Abstract

Flame spray pyrolysis (FSP) is an industrially scalable technology that enables the engineering of a wide range of metal-based nanomaterials with tailored properties nanoparticles. In the present review, we discuss the recent state-of-the-art advances in FSP technology with regard to nanostructure engineering as well as the FSP reactor setup designs. The challenges of in situ incorporation of nanoparticles into complex functional arrays are reviewed, underscoring FSP’s transformative potential in next-generation nanodevice fabrication. Key areas of focus include the integration of FSP into the technology readiness level (TRL) for nanomaterials production, the FSP process design, and recent advancements in nanodevice development. With a comprehensive overview of engineering methodologies such as the oxygen-deficient process, double-nozzle configuration, and in situ coatings deposition, this review charts the trajectory of FSP from its foundational roots to its contemporary applications in intricate nanostructure and nanodevice synthesis.

1. Introduction

Flame spray pyrolysis (FSP) is an industrially scalable technique for the synthesis of nanomaterials, which allows to produce many types of metal, or metal-oxide nanoparticles with tailored physicochemical properties [1]. At the heart of the FSP technology lies an intricate process design, involving precursor atomization, combustion, and nanoparticle formation [2]. This enables swift, single-step synthesis, eliminating the need for post-production treatments commonly required in other methodologies. Recent advancements have further elevated the prominence of FSP in the development of nanodevices, i.e., where nanoparticles can be in situ incorporated in complex functional arrays [3]. Thus, FSP not only revolutionizes nanomaterials’ production but, with recent innovations, also paves the way for the next generation of nanodevices [4]. In the present review article, we provide an updated overview of the current state-of-the-art in FSP technology regarding novel reactor and process designs, novel material production, and nanodevice engineering.

In the domain of nanotechnology, nanostructure synthesis represents a critical research area, encompassing a diverse range of methodologies alongside FSP. These alternative techniques, including, but not limited to, chemical vapor deposition, sol-gel processing, and electrospinning, offer unique properties in terms of particle size control, morphology, and chemical composition. The selection of an appropriate synthesis method is contingent upon a set of criteria closely related to the intended application of the nanostructures. Factors such as material versatility, environmental impact, synthesis time, and temperature range play a pivotal role in determining the suitability of a technique for specific applications, which vary from drug delivery systems to photovoltaic devices. In Table 1, we enumerate various methodologies employed in the synthesis of nanomaterials, including FSP, and delineate the specific criteria applicable to their utilization. This careful consideration ensures that the synthesis process aligns with the functional requirements of the end application, thereby maximizing the efficacy and utility of the nanostructures produced. Atomic layer deposition (ALD) [5,6] is an alternative to FSP, particularly for engineering thin films. ALD provides atomic-level precision and high-level conformality, producing highly uniform and defect-free films. The downsides include a slower deposition rate, the need for expensive and controlled-environment equipment, and potentially high costs for precursors [5,6].

Table 1.

The literature summary on various techniques for synthesizing nanostructures and the criteria for their application.

1.1. Integration of Flame Spray Pyrolysis into the Technology Readiness Level (TRL) Scale for Nanomaterial Production

FSP stands out as an innovative and advanced methodology for the synthesis of nanomaterials, which highlights its vital role in producing a wide array of metal oxide nanoparticles with tailored morphologies and compositions [24]. Inherent in FSP, synthesis at elevated temperatures enhances both the crystallinity and physicochemical attributes of the nanoparticles. By adeptly adjusting operational parameters, such as precursor solution concentration, solvent type, flame temperature, oxygen-to-fuel ratio, and particle residence time in the flame zone, researchers can effectively control the nanoparticle size, distribution, and phase composition. Regarding the technology readiness level (TRL) spectrum, FSP for device applications aligns with TRL 6–8 [25]. This placement signifies FSP’s evolution beyond foundational laboratory research [1]. Given the adoption of FSP by certain industries, this positions FSP in the late stages of development and early stages of commercialization, placing it in the TRL 7–8 range (see Figure 1) [25].

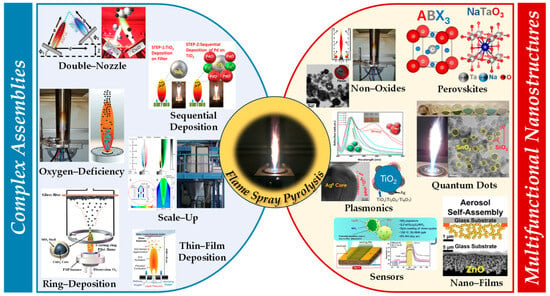

Figure 1.

Figure illustrating the complex assemblies in flame spray pyrolysis (FSP) discussed in this review. These include double-nozzle, sequential deposition, oxygen-deficiency process, ring deposition, sequential/thin-film deposition, and scale-up methods. The resultant advanced nanomaterials/nanodevices encompass perovskites, non-oxides, quantum dots, plasmonics, nanofilms, and sensors.

1.2. Process Design

The process design of FSP [26] begins with the preparation of a metal or metal-organic precursor solution, typically dissolved in an appropriate solvent. This solution undergoes atomization, often facilitated by a high-pressure nozzle, to form a fine spray of droplets [2]. Subsequent ignition of these droplets, often with the aid of an auxiliary flame, leads to the combustion of the solvent and the eventual decomposition of the metal precursors. Within this flame environment, characterized by elevated temperatures, the precursor decomposes, and metal or metal-oxide nanoparticles nucleate and grow [27]. The characteristics of the resultant nanoparticles—size, morphology, crystallinity, and phase composition—can be controlled by diligent choice of the metal precursor, its concentration in the solution, the solvent’s nature, the atomization method, flame temperature, oxygen-to-fuel ratio, and the residence time of particles within the flame. Both inorganic and organic metal salts—including nitrates, acetates, and 2-ethylhexanoates—as well as metalorganic compounds such as acetylacetonates or alkoxides, serve as prevalent precursors [28]. These compounds are soluble in organic solvents, notably xylene (with a standard enthalpy change in combustion [29], = −4550 kJ mol−1), toluene (−3910 kJ mol−1), ethanol (−1376 kJ mol−1), acetonitrile (−1256 kJ mol−1), etc. Another pivotal aspect of the FSP design is its continuous mode of operation that enhances its scalability potential, making it an attractive proposition for industrial applications.

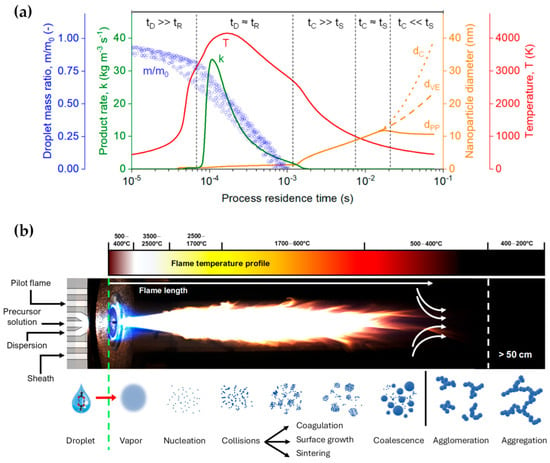

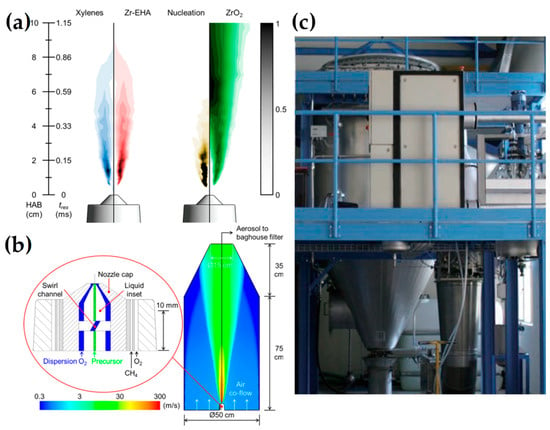

Furthermore, the high-temperature synthesis environment ensures rapid crystallization of particles, obviating the need for post-process annealing. Meierhofer et al. [1] delineated the relationship between temperature and process residence time during each phase of the droplet-to-particle formation, as represented by the red line in Figure 2a and the flame temperature profile in Figure 2b. At the nozzle’s apex, temperature fluctuations range from 500 to 400 °C within the initial 10 μs. Adjacent to the capillary tip, the flame’s core registers the peak temperatures, oscillating between 3500 and 2500 °C (Figure 2). At this juncture, the precursor solution vaporizes, initiating the nucleation of the primary particles. Following initial particle formation, particles fuse cohesively within the temperature range of 1700–600 °C during coagulation and sintering processes. Driven by Brownian motion, these particles collide and coalesce, forming larger entities. As the sintered particles move further through the flame and into cooler regions (<600 °C), they can stick together into agglomerates, forming loose clusters. This clustering is due to physical forces, such as van der Waals interactions. Subsequently, these agglomerates transform into aggregates, binding more firmly through chemical (covalent) bonds in the temperature range of 400–200 °C. The FSP setup typically comprises components like liquid atomizers, combustion chambers, flame torches, and substrate holders for potential direct deposition of nanoparticles.

Figure 2.

