Evaluation of TiO2 Nanoparticle-Enhanced Palm and Soybean Biodiesel Blends for Emission Mitigation and Improved Combustion Efficiency

Abstract

1. Introduction

The Objectives of This Study

- To evaluate the influence of TiO2 nanoparticles on the reduction in harmful emissions (CO, HC, and NOX) and the enhancement in combustion efficiency in soybean and palm biodiesel blends.

- To explore the potential of TiO2 nanoparticles in mitigating NOX emissions and lowering exhaust gas temperatures (EGTs), particularly at higher engine speeds.

2. Literature Review

Identification of Research Gaps

3. Methodology

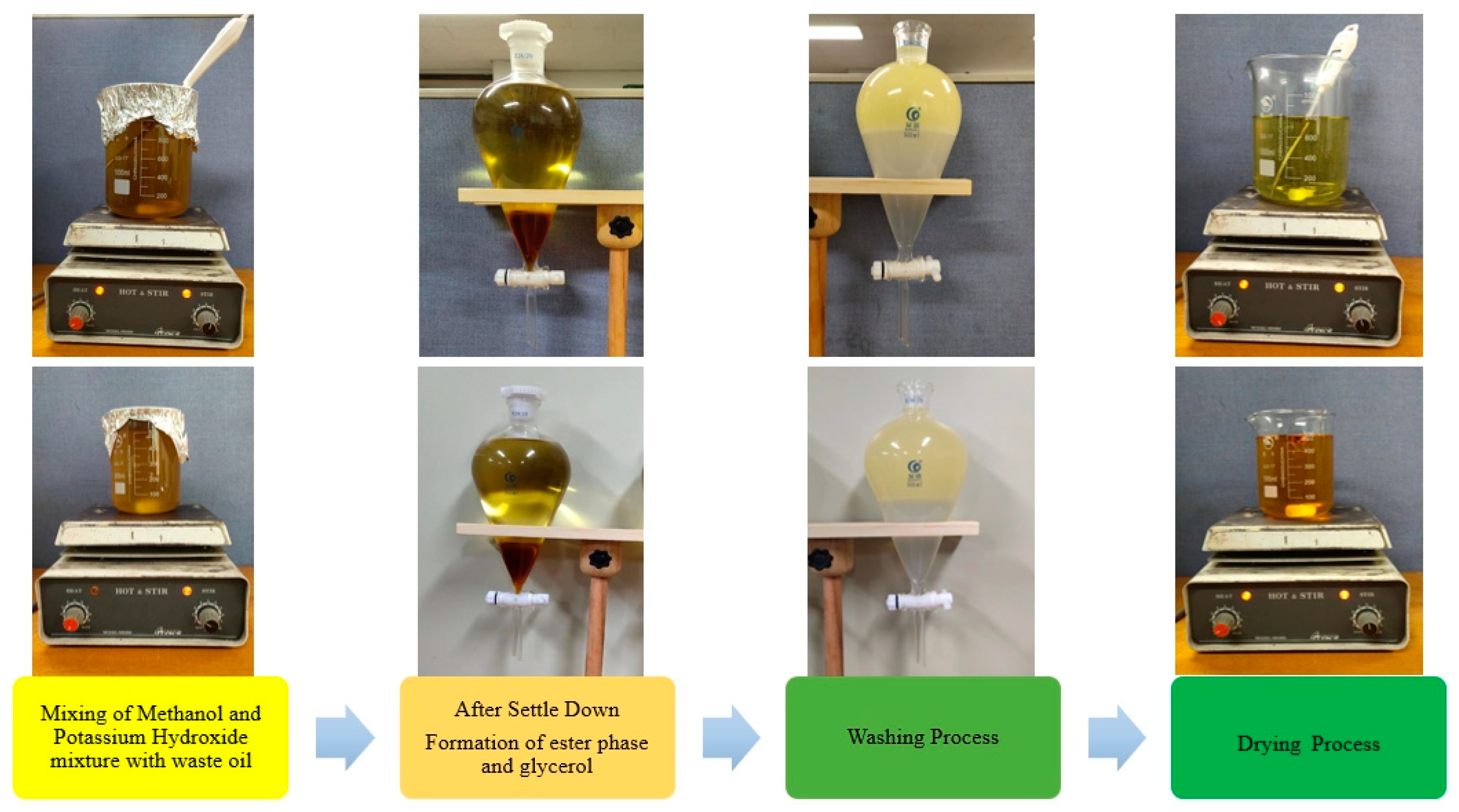

3.1. Biofuel Production

3.2. Incorporation of TiO2 Nanoparticles

- A concentration of 50 ppm: This moderate concentration was selected to evaluate the balance between catalytic enhancement and potential changes in fuel properties, such as viscosity and stability. It provides insights into optimal nanoparticle loading that can deliver noticeable benefits without compromising the fuel’s quality.

