Virtual Vernier Effect-Enabled Parallel Dual-Cavity Sensor for Temperature and Humidity Synchronization

Abstract

1. Introduction

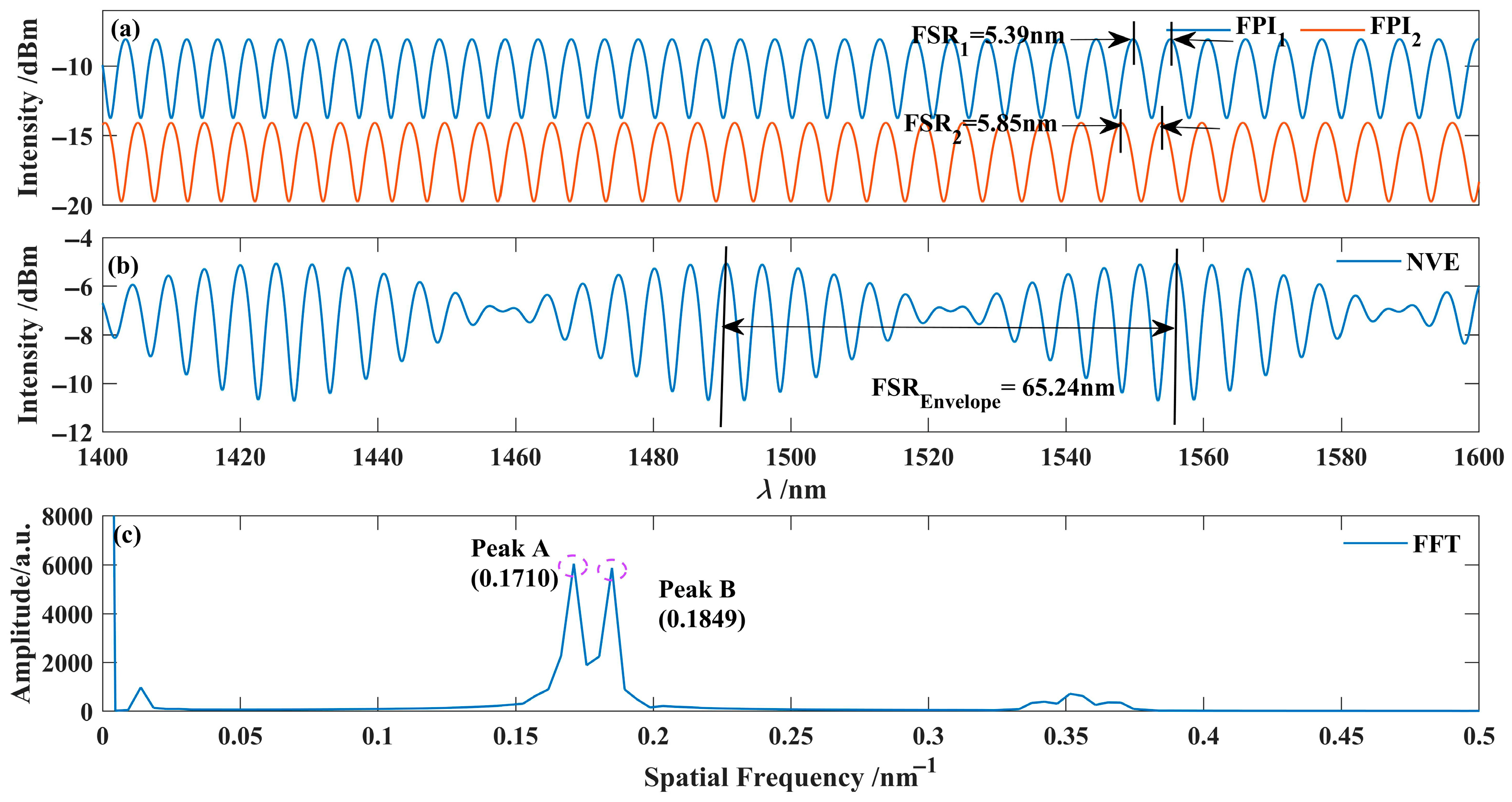

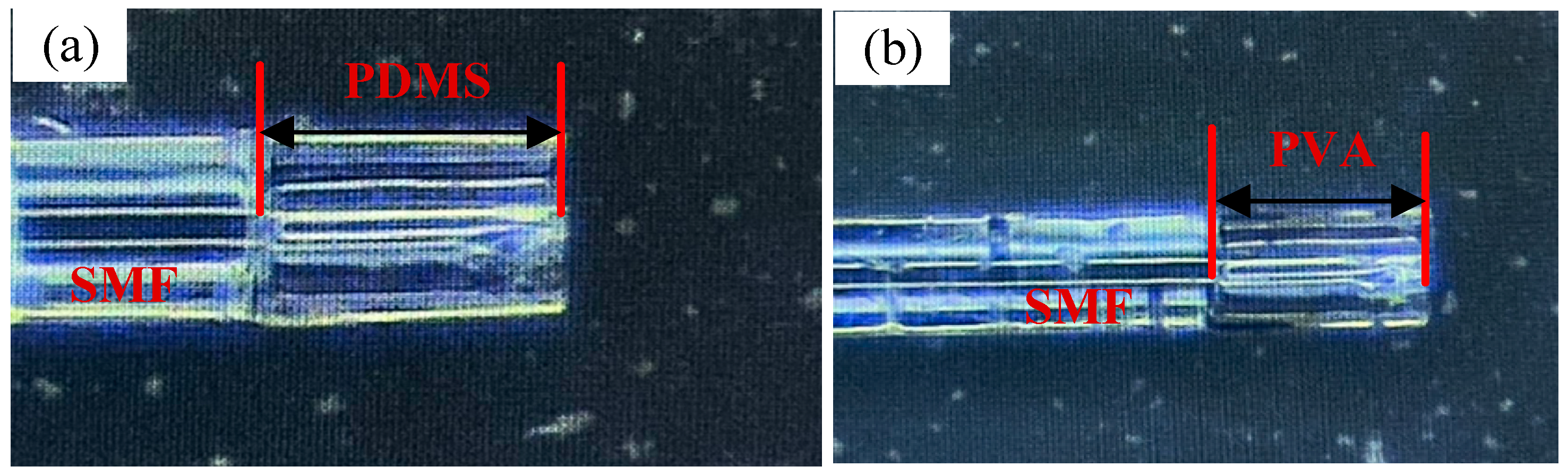

2. Sensor Principle and Simulation Analysis

2.1. Sensor Principle

2.2. Simulation Analysis

3. Sensor Experimental Results and Discussion

3.1. Temperature and Humidity Detection Results

3.2. Simultaneous Temperature and Humidity Detection Results

Evaluation of Sensor Repeatability and Long-Term Stability

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| VVE | Virtual Vernier Effect |

| VRI | Virtual Reference Interferometer |

References

- Khadka, I.B.; Rahman, S.A.; Jo, J.-S.; Kim, D.W.; Ghimire, M.P.; Haq, B.U.; Kim, W.Y.; Kim, S.-H.; Jang, J.-W. A Gold Nano-Urchin-Decorated Quasi-Freestanding Graphene-Based Humidity Sensor with Enhanced Responsivity and a Wide Relative Humidity Detection Range for Real-Time Applications. Sens. Actuators B Chem. 2025, 423, 136739. [Google Scholar] [CrossRef]

