Mo2TiAlC2 as a Saturable Absorber for a Passively Q-Switched Tm:YAlO3 Laser

Abstract

1. Introduction

2. Experimental Section

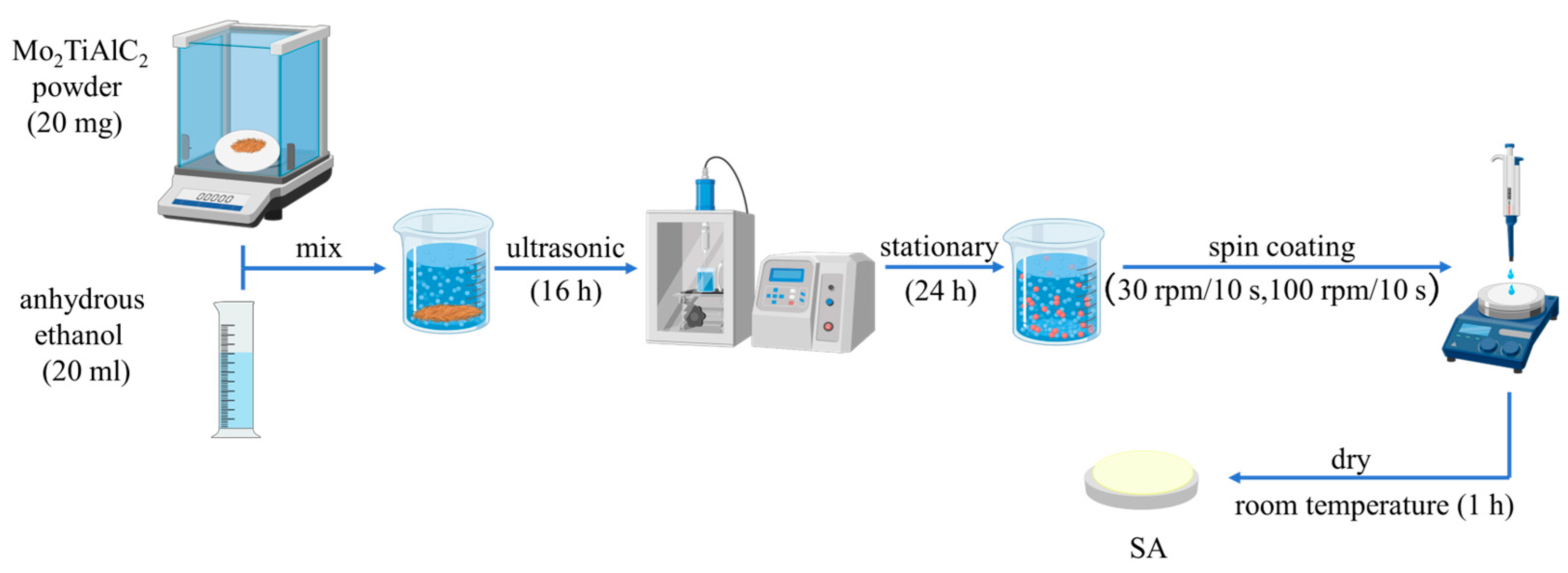

2.1. Preparation of Mo2TiAlC2-Based SA

