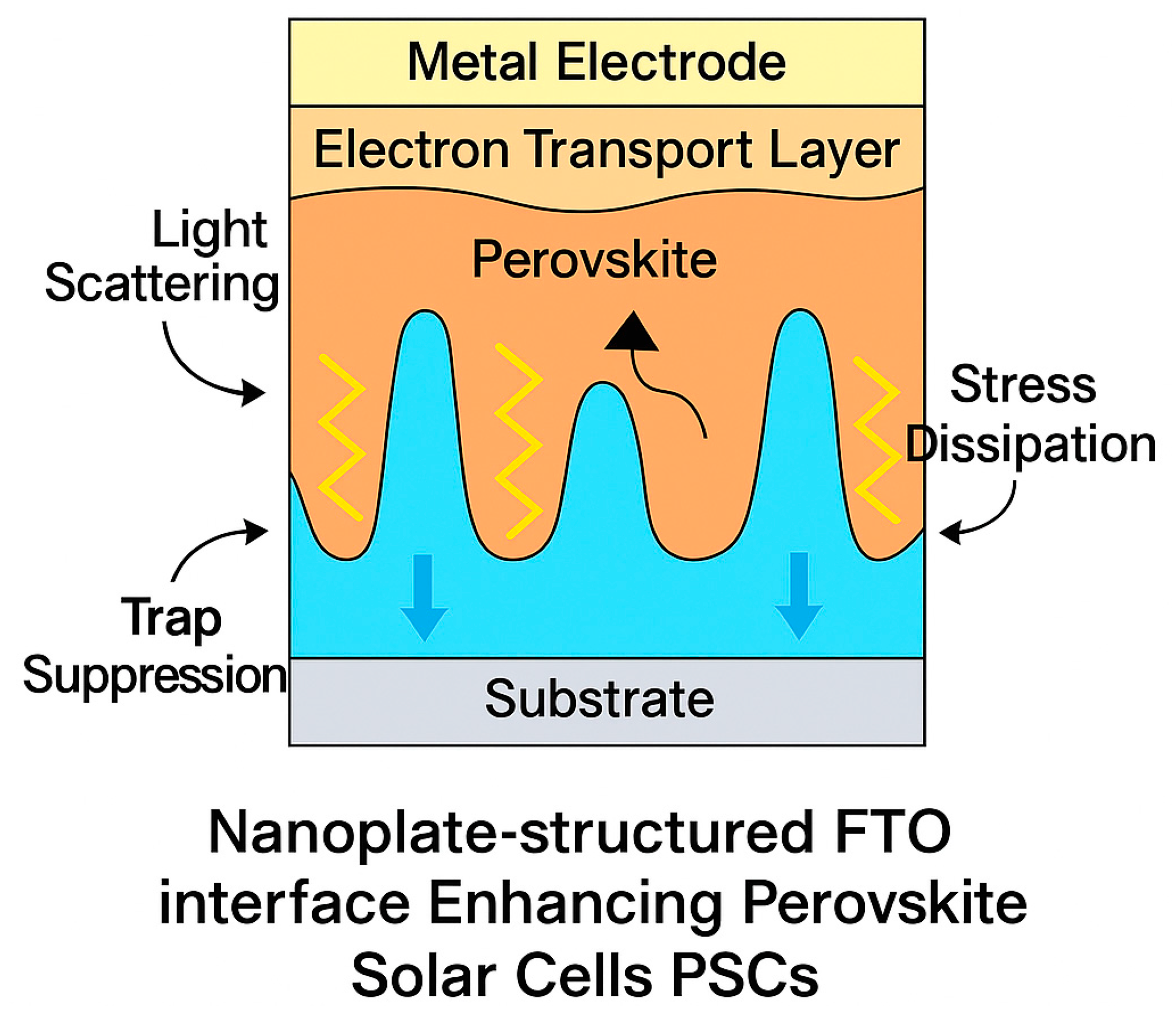

Dual Enhancement of Optoelectronic and Mechanical Performance in Perovskite Solar Cells Enabled by Nanoplate-Structured FTO Interfaces

