Synthesis of Helical Carbon Fibers and Related Materials: A Review on the Past and Recent Developments

Abstract

:1. Introduction

2. Synthesis of Helical Carbon Fibers (HCFs)

| S.No. | Carbon Source | Carrier gas | Promoter | Catalyst | Substrate | Temperature | Method & Final Product | Coil diameter & Length | Ref. | |

|---|---|---|---|---|---|---|---|---|---|---|

| 1. | C2H2 | N2 | H2S | Thin films of Au metal or Au/Ni alloy | Graphite plate | 700‒740 °C | CTCVD; CNCs | 50‒450 nm; 0.3‒3 µm | [8] | |

| 2. | Acetone dissolved C2H2 | H2, Ar | Thiophene, PCl3 | Ni powder | Graphite | 600‒800 °C | CTCVD; CCFs | 3‒5.4 µm; µm order | [9] | |

| 3. | Acetone dissolved C2H2 | H2, N2 | Thiophene | Ni powder | Graphite | 750 °C | CTCVD; CMCs | µm order; µm order | [10] | |

| 4. | C2H2 | H2, N2 | H2S | Fe alloy (54Fe-38Cr-4Mn-4Mo) | Graphite | 750‒790 °C | CTCVD; Spring-like CNCs | 100‒1000 nm; Several hundred µm to 1 mm | [12] | |

| 5. | C2H2 | Ar | --- | Ni plate & powder | --- | 350‒750 °C | CTCVD; Coiled carbon filaments | 2‒8 µm; 0.1‒5 mm | [17] | |

| 6. | C2H2 | Ar | --- | Cupric tartrate | --- | 380 °C | CTCVD; HCFs | 0.5‒1 µm; µm order | [38] | |

| 7. | C2H2 | H2 | --- | Ni nanoparticles | Ceramic plate | 450 °C | CTCVD; CNCs | 120‒500 nm; 30 µm | [50] | |

| 8. | C2H2 | H2, Ar | --- | Au and K metals | Graphite foils | 450 °C | CTCVD; CNCs | 110‒140 nm; 10 µm | [54] | |

| 9. | C2H2 | H2, N2 | Thiophene | Ni nanoparticles | Graphite plate | 750 °C | CTCVD; single-helix carbon nano/micro coils | 150 nm‒3 µm; µm order | [55] | |

| 10. | C2H2 | --- | --- | Nano Cu | --- | 250‒400 °C | CTCVD; HCNFs | 100 nm‒10 µm; µm order | [61] | |

| 11. | C2H2 | H2, N2 | Thiophene | Ni nanoparticles | Graphite | 750 °C | CTCVD; CCFs | 3 µm; --- | [62] | |

| 12. | C2H2 | N2 | --- | Co | Silica gel | 720 °C | CTCVD; Coiled CNTs | nm order; µm order | [65] | |

| 13. | C2H2 | H2, Ar | --- | Cu nanoparticles | --- | 350 °C | CTCVD; HCNFs | 80 nm; µm order | [67] | |

| 14. | C2H2 | --- | --- | Cu nanoparticles | Si wafers | 260 °C | CTCVD; CNCs | 80‒120 nm; µm order | [68] | |

| 15. | C2H2 | H2, He | --- | Ni nanoparticles | --- | 650 °C | CTCVD; HCNFs | ~150 nm; 6‒8 µm | [72] | |

| 16. | CH4 | Ar | --- | Co+Cu alloy film | SiO2/Si | 600 °C | Hot filament CVD; Carbon helix nanofibers | 20‒500 nm; µm order | [73] | |

| 17. | C2H2 | He | --- | Fe films | Indium tin oxide-coated glasses | 700 °C | CTCVD; CNCs | nm order; µm order | [81] | |

| 18. | C2H2 | Ar | Ammonia | Na2CO3 | Ceramic boat | 500 °C | CTCVD; N-doped CNCs | --- | [82] | |

| 19. | C2H2 | --- | Sulfur and phosphorus | Ni | Metal Plate | At various gas pressures | Arc-discharge; Carbon coils | 6‒10 µm; 50‒80 µm | [86] | |

| 20. | Acetone dissolved C2H2 | H2, N2 | Thiophene | Fine powder of WS2 | Graphite/ stainless steel plate | 775‒785 °C | CTCVD; CMCs | microns; millimeters | [89] | |

| 21. | C2H2 | H2, Ar | --- | Ni | SiC | 700 °C | Microwave CVD; Micro CCFs | --- | [90] | |

| 22. | C2H2 | Ar | --- | NaNO3 | Ceramic plate | 450 °C | CTCVD; HCNFs | nm order; µm order | [91] | |

| 23. | C2H2 | --- | --- | Cu nanoparticles | --- | 195 °C | CTCVD; HCNFs | 100 nm; 1 µm | [92] | |

| 24. | C2H2 | H2, Ar | --- | Pd nanoparticles | C60 | 550 °C | CTCVD; HCNFs | nm order; < 10 µm | [93] | |

| 25. | C2H2 | --- | --- | Cu | MgO | 237 °C | CTCVD; HCNFs | 100 nm; µm order | [94] | |

| 26. | C2H2 | H2 | Thiophene | Ni foam | Ni foam | 973‒1073 K | CTCVD; CMCs | 1.5‒2.5 µm; --- | [95] | |

| 27. | C2H2 | H2, N2 | Thiophene | Ni | Activated CNTs | 650‒800 °C | CTCVD; Carbon micro and nano coils | 4-7 µm, ---; 200 nm, --- | [96] | |

| 28. | C2H2 | N2 | Ni-sulfide | --- | 740 °C | CTCVD; CMCs | 3‒4 µm; millimeters | [97] | ||

| 29. | C2H2 | N2 | Thiophene | Ni powder | --- | 1100 °C | CTCVD; Double helical carbon micro coiled fibers | 3‒4 µm; millimeters | [98] | |

| 30. | C2H2 | --- | Cu | --- | 240 °C | CTCVD; HCNFs | nm order; --- | [99] | ||

| 31. | C2H2 | --- | Fe nanoparticles | --- | 475 °C | CTCVD; Helical CNTs | 120‒200 nm; µm order | [100] | ||