(a) Temporal scales in the fabrication of ZrO2 nanoparticles via FSP. A time-evolving analysis encompasses the dynamics of the droplet mass ratio, the rate of product formation, nanoparticle diameter, and gas temperature, serving to demarcate distinct phases within the manufacturing process. Reprinted (adapted) with permission from [1]. Copyright 2021 American Chemical Society. (b) Visualization of actual FSP flame, depicting the synthesis parameters (pilot flame, precursor solution, dispersion, sheath gas). Concurrently, a graphical representation of the flame’s temperature distribution, congruent with that depicted in (a), is presented. Below the flame, a comprehensive elucidation of the droplet-to-particle transformation process in the production of nanoparticles is provided.

1.3. Recent Advancements in Product/Nanodevice Development

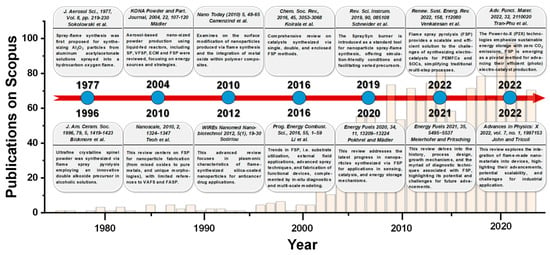

Figure 3 provides a chronological tracing of the literature articles related to FSP, highlighted by pertinent reviews. Introduced in the 1970s by Sokolowski et al. [30], FSP was utilized for synthesizing Al2O3 nanoparticles from an aluminum acetylacetonate precursor in a benzene-ethanol solution via an ultrasound nozzle. Despite the initial decline in interest, the technique was refined in the 1990s by Laine and colleagues at the University of Michigan [7,31]. In a pilot-scale FSP reactor, a double-alkoxide (Mg-Al) precursor in an alcoholic solution was employed to yield spinel MgAl2O4 nanoparticles at rates between 50 and 100 g/h. Concurrently, scientists at Tampere University of Technology employed the FSP method for various metal oxide syntheses and conducted detailed optical diagnostics on the produced aerosols [32]. By the commencement of the 21st century, Pratsinis’s team at the Swiss Federal Institute of Technology in Zürich further adapted FSP, highlighting its potential in catalytic material development [33].

Figure 3.

Timeline of the flame spray pyrolysis (FSP) technology, and some pertinent review articles. The bar graph depicts the annual publication frequency (1365 documents in total) from 1977 to 2023, sourced from Scopus using the keyword ‘Flame Spray Pyrolysis’ [1,2,30,31,34,35,36,37,38,39,40,41,42,43].

Mädler’s review in 2004 [34] emphasized the increasing use of liquid-fed reactors for the aerosol-based synthesis of nano-sized powders. The rising interest in aerosol processes and the growing demand for various functional metal oxides have accelerated the R&D of these reactors. He examined four primary spray techniques: spray pyrolysis in a tubular reactor (SP), vapor flame reactor spray pyrolysis (VFSP), emulsion combustion method (ECM), and flame spray pyrolysis (FSP), comparing their energy sources and reaction mechanisms. He also outlined methods to produce consistent products and their specific applications [34]. In 2010, Teoh and colleagues [2] presented an exhaustive review focusing on FSP as a method for nanoparticle synthesis, spanning from mixed oxides to pure metals and encompassing specialized morphologies, such as core-shell structures, with minimal references to VAFS and FASP. Conversely, Camenzind and associates [35] delve into the surface functionalization of nanoparticles generated through flame synthesis and the incorporation of metal oxide within polymer composites. Moreover, in 2013, Sotiriou [36] provided an in-depth review emphasizing the plasmonic properties of flame-synthesized silica-coated nanoparticles and their potential applications in anticancer drug delivery.

Koirala et al. in 2016 [37] conducted a thorough examination of catalysts produced through single, double, and enclosed FSP techniques. In the same year, Li and his colleagues [38] detailed advancements in FSP, encompassing substrate usage, applications of external fields, innovative spray methodologies, and the construction of functional apparatus, supplemented by in situ diagnostics and multi-scale simulations. In 2019, Schneider et al. [39] presented the SpraySyn burner as a benchmark instrument for the spray-flame synthesis of nanoparticles. This apparatus offers conditions amenable to simulation and accommodates a variety of precursors. One year later, Pokhrel and Mädler’s review [40] outlined recent advancements in nanoparticles produced through FSP for sensing, catalysis, and energy storage applications, while Meierhofer and Fritsching in 2021 [1] provided a detailed analysis of FSP’s historical context, design, growth mechanisms, and diagnostic methodologies, emphasizing its prospective opportunities and challenges.

Meanwhile, Venkatesan et al. [41] highlighted that FSP offers a scalable and proficient approach to address the complexities of electrocatalyst synthesis for polymer electrolyte membrane fuel cells (PEMFCs) and solid oxide cells (SOCs), streamlining conventional multistage procedures. In 2022, Tran-Phu et al. [42] presented a review on Power-to-X (P2X) technologies, underscoring the significance of sustainable energy storage with zero CO2 emissions. Within this context, FSP is identified as a crucial technique for enhancing the production of efficient (photo)electrocatalysts. Ultimately, within that year, John and Tricoli’s review [43] probed the particle formation mechanism, drawing insights from micro-explosions in single droplet experiments across diverse precursor–solvent pairs. The discussion emphasizes the importance of layer fabrication for industrial applications, including gas sensors, catalysis, and energy storage.

Herein in this review, we focus on recent advancements in product and nanodevice development by FSP. In Section 2, we review key aspects of engineering of complex assemblies via FSP, as well as mechanisms and process designs such as the oxygen-deficient process, double-nozzle configuration, in situ coatings, FSP deposition, sequential/nano-film deposition, and scale-up industrial production that enable the creation of intricate nanostructures. In Section 3, we discuss examples of complex functional nanostructures and nanodevices synthesized via FSP, such as perovskites, non-oxides, quantum dots, plasmonics, nanofilms, and sensors unraveling their potential applications and the scientific underpinnings that govern their multifaceted functionality.

2. Engineering of Complex Nanoassemblies by Flame Spray Pyrolysis

Complex configurations via FSP encompass a wide range of materials—see details in Section 3. In this section, we review the FSP process principles that can be used to achieve engineering of the advanced nanostructures. In brief, for the sake of the presentation, we can categorize the FSP methodologies as

- -

- Oxygen-deficient FSP process,

- -

- Double-nozzle FSP configuration,

- -

- In situ coatings FSP deposition,

- -

- Sequential/nanofilm FSP deposition.

Finally, we discuss some aspects of scale-up FSP. By this, we refer to the pilot FSP reactors that have been reported so far by various research laboratories and their application in novel nanomaterials engineering.

2.1. Oxygen-Deficient FSP Process

The concept of oxygen-deficient synthesis can pertain to anoxic or reduced metal oxides. In the literature, these are referenced as MKOL−x where K and L are the stoichiometry coefficients that determine the stable crystal phase MKOL. In this terminology, x signifies the O-deficiency coefficient.

Here, for the sake of the discussion, we classify these materials in three cases:

- [i]

- O-vacancies generation with no change in the crystal phase: lack of O atoms from the lattice, compared to the formal stoichiometry of the nominal crystal phase, with no modification of the crystal phase.

- [ii]

- Generation or reduced metal atoms with no change in the crystal phase: lack of O atoms from the lattice can stabilize lower-oxidation states of the metal atoms.

Often, cases [i] and [ii] are interlinked since the reduction in individual metal atoms in the lattice can be triggered thermodynamically from the generation of one or more O-vacancies in its immediate vicinity.

- [iii]

- Stabilization of a reduced crystal phase via lack of O atoms: certain O-deficient metal oxides can stabilize reduced phases. This occurs when a significant fraction part of the metal atoms is reduced. For example, magnetite Fe3O4, which contains one Fe2+ and two Fe3+, can be formed from Fe2O3 (two Fe3+) when 1/3 of the Fe3+-atoms is reduced to Fe2+. Further reduction in all Fe atoms to Fe2+ forms the FeO phase, while further reduction to Fe0-atoms forms the metallic, zero-valent-iron material. Similarly, Cu2O (SnO) is formed when all Cu2+ (Sn4+) atoms in CuO (SnO2) are reduced to the Cu1+ (Sn2+) state.