Abstract

1. Introduction

2. Methods

2.1. Materials

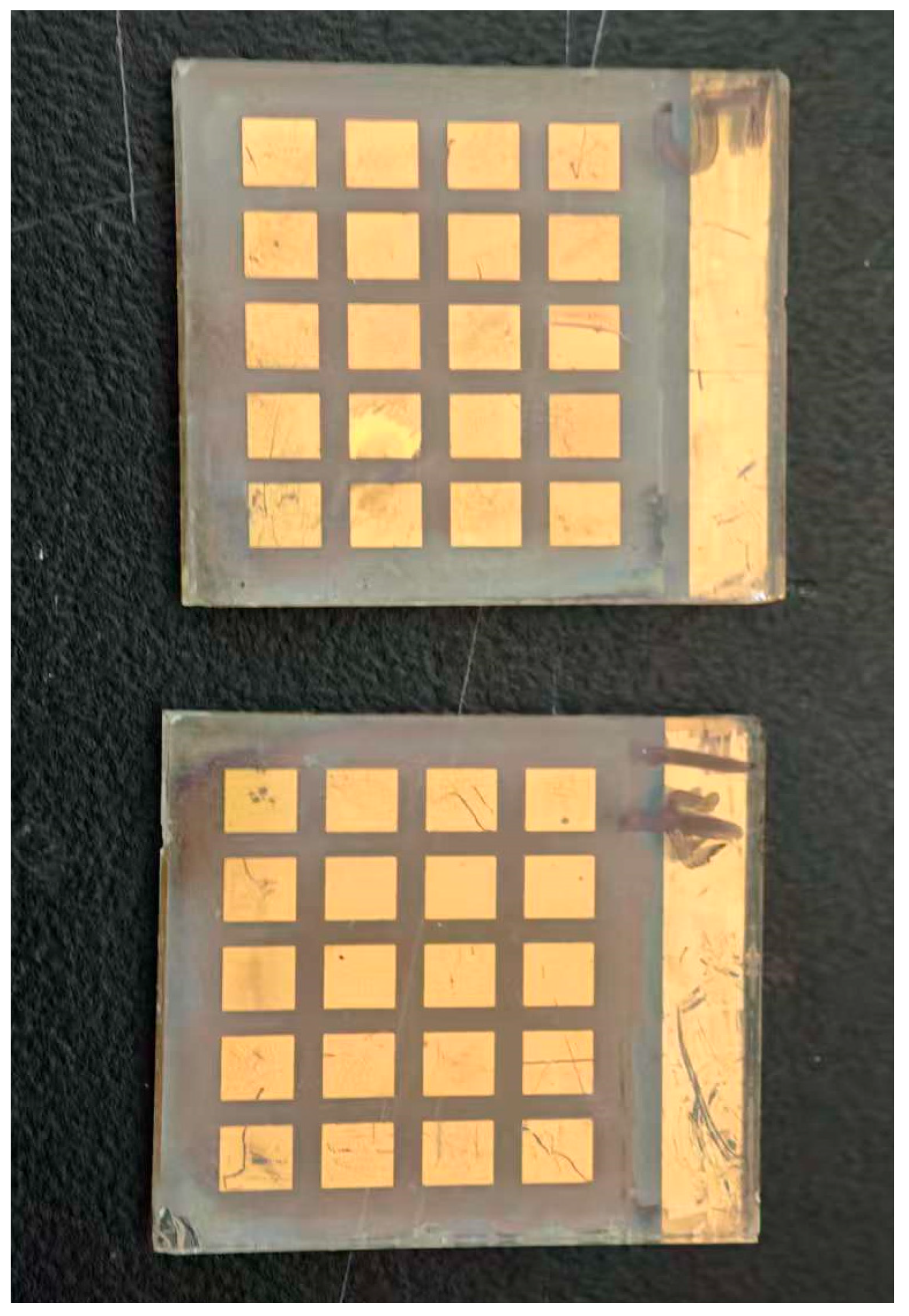

2.2. Device Fabrication

2.3. J–V Measurement Procedure

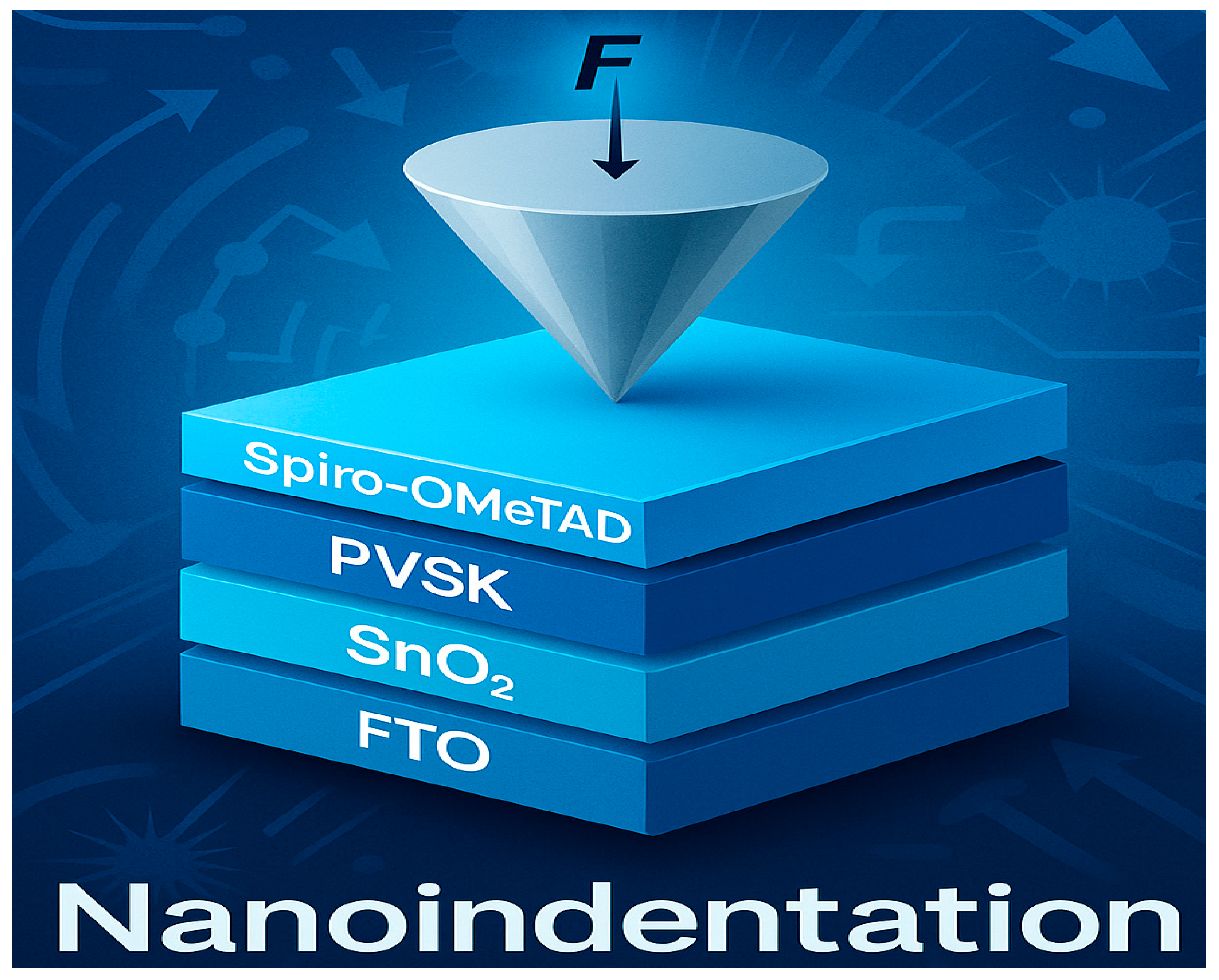

2.4. Nanoindentation Characterization

