Field-Emission Energy Distribution of Carbon Nanotube Film and Single Tube under High Current

Abstract

1. Introduction

2. Experimental

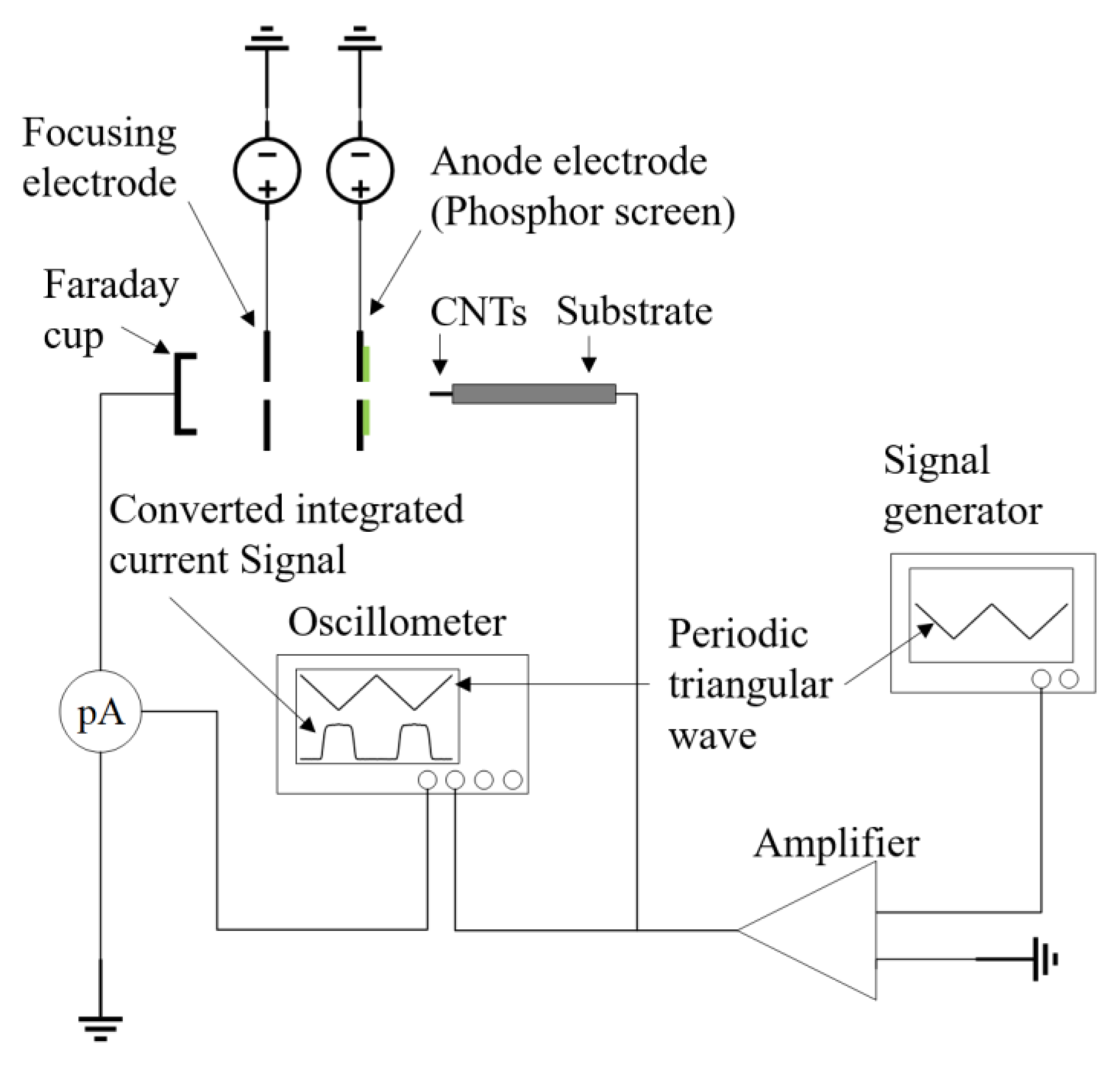