2.1. Chemical Vapor Deposition (CVD)

2.1.1. Catalytic Thermal CVD (CTCVD)

2.1.2. Microwave CVD

2.1.3. Hot Filament CVD

2.2. Arc Discharge

2.3. Purification of HCFs

3. Effect of Experimental Parameters on the Growth of HCFs

3.1. Effect of Preparation of the Catalysts for the Growth of HCFs

3.2. Effect of Various Types of Catalysts on the Growth of HCFs

3.2.1. Effect of Transition Metals

3.2.2. Effect of Metal Carbides

3.2.3. Effect of Mixture and Alloys of Metals

3.2.4. Effect of Supported Catalyst

3.3. Effect of Catalyst Particle Size on the Growth of HCFs

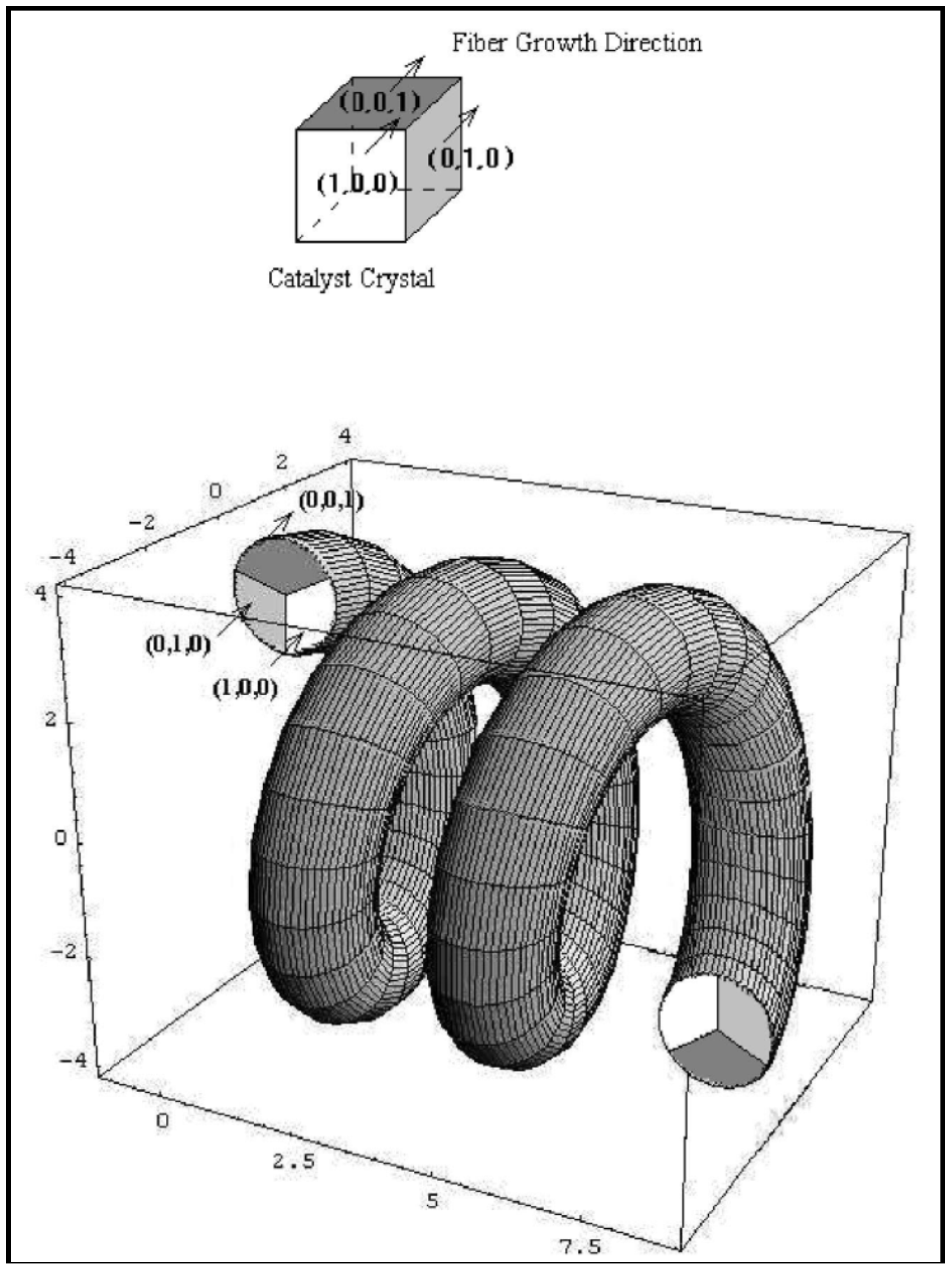

3.4. Effect of Shape Changes and Final Shape of Catalyst Particles on the Growth of HCFs

3.5. Effects of Reaction Temperature on the Growth of HCFs

3.5.1. Morphology of HCFs

3.5.2. Coil and Fiber Diameter of HCFs

3.5.3. Yield of HCFs

3.6. Effect of Type of Carbon Source on the Growth of HCFs

3.7. Effect of Reaction Time on the Growth of HCFs

3.8. Effect of Impurity Gas on the Growth of HCFs

3.9. Effect of External Electromagnetic (EM) Field and Bias Voltage on the Growth of HCFs

4. Synthesis of HCFs-Based Materials

5. Growth Mechanism of HCFs

6. Challenges and Future Prospects

7. Conclusions

Acknowledgements

Author Contributions

Abbreviation

| S. No. | Term | Abbreviation |

| 1. | Atomic layer deposition | ALD |

| 2. | Carbon fibers | CFs |

| 3. | Carbon microcoils | CMCs |

| 4. | Carbon microfibers | CMFs |

| 5. | Carbon nanocoils | CNCs |

| 6. | Carbon nanofibers | CNFs |

| 7. | Carbon nanostructures | CNSs |

| 8. | Carbon nanotubes | CNTs |

| 9. | Catalytic thermal chemical vapor deposition | CTCVD |

| 10. | Chemical vapor deposition | CVD |

| 11. | Coiled carbon fibers | CCFs |

| 12. | Copper nanoparticles | Cu NPs |

| 13. | Helical carbon fibers | HCFs |

| 14. | Helical carbon nanofibers | HCNFs |

| 15. | Nitrogen-doped | N-doped |

Conflicts of Interest

References

- Hughes, T.V.; Chambers, C.R. Manufacture of carbon filaments. US Patent No. 405, 1889. [Google Scholar]

- Kroto, H.W.; Heath, J.R.; O’Brien, S.C.; Curl, R.F.; Smalley, R.E. C60: Buckminsterfullerene. Nature 1985, 318, 162–163. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Baker, R.T.K.; Barber, M.A.; Harris, P.S.; Feates, F.S.; Waite, R.J. Nucleation and growth of carbon deposits from the nickel catalyzed decomposition of acetylene. J. Catal. 1972, 26, 51–62. [Google Scholar] [CrossRef]

- Rodriguez, N.M.; Chambers, A.; Baker, R.T.K. Catalytic engineering of carbon nanostructures. Langmuir 1995, 11, 3862–3866. [Google Scholar] [CrossRef]

