Calibrations, Validations, and Checks of a Dual 23 nm and 10 nm Diffusion Charger-Based Portable Emissions Measurement System (PEMS)

Abstract

1. Introduction

2. Materials and Methods

2.1. Laboratory and Portable Systems

- Sampling line (optional), typically heated at a temperature of 100 °C.

- Primary dilution unit, typically heated at a temperature of 150 °C.

- Catalytically active tube, called a catalytic stripper (CS), typically heated at a temperature of 350 °C, to remove volatile particles.

- Secondary dilution (optional).

- Particle number counter or detector. For LABSs, this is a condensation particle counter (CPC), while for portable systems, CPCs or DCs are used.

2.2. Theoretical Background of Diffusion Chargers

- Ion properties: For example, if alcohol and water vapor attach to the ions, their mass increases and their mobility reduces, with an impact of 10% on the theoretical average particle charge.

- Temperature: At higher temperatures the ion velocity increases, and larger particles can acquire more charge. For example, an increase of +10 °C can increase the average particle charge of 100 nm particles by 2%.

- Pressure: At lower pressures, the ion mobility increases and, consequently, the average charge acquired by particles increases. Compared to ambient pressure, 100 mbar lower pressure can result in a 3% higher average particle charge at 100 nm.

- Dielectric constant (relative permittivity) of particles: The dielectric properties have an effect on the image forces. For example, polystyrene latex particles have 15% less average charge at 100 nm than metal particles. Graphite, black carbon, and combustion soot have similar values, with graphite at the lower edge of combustion soot’s values [33,34,35].

- Morphology: Fractal particles acquire more charge than compact particles of the same mobility (see, e.g., [36,37,38,39]). Differences of 10–30% can be observed for 100 nm particles. Analysis indicated that the electrical capacitance of loose agglomerates is larger than that of spherical particles with the same mobility; therefore, loose agglomerates can gain more charges [16].

- Particle concentration: If the particle concentration entering the charger is high compared to the ion concentration, ion depletion leads to a lower average charge per particle.

2.3. PEMS Description

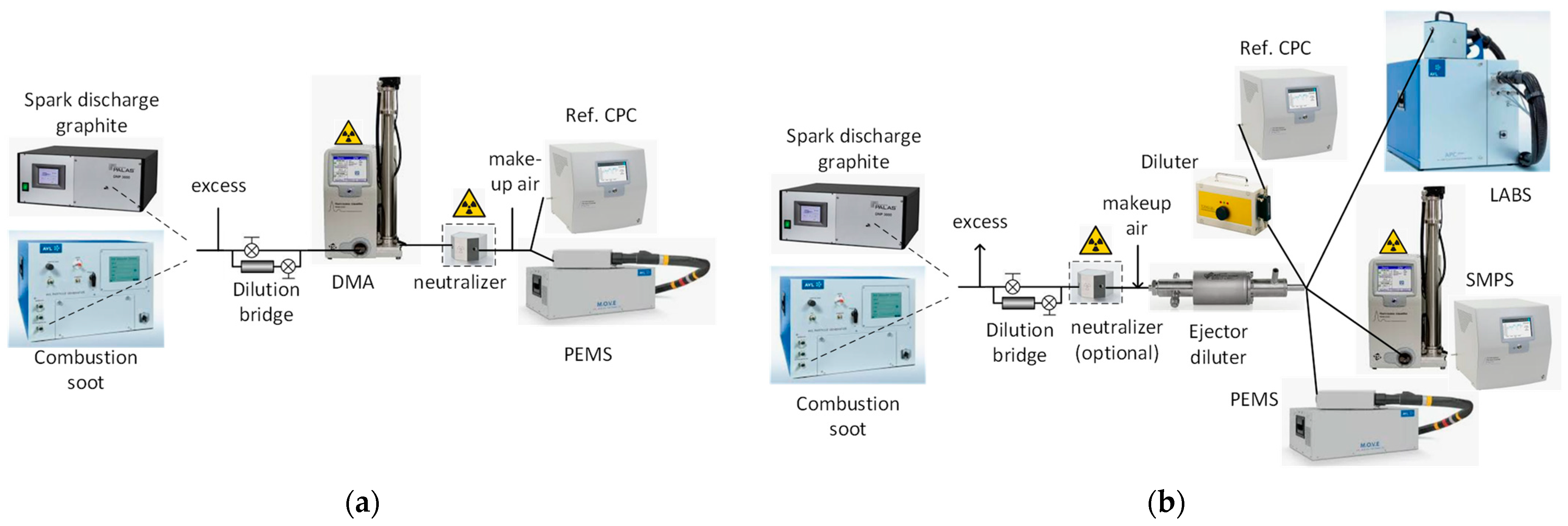

2.4. Experimental Setup

- Monodisperse calibration with laboratory soot-like aerosol vs. reference CPC, according to the calibration requirements described in Regulation (EU) 2017/1151 [46].

