Enhancing the Interfacial Adhesion of a Ductile Gold Electrode with PDMS Using an Interlocking Structure for Applications in Temperature Sensors

Abstract

1. Introduction

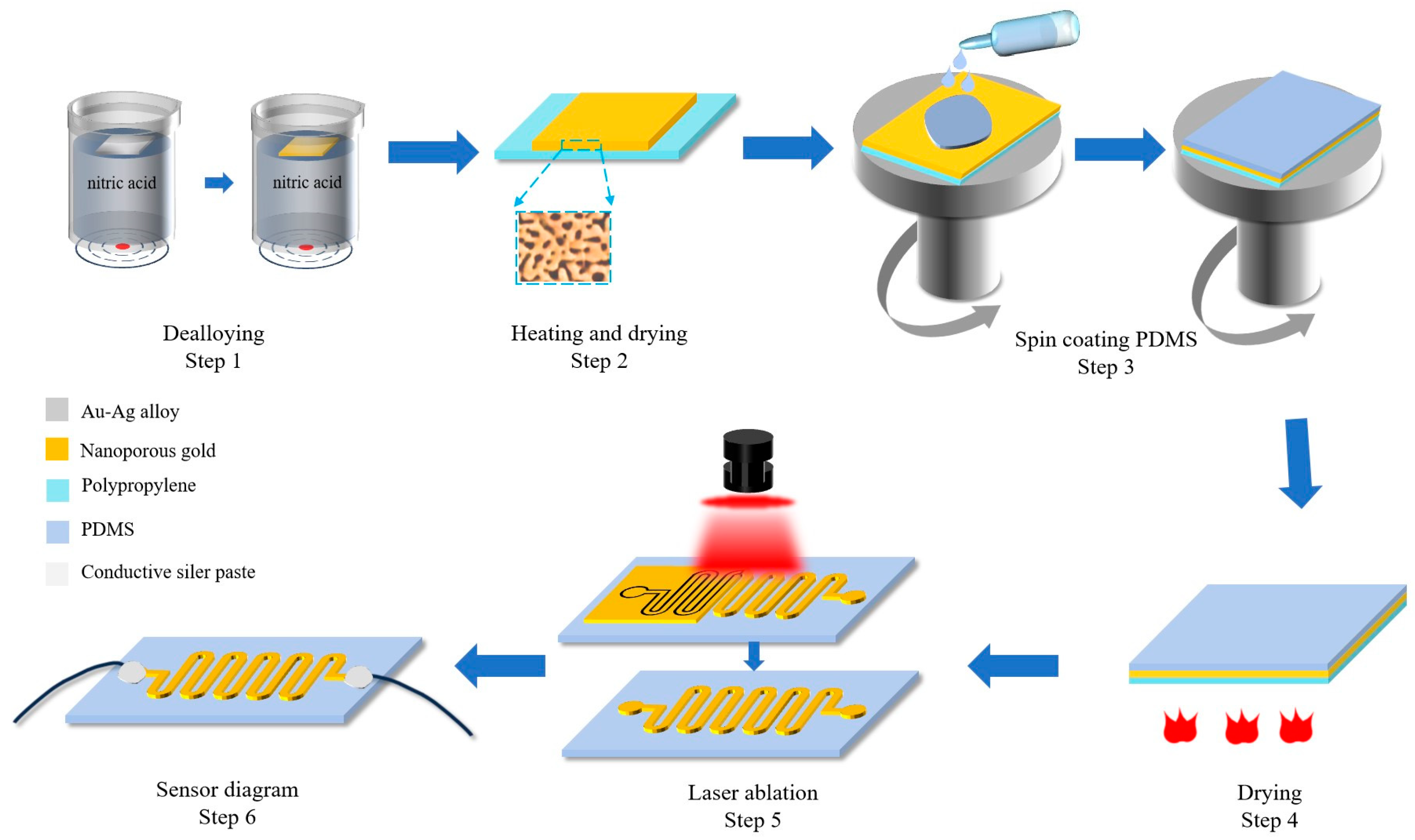

2. Materials and Methods

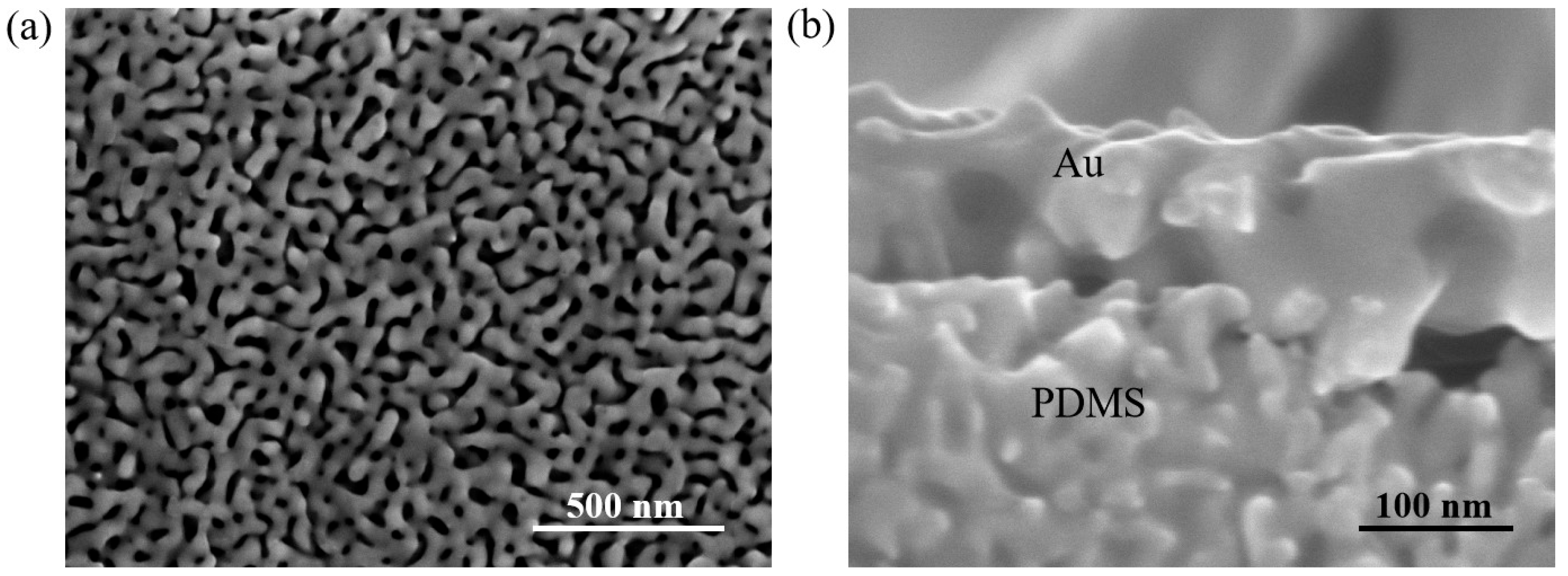

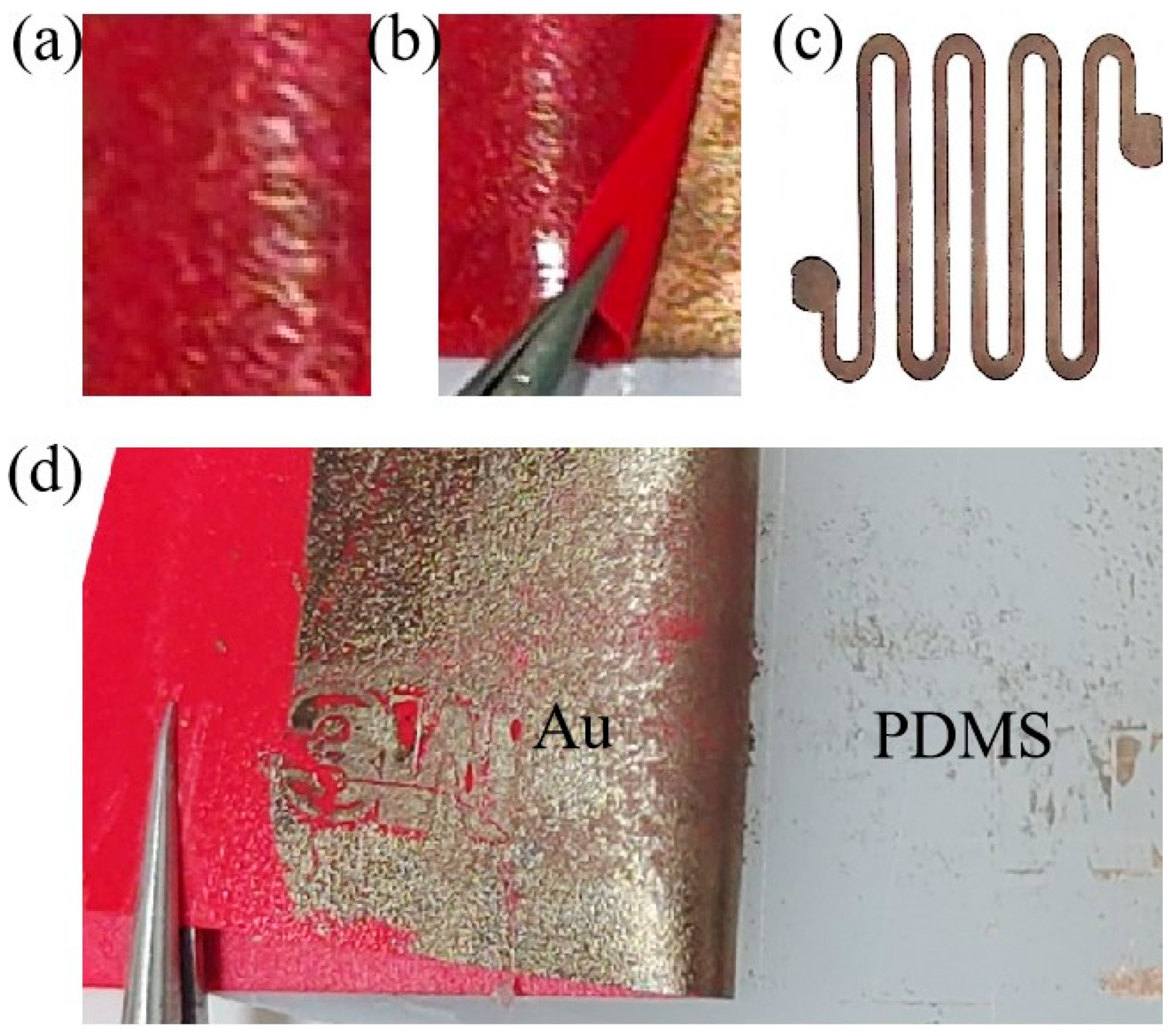

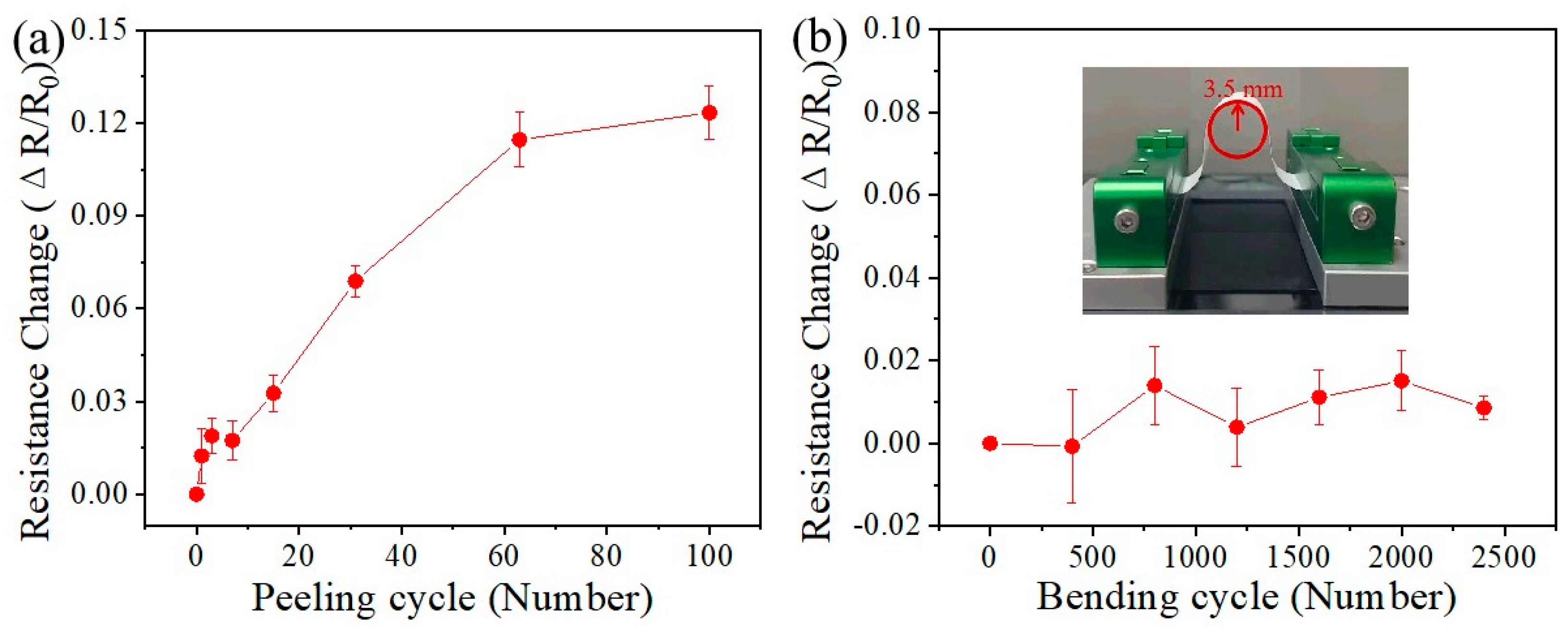

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shin, J.; Jeong, B.; Kim, J.; Nam, V.; Yoon, Y.; Jung, J.; Hong, S.; Lee, H.; Eom, H.; Yeo, J.; et al. Sensitive Wearable Temperature Sensor with Seamless Monolithic Integration. Adv. Mater. 2020, 32, 1905527. [Google Scholar] [CrossRef] [PubMed]

