductor properties. J. Am. Chem. Soc. 2010, 132, 14730–14732. [Google Scholar] [CrossRef] [PubMed]

- Liang, X.; Jung, Y.-S.; Wu, S.; Ismach, A.; Olynick, D.L.; Cabrini, S.; Bokor, J. Formation of bandgap and subbands in graphene nanomeshes with sub-10 nm ribbon width fabricated via nanoimprint lithography. Nano Lett. 2010, 10, 2454–2460. [Google Scholar] [CrossRef] [PubMed]

- Paul, R.K.; Badhulika, S.; Saucedo, N.M.; Mulchandani, A. Graphene nanomesh as highly sensitive chemiresistor gas sensor. Anal. Chem. 2012, 84, 8171–8178. [Google Scholar] [CrossRef] [PubMed]

- Fatyeyeva, K.; Dahi, A.; Chappey, C.; Langevin, D.; Valleton, J.-M.; Poncin-Epaillard, F.; Marais, S. Effect of cold plasma treatment on surface properties and gas permeability of polyimide films. RSC Adv. 2014, 4, 31036–31046. [Google Scholar] [CrossRef]

- Zarshenas, K.; Raisi, A.; Aroujalian, A. Surface modification of polyamide composite membranes by corona air plasma for gas separation applications. RSC Adv. 2015, 5, 19760–19772. [Google Scholar] [CrossRef]

- Chen, S.-H.; Chuang, W.-H.; Wang, A.A.; Ruaan, R.-C.; Lai, J.-Y. Oxygen/nitrogen separation by plasma chlorinated polybutadiene/polycarbonate composite membrane. J. Membr. Sci. 1997, 124, 273–281. [Google Scholar] [CrossRef]

- Chen, Z.; Tan, X. Monolithic fabrication of ionic polymer–metal composite actuators capable of complex deformation. Sens. Actuators A 2010, 157, 246–257. [Google Scholar] [CrossRef]

- Nikhil Dilip, P.; Mark, S.M. An investigation of the fracturing process in nitrogen-doped multiwalled carbon nanotubes (N-MWCNTs). Evidence for directional unzipping. Mater. Res. Express 2014, 1. [Google Scholar] [CrossRef]

- Jiao, L.; Zhang, L.; Wang, X.; Diankov, G.; Dai, H. Narrow graphene nanoribbons from carbon nanotubes. Nature 2009, 458, 877–880. [Google Scholar] [CrossRef] [PubMed]

- Poulsen, R.G. Plasma etching in integrated circuit manufacture—A review. J. Vac. Sci. Technol. 1977, 14, 266–274. [Google Scholar] [CrossRef]

- Vitale, S.A.; Berry, S. Etching selectivity of indium tin oxide to photoresist in high density chlorine- and ethylene-containing plasmas. J. Vac. Sci. Technol. B 2013, 31. [Google Scholar] [CrossRef]

- Laermer, F.; Urban, A. Challenges, developments and applications of silicon deep reactive ion etching. Microelectron. Eng. 2003, 67–68, 349–355. [Google Scholar] [CrossRef]

- Liao, Q.; Xu, Z.; Zhong, X.; Dang, W.; Shi, Q.; Zhang, C.; Weng, Y.; Li, Z.; Fu, H. An organic nanowire waveguide exciton-polariton sub-microlaser and its photonic application. J. Mater. Chem. C 2014, 2, 2773–2778. [Google Scholar] [CrossRef]

- Garcia-Frutos, E.M. Small organic single-crystalline one-dimensional micro- and nanostructures for miniaturized devices. J. Mater. Chem. C 2013, 1, 3633–3645. [Google Scholar] [CrossRef]

- Fang, H.; Wu, W.; Song, J.; Wang, Z.L. Controlled growth of aligned polymer nanowires. J. Phys. Chem. C 2009, 113, 16571–16574. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, Z.; Gartia, M.R.; Whitlock, D.; Lian, Y.; Liu, G.L. Ultrahigh throughput silicon nanomanufacturing by simultaneous reactive ion synthesis and etching. ACS Nano 2011, 5, 8002–8012. [Google Scholar] [CrossRef] [PubMed]

- Chandran, N.; Chandran, S.; Maria, H.J.; Thomas, S. Compatibilizing action and localization of clay in a polypropylene/natural rubber (PP/NR) blend. RSC Adv. 2015, 5, 86265–86273. [Google Scholar] [CrossRef]

- Jyotishkumar, P.; Koetz, J.; Tiersch, B.; Strehmel, V.; Özdilek, C.; Moldenaers, P.; Hässler, R.; Thomas, S. Complex phase separation in poly(acrylonitrile−butadiene−styrene)-modified epoxy/4,4′-diaminodiphenyl sulfone blends: Generation of new micro- and nanosubstructures. J. Phys. Chem. B 2009, 113, 5418–5430. [Google Scholar] [CrossRef] [PubMed]

- Kunaver, M.; Mozetič, M.; Klanjšek-Gunde, M. Selective plasma etching of powder coatings. Thin Solid Films 2004, 459, 115–117. [Google Scholar] [CrossRef]

- Kunaver, M.; Klanjsek-Gunde, M.; Mozetic, M.; Kunaver, M.; Hrovat, A. The degree of dispersion of pigments in powder coatings and the origin of some surface defects. Surf. Coat. Int. Part B 2003, 86, 175–179. [Google Scholar] [CrossRef]

- Mozetič, M.; Zalar, A.; Panjan, P.; Bele, M.; Pejovnik, S.; Grmek, R. A method of studying carbon particle distribution in paint films. Thin Solid Films 2000, 376, 5–8. [Google Scholar] [CrossRef]