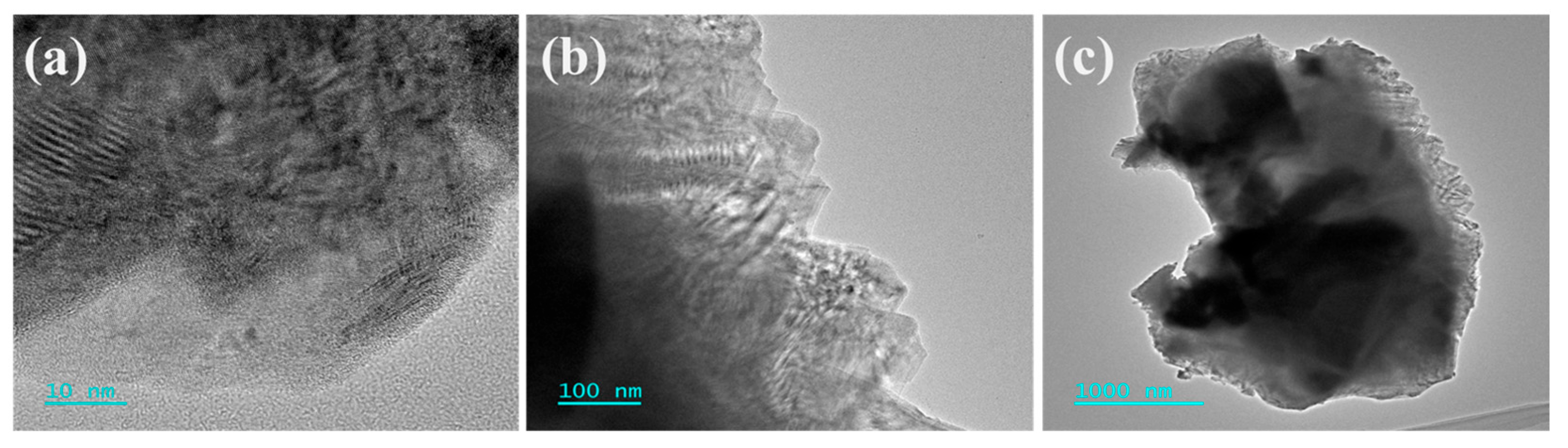

2.2. Characterization of Mo2TiAlC2 Material

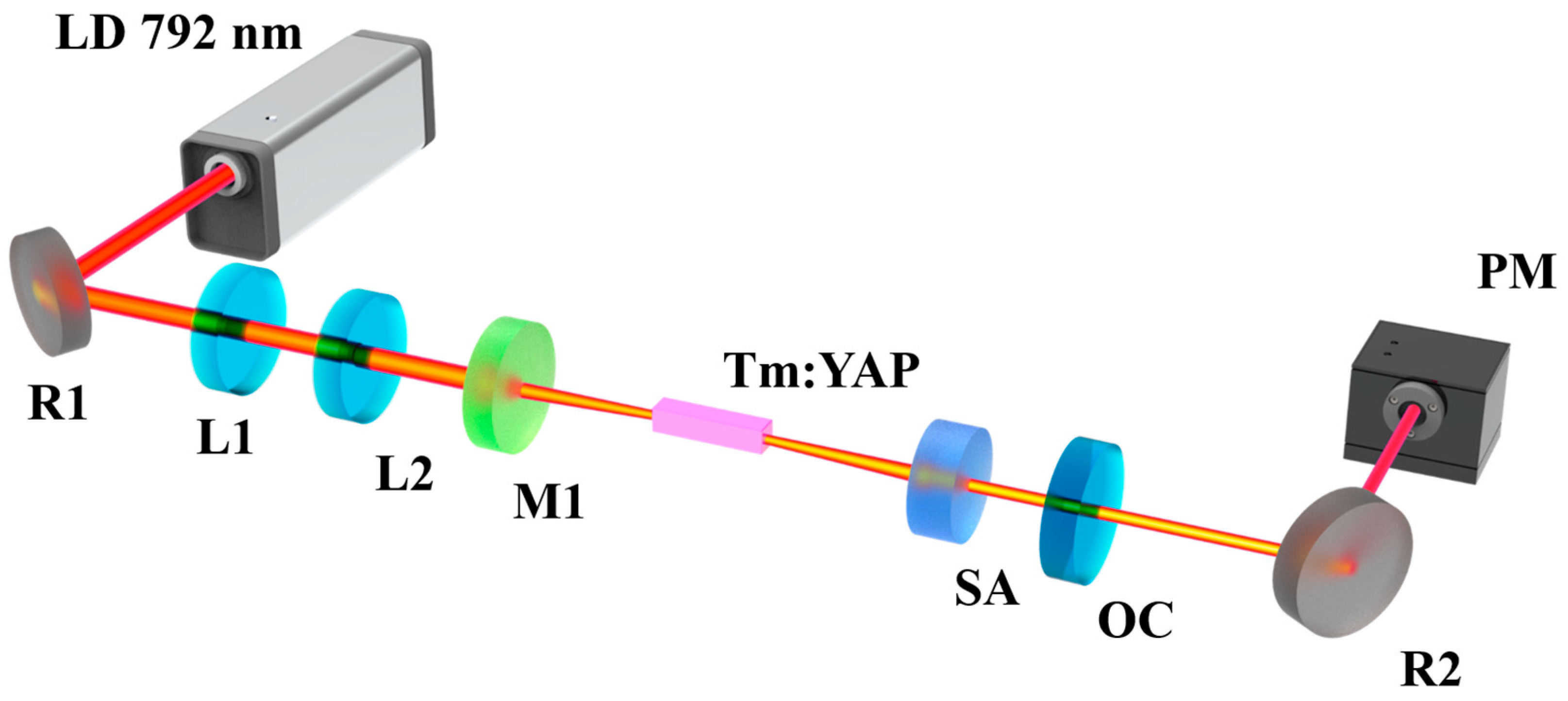

2.3. Experimental Setup of PQS Laser

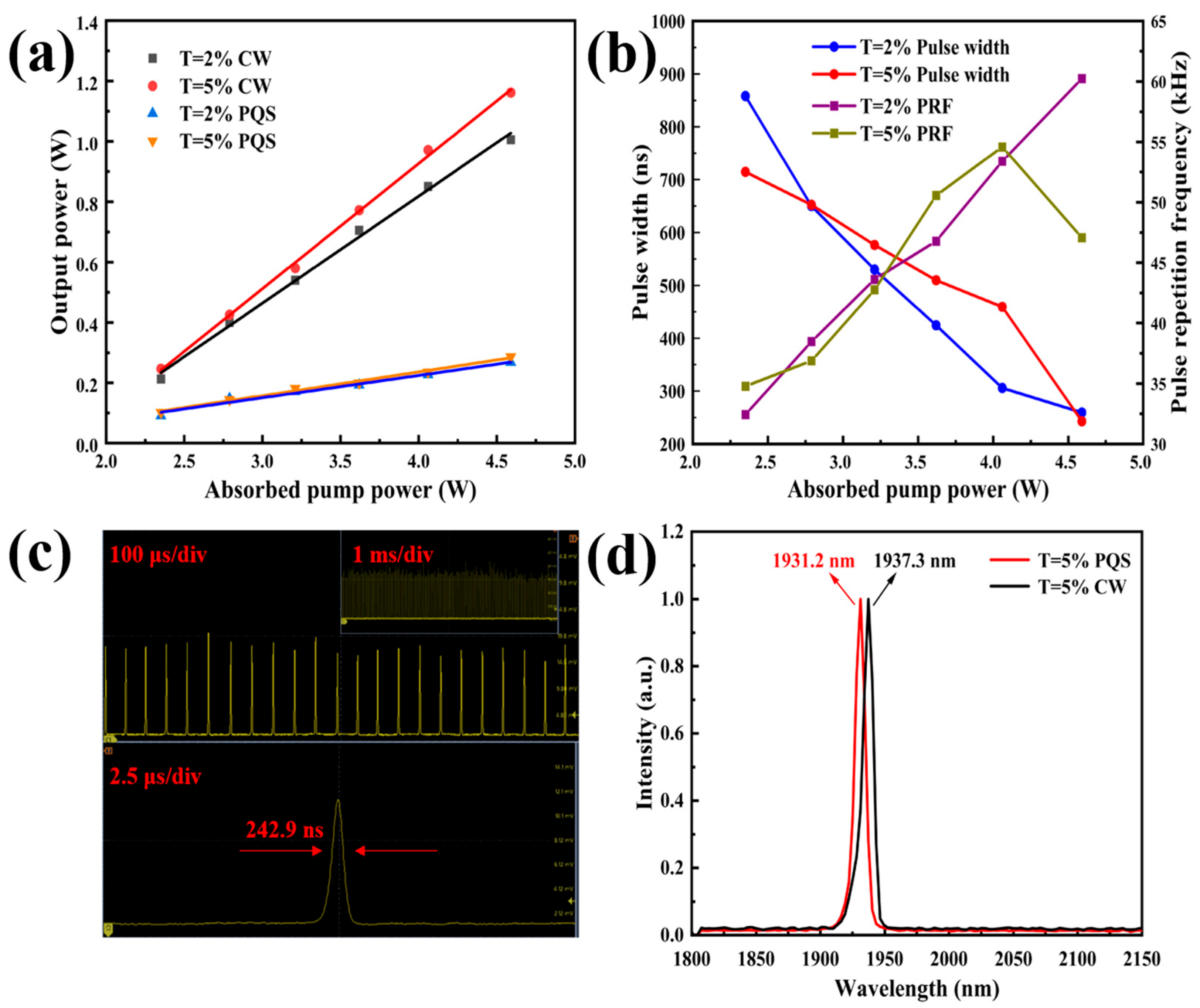

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gonzalez-Julian, J. Processing of MAX phases: From synthesis to applications. J. Am. Ceram. Soc. 2021, 104, 659–690. [Google Scholar] [CrossRef]