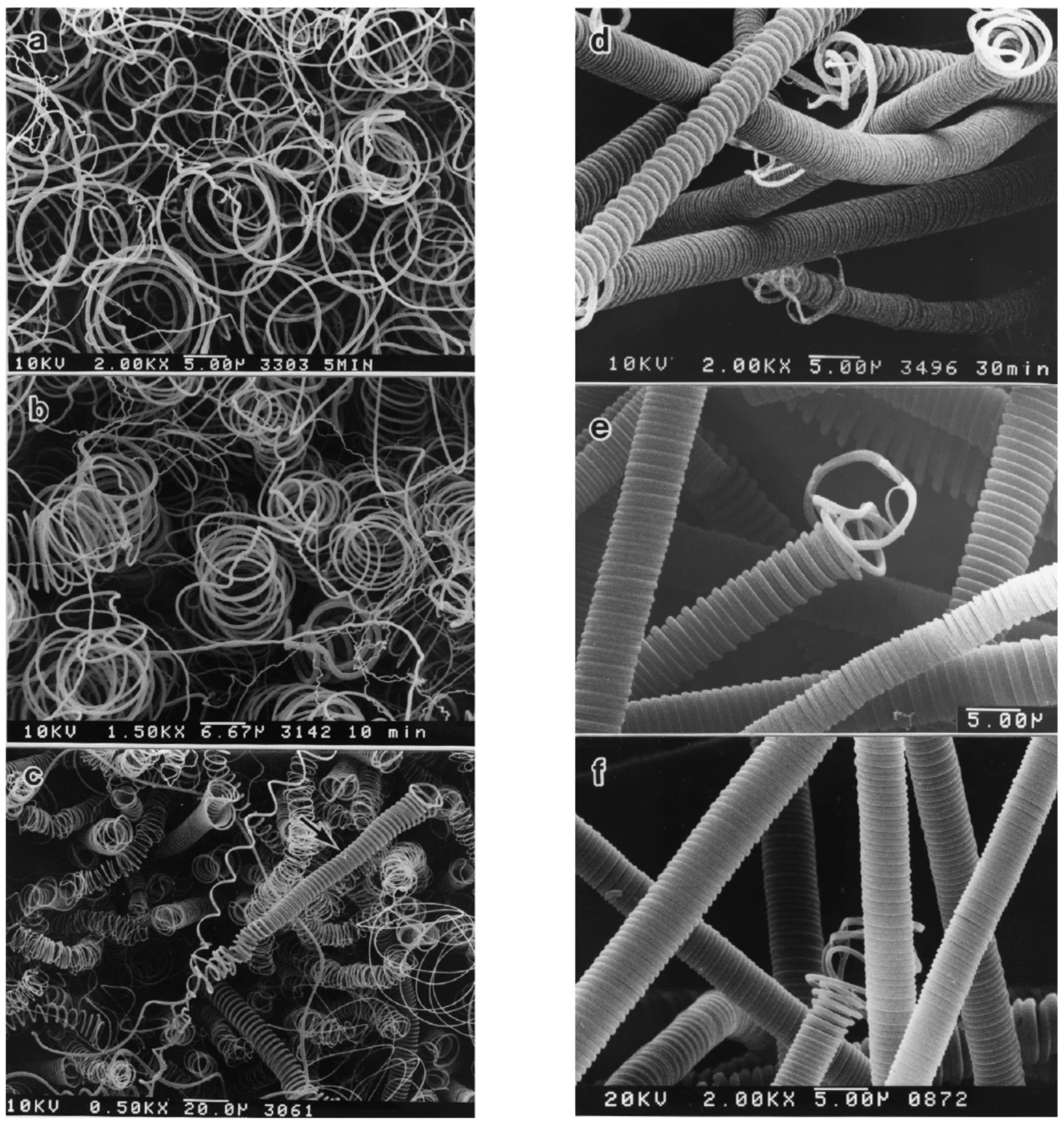

- Motojima, S.; Chen, Q. Three-dimensional growth mechanism of cosmo-mimetic carbon microcoils obtained by chemical vapor deposition. J. Appl. Phys. 1999, 85, 3919–3921. [Google Scholar] [CrossRef]

- Kuzuya, C.; In-Hwang, W.; Hirako, S.; Hishikawa, Y.; Motojima, S. Preparation, morphology, and growth mechanism of carbon nanocoils. Chem. Vapor Depos. 2002, 8, 57–62. [Google Scholar] [CrossRef]

- Motojima, S.; Hasegawa, I.; Kagiya, S.; Momiyama, M.; Kawaguchi, M.; Iwanaga, H. Preparation of coiled carbon fibers by pyrolysis of acetylene using a Ni catalyst and sulfur or phosphorus compound impurity. Appl. Phys. Lett. 1993, 62, 2322–2323. [Google Scholar] [CrossRef]

- Chen, X.; Yang, S.; Motojima, S. Morphology and growth models of circular and flat carbon coils obtained by the catalytic pyrolysis of acetylene. Mater. Lett. 2002, 57, 48–54. [Google Scholar] [CrossRef]

- Kuzuya, C.; Kohda, M.; Hishikawa, Y.; Motojima, S. Preparation of carbon micro-coils with the application of outer and inner electromagnetic fields and bias voltage. Carbon 2002, 40, 1991–2001. [Google Scholar] [CrossRef]

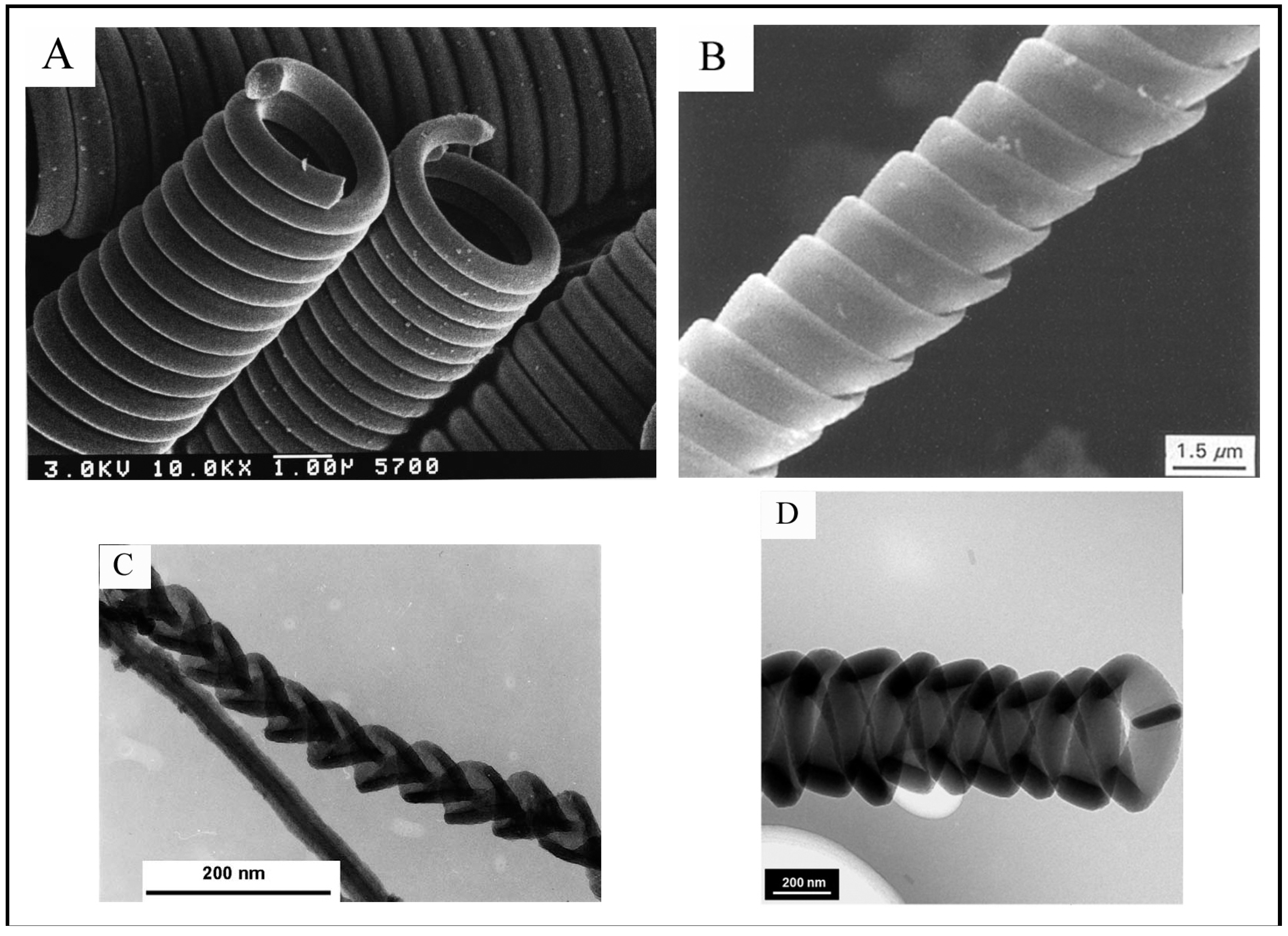

- Yang, S.; Chen, X.; Motojima, S.; Ichihara, M. Morphology and microstructure of spring-like carbon micro-coils/nano-coils prepared by catalytic pyrolysis of acetylene using Fe-containing alloy catalysts. Carbon 2005, 43, 827–834. [Google Scholar] [CrossRef]

