The Plastic Deformation Mechanism in Nano-Polycrystalline Al/Mg Layered Composites: A Molecular Dynamics Study

Abstract

1. Introduction

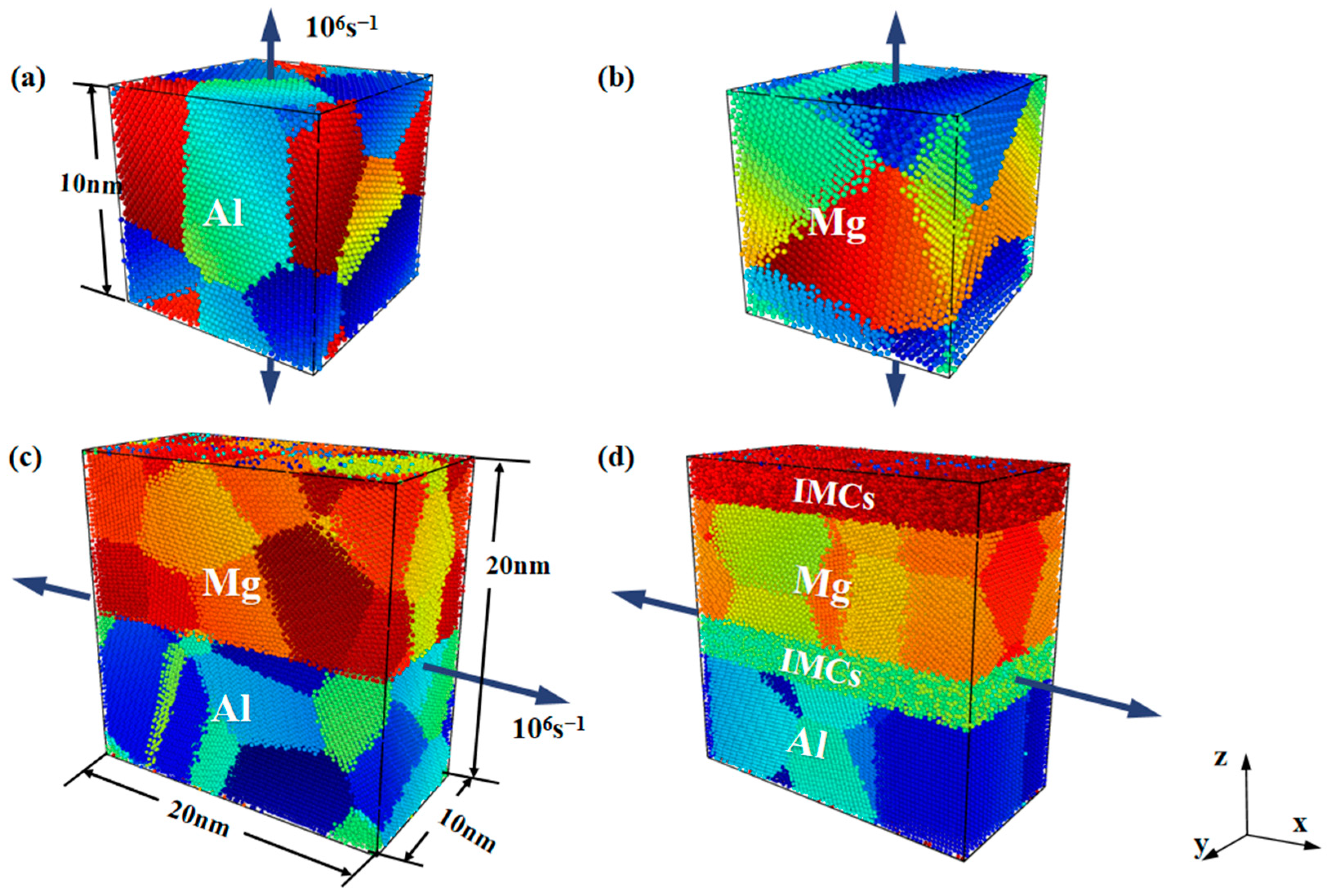

2. Materials and Methods

3. Results and Discussion

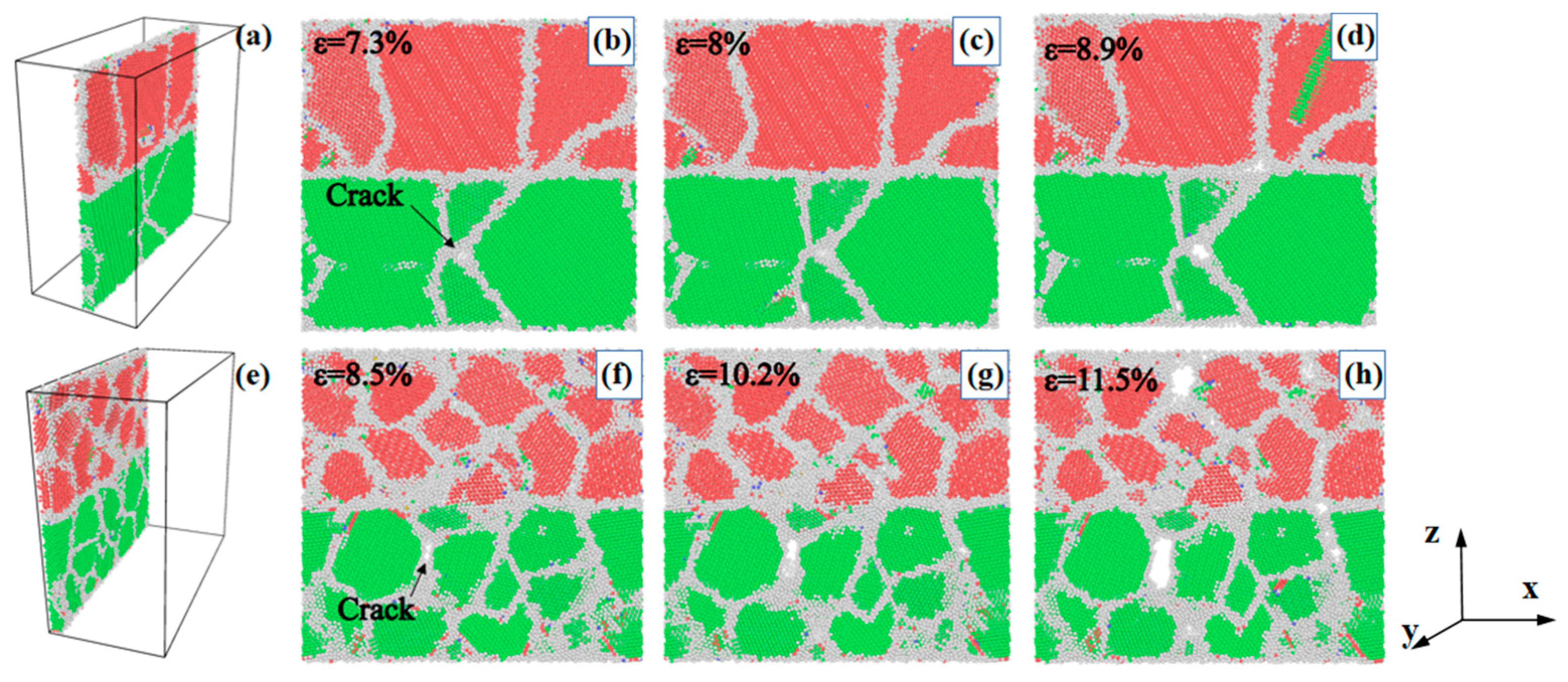

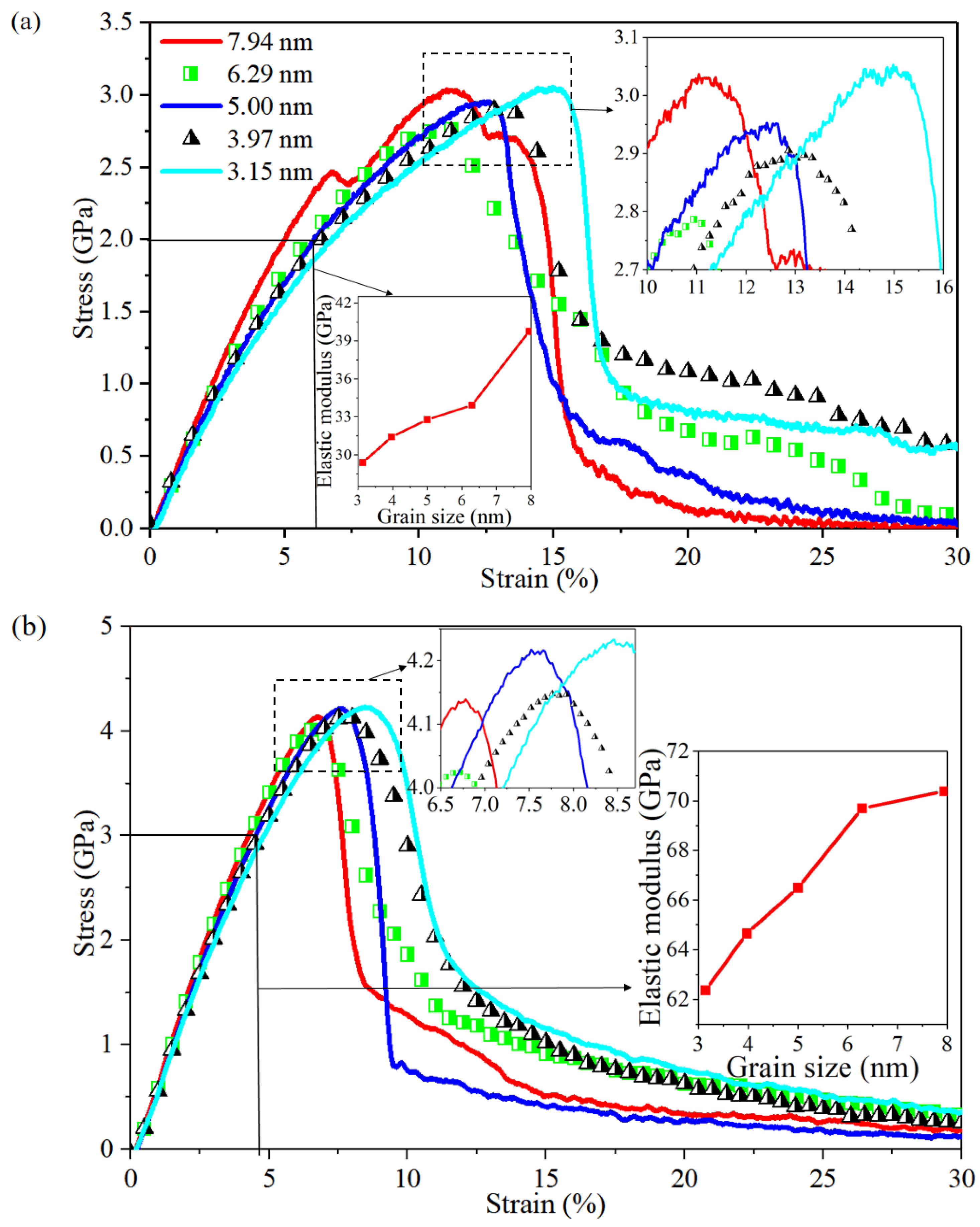

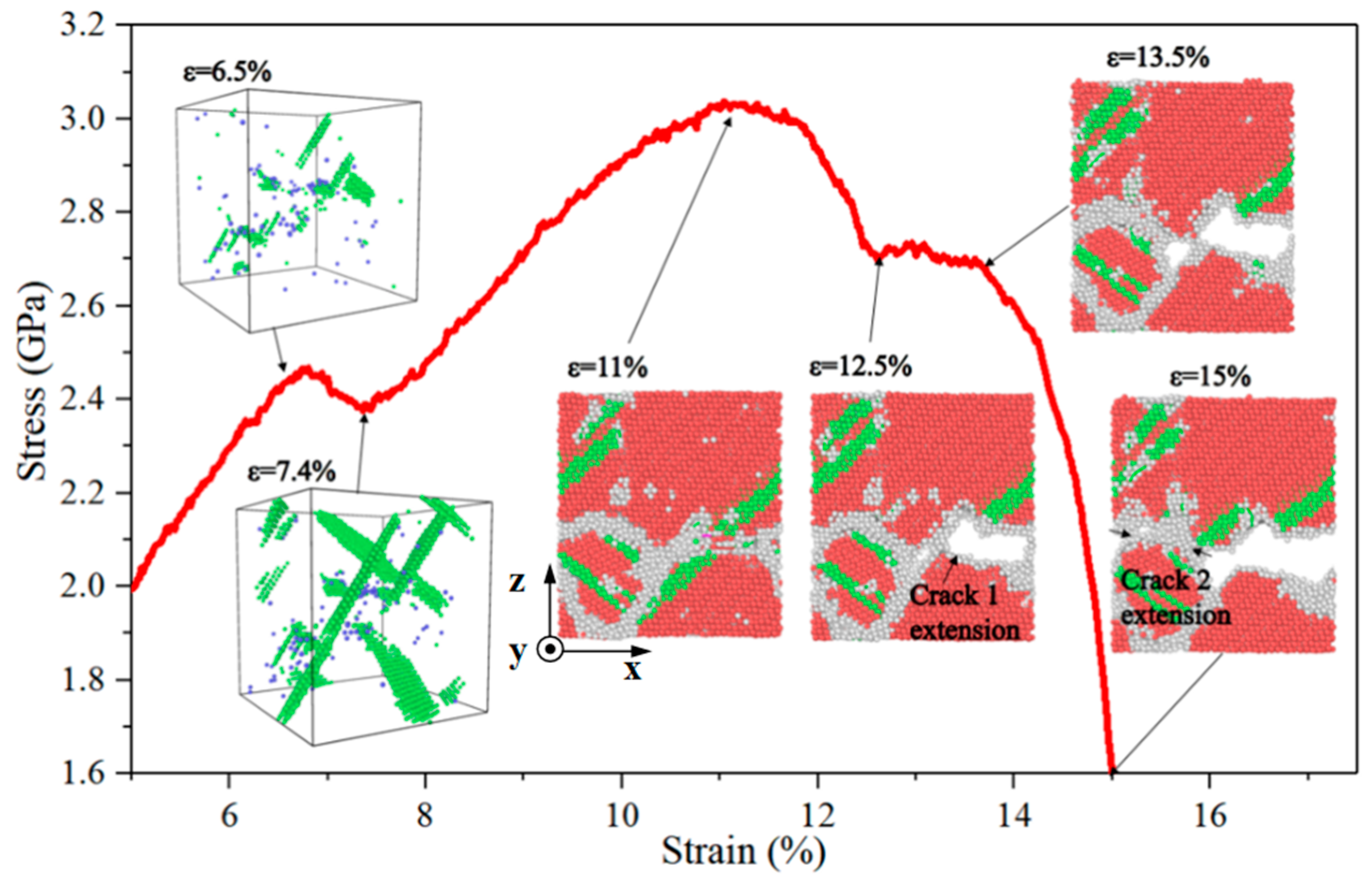

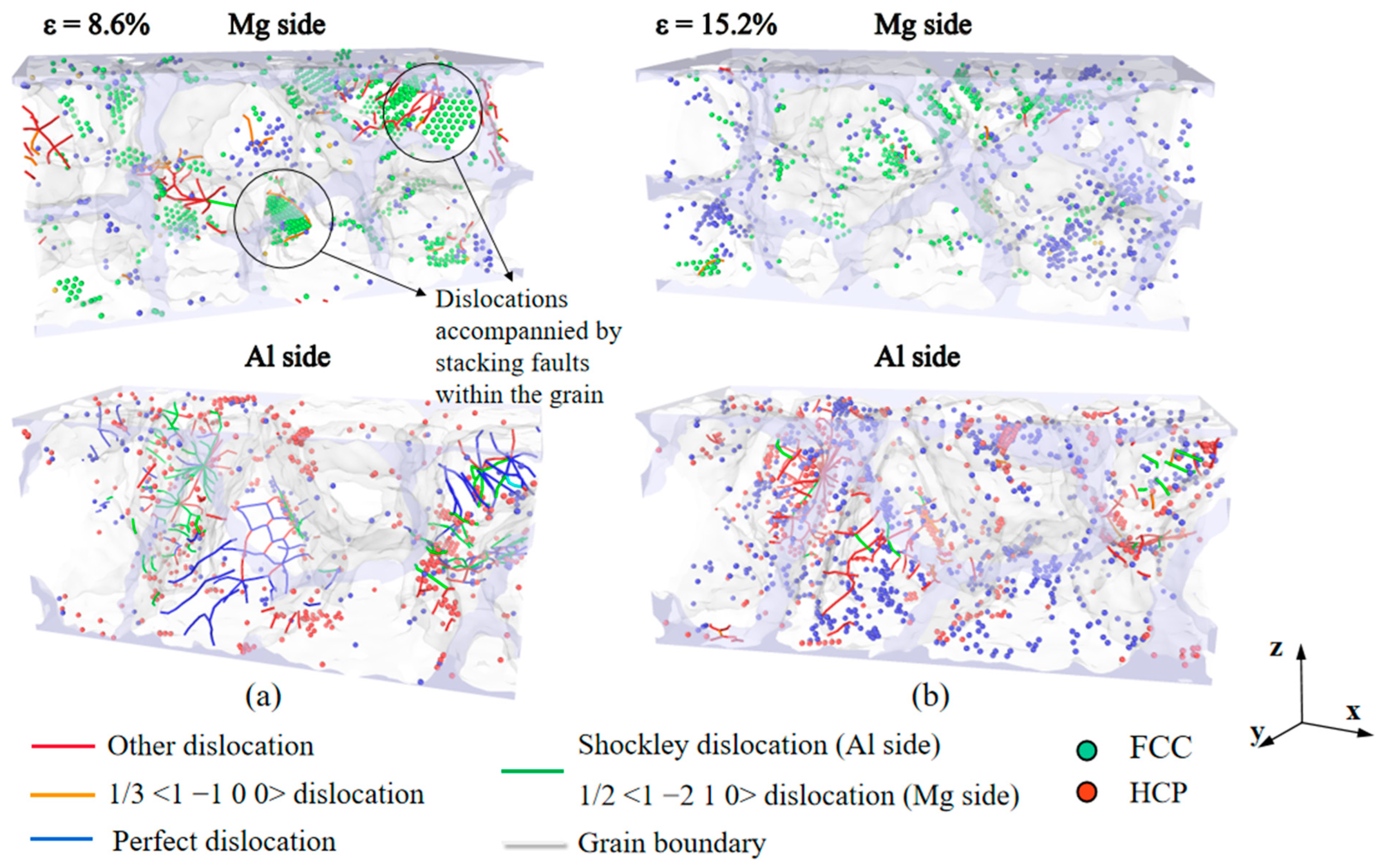

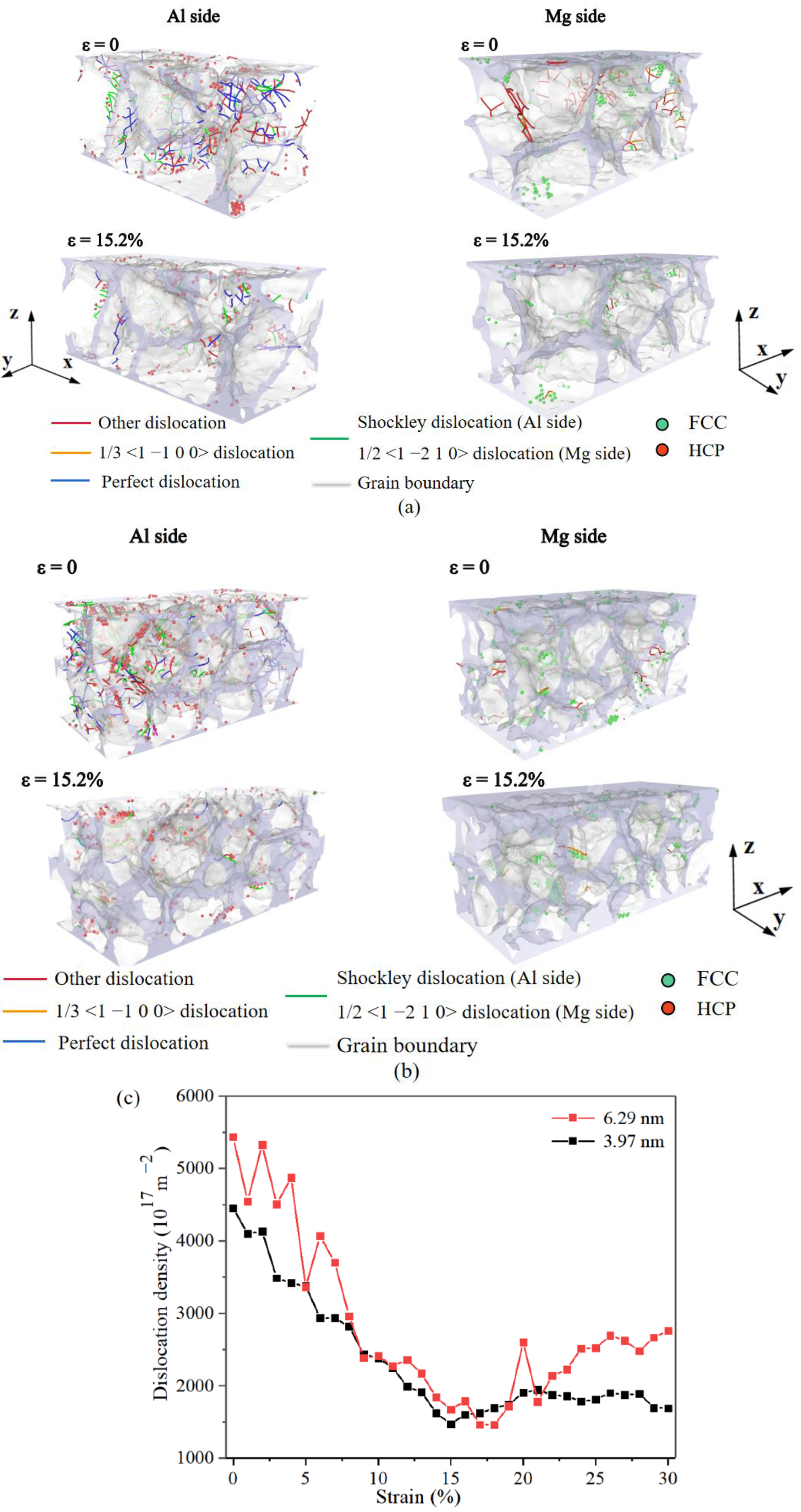

3.1. Mechanical Response and Structural Evolution of Al/Mg Composite with Varying Grain Sizes

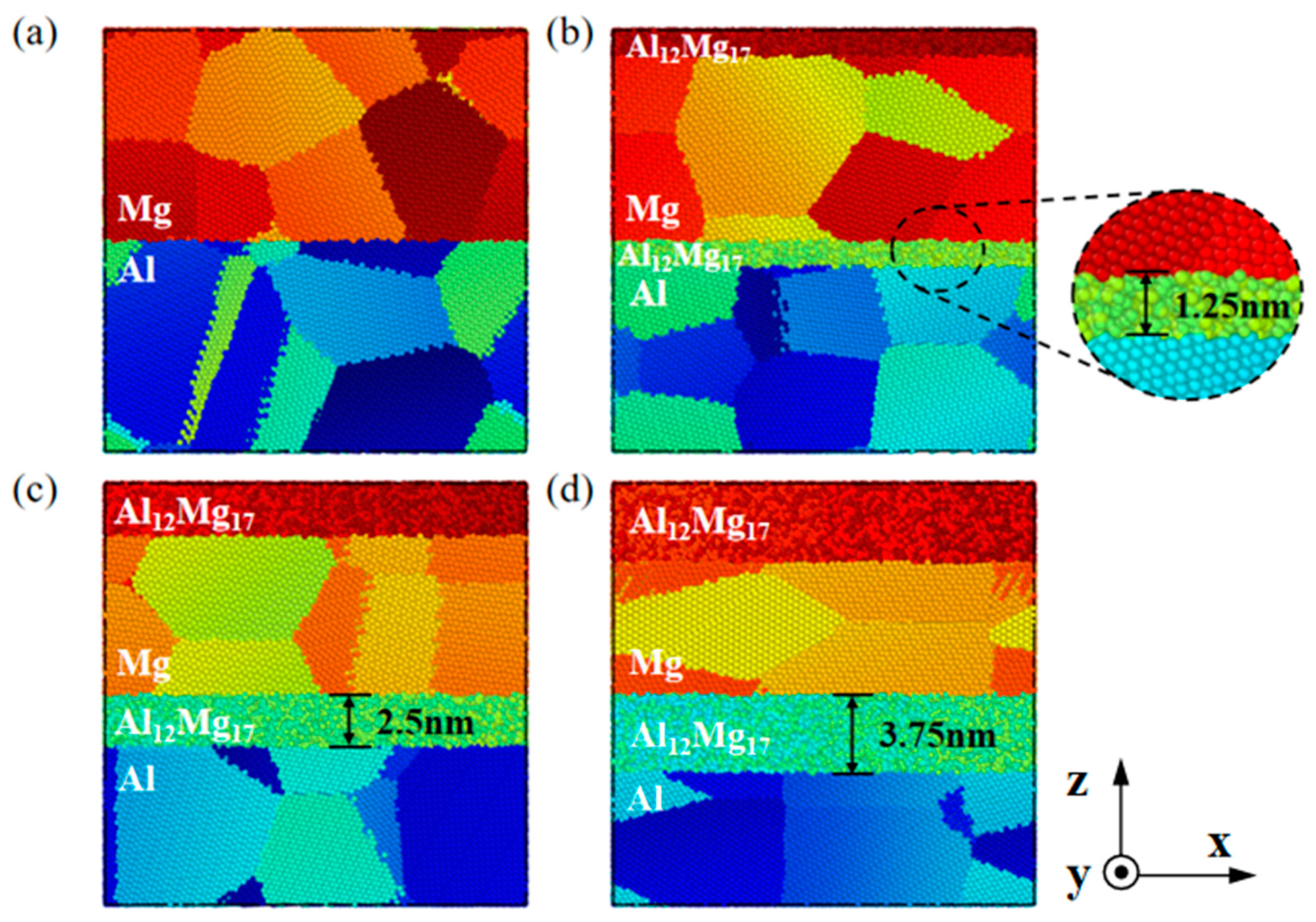