- A concentration of 75 ppm: The highest concentration was chosen to explore the upper limits of TiO2 incorporation. This level helps in understanding the maximum potential benefits and any possible drawbacks, such as increased costs or technical challenges, associated with higher nanoparticle loading.

3.3. Experimental Setup

3.4. Engine Specifications

3.5. Error Analysis and Uncertainty

4. Results and Discussion

4.1. Emission Analysis

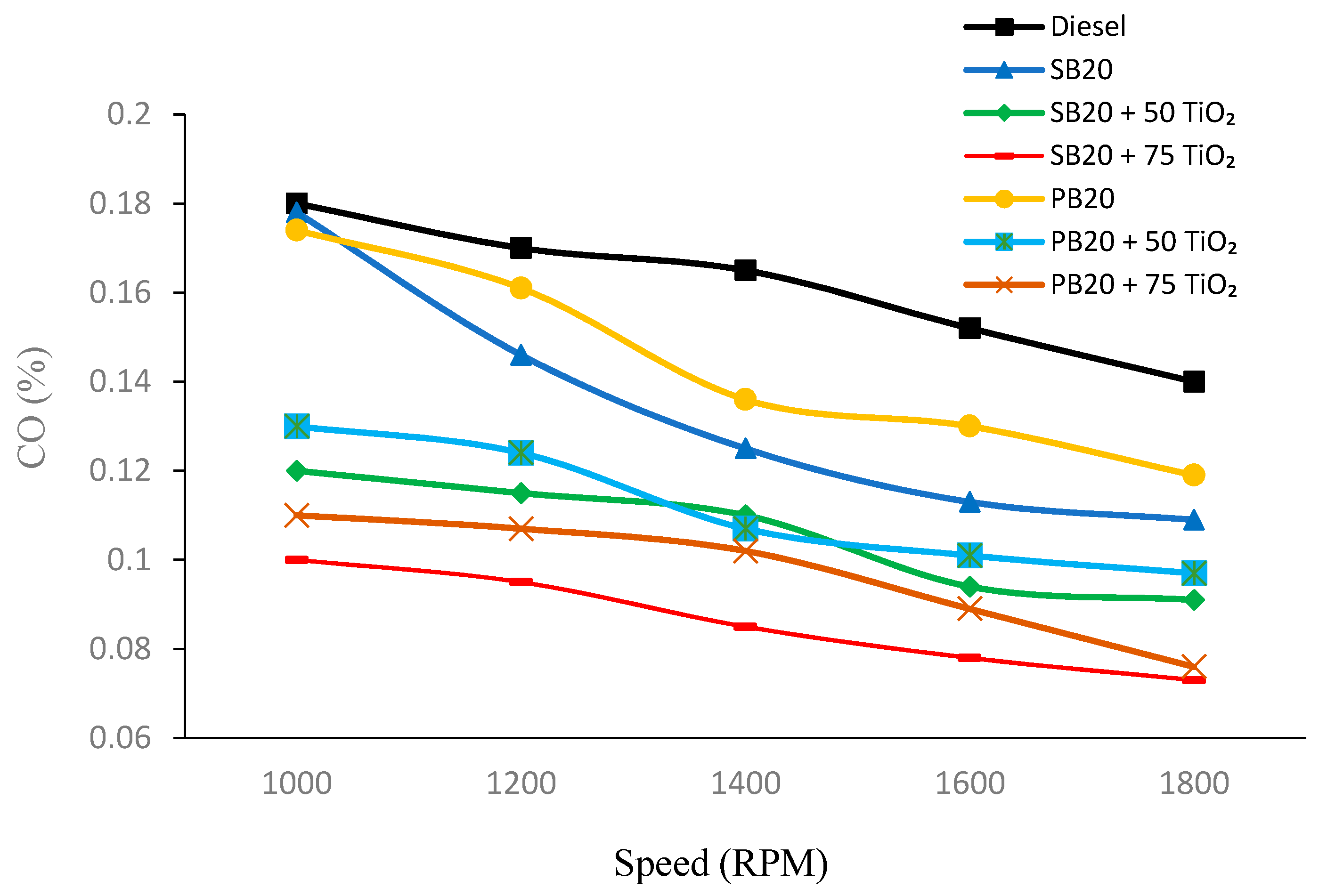

4.1.1. Carbon Monoxide (CO) Emissions

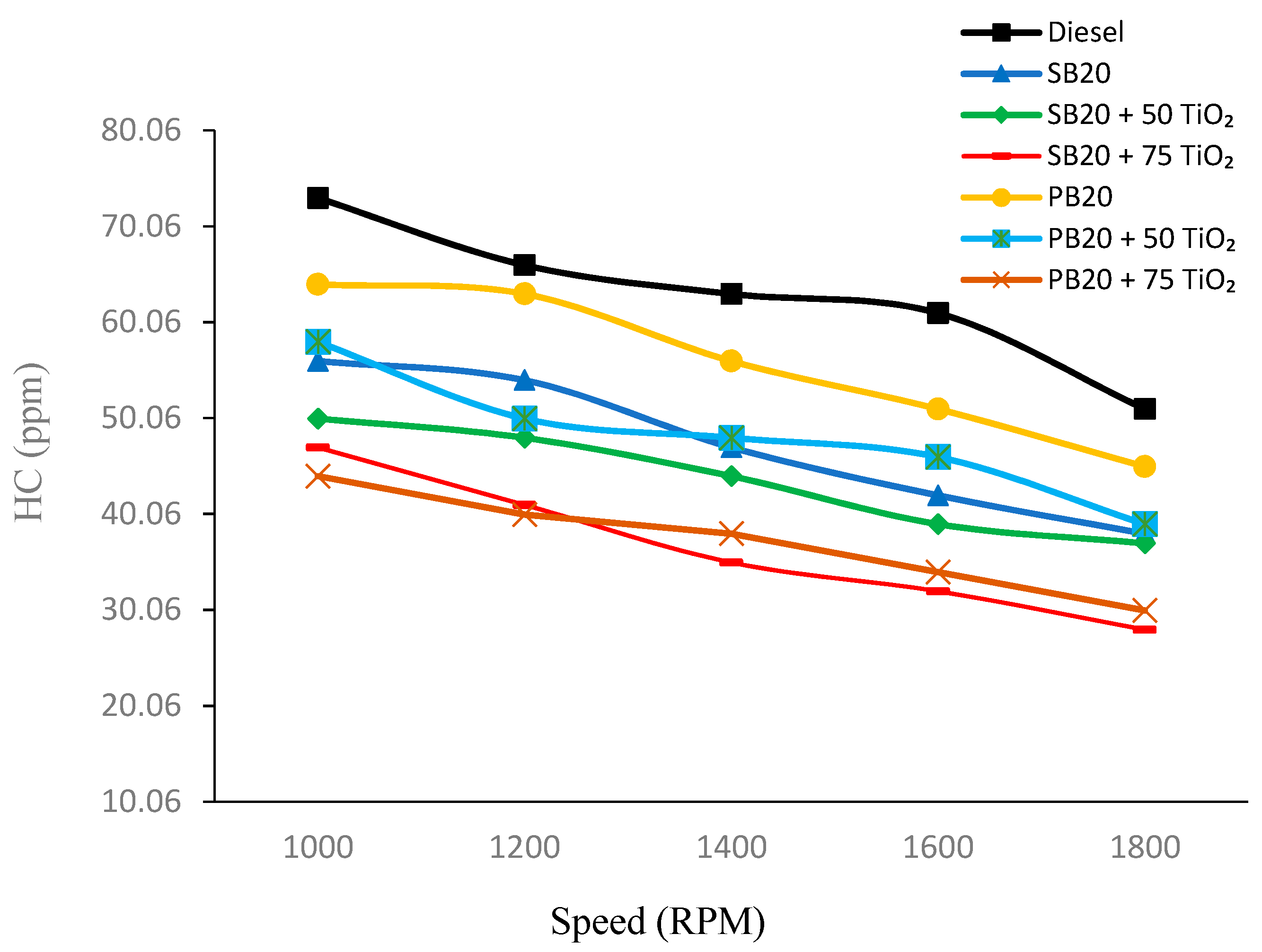

4.1.2. Hydrocarbon (HC) Emissions

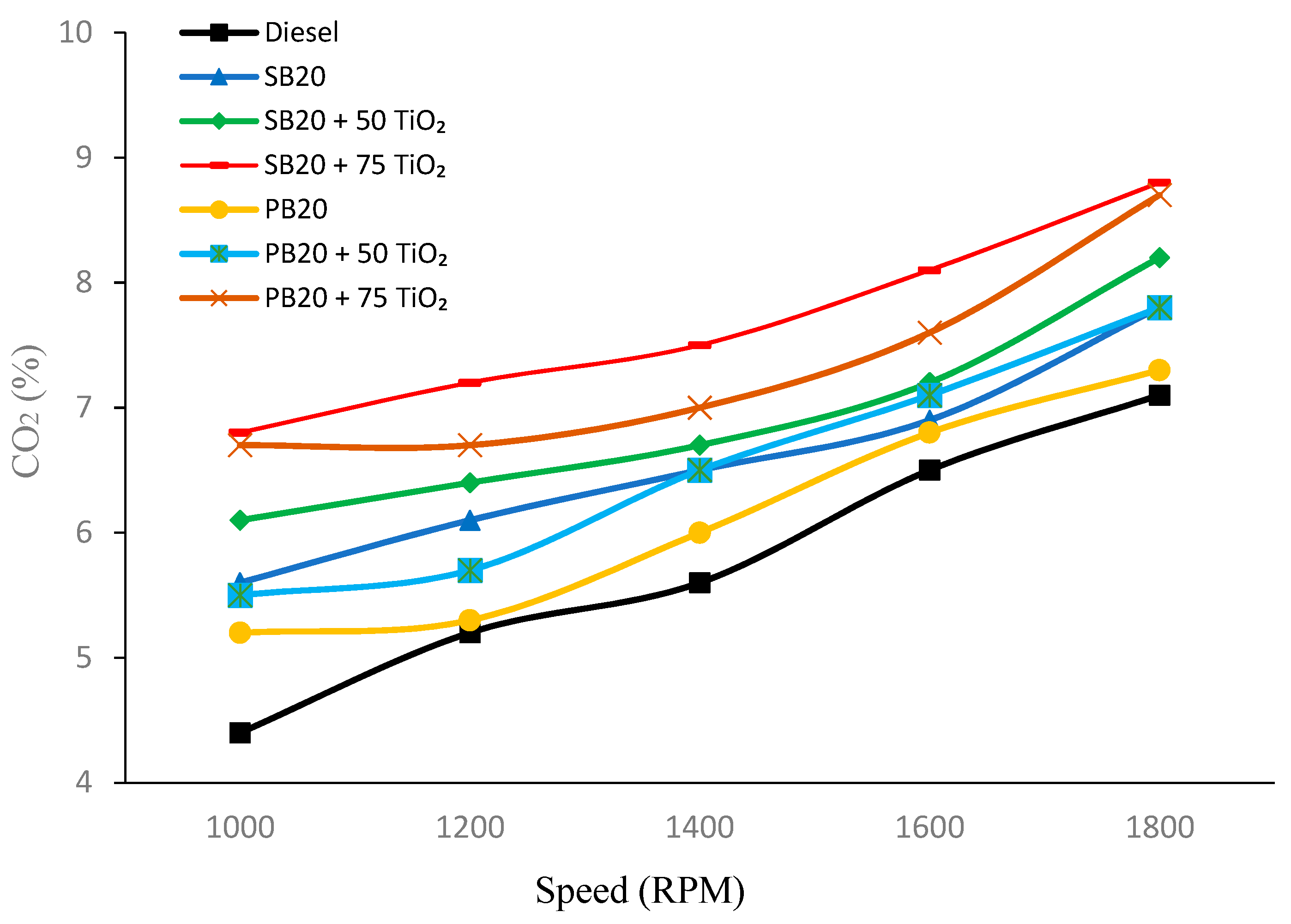

4.1.3. Carbon Dioxide (CO2) Emissions

4.1.4. Nitrogen Oxide (NOX) Emissions

4.1.5. Exhaust Gas Temperature (EGT)

5. Conclusions

6. Future Scope

- -

- The Fate of TiO2 Nanoparticles: Future studies should investigate whether TiO2 nanoparticles remain in the soot, are filtered, or are emitted into the atmosphere post-combustion.