2.1. Method of Measuring the Energy Distribution of Field-Emission Electrons

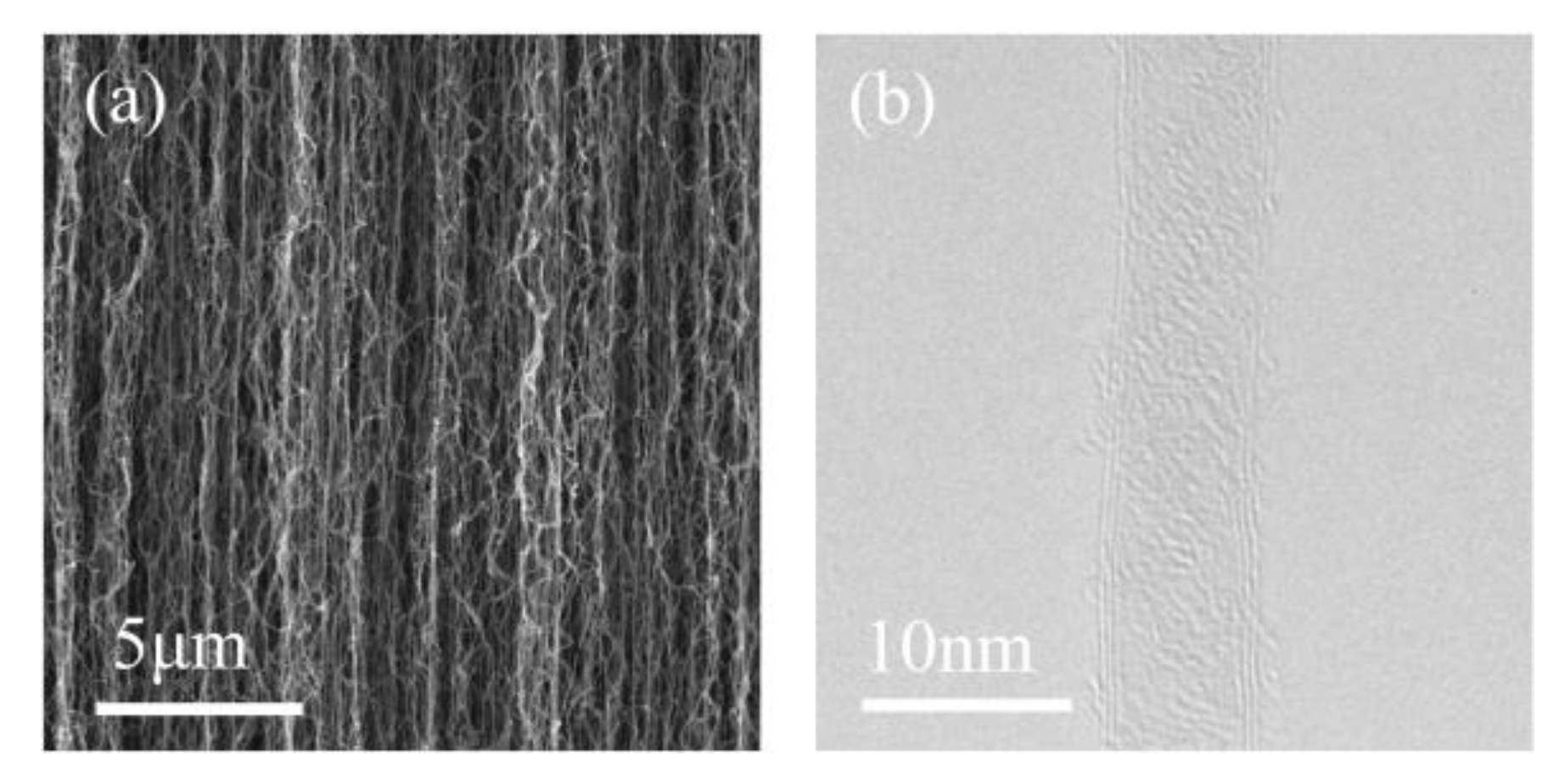

2.2. Preparation of CNT Emitters

3. Results and Discussion

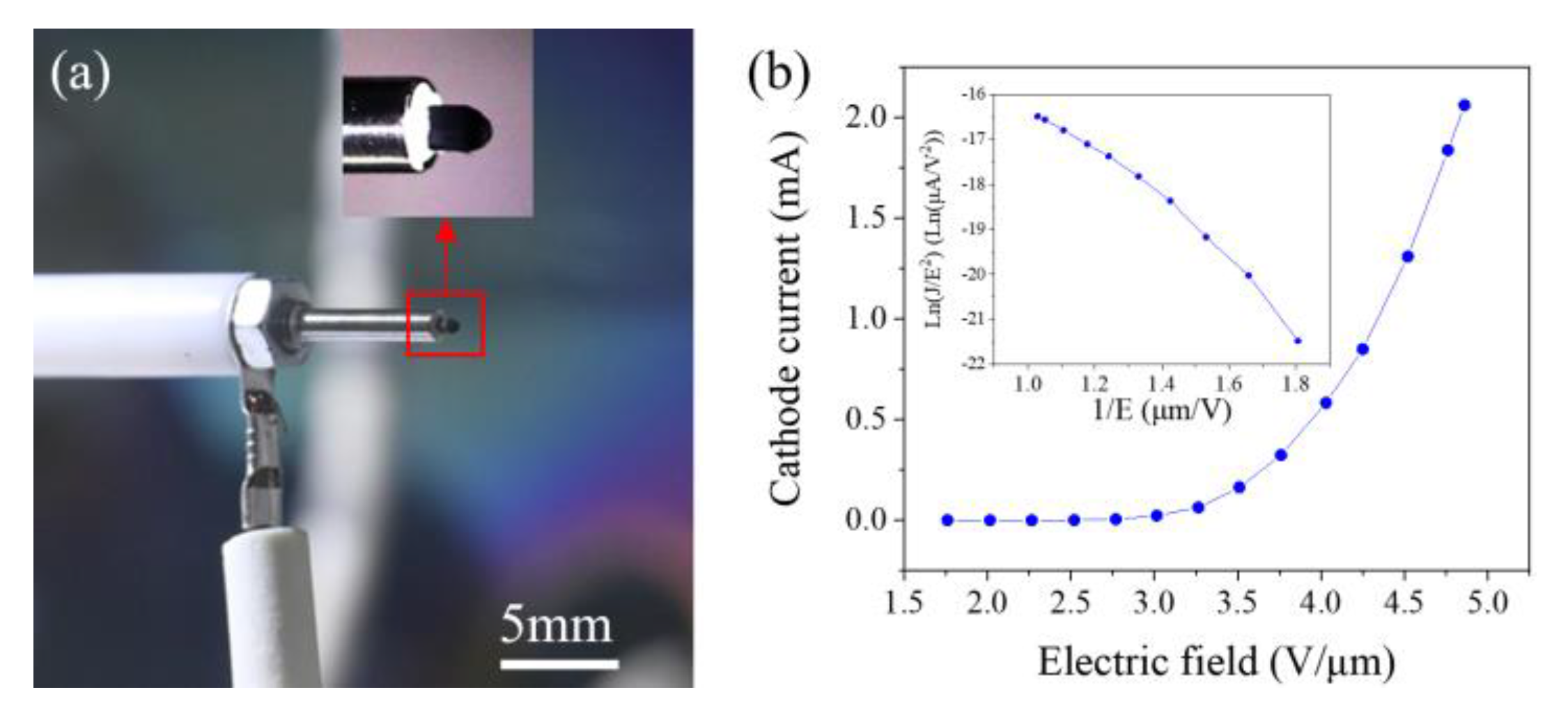