3. Results and Discussion

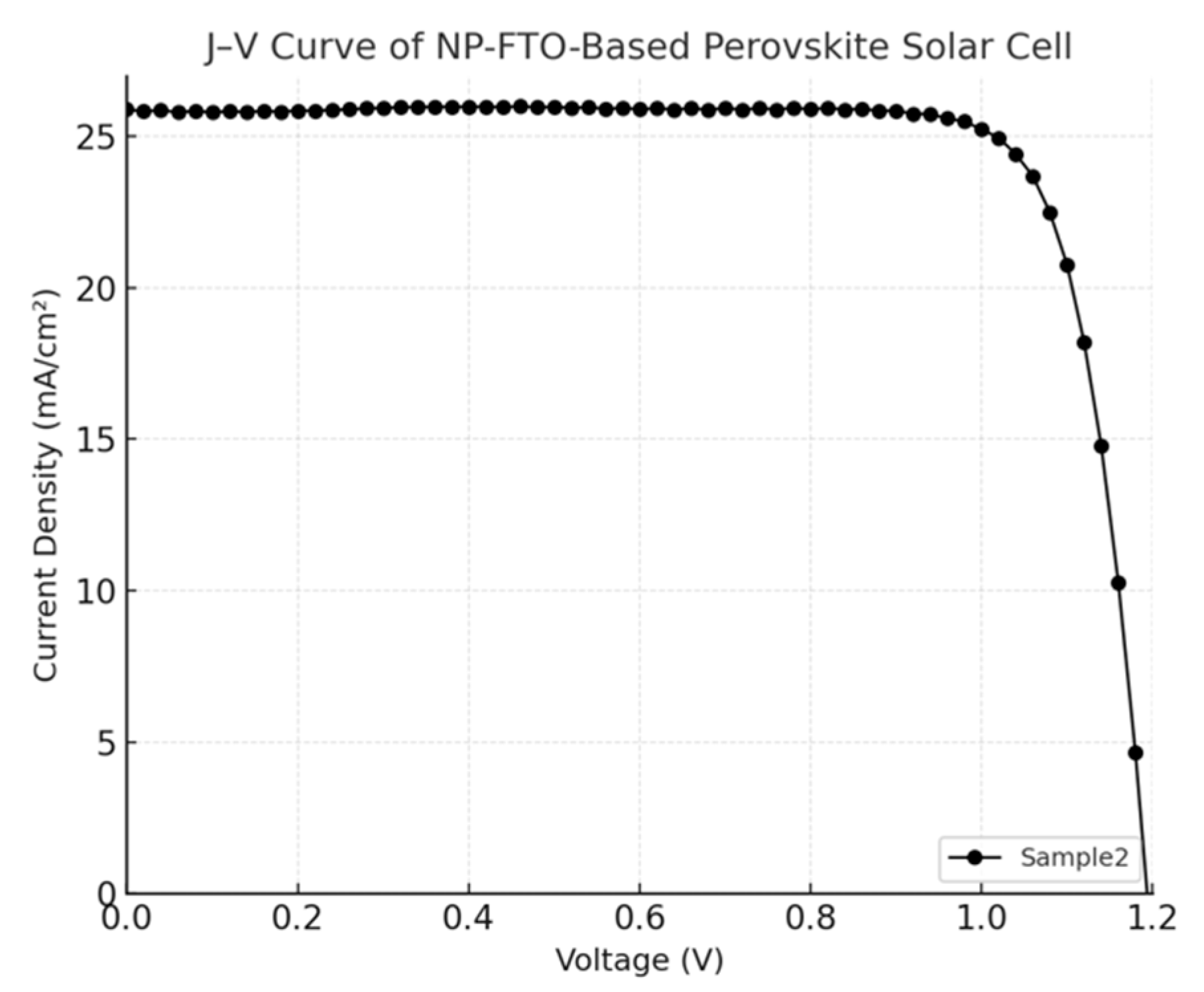

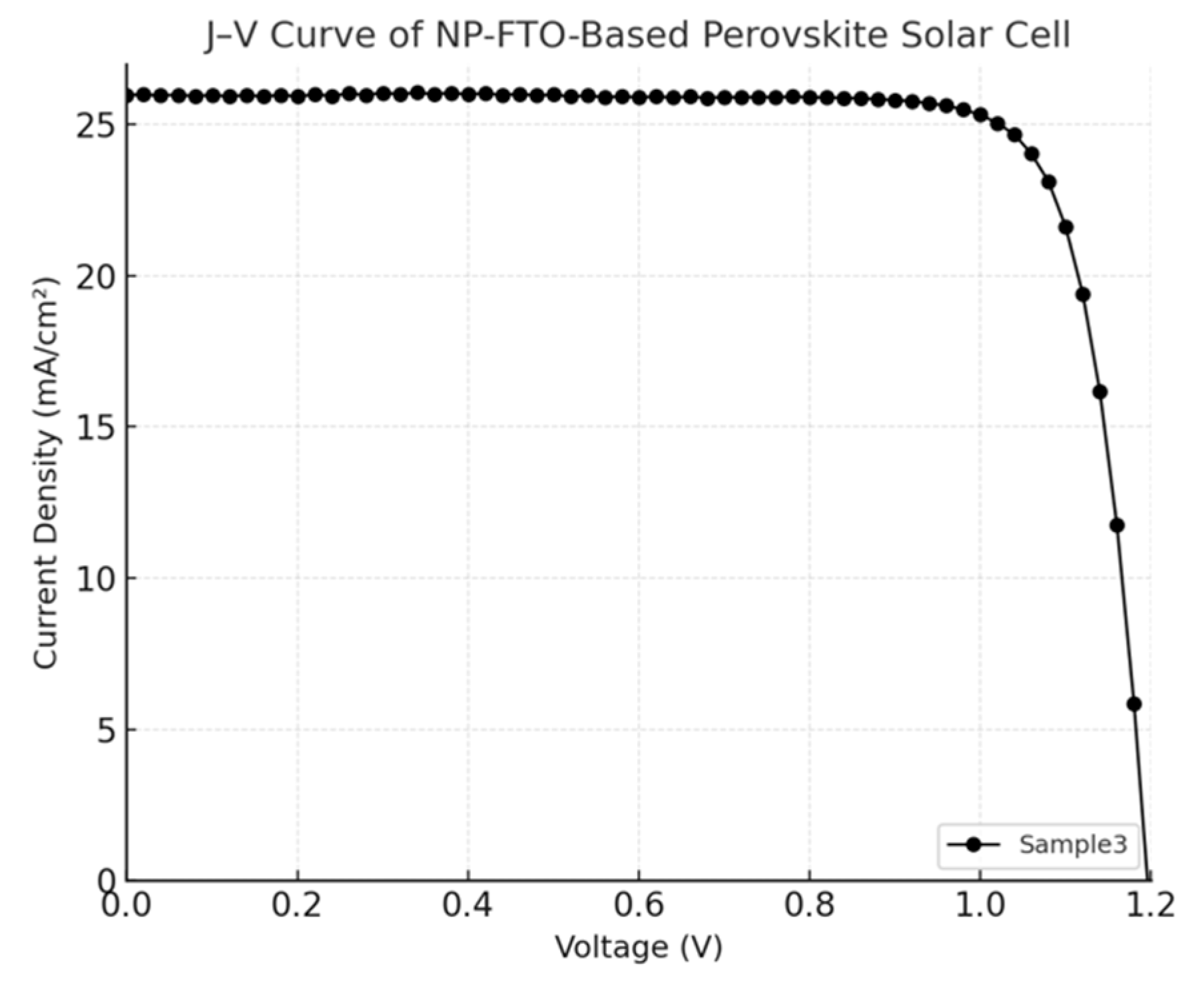

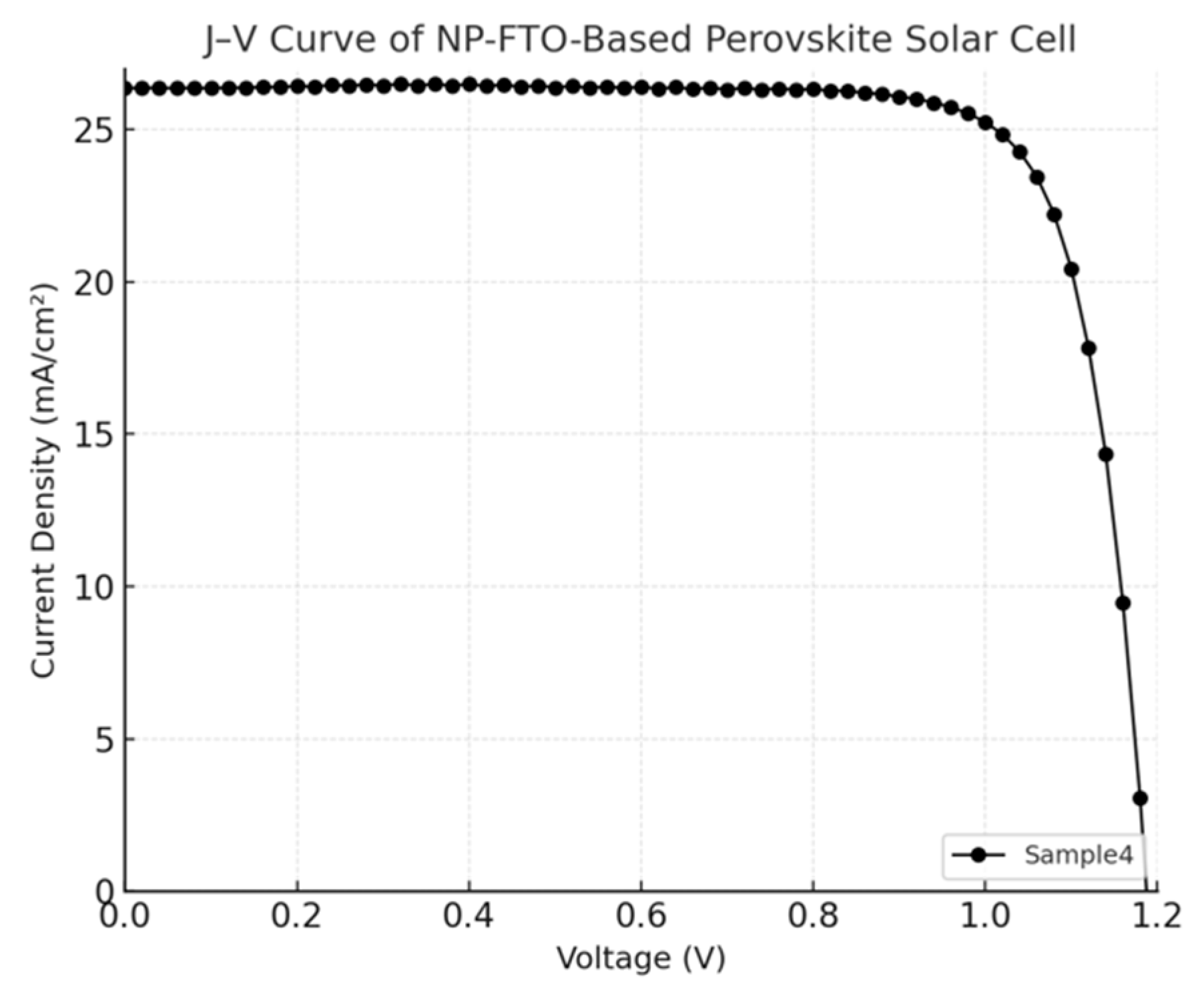

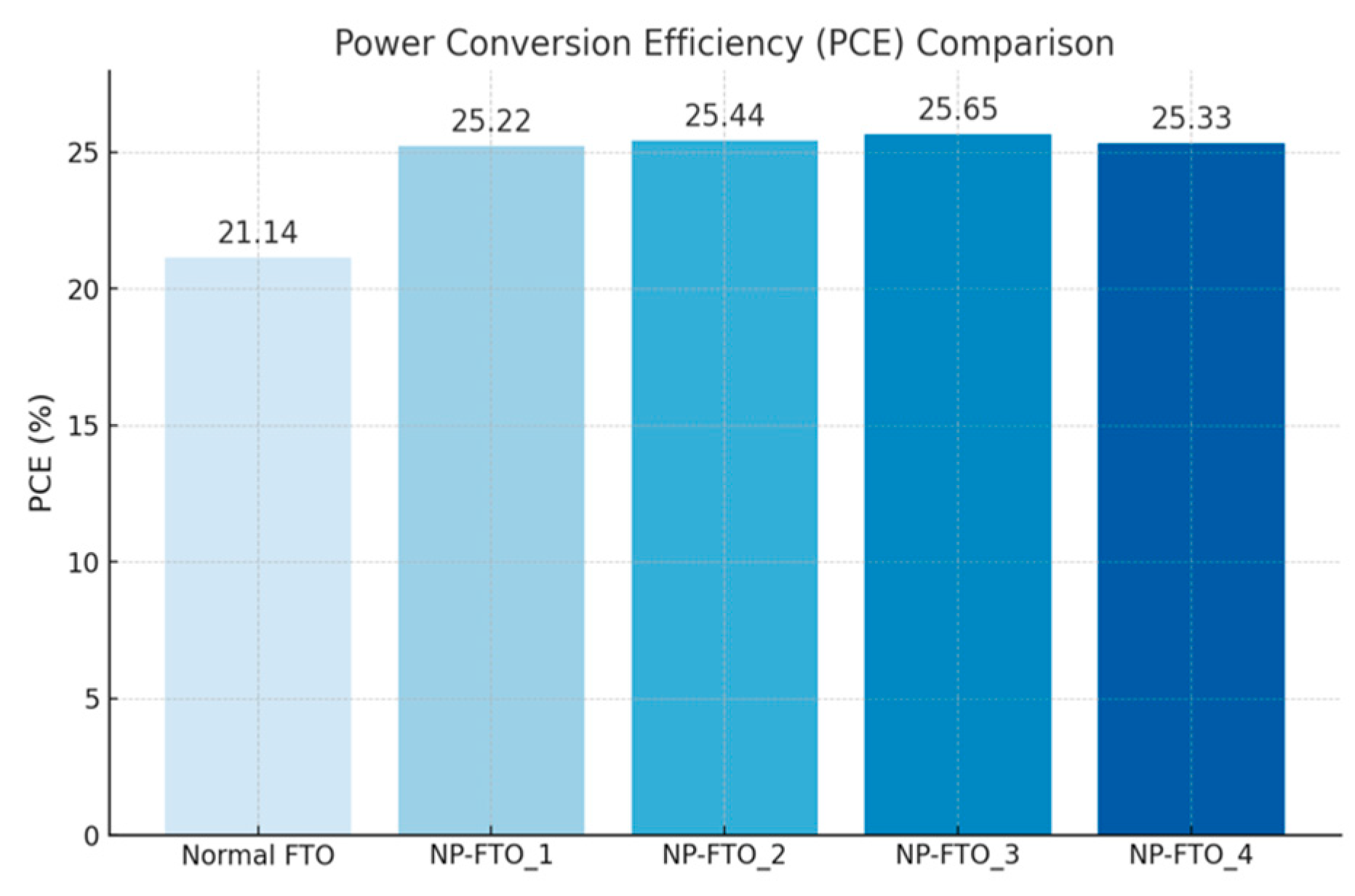