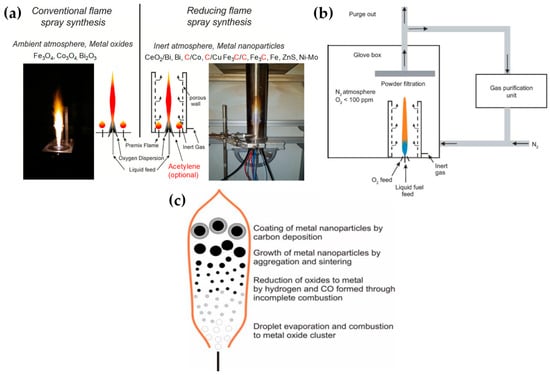

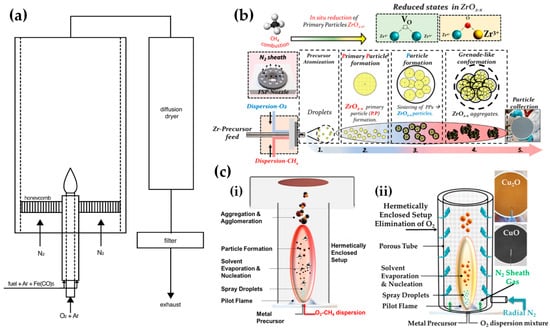

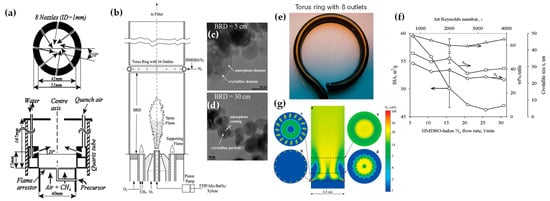

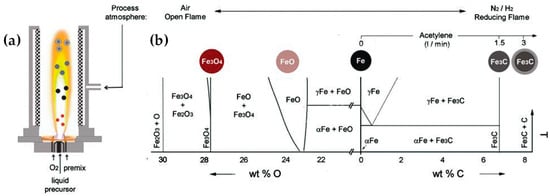

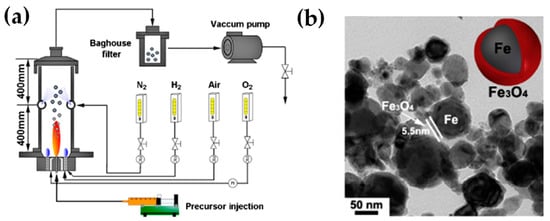

Table 2 presents a list of literature data on the use of anoxic FSP to engineer nanostructures. The concept of using an oxygen-lean FSP was pioneered by Grass et al. to produce oxygen-deficient metal-oxide particles [44] by placing the FSP nozzle inside a glove box filled with inert nitrogen and regulating the intake of oxidizing gas as illustrated in Figure 4b,c. The dispersion gas mixture in the flame can shift from a CO2/H2O composition (representing traditional, oxidizing flames, see Figure 4a) to a CO/H2/H2O mixture (under reducing conditions) [44]. Noble metal nanoparticles, including Pt, Au, Ag, and their alloys, can typically be produced even in oxygen-rich FSP, i.e., due to the thermodynamic preference of the metal state vs. the oxide state by the noble metal atoms. However, creating non-noble metals necessitates a reductive environment. When cobalt or bismuth organic precursors [45], such as cobalt(II)- and bismuth(III)-2-ethylhexanoate (more information in Table 2), are burned in a controlled atmosphere (with O2 levels less than 100 ppm) and with a high fuel-to-oxygen ratio (see Figure 4b), it enables the swift production of pure Co and Bi metal nanoparticles, enhancing the conventional flame process. With this experimental setup, Stark et al. have explored the creation of metallic bismuth nanoparticles ensuring no soot formation [46]. While the reducing environment might be beneficial for producing metallic particles on a large scale [45,47], it comes with the risks of incomplete combustion [1]. In the case where the oxygen supply is further constrained, a fine carbonaceous layer tends to form on these metal nanoparticles [47,48]. Using this experimental setup, NiMo nanoalloys [49] and ZnS nanocompounds [50] have been reported.

Figure 4.

(a) Conventional FSP (left) and our reducing FSP (right), where the anoxic flame is produced by in situ introduction of reducing dispersion gas, e.g., CH4. (b) An anoxic FSP reactor, used by Stark, with the whole reactor enclosed in a glove box filled with an inert atmosphere. By adjusting the gas flow rates, it is possible to achieve highly reduced conditions (O2 < 100 ppm). Used with permission of Royal Society of Chemistry from [45]; permission conveyed through Copyright Clearance Center, Inc. (c) Schematic depiction of the step-by-step transformation from precursor to oxide, metal, and carbon-coated metal nanoparticles during the reducing flame synthesis process: Initially, the precursor undergoes evaporation and combustion, resulting in oxide nanoparticles. These particles can then be further reduced to their metallic form by H2 and CO. Throughout this procedure, the nanoparticles increase in size due to aggregation and sintering. By introducing acetylene, these metal nanoparticles can acquire a carbon coating layer. Reproduced with permission from ref. [47,48]. Copyright 2007 Wiley-VCH.

Strobel and Pratsinis used an oxygen-deficiency FSP process [51] in order to synthesize Fe2O3, Fe3O4, and FeO nanoparticles. Their setup featured an FSP nozzle with a metal tube (4 cm in diameter and 40 cm in length) positioned directly above it (as shown in Figure 4b). Situated 20 cm above the FSP nozzle and angled at 45°, an internal mix spray nozzle was directed downward. This nozzle delivered deionized water at a rate of 10 mL/min, dispersed using 5 L/min of N2. A different oxygen-deficiency FSP setup for the production of Fe3O4 nanoparticles may be the utilization of a laminar, inverse diffusion flame [52]. This method takes advantage of the properties of the inverse flame, created when an oxidizer is injected into a flow of surrounding fuel [53]. Contrary to conventional flame approaches, this setup ensures that the iron particle formation occurs in a predominantly reducing atmosphere. As illustrated in Figure 5a, the burner features two concentric brass tubes with specific outer diameters, enclosed within an 11.4 cm diameter acrylic chamber. This chamber is crucial for protecting the flame from ambient air, preventing additional particle oxidation and potential secondary diffusion flame formation due to excess fuel reacting with room air. The oxidizer, either pure O2 or an O2-Ar mixture, is released from the innermost tube and is encircled by a blend of fuel (methane or ethylene), argon, and iron precursor vapor. A N2 flow enveloped the resulting inverse flame.

Figure 5.

(a) Experimental setup of laminar, inverse diffusion flame stabilized on a burner for the synthesis of magnetic iron oxide nanoparticles with reduced oxidation state. Reprinted from [52], with permission from Elsevier. (b) The concept of the novel anoxic FSP, as developed by our lab, for ZrO2−x production. Reprinted from [54]. (c) (i) Schematic representation of anoxic FSP reactor used for the synthesis of C@Cu2O/Cu0 nanoparticles. Reprinted from [55]. (ii) Anoxic FSP reactor configuration utilized for creating CuO and Cu2O nanomaterials. Reprinted from [55,56].

Recently, we have exemplified a novel anoxic FSP process, to engineer ZrO2–x (see Figure 5b) [54] and C@Cu2O/Cu0 (see Figure 5c) [55] nanoparticles. Our anoxic FSP concept relies on the combustion of CH4 in the dispersion gas. This introduces reducing agents that can modify the primary Zr particle by creating oxygen vacancies (VO). XPS and EPR confirm that the increased dispersion of the CH4 promotes the formation of oxygen vacancies [54]. A more complicated oxygen-deficiency FSP setup, which includes a dispersion feed consisting of {oxygen (O2)–methane (CH4)} mixture, in tandem with enclosed FSP flame with radial N2, is necessary for the synthesis of non-graphitized carbon/Cu2O/Cu0 heterojunction (see Figure 5c) [55]. The modification in the dispersion gas mixture leads to increased temperatures and generates reducing agents for the controlled phase transformation from CuO to Cu2O and Cu0 (see Figure 5c).

Table 2.

The literature summary of FSP characteristics/conditions for the production of oxygen-deficient nanostructures.

Table 2.

The literature summary of FSP characteristics/conditions for the production of oxygen-deficient nanostructures.

| Nano- Structure | FSP Configuration | Precursor(s) | Solvent | Molarity (mol L−1) | Precursor Flow (mL min−1) | Pilot Flame O2/CH4 (L min−1) | N2 Flow (L min−1) | Ref. |

|---|---|---|---|---|---|---|---|---|

| C-Co | The flame is encased in a porous tube enabling the addition of inert cooling gases and acetylene. The flame is operated in a glove box in an N2 atmosphere at an O2 < 100 ppm. | Cobalt(II) 2-ethylhexanoate | Tetrahydrofuran | 6 | 2.2/1.2 | 45 | [48,57] | |

| Bi | The spray nozzle was placed in a Glove box fed with N2. A sinter metal tube (inner diameter 25 mm) surrounding the flame allowed for N2 radial flow. | Bismuth(III) 2-ethylhexanoate | Tetrahydrofuran | 6 | 2.2/1.2 | 25 | [46] | |

| CeO2/Bi | Bismuth(III) 2-ethylhexanoate, Cerium(III) octoate | Tetrahydrofuran | 6 | 2.2/1.2 | 45 | [45] | ||

| C-Cu | The flame is encased in a porous tube enabling the addition of inert cooling gases. The flame is operated in a glove box in an N2 atmosphere at an O2 < 100 ppm. | Cu(II)-2-ethylhexanoate | Tetrahydrofuran | 4.5 | 2.2/1.2 | 45 | [47] | |

| Ni-Mo | Ni(II)-ethylhexanoate, Mo(II)-ethylhexanoate | Tetrahydrofuran | 6 | 2.2/1.2 | 45 | [49] | ||

| FexOy | FSP nozzle with an Inconel metal tube (ID = 4 cm, length = 40 cm). Water was fed into this nozzle and dispersed by N2 gas. | Fe(III) nitrate nonahydrate, Fe(II) naphthenate | 2-ethylhexanoic acid/THF/ethanol (2/2/1) | 0.9 | 5 | 2.5/1 | 40 | [51] |

| α-Fe/Fe3O4 | Laminar, inverse diffusion flame stabilized on a burner. | Iron pentacarbonyl | [52] | |||||

| ZrO2–x | A single-nozzle FSP reactor featuring an enclosed flame utilizing a mixture of dispersion gases, O2 and CH4, to establish a reductive reaction environment. | Zirconium(IV) Propoxide | Xylene/acetonitrile (2.2/1.0) | 0.25 | 3 | 4/2 | 15 | [54] |

| C@Cu2O/ CuO/Cu0, Cu2O/CuO | A single-nozzle FSP reactor featuring enclosed flame utilizing a mixture of dispersion gases, O2 and CH4, to establish a reductive reaction environment. A perforated tube permits the introduction of radial N2 gas. | Copper(II) nitrate trihydrate | Acetonitrile/ ethylenglycol (1/1) | 0.25 | 3 | 2/1.2 | 10 | [55,56] |