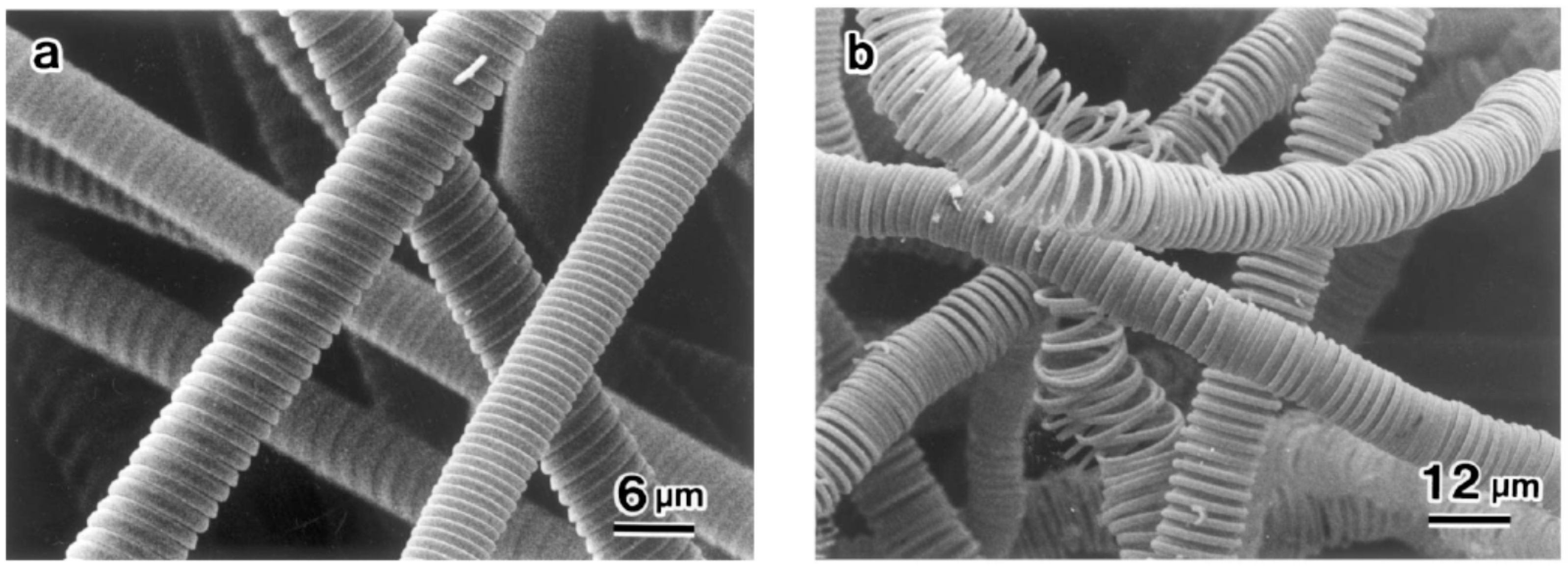

- Motojima, S.; Itoh, Y.; Asakura, S.; Iwanaga, H. Preparation of micro-coiled carbon fibres by metal powder-activated pyrolysis of acetylene containing a small amount of sulphur compounds. J. Mater. Sci. 1995, 30, 5049–5055. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, X.; Zhang, Y.; Chen, X.; Zhu, J. Nano-sized double helices and braids: Interesting carbon nanostructures. Mater. Res. Bull. 2003, 38, 261–267. [Google Scholar] [CrossRef]

- Shaikjee, A.; Franklyn, P.J.; Coville, N.J. The use of transmission electron microscopy tomography to correlate copper catalyst particle morphology with carbon fiber morphology. Carbon 2011, 49, 2950–2959. [Google Scholar] [CrossRef]

- Shaikjee, A.; Coville, N.J. The synthesis, properties and uses of carbon materials with helical morphology. J. Adv. Res. 2012, 3, 195–223. [Google Scholar] [CrossRef]

- Motojima, S.; Kawaguchi, M.; Nozaki, K.; Iwanaga, H. Growth of regularly coiled carbon filaments by Ni catalyzed pyrolysis of acetylene, and their morphology and extension characteristics. Appl. Phys. Lett. 1990, 56, 321–323. [Google Scholar] [CrossRef]

- Amelinckx, S.; Zhang, X.B.; Bernaerts, D.; Zhang, X.F.; Ivanov, V.; Nagy, J.B. A formation mechanism for catalytically grown helix-shaped graphite nanotubes. Science 1994, 265, 635–639. [Google Scholar] [CrossRef] [PubMed]

- Akagi, K.; Tamura, R.; Tsukada, M.; Itoh, S.; Ihara, S. Electronic structure of helically coiled cage of graphitic carbon. Phys. Rev. Lett. 1995, 74, 2307–2310. [Google Scholar] [CrossRef] [PubMed]

- Ihara, S.; Itoh, S. Helically coiled and toroidal cage forms of graphitic carbon. Carbon 1995, 33, 931–939. [Google Scholar] [CrossRef]

- Motojima, S.; Chen, X.; Yang, S.; Hasegawa, M. Properties and potential applications of carbon microcoils/nanocoils. Diam. Relat. Mater. 2004, 13, 1989–1992. [Google Scholar] [CrossRef]

- Wang, W.; Yang, K.; Gaillard, J.; Bandaru, P.R.; Rao, A.M. Rational synthesis of helically coiled carbon nanowires and nanotubes through the use of tin and indium catalysts. Adv. Mater. 2008, 20, 179–182. [Google Scholar] [CrossRef]

- Chen, X.; Motojima, S.; Iwanga, H. Vapor phase preparation of super-elastic carbon micro-coils. J. Crystal Growth 2002, 237‒239, 1931–1936. [Google Scholar] [CrossRef]

- Hayashida, T.; Pan, L.; Nakayama, Y. Mechanical and electrical properties of carbon tubule nanocoils. Phys. B 2002, 323, 352–353. [Google Scholar] [CrossRef]

- Kaneto, K.; Tsuruta, M.; Motojima, S. Electrical properties of carbon micro coils. Synth. Metals 1999, 103, 2578–2579. [Google Scholar] [CrossRef]

- Chiu, H.S.; Lin, P.I.; Wu, H.C.; Hsieh, W.H.; Chen, C.D.; Chen, Y.T. Electron hopping conduction in highly disordered carbon coils. Carbon 2009, 47, 1761–1769. [Google Scholar] [CrossRef]

- Pan, L.; Hayashida, T.; Zhang, M.; Nakayama, Y. Field emission properties of carbon tubule nanocoils. Jpn. J. Appl. Phys. 2001, 40, L235–L237. [Google Scholar] [CrossRef]