- Govindharaj, K.; Manoharan, M.; Muthumalai, K.; Poovarasan, S.; Thirugnanam, S.; Haldorai, Y.; Kumar, R.T.R. Interconnected SnO2 Nanoflakes Decorated WO3 Composites as Wearable and Ultrafast Sensors for Real-Time Wireless Sleep Quality Tracking and Breath Disorder Detection. Chem. Eng. J. 2024, 482, 148759. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, M.; Tang, M.; Song, X.; Zhang, X.; Kang, Z.; Liu, X.; Zhang, J.; Xue, Q. Recent Progress of Diversiform Humidity Sensors Based on Versatile Nanomaterials and Their Prospective Applications. Nano Res. 2023, 16, 11938–11958. [Google Scholar] [CrossRef]

- Duan, Z.; Jiang, Y.; Tai, H. Recent Advances in Humidity Sensors for Human Body Related Humidity Detection. J. Mater. Chem. C 2021, 9, 14963–14980. [Google Scholar] [CrossRef]

- Xie, W.; Yang, M.; Cheng, Y.; Li, D.; Zhang, Y.; Zhuang, Z. Optical Fiber Relative-Humidity Sensor with Evaporated Dielectric Coatings on Fiber End-Face. Opt. Fiber Technol. 2014, 20, 314–319. [Google Scholar] [CrossRef]

