Magnetoelectric Coupling in Room Temperature Multiferroic Ba2EuFeNb4O15/BaFe12O19 Epitaxial Heterostructures Grown by Laser Ablation

Abstract

1. Introduction

2. Materials and Methods

3. Results

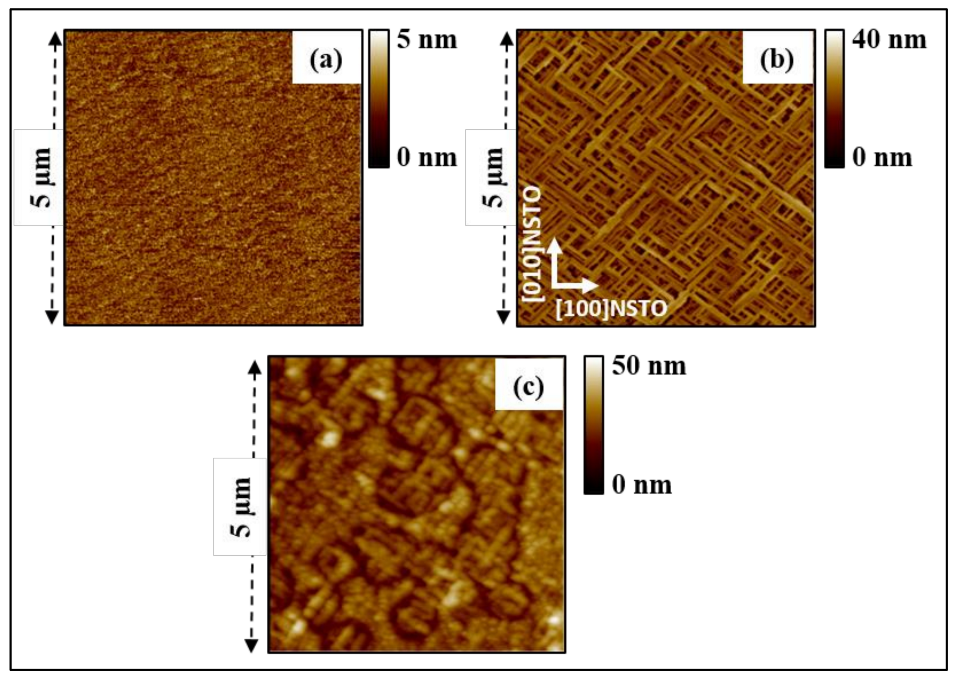

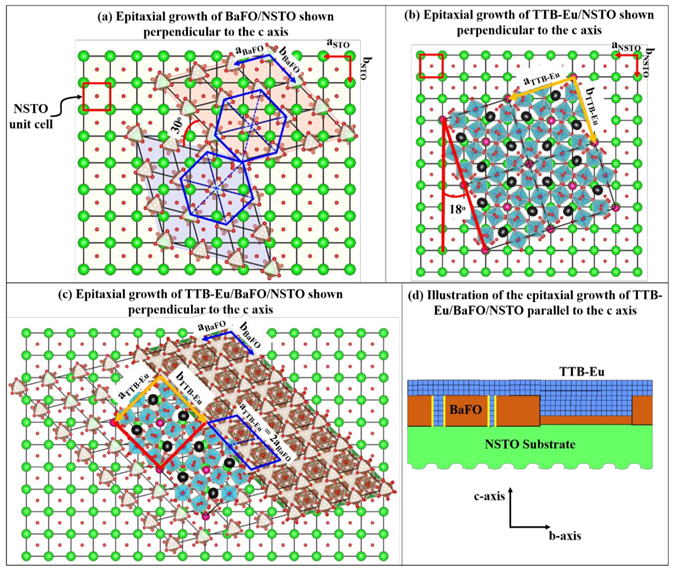

3.1. Topographic and Structural Characterization

3.1.1. Epitaxial Growth of BaFO and TTB-Eu on NSTO (001) Substrate

3.1.2. Epitaxial Growth of TTB-Eu on BaFO Layer

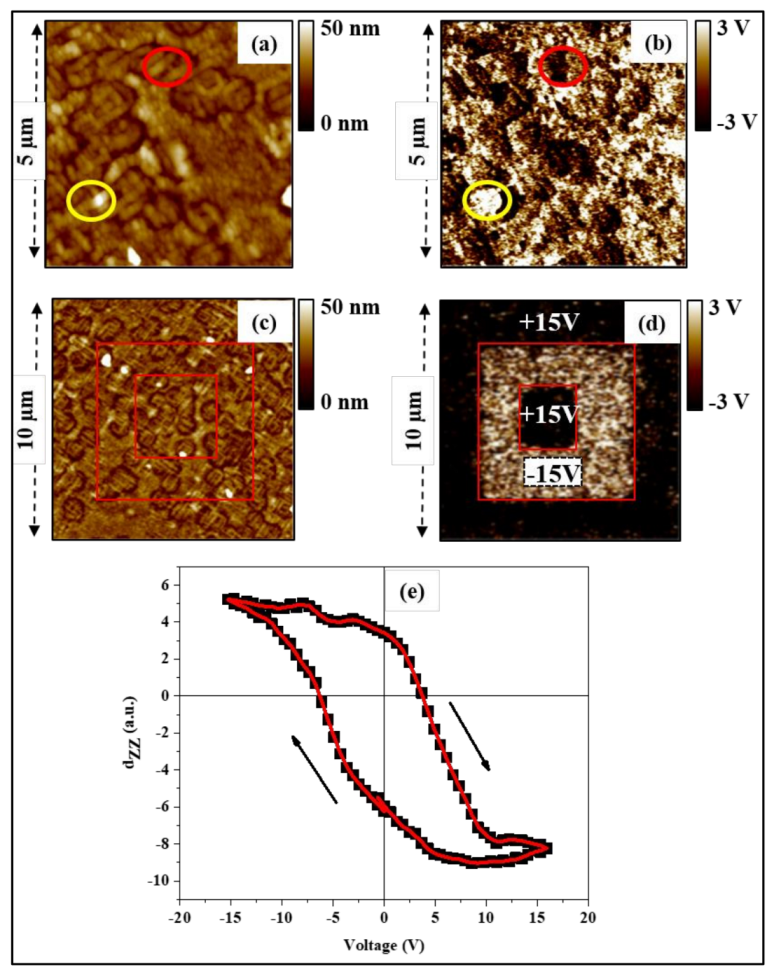

