Effect of n-C-S-H on Hydration and Reinforcement of Mineral Powder-Cement System at Low Temperatures

Abstract

1. Introduction

2. Materials and Methods

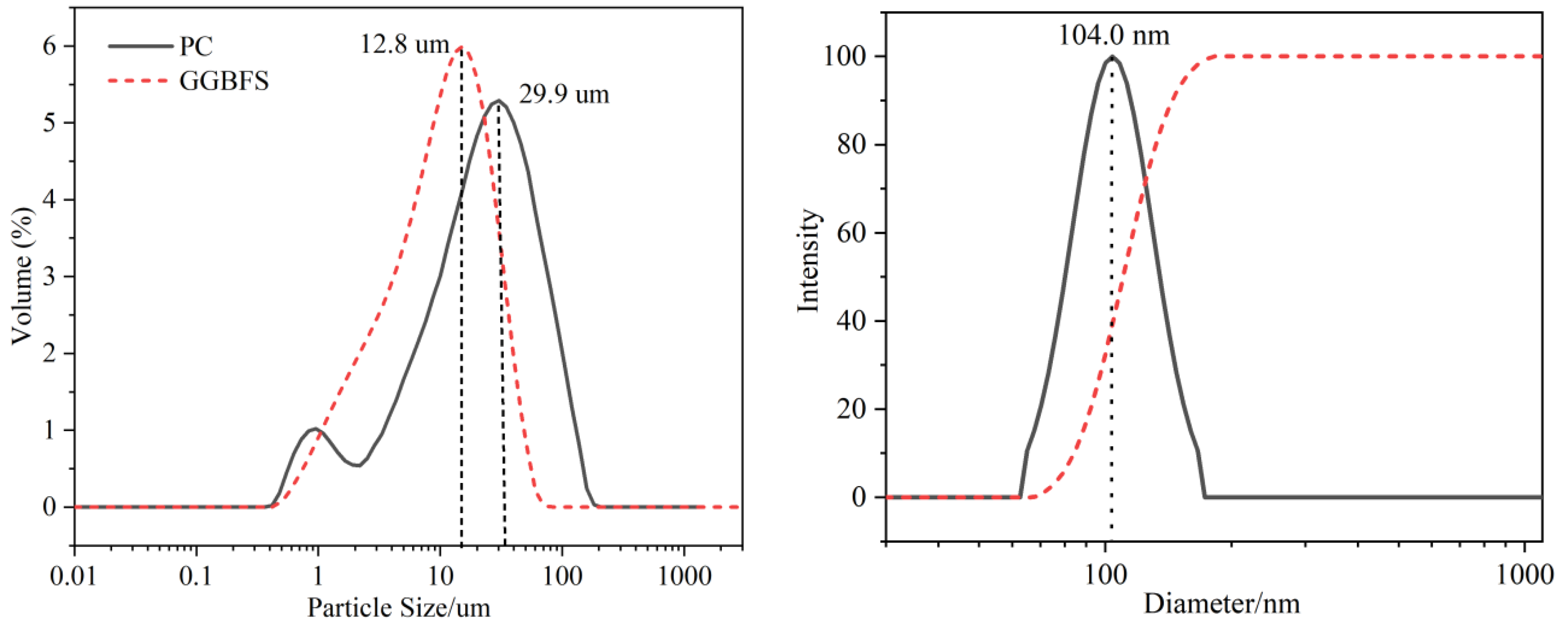

2.1. Materials

2.2. Methods

2.2.1. Fabrication of Cement Composites

2.2.2. Characterization

3. Results and Discussion

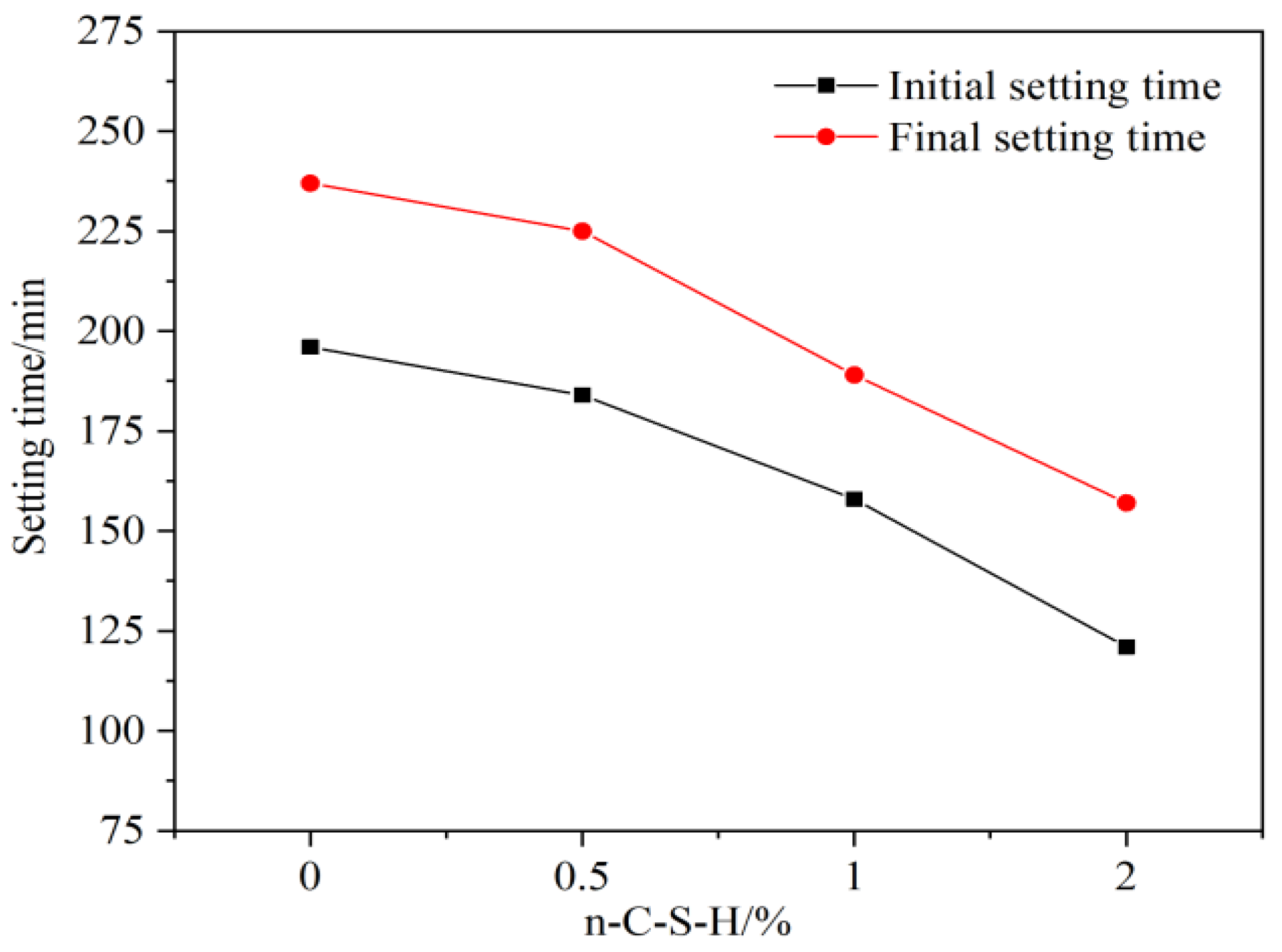

3.1. The Influence of n-C-S-H on Workability of Cement Paste

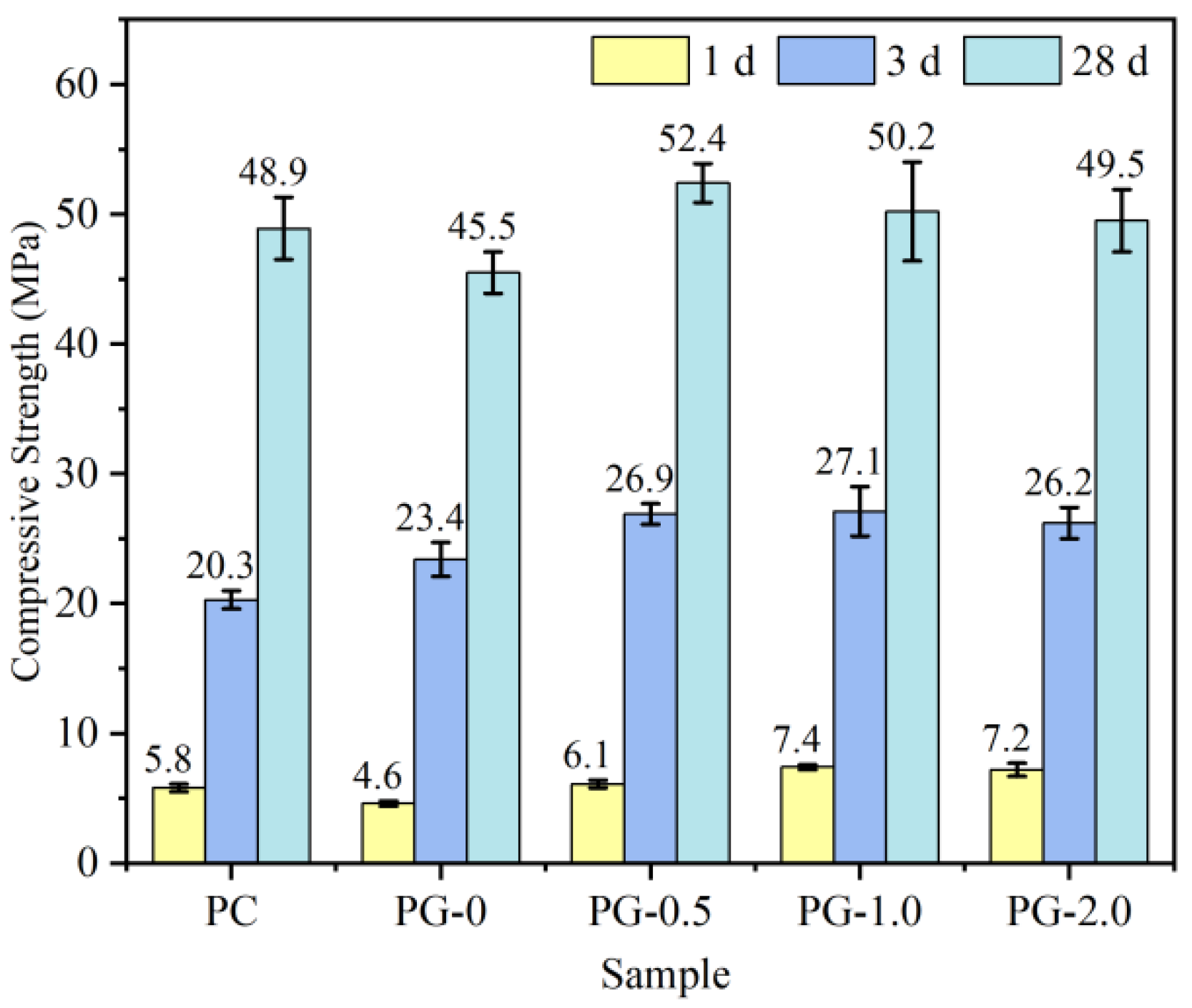

3.2. Effects of n-C-S-H on Mechanical Properties of Mortar

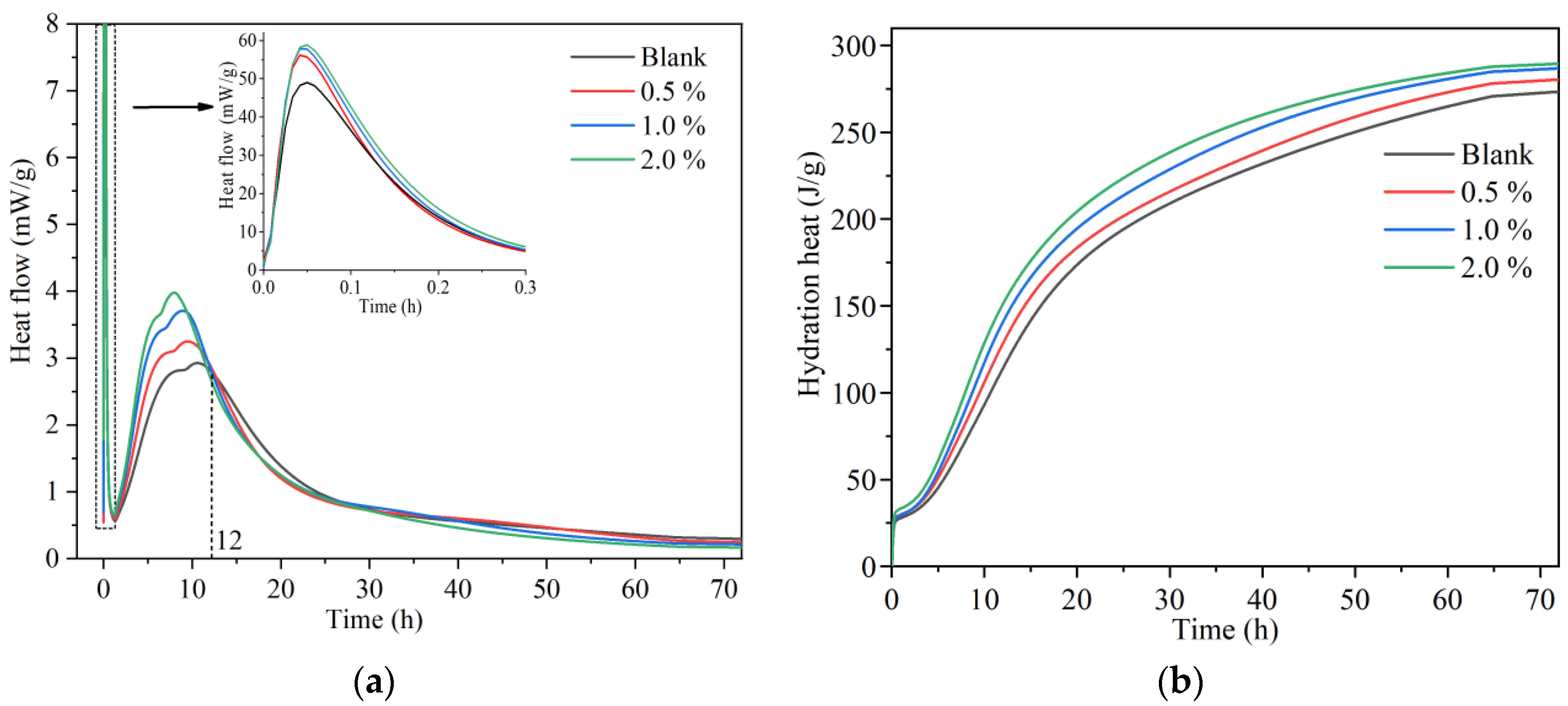