- Wu, S.; Cheng, H.; Ma, J.; Yang, X.; Wang, S.; Lu, P. Temperature-Independent Ultra-Sensitive Refractive Index Sensor Based on Hollow-Core Silica Tubes and Tapers. Opt. Express 2021, 29, 10939–10948. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Wang, J.; Wan, F.; Wang, P. Review of Optical Fibre Sensors for Electrical Equipment Characteristic State Parameters Detection. High Volt. 2019, 4, 271–281. [Google Scholar] [CrossRef]

- Wang, J.; Chew, S.X.; Song, S.; Li, L.; Nguyen, L.; Yi, X. On-Chip Simultaneous Measurement of Humidity and Temperature Using Cascaded Photonic Crystal Microring Resonators with Error Correction. Opt. Express 2022, 30, 35608. [Google Scholar] [CrossRef] [PubMed]

- Eryürek, M.; Tasdemir, Z.; Karadag, Y.; Anand, S.; Kilinc, N.; Alaca, B.E.; Kiraz, A. Integrated Humidity Sensor Based on SU-8 Polymer Microdisk Microresonator. Sens. Actuators B Chem. 2017, 242, 1115–1120. [Google Scholar] [CrossRef]

- Tian, X.; Gunawan, G.; Zhou, L.; Li, L.; Nguyen, L.; Minasian, R.; Yi, X. Athermal Microwave Photonic Sensor Based on Single Microring Resonance Assisted by Machine Learning. J. Light. Technol. 2022, 40, 6796–6804. [Google Scholar] [CrossRef]

- Wang, J.; Bian, C.; Gang, T.; Hu, M. High-Sensitive Mach-Zehnder Interferometer for Humidity Measurements Based on Concatenating Single-Mode Concave Cone and Core-Offset. Optik 2020, 208, 164465. [Google Scholar] [CrossRef]

- Fu, X.; Ran, R.; Li, Q.; Huang, Z.; Li, D.; Zhang, R.; Fu, G.; Jin, W.; Qi, Y.; Bi, W. A Few Mode Fiber Temperature Sensor Filled With PDMS Based on Vernier Effect. IEEE Photonics J. 2021, 13, 1–5. [Google Scholar] [CrossRef]

- Zhao, Y.; Peng, Y.; Chen, M.; Tong, R.-J. Humidity Sensor Based on Unsymmetrical U-Shaped Microfiber with a Polyvinyl Alcohol Overlay. Sens. Actuators B Chem. 2018, 263, 312–318. [Google Scholar] [CrossRef]

- Wu, S.; Yan, G.; Lian, Z.; Chen, X.; Zhou, B.; He, S. An Open-Cavity Fabry-Perot Interferometer with PVA Coating for Simultaneous Measurement of Relative Humidity and Temperature. Sens. Actuators B Chem. 2016, 225, 50–56. [Google Scholar] [CrossRef]

- He, Y.; Yang, H.; Lim, K.-S.; Ahmad, H.; Feng, Z.; Zhang, P.; Tian, Q.; Lu, K.; Han, Z.; Liu, J. Discriminative Measurement for Temperature and Humidity Using Hollow-Core Fabry-Perot Interferometer. Opt. Fiber Technol. 2019, 53, 102027. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.-X.; Zhang, W.-G.; Kong, L.-X.; Yan, T.-Y. Micro-Cap on 2-Core-Fiber Facet Hybrid Interferometer for Dual-Parameter Sensing. J. Light. Technol. 2019, 37, 6114–6120. [Google Scholar] [CrossRef]

- Gomes, A.D.; Ferreira, M.S.; Bierlich, J.; Kobelke, J.; Rothhardt, M.; Bartelt, H.; Frazão, O. Hollow Microsphere Combined with Optical Harmonic Vernier Effect for Strain and Temperature Discrimination. Opt. Laser Technol. 2020, 127, 106198. [Google Scholar] [CrossRef]

- Liu, S.; Lu, G.; Lv, D.; Chen, M.; Zhang, Z. Sensitivity Enhanced Temperature Sensor with Cascaded Sagnac Loops Based on Harmonic Vernier Effect. Opt. Fiber Technol. 2021, 66, 102654. [Google Scholar] [CrossRef]

- Li, Z.; Dang, W.; Dan, J.; Jin, K.; Nan, P.; Xin, G.; Lim, K.-S.; Ahmad, H.; Yang, H. High-Sensitivity Interferometric High-Temperature Strain Sensor Based on Optical Harmonic Vernier Effect. Opt. Fiber Technol. 2023, 79, 103361. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Mu, X.; Li, Y.; Zhang, Y.; Mo, C.; Xia, H.; Huang, Z. Sensitivity-Enhanced Optical Fiber Sensor Based on the Vernier Effect for Detection of Ammonia in Water. Opt. Express 2024, 32, 36686–36696. [Google Scholar] [CrossRef]