3.2. Multiferroic Properties

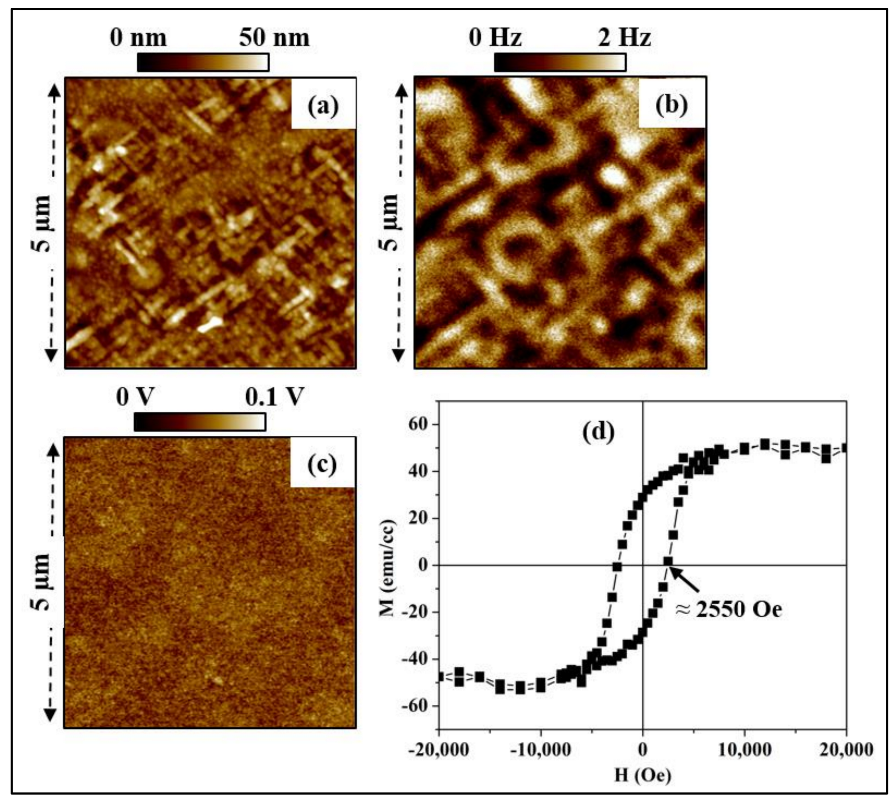

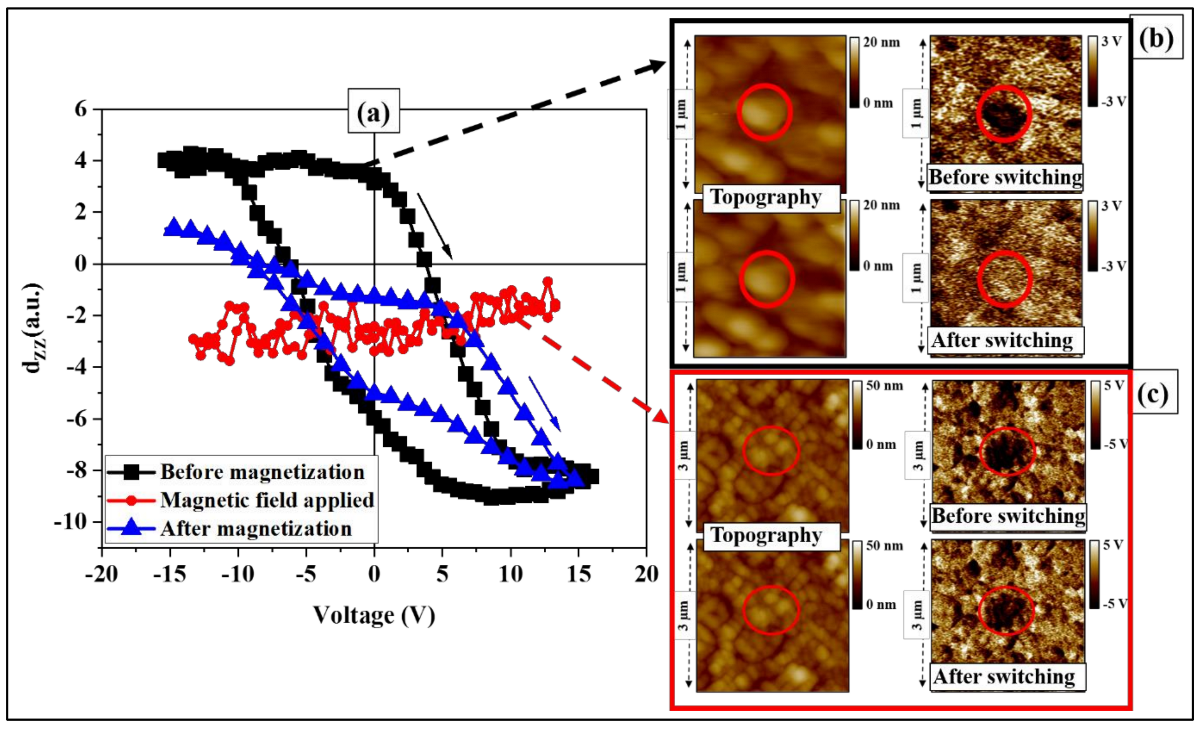

3.3. Magnetoelectric Coupling

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eerenstein, W.; Mathur, N.D.; Scott, J.F. Multiferroic and magnetoelectric materials. Nature 2006, 442, 759–765. [Google Scholar] [CrossRef] [PubMed]

- Martin, L.W.; Crane, S.P.; Chu, Y.-H.; Holcomb, M.; Gajek, M.; Huijben, M.; Yang, C.-H.; Balke, N.; Ramesh, R. Multiferroics and magnetoelectrics: Thin films and nanostructures. J. Phys. Condens. Matter 2008, 20, 434220. [Google Scholar] [CrossRef]

- Khomskii, D. Classifying multiferroics: Mechanisms and effects. Physics 2009, 2, 20. [Google Scholar] [CrossRef]

- Spaldin, N.A.; Cheong, S.-W.; Ramesh, R. Multiferroics: Past, present, and future. Phys. Today 2010, 63, 38–43. [Google Scholar] [CrossRef]

- Scott, J.F. Applications of magnetoelectrics. J. Mater. Chem. 2012, 22, 4567–4574. [Google Scholar] [CrossRef]