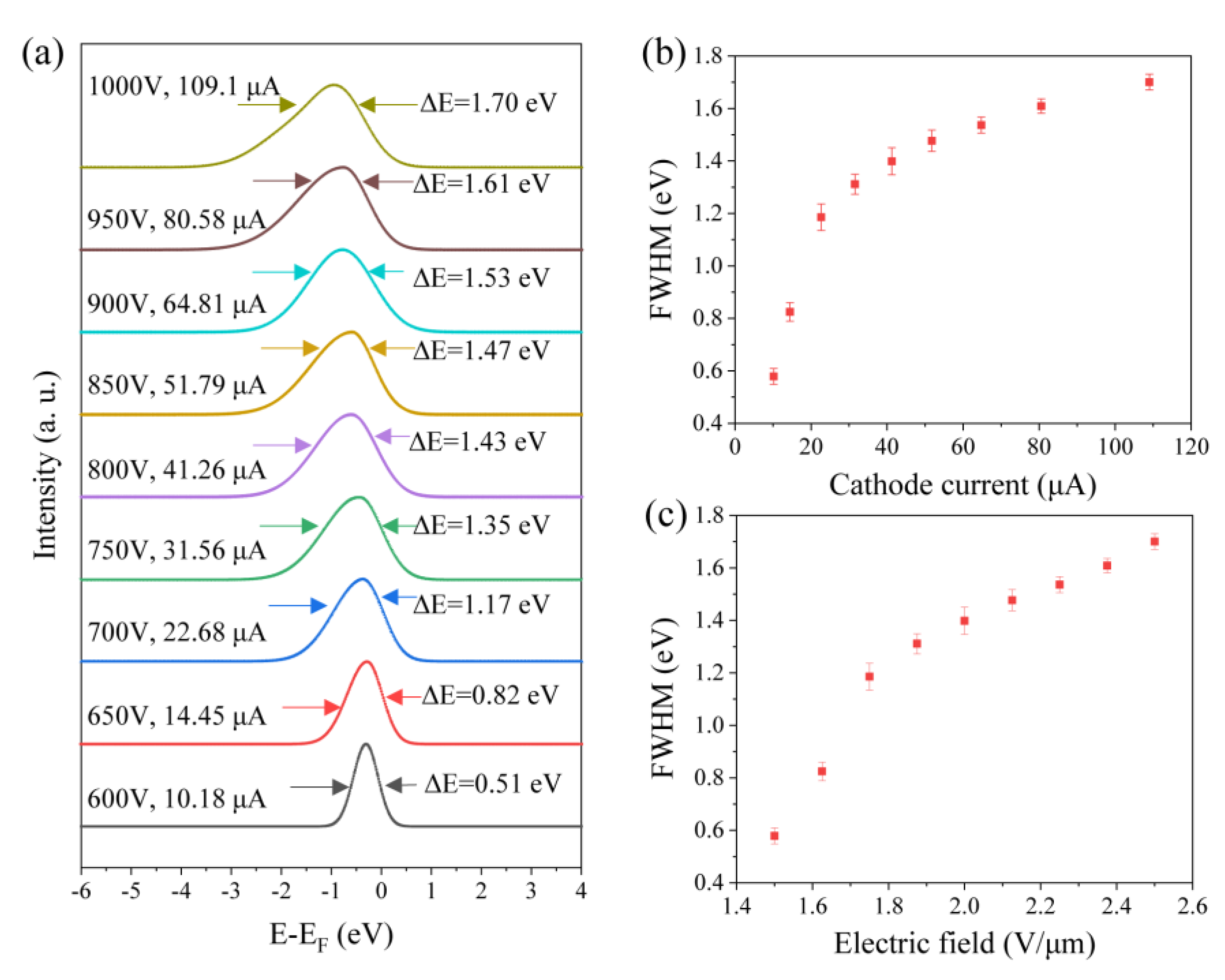

3.1. Field-Emission Energy Distribution of a Single CNT

3.2. Field-Emission Energy Distribution of a CNT Film

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shesterkin, V.I. Operating Emission Characteristics of Various Types of Field-Emission Cathodes. J. Commun. Technol. Electron. 2020, 65, 1–26. [Google Scholar] [CrossRef]