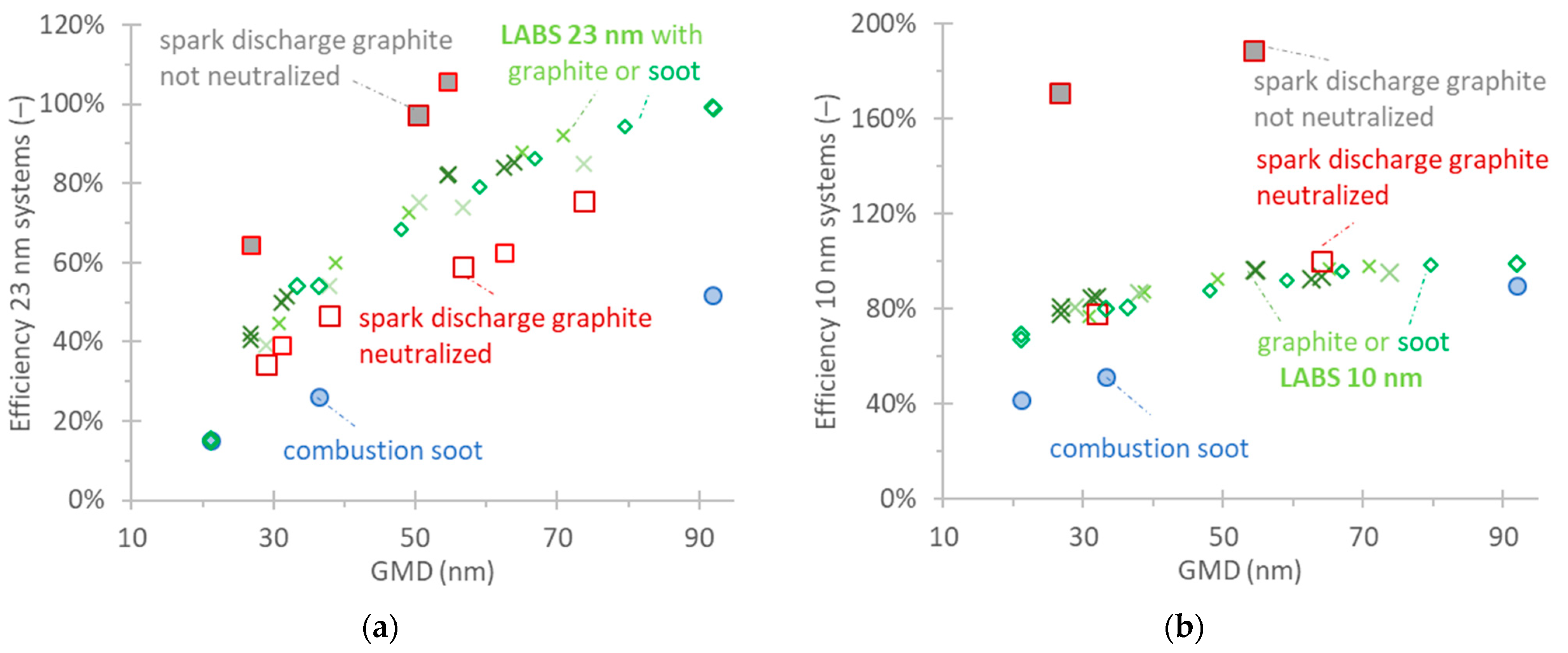

- Polydisperse checks vs. reference CPC and reference LABS using laboratory soot-like aerosol. This is a relatively fast check as a quality check, but it is not described in the regulation [47].

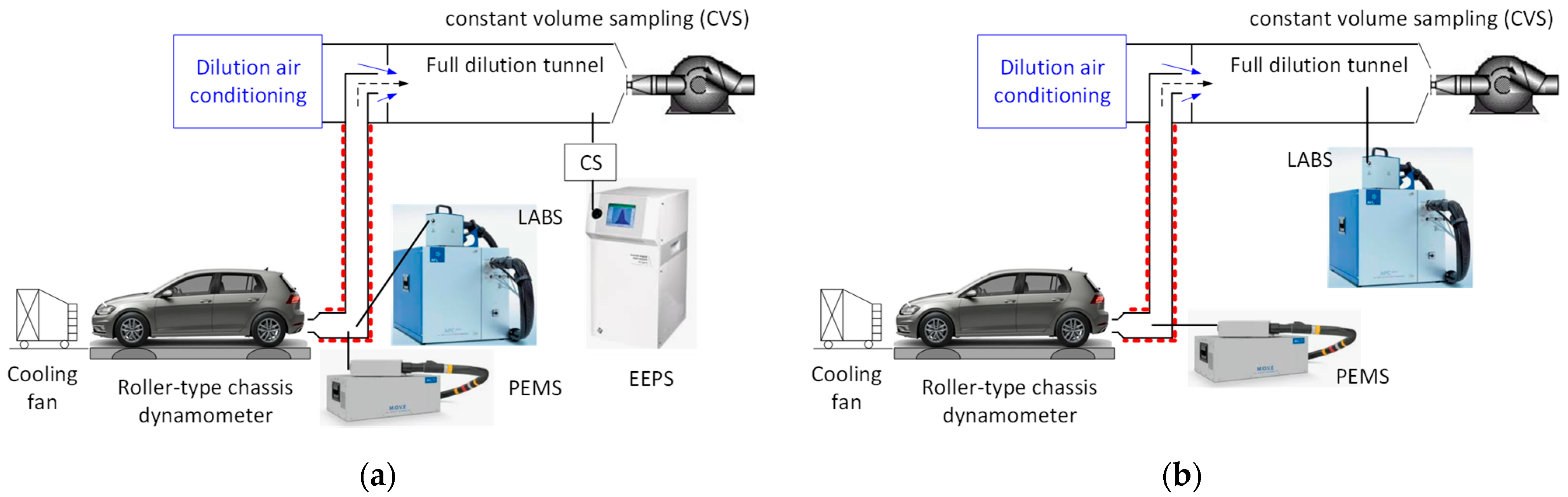

- Verifications vs. LABS at the tailpipe using vehicle exhaust. This check is not prescribed in the regulations, because LABSs are not allowed to be used at the tailpipe for light-duty applications. Nevertheless, the possibility to use LABSs at the tailpipe was developed for future introduction in the heavy-duty regulation and is described in a technical resolution [48]. It is common practice in engine laboratories [26,27,28].

- Validations vs. LABSs at the dilution tunnel using vehicle exhaust. The procedure is described in the regulation [46] as a check of the proper operation of the PEMS.

- AVL particle generator (APG) from AVL, which includes a diffusion flame (mini CAST) generator (model 6.203 from Jing Ltd., Zollikofen, Switzerland) [49]. More specifically, the (mini) CAST generator produces particles by propane and air co-flow diffusion flame. The flame is quenched by nitrogen to keep the particle concentration high. Dilution stages reduce the particle concentration to the desired levels, while an evaporation tube at 350 °C removes volatiles.

- High-voltage spark discharge graphite electrode generator (DNP 3000 from PALAS, Karlsruhe, Germany) [50]. More specifically, due to the high-voltage spark discharge between the two graphite electrodes, the graphite material is evaporated [51]. Nitrogen transfers the vapors, which start to nucleate and coagulate. Dilution is used to reduce the particle concentration to the desired levels.