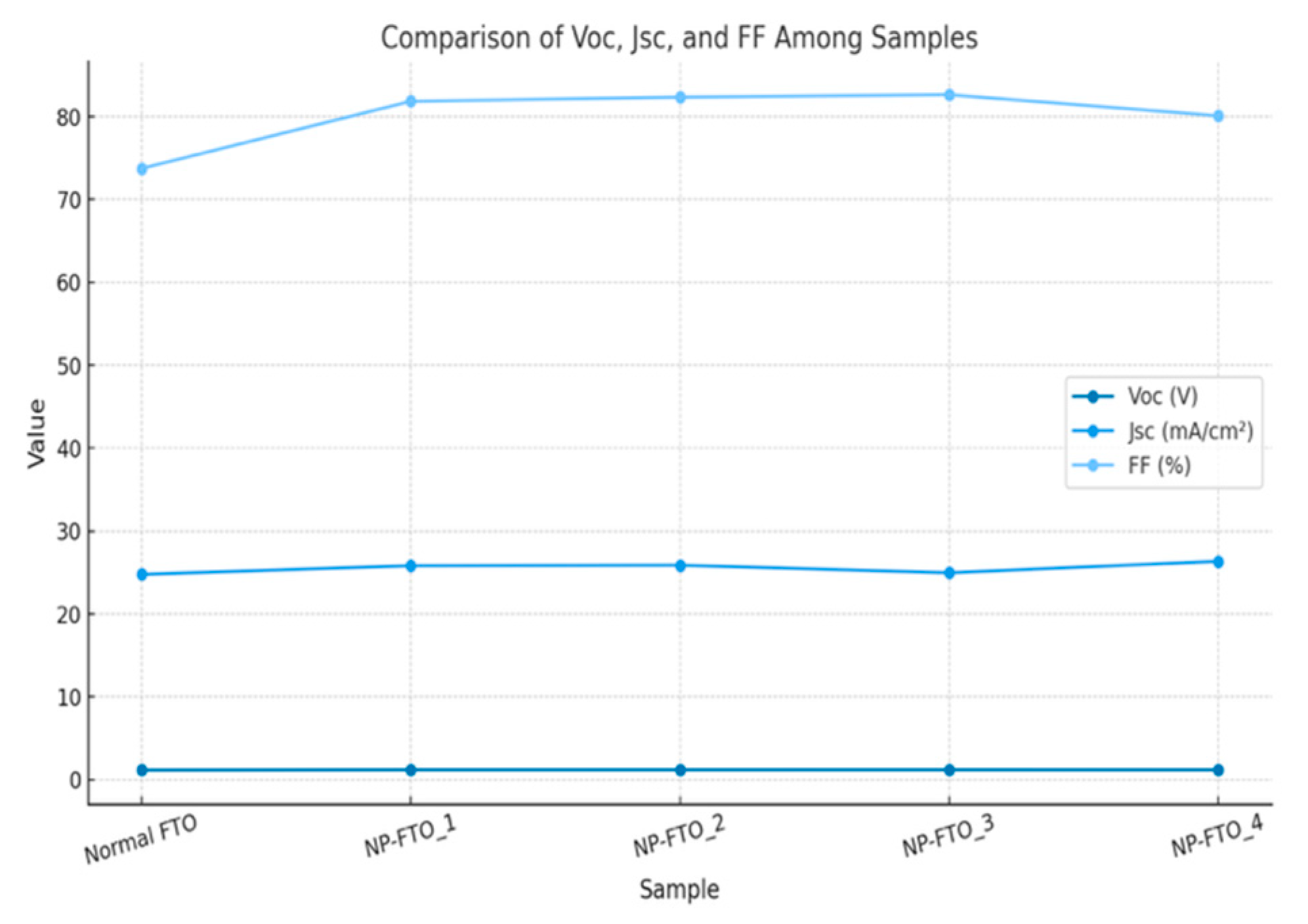

3.1. Photovoltaic Performance Enhancement via Nanoplate-Structured FTO

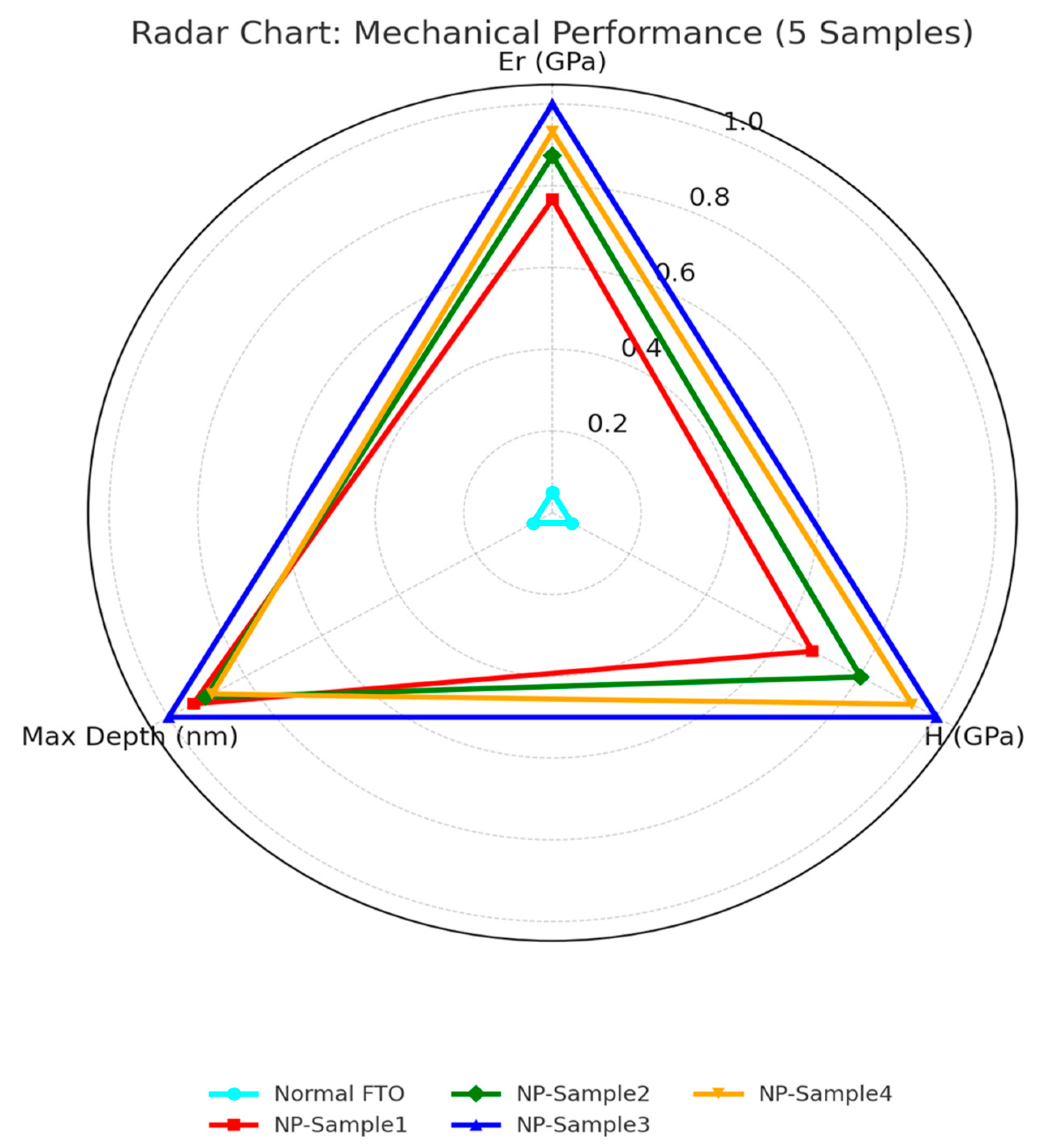

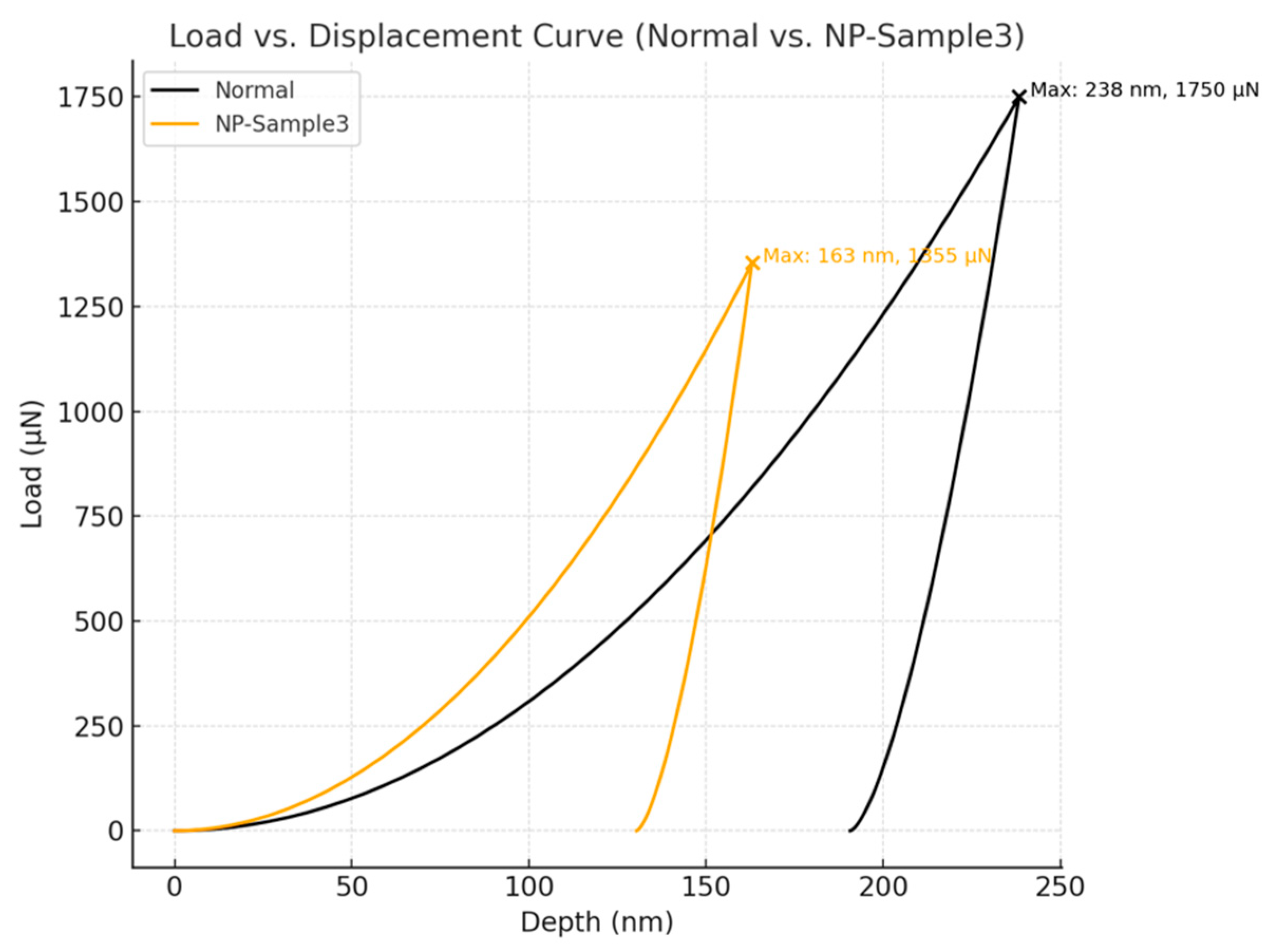

3.2. Interfacial Mechanical Reinforcement Characterized by Nanoindentation

3.3. Synergistic Mechanism and Practical Implications

- (a)

- Optical Management. Vertically aligned FTO nanoplates form a textured interface that promotes multi-angle light scattering and suppresses wide-angle reflection. Angle-resolved measurements confirm that NP-FTO increases average photon path lengths within the perovskite absorber, directly contributing to the observed Jsc improvement.