- de Jonge, N.; Bonard, J.M. Carbon nanotube electron sources and applications. Philos. Trans. R. Soc. A-Math. Phys. Eng. Sci. 2004, 362, 2239–2266. [Google Scholar] [CrossRef]

- Back, T.C.; Gruen, G.; Park, J.; Murray, P.T.; Ludwick, J.; Cahay, M.; Fairchild, S.B. Electron emission characteristics of wet spun carbon nanotube fibers. AIP Adv. 2019, 9, 5. [Google Scholar] [CrossRef]

- Dmitrovic, S.; Popovic, Z.P.; Damnjanovic, M.; Milosevic, I. Structural model of semi-metallic carbon nanotubes. Phys. Status Solidi B 2013, 250, 2627–2630. [Google Scholar] [CrossRef]

- Rinzler, A.G.; Hafner, J.H.; Nikolaev, P.; Nordlander, P.; Colbert, D.T.; Smalley, R.E.; Lou, L.; Kim, S.G.; Tomanek, D. Unraveling nanotubes: Field emission from an atomic wire. Science 1995, 269, 1550–1553. [Google Scholar] [CrossRef]

- Eidelman, E.D.; Arkhipov, A.V. Field emission from carbon nanostructures: Models and experiment. Phys. Usp. 2020, 63, 648–667. [Google Scholar] [CrossRef]

- Yu, S.G.; Yi, W.K.; Lee, J.; Jeong, T.; Jin, S.H.; Heo, J.; Kang, J.H.; Choi, Y.S.; Lee, C.S.; Yoo, J.B.; et al. Energy distribution for undergate-type triode carbon nanotube field emitters. Appl. Phys. Lett. 2002, 80, 4036–4038. [Google Scholar] [CrossRef]

- Maheswaran, R.; Shanmugavel, B.P. A Critical Review of the Role of Carbon Nanotubes in the Progress of Next-Generation Electronic Applications. J. Electron. Mater. 2022, 51, 2786–2800. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.A.; Wang, J.; Sun, Y.; Chen, S.; Xie, Z.; Yeow, J.T.W. High Field Emission Performance of Carbon Nanotube Bundle Field Emitters. In Proceedings of the 23rd IVEC, Monterey, CA, USA, 25–29 April 2022; pp. 138–139. [Google Scholar] [CrossRef]

- Lee, H.; Kim, D.; Rodiansyah, A.; Cho, B.; Lim, J.; Park, K.C. Investigation of the Effect of Structural Properties of a Vertically Standing CNT Cold Cathode on Electron Beam Brightness and Resolution of Secondary Electron Images. Nanomaterials 2021, 11, 1918. [Google Scholar] [CrossRef]

- Tang, X.Y.; Yue, H.X.; Liu, L.; Luo, J.; Wu, X.L.; Zheng, R.T.; Cheng, G.A. Vertically Aligned Carbon Nanotube Microbundle Arrays for Field-Emission Applications. ACS Appl. Nano Mater. 2020, 3, 7659–7667. [Google Scholar] [CrossRef]

- Hamanaka, M.H.M.O.; Mammana, V.P.; Tatsch, P.J. Review of Field Emission from Carbon Nanotubes: Highlighting Measuring Energy Spread. In NanoCarbon 2011: Selected Works from the Brazilian Carbon Meeting; Avellaneda, C., Ed.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 1–32. [Google Scholar]

- Bonard, J.M.; Salvetat, J.P.; Stöckli, T.; Forró, L.; Châtelain, A. Field emission from carbon nanotubes: Perspectives for applications and clues to the emission mechanism. Appl. Phys. A 1999, 69, 245–254. [Google Scholar] [CrossRef]