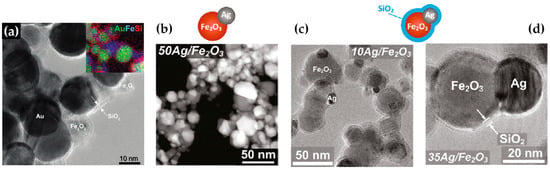

2.2. Double-Nozzle FSP Configuration

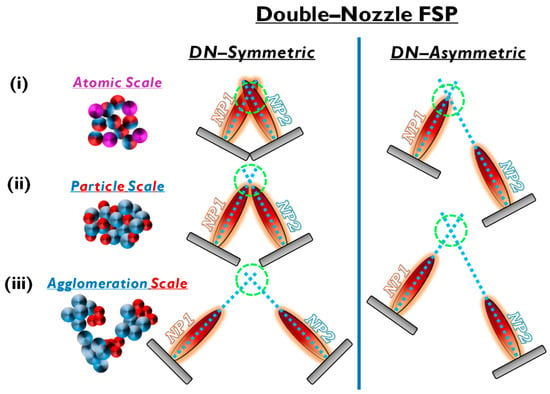

In the case of mixed structures, e.g., heterojunctions, core-shell compositions, etc., the application of two FSP nozzles that operate in tandem offers advantages. Typical examples include the cases where a nanomaterial (NP1) and a cocatalytic nanomaterial (NP2) are combined. In the conventional single-nozzle FSP, a single precursor contains both the elements of nanomaterial (NP1) and nanomaterial (NP2) and produces the combined material in a single flame (see Figure 6a).

Figure 6.

Symmetric and asymmetric DN-FSP configuration for two particle formation regarding the (i) atomic, (ii) particle, or (iii) agglomeration scale.

Double-nozzle FSP entails two independent spray flames, with the precursor of NP1 inserted in a different flame than NP2 (see Figure 6). This method unlocks several options for independent size control, mixing, and specific deposition for the two nanomaterials by altering the primary geometrical parameters of distance and intersection of the flames. As shown in Figure 6: (i) At a small flame-intersection distance, where the centers of the flames are in contact, the atoms are in the preliminary stages of crystallization, producing well-mixed particles, tending to be similar to the single-nozzle FSP. In this case, the second flame substantially increases the synthesis overall temperature. (ii) When the intersection occurs after the endpoints of the flames, the materials are well crystallized, resulting in well-mixed primary particles of NP1 and NP2. (iii) At increased intersection distance, the two materials mix at their sintering stage or bigger distances at the agglomeration stage.

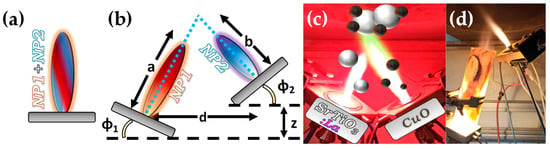

Thus, by changing the geometrical disposition of the two flames via the parameters a, b, d, Φ1, Φ2, and Z (see Figure 7b), the symmetrical/asymmetrical DN-FSP configuration offers a versatile technology that allows for the control of composite configurations at different synthesis stages, i.e., at the atomic scale, at the particle scale, or the aggregate’s scale (see Figure 6). Table 3 presents a list of the literature data on the use of DN-FSP to engineer nano-heterostructures.

Figure 7.

(a) Schematic example of SN-FSP where two precursors are mixed before being fed to the flame. (b) Geometry parameters of DN-FSP. (c) Example of a symmetrical DN-FSP, used for engineering of La-doped SrTiO3, with surface deposition of CuO. Reprinted from [58]. (d) Example of asymmetrical DN-FSP.

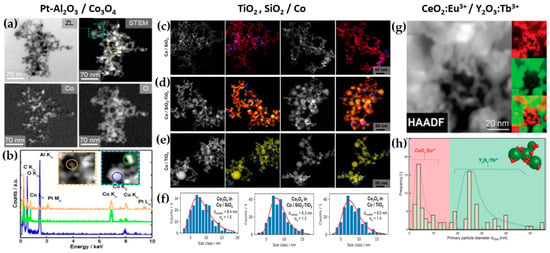

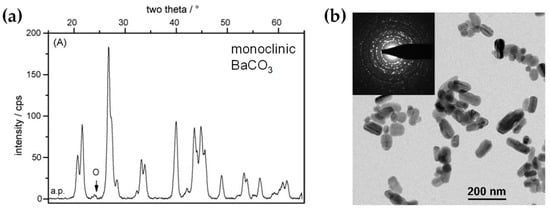

Al2O3: DN-FSP was first implemented by Strobel et al. [59], producing in one nozzle Al2O3 and in the second nozzle Pt/BaCO3, thus forming individual Al2O3 and monoclinic BaCO3 nanoparticles. Increasing the internozzle distance delayed flame product mixing, increasing the crystallinity of BaCO3. In contrast, the single-nozzle process yielded Al2O3 particles with amorphous Ba species. The two-nozzle process enhanced NOx storage behavior, while the single-nozzle approach showed negligible NOx retention [59]. Following this successful novelty method, a series of Al2O3-based articles were published, herein chronologically presented: Minnermann et al. [60] produced in one nozzle Al2O3 and in the other pure oxide or mixed CoOx. Single flame synthesis is inadequate for producing an effective Al2O3/Co FT catalyst due to inadequate reducible cobalt oxide support particle size. The DN-FSP geometry significantly influences the resulting catalyst, yielding smaller alumina particles as the intersection distance increases, resulting in good adhesion of the two oxides and good stabilization. Høj et al. [61] produced Al2O3/CoMo by DN-FSP, and varying flame mixing distances (81–175 mm) minimized the formation of CoAl2O4, detectable only at short flame distances. Notably, employing DN-FSP synthesis achieved superior promotion of the active molybdenum sulfide phase, potentially attributed to reduced CoAl2O4 formation, consequently enhancing Co availability for promotion. Schubert et al. [62], through DN-FSP, produced Al2O3/Co enhanced with Pt (0.03, 0.43 wt%) deposition in the first nozzle and other materials in the second nozzle. Noble metals enhance catalyst reducibility, yielding abundant metallic Co sites. Due to their high cost, optimizing synthetic strategies for low concentrations is essential. Regardless of the preparation approach, adding 0.03 wt% Pt significantly improves catalytic activity in CO2 methanation, and 0.43 wt% Pt marginally increases the catalyst reduction. Using DN-FSP, Horlyck et al. [63] produced Al2O3/Co with Lanthanum doping (0–15 wt%). Increased La content and wider nozzle distance suppressed undesirable CoAl2O4 spinel phase, promoting easily reducible Co species. La addition enhanced carbon resistance, ensuring maximum methane conversions at 15 wt% La without catalyst deactivation or carbon formation. Stahl et al. [64] used DN-FSP to produce Co/Al2O3; in the nozzle of Al2O3, one additional particle—SmOx, ZrOx, or Pt—was formed contributing different cocatalytic effects, enhancing surface hydrogen or carbon oxide concentrations (see Figure 8a,b). All catalysts had consistent morphology with interconnected 12 nm alumina oxides and 8 nm cobalt oxides. For CO2 methanation, Pt and zirconia proved optimal, aligning with Pt-enhanced H2 adsorption and zirconia’s higher CO2 adsorption due to oxide sites with medium basicity.

Figure 8.

(a) TEM images revealing the local distribution of cobalt and oxygen for Pt-Al2O3/Co3O4, (b) EDX measurements for chemical composition. Reprinted from [64]. DΝ-FSP-prepared (c) SiO2/Co, (d) SiO2-TiO2/Co, (e) and TiO2/Co; left images show STEM-HAADF and right images show EDX mappings of the elements Co (blue), Si (red) and Ti (yellow). (f) Particle size distributions of Co3O4 for the materials SiO2, SiO2-TiO2, and TiO2. Reproduced with permission from ref. [65]. Copyright 2022 Wiley-VCH. (g) STEM-HAADF of the nano-mixed CeO2:Eu3+/Y2O3:Tb3+ and its elemental mapping for Ce in red and Y in green, (h) dTEM distribution of CeO2:Eu3+ and Y2O3:Tb3+. Reprinted from [66], with permission from Elsevier.