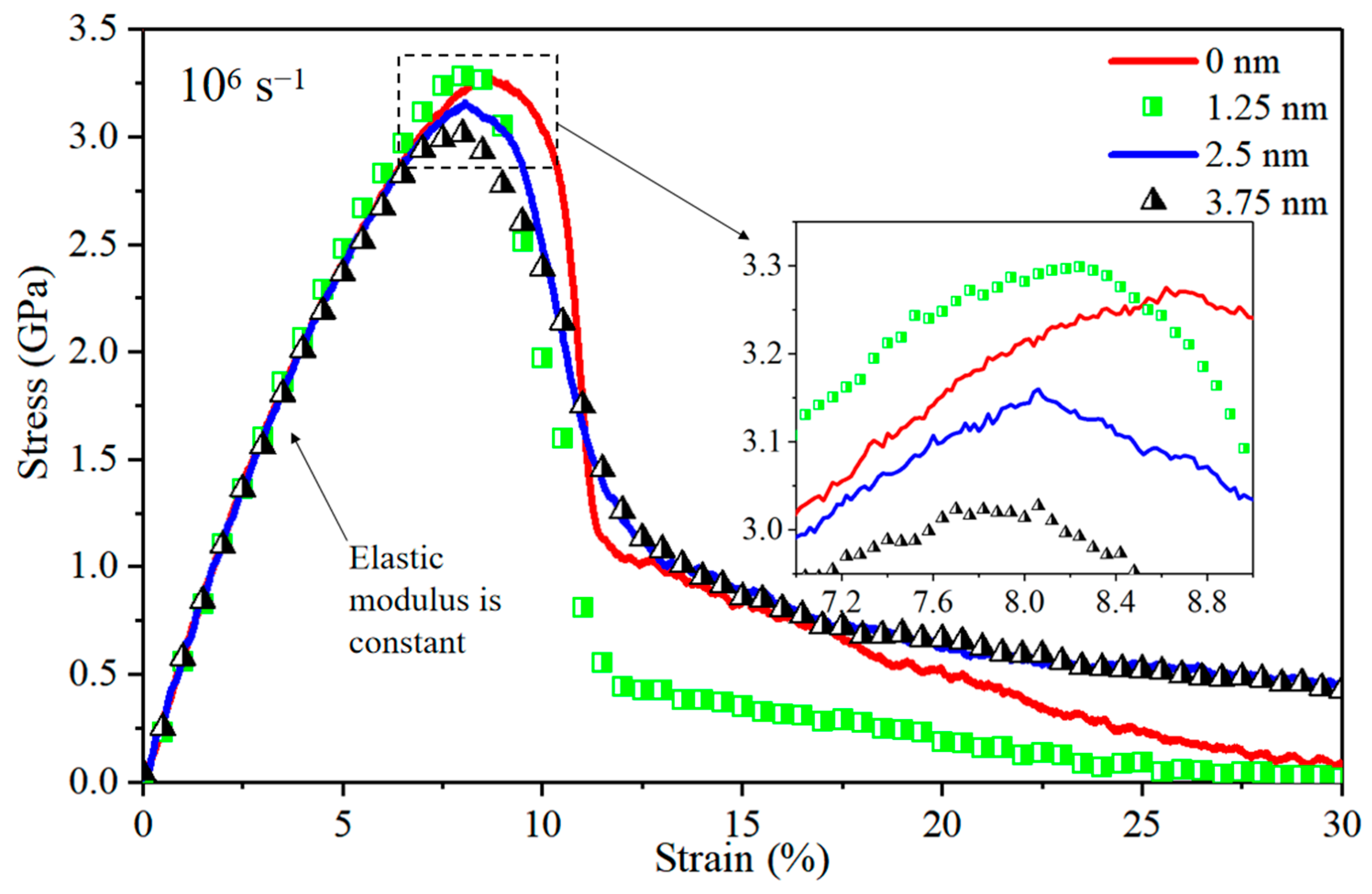

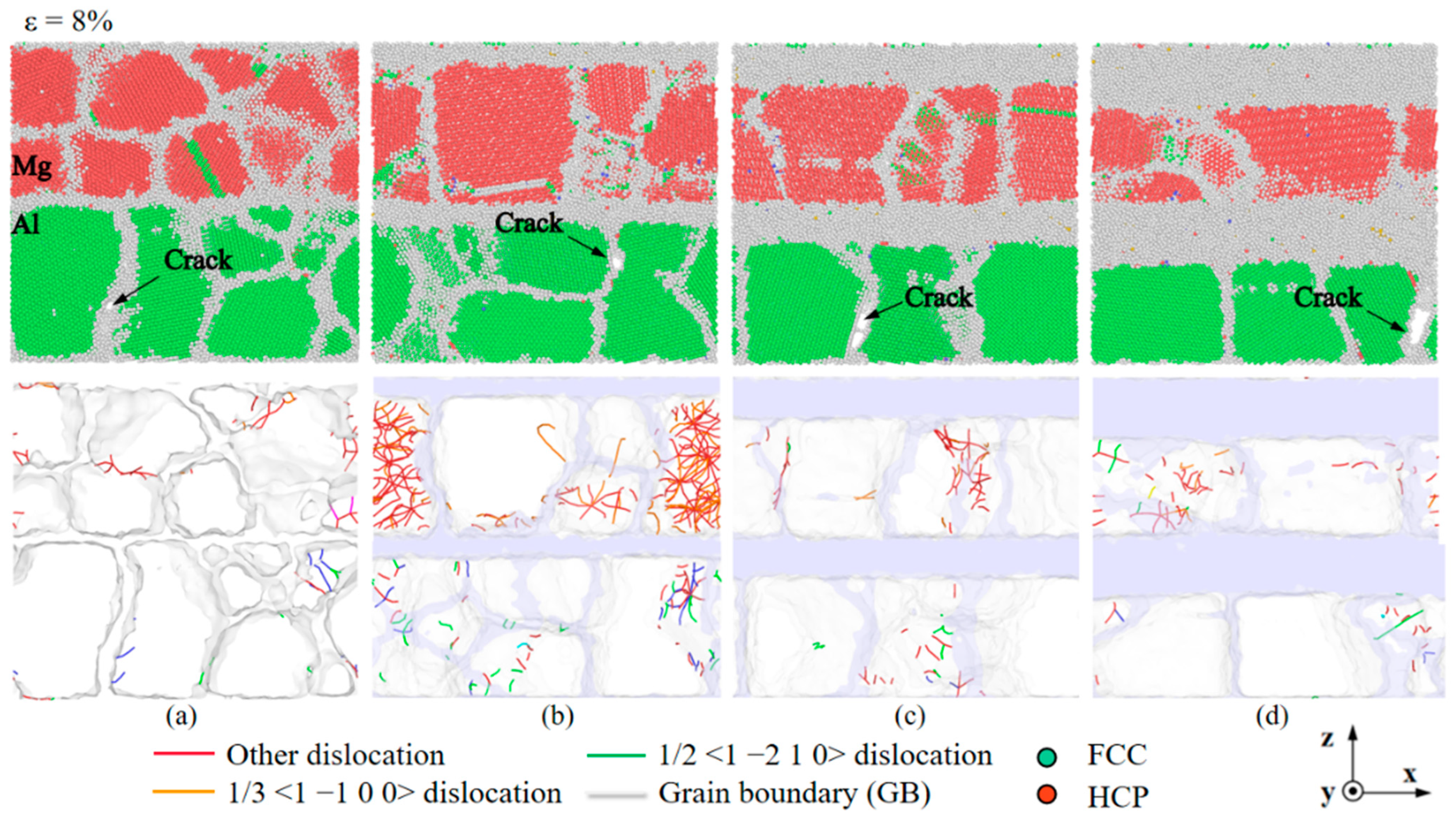

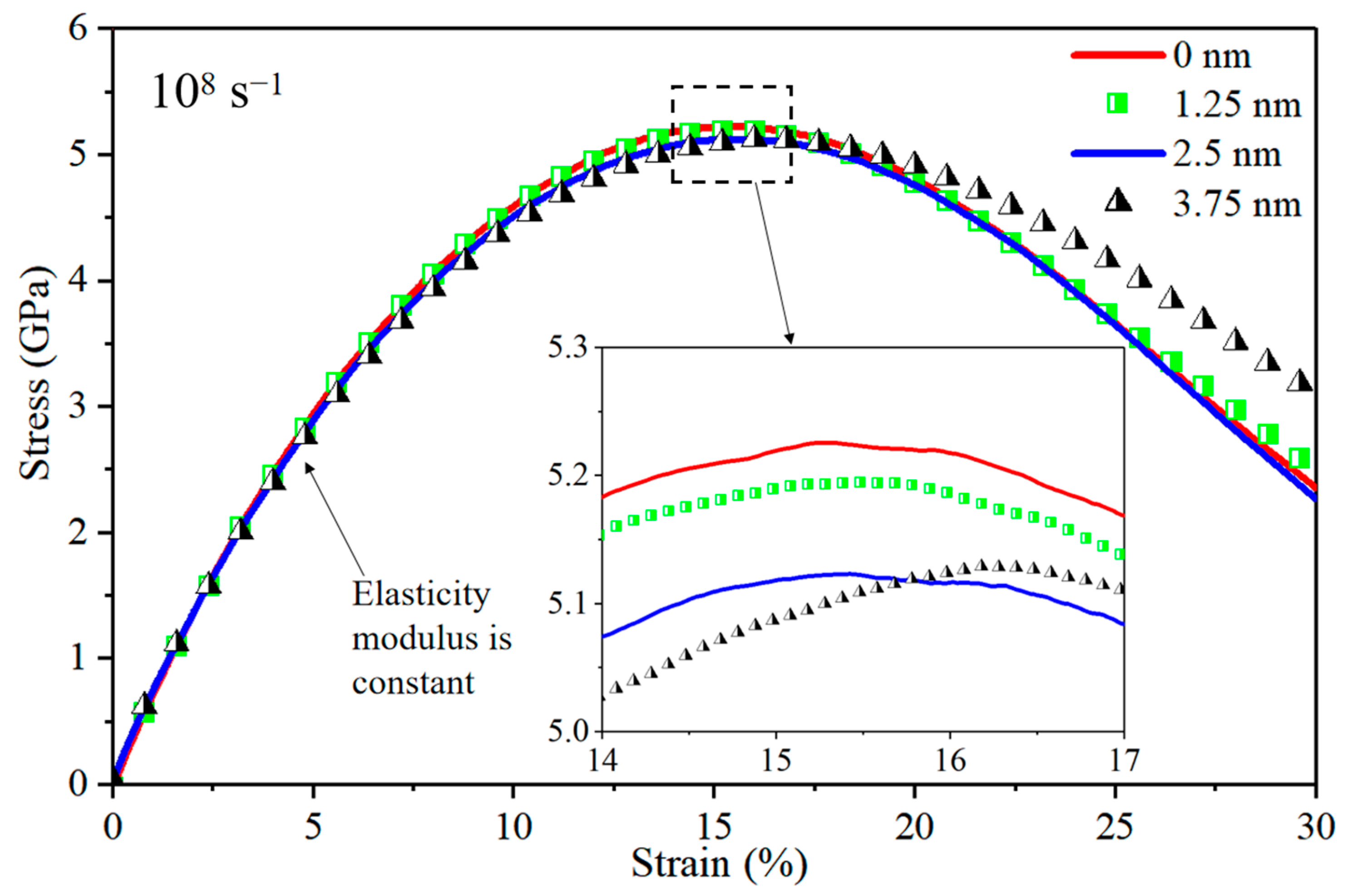

3.2. Influence of the Interlayer on the Plastic Deformation Behaviour

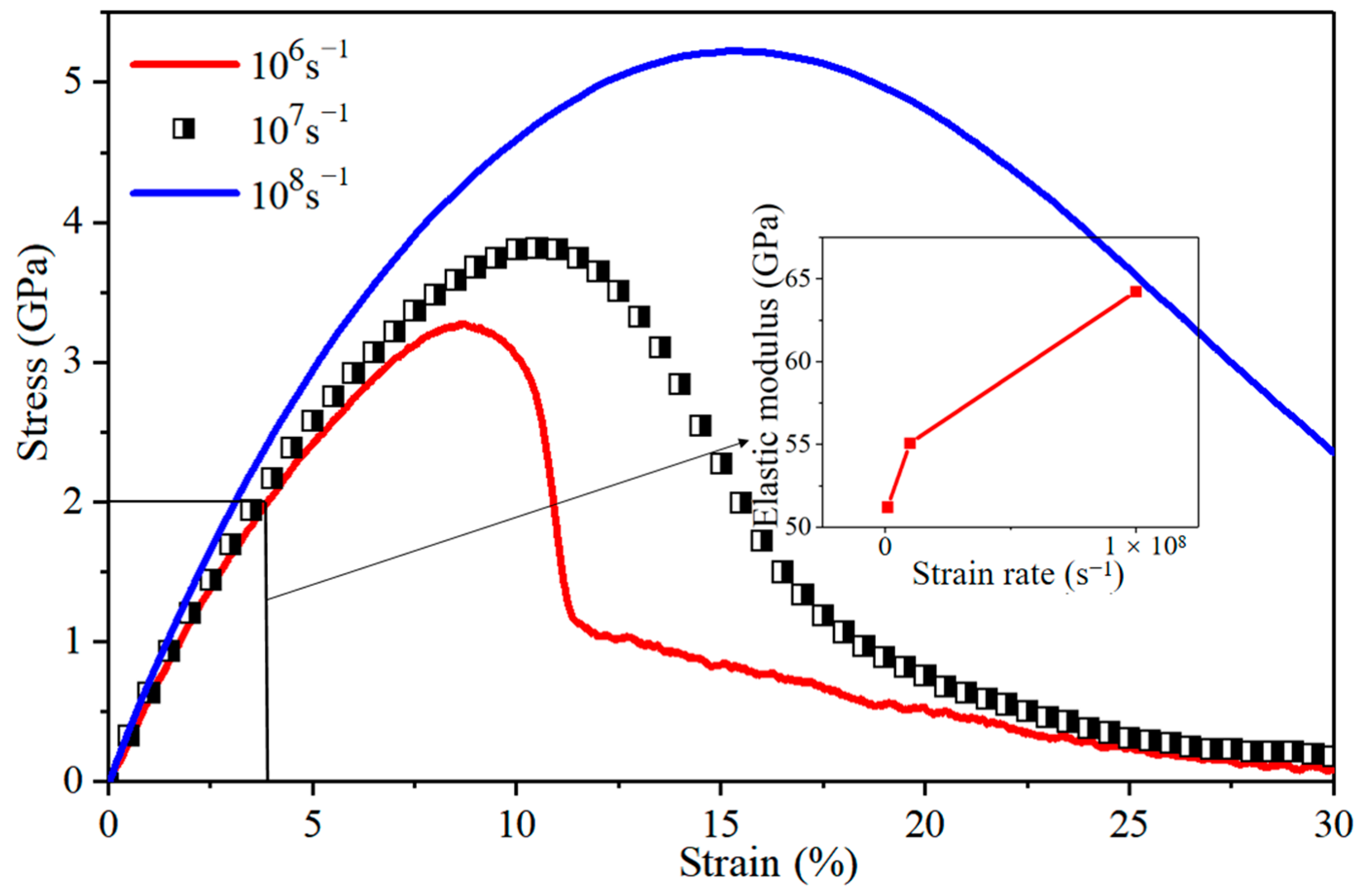

3.3. Strain-Rate-Induced Deformation Mechanisms in Al/Mg Composite

3.4. Combined Effect of Grain Size, Strain Rate, and Interlayer on Deformation Behaviour

4. Conclusions

- At the relatively low strain rate of 106 s−1, the relationship between grain size and strength in the Al/Mg multi-layered composites