3. Results

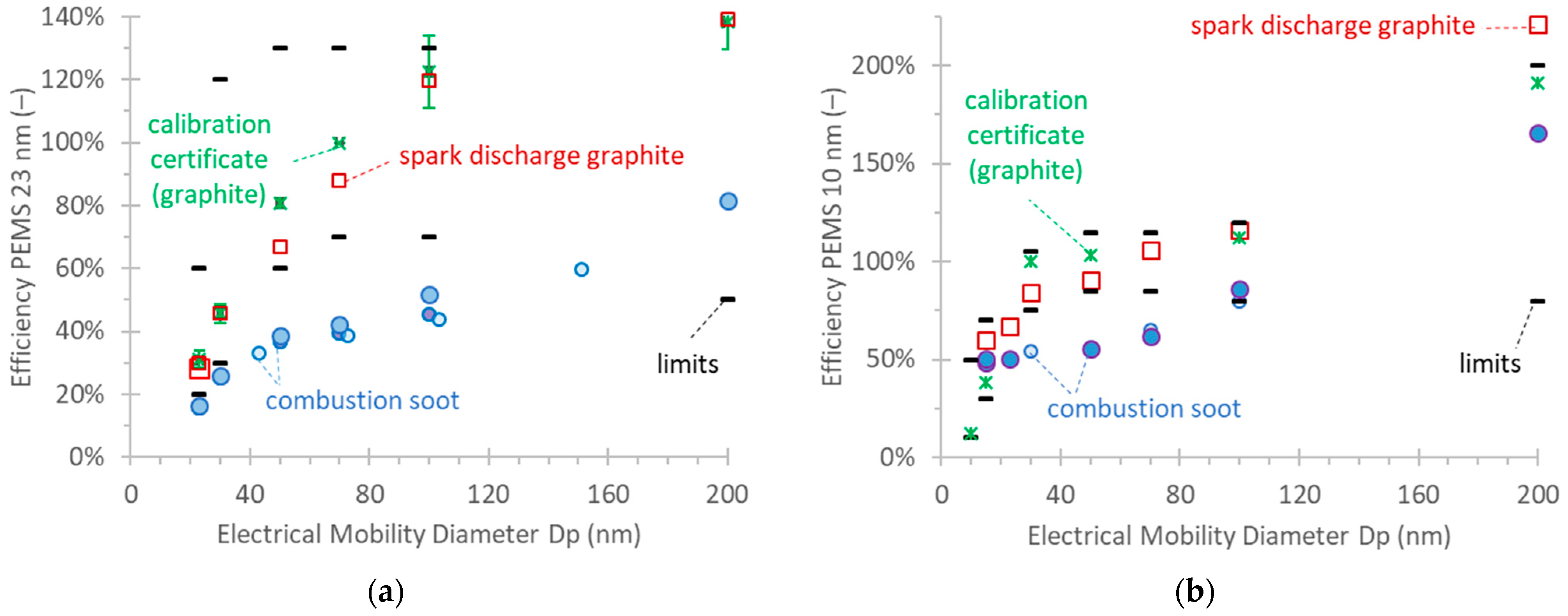

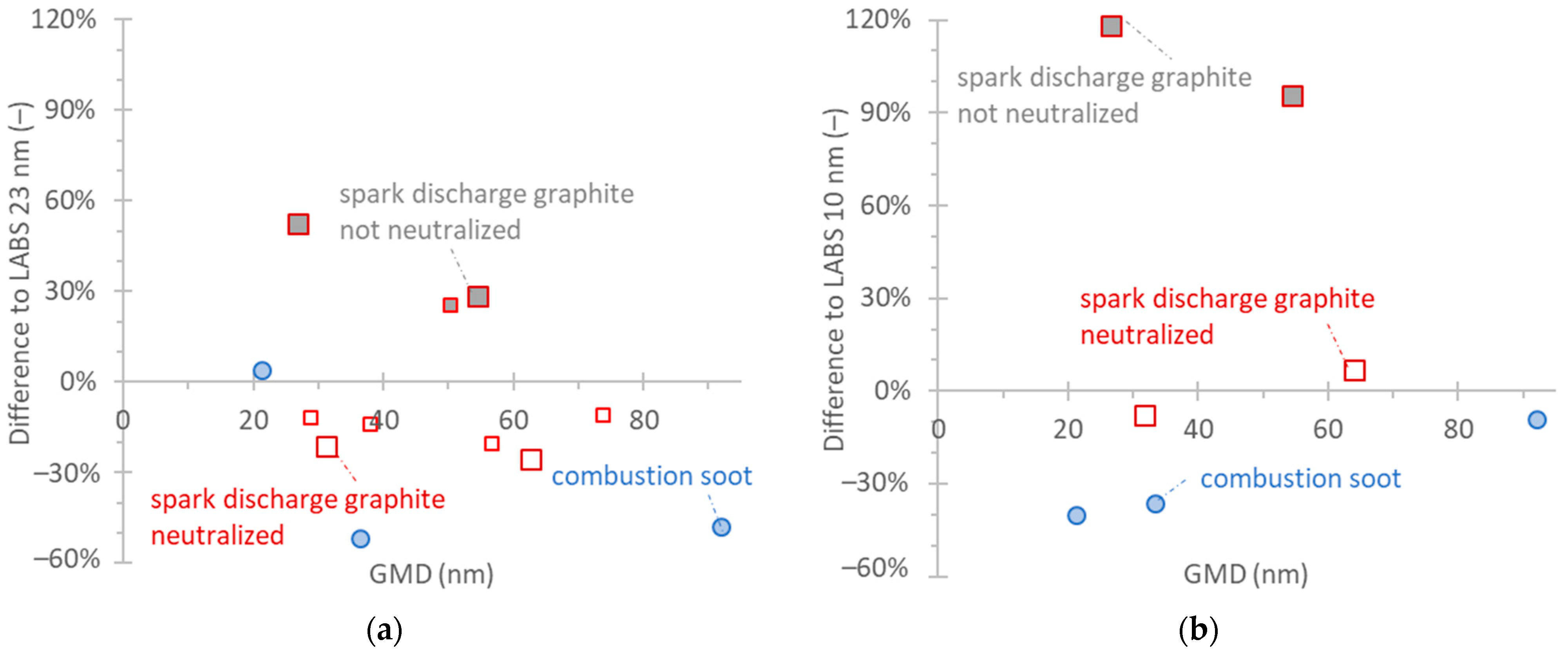

3.1. Laboratory Soot-like Aerosols

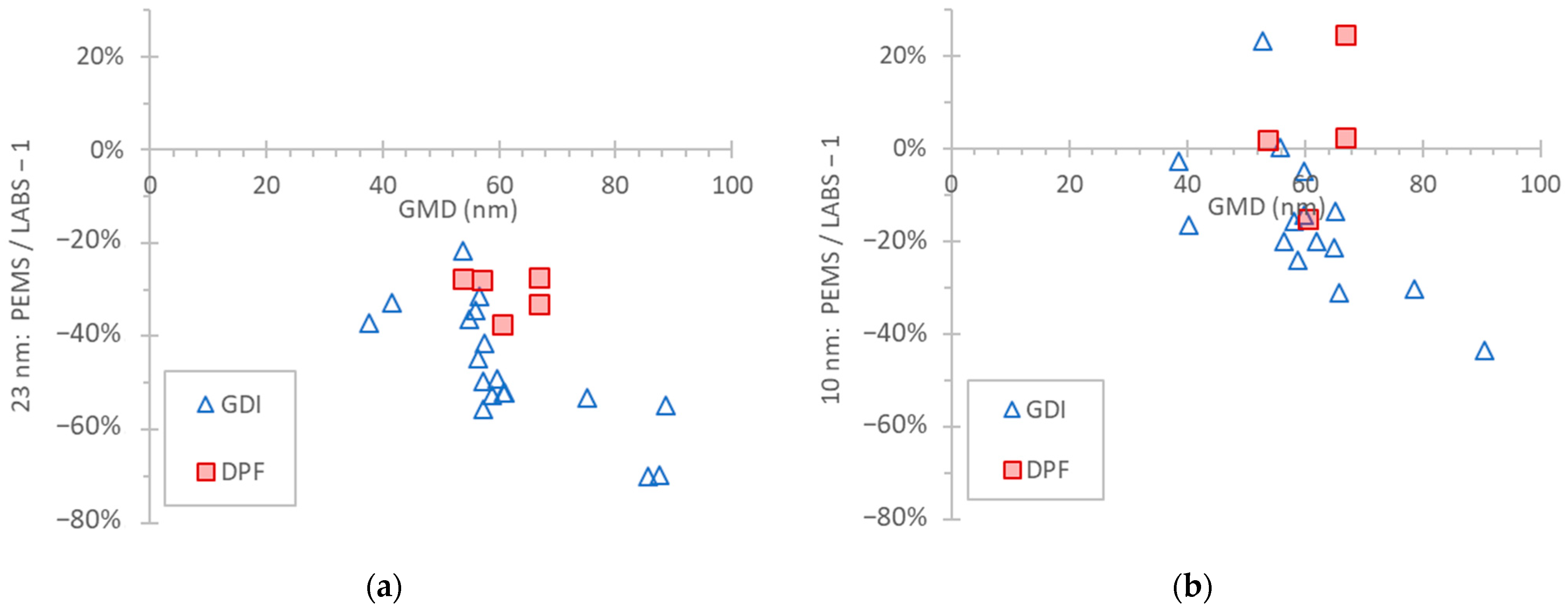

3.2. Vehicle Exhaust

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Disclaimer

Abbreviations

| APC | advanced particle counter |

| APG | AVL particle generator |

| CAST | combustion aerosol standard |

| CPC | condensation particle counter |

| CS | catalytic stripper |

| CVS | constant volume sampler (dilution tunnel) |

| DC | diffusion charger |

| DMA | differential mobility analyzer |

| DPF | diesel particulate filter |

| EEPS | engine exhaust particle sizer |

| EU | European Union |

| GDI | gasoline direct injection |

| GMD | geometric mean diameter |

| GPF | gasoline particulate filter |

| GTR | global technical regulation |

| HEPA | high-efficiency particle air (filter) |

| JRC | Joint Research Centre |

| LABS | laboratory-grade system |

| PEMS | portable emission measurement system |

| PM | particulate matter |

| PMP | particle measurement programme |

| PN | particle number |

| PTI | periodical technical inspection |

| SMPS | scanning mobility particle sizer |

| TP | tailpipe |

References