- Pan, L.; Konishi, Y.; Tanaka, H.; Suekane, O.; Nosaka, T.; Nakayama, Y. Effect of morphology on field emission properties of carbon nanocoils and carbon nanotubes. Jpn. J. Appl. Phys. 2005, 44, 1652–1654. [Google Scholar] [CrossRef]

- Sung, W.Y.; Ok, J.G.; Kim, W.J.; Lee, S.M.; Yeon, S.C.; Lee, H.Y.; Kim, Y.H. Synthesis and field emission characteristics of carbon nanocoils with a high aspect ratio supported by copper micro-tips. Nanotechnology 2007, 18, 245603:1–245603:5. [Google Scholar] [CrossRef]

- Liu, W.C.; Lin, H.K.; Chen, Y.L.; Lee, C.Y.; Chiu, H.T. Growth of carbon nanocoils from K and Ag cooperative bicatalyst assisted thermal decomposition of acetylene. ACS Nano 2010, 4, 4149–4157. [Google Scholar] [CrossRef] [PubMed]

- Motojima, S.; Hoshiya, S.; Hishikawa, Y. Electromagnetic wave absorption properties of carbon microcoils/PMMA composite beads in W bands. Carbon 2003, 41, 2658–2660. [Google Scholar] [CrossRef]

- Zhao, D.L.; Shen, Z.M. Preparation and microwave absorption properties of carbon nanocoils. Mater. Lett. 2008, 62, 3704–3706. [Google Scholar] [CrossRef]

- Tang, N.; Zhong, W.; Au, C.; Yang, Y.; Han, M.; Lin, K.; Du, Y. Synthesis, microwave electromagnetic, and microwave absorption properties of twin carbon nanocoils. J. Phys. Chem. C 2008, 112, 19316–19323. [Google Scholar] [CrossRef]

- Wang, G.; Gao, Z.; Tang, S.; Chen, C.; Duan, F.; Zhao, S.; Lin, S.; Feng, Y.; Zhou, L.; Qin, Y. Microwave absorption properties of carbon nanocoils coated with highly controlled magnetic materials by atomic layer deposition. ACS Nano 2012, 6, 11009–11017. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; He, P.; Zhou, K.; Chen, T. Microwave absorption properties of carbon fibers with carbon coils of different morphologies (double microcoils and single nanocoils) grown on them. J. Mater. Sci. 2014, 49, 4379–4386. [Google Scholar] [CrossRef]

- Yoshimura, K.; Nakano, K.; Miyake, T.; Hishikawa, Y.; Motojima, S. Effectiveness of carbon microcoils as a reinforcing material for a polymer matrix. Carbon 2006, 44, 2833–2838. [Google Scholar] [CrossRef]

- Katsuno, T.; Chen, X.; Yang, S.; Motojima, S.; Homma, M.; Maeno, T.; Konyo, M. Observation and analysis of percolation behavior in carbon microcoils/silicone-rubber composite sheets. Appl. Phys. Lett. 2006, 88, 232115:1–232115:3. [Google Scholar] [CrossRef]

- Jin, Y.; Chen, J.; Fu, Q.; Li, B.; Zhang, H.; Gong, Y. Low-temperature synthesis and characterization of helical carbon fibers by one-step chemical vapour deposition. Appl. Surf. Sci. 2015, 324, 438–442. [Google Scholar] [CrossRef]

- Reddy, A.L.M.; Jafri, R.I.; Jha, N.; Ramaprabhu, S.; Ajayan, P.M. Carbon nanocoils for multi-functional energy applications. J. Mater. Chem. 2011, 21, 16103–16107. [Google Scholar] [CrossRef]

- Barranco, V.; Celorrio, V.; Lazaro, M.J.; Rojo, J.M. Carbon nanocoils as unusual electrode materials for supercapacitors. J. Electrochem. Soc. 2012, 159, A464–A469. [Google Scholar] [CrossRef]

- Hu, G.; Nitze, F.; Sharifi, T.; Barzegar, H.R.; Wagberg, T. Self-assembled palladium nanocrystals on helical carbon nanofibers as enhanced electrocatalysts for electro-oxidation of small molecules. J. Mater. Chem. 2012, 22, 8541–8548. [Google Scholar] [CrossRef]

- Rodriguez, N.M.; Kim, M.S.; Baker, R.T.K. Carbon nanofibers: A unique catalyst support medium. J. Phys. Chem. 1994, 98, 13108–13111. [Google Scholar] [CrossRef]

- Zhang, L.; Li, F. Helical nanocoiled and microcoiled carbon fibers as effective catalyst supports for electrooxidation of methanol. Electrochim. Acta 2010, 55, 6695–6702. [Google Scholar] [CrossRef]

- Furuya, Y.; Hashishin, T.; Iwanaga, H.; Motojima, S.; Hishikawa, Y. Interaction of hydrogen with carbon coils at low temperature. Carbon 2004, 42, 331–335. [Google Scholar] [CrossRef]

- Jaybhaye, S.V.; Sharon, M.; Sharon, M.; Singh, L.N. Study of hydrogen adsorption by spiral carbon nano fibers synthesized from acetylene. Synth. React. Inorg. Metal-Organic Nano-Metal Chem. 2006, 36, 37–42. [Google Scholar] [CrossRef]

- Yamamoto, K.; Hirayama, T.; Kusunoki, M.; Yang, S.; Motojima, S. Electron holographic observation of micro-magnetic fields current-generated from single carbon coil. Ultramicroscopy 2006, 106, 314–319. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhang, S.; Dikin, D.A.; Ding, W.; Ruoff, R.S.; Pan, L.; Nakayama, Y. Mechanics of a carbon nanocoil. Nano Lett. 2003, 3, 1299–1304. [Google Scholar] [CrossRef]

- Yang, S.; Chen, X.; Motojima, S. Tactile sensing properties of protein-like single-helix carbon microcoils. Carbon 2006, 44, 3352–3355. [Google Scholar] [CrossRef]

- Chen, X.; Yang, S.; Sawada, N.; Motojima, S. The design and performance of tactile/proximity sensors made of carbon microcoils. Smart Sens. Sens. Technol. 2008, 20, 251–261. [Google Scholar]

- Tang, N.; Kuo, W.; Jeng, C.; Wang, L.; Lin, K.; Du, Y. Coil-in-coil carbon nanocoils: 11 gram-scale synthesis, single nanocoil electrical properties, and electrical contact improvement. ACS Nano 2010, 4, 781–788. [Google Scholar] [CrossRef] [PubMed]

- Davis, W.R.; Slawson, R.J.; Rigby, G.R. An unusual form of carbon. Nature 1953, 171, 756. [Google Scholar] [CrossRef]

- Boehm, H.P. Carbon from carbon monoxide disproportionation on nickel and iron catalysts: Morphological studies and possible growth mechanisms. Carbon 1973, 11, 583–586. [Google Scholar] [CrossRef]

- Baker, R.T.K.; Harris, P.S.; Terry, S. Unique form of filamentous carbon. Nature 1975, 253, 37–39. [Google Scholar] [CrossRef]

- Tsou, T.Y.; Lee, C.Y.; Chiu, H.T. K and Au bicatalyst assisted growth of carbon nanocoils from acetylene: Effect of deposition parameters on field emission properties. ACS Appl. Mater. Interfaces 2012, 4, 6505–6511. [Google Scholar] [CrossRef] [PubMed]