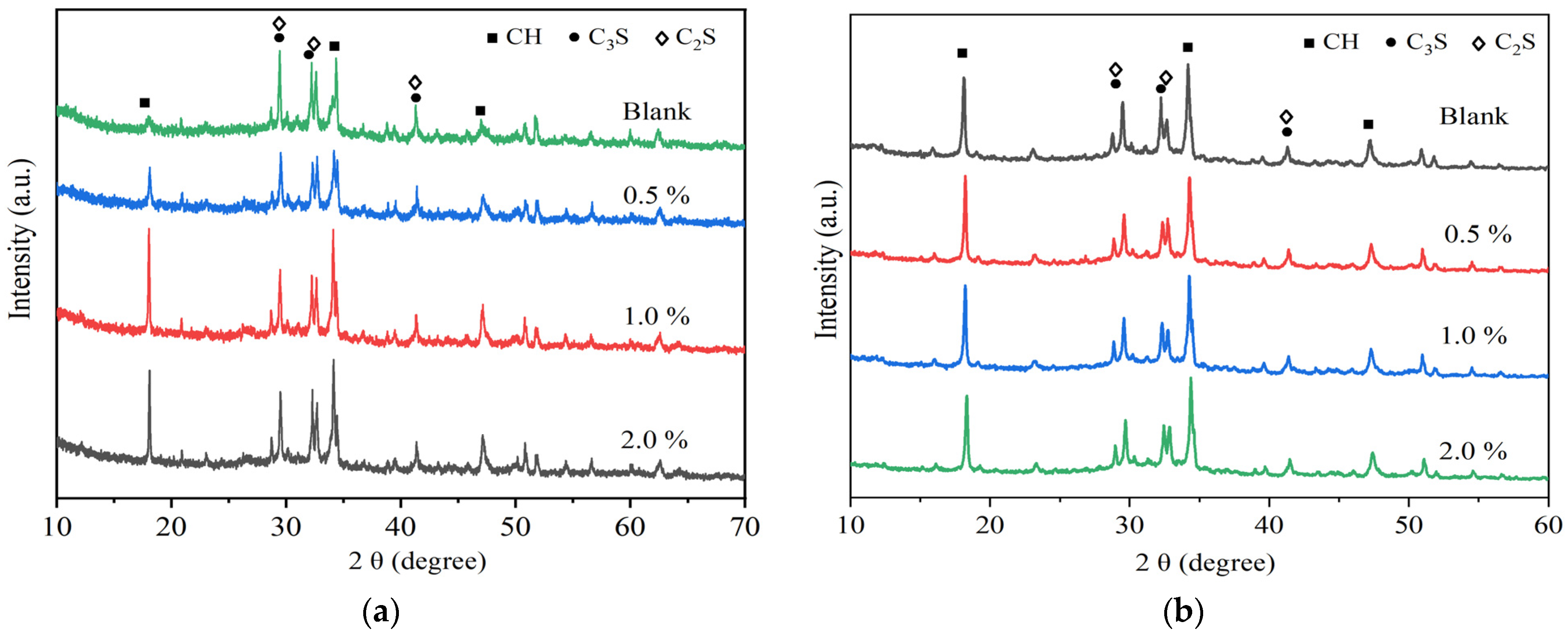

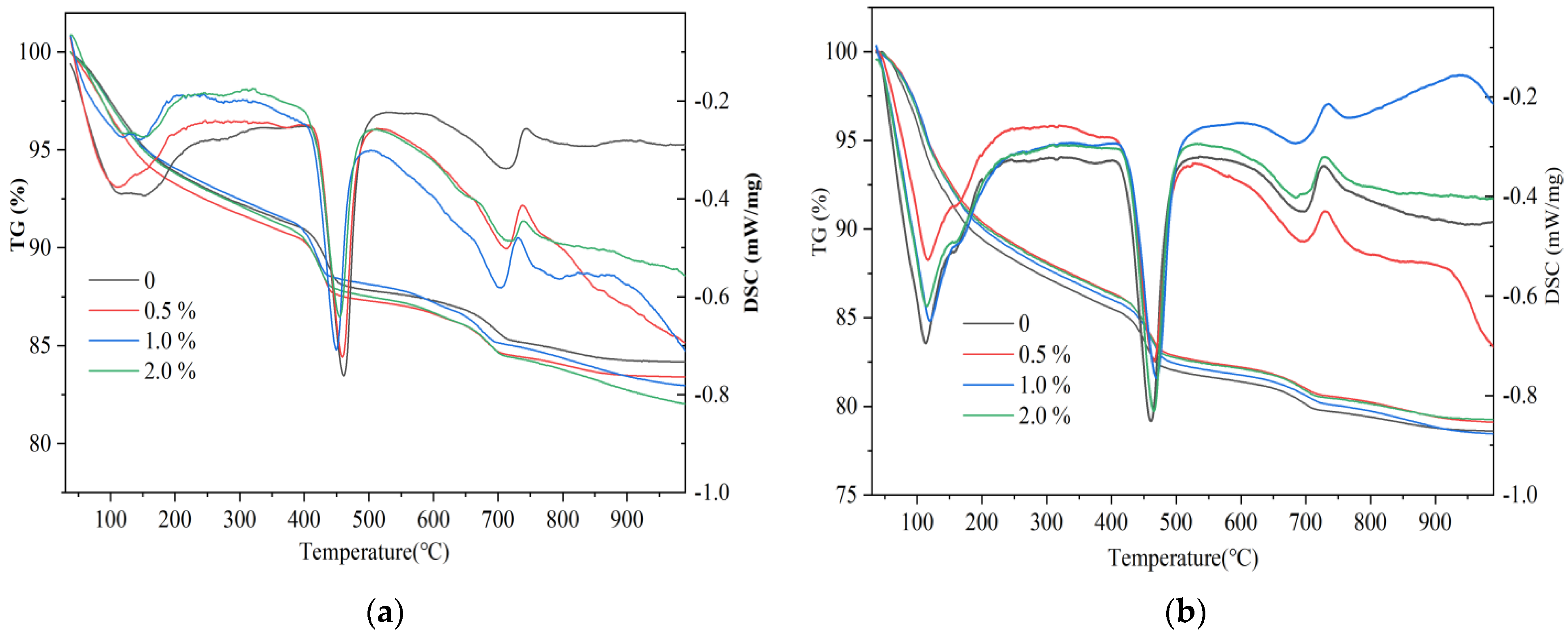

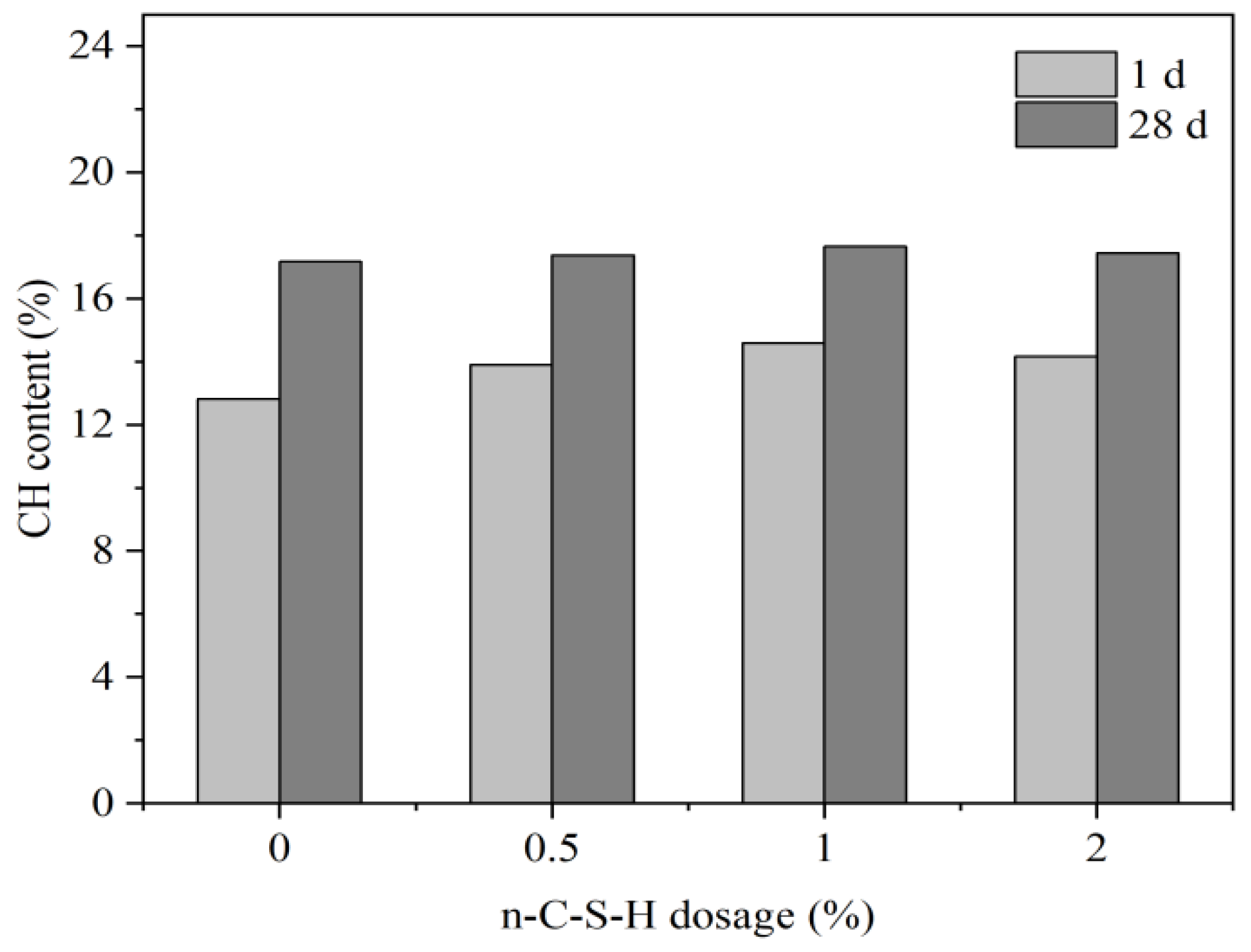

3.3. The Effect of n-C-S-H on Cement Hydration

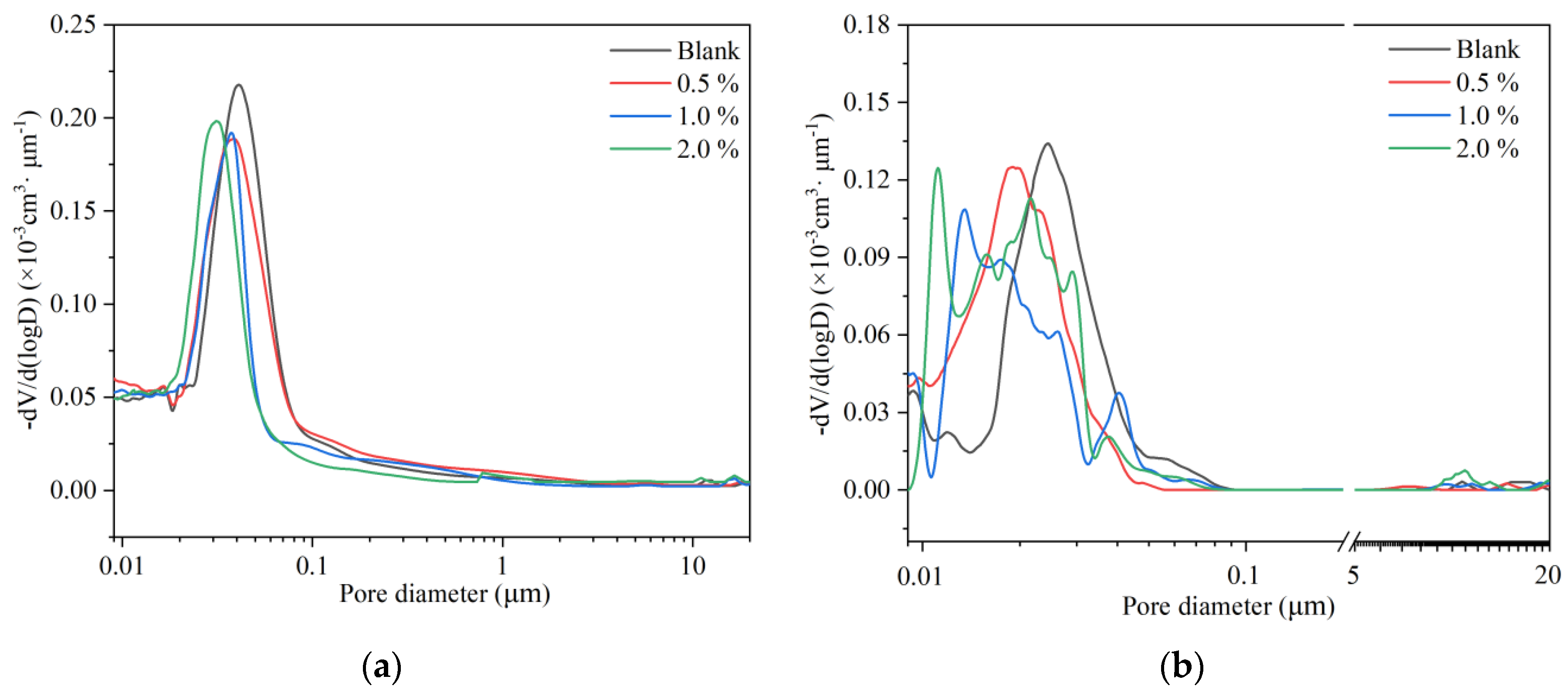

3.4. Effects of n-C-S-H on the Microstructure of Hardened Cement

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hoang, K.; Justnes, H.; Geiker, M. Early age strength increase of fly ash blended cement by a ternary hardening accelerating admixture. Cem. Concr. Res. 2016, 81, 59–69. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Siddique, R. Recent advances in understanding the role of supplementary mortar materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, L.; Gao, X.; Zhang, J. Effect of pulverized fuel ash, ground granulated blast-furnace slag and CO2 curing on performance of magnesium oxysulfate cement. Constr. Build. Mater. 2020, 230, 116990. [Google Scholar] [CrossRef]

- Wu, M.; Zhang, Y.; Ji, Y.; Liu, G.; Liu, C.; She, W.; Sun, W. Reducing environmental impacts and carbon emissions: Study of effects of superfine cement particles on blended cement containing high volume mineral admixtures. J. Clean. Prod. 2018, 196, 358–369. [Google Scholar] [CrossRef]

- He, J.; Long, G.; Ma, K.; Xie, Y. Influence of fly ash or slag on nucleation and growth of early hydration of cement. Thermochim. Acta 2021, 701, 178964. [Google Scholar] [CrossRef]

- Riding, K.; Silva, D.A.; Scrivener, K. Early age strength enhancement of blended cement systems by CaCl2 and diethanol-isopropanolamine. Cem. Concr. Res. 2010, 40, 935–946. [Google Scholar] [CrossRef]

- Ramachandran, V.S. Action of triethanolamine on the hydration of tricalcium aluminate. Cem. Concr. Res. 1973, 3, 41–54. [Google Scholar] [CrossRef]

- Mehdipour, I.; Kumar, A.; Khayat, K.H. Rheology, hydration, and strength evolution of interground limestone cement containing PCE dispersant and high volume supplementary mortar materials. Mater. Des. 2017, 127, 54–66. [Google Scholar] [CrossRef]

- Lothenbach, B.; Winnefeld, F.; Alder, C.; Wieland, E.; Lunk, P. Effect of temperature on the pore solution, microstructure and hydration products of Portland cement pastes. Cem. Concr. Res. 2007, 37, 483–491. [Google Scholar] [CrossRef]