- Cheng, L.; Wang, X.; Gong, F.; Liu, T.; Liu, Z. 2D nanomaterials for cancer theranostic applications. Adv. Mater. 2020, 32, 1902333. [Google Scholar] [CrossRef]

- Yang, J.; Fan, Y.; Tan, H.; Liu, W.; Kuang, Y.; Yang, X.; Li, J. Impact of Sintering Temperature Variation on Porous Structure of Mo2TiAlC2 Ceramics. Materials 2023, 16, 5682. [Google Scholar] [CrossRef] [PubMed]

- Niu, Y.; Fu, S.; Zhang, K.; Dai, B.; Zhang, H.; Grasso, S.; Hu, C. Synthesis, microstructure, and properties of high purity Mo2TiAlC2 ceramics fabricated by spark plasma sintering. J. Adv. Ceram. 2020, 9, 759–768. [Google Scholar] [CrossRef]

- Zhang, Z.; Duan, X.; Jia, D.; Zhou, Y.; Van Der Zwaag, S.J. On the formation mechanisms and properties of MAX phases: A review. Eur. Ceram. Soc. 2021, 41, 3851–3878. [Google Scholar] [CrossRef]

- Cui, H.; Zheng, K.; Xie, Z.; Yu, J.; Zhu, X.; Ren, H.; Chen, X. Tellurene nanoflake-based NO2 sensors with superior sensitivity and a sub-parts-per-billion detection limit. ACS Appl. Mater. Interfaces 2020, 12, 47704–47713. [Google Scholar] [CrossRef]

- Fu, L.; Xia, W. MAX phases as nanolaminate materials: Chemical composition, microstructure, synthesis, properties, and applications. Adv. Eng. Mater. 2021, 23, 2001191. [Google Scholar] [CrossRef]

- Wang, H.; Chai, L.; Xie, Z.; Zhang, H. Recent advance of tellurium for biomedical applications. Chem. Res. Chin. Univ. 2020, 36, 551–559. [Google Scholar] [CrossRef]

- Zhang, B.; Fan, T.; Xie, N.; Nie, G.; Zhang, H. Versatile applications of metal single-atom@ 2D material nanoplatforms. Adv. Sci. 2019, 6, 1901787. [Google Scholar] [CrossRef]

- Sarycheva, A.; Gogotsi, Y. Raman Spectroscopy Analysis of the Structure and Surface Chemistry of Ti3C2Tx MXene; Jenny Stanford Publishing: Singapore, 2023; MXenes; pp. 333–355. [Google Scholar] [CrossRef]

- Alhabeb, M.; Maleski, K.; Mathis, T.S.; Sarycheva, A.; Hatter, C.B.; Uzun, S.; Gogotsi, Y. Selective Etching of Silicon from Ti3SiC2 (MAX) to Obtain 2D Titanium Carbide (MXene); Jenny Stanford Publishing: Singapore, 2023; MXenes; pp. 451–462. [Google Scholar] [CrossRef]

- Nemani, S.K.; Zhang, B.; Wyatt, B.C.; Hood, Z.D.; Manna, S.; Khaledialidusti, R.; Anasori, B. High-Entropy 2D carbide Mxenes: TiVNbMoC3 and TiVCrMoC3. ACS Nano 2021, 15, 12815–12825. [Google Scholar] [CrossRef]

- Ouadha, I.; Rached, H.; Azzouz-Rached, A.; Reggad, A.; Rached, D. Study of the structural, mechanical and thermodynamic properties of the new MAX phase compounds (Zr1−xTix)3AlC2. Comput. Condens. Matter 2020, 23, e00468. [Google Scholar] [CrossRef]

- Hui, X.; Ge, X.; Zhao, R.; Li, Z.; Yin, L. Interface chemistry on MXene-based materials for enhanced energy storage and conversion performance. Adv. Funct. Mater. 2020, 30, 2005190. [Google Scholar] [CrossRef]

