Molecular Dynamics Simulation of the Effect of Defect Size on Magnetostrictive Properties of Low-Dimensional Iron Thin Films

Abstract

:1. Introduction

2. Computational Model

3. Calculation Method

4. Results and Discussion

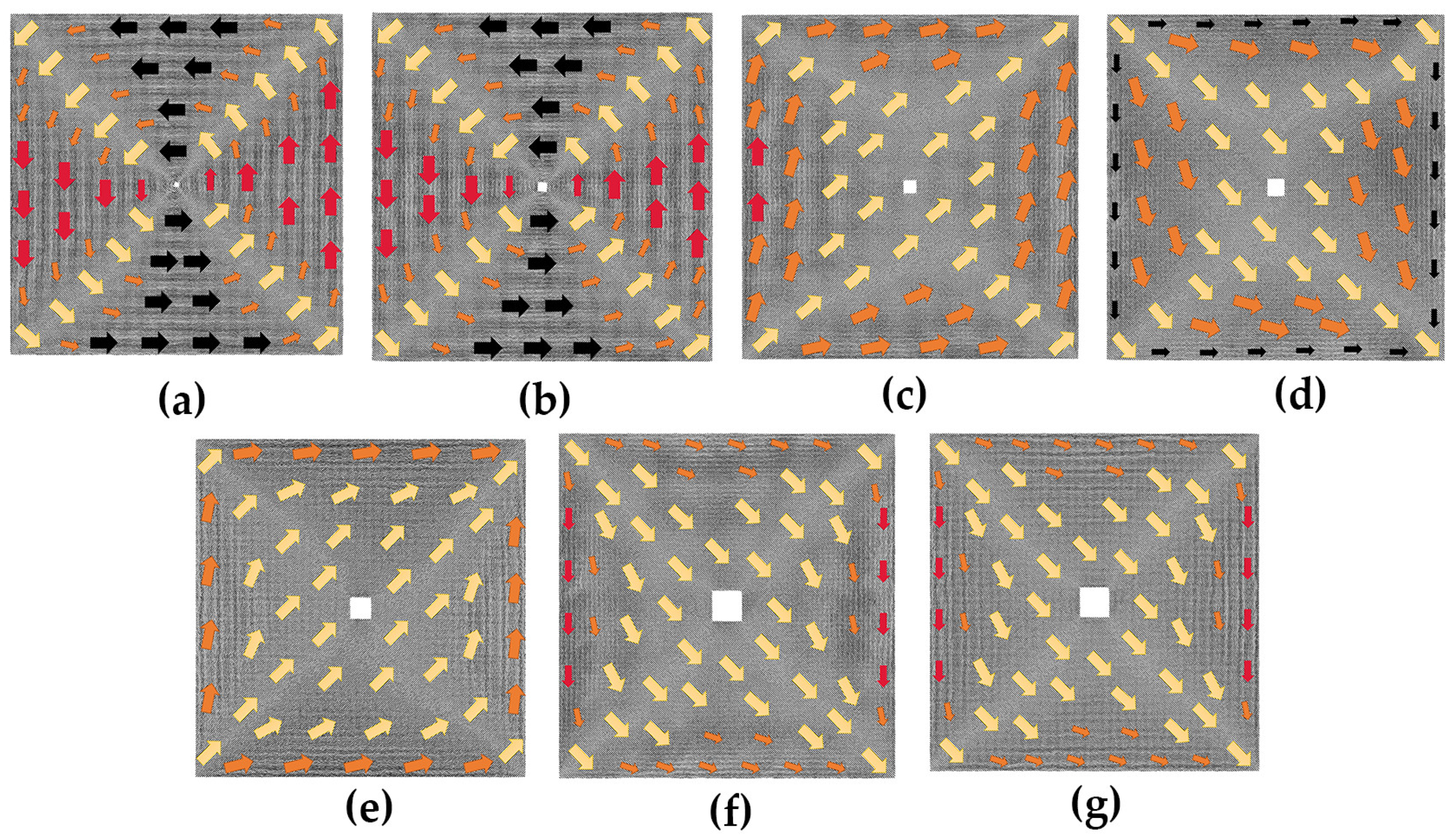

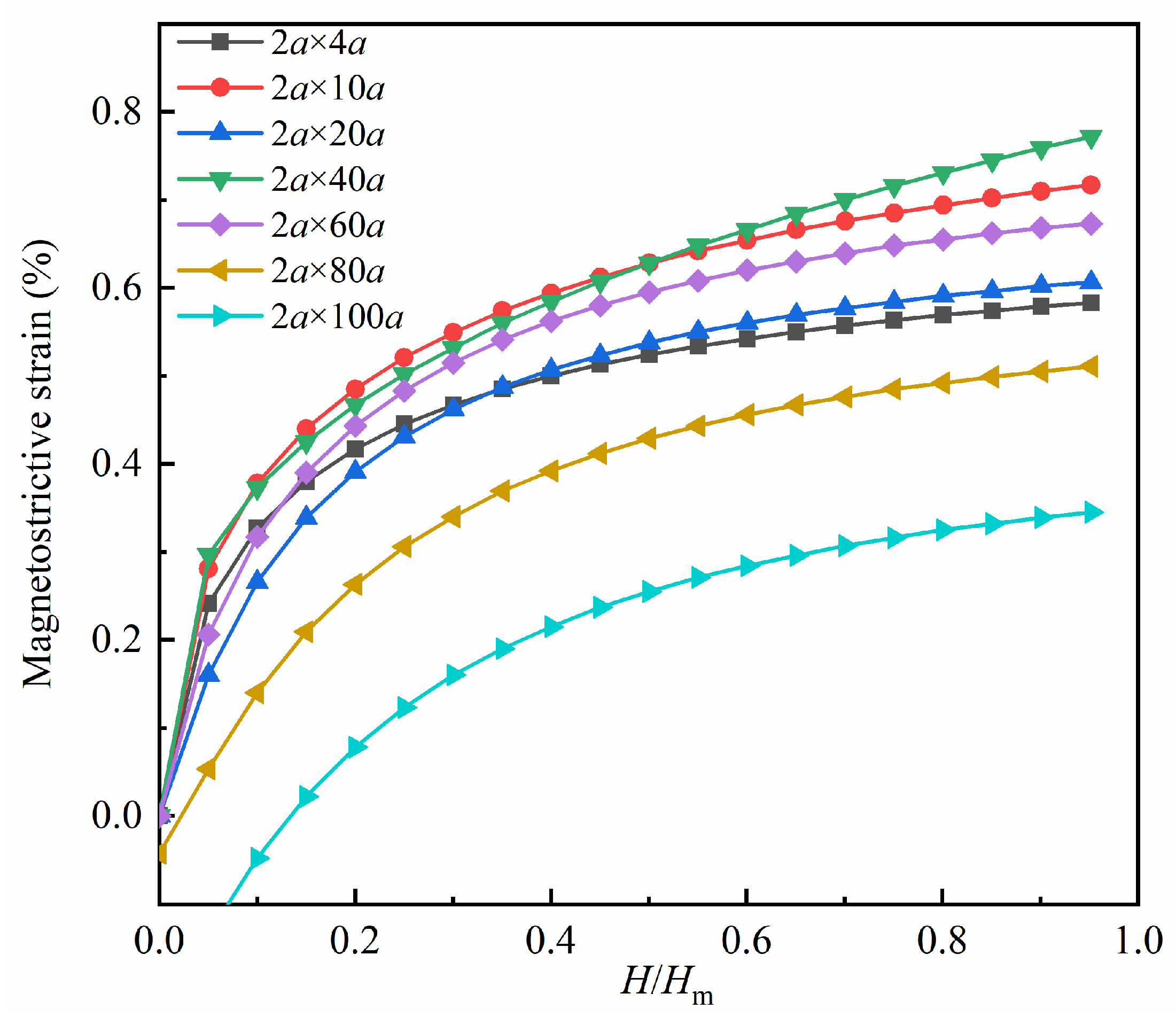

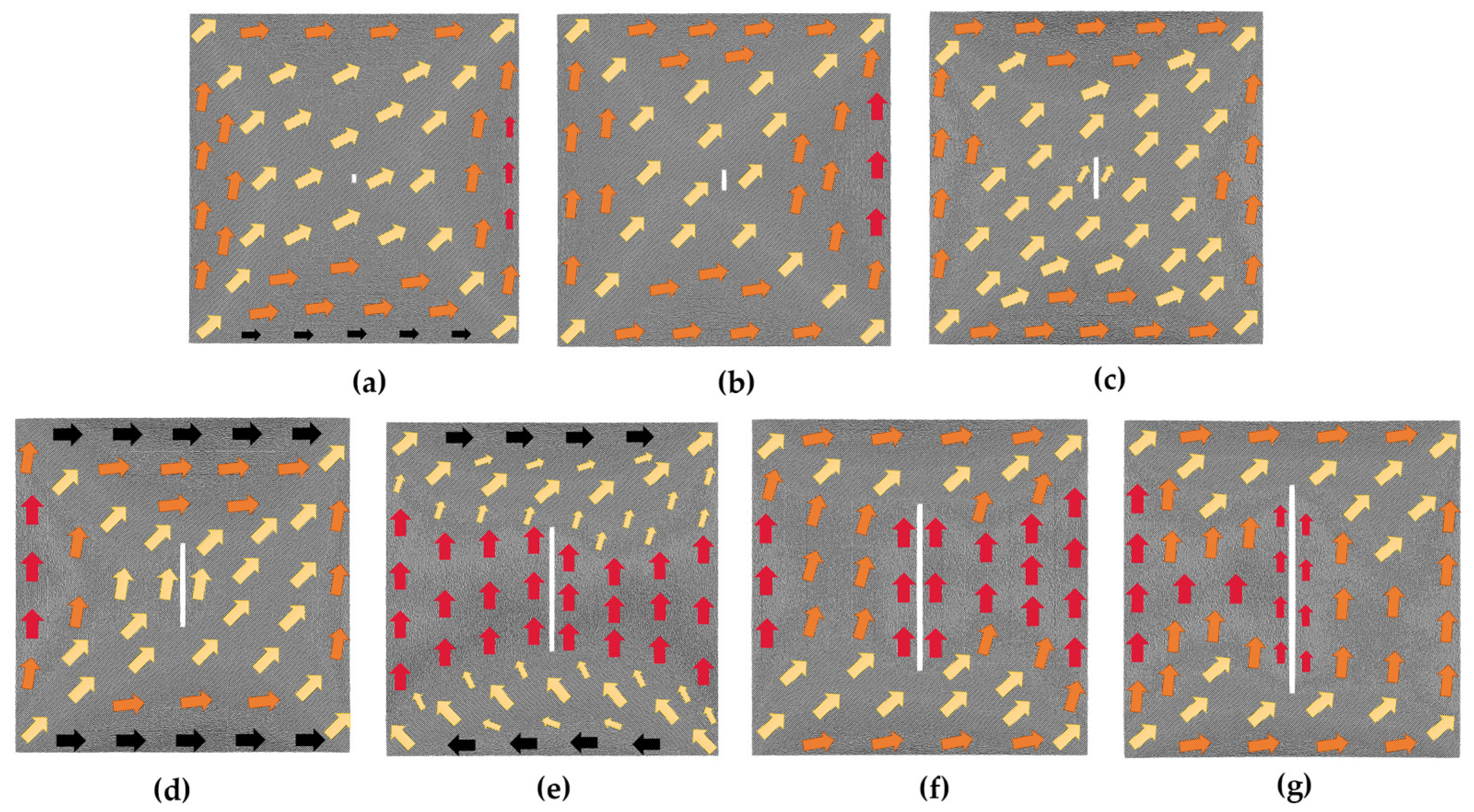

4.1. The Effect of the Size of the Hole on Magnetostrictive Properties of Thin Films

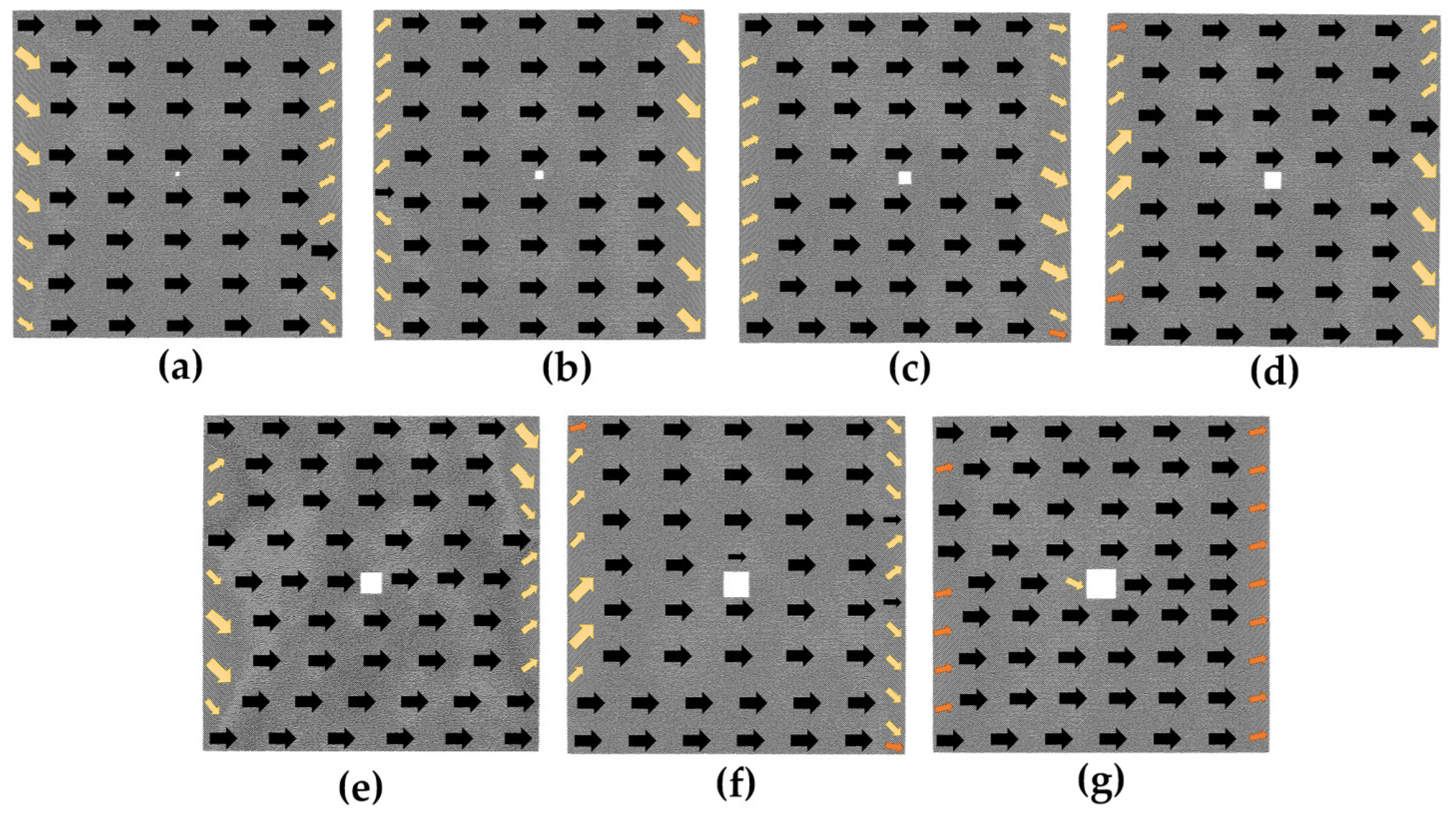