adheres to a Hall–Petch pattern. Stacking faults within large grains contribute to stress fluctuations in this scenario. Conversely, at a higher strain rate of 108 s−1, the elastic modulus of the composite demonstrates a continuous increase with the growing grain size.

- The interlayer of IMCs can hinder crack extension and reduce stress concentration, but excessive thickness of the IMCs can compromise the overall strength of the composite. The interlayer with a thickness of 1.25 nm demonstrates optimal enhancement in the tensile strength of the Al/Mg multi-layered composites. It is noteworthy that the reinforcing effect of the IMCs interlayer is weakened when the strain rate rises from 106 s−1 to 108 s−1.

- The Al/Mg multi-layered composites exhibit an increase in both the elastic modulus and yield stress as the strain rate elevates. At a strain rate of 106 s−1, internal grain deformation prevails as the dominant deformation mechanisms, while at 108 s−1, sliding along the GBs becomes the primary mechanism within the composite.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gu, D.; Shi, X.; Poprawe, R.; Bourell, D.L.; Setchi, R.; Zhu, J. Material-structure-performance integrated laser-metal additive manufacturing. Science 2021, 372, eabg1487. [Google Scholar] [CrossRef] [PubMed]

- Trost, C.O.; Žák, S.; Ruderes, K.; Hammer, R.; Rosc, J.; Krivec, T.; Schell, N.; Gänser, H.P.; Hohenwarter, A.; Cordill, M.J. Fatigue life assessment of metal foils in multifunctional composites via combined experiments and simulations. Compos. Part B Eng. 2023, 259, 110715. [Google Scholar] [CrossRef]

- Li, Z.; Cao, L.; Huo, M.; Jiang, Z. Evidence-based uncertainty quantification for bending properties of bimetal composites. Appl. Math. Model. 2023, 121, 59–74. [Google Scholar] [CrossRef]

- Samal, P.; Vundavilli, P.R.; Meher, A.; Mahapatra, M.M. Recent progress in aluminum metal matrix composites: A review on processing, mechanical and wear properties. J. Manuf. Process. 2020, 59, 131–152. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, C.; Pei, L.; Li, J.; Wang, R. The wrinkling and buckling of graphene induced by nanotwinned copper matrix: A molecular dynamics study. Nano Mater. Sci. 2021, 3, 95–103. [Google Scholar] [CrossRef]