- Gong, X.; Zhang, L.; Huang, Y.; Wang, S.; Pan, G.; Li, L. Directly writing flexible temperature sensor with graphene nanoribbons for disposable healthcare devices. Rsc Adv. 2020, 10, 22222–22229. [Google Scholar] [CrossRef]

- Mahmoud, W.; Al-Bluwi, S. Development of highly sensitive temperature sensor made of graphene monolayers doped P(VDF-TrFE) nanocomposites. Sens. Actuators A Phys. 2020, 312, 112101. [Google Scholar] [CrossRef]

- Salas-Juárez, C.; Navarro, R.; Pérez-Rodríguez, A.; Orozco-Valencia, U.; Aceves, R. Visual temperature sensor and luminescent thermometer based on the complex Tb/Eu-TPTZ incorporated in transparent PMMA film. Sens. Actuators A Phys. 2020, 315, 112293. [Google Scholar] [CrossRef]

- Linh, V.; Han, S.; Koh, E.; Kim, S.; Jung, H.; Koo, J. Advances in wearable electronics for monitoring hum-an organs: Bridging external and internal health assessments. Biomaterials 2024, 314, 122865. [Google Scholar]

- Dagdeviren, C.; Su, Y.; Joe, P.; Yona, R.; Liu, Y.; Kim, Y.; Huang, Y.; Damadoran, A.; Xia, J.; Martin, L.; et al. Conformable amplified lead zirconate titanate sensors with enhanced piezoelectric response for cutaneous pressure monitoring. Nat. Commun. 2014, 5, 4496. [Google Scholar] [CrossRef]

- Guo, H.; D’Andrea, D.; Zhao, J.; Xu, Y.; Qiao, Z.; Janes, L.; Murthy, N.; Li, R.; Xie, Z.; Song, Z.; et al. Advanced Materials in Wireless, Implantable Electrical Stimulators that Offer Rapid Rates of Bioresorption for Peripheral Axon Regeneration. Adv. Funct. Mater. 2021, 31, 2102724. [Google Scholar] [CrossRef] [PubMed]

- Bandodkar, A.; Gutruf, P.; Choi, J.; Lee, K.; Sekine, Y.; Reeder, J.; Jeang, W.; Aranyosi, A.; Lee, S.; Model, J.; et al. Battery-free, skin-interfaced microfluidic/electronic systems for simultaneous electrochemical, colorimetric, and volumetric analysis of sweat. Sci. Adv. 2019, 5, eaav3294. [Google Scholar] [CrossRef]

- Assi, L.; Chamseddine, F.; Ibrahim, P.; Sabbagh, H.; Rosman, L.; Congdon, N.; Evans, J.; Ramke, J.; Kuper, H.; Burton, M.; et al. A global assessment of eye health and quality of life: A systematic review of systematic reviews. JAMA Ophthalmol. 2021, 139, 526–541. [Google Scholar] [CrossRef]