4.2. The Effect of the Size of the Transverse Crack on Magnetostrictive Properties of Thin Films

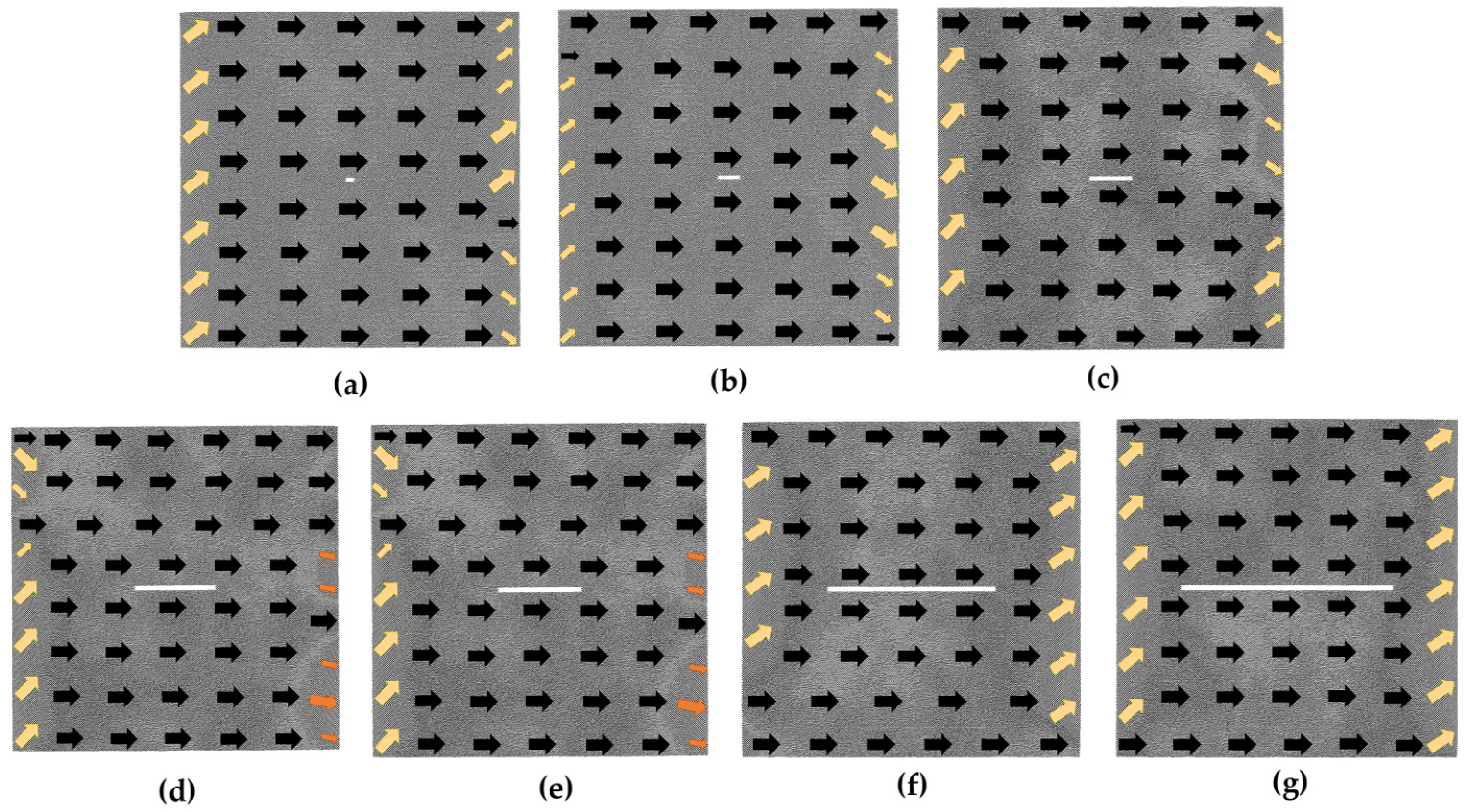

4.3. The Effect of the Size of the Vertical Crack on Magnetostrictive Properties of Thin Films

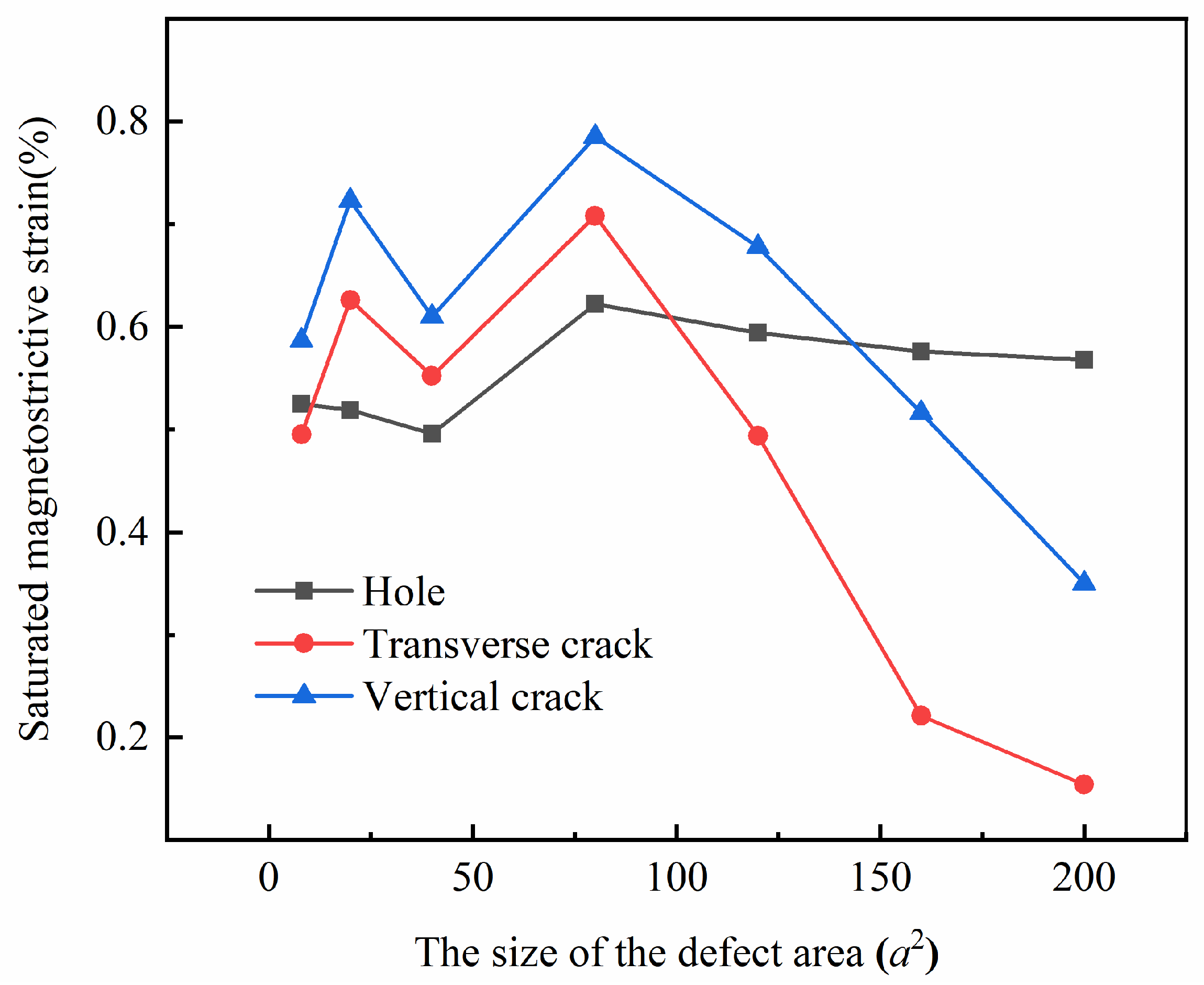

4.4. Analysis and Comparison

5. Conclusions

- The saturation magnetostrictive strain of the defect model does not exhibit monotonic variation with increasing defect size.