- Liu, L.; Sun, C.; Geng, G.; Feng, P.; Li, J.; Dähn, R. Influence of decalcification on structural and mechanical properties of synthetic calcium silicate hydrate (C-S-H). Cem. Concr. Res. 2019, 123, 105793. [Google Scholar] [CrossRef]

- Bost, P.; Regnier, M.; Horgnies, M. Comparison of the accelerating effect of various additions on the early hydration of Portland cement. Constr. Build. Mater. 2016, 113, 290–296. [Google Scholar] [CrossRef]

- Sun, J.; Shi, H.; Qian, B.; Xu, Z.; Li, W.; Shen, X. Effects of synthetic C-S-H/PCE nanocomposites on early cement hydration. Constr. Build. Mater. 2017, 140, 282–292. [Google Scholar] [CrossRef]

- Nicoleau, L. Accelerated growth of calcium silicate hydrates: Experiments and simulations. Cem. Concr. Res. 2011, 41, 1339–1348. [Google Scholar] [CrossRef]

- Nicoleau, L.; Nonat, A. A reply to the discussion “Accelerated growth of calcium silicate hydrates: Experiments and simulations” by S. Bishnoi and K. Scrivener. Cem. Concr. Res. 2012, 42, 881–887. [Google Scholar] [CrossRef]