- Health Effects Institute. State of Global Air 2024; Special Report; Health Effects Institute: Boston, MA, USA, 2024; ISSN 2578-6873. [Google Scholar]

- Manisalidis, I.; Stavropoulou, E.; Stavropoulos, A.; Bezirtzoglou, E. Environmental and Health Impacts of Air Pollution: A Review. Front. Public Health 2020, 8, 14. [Google Scholar] [CrossRef]

- Aslam, I.; Roeffaers, M.B.J. Carbonaceous Nanoparticle Air Pollution: Toxicity and Detection in Biological Samples. Nanomaterials 2022, 12, 3948. [Google Scholar] [CrossRef]

- Chauhan, B.V.S.; Corada, K.; Young, C.; Smallbone, K.L.; Wyche, K.P. Review on Sampling Methods and Health Impacts of Fine (PM2.5, ≤2.5 μm) and Ultrafine (UFP, PM0.1, ≤0.1 μm) Particles. Atmosphere 2024, 15, 572. [Google Scholar] [CrossRef]

- European Environmental Agency (EEA). Air Quality in Europe 2022; Report No. 05/2022; European Environmental Agency (EEA): Copenhagen, Denmark, 2022; ISBN 978-92-9480-515-7. Available online: https://www.eea.europa.eu/publications/air-quality-in-europe-2022 (accessed on 5 July 2024).

- European Environmental Agency (EEA). Premature Deaths Due to Exposure to Fine Particulate Matter in Europe. 2023. Available online: https://www.eea.europa.eu/en/analysis/indicators/health-impacts-of-exposure-to (accessed on 5 July 2024).