- -

- Fuel Consumption: Future research should evaluate the impact of TiO2 on fuel economy, which was not assessed in this study.

- -

- Smoke and Particulate Emissions: Measuring smoke opacity and particulate matter emissions will provide a more comprehensive understanding of TiO2’s environmental impact.

- -

- Stability, Costs, and Life Cycle Impact: Studies should assess the long-term stability, cost-effectiveness, and environmental life cycle of TiO2-enhanced biofuels.

- -

- Nanoparticle Dispersion: While ultrasonic mixing was used to disperse TiO2, future work should employ techniques like SEM or TEM to verify nanoparticle distribution and long-term stability in biofuels.

- -

- Sample Testing: Testing each fuel sample three times would improve statistical reliability. Future studies should aim to carry out triplicate testing to enhance data robustness.

- -

- The Uniformity of TiO2 Dispersion: Variations in viscosity and calorific value may result from slight inconsistencies in nanoparticle dispersion. Future work will focus on advanced testing to ensure better uniformity in the samples.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| kg/m3 | Kilograms per cubic meter (density) |

| cSt | Centistokes (viscosity) |

| °C | Degrees Celsius (flash point) |

| ppm | Parts per million (nanoparticle concentration) |

| MJ/kg | Megajoules per kilogram (calorific value) |

| % | Percentage |

| NOX | Nitrogen oxide |

| CO | Carbon monoxide |

| HC | Hydrocarbon |

| CO2 | Carbon dioxide |

| EGT | Exhaust gas temperature |

| CI Engine | Compression ignition engine |

| TiO2 | Titanium dioxide |

| SB20 | 20% soybean biodiesel and 80% diesel blend |

| SB20 + 50 ppm TiO2 | SB20 blend with 50 ppm TiO2 nanoparticles |

| SB20 + 75 ppm TiO2 | SB20 blend with 75 ppm TiO2 nanoparticles |

| PB20 | 20% palm biodiesel and 80% diesel blend |

| PB20 + 50 ppm TiO2 | PB20 blend with 50 ppm TiO2 nanoparticles |

| PB20 + 75 ppm TiO2 | PB20 blend with 75 ppm TiO2 nanoparticles |

References

- El-Adawy, M. Effects of diesel-biodiesel fuel blends doped with zinc oxide nanoparticles on performance and combustion attributes of a diesel engine. Alex. Eng. J. 2023, 80, 269–281. [Google Scholar] [CrossRef]

- Bayindirli, C.; Celik, M.; Zan, R. Optimizing the thermophysical properties and combustion performance of biodiesel by graphite and reduced graphene oxide nanoparticle fuel additive. Eng. Sci. Technol. Int. J. 2023, 37, 101295. [Google Scholar] [CrossRef]

- Zheng, F.; Cho, H.M. The Effect of Different Mixing Proportions and Different Operating Conditions of Biodiesel Blended Fuel on Emissions and Performance of Compression Ignition Engines. Energies 2024, 17, 344. [Google Scholar] [CrossRef]

- Lee, K.; Cho, H. Comparative Analysis of Performance and Emission Characteristics of Biodiesels from Animal Fats and Vegetable Oils as Fuel for Common Rail Engines. Energies 2024, 17, 1711. [Google Scholar] [CrossRef]

- Khujamberdiev, R.; Cho, H. Impact of Biodiesel Blending on Emission Characteristics of One-Cylinder Engine Using Waste Swine Oil. Energies 2023, 16, 5489. [Google Scholar] [CrossRef]