- Ramesh, R.; Spaldin, N.A. Multiferroics: Progress and prospects in thin films. Nat. Mater. 2007, 6, 21–29. [Google Scholar] [CrossRef]

- Zurbuchen, M.A.; Wu, T.; Saha, S.; Mitchell, J.; Streiffer, S.K. Multiferroic composite ferroelectric-ferromagnetic films. Appl. Phys. Lett. 2005, 87, 232908. [Google Scholar] [CrossRef]

- Nan, C.-W.; Bichurin, M.I.; Dong, S.; Viehland, D.; Srinivasan, G. Multiferroic magnetoelectric composites: Historical perspective, status, and future directions. J. Appl. Phys. 2008, 103, 031101. [Google Scholar] [CrossRef]

- Palneedi, H.; Annapureddy, V.; Priya, S.; Ryu, J. Status and Perspectives of Multiferroic Magnetoelectric Composite Materials and Applications. Actuators 2016, 5, 9. [Google Scholar] [CrossRef]

- Kleemann, W. Multiferroic and magnetoelectric nanocomposites for data processing. J. Phys. D Appl. Phys. 2017, 50, 223001. [Google Scholar] [CrossRef]

- Sreenivasulu, G.; Qu, P.; Petrov, V.; Qu, H.; Srinivasan, G. Sensitivity Enhancement in Magnetic Sensors Based on Ferroelectric-Bimorphs and Multiferroic Composites. Sensors 2016, 16, 262. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Viehland, D. Magnetoelectrics for magnetic sensor applications: Status, challenges and perspectives. Mater. Today 2014, 17, 269–275. [Google Scholar] [CrossRef]

- Kozlovskiy, A.; Zdorovets, M. Effect of doping of Ce4+/3+ on optical, strength and shielding properties of (0.5-x)TeO2-0.25MoO-0.25Bi2O3-xCeO2 glasses. Mater. Chem. Phys. 2021, 263, 124444. [Google Scholar] [CrossRef]

- Almessiere, M.A.; Slimani, Y.; Algarou, N.A.; Vakhitov, M.G.; Klygach, D.S.; Baykal, A.; Zubar, T.I.; Trukhanov, S.V.; Trukhanov, A.V.; Attia, H.; et al. Tuning the Structure, Magnetic, and High Frequency Properties of Sc-Doped Sr0.5Ba0.5ScxFe12-xO19/NiFe2O4 Hard/Soft Nanocomposites. Adv. Electron. Mater. 2021, 8, 2101124. [Google Scholar] [CrossRef]

- Bibes, M.; Barthélémy, A. Towards a magnetoelectric memory. Nat. Mater. 2008, 7, 425–426. [Google Scholar] [CrossRef]

- Hu, J.-M.; Nan, T.; Sun, N.X.; Chen, L.-Q. Multiferroic magnetoelectric nanostructures for novel device applications. MRS Bull. 2015, 40, 728–735. [Google Scholar] [CrossRef]

- Josse, M.; Bidault, O.; Roulland, F.; Castel, E.; Simon, A.; Michau, D.; Von der Mühll, R.; Nguyen, O.; Maglione, M. The Ba2LnFeNb4O15 “tetragonal tungsten bronze”: Towards RT composite multiferroics. Solid State Sci. 2009, 11, 1118–1123. [Google Scholar] [CrossRef]

- Roulland, F.; Josse, M.; Castel, E.; Maglione, M. Influence of ceramic process and Eu content on the composite multiferroic properties of the Ba6-2xLn2xFe1+xNb9-xO30 TTB system. Solid State Sci. 2009, 11, 1709–1716. [Google Scholar] [CrossRef]

- Castel, E.; Josse, M.; Roulland, F.; Michau, D.; Raison, L.; Maglione, M. In-situ formation of barium ferrite in iron-doped “tetragonal tungsten bronze”: Elaboration of room temperature multiferroic composites. J. Magn. Magn. Mater. 2009, 321, 1773–1777. [Google Scholar] [CrossRef]

- Hajlaoui, T.; Hajlaoui, M.E.; Josse, M.; Dhahri, E.; Pignolet, A. Tetragonal tungsten bronze/barium hexaferrite room-temperature multiferroic composite ceramics. SN Appl. Sci. 2020, 2, 1861. [Google Scholar] [CrossRef]