- Harris, S.J.; Maricq, M.M. Signature Size Distributions for Diesel and Gasoline Engine Exhaust Particulate Matter. J. Aerosol Sci. 2001, 32, 749–764. [Google Scholar] [CrossRef]

- Müller, J.-O.; Su, D.S.; Jentoft, R.E.; Wild, U.; Schlögl, R. Diesel Engine Exhaust Emission: Oxidative Behavior and Microstructure of Black Smoke Soot Particulate. Environ. Sci. Technol. 2006, 40, 1231–1236. [Google Scholar] [CrossRef]

- Barone, T.L.; Storey, J.M.E.; Youngquist, A.D.; Szybist, J.P. An Analysis of Direct-Injection Spark-Ignition (DISI) Soot Morphology. Atmos. Environ. 2012, 49, 268–274. [Google Scholar] [CrossRef]

- Liati, A.; Dimopoulos Eggenschwiler, P.; Schreiber, D.; Zelenay, V.; Ammann, M. Variations in Diesel Soot Reactivity along the Exhaust After-Treatment System, Based on the Morphology and Nanostructure of Primary Soot Particles. Combust. Flame 2013, 160, 671–681. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Melas, A.; Martini, G.; Dilara, P. Overview of Vehicle Exhaust Particle Number Regulations. Processes 2021, 9, 2216. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Joshi, A.; Ntziachristos, L.; Dilara, P. European Regulatory Framework and Particulate Matter Emissions of Gasoline Light-Duty Vehicles: A Review. Catalysts 2019, 9, 586. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Bonnel, P.; Perujo, A.; Dilara, P. Solid Particle Number (SPN) Portable Emissions Measurement Systems (PEMS) in the European Legislation: A Review. Int. J. Environ. Res. Public Health 2019, 16, 4819. [Google Scholar] [CrossRef]

- Knoll, M.; Schriefl, M.A.; Nishida, R.T.; Bergmann, A. Impact of Pre-Charged Particles on Steady State and Pulsed Modes of Unipolar Diffusion Chargers. Aerosol Sci. Technol. 2021, 55, 512–525. [Google Scholar] [CrossRef]

- Schriefl, M.A.; Bergmann, A.; Fierz, M. Design Principles for Sensing Particle Number Concentration and Mean Particle Size with Unipolar Diffusion Charging. IEEE Sens. J. 2019, 19, 1392–1399. [Google Scholar] [CrossRef]

- Shin, W.G.; Wang, J.; Mertler, M.; Sachweh, B.; Fissan, H.; Pui, D.Y.H. The Effect of Particle Morphology on Unipolar Diffusion Charging of Nanoparticle Agglomerates in the Transition Regime. J. Aerosol Sci. 2010, 41, 975–986. [Google Scholar] [CrossRef]

- Vasilatou, K.; Wälchli, C.; Auderset, K.; Burtscher, H.; Hammer, T.; Giechaskiel, B.; Melas, A. Effects of the Test Aerosol on the Performance of Periodic Technical Inspection Particle Counters. J. Aerosol Sci. 2023, 172, 106182. [Google Scholar] [CrossRef]

- Wang, X.; Caldow, R.; Sem, G.J.; Hama, N.; Sakurai, H. Evaluation of a Condensation Particle Counter for Vehicle Emission Measurement: Experimental Procedure and Effects of Calibration Aerosol Material. J. Aerosol Sci. 2010, 41, 306–318. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Melas, A. Impact of Material on Response and Calibration of Particle Number Systems. Atmosphere 2022, 13, 1770. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Lähde, T.; Melas, A.D.; Valverde, V.; Clairotte, M. Uncertainty of Laboratory and Portable Solid Particle Number Systems for Regulatory Measurements of Vehicle Emissions. Environ. Res. 2021, 197, 111068. [Google Scholar] [CrossRef]

- European Commission Commission Regulation (EU). 2023/443 of 8 February 2023 Amending Regulation (EU) 2017/1151 as Regards the Emission Type Approval Procedures for Light Passenger and Commercial Vehicles. Off. J. Eur. Union 2023, L66, 1–237. [Google Scholar]

- Giechaskiel, B.; Mamakos, A.; Andersson, J.; Dilara, P.; Martini, G.; Schindler, W.; Bergmann, A. Measurement of Automotive Nonvolatile Particle Number Emissions within the European Legislative Framework: A Review. Aerosol Sci. Technol. 2012, 46, 719–749. [Google Scholar] [CrossRef]

- GTR Global Technical Regulation 15. Available online: https://unece.org/transport/standards/transport/vehicle-regulations-wp29/global-technical-regulations-gtrs (accessed on 5 July 2024).

- Giechaskiel, B.; Lähde, T.; Gandi, S.; Keller, S.; Kreutziger, P.; Mamakos, A. Assessment of 10-nm Particle Number (PN) Portable Emissions Measurement Systems (PEMS) for Future Regulations. Int. J. Environ. Res. Public Health 2020, 17, 3878. [Google Scholar] [CrossRef]

- European Commission Regulation (EU). 2024/1257 of the European Parliament and of the Council of 24 April 2024 on Type-Approval of Motor Vehicles and Engines and of Systems, Components and Separate Technical Units Intended for Such Vehicles, with Respect to Their Emissions and Battery Durability (Euro 7), Amending Regulation (EU) 2018/858 of the European Parliament and of the Council and Repealing Regulations (EC) No 715/2007 and (EC) No 595/2009 of the European Parliament and of the Council, Commission Regulation (EU) No 582/2011, Commission Regulation (EU) 2017/1151, Commission Regulation (EU) 2017/2400 and Commission Implementing Regulation (EU) 2022/1362. Text with EEA Relevance. Off. J. Eur. Union 2024, L1257, 1–49. [Google Scholar]

- Giechaskiel, B.; Schwelberger, M.; Delacroix, C.; Marchetti, M.; Feijen, M.; Prieger, K.; Andersson, S.; Karlsson, H.L. Experimental Assessment of Solid Particle Number Portable Emissions Measurement Systems (PEMS) for Heavy-Duty Vehicles Applications. J. Aerosol Sci. 2018, 123, 161–170. [Google Scholar] [CrossRef]