- Jian, X.; Wang, D.; Liu, H.; Jiang, M.; Zhou, Z.; Lu, J.; Xu, X.; Wang, Y.; Wang, L.; Gong, Z.; et al. Controllable synthesis of carbon coils and growth mechanism for twinning double-helix catalyzed by Ni nanoparticle. Compos. B 2014, 61, 350–357. [Google Scholar] [CrossRef]

- Yang, Q.; Wang, Q.; Wang, D.; Xu, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. High yield synthesis of helical carbon nanotubes catalyzed by porous precursor with terrace morphology. Diam. Relat. Mater. 2014, 50, 123–128. [Google Scholar] [CrossRef]

- Tang, N.; Zhong, W.; Gedanken, A.; Du, Y. High magnetization helical carbon nanofibers produced by nanoparticle catalysis. J. Phys. Chem. B 2006, 110, 11772–11774. [Google Scholar] [CrossRef] [PubMed]

- Pan, L.; Hayashida, T.; Harada, A.; Nakayama, Y. Effects of iron and indium tin oxide on the growth of carbon tubule nanocoils. Phys. B 2002, 323, 350–351. [Google Scholar] [CrossRef]

- Wen, Y.; Shen, Z. Synthesis of regular coiled carbon nanotubes by Ni-catalyzed pyrolysis of acetylene and a growth mechanism analysis. Carbon 2001, 39, 2369–2374. [Google Scholar] [CrossRef]

- Chen, X.; Motojima, S. Morphologies of carbon micro-coils grown by chemical vapor deposition. J. Mater. Sci. 1999, 34, 5519–5524. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, Z.; Cui, Z. Helical carbon nanofibers prepared by pyrolysis of acetylene with a catalyst derived from the decomposition of copper tartrate. Carbon 2003, 41, 3072–3074. [Google Scholar] [CrossRef]

- Jian, X.; Zhou, Z.; Wu, S.; Chen, L.; Zeng, Q.; Wang, C. Controllable preparation of Ni nanoparticles for catalysis of coiled carbon fibers growth. Nanoscale Res. Lett. 2014, 9, 370. [Google Scholar] [CrossRef] [PubMed]

- Pan, L.; Hayashida, T.; Nakayama, Y. Growth and density control of carbon tubule nanocoils using catalyst of iron compounds. J. Mater. Res. 2002, 17, 145–148. [Google Scholar] [CrossRef]

- Zhang, X.B.; Zhang, X.F.; Bernaerts, D.; Tendeloo, G.V.; Amelinckx, S.; Landuyt, J.V.; Ivanov, V.; Nagy, J.B.; Lambin, P.; Lucas, A.A. The texture of catalytically grown coil-shaped carbon nanotubules. Europhys. Lett. 1994, 27, 141–146. [Google Scholar] [CrossRef]

- Hernadi, K.; Thien-Nga, L.; Forro, L. Growth and microstructure of catalytically produced coiled carbon nanotubes. J. Phys. Chem. B 2001, 105, 12464–12468. [Google Scholar] [CrossRef]

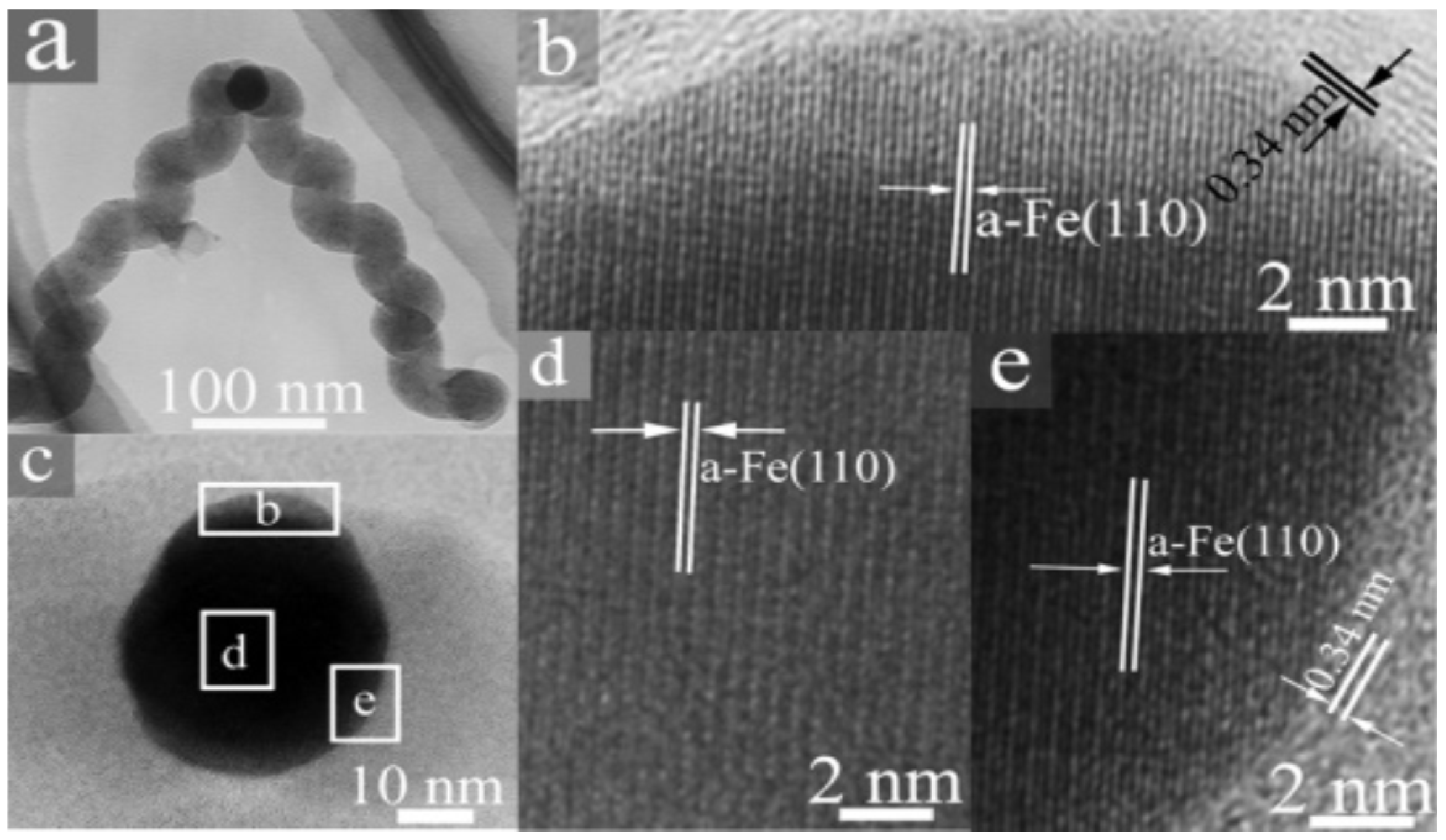

- Jian, X.; Jiang, M.; Zhou, Z.; Yang, M.; Lu, J.; Hu, S.; Wang, Y.; Hui, D. Preparation of high purity helical carbon nanofibers by the catalytic decomposition of acetylene and their growth mechanism. Carbon 2010, 48, 4535–4541. [Google Scholar] [CrossRef]

- Li, X.; Xu, Z. Controllable synthesis of helical, straight, hollow and nitrogen-doped carbon nanofibers and their magnetic properties. Mater. Res. Bull. 2012, 47, 4383–4391. [Google Scholar] [CrossRef]