- Lin, X.; Zhang, G.; Zhang, W.; Li, Y.; Li, B.; Wang, B. Microstructure and mechanical properties of Mo-12Si-8.5 B alloy reinforced by layered Mo2TiAlC2 MAX phase. Int. J. Refract. Met. Hard Mater. 2022, 109, 105967. [Google Scholar] [CrossRef]

- Sokol, M.; ElMeligy, T.A.; Plummer, G.; Tucker, G.J.; Barsoum, M.W. Tensile creep of textured Ti2AlC in the 1000–1150 °C temperature range. Acta Mater. 2023, 261, 119350. [Google Scholar] [CrossRef]

- VahidMohammadi, A.; Rosen, J.; Gogotsi, Y. The world of two-dimensional carbides and nitrides (MXenes). Science 2021, 372, eabf1581. [Google Scholar] [CrossRef]

- Wang, X.; Han, X.; Li, C.; Chen, Z.; Huang, H.; Chen, J.; Zhang, H. 2D materials for bone therapy. Adv. Drug Deliv. Rev. 2021, 178, 113970. [Google Scholar] [CrossRef]

- Qadir, A.; Le, T.K.; Malik, M.; Min-Dianey, K.A.A.; Saeed, I.; Yu, Y.; Pham, P.V. Representative 2D-material-based nanocomposites and their emerging applications: A review. RSC Adv. 2021, 11, 23860–23880. [Google Scholar] [CrossRef]

- Ahmad, H.; Kahar, N.A.; Ramli, R.; Yusoff, N.; Reduan, S.A.; Ismail, M.F.; Yasin, M. The performance of Ti2C MXene and Ti2AlC MAX Phase as saturable absorbers for passively mode-locked fiber laser. Opt. Fiber Technol. 2021, 67, 102683. [Google Scholar] [CrossRef]

- Sun, G.; Feng, M.; Zhang, K.; Wang, T.; Li, Y.; Han, D.; Song, F. Q-Switched and Mode-Locked Er-doped fiber laser based on MAX phase Ti2AlC saturable absorber. Results Phys. 2021, 26, 104451. [Google Scholar] [CrossRef]

- Kwon, S.; Lee, J.; Lee, J.H. A Q-switched fiber laser using a Ti2AlN-based saturable absorber. Laser Phys. 2021, 31, 025103. [Google Scholar] [CrossRef]

- Al-Hiti, A.S.; Mohammed, N.A.; Nabeel, M.; Sattar, N.A. Max Phase Chromium-Titanium-Aluminum Carbide for Ultrafast Laser Generation in the 1.55 μm Range. J. Russ. Laser Res. 2024, 45, 162–168. [Google Scholar] [CrossRef]

- Ridha, F.F.; Al-Janabi, A.H.; Abdalhadi, A.H. Self-Starting Q-switched pulse generation in EDFL ring cavity based on Ta2AlC MAX-phase saturable absorber. Infrared Phys. Technol. 2022, 123, 104183. [Google Scholar] [CrossRef]

- Al-Hiti, A.S.; Yasin, M.; Harun, S.W. Soliton ultrafast fiber laser with V4AlC3 MAX phase in 2 µm region. Opt. Fiber Technol. 2023, 81, 103585. [Google Scholar] [CrossRef]

- Omar, S.; Musa, B.; Rosol, A.H.A.; Jusoh, Z.; Yasin, M.; Harun, S.W. Generation of bright-dark Q-switched pulse pair in thulium-doped fiber laser cavity with titanium aluminum carbide absorber. Microw. Opt. Technol. Lett. 2023, 65, 3333–3340. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, Y.; Zhao, G.; Wu, H.; Hu, Y.; Wang, M. Graphdiyne-based all-solid-state passively Q-switched Tm: YAP laser at 2 μm. Nanomaterials 2023, 13, 2171. [Google Scholar] [CrossRef]

- Chen, X.; Wang, N.; He, C.; Lin, X. Development of all-fiber nanosecond oscillator using actively Q-switched technologies and modulators. Opt. Laser Technol. 2023, 157, 108709. [Google Scholar] [CrossRef]

- Chao, M.; He, L.; Gong, M.; Li, N.; Li, X.; Peng, L.; Wan, P. Breathable Ti3C2Tx MXene/Protein nanocomposites for ultrasensitive medical pressure sensor with degradability in solvents. ACS Nano 2021, 15, 9746–9758. [Google Scholar] [CrossRef]