- Khan, M.Y.; Patel, M.; Scott, N.; Liew, C.M.; Peng, C.; Luo, W.; Rahman, M.; Gramlich, N.; Eames, J.; Phillips, J.A. Assessment of In-Use Solid Particle Number Measurement Systems against Laboratory Systems; SAE Technical Paper 2020-01-5074; SAE: Warrendale, PA, USA, 2020. [Google Scholar]

- Khan, M.Y.; Agarwal, N.; Panda, S.; Desai, A.T.; Wilkinson, J.C.; Chaille, E.; Vats, S.; Salemme, T.L.; Ragupathy, T. Assessment of Condensation Particle Counter-Based Portable Solid Particle Number System for Applications with High Water Content in Exhaust; SAE Technical Paper 2024-01-5048; SAE: Warrendale, PA, USA, 2024. [Google Scholar]

- Siegmann, K.; Siegmann, H.C. Fast and Reliable “In Situ” Evaluation of Particles and Their Surfaces with Special Reference to Diesel Exhaust; SAE Technical Paper 2000-01-1995; SAE: Warrendale, PA, USA, 2000. [Google Scholar]

- Ku, B.K.; Kulkarni, P. Comparison of Diffusion Charging and Mobility-Based Methods for Measurement of Aerosol Agglomerate Surface Area. J. Aerosol Sci. 2012, 47, 100–110. [Google Scholar] [CrossRef][Green Version]

- Ku, B.K.; Maynard, A.D. Comparing Aerosol Surface-Area Measurements of Monodisperse Ultrafine Silver Agglomerates by Mobility Analysis, Transmission Electron Microscopy and Diffusion Charging. J. Aerosol Sci. 2005, 36, 1108–1124. [Google Scholar] [CrossRef]

- Dhaniyala, S.; Fierz, M.; Keskinen, J.; Marjamäki, M. Instruments Based on Electrical Detection of Aerosols. In Aerosol Measurement: Principles, Techniques, and Applications, 3rd ed.; Kulkarni, P., Baron, P.A., Willeke, K., Eds.; Wiley: Hoboken, NJ, USA, 2011; ISBN 978-0-470-38741-2. [Google Scholar]

- Ouf, F.-X.; Sillon, P. Charging Efficiency of the Electrical Low Pressure Impactor’s Corona Charger: Influence of the Fractal Morphology of Nanoparticle Aggregates and Uncertainty Analysis of Experimental Results. Aerosol Sci. Technol. 2009, 43, 685–698. [Google Scholar] [CrossRef]

- Gümüş, E.; Yağımlı, M.; Arca, E. Investigation of the Dielectric Properties of Graphite and Carbon Black-Filled Composites as Electromagnetic Interference Shielding Coatings. Appl. Sci. 2023, 13, 8893. [Google Scholar] [CrossRef]

- Walter, S.; Schwanzer, P.; Hagen, G.; Rabl, H.-P.; Dietrich, M.; Moos, R. Soot Monitoring of Gasoline Particulate Filters Using a Radio-Frequency-Based Sensor. Sensors 2023, 23, 7861. [Google Scholar] [CrossRef]

- Oh, H.; Park, H.; Kim, S. Effects of Particle Shape on the Unipolar Diffusion Charging of Nonspherical Particles. Aerosol Sci. Technol. 2004, 38, 1045–1053. [Google Scholar] [CrossRef]

- Jung, H.; Kittelson, D.B. Characterization of Aerosol Surface Instruments in Transition Regime. Aerosol Sci. Technol. 2005, 39, 902–911. [Google Scholar] [CrossRef]

- Wang, J.; Shin, W.G.; Mertler, M.; Sachweh, B.; Fissan, H.; Pui, D.Y.H. Measurement of Nanoparticle Agglomerates by Combined Measurement of Electrical Mobility and Unipolar Charging Properties. Aerosol Sci. Technol. 2010, 44, 97–108. [Google Scholar] [CrossRef]

- Bełkowska-Wołoczko, D. Introduction of Fractal-like Agglomerates to the Algorithm for Calculating Surface Area Concentrations of PM1. Air Qual. Atmos. Health 2019, 12, 297–303. [Google Scholar] [CrossRef]

- Qi, C.; Asbach, C.; Shin, W.G.; Fissan, H.; Pui, D.Y.H. The Effect of Particle Pre-Existing Charge on Unipolar Charging and its Implication on Electrical Aerosol Measurements. Aerosol Sci. Technol. 2009, 43, 232–240. [Google Scholar] [CrossRef]

- Schwelberger, M.; Mamakos, A.; Fierz, M.; Giechaskiel, B. Experimental Assessment of an Electrofilter and a Tandem Positive-Negative Corona Charger for the Measurement of Charged Nanoparticles Formed in Selective Catalytic Reduction Systems. Appl. Sci. 2019, 9, 1051. [Google Scholar] [CrossRef]

- Fierz, M.; Meier, D.; Steigmeier, P.; Burtscher, H. Aerosol Measurement by Induced Currents. Aerosol Sci. Technol. 2014, 48, 350–357. [Google Scholar] [CrossRef]

- Todea, A.M.; Beckmann, S.; Kaminski, H.; Asbach, C. Accuracy of Electrical Aerosol Sensors Measuring Lung Deposited Surface Area Concentrations. J. Aerosol Sci. 2015, 89, 96–109. [Google Scholar] [CrossRef]

- Todea, A.M.; Beckmann, S.; Kaminski, H.; Bard, D.; Bau, S.; Clavaguera, S.; Dahmann, D.; Dozol, H.; Dziurowitz, N.; Elihn, K.; et al. Inter-Comparison of Personal Monitors for Nanoparticles Exposure at Workplaces and in the Environment. Sci. Total Environ. 2017, 605–606, 929–945. [Google Scholar] [CrossRef] [PubMed]