- Li, Z.; Mo, H.; Tian, J.; Li, J.; Hu, X.; Xia, S.; Lu, Y.; Jiang, Z. A novel Ti/Al interpenetrating phase composite with enhanced mechanical properties. Mater. Lett. 2024, 357, 135723. [Google Scholar] [CrossRef]

- Gao, T.; Wang, X.; Liu, C.; Xiao, J.; Zhao, C. Experimental study on the influence of lamination parameters on the vibration characteristics of variable stiffness composite laminates. Compos. Struct. 2023, 312, 116882. [Google Scholar] [CrossRef]

- Liu, T.; Song, B.; Huang, G.; Jiang, X.; Guo, S.; Zheng, K.; Pan, F. Preparation, structure and properties of Mg/Al laminated metal composites fabricated by roll-bonding, a review. J. Magnes. Alloys 2022, 10, 2062–2093. [Google Scholar] [CrossRef]

- Lin, F.; Ren, M.; Wu, H.; Lu, Y.; Yang, M.; Chen, Z.; Jiang, Z. Characterisation of microstructure, microhardness and tribological properties of Al matrix hybrid nanocomposites reinforced with B4C and in-situ GNSs. Wear 2023, 522, 204691. [Google Scholar] [CrossRef]

- Wang, C.; Ding, K.; Song, Y.; Jia, X.; Lin, N.; Duan, J.a. Femtosecond laser patterned superhydrophobic surface with anisotropic sliding for droplet manipulation. Opt. Laser Technol. 2024, 168, 109829. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R. Optimizing electric conductivity of innovative Al-Cu laminated composites via thermomechanical treatment. Mater. Des. 2022, 215, 110441. [Google Scholar] [CrossRef]

- Xing, B.-h.; Huang, T.; Song, K.-x.; Xu, L.-j.; Xiang, N.; Chen, X.-w.; Chen, F.-x. Effect of electric current on formability and microstructure evolution of Cu/Al laminated composite. J. Mater. Res. Technol. 2022, 21, 1128–1140. [Google Scholar] [CrossRef]

- Lu, W.; Zhang, Y.; Guo, Z.; Liu, Y.; Yu, D. Double laser welding of TC4 alloy and 304 stainless steel using an explosion welded composite plate as an interlayer. Mater. Lett. 2023, 330, 133382. [Google Scholar] [CrossRef]

- Mo, T.; Xiao, H.; Lin, B.; Li, W.; Wang, P.; Ma, K. Improvement of mechanical properties of tri-metallic 7075Al/1060Al/304 SS composite via collaborative strengthening behavior. Mater. Sci. Eng. A 2022, 857, 144072. [Google Scholar] [CrossRef]

- Bak, J.H.; Kim, Y.D.; Hong, S.S.; Lee, B.Y.; Lee, S.R.; Jang, J.H.; Kim, M.; Char, K.; Hong, S.; Park, Y.D. High-frequency micromechanical resonators from aluminium–carbon nanotube nanolaminates. Nat. Mater. 2008, 7, 459–463. [Google Scholar] [CrossRef]

- Lin, F.; Ren, M.; Jia, F.; Huo, M.; Yang, M.; Chen, Z.; Jiang, Z. Achieving balanced strength-ductility of heterostructured TiC/graphene nanoplatelets (GNPs) reinforced Al matrix composites by tuning TiC-to-GNPs ratio. Compos. Commun. 2023, 38, 101529. [Google Scholar] [CrossRef]

- Cao, Y.; Ni, S.; Liao, X.; Song, M.; Zhu, Y. Structural evolutions of metallic materials processed by severe plastic deformation. Mater. Sci. Eng. R Rep. 2018, 133, 1–59. [Google Scholar] [CrossRef]

- Zeng, L.F.; Gao, R.; Fang, Q.F.; Wang, X.P.; Xie, Z.M.; Miao, S.; Hao, T.; Zhang, T. High strength and thermal stability of bulk Cu/Ta nanolamellar multilayers fabricated by cross accumulative roll bonding. Acta Mater. 2016, 110, 341–351. [Google Scholar] [CrossRef]

- Kumar, D.; Phanden, R.K.; Thakur, L. A review on environment friendly and lightweight Magnesium-Based metal matrix composites and alloys. Mater. Today Proc. 2021, 38, 359–364. [Google Scholar] [CrossRef]

- Wang, J.; Guan, F.; Jiang, W.; Li, G.; Zhang, Z.; Fan, Z. The role of vibration time in interfacial microstructure and mechanical properties of Al/Mg bimetallic composites produced by a novel compound casting. J. Mater. Res. Technol. 2021, 15, 3867–3879. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Jiang, S.; Bai, L.; An, Q.; Yan, Z.; Li, W.; Ming, K.; Zheng, S. Dependence of Plastic Stability on 3D Interface Layer in Nanolaminated Materials. Acta Metall. Sin. (Engl. Lett.) 2022, 35, 1759–1764. [Google Scholar] [CrossRef]

- Li, Z.; Lin, Y.C.; Zhang, L.; Zheng, J.; Zhao, J.; Wang, R.; Jiang, Z. In-situ investigation on tensile properties of a novel Ti/Al composite sheet. Int. J. Mech. Sci. 2022, 231, 107592. [Google Scholar] [CrossRef]

- Yan, Z.; Liu, Z.; Yao, B.; An, Q.; Zhang, R.; Zheng, S. Effect of amorphous complexions on plastic deformation of nanolayered composites. Scr. Mater. 2023, 231, 115470. [Google Scholar] [CrossRef]

- Xiangyu, G.; Wenquan, N.; Wenle, P.; Zhiquan, H.; Tao, W.; Lifeng, M. Deformation behavior and bonding properties of Cu/Al laminated composite plate by corrugated cold roll bonding. J. Mater. Res. Technol. 2023, 22, 3207–3217. [Google Scholar] [CrossRef]

- Wang, X.; Meng, B.; Han, J.; Wan, M. Effect of grain size on superplastic deformation behavior of Zn-0.033 Mg alloy. Mater. Sci. Eng. A 2023, 870, 144877. [Google Scholar] [CrossRef]

- Savaedi, Z.; Mirzadeh, H.; Aghdam, R.M.; Mahmudi, R. Effect of grain size on the mechanical properties and bio-corrosion resistance of pure magnesium. J. Mater. Res. Technol. 2022, 19, 3100–3109. [Google Scholar] [CrossRef]

- Fu, Q.; Wang, C.; Wu, C.; Wu, Y.; Dai, X.; Jin, W.; Guo, B.; Song, M.; Li, W.; Yu, Z. Investigating the combined effects of wide stacking faults and grain size on the mechanical properties and corrosion resistance of high-purity Mg. J. Alloys Compd. 2022, 927, 167018. [Google Scholar] [CrossRef]

- Sun, J.L.; Trimby, P.W.; Yan, F.K.; Liao, X.Z.; Tao, N.R.; Wang, J.T. Grain size effect on deformation twinning propensity in ultrafine-grained hexagonal close-packed titanium. Scr. Mater. 2013, 69, 428–431. [Google Scholar] [CrossRef]

- Liu, X. Investigation on the Mechanical Properties of Polycrystalline Mg Using Molecular Dynamics Simulation. Comput. Model. Eng. Sci. 2022, 131, 919–927. [Google Scholar] [CrossRef]

- Chandiran, E.; Ogawa, Y.; Ueji, R.; Somekawa, H. An inverse Hall-Petch relationship during room-temperature compression of commercially pure magnesium. J. Alloys Compd. 2023, 930, 167443. [Google Scholar] [CrossRef]