- Ahmad, H.; Makhfuz, M.J.M.; Yusoff, N.; Sadafi, N.; Samion, M.Z.; Yasin, M. Mode-locked operation in thulium-holmium doped fiber laser based on Cr2AlC MAX phase SA coated arc-shaped fiber. Opt. Quantum Electron. 2023, 55, 228. [Google Scholar] [CrossRef]

- Zaini, M.A.Z.; Rahman, M.F.A.; Latiff, A.A.; Rusdi, M.F.M.; Roslan, I.A.Z.; Harun, S.W. Passive Q-switched pulse fibre laser with molybdenum titanium aluminum carbide (Mo2TiAlC2) saturable absorber. J. Mod. Opt. 2023, 70, 661–672. [Google Scholar] [CrossRef]

- Safuan, N.Z.M.; Rosol, A.H.A.; Zulkipli, N.; Yasin, M.; Harun, S.W. Generation of Picosecond Pulses in Erbium-Doped Fiber Lasers Via Mode Locking Using V4AlC3 Thin Film. J. Russ. Laser Res. 2023, 44, 384–391. [Google Scholar] [CrossRef]

- Yang, J.; Zou, H.; Chen, J.; Wen, Y.; Fan, Y.; Liu, Y.; Li, X. Reactive synthesis of porous Mo2Ti2AlC3 ceramic and its basic application properties. Ceram. Int. 2022, 48, 9205–9217. [Google Scholar] [CrossRef]

- Salam, S.; Nizamani, B.; Zain, H.A.; Jafry, A.A.A.; Rosol, A.H.A.; Diblawe, A.M.; Harun, S.W. MAX phase (Mo2Ti2AlC3) as a mode-locker for ultrafast fiber laser. Opt. Fiber Technol. 2023, 81, 103500. [Google Scholar] [CrossRef]

- Li, G.; Natu, V.; Shi, T.; Barsoum, M.W.; Titova, L.V. Two-dimensional MXenes Mo2Ti2C3Tz and Mo2TiC2Tz: Microscopic conductivity and dynamics of photoexcited carriers. ACS Appl. Energy Mater. 2020, 3, 1530–1539. [Google Scholar] [CrossRef]

- Sahib, M.A.A.B.; Zakaria, R.; Zulkipli, N.F.; Rosol, A.H.; Yasin, M.; Harun, S.W. The Ti3SiC2 Max Phase Material for Q-Switched Pulse Generation. J. Russ. Laser Res. 2023, 44, 296–302. [Google Scholar] [CrossRef]

- Anasori, B.; Halim, J.; Lu, J.; Voigt, C.A.; Hultman, L.; Barsoum, M.W. Mo2TiAlC2: A new ordered layered ternary carbide. Scr. Mater. 2015, 101, 5–7. [Google Scholar] [CrossRef]

- Li, Y.F.; Xiao, B.; Sun, L.; Wang, X.Z.; Gao, Y.M.; Wang, Y.R. Phonon spectrum, IR and Raman modes, thermal expansion tensor and thermal physical properties of M2TiAlC2 (M = Cr, Mo, W). Comput. Mater. Sci. 2017, 134, 67–83. [Google Scholar] [CrossRef]

- Cao, L.; Pan, H.; Tang, W.; Li, Y.; Chu, H.; Pan, Z.; Zhao, S.; Ji, W.; Li, D. Broadband saturable absorption responses of few-layered MoSe2 nanosheets for all-solid-state Q-switched lasers. Opt. Mater. 2023, 136, 113387. [Google Scholar] [CrossRef]

- Xue, Z.; Li, G.; Rui, L.; Wei, W.; Ying, S. CH3NH3PbBr3 as a saturable absorber for infrared passively Q-switched solid-state laser. Infrared Phys. Technol. 2024, 140, 105382. [Google Scholar] [CrossRef]

- Tian, Q.; Han, W.; Ming, L.; Xue, H.; Ying, S.; Xiao, D.; Wen, L.; Ying, B.; Guo, Z.; Zi, P.; et al. Operation of a passively mode-locked Tm:YAG laser with tantalum aluminum carbide as a saturable absorber. Microw. Opt. Technol. Lett. 2024, 66, e33776. [Google Scholar] [CrossRef]