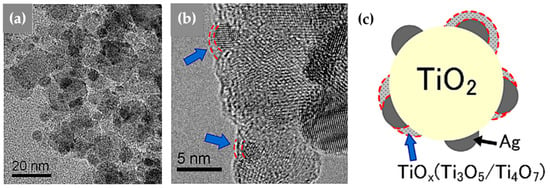

TiO2: Grossmann et al., through the utilization of DN-FSP, produced TiO2 with deposited Pt particles [67]. Geometric configurations in DN-FSP strongly influenced Pt particle size and distribution on TiO2. Larger intersection distances and smaller angles result in nonuniform large and broadly distributed Pt clusters on TiO2. Conversely, smaller distances and larger angles enhance Pt dispersion and a uniform mixing, akin to single flame; however, DN-FSP allows for individual tuning of compound particle sizes. Solakidou et al. produced {TiO2-Noble metal} nanohybrids, with deposition of Pt0, Pd0, Au0, or Ag0 [68]. As shown, DN-FSP is superior vs. single-nozzle-FSP for finely dispersing noble metals on TiO2 support, achieving a narrower size distribution [50]. DN-FSP promoted intraband states in TiO2/noble metal, reducing the band gap. Efficient H2 generation presented the following trend: Pt0 > Pd0 > Au0 > Ag0, in line with a higher Schottky barrier upon TiO2 contact [50]. Gäßler et al. produced SiO2, TiO2, and SiO2-TiO2 mixture with DN-FSP deposition of Co3O4 (see Figure 8c–f) [65]: titania, comprising anatase and rutile phases, the SiO2-TiO2 mixed support, with separate anatase and silica phases. H2O adsorption varies significantly based on the support: SiO2 < SiO2-TiO2 < TiO2. CH4 formation rate increased with higher TiO2 fractions, while CO formation rate peaked in the mixed support. Psathas et al. used DN-FSP to engineer heterojunctions of perovskite SrTiO3 with deposited CuO nanoparticles (0.5 to 2 wt%) [58]. Higher CuO deposition led to larger SrTiO3 particle sizes due to increased enthalpy from the second flame [40]. Scanning TEM depicted small CuO particles (<2 nm), mainly found on the surface of SrTiO3. The dopant concentration significantly controlled the selective production of H2 or CH4 from H2O/CH3OH. CuO incorporation drastically shifted production to CH4, achieving a rate of 1.5 mmol g−1 h−1 for the La:SrTiO3/CuO catalyst (0.5 wt%) [58].

Table 3.

The literature summary of characteristics/conditions for nanostructures synthesized by symmetric and asymmetric DN-FSP methods.

Table 3.

The literature summary of characteristics/conditions for nanostructures synthesized by symmetric and asymmetric DN-FSP methods.

| Nanomaterial | Geometric Parameters (cm) | Precursor(s) * | Molarity * (mol L−1) | Precursor * (mL min−1) | Oxygen * (L min−1) | Size (nm) | SSA (m2 g−1) | Ref. |

|---|---|---|---|---|---|---|---|---|

| Symmetric DN–FSP | ||||||||

| Al2O3/Pt/Ba | φ = 30°, d = 3–7 | Al(III) tri-sec-butoxide/ Ba(II) 2-ethylhexanoate, Pt(II) acetylacetonate | 0.5/ 15.4 wt% Ba, <1 wt% Pt | 5/ 3 | 5/ 5 | 10–20 | 120–160 | [59] |

| Al2O3/Co | φ = 20°, d = 11, a = 16 | Al-sec-butoxide/Co naphthenate | 0.5/ 10 wt% Co | 5/ 5 | 5/ 5 | 15–30 | 111–122 | [63] |

| TiO2/Pt0, Pd0, Au0, Ag0 | φ = 30°, d = 11 | Ti(IV) isopropoxide/ Pt(II), Pd(II), Au(III), Ag(I) acetylacetonate | 0.64/ 0–5 wt% | 5/ 3–7 | 5/ 3–7 | 10–20 | 72–200 | [68] |

| TiO2-SiO2/ Co | φ = 20° d = 15, a = 22 | Ti(IV) isopropoxide, TEOS/ Co naphthenate | 0.9/ 9 wt% Co | 5/ 5 | 5/ 5 | 7–16 | 86–284 | [65] |

| SrTiO3/CuO | φ = 20°, d = 8, a = 10 | Sr acetate, Ti(VI) isopropoxide/ Cu(II) nitrate trihydrate | 0.4/ 2–0.5 wt% Cu | 5/ 5 | 5/ 5 | 45–55 | 32–57 | [58] |

| ZrO2/CuO | φ = 10° | Zr 2-ethylhexanoate/Cu(II) 2-ethylhexanoate | 0.5/ 11 wt% Cu | 5/ 5 | 5/ 5 | 10–20 | 106–114 | [69] |

| LiMn2O4/AlPO4 | φ = 20°, d = 17 | Li and Mn(III) acetylacetonate/Al-tri-sec-butoxide, triethyl phosphate | –/ 0–5 wt% AlPO4 | 3–7/ 5 | 3–7/ 5 | 7–22 | 64–195 | [70] |

| CeO2:Eu3+/ Y2O3:Tb3+ | φ = 30° | Ce 2-ethylhexanoate/Y nitrate hexahydrate | 0.3/ 0.4 | 3–12/ 3–12 | 3–8/ 3–8 | 5 | 185 | [66] |

| Asymmetric DN–FSP | ||||||||

| SiO2/Ce0.7 Zr0.3O2 | φ1 = 20°, φ2 = 35°, a = 23, b = 5 d = 11, z = 10 | TEOS/Ce 2-ethylhexanoate, Zr(IV) n-propoxide | 0.5/ 0.19 | 3–7/ 5 | 5/ 5 | 18.5–28.5 | 217–363 | [71] |

| NaTaO3/NiO–Pt0 | φ1 = 30°, φ2 = 15°, a = 20, b = 24, d = 11, z = 3 | Na 2-ethylhexanoate, Ta(V) chloride/Ni(II) 2-ethylhexanoate, Pt(II) acetylacetonate | 0.1–0.6/ 0.5 wt% Ni, 0.5 wt% Pt | 3–9/ 5 | 3–9/ 5 | 12–34 | 19–84 | [72] |

* In the setup, because there are two distinct nozzles, parameters related to them are differentiated and denoted using a slash: nozzle 1/nozzle 2.

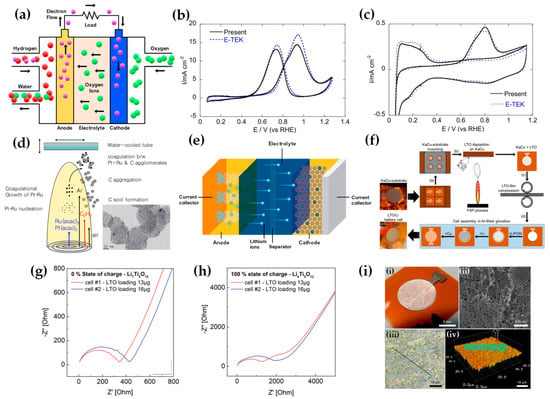

Other particles: Tada et al., using DN-FSP, produced a ZrO2/CuO heterostructure [69]. Changing the geometrical parameters of DN-FSP altered the proportion of interfacial sites vs. copper surface sites. As active sites are primarily at the metal–oxide interface, ZrO2/CuO with smaller CuO clusters exhibited higher activity in methanol synthesis via CO2 hydrogenation. Gockeln et al., by a combination of DN-FSP and a lamination technique [73], synthesized in situ carbon-coated nano-Li4Ti5O12 Li-ion battery electrodes. Li et al. synthesized LiMn2O4 spinel as a cathode material for Li-ion batteries via screening 16 different precursor–solvent combinations [70]. To overcome the drawback of capacity fading, the deposition of AlPO4 (1–5%) via DN-FSP was homogeneously mixed with LiMn2O4. The optimal 1% AlPO4 with LiMn2O4 demonstrated an energy density of 116.1 mA h g−1 at 1 C (one-hour discharge). Henning et al. used DN-FSP to engineer luminescent biosensors CeO2:Eu3+/Y2O3:Tb3+ [66]. CeO2:Eu3+ nanoparticles (6 nm, 22 wt%) and Y2O3:Tb3+ nanoparticles (32.5 nm, 78 wt%) were shown to function as robust optical-based ratiometric H2O2 biosensors (see Figure 8g,h). Based on the collective effect, H2O2 caused significant luminescence quenching in CeO2:Eu3+ nanocrystals, but Y2O3:Tb3+ nanoparticles were unaffected [48].

Asymmetric Double Flame: Lovell et al. utilized asymmetric-DN-FSP geometry to control the SiO2 interaction with Ce0.7Zr0.3O2 nanoparticles [71]. Tuning the intersection distance during DN-FSP (18.5 to 28.5 cm) prevented silica coating. Short intersection distances led to high surface-area silica encapsulating ceria-zirconia, while longer distances suppressed this encapsulation. The material at longer intersection distances, used as Ni support for dry methane reforming, showed enhanced oxygen storage capacity and basicity, yielding a highly selective catalyst. Psathas et al. used asymmetrical-DN-FSP-deposited NiO or Pt0 nanomaterials on the surface of Ta2O5 or the perovskite NaTaO3 [72]. Single-step synthesis of the smallest produced NaTaO3 (<15 nm), with finely dispersed NiO or Pt0 (<3 nm). NaTaO3/NiO produced from FSP had half the photocatalytic hydrogen production than those from DN-FSP. Also, DN-FSP had a ten times higher yield than the conventional deposition of wet-impregnated NiO. Similar results were found for the photocatalytic efficiency of NaTaO3/Pt0, which was 30% more photocatalytically active than the conventional liquid-Pt photo-deposition method [54].