- Pedrosa, H.C.; Reales, O.M.; Reis, V.D.; das Dores Paiva, M.; Fairbairn, E.M.R. Hydration of Portland cement accelerated by C-S-H seeds at different temperatures. Cem. Concr. Res. 2020, 129, 105978. [Google Scholar] [CrossRef]

- Fu, H.; Tian, L.; Wang, P.; Zuo, W.; Zhao, T.; Han, X. Microstructure, deformation and durability of high-strength non-steam-cured concrete with CSH seed. Constr. Build. Mater. 2023, 374, 130953. [Google Scholar] [CrossRef]

- Ludwig, H.M.; Dressel, D. Synthetische calcium-silikat-hydrate in fertigteilbetonen. BWI 2011, 5, 46–50. [Google Scholar]

- ASTM C191-13; Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle. ASTM International: West Conshohocken, PA, USA, 2018.

- Standardization Administration of China. Method of Testing Cements-Determination of Strength: GB/T 17671-2021 [S]; Standards Press of China: Beijing, China, 2021. (In Chinese) [Google Scholar]

- Fares, H.; Remond, S.; Noumowe, A.; Cousture, A. High temperature behaviour of self-consolidating concrete: Microstructure and physicochemical properties. Cem. Concr. Res. 2010, 40, 488–496. [Google Scholar] [CrossRef]

- Das, B.B.; Kondraivendhan, B. Implication of pore size distribution parameters on compressive strength, permeability and hydraulic diffusivity of concrete. Constr. Build. Mater. 2012, 28, 382–386. [Google Scholar] [CrossRef]

- Kumar, R.; Bhattacharjee, B. Porosity, pore size distribution and in situ strength of concrete. Cem. Concr. Res. 2003, 33, 155–164. [Google Scholar] [CrossRef]

| Composition | Percentage/% |

|---|---|

| CaO | 64.42 |

| SiO2 | 21.72 |

| Al2O3 | 4.52 |

| Fe2O3 | 3.16 |

| SO3 | 0.56 |

| MgO | 1.64 |

| K2O | 0.69 |

| Na2O | 0.16 |

| P2O5 | 0.14 |

| MnO | 0.10 |

| LOI | 1.82 |

| Sample | Cement (g) | GGBFS(g) | Standard Sand (g) | Water (mL) | Dosage of n-C-S-H (w/%) |

|---|---|---|---|---|---|

| PG-0 | 270 | 180 | 1350 | 180.0 | 0 |

| PG-0.5 | 270 | 180 | 1350 | 178.0 | 0.5 |

| PG-1.0 | 270 | 180 | 1350 | 176.0 | 1.0 |

| PG-2.0 | 270 | 180 | 1350 | 172.1 | 2.0 |

| n-C-S-H (%) | 12 h | 24 h | 72 h |

|---|---|---|---|

| 0 | 114 | 190 | 273 |

| 0.5 | 128 | 199 | 280 |

| 1.0 | 140 | 211 | 286 |

| 2.0 | 151 | 220 | 289 |

| n-C-S-H (%) | Porosity (%) | Median Pore Diameter (nm) | ||

|---|---|---|---|---|

| 1 d | 28 d | 1 d | 28 d | |

| 0 | 25.80 | 15.21 | 35 | 26 |

| 0.5 | 26.16 | 15.11 | 32 | 21 |

| 1.0 | 22.48 | 12.69 | 30 | 19 |

| 2.0 | 26.64 | 14.86 | 27 | 21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Qian, C.; Li, Q.; Wang, K.; Zheng, C.; Zhang, Y. Effect of n-C-S-H on Hydration and Reinforcement of Mineral Powder-Cement System at Low Temperatures. Nanomaterials 2024, 14, 524. https://doi.org/10.3390/nano14060524

Li W, Qian C, Li Q, Wang K, Zheng C, Zhang Y. Effect of n-C-S-H on Hydration and Reinforcement of Mineral Powder-Cement System at Low Temperatures. Nanomaterials. 2024; 14(6):524. https://doi.org/10.3390/nano14060524

Chicago/Turabian StyleLi, Wei, Chunxiang Qian, Qingchao Li, Kehan Wang, Chunyang Zheng, and Yanli Zhang. 2024. "Effect of n-C-S-H on Hydration and Reinforcement of Mineral Powder-Cement System at Low Temperatures" Nanomaterials 14, no. 6: 524. https://doi.org/10.3390/nano14060524

APA StyleLi, W., Qian, C., Li, Q., Wang, K., Zheng, C., & Zhang, Y. (2024). Effect of n-C-S-H on Hydration and Reinforcement of Mineral Powder-Cement System at Low Temperatures. Nanomaterials, 14(6), 524. https://doi.org/10.3390/nano14060524