- Park, J.; Hyun, W.; Mun, S.; Park, Y.; Park, Q. Highly Stretchable and Wearable Graphene Strain Sensor-s with Controllable Sensitivity for Human Motion Monitoring. ACS Appl. Mater. Interfaces 2015, 7, 6317–6324. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Qi, D.; Xu, C.; Yu, J.; Liu, Y.; Jiang, Y.; Liedberg, B.; Chen, X. High-Adhesion Stretchable Electrodes Based on Nanopile Interlocking. Adv. Mater. 2017, 29, 1603382. [Google Scholar] [CrossRef]

- Goh, G.; Zhang, H.; Chong, T.; Yeong, W. 3D printing of multilayered and multimaterial electronics: A review. Adv. Electron. Mater. 2021, 7, 2100445. [Google Scholar] [CrossRef]

- Rogers, J.; Someya, T.; Huang, Y. Materials and Mechanics for Stretchable Electronics. Science 2010, 327, 1603. [Google Scholar] [CrossRef] [PubMed]

- Magennis, E.; Hook, A.; Williams, P.; Alexander, M. Making Silicone Rubber Highly Resistant to Bacterial Attachment Using Thiol-ene Grafting. ACS Appl. Mater. Interfaces 2016, 8, 30780–30787. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Hu, H.; Shen, Y.; Zhou, X.; Zheng, Z. Stretchable conductors with ultrahigh tensile strain and stable metallic conductance enabled by prestrained polyelectrolyte nanoplatforms. Adv. Mater. 2011, 23, 3090–3094. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, K.; Dai, X.; Li, Y.; Guo, J.; Liu, H.; Li, G.; Tan, Y.; Zeng, J.; Guo, Z. Enhanced electrical conductivity and piezoresistive sensing in multi-wall carbon nanotubes/polydimethylsiloxane nanocomposites via the construction of a self-segregated structure. Nanoscale 2017, 9, 11017–11026. [Google Scholar] [CrossRef]

- Bae, G.; Pak, S.; Kim, D.; Lee, G.; Kim, D.H.; Chung, Y.; Cho, K. Linearly and Highly Pressure-Sensitive Electronic Skin Based on a Bioinspired Hierarchical Structural Array. Adv. Mater. 2016, 28, 5300–5306. [Google Scholar] [CrossRef]

- Lipomi, D.; Lee, J.; Vosgueritchian, M.; Tee, B.; Bolander, J.; Bao, Z. Electronic Properties of Transparent Conductive Films of PEDOT:PSS on Stretchable Substrates. Chem. Mater. 2012, 24, 373–382. [Google Scholar] [CrossRef]

- Li, X.; Cai, J.; Shi, Y.; Yue, Y.; Zhang, D. Remarkable Conductive Anisotropy of Metallic Microcoil/PDMS Composites Made by Electric Field Induced Alignment. ACS Appl. Mater. Interfaces 2017, 9, 1593–1601. [Google Scholar] [CrossRef]

- Duan, S.; Wang, Z.; Zhang, L.; Liu, J.; Li, C. Three-Dimensional Highly Stretchable Conductors from Elastic Fiber Mat with Conductive Polymer Coating. ACS Appl. Mater. Interfaces 2017, 9, 30772–30778. [Google Scholar] [CrossRef]

- Jiang, J.; Bao, B.; Li, M.; Sun, J.; Zhang, C.; Li, Y.; Li, F.; Yao, X.; Song, Y. Fabrication of Transparent Multilayer Circuits by Inkjet Printing. Adv. Mater. 2016, 28, 1420–1426. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Zhang, L.; Duan, S.; Jing, S.; Jiang, H.; Li, C. Highly Stretchable Conductors Integrated with a Conductive Carbon Nanotube/Graphene Network and 3D Porous Poly(dimethylsiloxane). Adv. Funct. Mater. 2014, 24, 7548–7556. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, J.; Ladani, R.; Ravindran, A.; Mouritz, A.; Kinloch, A.; Wang, C. Novel Electrically Conductive Porous PDMS/Carbon Nanofiber Composites for Deformable Strain Sensors and Conductors. ACS Appl. Mater. Interfaces 2017, 9, 14207–14215. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.; Wang, H.; Xie, X.; Xue, Q.; Zhang, J.; Kang, S.; Wang, C.; Liang, J.; Chen, Y. Bioinspired Ultrasensitive and Stretchable MXene-Based Strain Sensor via Nacre-Mimetic Microscale “Brick-and-Mortar” Architecture. ACS Nano 2019, 13, 649–659. [Google Scholar] [CrossRef]