- Laguta, V.; Elissalde, C.; Maglione, M.; Artemenko, A.; Chlan, V.; Štěpánková, H.; Zagorodniy, Y. Crystal structure transformations induced by surface stresses in BaTiO3 and BaTiO3@SiO2 nanoparticles and ceramics. Phase Transit. 2015, 88, 761–775. [Google Scholar] [CrossRef]

- Chung, U.-C.; Michau, D.; Elissalde, C.; Li, S.; Klein, A.; Maglione, M. Evidence of diffusion at BaTiO3/silicon interfaces. Thin Solid Film. 2012, 520, 1997–2000. [Google Scholar] [CrossRef]

- Sharma, M.; Kashyap, S.C.; Gupta, H.C.; Dimri, M.C.; Asokan, K. Enhancement of Curie temperature of barium hexaferrite by dense electronic excitations. AIP Adv. 2014, 4, 077129. [Google Scholar] [CrossRef]

- Chen, D.; Harward, I.; Baptist, J.; Goldman, S.; Celinski, Z. Curie temperature and magnetic properties of aluminum doped barium ferrite particles prepared by ball mill method. J. Magn. Magn. Mater. 2015, 395, 350–353. [Google Scholar] [CrossRef]

- Chen, Z.; Yang, F. Barium Hexa-Ferrite Technology for MAMR and Advanced Magnetic Recording Applications. U.S. Patent Application No. 14,799,313, 19 January 2017. Available online: https://patentscope.wipo.int/search/en/detail.jsf?docId=US191081266&_fid=GB210000972 (accessed on 10 March 2021).

- Sharrock, M.; Carlson, L. The application of barium ferrite particles in advanced recording media. IEEE Trans. Magn. 1995, 31, 2871–2876. [Google Scholar] [CrossRef]

- Ozah, S.; Bhattacharyya, N. Nanosized barium hexaferrite in novolac phenolic resin as microwave absorber for X-band application. J. Magn. Magn. Mater. 2013, 342, 92–99. [Google Scholar] [CrossRef]

- Trukhanov, A.V.; Trukhanov, S.V.; Panina, L.V.; Kostishyn, V.G.; Chitanov, D.N.; Kazakevich, I.S.; Trukhanov, A.V.; Turchenko, V.A.; Salem, M.M. Strong corelation between magnetic and electrical subsystems in diamagnetically substituted hexaferrites ceramics. Ceram. Int. 2017, 43, 5635–5641. [Google Scholar] [CrossRef]

- Trukhanov, A.V.; Kostishin, V.G.; Panina, L.V.; Salem, M.M.; Kazakevich, I.S.; Turchenko, V.A.; Kochervinskii, V.V.; Krivchenya, D.A. Multiferroic properties and structural features of M-type Al-substituted barium hexaferrites. Phys. Solid State 2017, 59, 737–745. [Google Scholar] [CrossRef]

- Hajlaoui, T.; Josse, M.; Harnagea, C.; Pignolet, A. Tetragonal tungsten bronze Ba2EuFeNb4O15—based composite thin films multiferroic at room temperature. Mater. Res. Bull. 2017, 86, 30–37. [Google Scholar] [CrossRef]

- Bodeux, R.; Michau, D.; Josse, M.; Maglione, M. Dielectric properties of tetragonal tungsten bronze films deposited by RF magnetron sputtering. Solid State Sci. 2014, 38, 112–118. [Google Scholar] [CrossRef]

- Kadyrzhanov, K.K.; Shlimas, D.I.; Kozlovskiy, A.L.; Zdorovets, M.V. Research of the shielding effect and radiation resistance of composite CuBi2O4 films as well as their practical applications. J. Mater. Sci. Mater. Electron. 2020, 31, 11729–11740. [Google Scholar] [CrossRef]

- Zubar, T.I.; Usovich, T.I.; Tishkevich, D.I.; Kanafyev, O.D.; Fedkin, V.A.; Kotelnikova, A.N.; Panasyuk, M.I.; Kurochka, A.S.; Nuriev, A.V.; Idris, A.M.; et al. Features of Galvanostatic Electrodeposition of NiFe Films with Composition Gradient: Influence of Substrate Characteristics. Nanomaterials 2022, 12, 2926. [Google Scholar] [CrossRef] [PubMed]

- Willmott, P. Deposition of complex multielemental thin films. Prog. Surf. Sci. 2004, 76, 163–217. [Google Scholar] [CrossRef]