- (b)

- Electronic Optimization. The conformal NP-FTO architecture reduces interfacial voids and trap densities, as evidenced by enhanced PLQY and increased QFLS in TRPL and TRMC studies. Improved band alignment at the NP-FTO/SnO2 and perovskite interface mitigates non-radiative recombination, yielding higher Voc and fill factor (FF).

- (c)

- Mechanical Reinforcement. The three-dimensional nanoplate network provides mechanical anchoring and efficient stress redistribution under load. Nanoindentation results show a ~28% increase in reduced elastic modulus (Er) and a >70% enhancement in hardness, accompanied by a ~32% reduction in maximum indentation depth relative to planar FTO devices.

4. Conclusions

4.1. Scalability and R2R Feasibility

4.2. Comparison to Other Interfacial Strategies

4.3. Stability Outlook and Planned ISOS Tests

- ISOS-D-1/D-3 (ambient and damp-heat storage), 85 °C/85% RH;

- Thermal cycling (−20 ↔ 85 °C);

- Bending fatigue (R = 5–10 mm, 1–5 k cycles).

5. Future Study

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Park, N.-G. Perovskite solar cells: An emerging photovoltaic technology. Mater. Today 2015, 18, 65–72. [Google Scholar] [CrossRef]

- Green, M.A.; Ho-Baillie, A.; Snaith, H.J. The emergence of perovskite solar cells. Nat. Photonics 2014, 8, 506–514. [Google Scholar] [CrossRef]

- Fu, Q.; Tang, X.; Huang, B.; Hu, T.; Tan, L.; Chen, L.; Chen, Y. Recent Progress on the Long-Term Stability of Perovskite Solar Cells. Adv. Sci. 2018, 5, 1700387. [Google Scholar] [CrossRef] [PubMed]

- Dastgeer, G.; Nisar, S.; Zulfiqar, M.W.; Eom, J.; Imran, M.; Akbar, K. A review on recent progress and challenges in high-efficiency perovskite solar cells. Nano Energy 2024, 132, 110401. [Google Scholar] [CrossRef]

- Stolterfoht, M.; Wolff, C.M.; Márquez, J.A.; Zhang, S.; Hages, C.J.; Rothhardt, D.; Albrecht, S.; Burn, P.L.; Meredith, P.; Unold, T.; et al. Visualization and suppression of interfacial recombination for high-efficiency large-area pin perovskite solar cells. Nat. Energy 2018, 3, 847–854. [Google Scholar] [CrossRef]

- Djurišić, A.; Liu, F.; Tam, H.; Wong, M.; Ng, A.; Surya, C.; Chen, W.; He, Z. Perovskite solar cells—An overview of critical issues. Prog. Quantum Electron. 2017, 53, 1–37. [Google Scholar] [CrossRef]

- Li, N.; Niu, X.; Chen, Q.; Zhou, H. Towards commercialization: The operational stability of perovskite solar cells. Chem. Soc. Rev. 2020, 49, 8235–8286. [Google Scholar] [CrossRef]

- Kim, J.Y.; Lee, J.-W.; Jung, H.S.; Shin, H.; Park, N.-G. High-efficiency perovskite solar cells. Chem. Rev. 2020, 120, 7867–7918. [Google Scholar] [CrossRef]

- Wu, T.; Qin, Z.; Wang, Y.; Wu, Y.; Chen, W.; Zhang, S.; Cai, M.; Dai, S.; Zhang, J.; Liu, J.; et al. The Main Progress of Perovskite Solar Cells in 2020–2021. Nano-Micro Lett. 2021, 13, 152. [Google Scholar] [CrossRef]

- Tayari, F.; Teixeira, S.S.; Graca, M.P.F.; Nassar, K.I. Progress and Developments in the Fabrication and Characterization of Metal Halide Perovskites for Photovoltaic Applications. Nanomaterials 2025, 15, 613. [Google Scholar] [CrossRef]

- Jeon, N.J.; Noh, J.H.; Yang, W.S.; Kim, Y.C.; Ryu, S.; Seo, J.; Seok, S.I. Compositional engineering of perovskite materials for high-performance solar cells. Nature 2015, 517, 476–480. [Google Scholar] [CrossRef] [PubMed]

- Ahn, N.; Kwak, K.; Jang, M.S.; Yoon, H.; Lee, B.Y.; Lee, J.-K.; Pikhitsa, P.V.; Byun, J.; Choi, M. Trapped charge-driven degradation of perovskite solar cells. Nat. Commun. 2016, 7, 13422. [Google Scholar] [CrossRef]

- Li, R.; Shi, Y.; Wu, M.; Hong, S.; Wang, P. Improving atmospheric water production yield: Enabling multiple water harvesting cycles with nano sorbent. Nano Energy 2020, 67, 104255. [Google Scholar] [CrossRef]

- Correa-Baena, J.-P.; Abate, A.; Saliba, M.; Tress, W.; Jacobsson, T.J.; Grätzel, M.; Hagfeldt, A. The rapid evolution of highly efficient perovskite solar cells. Energy Environ. Sci. 2017, 10, 710–727. [Google Scholar] [CrossRef]

- Ball, J.M.; Stranks, S.D.; Hörantner, M.T.; Hüttner, S.; Zhang, W.; Crossland, E.J.W.; Ramirez, I.; Riede, M.; Johnston, M.B.; Friend, R.H.; et al. Optical properties and limiting photocurrent of thin-film perovskite solar cells. Energy Environ. Sci. 2015, 8, 602–609. [Google Scholar] [CrossRef]