- Asbach, C.; Alexander, C.; Clavaguera, S.; Dahmann, D.; Dozol, H.; Faure, B.; Fierz, M.; Fontana, L.; Iavicoli, I.; Kaminski, H.; et al. Review of Measurement Techniques and Methods for Assessing Personal Exposure to Airborne Nanomaterials in Workplaces. Sci. Total Environ. 2017, 603–604, 793–806. [Google Scholar] [CrossRef] [PubMed]

- European Commission Commission Regulation (EU). 2017/1151 Supplementing Regulation (EC) No 715/2007 of the European Parliament and of the Council on Type-Approval of Motor Vehicles with Respect to Emissions from Light Passenger and Commercial Vehicles (Euro 5 and Euro 6) and on Access to Vehicle Repair and Maintenance Information, Amending Directive 2007/46/EC of the European Parliament and of the Council, Commission Regulation (EC) No 692/2008 and Commission Regulation (EU) No 1230/2012 and Repealing Commission Regulation (EC) No 692/2008. Off. J. Eur. Union 2017, L175, 1–643, Consolidated version. Available online: http://data.europa.eu/eli/reg/2017/1151/2023-09-01 (accessed on 5 July 2024).

- Giechaskiel, B.; Bergmann, A. On-Site Checks of the Particle Number Measurement Systems with Polydisperse Aerosol. SAE Int. J. Engines 2012, 5, 649–662. [Google Scholar] [CrossRef]

- PMP GRPE 85-04: Proposed Amendments to ECE/TRANS/WP.29/GRPE/2021/17. 2021. Available online: https://unece.org/transport/events/wp29grpe-working-party-pollution-and-energy-85th-session (accessed on 5 July 2024).

- Giechaskiel, B.; Melas, A. Comparison of Particle Sizers and Counters with Soot-like, Salt, and Silver Particles. Atmosphere 2022, 13, 1675. [Google Scholar] [CrossRef]

- Schwyn, S.; Garwin, E.; Schmidt-Ott, A. Aerosol Generation by Spark Discharge. J. Aerosol Sci. 1988, 19, 639–642. [Google Scholar] [CrossRef]

- Horvath, H.; Gangl, M. A Low-Voltage Spark Generator for Production of Carbon Particles. J. Aerosol Sci. 2003, 34, 1581–1588. [Google Scholar] [CrossRef]

- Mamakos, A.; Khalek, I.; Giannelli, R.; Spears, M. Characterization of Combustion Aerosol Produced by a Mini-CAST and Treated in a Catalytic Stripper. Aerosol Sci. Technol. 2013, 47, 927–936. [Google Scholar] [CrossRef][Green Version]

- Ess, M.N.; Vasilatou, K. Characterization of a New miniCAST with Diffusion Flame and Premixed Flame Options: Generation of Particles with High EC Content in the Size Range 30 nm to 200 nm. Aerosol Sci. Technol. 2019, 53, 29–44. [Google Scholar] [CrossRef]

- Haller, T.; Rentenberger, C.; Meyer, J.C.; Felgitsch, L.; Grothe, H.; Hitzenberger, R. Structural Changes of CAST Soot during a Thermal–Optical Measurement Protocol. Atmos. Meas. Tech. 2019, 12, 3503–3519. [Google Scholar] [CrossRef]

- Meuller, B.O.; Messing, M.E.; Engberg, D.L.J.; Jansson, A.M.; Johansson, L.I.M.; Norlén, S.M.; Tureson, N.; Deppert, K. Review of Spark Discharge Generators for Production of Nanoparticle Aerosols. Aerosol Sci. Technol. 2012, 46, 1256–1270. [Google Scholar] [CrossRef]

- Pfeiffer, T.V.; Feng, J.; Schmidt-Ott, A. New Developments in Spark Production of Nanoparticles. Adv. Powder Technol. 2014, 25, 56–70. [Google Scholar] [CrossRef]

- Maisser, A.; Barmpounis, K.; Attoui, M.B.; Biskos, G.; Schmidt-Ott, A. Atomic Cluster Generation with an Atmospheric Pressure Spark Discharge Generator. Aerosol Sci. Technol. 2015, 49, 886–894. [Google Scholar] [CrossRef]

- Kornyushin, D.; Musaev, A.; Patarashvili, A.; Buchnev, A.; Arsenov, P.; Ivanov, M.; Vershinina, O.; Kameneva, E.; Volkov, I.; Efimov, A.; et al. Effect of the Gas Temperature on Agglomeration of Au Nanoparticles Synthesized by Spark Discharge and Their Application in Surface-Enhanced Raman Spectroscopy. Metals 2023, 13, 301. [Google Scholar] [CrossRef]

- Lizunova, A.A.; Borisov, V.I.; Malo, D.; Musaev, A.G.; Kameneva, E.I.; Efimov, A.A.; Volkov, I.A.; Buchnev, A.I.; Shuklov, I.A.; Ivanov, V.V. Spark Discharge Synthesis and Characterization of Ge/Sn Janus Nanoparticles. Nanomaterials 2023, 13, 1701. [Google Scholar] [CrossRef]

- Moore, R.H.; Ziemba, L.D.; Dutcher, D.; Beyersdorf, A.J.; Chan, K.; Crumeyrolle, S.; Raymond, T.M.; Thornhill, K.L.; Winstead, E.L.; Anderson, B.E. Mapping the Operation of the Miniature Combustion Aerosol Standard (Mini-CAST) Soot Generator. Aerosol Sci. Technol. 2014, 48, 467–479. [Google Scholar] [CrossRef]

- Kim, J.; Bauer, H.; Dobovičnik, T.; Hitzenberger, R.; Lottin, D.; Ferry, D.; Petzold, A. Assessing Optical Properties and Refractive Index of Combustion Aerosol Particles Through Combined Experimental and Modeling Studies. Aerosol Sci. Technol. 2015, 49, 340–350. [Google Scholar] [CrossRef]

- Liu, B.Y.H.; Pui, D.Y.H. On the Performance of the Electrical Aerosol Analyzer. J. Aerosol Sci. 1975, 6, 249–264. [Google Scholar] [CrossRef]