- Lai, C.-M.; Loo, D.L.; Teoh, Y.H.; How, H.G.; Le, T.D.; Nguyen, H.T.; Ghfar, A.A.; Sher, F. Optimization and performance characteristics of diesel engine using green fuel blends with nanoparticles additives. Fuel 2023, 347, 128462. [Google Scholar] [CrossRef]

- Sandhi, R.S.; Chebattina, K.R.R.; Sambana, N.R.; Vadapalli, S.; Pullagura, G.; Pathem, U.C. Evaluation of TiO2 nanoparticles as an additive in diesel-n-butanol-Bombax ceiba biodiesel blends for enhance performance and emissions control of a CI engine. Int. J. Heat Technol. 2021, 39, 1930–1936. [Google Scholar] [CrossRef]

- Zheng, F.; Cho, H.M. The Comprehensive Effects of Nano Additives on Biodiesel Engines—A Review. Energies 2024, 17, 4126. [Google Scholar] [CrossRef]

- Pullagura, G.; Bikkavolu, J.; Vadapalli, S.; Chebattina, K.R.R.; Kuchipudi, V. Comparative study of TiO2 nanoparticles and alcoholic fuel additives-biodiesel-diesel blend for combustion, performance, and emission improvements. Int. J. Heat Technol. 2022, 40, 1249–1257. [Google Scholar] [CrossRef]

- Simhadri, K.; Rao, P.S.; Paswan, M. Improving the combustion and emission performance of a diesel engine with TiO2 nanoparticle blended Mahua biodiesel at different injection pressures. Int. J. Thermofluids 2024, 21, 100563. [Google Scholar] [CrossRef]

- Jan, H.A.; Saqib, N.U.; Khusro, A.; Sahibzada, M.U.K.; Rauf, M.; Alghamdi, S.; Almehmadi, M.; Khandaker, M.U.; Bin Emran, T.; Mohafez, H. Synthesis of biodiesel from Carthamus tinctorius L. oil using TiO2 nanoparticles as a catalyst. J. King Saud Univ.-Sci. 2022, 34, 102317. [Google Scholar] [CrossRef]

- Jain, A.; Bora, B.J.; Kumar, R.; Sharma, P.; Medhi, B.J.; Farooque, A.A.; Tirth, V.; Senthilkumar, N.; Peyyala, P.K. Impact of titanium dioxide (TiO2) nanoparticles addition in Eichhornia Crassipes biodiesel used to fuel compression ignition engine at variable injection pressures. Case Stud. Therm. Eng. 2023, 49, 103295. [Google Scholar] [CrossRef]

- Illipilla, M.; Lankapalli, S.V.P.; Sagari, J. Influence of dispersant-mixed TiO2 nanoparticles on stability and physicochemical properties of Semecarpus anacardium biodiesel blend. Int. Nano Lett. 2022, 13, 53–62. [Google Scholar] [CrossRef]

- Fayad, M.A.; Sobhi, M.; Chaichan, M.T.; Badawy, T.; Abdul-Lateef, W.E.; Dhahad, H.A.; Yusaf, T.; Isahak, W.N.R.W.; Takriff, M.S.; Al-Amiery, A.A. Reducing soot nanoparticles and NOx emissions in CRDI diesel engine by incorporating TiO2 nano-additives into biodiesel blends and using high rate of EGR. Energies 2023, 16, 3921. [Google Scholar] [CrossRef]

- Rajak, U.; Verma, T.N. Influence of combustion and emission characteristics on a compression ignition engine from a different generation of biodiesel. Eng. Sci. Technol. Int. J. 2019, 23, 10–20. [Google Scholar] [CrossRef]

- Bari, S.; Zhang, C. Analysis of Performance and Emission of Diesel Engines Operating on Palm Oil Biodiesel. SAE Int. J. Adv. Curr. Pract. Mobil. 2020, 2, 1862–1869. [Google Scholar] [CrossRef]

- Kumar, P.V.; Ashok, B.; Vignesh, R.; Bhasker, J.P.; Kumar, A.N. Evaluation of performance, emissions and combustion attributes of CI engine using palmyra biodiesel blend with distinct compression ratios, EGR rates and nano additives. Fuel 2022, 321, 124092. [Google Scholar] [CrossRef]