- Wang, G.; Ran, G.; Wan, G.; Yang, P.; Gao, Z.; Lin, S.; Fu, C.; Qin, Y. Size-selective catalytic growth of nearly 100% pure carbon nanocoils with copper nanoparticles produced by atomic layer deposition. ACS Nano 2014, 8, 5330–5338. [Google Scholar] [CrossRef] [PubMed]

- Qi, X.S.; Ding, Q.; Zhong, W.; Deng, C.Y.; Du, Y.W. Large-scale and selective synthesis of carbon nanofiber bundles, curved carbon nanofibers and helical carbon nanofibers. J. Nanosci. Nanotechnol. 2015, 15, 2384–2388. [Google Scholar] [CrossRef]

- Ding, D.Y.; Wang, J.N.; Dozier, A. Symmetry-related growth of carbon nanocoils from Ni-P based alloy particles. J. Appl. Phys. 2004, 95, 5006–5009. [Google Scholar] [CrossRef]

- Yu, L.; Qin, Y.; Cui, Z. Synthesis of coiled carbon nanofibers by Cu-Ni alloy nanoparticles catalyzed decomposition of acetylene at the low temperature of 241 °C. Mater. Lett. 2005, 59, 459–462. [Google Scholar] [CrossRef]

- Raghubanshi, H.; Hudson, M.S.L.; Srivastava, O.N. Synthesis of helical carbon nanofibres and its application in hydrogen desorption. Int. J. Hydrog. Energy 2011, 36, 4482–4490. [Google Scholar] [CrossRef]

- Jayatissa, A.H.; Guo, K. Carbon helixes produced by hot filament assisted chemical vapor deposition. J. Mater. Sci.: Mater. Electron. 2010, 21, 509–513. [Google Scholar] [CrossRef]

- Hu, G.; Nitze, F.; Barzegar, H.R.; Sharifi, T.; Mikołajczuk, A.; Tai, C.W.; Borodzinski, A.; Wagberg, T. Palladium nanocrystals supported on helical carbon nanofibers for highly efficient electro-oxidation of formic acid, methanol and ethanol in alkaline electrolytes. J. Power Sources 2012, 209, 236–242. [Google Scholar] [CrossRef]

- Nitze, F.; Mazurkiewicz, M.; Malolepszy, A.; Mikolajczuk, A.; Kedzierzawski, P.; Tai, C.W.; Hu, G.; Kurzydłowski, K.J.; Stobinski, L.; Borodzinski, A.; et al. Synthesis of palladium nanoparticles decorated helical carbon nanofiberas highly active anodic catalyst for direct formic acid fuel cells. Electrochim. Acta 2012, 63, 323–328. [Google Scholar] [CrossRef]

- Singh, R.K.; Raghubanshi, H.; Pandey, S.K.; Srivastava, O.N. Effect of admixing different carbon structural variants on the decomposition and hydrogen sorption kinetics of magnesium hydride. Int. J. Hydrog. Energy 2010, 35, 4131–4137. [Google Scholar] [CrossRef]

- Jia, X.; Hu, G.; Nitze, F.; Barzegar, H.R.; Sharifi, T.; Tai, C.W.; Wågberg, T. Synthesis of palladium/helical carbon nanofiber hybrid nanostructures and their application for hydrogen peroxide and glucose detection. ACS Appl. Mater. Interfaces 2013, 5, 12017–12022. [Google Scholar] [CrossRef] [PubMed]

- Xie, G.; Wang, Z.; Cui, Z.; Shi, Y. Ni-Fe-Co-P coatings on coiled carbon nanofibers. Carbon 2005, 43, 3181–3183. [Google Scholar] [CrossRef]

- Coville, N.J.; Mhlanga, S.D.; Nxumalo, E.N.; Shaikjee, A. A review of shaped carbon nanomaterials. S. Afr. J. Sci. 2011, 107. [Google Scholar] [CrossRef]

- Fejes, D.; Hernádi, K. A Review of the properties and CVD synthesis of coiled carbon nanotubes. Materials 2010, 3, 2618–2642. [Google Scholar] [CrossRef]

- Pan, L.; Zhang, M.; Nakayama, Y. Growth mechanism of carbon nanocoils. J. Appl. Phys. 2002, 91, 10058–10061. [Google Scholar] [CrossRef]

- Ding, Q.; Song, X.; Yao, X.; Qi, X.; Au, C.T.; Zhong, W.; Du, Y. Large-scale and controllable synthesis of metal-free nitrogen-doped carbon nanofibers and nanocoils over water-soluble Na2CO3. Nanoscale Res. Lett. 2013, 8, 545. [Google Scholar] [CrossRef] [PubMed]

- Lau, K.T.; Lu, M.; Hui, D. Coiled carbon nanotubes: Synthesis and their potential applications in advanced composite structures. Compos. Part B 2006, 37, 437–448. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, L.P.; Johnson, D.J.; Prince, R.H. Plasma-induced low-temperature growth of graphitic nanofibers on nickel substrates. J. Crystal Growth 1998, 193, 342–346. [Google Scholar] [CrossRef]

- Huang, C.W.; Wu, H.C.; Lin, W.H.; Li, Y.Y. Temperature effect on the formation of catalysts for growth of carbon nanofibers. Carbon 2009, 47, 795–803. [Google Scholar] [CrossRef]

- Zhang, L.; Zhu, Y.B.; Ge, C.L.; Wei, C.; Wang, Q.L. The synthesis of carbon coils using catalyst arc discharge in anacetylene atmosphere. Solid State Commun. 2007, 142, 541–544. [Google Scholar] [CrossRef]

- Wang, L.; Li, C.; Gu, F.; Zhang, C. Facile flame synthesis and electrochemical properties of carbon nanocoils. J. Alloys Compd. 2009, 473, 351–355. [Google Scholar] [CrossRef]

- Sevilla, M.; Sanchís, C.; Valdés-Solís, T.; Morallón, E.; Fuertes, A.B. Highly dispersed platinum nanoparticles on carbon nanocoils and their electrocatalytic performance for fuel cell reactions. Electrochim. Acta 2009, 54, 2234–2238. [Google Scholar] [CrossRef]

- Yang, S.; Chen, X.; Motojima, S. Coiling-chirality changes in carbon microcoils obtained by catalyzed pyrolysis of acetylene and its mechanism. Appl. Phys. Lett. 2002, 81, 3567–3569. [Google Scholar] [CrossRef]

- Xie, J.; Sharma, P.K.; Varadan, V.V.; Varadan, V.K.; Pradhan, B.K.; Eser, S. Thermal, Raman and surface area studies of microcoiled carbon fiber synthesized by CVD microwave system. Mater. Chem. Phys. 2002, 76, 217–223. [Google Scholar] [CrossRef]

- Qi, X.; Ding, Q.; Zhong, W.; Au, C.T.; Du, Y. Controllable synthesis and purification of carbon nanofibers and nanocoils over water-soluble NaNO3. Carbon 2013, 56, 383–385. [Google Scholar] [CrossRef]

- Qin, Y.; Jiang, X.; Cui, Z. Low-temperature synthesis of amorphous carbon nanocoils via acetylene coupling on copper nanocrystal surfaces at 468 K: A reaction mechanism analysis. J. Phys. Chem. B 2005, 109, 21749–21754. [Google Scholar] [CrossRef] [PubMed]