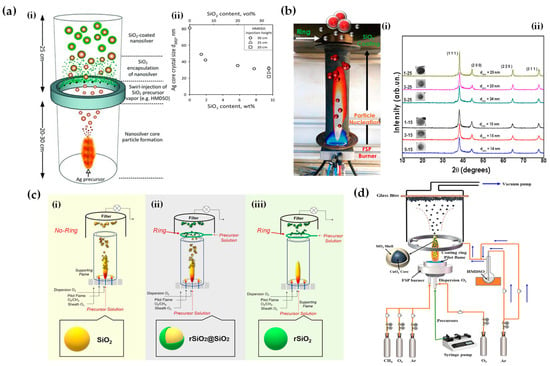

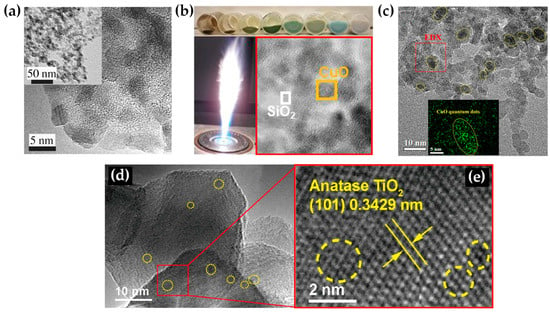

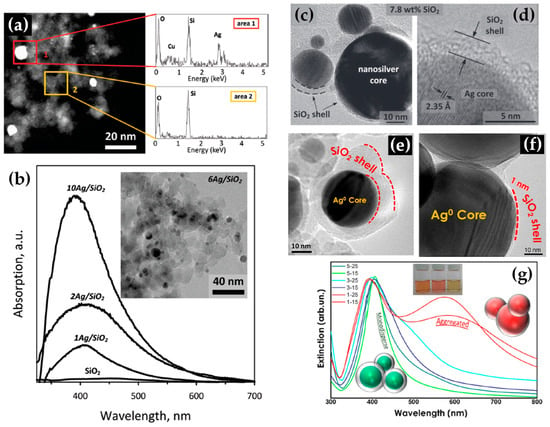

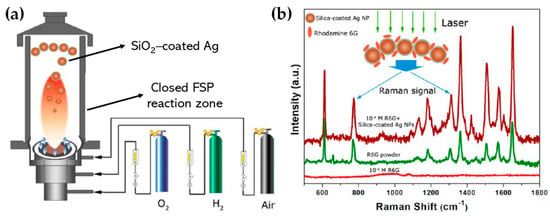

2.3. In Situ Coatings by FSP

Apart from heterojunction engineering, FSP allows for in situ engineering of core-shell structures, i.e., where a hermetic layer can be deposited on the core particle. Hansen et al. were the first to present this concept, using a spraying-ring apparatus, which facilitated the synthesis of ZnO particles (see Figure 9a) [74]. This research revolved around the exploration of how introducing cold air to cool a flame could influence the formation of ZnO particles. Their findings indicated that a swift drop in temperature downstream from the peak greatly benefitted the creation of particles with significant specific surface area [74]. Later on, this ring-spraying setup was predominantly employed to produce core-shell particles. Teleki et al. demonstrated that a hermetic SiO2-layer can be formed around TiO2 nanoparticle FSP reactor via injection of hexamethyldisiloxane (HMDSO) vapor—a precursor for SiO2—on the TiO2-forming stream (see Figure 9b–d) [75]. Addressing the problem of distinct Si and Ti domains found in earlier research [76], they incorporated a toroidal ring in an encapsulated FSP reactor. This facilitated the separate introduction of the gaseous Si precursor, HMDSO. The study emphasized that under specific conditions, it is possible to achieve the desired coatings in a single-phase system, avoiding the complexities of multiple phases [76]. In subsequent research, the same team (see Figure 9e–g) [77] utilized experimental and computational fluid dynamics (CFD) techniques to investigate the integrity of resultant coatings. Flame-made nanoparticles have been effectively coated in a single step, achieving notable production rates of 30 g/h. Predominantly, rutile TiO2 nanoparticles (enriched with Al) with an approximate diameter of 40 nm were synthesized with an in situ coating of 20 wt% SiO2. CFD further clarified the effects of merging the TiO2 aerosol with the HMDSO vapor stream jets (see Figure 9g).

Figure 9.

(a) Overhead perspective of the stainless steel segment in the quench ring according to the research work of Hansen et al. [74]; every nozzle is angled at 10° compared with a hypothetical line passing through the central axis. Reproduced with permission from ref. [74]. Copyright 2001 Wiley-VCH. (b) Experimental configuration for in situ SiO2 coating of TiO2 nanoparticles produced by Teleki et al. [75], using a toroidal pipe ring with 16 gas exits to inject HMDSO-laden N2. At burner ring distances (BRD) of (c) 5 cm and (d) 30 cm, this leads to distinct SiO2/Al2O3/TiO2 or SiO2-layered Al/TiO2 particles, each containing 4 wt% Al2O3 and 20 wt% SiO2, respectively. Reprinted (adapted) with permission from [75]. Copyright 2008 American Chemical Society. (e) Toroidal pipe ring equipped with 8 outlets for injection of the HMDSO-laden N2. (f) Impact of the ring N2 flow rate (along with the associated jet Reynolds number at 300 K) under standard coating conditions on SSA (depicted by circles), rutile weight percentage (represented by triangles), anatase (shown as squares), and rutile (illustrated by diamonds) crystallite sizes of 20Si-coated Al/TiO2. (g) Graphical representations of the (a) N2 volume percentage for 16 jets with a combined volume flow of 15.8 L/min N2 (v0 = 58 m/s). The related cross-sectional views are displayed at heights of 0 (b), 0.2 (c), 1 (d), and 3 cm (e) above the outlet level. The logarithmic color gradient extends from <1 (in blue) to 100 (in red) % v/v of N2. Reprinted (adapted) with permission from [77]. Copyright 2009 American Chemical Society.

Building upon similar principles, Sotiriou et al. demonstrated the one-step production of Ag/SiO2 core-shell nanoparticles [78]. The innovative design of their apparatus, featuring a torus ring with multiple jets, ensured the accurate in-flight coating of particles (shown in Figure 10a). A crucial aspect of their work was to understand how the SiO2 content in resultant particles can be manipulated through process adjustments, influencing the size of the nanosilver particles and preventing their agglomeration. The particles were covered in-flight by injecting HMDSO through a torus ring equipped with multiple evenly spaced and uniform jets, each having a diameter of 0.6 mm. This injection occurred at a specific height referred to as the burner ring distance (BRD). Regardless of the BRD values, the length of the tube above the torus ring was maintained at 40 cm. HMDSO vapor-laden N2 gas at a flow rate of 0.8 L/min was obtained by bubbling nitrogen gas through liquid HMDSO at varying temperatures, through the jet openings. The amount of HMDSO injected was adjusted to achieve a targeted theoretical coating thickness (CT) of either 3 or 6 nm [79]. The SiO2 content in the resulting particles was determined under complete saturation conditions. Our research group extended this knowledge and developed Ag@SiO2 particles with a slightly modified experimental setup [80,81] illustrated in Figure 10b. The HMDSO vapor was generated by bubbling N2 gas through 300 cm3 of HMDSO contained in a glass flask, which was maintained at a temperature of 10 °C. Under saturation conditions, this configuration resulted in a theoretical SiO2 production rate of 5.9 g/h, equal to 20 wt% SiO2 in the product powder [80]. More recently, we have demonstrated that ring-coating FSP allows engineering safe-by-design core-shell SiO2 materials with diminished reactive oxygen species (ROS) generation [82]. As shown in [64], this stems from the flexibility of ring-coating FSP toward modulating the thermal profile during nano-SiO2 synthesis. A cooler SiO2-formation process allowed for the surface passivation of the nanosilica, consequently decreasing its ROS generation potential [64]. In this process, the N2 gas, which served as a carrier of the atom to be dispersed, played a pivotal role in the cooling dynamics [83]. More recent research works include the use of ring-spraying FSP for the production of stable core-shell ZnO@SiO2 [84], CuOx@SiO2 (see Figure 10d) [85], SiO2@YAlO3:Nd3+ [86], and SiO2-coated Y2O3:Tb3+ [87] along with their FSP characteristics listed in Table 4.

Figure 10.

(a) (i) Illustration of the enclosed FSP setup for producing Ag@SiO2 nanoparticles, originally developed by Sotiriou et al. [78]. The ring situated between the two tubes aids in swirling the SiO2 precursor vapor, ensuring the precise control of the SiO2 core. (ii) Adjustment of the crystallite size of nanosilver can be achieved by varying the SiO2 content in the final nanosilver particles and by altering the injection height of the SiO2 precursor vapor to 30 (circles), 25 (triangles), or 20 cm (squares) above the flame spray burner. Enhancing the SiO2 content helps to prevent the agglomeration and crystal growth of Ag nanoparticles. Additionally, introducing HMDSO (the SiO2 precursor) at reduced heights cools the flame aerosol, further inhibiting Ag crystal growth. Reproduced with permission from ref. [78]. Copyright 2010 Wiley-VCH. (b) (i) Schematic depiction of the enclosed FSP reactor where the one-step Ag coating SiO2 particles occur in-flight [80]. Contrary to Sotiriou et al.’s findings [78], the metal ring was at the top of the FSP-enclosed flame. (ii) XRD patterns of SiO2@Ag0 nanoparticles with variations in size and shell thickness. Reprinted (adapted) with permission from [80]. Copyright 2019 American Chemical Society. (c) Schematic illustration of FSP reactor configurations: (i) designed for high-temperature nano-SiO2 production, (ii) tailored for the hybrid rSiO2@SiO2 nanosilica, and (iii) set up for low-temperature nano-rSiO2 synthesis. Reprinted (adapted) with permission from [82]. Copyright 2022 American Chemical Society. (d) FSP apparatus for creating core-shell CuOx@SiO2 nanoparticles. Reprinted from [85], with permission from Elsevier.