- Ashfold, M.N.R.; Claeyssens, F.; Fuge, G.M.; Henley, S.J. Pulsed laser ablation and deposition of thin films. Chem. Soc. Rev. 2003, 33, 23–31. [Google Scholar] [CrossRef] [PubMed]

- Moon, E.J.; Goyal, A. Combinatorial synthesis of heteroepitaxial, multi-cation, thin-films via pulsed laser deposition coupled with in-situ, chemical and structural characterization. Sci. Rep. 2022, 12, 3219. [Google Scholar] [CrossRef] [PubMed]

- Hajlaoui, T.; Corbellini, L.; Harnagea, C.; Josse, M.; Pignolet, A. Enhanced ferroelectric properties in multiferroic epitaxial Ba2 EuFeNb4 O15 thin films grown by pulsed laser deposition. Mater. Res. Bull. 2017, 87, 186–192. [Google Scholar] [CrossRef]

- Hajlaoui, T.; Chabanier, C.; Harnagea, C.; Pignolet, A. Epitaxial Ba2NdFeNb4O15-based multiferroic nanocomposite thin films with tetragonal tungsten bronze structure. Scr. Mater. 2017, 136, 1–5. [Google Scholar] [CrossRef]

- Hajlaoui, T.; Harnagea, C.; Pignolet, A. Influence of lanthanide ions on multiferroic properties of Ba2LnFeNb4O15 (Ln = Eu3+, Sm3+ and Nd3+) thin films grown on silicon by pulsed laser deposition. Mater. Lett. 2017, 198, 136–139. [Google Scholar] [CrossRef]

- Hajlaoui, T.; Harnagea, C.; Michau, D.; Josse, M.; Pignolet, A. Highly oriented multiferroic Ba2 NdFeNb4O15-based composite thin films with tetragonal tungsten bronze structure on silicon substrates. J. Alloys Compd. 2017, 711, 480–487. [Google Scholar] [CrossRef]

- Zhang, X.; Meng, S.; Song, D.; Zhang, Y.; Yue, Z.; Harris, V.G. Epitaxially grown BaM hexaferrite films having uniaxial axis in the film plane for self-biased devices. Sci. Rep. 2017, 7, 44193. [Google Scholar] [CrossRef]

- Liu, X.; Hong, M.; Song, W.; Chen, G.; Lam, H.; Wang, J.; Chong, T.C. Barium ferrite (BaFe12O19) thin films prepared by pulsed laser deposition on MgO buffered Si substrates. Appl. Phys. A 2005, 80, 611–614. [Google Scholar] [CrossRef]

- Yourdkhani, A.; Caruntu, D.; Perez, A.K.; Caruntu, G. Liquid Phase Deposition of Barium Hexaferrite Thin Films. J. Phys. Chem. C 2014, 118, 1774–1782. [Google Scholar] [CrossRef]

- Hajlaoui, T.; Pinsard, M.; Kalhori, H.; Légaré, F.; Pignolet, A. Second harmonic generation in ferroelectric Ba2EuFeNb4O15-based epitaxial thin films. Opt. Mater. Express 2020, 10, 1323–1334. [Google Scholar] [CrossRef]

- Kikukawa, A.; Hosaka, S.; Imura, R. Silicon pn junction imaging and characterizations using sensitivity enhanced Kelvin probe force microscopy. Appl. Phys. Lett. 1995, 66, 3510–3512. [Google Scholar] [CrossRef]

- Zerweck, U.; Loppacher, C.; Otto, T.; Grafström, S.; Eng, L.M. Accuracy and resolution limits of Kelvin probe force microscopy. Phys. Rev. B 2005, 71, 125424. [Google Scholar] [CrossRef]

- Sommerhalter, C.; Matthes, T.W.; Glatzel, T.; Jäger-Waldau, A.; Lux-Steiner, M.C. High-sensitivity quantitative Kelvin probe microscopy by noncontact ultra-high-vacuum atomic force microscopy. Appl. Phys. Lett. 1999, 75, 286–288. [Google Scholar] [CrossRef]

- Kim, D.H.; Han, S.H.; Kang, Y.-M.; Yang, D.; Ross, C.A. Structure and magnetic properties of pulsed laser deposited SrFe12O19 thin films on SrTiO3 (100) and (111) substrates. J. Alloys Compd. 2017, 692, 545–551. [Google Scholar] [CrossRef]