- Nitze, F.; Abou-Hamad, E.; Wagberg, T. Carbon nanotubes and helical carbonnanofibers grownby chemical vapour deposition on C60fullerenesupported Pd nanoparticles. Carbon 2011, 49, 1101–1107. [Google Scholar] [CrossRef]

- Ren, X.; Zhang, H.; Cui, Z. Acetylene decomposition to helical carbon nanofibers oversupported copper catalysts. Mater. Res. Bull. 2007, 42, 2202–2210. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, C.; Du, J.H.; Cheng, H.M. Preparation of carbon microcoils by catalytic decomposition of acetylene using nickel foam as both catalyst and substrate. Carbon 2005, 43, 1874–1878. [Google Scholar] [CrossRef]

- Liu, Y.; Shen, Z. Preparation of carbon microcoils and nanocoils using activated carbon nanotubes as catalyst support. Carbon 2005, 43, 1574–1577. [Google Scholar] [CrossRef]

- Mukhopadhyay, K.; Ram, K.; Rao, K.U.B. Thin film of carbon micro-spring forest. Mater. Lett. 2007, 61, 2004–2006. [Google Scholar] [CrossRef]

- Mukhopadhyay, K.; Ram, K.; Lal, D.; Mathur, G.N.; Rao, K.U.B. Double helical carbon microcoiled fibers synthesis by CCVD method. Carbon 2005, 43, 2400–2402. [Google Scholar] [CrossRef]

- Dong, L.; Yu, L.; Cui, Z.; Dong, H.; Ercius, P.; Song, C.; Duden, T. Direct imaging of copper catalyst migration inside helical carbon nanofibers. Nanotechnology 2012, 23, 035702:1–035702:6. [Google Scholar] [CrossRef] [PubMed]

- Tang, N.; Wen, J.; Zhang, Y.; Liu, F.; Lin, K.; Du, Y. Helical carbon nanotubes: Catalytic particle size-dependent growth and magnetic properties. ACS Nano 2010, 4, 241–250. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Nakayama, Y.; Pan, L. Synthesis of carbon tubule nanocoils in high yield using iron-coated indium tin oxide as catalyst. Jpn. J. Appl. Phys. 2000, 39, L1242–L1244. [Google Scholar] [CrossRef]

- Qin, Y.; Li, H.; Zhang, Z.; Cui, Z. Symmetric and helical growth of polyacetylene fibers over a single copper crystal derived from copper tartrate decomposition. Org. Lett. 2002, 4, 3123–3125. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.S.; Rodriguez, N.M.; Baker, R.T.K. The role of interfacial phenomena in the structure of carbon deposits. J. Catal. 1992, 134, 253–268. [Google Scholar] [CrossRef]

- Okazaki, N.; Hosokawa, S.; Goto, T.; Nakayama, Y. Synthesis of carbon tubule nanocoils using Fe-In-Sn-O fine particles as catalysts. J. Phys. Chem. B 2005, 109, 17366–17371. [Google Scholar] [CrossRef] [PubMed]

- Raghubanshi, H.; Srivastava, O.N. Synthesis of carbon nanostructures using hydrogen storage alloys as catalysts. J. Nanoeng. Nanomanuf. 2014, 4, 98–105. [Google Scholar] [CrossRef]

- Escobar, M.; Giuliani, L.; Candal, R.J.; Lamas, D.G.; Caso, A.; Rubiolo, G.; Grondona, D.; Goyanes, S.; Márquez, A. Carbon nanotubes and nanofibers synthesized by CVD on nickel coatings deposited with a vacuum arc. J. Alloys Compd. 2010, 495, 446–449. [Google Scholar] [CrossRef]

- Motojima, S.; Asakura, S.; Kasemura, T.; Takeuchi, S.; Iwanaga, H. Catalytic effects of metal carbides, oxides and Ni single crystal on the vapor growth of microcoiled carbon fibers. Carbon 1996, 34, 289–296. [Google Scholar] [CrossRef]

- Motojima, S.; Asakura, S.; Hirata, M.; Iwanaga, H. Effect of metal impurities on the growth of micro-coiled carbon fibres by pyrolysis of acetylene. Mater. Sci. Eng. B 1995, 34, L9–L11. [Google Scholar] [CrossRef]

- Chen, X.; Takeuchi, K.; Yang, S.S.; Motojima, S. Morphology and growth mechanism of single-helix spring-like carbon nanocoils with laces prepared using Ni/molecular sieve (Fe) catalyst. J. Mater. Sci. 2006, 41, 2351–2357. [Google Scholar] [CrossRef]

- Park, S.; Kim, S.H. Controlled geometry formation of the carbon coils by the substrate pretreatment. ISRN Nanomater. 2013, 2013, 893636:1–893636:8. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, Z.; Cui, Z. Helical carbon nanofibers with a symmetric growth mode. Carbon 2004, 42, 1917–1922. [Google Scholar] [CrossRef]

- Chen, X.; Motojima, S. The growth patterns and morphologies of carbon micro-coils produced by chemical vapor deposition. Carbon 1999, 37, 1817–1823. [Google Scholar] [CrossRef]

- Kawaguchi, M.; Nozaki, K.; Motojima, S.; Iwanaga, H. A growth mechanism of regularly coiled carbon fibers through acetylene pyrolysis. J. Crystal Growth 1992, 118, 309–313. [Google Scholar] [CrossRef]

- Chen, X.; Motojima, S. Growth of carbon micro-coils by pre-pyrolysis of propane. J. Mater. Sci. 1999, 34, 3581–3585. [Google Scholar] [CrossRef]

- Kim, M.S.; Rodriguez, N.M.; Baker, R.T.K. The interplay between sulfur adsorption and carbon deposition on cobalt catalysts. J. Catal. 1993, 143, 449–463. [Google Scholar] [CrossRef]

- In-Hwang, W.; Chen, X.; Kuzuya, T.; Kawabe, K.; Motojima, S. Effect of external electromagnetic field and bias voltage on the vapor growth, morphology and properties of carbon micro coils. Carbon 2000, 38, 565–571. [Google Scholar] [CrossRef]

- Blank, V.D.; Kulnitskiy, B.A. Proposed formation mechanism for helically coiled carbon nanofibers. Carbon 2004, 42, 3009–3011. [Google Scholar] [CrossRef]

- Bandaru, P.R.; Daraio, C.; Yang, K.; Rao, A.M. A plausible mechanism for the evolution of helical forms in nanostructure growth. J. Appl. Phys. 2007, 101, 094307:1–094307:4. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raghubanshi, H.; Dikio, E.D. Synthesis of Helical Carbon Fibers and Related Materials: A Review on the Past and Recent Developments. Nanomaterials 2015, 5, 937-968. https://doi.org/10.3390/nano5020937

Raghubanshi H, Dikio ED. Synthesis of Helical Carbon Fibers and Related Materials: A Review on the Past and Recent Developments. Nanomaterials. 2015; 5(2):937-968. https://doi.org/10.3390/nano5020937

Chicago/Turabian StyleRaghubanshi, Himanshu, and Ezekiel Dixon Dikio. 2015. "Synthesis of Helical Carbon Fibers and Related Materials: A Review on the Past and Recent Developments" Nanomaterials 5, no. 2: 937-968. https://doi.org/10.3390/nano5020937

APA StyleRaghubanshi, H., & Dikio, E. D. (2015). Synthesis of Helical Carbon Fibers and Related Materials: A Review on the Past and Recent Developments. Nanomaterials, 5(2), 937-968. https://doi.org/10.3390/nano5020937