Table 4.

The literature summary of FSP characteristics/conditions for the production of core-shell nanostructures.

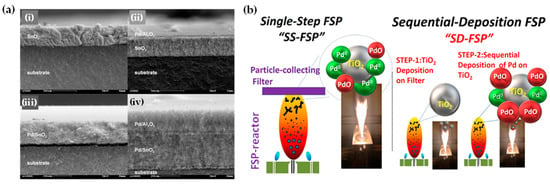

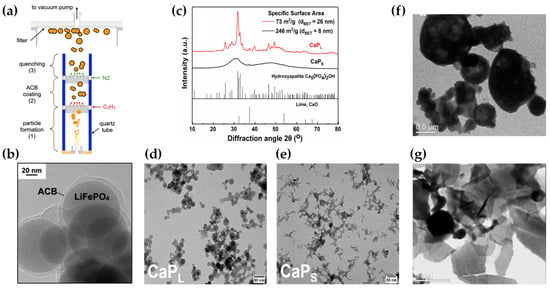

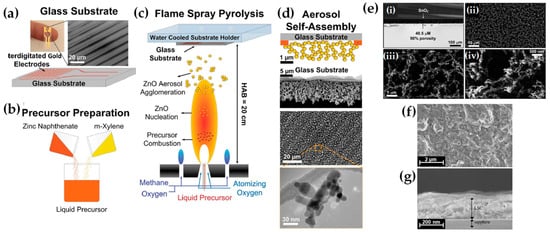

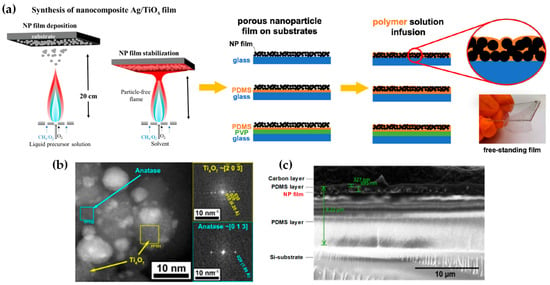

2.4. Sequential FSP Deposition

The concept of sequential deposition was originally used for the fabrication of multilayer films, sensors [89], and fuel-cell applications [41]. Mädler and his colleagues fabricated multilayer films for gas sensing where two different sensing layers were deposited on ceramic substrates sequentially: pure SnO2 onto Pd/SnO2 [90] or Pd/Al2O3 layer on top of a Pd/SnO2 layer (refer to Figure 11a) [89]. Recently, we have developed a sequential-deposition flame spray pyrolysis (SD-FSP) technique for the controlled synthesis of PdO/Pd0/TiO2 nano-heterostructures [91]. SD-FSP is a two-phase process in which a nanometric TiO2 particle layer is deposited on a glass-fiber filter in the first FSP step. Then, in a second FSP phase, Pd particles are produced in an FSP flame under conditions that permit control over the Pd NP size and PdO/Pd0 ratio (as shown in Figure 11b). In this SD-FSP process, combustion of the Pd precursor under open-flame conditions permits ambient O2 entrainment without O2 consumption by TiO2 formation during the combustion [91].

Figure 11.

(a) The concept of sequential deposition technique, as originally exemplified by Sahm et al. [89], for the engineering of multilayer films. Cross-sectional SEM images of a SnO2 layer are shown (i); a Pd/Al2O3 layer over a SnO2 layer (ii); a Pd/SnO2 layer (iii); and a Pd/Al2O3 layer on the top of a Pd/SnO2 layer (iv)—all of which were deposited on ceramic bases. Reprinted from [89], with permission from Elsevier. (b) A schematic depiction of the FSP process employed for the deposition of Pd onto the TiO2 surface in two stages (sequential deposition, SD-FSP). Reprinted (adapted) with permission from [91]. Copyright 2020 American Chemical Society.

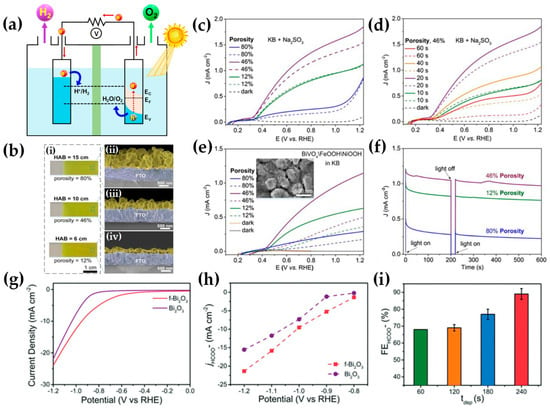

FSP has been adeptly employed for the synthesis of films characterized by a porous network comprising nanoparticles whose porosity can be modulated. Such films have exhibited superior efficacy in applications like chemical sensors [92], photodetectors [93], and solar cells [94]. Homogeneity in films still remains a challenge, especially since cracks can easily form when drying films, i.e., created through traditional wet-phase coating methods. However, films formed in the gas phase [2] do not require drying, leading to more consistent layers, e.g., as in chemical vapor deposition (CVD) methods [95]. The film’s structure resulting from FSP deposition largely relies on the substrate temperature and the stage of particle formation when reaching the substrate. Characteristically, Figure 12b illustrates a schematic of a nanofilm deposition procedure. The nature of the deposit—whether it be precursor droplets, a mix of precursor and product vapors, or product particles exhibiting various agglomeration levels—depends on the particle’s formation phase when it reaches the substrate. This characteristic can be controlled by adjusting the substrate’s position or by modulating the precursor and gas flow rates. When uncovered precursor comes into contact with the substrate, it produces denser films [28] whereas airborne product particles result in highly porous particle films, as depicted in Figure 13a. The porosity of such films can either remain intact or transform into denser formations through a sintering process, contingent on the substrate’s temperature. The nanofilm deposition procedure can be clarified in the research work of Kavitha et al. where they produced TiO2, ZnO [96], and Al2O3, ZnO, ZnO-20 mol% MgO, and ZrO2-Y2O3 [97] films. Films of the aforementioned oxides were applied onto amorphous silica bases measuring 10 mm 10 mm. The setup for deposition, as depicted in Figure 13b, comprises a liquid sprayer, a division chamber, a flame, and a holder for the substrate. In [38], a combination of precursor solution and pressurized air (at 16 lpm) was directed into the atomizer, which generated atomized droplets of the solution and injected them into the separation chamber. Adjustments to this temperature can be made by altering either the gas flow rates or the distance between the substrate and nozzle [96]. A straightforward relationship between the process parameters and the rate of film formation were established by Tricoli et al. [98] in the case of SnO2 films deposited on substrates at temperatures 323 to 723 K in order to study the particle size distribution and deposition dynamics.

Figure 12.

(a) Schematic illustration of the creation of porous or solid films through the flame deposition of droplets, vapors, or particles. (b) Illustrative diagram of the flame spray pyrolysis deposition setup; the embedded image displays an external mix atomizer for film deposition. Reprinted from [96], with permission from Elsevier. (c) FSP burner combined with a temperature-regulated substrate holder designed for nanofilm creation and deposition. Reproduced with permission from ref. [98] Copyright 2012 Wiley-VCH. (d) Diagrammatic representation: (i) Flame-made nanoparticle layers, exhibiting a high porosity of 98%, are methodically deposited onto a silicon wafer using a shadow mask. Subsequently, (ii) these layers undergo in situ mechanical stabilization via an impinging xylene flame devoid of particles. Reproduced with permission from ref. [99] Copyright 2008 Wiley-VCH.

Incorporating flame-based aerosol techniques to industrial-scale semiconductor device engineering poses new challenges. The mechanical integrity of nanostructured layers hinges on the substrate temperature at the time of deposition. While mechanically robust layers can be achieved at elevated temperatures (850 °C), these temperatures do not align with complementary metal oxide semiconductor (CMOS) substrates that host circuit components, as they cannot withstand temperatures exceeding 400 °C. Thus, Tricoli and his colleagues introduced a strategy for stabilizing deposits thermally by using an in situ rapid flame treatment on nanoparticle micropatterns deposited at low temperatures [99]. This technique can be applied while keeping the substrate at low temperatures, and the original crystallite size remains unchanged. The synthesis of metal oxide nanoparticles occurs through the dispersion and ignition of a precursor spray solution of the target material—in [98], it was SnO2. Particle growth progresses through condensation, surface growth, coagulation, and sintering, producing nanocrystalline material (as seen in Figure 12d(i)). Factors like high-temperature particle residence time (HTPRT), metal concentration, and droplet dispersion during FSP influence the particle size [2]. Nanostructured particles then adhere to the substrate in situ, usually forming a highly porous layer. However, due to the substrate’s low temperature (150 °C), this layer has limited mechanical resilience. To enhance its stability, a second phase involves subjecting to thermal curing in FSP, e.g., an “impinging” step, for 30 s using a particle-free xylene flame, as depicted in Figure 12d(ii). This treatment profoundly alters the layer’s texture, enhancing its adhesion to the substrate. Patterns of nanoparticles, with sizes as small as 100 µm, were created by positioning a shadow mask, designed with a series of circular openings, against a Si-wafer (coated with a thin layer of silicon nitride), as shown in Figure 12d [99].

2.5. Scale-Up FSP

Several of the methods used for nanoparticle synthesis are not scalable, i.e., to transcend laboratory production toward industrial scale for large-volume production. These facts are against the actual implementation of real-life applications, hindering the connection of lab research to market-level production. When more complex nanoparticles require time-consuming synthesis protocols with complex processes, these factors lead to very high prices per kilo of particles [100].