- Zhang, X.; Yue, Z.; Meng, S.; Yuan, L. Magnetic properties of in-plane oriented barium hexaferrite thin films prepared by direct current magnetron sputtering. J. Appl. Phys. 2014, 116, 243909. [Google Scholar] [CrossRef]

- Zhou, Z.; Peng, B.; Zhu, M.; Liu, M. Voltage control of ferromagnetic resonance. J. Adv. Dielectr. 2016, 6, 1630005. [Google Scholar] [CrossRef]

- Liu, M.; Sun, N.X. Voltage control of magnetism in multiferroic heterostructures. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20120439. [Google Scholar] [CrossRef]

- Feng, M.; Wang, W.; Zhou, Y.; Li, H.; Jia, D. Influence of residual stress on magnetoelectric coupling of bilayered CoFe2O4/PMN–PT thin films. J. Mater. Chem. 2011, 21, 10738–10743. [Google Scholar] [CrossRef]

- Kobayashi, S. X-ray thin-film measurement techniques. Rigaku J. 2010, 26, 3–11. [Google Scholar]

- Roelofs, A.; Böttger, U.; Waser, R.; Schlaphof, F.; Trogisch, S.; Eng, L.M. Differentiating 180° and 90° switching of ferroelectric domains with three-dimensional piezoresponse force microscopy. Appl. Phys. Lett. 2000, 77, 3444. [Google Scholar] [CrossRef]

- Harnagea, C.; Cojocaru, C.V.; Pignolet, A. Local ferroelectric switching properties in BiFeO3microstructures and their piezomagnetic response. MRS Proc. 2005, 902, 1057. [Google Scholar] [CrossRef]

- Harnagea, C.; Cojocaru, C.; Nechache, R.; Gautreau, O.; Rosei, F.; Pignolet, A. Towards ferroelectric and multiferroic nanostructures and their characterisation. Int. J. Nanotechnol. 2008, 5, 930. [Google Scholar] [CrossRef]

- Lisfi, A.; Lodder, J.C. Magnetic domains in epitaxial BaFe12O19thin films with perpendicular anisotropy. J. Phys. Condens. Matter 2002, 14, 12339–12352. [Google Scholar] [CrossRef]

- Lakshmi, N.; Sebastian, V.; Venugopalan, K. Clustering in Heusler Alloys. In Advances in Nanoscale Magnetism; Part of the Springer Proceedings in Physics Book Series; Aktas, B., Mikailov, F., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; Volume 122, pp. 21–35. [Google Scholar] [CrossRef]

- Matsuoka, M.; Naoe, M.; Hoshi, Y. Ba–ferrite thin-film disk for perpendicular magnetic recording. J. Appl. Phys. 1985, 57, 4040–4042. [Google Scholar] [CrossRef]

- Wang, S.G.; Yoon, S.D.; Vittoria, C. Microwave and magnetic properties of double-sided hexaferrite films on (111) magnesium oxide substrates. J. Appl. Phys. 2002, 92, 6728–6732. [Google Scholar] [CrossRef]

- Bodeux, R.; Michau, D.; Maglione, M.; Josse, M. Thin films sputtered from Ba2NdFeNb4O15 multiferroic targets on BaFe12O19 coated substrates. Mater. Res. Bull. 2016, 81, 49–54. [Google Scholar] [CrossRef]

- Gautreau, O.; Harnagea, C.; Gunawan, L.; Nechache, R.; Singh, M.; Fournier, P.; Botton, G.A.; Pignolet, A. Piezoresponse force microscopy and magnetic force microscopy characterization of γ-Fe2O3–BiFeO3 nanocomposite/Bi3.25La0.75Ti3O12 multiferroic bilayers. J. Magn. Magn. Mater. 2009, 321, 1799–1802. [Google Scholar] [CrossRef]

- Palkar, V.R.; Purandare, S.C.; Gohil, S.; John, J.; Bhattacharya, S. Scanning probe imaging of coexistent ferromagnetism and ferroelectricity at room temperature. Appl. Phys. Lett. 2007, 90, 172901. [Google Scholar] [CrossRef]

- Liu, C.; Ma, J.; Ma, J.; Zhang, Y.; Chen, J.; Nan, C.-W. Cautions to predicate multiferroic by atomic force microscopy. AIP Adv. 2017, 7, 055003. [Google Scholar] [CrossRef]