- Krywopusk, N.M.; Kecskes, L.J.; Weihs, T.P. The effect of strain rate on the microstructural evolution of pure Mg during ECAE. Mater. Charact. 2021, 178, 111209. [Google Scholar] [CrossRef]

- Lin, Z.; Pang, W.; Xin, K.; Feng, X.; Yin, F. The effect of loading strain rates on deformation behavior of Cu/Fe composite. Phys. Lett. A 2021, 388, 127070. [Google Scholar] [CrossRef]

- Bian, X.; Wang, A.; Xie, J.; Liu, P.; Mao, Z.; Chen, Y.; Liu, Z.; Gao, Y. Atomic-scale deformation mechanisms of nano-polycrystalline Cu/Al layered composites: A molecular dynamics simulation. J. Mater. Res. Technol. 2023, 24, 1177–1189. [Google Scholar] [CrossRef]

- Ji, C.; Cai, X.; Zhou, Z.; Dong, F.; Liu, S.; Gao, B. Effects of intermetallic compound layer thickness on the mechanical properties of silicon-copper interface. Mater. Des. 2021, 212, 110251. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, J.; Jia, F.; Lu, Y.; Zhang, Q.; Jiao, S.; Jiang, Z. Analysis of flow behaviour and strain partitioning mechanism of bimetal composite under hot tensile conditions. Int. J. Mech. Sci. 2020, 169, 105317. [Google Scholar] [CrossRef]

- Li, J.; Lu, C.; Pei, L.; Zhang, C.; Wang, R.; Tieu, K. Atomistic simulations of hydrogen effects on tensile deformation behaviour of [0 0 1] twist grain boundaries in nickel. Comput. Mater. Sci. 2019, 159, 12–23. [Google Scholar] [CrossRef]

- Xue, C.; Li, S.; Chu, Z.; Yang, Q.; Li, Y.; Ma, L.; Tuo, L. Molecular dynamics study on the effect of temperature on HCP→FCC phase transition of magnesium alloy. J. Magnes. Alloys 2022, 11, 3749–3764. [Google Scholar] [CrossRef]

- Yang, W.; Ayoub, G.; Salehinia, I.; Mansoor, B.; Zbib, H. Multiaxial tension/compression asymmetry of Ti/TiN nano laminates: MD investigation. Acta Mater. 2017, 135, 348–360. [Google Scholar] [CrossRef]

- Zhang, R.F.; Germann, T.C.; Liu, X.Y.; Wang, J.; Beyerlein, I.J. Layer size effect on the shock compression behavior of fcc–bcc nanolaminates. Acta Mater. 2014, 79, 74–83. [Google Scholar] [CrossRef]

- Tian, Y.-Y.; Li, J.; Hu, Z.-Y.; Wang, Z.-P.; Fang, Q.-H. Molecular dynamics study of plastic deformation mechanism in Cu/Ag multilayers. Chin. Phys. B 2017, 26, 126802. [Google Scholar] [CrossRef]

- Hirel, P. Atomsk: A tool for manipulating and converting atomic data files. Comput. Phys. Commun. 2015, 197, 212–219. [Google Scholar] [CrossRef]

- Nouri, N.; Ziaei-Rad, V.; Ziaei-Rad, S. An approach for simulating microstructures of polycrystalline materials. Comput. Mech. 2012, 52, 181–192. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Stukowski, A.; Bulatov, V.V.; Arsenlis, A. Automated identification and indexing of dislocations in crystal interfaces. Model. Simul. Mater. Sci. Eng. 2012, 20, 085007. [Google Scholar] [CrossRef]

- Shao, W.; Wu, S.; Yang, W.; He, J.; Lu, S.; Xu, D.; Chen, J. Effect of modulation period on microstructure and mechanical properties of (AlSiTiVNbCr)N/(AlSiTiVNbCr)CN nano-multilayer films. Vacuum 2023, 207, 111660. [Google Scholar] [CrossRef]

- Lu, Y.Y.; Kotoka, R.; Ligda, J.P.; Cao, B.B.; Yarmolenko, S.N.; Schuster, B.E.; Wei, Q. The microstructure and mechanical behavior of Mg/Ti multilayers as a function of individual layer thickness. Acta Mater. 2014, 63, 216–231. [Google Scholar] [CrossRef]

- Naoki, M.; Takanori, H.; Susumu, O. Molecular dynamics study of interactions between prismatic <a> slip and oxygen-segregated twin boundaries in α-Ti. Materialia 2022, 21, 101363. [Google Scholar] [CrossRef]

- Ackland, G.J. Theoretical study of titanium surfaces and defects with a new many-body potential. Philos. Mag. A 1992, 66, 917–932. [Google Scholar] [CrossRef]

- Srinivasan, P.; Nicola, L.; Simone, A. Modeling pseudo-elasticity in NiTi: Why the MEAM potential outperforms the EAM-FS potential. Comput. Mater. Sci. 2017, 134, 145–152. [Google Scholar] [CrossRef]

- Kim, Y.-M.; Kim, N.J.; Lee, B.-J. Atomistic Modeling of pure Mg and Mg–Al systems. Calphad 2009, 33, 650–657. [Google Scholar] [CrossRef]

- Jang, H.-S.; Lee, J.-K.; Tapia, A.J.S.F.; Kim, N.J.; Lee, B.-J. Activation of non-basal <c + a> slip in multicomponent Mg alloys. J. Magnes. Alloys 2022, 10, 585–597. [Google Scholar] [CrossRef]

- Lei, J.; Ma, L.; Cai, Z.; Jia, W.; Zhi, C.; Yuan, Y.; Pan, H.; Xie, H. Interfacial fracture characteristics of Mg/Al composite plates with different thickness ratios by asymmetrical rolling with differential temperature rolls. Mater. Sci. Eng. A 2023, 869, 144764. [Google Scholar] [CrossRef]

- Ruestes, C.; Bertolino, G.; Ruda, M.; Farkas, D.; Bringa, E. Grain size effects in the deformation of [0 0 0 1] textured nanocrystalline Zr. Scr. Mater. 2014, 71, 9–12. [Google Scholar] [CrossRef]

- Masumura, R.A. Yield stress of fine grained materials. Acta Mater. 1998, 46, 4527–4534. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Shen, T.; Hu, X.; Zhang, L.; Jia, X.; Li, J.; Zhang, C. The Plastic Deformation Mechanism in Nano-Polycrystalline Al/Mg Layered Composites: A Molecular Dynamics Study. Nanomaterials 2024, 14, 114. https://doi.org/10.3390/nano14010114

Li Z, Shen T, Hu X, Zhang L, Jia X, Li J, Zhang C. The Plastic Deformation Mechanism in Nano-Polycrystalline Al/Mg Layered Composites: A Molecular Dynamics Study. Nanomaterials. 2024; 14(1):114. https://doi.org/10.3390/nano14010114

Chicago/Turabian StyleLi, Zhou, Tong Shen, Xiao Hu, Lu Zhang, Xianshi Jia, Jiaqing Li, and Che Zhang. 2024. "The Plastic Deformation Mechanism in Nano-Polycrystalline Al/Mg Layered Composites: A Molecular Dynamics Study" Nanomaterials 14, no. 1: 114. https://doi.org/10.3390/nano14010114

APA StyleLi, Z., Shen, T., Hu, X., Zhang, L., Jia, X., Li, J., & Zhang, C. (2024). The Plastic Deformation Mechanism in Nano-Polycrystalline Al/Mg Layered Composites: A Molecular Dynamics Study. Nanomaterials, 14(1), 114. https://doi.org/10.3390/nano14010114