- When the initial magnetic moment configuration contains more atoms with magnetic moments oriented opposite or perpendicular to the magnetization direction, it becomes more difficult to align the magnetic moments of the atoms with the magnetization direction in a small magnetic field. This can lead to a tendency for the sample to shrink in the magnetization direction.

- By controlling the variation in defect size within a certain defect area interval, the saturation magnetostrictive strain varies by approximately 0.12% for the hole models, nearly 0.56% for the transverse crack models, and about 0.44% for the vertical crack models. By comparing the magnitudes of these changes, it can be concluded that the size of the hole defect has a small effect on the magnetostrictive performance of the thin films, whereas the size of the crack defect has a large effect on the magnetostrictive performance. Additionally, the transverse crack has a slightly larger effect than the vertical crack.

- At the microscopic level, the magnetostrictive properties are influenced by the arrangement of atomic magnetic moments in the initial magnetic moment configuration. The hole size has little effect on the initial magnetic moment configuration and thus has little effect on the magnetostrictive properties. Changes in the size of cracks, on the other hand, have a significant impact on the arrangement of atomic magnetic moments in the initial magnetic moment configuration. The change in atomic magnetic moment arrangement is slightly greater in the transverse crack model than in the vertical crack model; thus, the effect of transverse crack size on magnetostrictive properties is slightly larger than the effect of vertical crack size on magnetostrictive properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Robert, C.; Handley, O. Modern Magnetic Materials: Principles and Applications; John Wiley & Sons, Inc.: New York, NY, USA, 2000; p. 23. [Google Scholar]