- Salalha, W.; Dror, Y.; Khalfin, R.L.; Cohen, Y.; Yarin, A.L.; Zussman, E. Single-walled carbon nanotubes embedded in oriented polymeric nanofibers by electrospinning. Langmuir 2004, 20, 9852–9855. [Google Scholar] [CrossRef] [PubMed]

- Ponnamma, D.; Sadasivuni, K.K.; Grohens, Y.; Guo, Q.; Thomas, S. Carbon nanotube based elastomer composites—An approach towards multifunctional materials. J. Mater. Chem. C 2014, 2, 8446–8485. [Google Scholar] [CrossRef]

- Cvelbar, U.; Pejovnik, S.; Mozetiè, M.; Zalar, A. Increased surface roughness by oxygen plasma treatment of graphite/polymer composite. Appl. Surf. Sci. 2003, 210, 255–261. [Google Scholar] [CrossRef]

- Malara, F.; Manca, M.; De Marco, L.; Pareo, P.; Gigli, G. Flexible carbon nanotube-based composite plates as efficient monolithic counter electrodes for dye solar cells. ACS Appl. Mater. Interfaces 2011, 3, 3625–3632. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Li, J.; An, G.; He, X. Highly porous SnO2 fibers by electrospinning and oxygen plasma etching and its ethanol-sensing properties. Sens. Actuators B 2010, 144, 43–48. [Google Scholar] [CrossRef]

- Ramgir, N.; Datta, N.; Kaur, M.; Kailasaganapathi, S.; Debnath, A.K.; Aswal, D.K.; Gupta, S.K. Metal oxide nanowires for chemiresistive gas sensors: Issues, challenges and prospects. Colloids Surf. A 2013, 439, 101–116. [Google Scholar] [CrossRef]

- Bandgar, D.K.; Navale, S.T.; Nalage, S.R.; Mane, R.S.; Stadler, F.J.; Aswal, D.K.; Gupta, S.K.; Patil, V.B. Simple and low-temperature polyaniline-based flexible ammonia sensor: A step towards laboratory synthesis to economical device design. J. Mater. Chem. C 2015, 3, 9461–9468. [Google Scholar] [CrossRef]

- Han, J.-W.; Kim, B.; Li, J.; Meyyappan, M. Carbon nanotube based humidity sensor on cellulose paper. J. Phys. Chem. C 2012, 116, 22094–22097. [Google Scholar] [CrossRef]

- Raghu, M.; Suresh, R.; Vijay, P.S. MWCNT–polymer composites as highly sensitive and selective room temperature gas sensors. Nanotechnology 2011, 22. [Google Scholar] [CrossRef]

- Ernest, M.; Jahir, O.; Cecilia, J.-J.; Ana, B.G.-G.; Ana, C.; Laura, M.L.; César, F.-S. Scalable fabrication of immunosensors based on carbon nanotube polymer composites. Nanotechnology 2008, 19. [Google Scholar] [CrossRef]

- Sullalti, S.; Colonna, M.; Berti, C.; Fiorini, M.; Karanam, S. Effect of phosphorus based flame retardants on UL94 and comparative tracking index properties of poly(butylene terephthalate). Polym. Degrad. Stab. 2012, 97, 566–572. [Google Scholar] [CrossRef]

| Wet Chemical Etching | Plasma Etching | |

|---|---|---|

| Etchant: | Chemical (acids, alkali, etc.). | Reactive gas (radicals, ions, etc.). |

| Etch rate and selectivity: | High. | Good, controllable. |

| Advantageous: | Low equipment cost, fast processing and easy to implement. | Capable of small scale etching (~10 nm), no contamination issues, no hazardous chemicals, ecologically benign technology. |

| Disadvantageous: | Inadequate to define small feature size less than 1 µm, handling of hazardous chemicals, contamination issues, ecologically unfriendly technology with need of waste processing. | High equipment cost, implementation dependent on application, potential radiation damage. |

| Directionality: | Only isotropic etching. | Can be isotropic or anisotropic. |

| No. | Polymer | krel | Gs |

|---|---|---|---|

| 1 | Poly(α-methylstyrene) | 1.11 | 0.3 |

| 2 | Polyphenyl methacrylate | 1.33 | ----- |

| 3 | Polyviny1 methyl ketone | 1.48 | ----- |

| 4 | Polymethy1 methacrylate (PMMA) | 2.37 | 1.2 |

| 5 | Polymethyl methacrylate-co-methacrylonitrile (94:6 mol %) | 2.70 | 2.03 |

| 6 | Polyisobutylene | 3.56 | 4 |

| 7 | Polybutene-1 sulfone | 7.11 | 8 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Puliyalil, H.; Cvelbar, U. Selective Plasma Etching of Polymeric Substrates for Advanced Applications. Nanomaterials 2016, 6, 108. https://doi.org/10.3390/nano6060108

Puliyalil H, Cvelbar U. Selective Plasma Etching of Polymeric Substrates for Advanced Applications. Nanomaterials. 2016; 6(6):108. https://doi.org/10.3390/nano6060108

Chicago/Turabian StylePuliyalil, Harinarayanan, and Uroš Cvelbar. 2016. "Selective Plasma Etching of Polymeric Substrates for Advanced Applications" Nanomaterials 6, no. 6: 108. https://doi.org/10.3390/nano6060108

APA StylePuliyalil, H., & Cvelbar, U. (2016). Selective Plasma Etching of Polymeric Substrates for Advanced Applications. Nanomaterials, 6(6), 108. https://doi.org/10.3390/nano6060108