- Zhou, C.; Song, Y.; Zhou, Q.; Tian, J.; Yao, Y. Ultra-High-Sensitivity Humidity Fiber Sensor Based on Harmonic Vernier Effect in Cascaded FPI. Sensors 2022, 22, 4816. [Google Scholar] [CrossRef] [PubMed]

- Cuando-Espitia, N.; Fuentes-Fuentes, M.A.; Velázquez-Benítez, A.; Amezcua, R.; Hernández-Cordero, J.; May-Arrioja, D.A. Vernier Effect Using In-Line Highly Coupled Multicore Fibers. Sci. Rep. 2021, 11, 18383. [Google Scholar] [CrossRef]

- Zhao, K.; Song, B.; Ye, C.; Jin, X.; Yu, C.; Zhou, G.; Pan, J.; Huang, X. Fiber Optic Relative Humidity and Temperature Sensor with the Cascaded Vernier Effect Based on the C-Shaped Cavity Structure. Opt. Express 2024, 32, 29887–29901. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Han, Q.; Liang, Z.; Jiang, J.; Cheng, Z. A Fabry–Perot Sensor with Cascaded Polymer Films Based on Vernier Effect for Simultaneous Measurement of Relative Humidity and Temperature. Sensors 2023, 23, 2800. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhang, Y.; Mu, X.; Sun, L.; Wang, J.; Li, Y.; Gao, J.; Bi, L. Fiber Optic Temperature Sensor Based on the Harmonic Vernier Effect Generated by Two Sagnac Interferometers. IEEE Sens. J. 2024, 24, 12419–12425. [Google Scholar] [CrossRef]

- Gao, J.; Yang, Y.; Mu, X.; Zhang, Y.; Li, Y.; Li, Y. Fiber-optic temperature sensor based on enhanced Vernier effect. Opt. Precis. Eng. 2023, 31, 3531. [Google Scholar] [CrossRef]

- Nie, W.; Wang, Y.; Ling, Q.; Wang, X.; He, Y.; Zhang, J.; Chen, H.; Yu, Z.; Chen, D.; Gu, Z. Cavity-Length Controllable Fabry–Perot Interferometer Based on Vernier Effect. Opt. Quantum Electron. 2024, 56, 1436. [Google Scholar] [CrossRef]

- Yang, P.; Jiang, S.; Wang, Z.; Peng, B. Hybrid Interferometer Sensor Based on the Enhanced Vernier Effect for the Simultaneous Measurement of Strain and Temperature. IEEE Trans. Instrum. Meas. 2024, 73, 1–10. [Google Scholar] [CrossRef]

- Tong, R.-J.; Xing, B.; Chen, Z.-H.; Zheng, H.-N.; Zhou, L.-M. High-Sensitivity Fiber Optic Temperature Sensor Based on Enhanced Vernier Effect. IEEE Trans. Instrum. Meas. 2024, 73, 1–8. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, P.; Wei, W.; Jiang, S.; Bao, W.; Zhu, X.; Wu, G.; Chen, D. Highly Sensitive Salinity Sensor Based on Virtual Vernier Effect of Micro–Nano Fiber Mode Interferometer. IEEE Sens. J. 2024, 24, 16121–16129. [Google Scholar] [CrossRef]

- Yang, X.; Luo, B.; Shi, S.; Zou, X.; Wu, D.; Chen, H.; Li, Y.; Gu, H.; Zhao, M. High sensitivity temperature sensor of sandwich multimode fiber Mach Zehnder interferometer based on virtual vernier effect. Laser Optoelectron. Prog. 2023, 60, 1706002. [Google Scholar]

- Li, J.; Zhang, J.; Sun, H.; Yang, Y.; Ye, Y.; Cui, J.; He, W.; Yong, X.; Xie, Y. An Optical Fiber Sensor Based on Carboxymethyl Cellulose/Carbon Nanotubes Composite Film for Simultaneous Measurement of Relative Humidity and Temperature. Opt. Commun. 2020, 467, 125740. [Google Scholar] [CrossRef]