- Collins, L.; Belianinov, A.; Proksch, R.; Zuo, T.; Zhang, Y.; Liaw, P.K.; Kalinin, S.V.; Jesse, S. G-mode magnetic force microscopy: Separating magnetic and electrostatic interactions using big data analytics. Appl. Phys. Lett. 2016, 108, 193103. [Google Scholar] [CrossRef]

- Jaafar, M.; Iglesias-Freire, O.; Serrano-Ramon, L.; Ibarra, M.R.; de Teresa, J.M.; Asenjo, A. Distinguishing magnetic and electrostatic interactions by a Kelvin probe force microscopy–magnetic force microscopy combination. Beilstein J. Nanotechnol. 2011, 2, 552–560. [Google Scholar] [CrossRef] [PubMed]

- Arenas, M.P.; Lanzoni, E.M.; Pacheco, C.J.; Costa, C.A.; Eckstein, C.B.; de Almeida, L.H.; Rebello, J.M.; Deneke, C.F.; Pereira, G.R. Separating the influence of electric charges in magnetic force microscopy images of inhomogeneous metal samples. J. Magn. Magn. Mater. 2018, 446, 239–244. [Google Scholar] [CrossRef]

- Angeloni, L.; Passeri, D.; Reggente, M.; Mantovani, D.; Rossi, M. Removal of electrostatic artifacts in magnetic force microscopy by controlled magnetization of the tip: Application to superparamagnetic nanoparticles. Sci. Rep. 2016, 6, 26293. [Google Scholar] [CrossRef]

- Sommerhalter, C.; Glatzel, T.; Matthes, T.; Jäger-Waldau, A.; Lux-Steiner, M. Kelvin probe force microscopy in ultra high vacuum using amplitude modulation detection of the electrostatic forces. Appl. Surf. Sci. 2000, 157, 263–268. [Google Scholar] [CrossRef]

- Tian, G.; Zhang, F.; Yao, J.; Fan, H.; Li, P.; Li, Z.; Song, X.; Zhang, X.; Qin, M.; Zeng, M.; et al. Magnetoelectric Coupling in Well-Ordered Epitaxial BiFeO3/CoFe2O4/SrRuO3 Heterostructured Nanodot Array. ACS Nano 2015, 10, 1025–1032. [Google Scholar] [CrossRef]

- Tang, R.; Zhou, H.; Zhao, R.; Jian, J.; Wang, H.; Huang, J.; Fan, M.; Zhang, W.; Wang, H.; Yang, H. Dielectric relaxation and polaronic conduction in epitaxial BaFe12O19hexaferrite thin film. J. Phys. D Appl. Phys. 2016, 49, 115305. [Google Scholar] [CrossRef]

- Lian, L.; Sottos, N.R. Stress effects in sol-gel derived ferroelectric thin films. J. Appl. Phys. 2004, 95, 629–634. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hajlaoui, T.; Harnagea, C.; Pignolet, A. Magnetoelectric Coupling in Room Temperature Multiferroic Ba2EuFeNb4O15/BaFe12O19 Epitaxial Heterostructures Grown by Laser Ablation. Nanomaterials 2023, 13, 761. https://doi.org/10.3390/nano13040761

Hajlaoui T, Harnagea C, Pignolet A. Magnetoelectric Coupling in Room Temperature Multiferroic Ba2EuFeNb4O15/BaFe12O19 Epitaxial Heterostructures Grown by Laser Ablation. Nanomaterials. 2023; 13(4):761. https://doi.org/10.3390/nano13040761

Chicago/Turabian StyleHajlaoui, Thameur, Catalin Harnagea, and Alain Pignolet. 2023. "Magnetoelectric Coupling in Room Temperature Multiferroic Ba2EuFeNb4O15/BaFe12O19 Epitaxial Heterostructures Grown by Laser Ablation" Nanomaterials 13, no. 4: 761. https://doi.org/10.3390/nano13040761

APA StyleHajlaoui, T., Harnagea, C., & Pignolet, A. (2023). Magnetoelectric Coupling in Room Temperature Multiferroic Ba2EuFeNb4O15/BaFe12O19 Epitaxial Heterostructures Grown by Laser Ablation. Nanomaterials, 13(4), 761. https://doi.org/10.3390/nano13040761