- Ma, Y.; Sun, H.; Ran, B.; Zhang, S.; Zhang, H.; Tittel, F.K.; Lv, Z. Passively Q-switched Tm: YAlO3 laser based on WS2/MoS2 two-dimensional nanosheets at 2 μm. Opt. Laser Technol. 2020, 126, 106084. [Google Scholar] [CrossRef]

- Li, L.; Cui, W.; Yang, X.; Zhou, L.; Yang, Y.; Xie, W.; Han, J. A high-beam-quality passively Q-switched 2 μm solid-state laser with a WSe2 saturable absorber. Opt. Laser Technol. 2020, 125, 105960. [Google Scholar] [CrossRef]

- Yang, Y.; Gao, L.; Han, Y.; Gao, Q.; Lan, R.; Shen, Y. Passively Q-switched Tm: YAP laser based on WSe2/CuO heterojunction saturable absorber. Appl. Phys. B 2024, 130, 171. [Google Scholar] [CrossRef]

- Shi, Z.; Sun, X.; Xun, J.; Xie, W.; Zhou, L.; Ma, H.; Yang, X. A diode-pumped SnS2 passively Q-switched Tm-doped pulsed laser. Microw. Opt. Technol. Lett. 2023, 65, 1415–1420. [Google Scholar] [CrossRef]

- He, X.; Qi, T.; Gao, Q.; Yang, W.; Yu, S. Passive Q-switched operation of Tm: YAP laser with a TaTe2 saturable absorber. Microw. Opt. Technol. Lett. 2023, 65, 1398–1403. [Google Scholar] [CrossRef]

- Niu, Z.; Feng, T.; Li, T.; Yang, K.; Zhao, J.; Li, G.; Liu, Y. Theoretical and experimental investigations on Nb2CTx MXene Q-switched Tm: YAP laser at 2 μm for the nonlinear optical response. Nanotechnology 2021, 32, 375709. [Google Scholar] [CrossRef]

- Yuan, J.; Li, J.; Wu, Z.; Li, S.; Han, J.; Li, L. Passively Q-switched operation of a 1.94 µm thulium-doped solid-state laser based on MXene V2CTx. Chin. Opt. Lett. 2023, 21, 021402. [Google Scholar] [CrossRef]

- Zong, T.; Li, L.; Gao, Q.; Liu, B.; Yang, X.; Yang, Y.; Cui, H. Passively Q-switched Tm: YAP laser with a tantalum aluminum carbide saturable absorber. Appl. Opt. 2022, 61, 2432–2437. [Google Scholar] [CrossRef]

| SAs | Crystals | Wavelength (nm) | Pulse Width (ns) | Repetition Frequency (kHz) | Pulse Energy (μJ) | Output Power (mW) | Year | Ref. |