- Yan, Y.; Warren, S.; Fuller, P.; Grzybowski, B. Chemoelectronic circuits based on metal nanoparticles. Nat. Nanotechnol. 2016, 11, 603–608. [Google Scholar] [CrossRef]

- Tee, B.; Wang, C.; Allen, R.; Bao, Z. An electrically and mechanically self-healing composite with pressure- and flexion-sensitive properties for electronic skin applications. Nat. Nanotechnol. 2012, 7, 825–832. [Google Scholar] [CrossRef]

- Yang, Y.; Huang, Q.; Niu, L.; Wang, D.; Yan, C.; She, Y.; Zheng, Z. Waterproof, Ultrahigh Areal Capacitance, Wearable Supercapacitor Fabrics. Adv. Mater. 2017, 29, 1606679. [Google Scholar] [CrossRef]

- Gao, W.; Emaminejad, S.; Nyein, H.; Challa, S.; Chen, K.; Peck, A.; Fahad, H.; Ota, H.; Shiraki, H.; Kiriya, D.; et al. Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Nature 2016, 529, 509–514. [Google Scholar] [CrossRef]

- Oh, J.; Rondeau-Gagne, S.; Chiu, Y.; Chortos, A.; Lissel, F.; Wang, G.; Schroeder, B.; Kurosawa, T.; Lopez, J.; Katsumata, T.; et al. Intrinsically stretchable and healable semiconducting polymer for organic transistors. Nature 2016, 539, 411–415. [Google Scholar] [CrossRef]

- Qi, D.; Liu, Z.; Liu, Y.; Jiang, Y.; Leow, W.; Pal, M.; Pan, S.; Yang, H.; Wang, Y.; Zhang, X.; et al. Highly Stretchable, Compliant, Polymeric Microelectrode Arrays for In Vivo Electrophysiological Interfacing. Adv. Mater. 2017, 25, 1702800. [Google Scholar] [CrossRef]

- Liu, Z.; Fang, S.; Moura, F.; Ding, J.; Jiang, N.; Di, J.; Zhang, M.; Lepro, X.; Galvao, D.; Haines, C.; et al. Hierarchically buckled sheath-corefibers for superelastic electronics, sensors, and muscles. Science 2015, 349, 400–404. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Zhang, L.; Tao, X.; Ding, X. Review of flexible temperature sensing networks for wearable physiological monitoring. Adv. Health. Mater. 2017, 6, 1601371. [Google Scholar] [CrossRef]

- Han, J.; Cheng, P.; Wang, H.; Zhang, C.; Zhang, J.; Wang, Y.; Duan, L.; Ding, G. MEMS-based Pt film temperature sensor on an alumina substrate. Mater. Lett. 2014, 125, 224–226. [Google Scholar] [CrossRef]

- Kim, D.; Xiao, J.; Song, J.; Huang, Y.; Rogers, J. Stretchable, curvilinear electronics based on inorganic materials. Adv. Mater. 2010, 22, 2108–2124. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Ahn, J.; Feng, X.; Wang, S.; Huang, Y.; Rogers, J. Theoretical and Experimental Studies of Bending of Inorganic El-ectronic Materials on Plastic Substrates. Adv. Funct. Mater. 2008, 18, 2673–2684. [Google Scholar] [CrossRef]

- Jian, A.; Tang, X.; Feng, Q. A PDMS surface stress biosensor with optimized micromembrane: Fabrication and application. Sens. Actuators B Chem. 2017, 242, 969–976. [Google Scholar] [CrossRef]

- Zhang, L.; Yan, W.; Gao, N. Reversible strain-dependent properties of wrinkled Au/PDMS surface. Mater. Lett. 2018, 218, 317–320. [Google Scholar] [CrossRef]

- Scott, A.; Gupta, R.; Kulkarni, G. A simple water-based synthesis of Au nanoparticle/PDMS Composites for water purification and targeted drug release. Macromol. Chem. Phys. 2010, 211, 1640–1647. [Google Scholar] [CrossRef]

- Hurst, S.; Payne, E.; Qin, L.; Mirkin, C. Multisegmented one-dimensional nanorods prepared by hard-template synthetic methods. Angew. Chem. Int. Ed. 2006, 45, 2672–2692. [Google Scholar] [CrossRef]