- Ying, Y.; Cheng, S.; Hu, N.; Gao, Z.; Guo, X.; Si, G. Temperature and Humidity Sensor Based on a Double D-Shaped Optical Fiber with Incorporated Toluene and Polyethylene. Instrum. Sci. Technol. 2021, 49, 404–415. [Google Scholar] [CrossRef]

- Sun, D.; Liu, S.; Xu, S.; Fu, Y.; Wang, T.; Ji, C.; Ma, J. A U-Shaped Microfiber Interferometer Coated with MoS2 Film for Simultaneous Measuring Relative Humidity and Temperature. Opt. Fiber Technol. 2022, 73, 103009. [Google Scholar] [CrossRef]

| Serial Number | Temperature Demodulation Result (°C) | Temperature Measurement Result (°C) | Error 1(%) | Humidity Demodulation Result (%RH) | Humidity Measurement Result (%RH) | Error 2 (%) |

|---|---|---|---|---|---|---|

| 1 | 35.079 | 35 | 0.23 | 39.581 | 40 | 1.05 |

| 2 | 35.477 | 36 | 0.89 | 45.469 | 45 | 1.04 |

| 3 | 36.165 | 37 | 0.63 | 49.304 | 50 | 1.39 |

| 4 | 37.313 | 38 | 0.81 | 54.365 | 55 | 1.15 |

| 5 | 38.411 | 39 | 0.98 | 59.343 | 60 | 1.09 |

| 6 | 39.488 | 40 | 0.29 | 64.139 | 65 | 1.32 |

| 7 | 40.443 | 41 | 0.62 | 69.544 | 70 | 0.65 |

| Structure and Materials | Temperature Sensitivity | Humidity Sensitivity | Key Features | Ref. |

|---|---|---|---|---|

| Side-hole fiber coated with PVA | −6.14 pm/°C | −23.1 pm/%RH | High sensitivity; high loss; poor stability | [14] |

| FPI with PCF + hollow-core fiber | 0.01064 nm/°C | 0.06273 dB/%RH | Low cross-sensitivity; fast response; complex fabrication | [15] |

| Cascaded FPI + MI, Fourier demodulation | 0.38 nm/°C and −0.08 nm/°C | 0.52 nm/%RH and −0.20 nm/%RH | High integration; flexible demodulation; heavy computation | [16] |

| FBG + CMC/CNT film on hollow-core fiber | 0.0263 nm/°C | 0.1705 nm/%RH | Hybrid design; reduced crosstalk; costly coating | [32] |

| Dual D-shaped fibers with toluene and PVA coatings | 1.02 nm/°C | 0.79 nm/%RH | High sensitivity; FEM optimization; expensive fabrication | [33] |

| U-shaped microfiber with MoS2 coating | −0.013 nm/°C | 0.116 nm/%RH | High sensitivity; fast response | [34] |

| Dual FPI (PDMS + PVA) with Virtual Vernier Effect | 7.62 nm/°C | −3.07 nm/% RH | High sensitivity; Reduced cross-sensitivity; no physical reference cavity; low cost; dynamically tunable M factor | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Mu, X.; Yang, Y.; Xia, H.; Zhang, Y.; Mo, C.; Huang, Z.; Li, Y.; Li, F. Virtual Vernier Effect-Enabled Parallel Dual-Cavity Sensor for Temperature and Humidity Synchronization. Nanomaterials 2025, 15, 1427. https://doi.org/10.3390/nano15181427

Li Y, Mu X, Yang Y, Xia H, Zhang Y, Mo C, Huang Z, Li Y, Li F. Virtual Vernier Effect-Enabled Parallel Dual-Cavity Sensor for Temperature and Humidity Synchronization. Nanomaterials. 2025; 15(18):1427. https://doi.org/10.3390/nano15181427

Chicago/Turabian StyleLi, Yuting, Xiaoguang Mu, Yuqiang Yang, Han Xia, Yuying Zhang, Chengyu Mo, Zhihao Huang, Yitong Li, and Fujiang Li. 2025. "Virtual Vernier Effect-Enabled Parallel Dual-Cavity Sensor for Temperature and Humidity Synchronization" Nanomaterials 15, no. 18: 1427. https://doi.org/10.3390/nano15181427

APA StyleLi, Y., Mu, X., Yang, Y., Xia, H., Zhang, Y., Mo, C., Huang, Z., Li, Y., & Li, F. (2025). Virtual Vernier Effect-Enabled Parallel Dual-Cavity Sensor for Temperature and Humidity Synchronization. Nanomaterials, 15(18), 1427. https://doi.org/10.3390/nano15181427