|---|---|---|---|---|---|---|---|---|

| MoS2 | Tm:YAP | 1936.0 | 2500 | 24.0 | 3.8 | 100 | 2020 | [42] |

| WSe2 | Tm:YAP | 1988.3 | 392 | 113.7 | 11.4 | 1290 | 2020 | [43] |

| WSe2/CuO | Tm:YAP | 1986.8 | 752 | 68.68 | 33.7 | 2320 | 2024 | [44] |

| SnS2 | Tm:YAP | 1987.9 | 3061 | 70 | 12.4 | 621 | 2023 | [45] |

| TaTe2 | Tm:YAP | 1987.9 | 585 | 191.1 | 9.7 | 1860 | 2023 | [46] |

| Nb2CTx | Tm:YAP | 1938.0 | 1960 | 80.0 | 7.7 | 620 | 2021 | [47] |

| V2CTx | Tm:YAP | 1937.4 | 528 | 65.9 | 6.3 | 350 | 2023 | [48] |

| Ta4AlC3 | Tm:YAP | 1991.8 | 926 | 143.8 | 5.4 | 780 | 2023 | [49] |

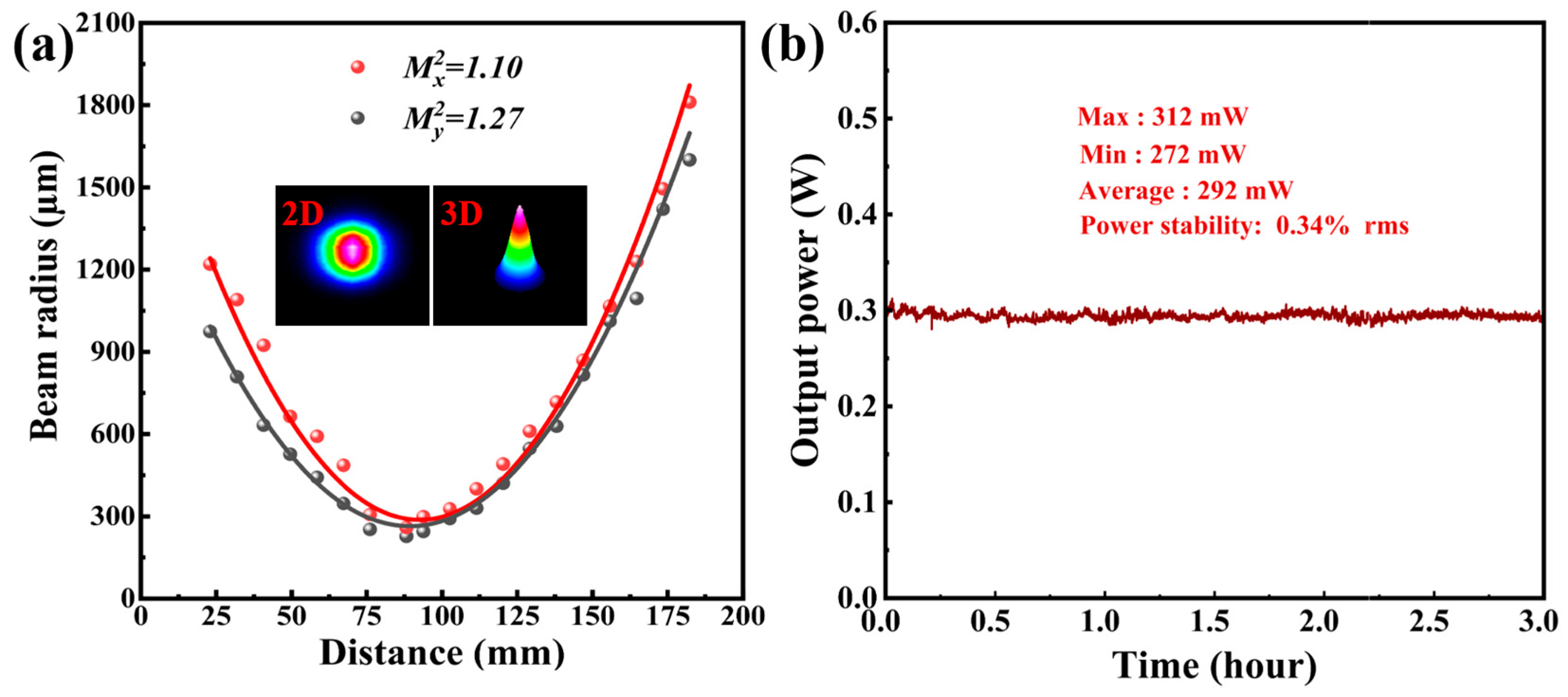

| Mo2TiAlC2 | Tm:YAP | 1931.2 | 242.9 | 47.07 | 6.2 | 292 | 2024 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Chen, T.; Meng, Z.; Niu, S.; Li, Z.; Yang, X. Mo2TiAlC2 as a Saturable Absorber for a Passively Q-Switched Tm:YAlO3 Laser. Nanomaterials 2024, 14, 1823. https://doi.org/10.3390/nano14221823

Wang C, Chen T, Meng Z, Niu S, Li Z, Yang X. Mo2TiAlC2 as a Saturable Absorber for a Passively Q-Switched Tm:YAlO3 Laser. Nanomaterials. 2024; 14(22):1823. https://doi.org/10.3390/nano14221823

Chicago/Turabian StyleWang, Chen, Tianjie Chen, Zhe Meng, Sujian Niu, Zhaoxue Li, and Xining Yang. 2024. "Mo2TiAlC2 as a Saturable Absorber for a Passively Q-Switched Tm:YAlO3 Laser" Nanomaterials 14, no. 22: 1823. https://doi.org/10.3390/nano14221823

APA StyleWang, C., Chen, T., Meng, Z., Niu, S., Li, Z., & Yang, X. (2024). Mo2TiAlC2 as a Saturable Absorber for a Passively Q-Switched Tm:YAlO3 Laser. Nanomaterials, 14(22), 1823. https://doi.org/10.3390/nano14221823