- Meng, F.; Hervault, Y.; Shao, Q.; Hu, B.; Norel, L.; Rigaut, S.; Chen, X. Orthogonally modulated molecular transport junctions for resettable electronic logic gates. Nat. Commun. 2014, 5, 3023. [Google Scholar] [CrossRef]

- Shi, S.; Wen, X.; Sang, Q.; Yin, S.; Wang, K.; Zhang, J.; Hu, M.; Yin, H.; He, J.; Ding, Y. Ultrathin nanoporous metal electrodes facilitate high proton conduction for low-Pt PEMFCs. Nano Res. 2021, 14, 2681–2688. [Google Scholar] [CrossRef]

- Al Hashimi, H.; Chaalal, O. Flexible temperature sensor fabrication using photolithography technique. Therm. Sci. Eng. Prog. 2021, 22, 100857. [Google Scholar] [CrossRef]

- Hao, Y.; Yan, Q.; Liu, H.; He, X.; Zhang, P.; Qin, X.; Wang, R.; Sun, J.; Wang, L.; Cheng, Y. A Stretchable, Breathable, And Self-Adhesive Electronic Skin with Multimodal Sensing Capabilities for Human-Centered Healthcare. Adv. Funct. Mater. 2023, 33, 2303881. [Google Scholar] [CrossRef]

- Yu, S.; Wang, S.; Zhao, L.; Shi, S.; Wang, L.; Zheng, H. Ultra-flexible transparent temperature sensor with laser-direct writing of silver nanowire electrodes. Inorg. Chem. Commun. 2024, 170, 113219. [Google Scholar] [CrossRef]

- Li, F.; Xue, H.; Lin, X.; Zhao, H.; Zhang, T. Wearable temperature sensor with high resolution for skin temperature monitoring. ACS Appl. Mater. Interfaces 2022, 14, 43844–43852. [Google Scholar] [CrossRef]

- Zhao, L.; Yang, P.; Shi, S.; Wang, X.; Yu, S. Enhanced the thermal/chemical stability of Cu NWs with solution-grown Al2O3 nanoshell for application in ultra-flexible temperature detection sensors. Chem. Eng. J. 2023, 473, 145156. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Harada, S.; Yamamoto, D.; Honda, W.; Arie, T.; Akita, S.; Takei, K. Printed multifunctional flexible device with an integrated motion sensor for health care monitoring. Sci. Adv. 2016, 2, 1601473. [Google Scholar] [CrossRef]

- Choi, H.; Kim, Y.; Kim, S.; Jung, H.; Lee, S.; Kim, K.; Han, H.; Kim, J.; Shin, M.; Son, D. Adhesive bioelectronics for sutureless epicardial interfacing. Nat. Electron. 2023, 6, 779. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, S.; Zhao, P.; Yang, P.; Zhao, L.; Yi, J.; Wang, Z.; Yu, S. Enhancing the Interfacial Adhesion of a Ductile Gold Electrode with PDMS Using an Interlocking Structure for Applications in Temperature Sensors. Nanomaterials 2025, 15, 1001. https://doi.org/10.3390/nano15131001

Shi S, Zhao P, Yang P, Zhao L, Yi J, Wang Z, Yu S. Enhancing the Interfacial Adhesion of a Ductile Gold Electrode with PDMS Using an Interlocking Structure for Applications in Temperature Sensors. Nanomaterials. 2025; 15(13):1001. https://doi.org/10.3390/nano15131001

Chicago/Turabian StyleShi, Shuai, Penghao Zhao, Pan Yang, Le Zhao, Jingguang Yi, Zuohui Wang, and Shihui Yu. 2025. "Enhancing the Interfacial Adhesion of a Ductile Gold Electrode with PDMS Using an Interlocking Structure for Applications in Temperature Sensors" Nanomaterials 15, no. 13: 1001. https://doi.org/10.3390/nano15131001

APA StyleShi, S., Zhao, P., Yang, P., Zhao, L., Yi, J., Wang, Z., & Yu, S. (2025). Enhancing the Interfacial Adhesion of a Ductile Gold Electrode with PDMS Using an Interlocking Structure for Applications in Temperature Sensors. Nanomaterials, 15(13), 1001. https://doi.org/10.3390/nano15131001