- Seraç, M.R.; Aydın, S.; Şevik, S. Evaluation of comparative combustion, performance, and emission of soybean-based alternative biodiesel fuel blends in a CI engine. Renew. Energy 2019, 148, 1065–1073. [Google Scholar] [CrossRef]

- Vellaiyan, S. Combustion, performance and emission evaluation of a diesel engine fueled with soybean biodiesel and its water blends. Energy 2020, 201, 117633. [Google Scholar] [CrossRef]

- Hussain, F.; Soudagar, M.E.; Afzal, A.; Mujtaba, M.A.; Fattah, I.; Naik, B.; Mulla, M.H.; Badruddin, I.A.; Khan, T.M.; Raju, V.D.; et al. Enhancement in Combustion, Performance, and Emission Characteristics of a Diesel Engine Fueled with Ce-ZnO Nanoparticle Additive Added to Soybean Biodiesel Blends. Energies 2020, 13, 4578. [Google Scholar] [CrossRef]

- Lin, C.; Lin, K. Comparison of the Engine Performance of Soybean Oil Biodiesel Emulsions Prepared by Phase Inversion Temperature and Mechanical Homogenization Methods. Processes 2023, 11, 907. [Google Scholar] [CrossRef]

- Venu, H.; Subramani, L.; Raju, V.D. Emission reduction in a DI diesel engine using exhaust gas recirculation (EGR) of palm biodiesel blended with TiO2 nano additives. Renew. Energy 2019, 140, 245–263. [Google Scholar] [CrossRef]

- Mujtaba, M.; Masjuki, H.H.; Kalam, M.A.; Noor, F.; Farooq, M.; Ong, H.C.; Gul, M.; Soudagar, M.E.M.; Bashir, S.; Fattah, I.M.R.; et al. Effect of Additivized Biodiesel Blends on Diesel Engine Performance, Emission, Tribological Characteristics, and Lubricant Tribology. Energies 2020, 13, 3375. [Google Scholar] [CrossRef]

- Jayabalaji, G.; Shanmughasundaram, P. Effect of Titanium Dioxide (TiO2) Nano-Fluid on Performance and Emission Features of a Diesel Engine Operated on Aphanizomenon Flos Biodiesel-Diesel Blend. Mater. Sci. Forum 2019, 969, 421–426. [Google Scholar] [CrossRef]

- Gunasekar, P.; Manigandan, S.; Ilangovan, N.; Nithya, S.; Devipriya, J.; Saravanan, W.S. Effect of TiO2 and nozzle geometry on diesel emissions fuelled with biodiesel blends. Int. J. Ambient. Energy 2019, 40, 477–481. [Google Scholar] [CrossRef]

- Sarma, C.J.; Sharma, P.; Bora, B.J.; Bora, D.K.; Senthilkumar, N.; Balakrishnan, D.; Ayesh, A.I. Improving the combustion and emission performance of a diesel engine powered with mahua biodiesel and TiO2 nanoparticles additive. Alex. Eng. J. 2023, 72, 387–398. [Google Scholar] [CrossRef]

- Kurre, S.K.; Yadav, J.K.; Khan, M.K.; Yadav, P.; Munaf Dhebar, M.; Rawat, B.S. Experimental evaluation of performance and emission of diesel engine fueled with nano-material titanium dioxide (TiO2) nanoparticles supplemented diesel-biodiesel-ethanol blends. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Fangsuwannarak, K.; Fangsuwannarak, T.; Khotbut, Y. Effect of Nano-TiO2 Additives Blended in Palm Biodiesel on Compression Ignition Engine Performance. J. Clean Energy Technol. 2020, 8, 20–23. [Google Scholar] [CrossRef]

- Madhuri, R.J.; Naik, J.V.; Roa, V. Effects of Aloe Vera Biodiesel Blends with TiO2 on the Emission and Performance Characteristics of a DI Diesel Engine. Biotechnol. J. Int. 2023, 27, 1–7. [Google Scholar] [CrossRef]

- Prasetya, H.; Apriyanto, H.; Agustina, L. Determination of optimum technologies implementation scenarios toward net zero emissions in palm oil biodiesel production. IOP Conf. Ser. Earth Environ. Sci. 2023, 1187, 012029. [Google Scholar] [CrossRef]