- Adhikari, B.C.; Ketan, B.; Patil, R.; Choi, E.H.; Park, K.C. Optimization of vertically aligned carbon nanotube beam trajectory with the help of focusing electrode in the microchannel plate. Sci. Rep. 2023, 13, 15630. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Xu, J.; Ji, D.; Xu, H.; Sun, M.; Wu, L.; Li, X.; Wang, Q.; Zhang, X. Development of an electron gun based on CNT-cathode for traveling wave tube application. Vacuum 2021, 186, 110029. [Google Scholar] [CrossRef]

- Shimoi, N.; Tohji, K. High-power switching device based on field emission mechanism fabricated using highly crystalline single-walled carbon nanotubes. Appl. Mater. Today 2022, 26, 101284. [Google Scholar] [CrossRef]

- Workowski, C.J. A retarding potential field electron emission spectrometer. J. Phys. E Sci. Instrum. 1980, 13, 67–73. [Google Scholar] [CrossRef]

- Jenkins, D.W. Emission area of a field emitter array. IEEE Trans. Electron Devices 1993, 40, 666–672. [Google Scholar] [CrossRef]

- Xu, N.S.; Chen, Y.; Deng, S.Z.; Chen, J.; Ma, X.C.; Wang, E.G. Vacuum gap dependence of field electron emission properties of large area multi-walled carbon nanotube films. J. Phys. D Appl. Phys. 2001, 34, 1597. [Google Scholar] [CrossRef]

- Purcell, S.T.; Vincent, P.; Journet, C.; Binh, V.T. Hot Nanotubes: Stable Heating of Individual Multiwall Carbon Nanotubes to 2000 K Induced by the Field-Emission Current. Phys. Rev. Lett. 2002, 88, 105502. [Google Scholar] [CrossRef]

- Begtrup, G.E.; Ray, K.G.; Kessler, B.M.; Yuzvinsky, T.D.; Garcia, H.; Zettl, A. Probing Nanoscale Solids at Thermal Extremes. Phys. Rev. Lett. 2007, 99, 155901. [Google Scholar] [CrossRef]

- Miyamoto, Y.; Berber, S.; Yoon, M.; Rubio, A.; Tománek, D. Onset of nanotube decay under extreme thermal and electronic excitations. Phys. B Condens. Matter 2002, 323, 78–85. [Google Scholar] [CrossRef]

- Diehl, R.; Choueib, M.; Choubak, S.; Martel, R.; Perisanu, S.; Ayari, A.; Vincent, P.; Purcell, S.T.; Poncharal, P. Narrow energy distributions of electrons emitted from clean graphene edges. Phys. Rev. B 2020, 102, 035416. [Google Scholar] [CrossRef]

- Modinos, A.; Xanthakis, J.P. Energy-broadening of field-emitted electrons due to Coulomb collisions. Surf. Sci. 1991, 249, 373–378. [Google Scholar] [CrossRef]

- Jansen, G.H. Coulomb interactions in particle beams. Nucl. Instrum. Methods Phys. Res. Sect. A 1990, 298, 496–504. [Google Scholar] [CrossRef][Green Version]

- Fransen, M.J.; van Rooy, T.L.; Kruit, P. Field emission energy distributions from individual multiwalled carbon nanotubes. Appl. Surf. Sci. 1999, 146, 312–327. [Google Scholar] [CrossRef]

- De Jonge, N.; Allioux, M.; Oostveen, J.T.; Teo, K.B.K.; Milne, W.I. Optical performance of carbon-nanotube electron sources. Phys. Rev. Lett. 2005, 94, 186807. [Google Scholar] [CrossRef] [PubMed]

- Hino, S.; Miyazaki, N.; Iwasaki, K.; Kondo, S.; Saito, Y. Energy distribution of field emitted electrons from multiwall carbon nanotubes. Synth. Met. 2001, 121, 1213–1214. [Google Scholar] [CrossRef]