- Snaith, H.J. Present status and future prospects of perovskite photovoltaics. Nat. Mater. 2018, 17, 372–376. [Google Scholar] [CrossRef]

- Mahapatra, A.; Prochowicz, D.; Tavakoli, M.M.; Trivedi, S.; Kumar, P.; Yadav, P. A review of aspects of additive engineering in perovskite solar cells. J. Mater. Chem. A 2020, 8, 27–54. [Google Scholar] [CrossRef]

- Sha, W.E.I.; Zhang, H.; Wang, Z.S.; Zhu, H.L.; Ren, X.; Lin, F.; Jen, A.K.; Choy, W.C.H. Quantifying efficiency loss of perovskite solar cells by a modified detailed balance model. Adv. Energy Mater. 2018, 8, 1701586. [Google Scholar] [CrossRef]

- Chen, H.; Liu, G.; Ke, L.; Liu, G.; Zhou, C.; Li, H. Alleviating the Angular Dependence of Perovskite Solar Cells via Light-Harvesting Nanostructure. Sol. RRL 2024, 8, 2400214. [Google Scholar] [CrossRef]

- Lee, K.; Park, J.; Seo, K. Neutral-colored transparent solar cells with radiative cooling and wide-angle anti-reflection. Cell Rep. Phys. Sci. 2023, 4, 101744. [Google Scholar] [CrossRef]

- Deng, K.; Liu, Z.; Wang, M.; Li, L. Nanoimprinted grating-embedded perovskite solar cells with improved light management. Adv. Funct. Mater. 2019, 29, 1900830. [Google Scholar] [CrossRef]

- Battaglia, C.; Escarré, J.; Söderström, K.; Charrière, M.; Despeisse, M.; Haug, F.-J.; Ballif, C. Nanomoulding of transparent zinc oxide electrodes for efficient light trapping in solar cells. Nat. Photonics 2011, 5, 535–538. [Google Scholar] [CrossRef]

- Ge, Y.; Zheng, L.; Wang, H.; Gao, J.; Yao, F.; Wang, C.; Li, G.; Guan, H.; Wang, S.; Cui, H.; et al. Suppressing wide-angle light loss and non-radiative recombination for efficient perovskite solar cells. Nat. Photonics 2025, 19, 170–177. [Google Scholar] [CrossRef]

- Tayari, F.; Nassar, K.I.; Carvalho, J.P.; Teixeira, S.S.; Hammami, I.; Gavinho, S.R.; Graça, M.P.F.; Valente, M.A. Sol–Gel Synthesis and Comprehensive Study of Structural, Electrical, and Magnetic Properties of BiBaO3 Perovskite. Gels 2025, 11, 450. [Google Scholar] [CrossRef] [PubMed]

- Dong, Q.; Zhu, C.; Chen, M.; Jiang, C.; Guo, J.; Feng, Y.; Dai, Z.; Yadavalli, S.K.; Hu, M.; Cao, X.; et al. Interpenetrating interfaces for efficient perovskite solar cells with high operational stability and mechanical robustness. Nat. Commun. 2021, 12, 973. [Google Scholar] [CrossRef]

- Li, Q.; Zheng, Y.; Wang, H.; Liu, X.; Lin, M.; Sui, X.; Leng, X.; Liu, D.; Wei, Z.; Song, M.; et al. Graphene-polymer reinforcement of perovskite lattices for durable solar cells. Science 2025, 387, 1069–1077. [Google Scholar] [CrossRef]

- Azad, S.S.; Keshavarzi, R.; Mirkhani, V.; Moghadam, M.; Tangestaninejad, S.; Mohammadpoor-Baltork, I. Stability enhancement of perovskite solar cells using multifunctional inorganic materials with UV protective, self cleaning, and high wear resistance properties. Sci. Rep. 2024, 14, 6466. [Google Scholar] [CrossRef]

| Sample | Voc (V) | Jsc (mA/c2) | FF (%) | PCE (%) |

|---|---|---|---|---|

| Normal FTO | 1.156 | 24.78 | 73.75 | 21.14 |

| NP-FTO-Sample1 | 1.193 | 25.82 | 81.85 | 25.22 |

| NP-FTO-Sample2 | 1.194 | 25.88 | 82.36 | 25.44 |

| NP-FTO-Sample3 | 1.196 | 24.97 | 82.65 | 25.65 |

| NP-FTO-Sample4 | 1.187 | 26.35 | 80.10 | 25.33 |

| Sample | Er (GPa) | H (GPa) | Max Indentation Depth (nm) |

|---|---|---|---|

| Normal FTO | 37.22 ± 1.02 | 2.43 ± 0.24 | 224.80 ± 12.83 |

| NP-Sample1 | 45.1 ± 2.03 | 3.29 ± 0.13 | 167 ± 11.58 |

| NP-Sample2 | 46.2 ± 1.92 | 3.45 ± 0.18 | 169 ± 11.6 |

| NP-Sample3 | 47.5 ± 1.66 | 3.70 ± 0.12 | 163 ± 10.3 |

| NP-Sample4 | 46.8 ± 1.98 | 3.62 ± 0.17 | 170 ± 10.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, R.; Calderon, A.D.; Fang, Q.; Liu, X. Dual Enhancement of Optoelectronic and Mechanical Performance in Perovskite Solar Cells Enabled by Nanoplate-Structured FTO Interfaces. Nanomaterials 2025, 15, 1430. https://doi.org/10.3390/nano15181430

Tian R, Calderon AD, Fang Q, Liu X. Dual Enhancement of Optoelectronic and Mechanical Performance in Perovskite Solar Cells Enabled by Nanoplate-Structured FTO Interfaces. Nanomaterials. 2025; 15(18):1430. https://doi.org/10.3390/nano15181430

Chicago/Turabian StyleTian, Ruichen, Aldrin D. Calderon, Quanrong Fang, and Xiaoyu Liu. 2025. "Dual Enhancement of Optoelectronic and Mechanical Performance in Perovskite Solar Cells Enabled by Nanoplate-Structured FTO Interfaces" Nanomaterials 15, no. 18: 1430. https://doi.org/10.3390/nano15181430

APA StyleTian, R., Calderon, A. D., Fang, Q., & Liu, X. (2025). Dual Enhancement of Optoelectronic and Mechanical Performance in Perovskite Solar Cells Enabled by Nanoplate-Structured FTO Interfaces. Nanomaterials, 15(18), 1430. https://doi.org/10.3390/nano15181430