- de Lacheisserie, E.D.T.; Gignoux, D.; Schlenker, M. Magnetism; Springer Science & Business Media: Berlin, Germany, 2005; Volume 1, pp. 213–214. [Google Scholar]

- Ryu, J.; Carazo, A.V.; Uchino, K.; Kim, H.E. Magnetoelectric properties in piezoelectric and magnetostrictive laminate composites. Jpn. J. Appl. Phys. Part 1 Regul. Pap. Short Notes Rev. Pap. 2001, 40, 4948–4951. [Google Scholar] [CrossRef]

- Wu, R.Q.; Yang, Z.X.; Hong, J.S. First-principles determination of magnetic properties. J. Phys. Condes. Matter 2003, 15, S587–S598. [Google Scholar] [CrossRef]

- Alrub, A.M.; Lim, K.G.; Chew, K.H. Effect of magnetic and electric fields on electrical and magnetic properties of multiferroic BiMnO3 films. J. Magn. Magn. Mater 2018, 458, 285–291. [Google Scholar] [CrossRef]

- Arora, D.; Kumar, P.; Kaushlendra, K.; Kaur, D. Unravelling the magnetodielectric characteristics of strain-coupled PMN-PT/FSMA multiferroic heterojunction toward flexible MEMS applications. J. Phys. D-Appl. Phys. 2022, 55, 11. [Google Scholar] [CrossRef]

- Talebian, S. Theoretical and experimental study on optimum operational conditions of a magnetostrictive force sensor. J. Magn. Magn. Mater 2022, 562, 8. [Google Scholar] [CrossRef]

- Apicella, V.; Clemente, C.S.; Davino, D.; Leone, D.; Visone, C. Review of Modeling and Control of Magnetostrictive Actuators. Actuators 2019, 8, 45. [Google Scholar] [CrossRef]

- Yang, Z.J.; Li, J.H.; Zhou, Z.G.; Gong, J.X.; Bao, X.Q.; Gao, X.X. Recent Advances in Magnetostrictive Tb-Dy-Fe Alloys. Metals 2022, 12, 341. [Google Scholar] [CrossRef]

- Chen, L.; Zhu, Y.C.; Ling, J.; Zhang, M.M. Development and Characteristic Investigation of a Multidimensional Discrete Magnetostrictive Actuator. IEEE-ASME Trans. Mechatron. 2022, 27, 2071–2079. [Google Scholar] [CrossRef]

- Wastlbauer, G.; Bland, J.A.C. Structural and magnetic properties of ultrathin epitaxial Fe films on GaAs(001) and related semiconductor substrates. Adv. Phys. 2005, 54, 137–219. [Google Scholar] [CrossRef]

- Chlenova, A.A.; Kurlyandskaya, G.V.; Safronov, A.P.; Larrañaga, A.; Fernandez Armas, S.; Zalbidea Arechaga, I.; Lepalovskij, V.N. Surface modification of thin iron films in aromatic solvents at ambient conditions. Solid State Phenom. 2015, 233, 657–661. [Google Scholar] [CrossRef]

- Serizawa, K.; Ohtake, M.; Kawai, T.; Futamoto, M.; Kirino, F.; Inaba, N. Influence of crystal orientation on the magnetostriction behavior of Fe films formed on MgO single-crystal substrates. J. Magn. Magn. Mater 2019, 477, 420–426. [Google Scholar] [CrossRef]

- Kawai, T.; Ouchi, S.; Ohtake, M.; Futamoto, M. Thickness Effect on Magnetostriction of Fe and Fe98B2 Thin Films. IEEE Trans. Magn. 2012, 48, 1585–1588. [Google Scholar] [CrossRef]

- Aida, T.; Kawai, T.; Ohtake, M.; Futamoto, M.; Inaba, N. Relationship Between Magnetostriction and Magnetic Domain Structure in Fe-Based Alloy Single-Crystal Films With bcc(001) Orientation. IEEE Trans. Magn. 2014, 50, 4. [Google Scholar] [CrossRef]

- Zhu, L.L.; Li, K.S.; Luo, Y.; Yu, D.B.; Wang, Z.L.; Wu, G.Y.; Xie, J.J.; Tang, Z.F. Magnetostrictive properties and detection efficiency of TbDyFe/FeCo composite materials for nondestructive testing. J. Rare Earths 2019, 37, 166–170. [Google Scholar] [CrossRef]