- De Jonge, N.; van Druten, N.J. Field emission from individual multiwalled carbon nanotubes prepared in an electron microscope. Ultramicroscopy 2003, 95, 85–91. [Google Scholar] [CrossRef] [PubMed]

- Purcell, S.T.; Vincent, P.; Rodriguez, M.; Journet, C.; Vignoli, S.; Guillot, D.; Ayari, A. Evolution of the field-emission properties of individual multiwalled carbon nanotubes submitted to temperature and field treatments. Chem. Vap. Depos. 2006, 12, 331–344. [Google Scholar] [CrossRef]

- Milne, W.I.; Teo, K.B.K.; Mann, M.; Bu, I.Y.Y.; Amaratunga, G.A.J.; De Jonge, N.; Allioux, M.; Oostveen, J.T.; Legagneux, P.; Minoux, E. Carbon nanotubes as electron sources. Phys. Status Solidi A 2006, 203, 1058–1063. [Google Scholar] [CrossRef]

- Williams, D.B.; Carter, C.B. Electron sources. In Transmission Electron Microscopy, 2nd ed.; Springer: New York, NY, USA, 2009; Volume 5, pp. 73–89. [Google Scholar]

- Gold, S.H.; Nusinovich, G.S. Review of high-power microwave source research. Rev. Sci. Instrum. 1997, 68, 3945–3974. [Google Scholar] [CrossRef]

- Teo, K. Carbon nanotube electron source technology. JOM 2007, 59, 29–32. [Google Scholar] [CrossRef]

- Wells, T.; El-Gomati, M. The energy spread of a LaB6 cathode operated in the virtual source mode. J. Phys. Conf. Ser. 2014, 522, 012054. [Google Scholar] [CrossRef]

- Franzen, W.; Porter, J.H. Energy Spectrum of Electrons Emitted by a Hot Cathode. Adv. Electron. Electron Phys. 1976, 39, 73–119. [Google Scholar] [CrossRef]

| Low Current | High Current | |

|---|---|---|

| Fransen M.J. [26] | 0.11 eV @ - | 0.75 eV @ 110 nA |

| De Jonge N. [27] | 0.20 eV @ 10 nA | 0.35 eV @ 500 nA |

| Hino S. [28] | 0.3 eV @ 800 V | 1.0 eV @ 1400 V |

| De Jonge N. [29] | 0.20 eV @ 2.4 nA | 0.30 eV @ 100 nA |

| Stephen T. Purcell [30] | 0.2 eV @ 1 nA | 0.9 eV @ 3.2 μA |

| This work | 0.71 eV @ 0.53 μA | 1.35 eV @ 10.12μA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Wu, Y.; Jiang, J.; Tang, S.; Ke, Y.; Zhang, Y.; Deng, S. Field-Emission Energy Distribution of Carbon Nanotube Film and Single Tube under High Current. Nanomaterials 2024, 14, 888. https://doi.org/10.3390/nano14100888

Wang L, Wu Y, Jiang J, Tang S, Ke Y, Zhang Y, Deng S. Field-Emission Energy Distribution of Carbon Nanotube Film and Single Tube under High Current. Nanomaterials. 2024; 14(10):888. https://doi.org/10.3390/nano14100888

Chicago/Turabian StyleWang, Lizhou, Yiting Wu, Jun Jiang, Shuai Tang, Yanlin Ke, Yu Zhang, and Shaozhi Deng. 2024. "Field-Emission Energy Distribution of Carbon Nanotube Film and Single Tube under High Current" Nanomaterials 14, no. 10: 888. https://doi.org/10.3390/nano14100888

APA StyleWang, L., Wu, Y., Jiang, J., Tang, S., Ke, Y., Zhang, Y., & Deng, S. (2024). Field-Emission Energy Distribution of Carbon Nanotube Film and Single Tube under High Current. Nanomaterials, 14(10), 888. https://doi.org/10.3390/nano14100888