- Wiedensohler, A. An Approximation of the Bipolar Charge Distribution for Particles in the Submicron Size Range. J. Aerosol Sci. 1988, 19, 387–389. [Google Scholar] [CrossRef]

- Ji, J.H.; Bae, G.N.; Hwang, J. Characteristics of Aerosol Charge Neutralizers for Highly Charged Particles. J. Aerosol Sci. 2004, 35, 1347–1358. [Google Scholar] [CrossRef]

- Gopalakrishnan, R.; McMurry, P.H.; Hogan, C.J. The Bipolar Diffusion Charging of Nanoparticles: A Review and Development of Approaches for Non-Spherical Particles. Aerosol Sci. Technol. 2015, 49, 1181–1194. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Melas, A.; Mamakos, A. Assessment of Two Condensation Particle Counters (CPCs) in Photometric Mode for High Concentration Exhaust Emission Measurements. Combust. Engines 2023, 193, 15–23. [Google Scholar] [CrossRef]

- Wang, S.C.; Flagan, R.C. Scanning Electrical Mobility Spectrometer. Aerosol Sci. Technol. 1990, 13, 230–240. [Google Scholar] [CrossRef]

- Maricq, M.M. On the Electrical Charge of Motor Vehicle Exhaust Particles. J. Aerosol Sci. 2006, 37, 858–874. [Google Scholar] [CrossRef]

- Bau, S.; Witschger, O.; Gensdarmes, F.; Thomas, D.; Borra, J.-P. Electrical Properties of Airborne Nanoparticles Produced by a Commercial Spark-Discharge Generator. J. Nanoparticle Res. 2010, 12, 1989–1995. [Google Scholar] [CrossRef]

- Maricq, M.M. Monitoring Motor Vehicle PM Emissions: An Evaluation of Three Portable Low-Cost Aerosol Instruments. Aerosol Sci. Technol. 2013, 47, 564–573. [Google Scholar] [CrossRef]

- Keller, A.; Fierz, M.; Siegmann, K.; Siegmann, H.C.; Filippov, A. Surface Science with Nanosized Particles in a Carrier Gas. J. Vac. Sci. Technol. A Vac. Surf. Film. 2001, 19, 1–8. [Google Scholar] [CrossRef]

- Heitbrink, W.A.; Evans, D.E.; Ku, B.K.; Maynard, A.D.; Slavin, T.J.; Peters, T.M. Relationships Among Particle Number, Surface Area, and Respirable Mass Concentrations in Automotive Engine Manufacturing. J. Occup. Environ. Hyg. 2008, 6, 19–31. [Google Scholar] [CrossRef]

- Gini, M.I.; Helmis, C.; Melas, A.D.; Papanastasiou, D.; Orfanopoulos, G.; Giannakopoulos, K.P.; Drossinos, Y.; Eleftheriadis, K. Characterization of Carbon Fractal-like Aggregates by Size Distribution Measurements and Theoretical Calculations. Aerosol Sci. Technol. 2016, 50, 133–147. [Google Scholar] [CrossRef]

- Nishida, R.T.; Johnson, T.J.; Boies, A.M.; Hochgreb, S. Measuring Aerosol Active Surface Area by Direct Ultraviolet Photoionization and Charge Capture in Continuous Flow. Aerosol Sci. Technol. 2019, 53, 1429–1440. [Google Scholar] [CrossRef]

- Schriefl, M.A.; Nishida, R.T.; Knoll, M.; Boies, A.M.; Bergmann, A. Characterization of Particle Number Counters Based on Pulsed-Mode Diffusion Charging. Aerosol Sci. Technol. 2020, 54, 772–789. [Google Scholar] [CrossRef]

- Sorensen, C.M. The Mobility of Fractal Aggregates: A Review. Aerosol Sci. Technol. 2011, 45, 765–779. [Google Scholar] [CrossRef]

- Tabrizi, N.S.; Ullmann, M.; Vons, V.A.; Lafont, U.; Schmidt-Ott, A. Generation of Nanoparticles by Spark Discharge. J. Nanoparticle Res. 2009, 11, 315–332. [Google Scholar] [CrossRef]

| Test | Calibration Aerosol | Ref. Instruments | PEMS | Setup |

|---|---|---|---|---|

| Monodisperse calibration | Graphite or combustion soot | Ref. CPC | #1 | Figure 1a |

| Polydisperse checks | Graphite or combustion soot | Ref. CPC, SMPS, LABS | #1 | Figure 1b |

| Verifications | Vehicle exhaust (1 × DPF, 1 × GDI) | LABS at tailpipe | #1, #2 | Figure 2a |

| Validations | Vehicle exhaust (many) | LABS at CVS | #1, #2, #3 | Figure 2b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melas, A.; Trikka, M.; Valentini, S.; Cotogno, G.; Giechaskiel, B. Calibrations, Validations, and Checks of a Dual 23 nm and 10 nm Diffusion Charger-Based Portable Emissions Measurement System (PEMS). Nanomaterials 2024, 14, 1258. https://doi.org/10.3390/nano14151258

Melas A, Trikka M, Valentini S, Cotogno G, Giechaskiel B. Calibrations, Validations, and Checks of a Dual 23 nm and 10 nm Diffusion Charger-Based Portable Emissions Measurement System (PEMS). Nanomaterials. 2024; 14(15):1258. https://doi.org/10.3390/nano14151258

Chicago/Turabian StyleMelas, Anastasios, Maria Trikka, Sara Valentini, Giulio Cotogno, and Barouch Giechaskiel. 2024. "Calibrations, Validations, and Checks of a Dual 23 nm and 10 nm Diffusion Charger-Based Portable Emissions Measurement System (PEMS)" Nanomaterials 14, no. 15: 1258. https://doi.org/10.3390/nano14151258

APA StyleMelas, A., Trikka, M., Valentini, S., Cotogno, G., & Giechaskiel, B. (2024). Calibrations, Validations, and Checks of a Dual 23 nm and 10 nm Diffusion Charger-Based Portable Emissions Measurement System (PEMS). Nanomaterials, 14(15), 1258. https://doi.org/10.3390/nano14151258