- Clark, A.E.; Hathaway, K.B.; Wun-Fogle, M.; Restorff, J.B.; Lograsso, T.A.; Keppens, V.M.; Petculescu, G.; Taylor, R.A. Extraordinary magnetoelasticity and lattice softening in bcc Fe-Ga alloys. J. Appl. Phys. 2003, 93, 8621–8623. [Google Scholar] [CrossRef]

- Laroche, R.A.; Guruswamy, S. Influence of Ga content and high temperature annealing on the short range order and magnetostriction of Fe-Ga single crystals. J. Appl. Phys. 2020, 128, 11. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.N.; Wu, R.Q.; Sun, L.Z.; Xu, D.S.; Zhang, Z.D. Understanding strong magnetostriction in Fe100-xGax alloys. Sci. Rep. 2013, 3, 5. [Google Scholar] [CrossRef]

- Matyunina, M.V.; Zagrebin, M.A.; Sokolovskiy, V.V.; Buchelnikov, V.D. Magnetostriction of Fe100-xGax alloys from first principles calculations. J. Magn. Magn. Mater 2019, 476, 120–123. [Google Scholar] [CrossRef]

- Yang, H.W.; Zhang, M.; Long, L.C. Effect of Crack Defects on Magnetostriction and Magnetic Moment Evolution of Iron Thin Films. Nanomaterials 2022, 12, 1236. [Google Scholar] [CrossRef]

- Chamati, H.; Papanicolaou, N.I.; Mishin, Y.; Papaconstantopoulos, D.A. Embedded-atom potential for Fe and its application to self-diffusion on Fe(100). Surf. Sci. 2006, 600, 1793–1803. [Google Scholar] [CrossRef]

- Tranchida, J.; Plimpton, S.J.; Thibaudeau, P.; Thompson, A.P. Massively parallel symplectic algorithm for coupled magnetic spin dynamics and molecular dynamics. J. Comput. Phys. 2018, 372, 406–425. [Google Scholar] [CrossRef]

- Jeong, J.; Goremychkin, E.A.; Guidi, T.; Nakajima, K.; Jeon, G.S.; Kim, S.A.; Furukawa, S.; Kim, Y.B.; Lee, S.; Kiryukhin, V.; et al. Spin Wave Measurements over the Full Brillouin Zone of Multiferroic BiFeO3. Phys. Rev. Lett. 2012, 108, 5. [Google Scholar] [CrossRef] [PubMed]

- Kvashnin, Y.O.; Cardias, R.; Szilva, A.; Di Marco, I.; Katsnelson, M.I.; Lichtenstein, A.I.; Nordstrom, L.; Klautau, A.B.; Eriksson, O. Microscopic Origin of Heisenberg and Non-Heisenberg Exchange Interactions in Ferromagnetic bcc Fe. Phys. Rev. Lett. 2016, 116, 5. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Ma, P.; Zhang, M.; Long, L.; Yang, Q. Molecular Dynamics Simulation of the Effect of Defect Size on Magnetostrictive Properties of Low-Dimensional Iron Thin Films. Nanomaterials 2023, 13, 3009. https://doi.org/10.3390/nano13233009

Yang H, Ma P, Zhang M, Long L, Yang Q. Molecular Dynamics Simulation of the Effect of Defect Size on Magnetostrictive Properties of Low-Dimensional Iron Thin Films. Nanomaterials. 2023; 13(23):3009. https://doi.org/10.3390/nano13233009

Chicago/Turabian StyleYang, Hongwei, Panpan Ma, Meng Zhang, Lianchun Long, and Qianqian Yang. 2023. "Molecular Dynamics Simulation of the Effect of Defect Size on Magnetostrictive Properties of Low-Dimensional Iron Thin Films" Nanomaterials 13, no. 23: 3009. https://doi.org/10.3390/nano13233009

APA StyleYang, H., Ma, P., Zhang, M., Long, L., & Yang, Q. (2023). Molecular Dynamics Simulation of the Effect of Defect Size on Magnetostrictive Properties of Low-Dimensional Iron Thin Films. Nanomaterials, 13(23), 3009. https://doi.org/10.3390/nano13233009