- Razzaq, L.; Abbas, M.M.; Waseem, A.; Jauhar, T.A.; Fayaz, H.; Kalam, M.A.; Soudagar, M.E.; Silitonga, A.S.; Husnain, S.U.; Ishtiaq, U. Influence of varying concentrations of TiO2 nanoparticles and engine speed on the performance and emissions of diesel engine operated on waste cooking oil biodiesel blends using response surface methodology. Heliyon 2023, 9, e17758. [Google Scholar] [CrossRef] [PubMed]

- Mehregan, M.; Moghiman, M. Experimental investigation of the distinct effects of nanoparticles addition and urea-SCR after-treatment system on NOx emissions in a blended-biodiesel fueled internal combustion engine. Fuel 2020, 262, 116609. [Google Scholar] [CrossRef]

| Detail | Properties |

|---|---|

| Name (TiO2) | Nanoparticles of titanium dioxide |

| Appearance | White |

| Purity of TiO2 | 96% |

| Particle size | 20–50 nm |

| Surface area | >42 m2/g |

| Melting point | >233 °C |

| Fuel Type | Density (kg/m3) | Viscosity (cSt) | Flash Point (°C) | Cetane Number | Calorific Value (MJ/kg) | Ester Content (%) |

|---|---|---|---|---|---|---|

| Diesel | 0.820 | 2.87 | 58 | 48.7 | 45.515 | - |

| SB20 | 0.834 | 2.92 | 79 | 52 | 43.536 | 96.2 |

| SB20 + 50 ppm TiO2 | 0.841 | 3.19 | 86 | 53.5 | 43.607 | 96.5 |

| SB20 + 75 ppm TiO2 | 0.846 | 3.27 | 89 | 53.8 | 43.695 | 96.8 |

| PB20 | 0.862 | 3.10 | 82 | 51.5 | 43.201 | 97.1 |

| PB20 + 50 ppm TiO2 | 0.868 | 3.36 | 88 | 52.9 | 43.272 | 97.4 |

| PB20 + 75 ppm TiO2 | 0.872 | 3.45 | 91 | 53.2 | 43.335 | 97.7 |

| Parameters | Specifications |

|---|---|

| Engine Type | Electronic, four-cylinder, four-stroke type |

| Injection Sequence | 1-3-4-2 |

| Stroke Length (mm) | 90 |

| Bore (mm) | 84 |

| Compression Ratio | 16:1 |

| Displacement (cc) | 1995 |

| Exhaust Emission | Range | Resolution | Accuracy and Uncertainties |

|---|---|---|---|

| CO | 0.00–10.00 | % | ±0.001% |

| HC | 0–10,000 | ppm | ±1 ppm |

| CO2 | 0.0–20.0 | % | ±0.01% |

| O2 | 0.00–25.00 | % | ±0.01% |

| NOX | 0–5000 | ppm | ±1 ppm |

| Smoke | 0–100 | % | ±0.05% |

| Thermocouple (K-Type) | 0–1200 | ℃ | ±0.1 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khujamberdiev, R.; Cho, H.M. Evaluation of TiO2 Nanoparticle-Enhanced Palm and Soybean Biodiesel Blends for Emission Mitigation and Improved Combustion Efficiency. Nanomaterials 2024, 14, 1570. https://doi.org/10.3390/nano14191570

Khujamberdiev R, Cho HM. Evaluation of TiO2 Nanoparticle-Enhanced Palm and Soybean Biodiesel Blends for Emission Mitigation and Improved Combustion Efficiency. Nanomaterials. 2024; 14(19):1570. https://doi.org/10.3390/nano14191570

Chicago/Turabian StyleKhujamberdiev, Ramozon, and Haeng Muk Cho. 2024. "Evaluation of TiO2 Nanoparticle-Enhanced Palm and Soybean Biodiesel Blends for Emission Mitigation and Improved Combustion Efficiency" Nanomaterials 14, no. 19: 1570. https://doi.org/10.3390/nano14191570

APA StyleKhujamberdiev, R., & Cho, H. M. (2024). Evaluation of TiO2 Nanoparticle-Enhanced Palm and Soybean Biodiesel Blends for Emission Mitigation and Improved Combustion Efficiency. Nanomaterials, 14(19), 1570. https://doi.org/10.3390/nano14191570