Gas-phase synthesis has already shown much promise for the industrial production of nanoparticles. So far, single-metal nanomaterials are produced through gas-phase processes [27]. Gas-phase synthesis includes many essential commodity products that have been widely produced for many years, with some of the most widespread nanomaterials for the industry, such as carbon black by the company Cabot [101] as a reinforcing agent, P25 (TiO2) by Evonik Industries [102] renowned for its photocatalytic properties, pigmentary titania by the companies DuPont, Cristal, and Ishihara, fumed silica (SiO2) by Cabot and Evonik, as well as ceramic-based nanoparticles with the application of flame aerosol processes. The production of flame-made nanoparticles generates millions of tons with a valuation reaching $15 billion/year [38].

The successful utilization of aerosol-made nanomaterials in the market indicates that the industrial-scale manufacturing of gas phase will expand further with future applications, using more complex particles and multicomponent particles that cannot be easily produced at industrial scale with other methods [1]. Utilizing the advantages of FSP, several start-up companies have grown to produce various particles with controlled characteristics to fill the demand for niche markets [103]. Today, Hemotune AG (Schlieren, Switzerland) [104] produces polymer-decorated iron nanoparticles with carbon encapsulation for the purpose of blood purification. Examples are Anavo Medical (Zurich, Switzerland), for bioactive hybrid metal oxides, and Avantama AG (Stäfa, Switzerland), for the production of several metal oxides [103]. Such start-up companies include Turbobeads AG (Zurich, Switzerland) [105], which creates amine-functionalized cobalt carbon-coated nanoparticles. HeiQ Inc. (Schlieren, Switzerland) [106], which recently had an IPO with a valuation of 127 M£, produces nanosilver by FSP, the third most market-demanded nanomaterial, following carbon black and fumed oxides [107].

FSP synthesis can be implemented by laboratory FSP with production of 10 g h−1 to establish the synthesis optimization protocol and the initial exploration for complex particles and industrial-scale FSP with production rates at kg h−1 [108]. With lab-scale FSP, many particles reach 10 g h−1. Examples include HfO2 (5 nm, 89 SSA) at 15 g h−1 [109] and CeO2 (8 nm, 101 SSA) at 10 g h−1 [110]. Pratsinis et al. synthesized particles of silica/titania with a production rate of 200 g h−1 [111,112], showing very different results with the change in the fuel flow rate and the oxygen flow rate parameters. In this context, many simple oxides have been synthesized with FSP, such as WO3/TiO2 [113], or more complex nanoparticles, such as La0.6Sr0.4Co0.2Fe0.8O3−δ with production rates as high as 400 g h−1 [114].

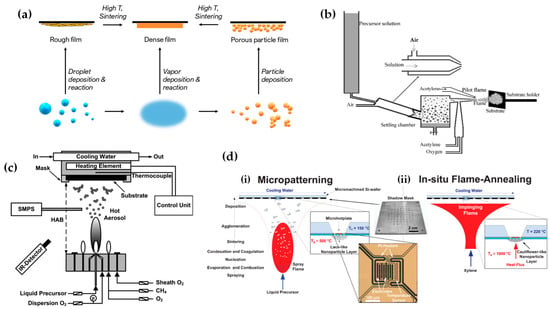

Industrial FSP: In Table 5, the industrial-scale FSP publications are presented in chronological order and their synthesis/structural characteristics are listed. The first industrial-scale FSP production was demonstrated for SiO2, by Mueller et al., producing uniform 25 nm particles at 1.1 kg h−1 [115]. The study investigated the primary particle diameter, morphology, and carbon content by HMDSO in EtOH at 1.26 M and 3.0 M, as well as pure HMDSO at 4.7 M. Notably, the average primary particle size of the product was precisely controlled within the range of 10 to 75 nm, irrespective of the precursor concentration. Additionally, it was observed that utilizing air instead of O2 as the dispersion gas resulted in minimal variation in the product particle size. Mueller et al. achieved ZrO2 with a production rate of 0.6 kg h−1 with an average size of 30 nm [116]. The study evaluated zirconium n-propoxide in EtOH at 0.5 M and 1 M concentrations. Primary particle size ranged from 6 to 35 nm, with the crystal structure mainly tetragonal (80–95 wt%). The primary particles showed weak agglomeration, forming loosely agglomerated single crystals. Gröhn et al. produced ZrO2 at 0.5 kg h−1 [117] with increased technological expertise by a three-dimensional computational fluid dynamics model showing the fundamentals of the high-temperature particle residence time (HTPRT) for the scale-up synthesis of nanomaterials (see Figure 13a,b). HTPRT effectively regulated primary particle and agglomerate size, morphology, and ZrO2 crystallinity. Maintaining a constant HTPRT while scaling up the production rate from ∼100 to 500 g h−1 showed no significant alteration in product particle properties. In this context, Meierhofer et al. explored CFD-PBM modeling of ZrO2 FSP synthesis [118] at high productions to discover the attributes of the resulting nanoparticles. Jossen et al. produced yttria-stabilized zirconia (Y2O3/ZrO2) with the same parameters, with only the molarity dropped by half, decreasing the production rate at 0.35 kg h−1 [119]. Homogeneous Y2O3/ZrO2 exhibited an average crystallite and particle diameter ranging from 8 to 31 nm, with yttria content varying between 3 and 10 mol%. Interestingly, the yttria content had no discernible impact on the primary particle and crystal sizes.

Table 5.

Industrial production of nanoparticles by FSP, parameters, production rate, size, and SSA.

Table 5.

Industrial production of nanoparticles by FSP, parameters, production rate, size, and SSA.

| Nanomaterial | Production Rate (kg h−1) | Precursors | Solvents | Molarity (mol L−1) | Precursor (mL min−1) | Oxygen (L min−1) | Size (nm) | SSA (m2 g−1) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | 1.1 | HMDSO | Ethanol | 4.7 | 33.3 | 50 | 26 | 108 | [115] |

| ZrO2 | 0.6 | Zr n-propoxide | Ethanol | 1 | 81 | 50 | 30 | 33 | [116] |

| ZrO2 | 0.5 | Zr 2-thylhexanoate | Xylene | 1 | 64 | 80 | 25 | 42 | [117] |

| Y2O3/ZrO2 | 0.35 | Zr n-propoxide/Y nitrate hydrate | Ethanol | 0.5 | 81 | 50 | 31 | 32 | [119] |

| FePO4 | 0.27 | Fe nitrate/tributyl phosphate | 2-ethylhexanoic acid | – | 20 | 40 | 129 | 108 | [108] |

| ZnO | 3 | Zinc nitrate hexahydrate | Ethanol, methanol, 1-propanol, 1-octanol | 3.3 | 200 | 120 | 30 | 26.2 | [120] |

| Ca2SiO4 (Belite) | 0.03 | TEOS/calcium propionate | Ethanol, methanol, deionized water | 1.1 | 30 | 30 | 54 | 34 | [121] |

Figure 13.

(a) Predicted normalized gas-phase mass fractions, the ZrO2 formation profile (brown), and volume concentration (green). (b) Schematic of FSP two-phase atomizer geometry. Reprinted (adapted) with permission from [117]. Copyright 2014 American Chemical Society. (c) A flame spray pyrolysis (FSP) pilot plant is designed to produce multiple kg h−1 of nanoparticles, incorporating a baghouse filter for nanoparticle collection with an approximate filtration area of 50 m2. Reprinted from [108].

Wegner et al. produced FePO4 nanoparticles with 0.27 kg h−1 with a mean size of 129 nm (see Figure 13c) [108]. Additionally, a cost analysis for the scale-up FSP was calculated with the pilot plant production costs for simple oxides projected to be less than 100 EUR per kilogram. Among the cost components, raw materials constitute the most significant cost factor in this estimation.

Hembram et al. manufactured ZnO nanorods with the highest production rate so far, at 3 kg h−1. The resulting nanorods had a length of 30 nm and a mean aspect ratio of the rods at 2.3 [120]. Numerous nanorods self-aligned by creating junctions at the basal planes and some were further assembled into tetrapods. The nanorod aspect ratio was controllable through adjustments in the concentration of Zn ions in the initial precursor solution, its delivery rate, and the oxygen flow into the reactor. Betancur-Granados et al., with a production of belite, achieved in scale-up conditions with a production of 0.03 kg h−1—the low production is due to the formation of amorphous and other derivatives, such as alite, CaCO3, etc. [121]. The hydraulic samples exhibit a full hydration reaction within a 24 h duration upon contact with water. This substantiates the technique’s potential in developing highly reactive materials suitable for prospective sustainable construction practices.

3. Complex Functional FSP Nanostructures and Nanodevices

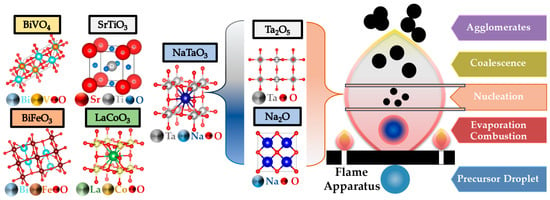

The innovative exploitation of FSP’s potential enables the engineering of unconventional materials, such as non-oxides and complex structures or nanodevices, including perovskites, nanosensors, and fuel-cell-materials.

3.1. Engineering of Perovskites by FSP

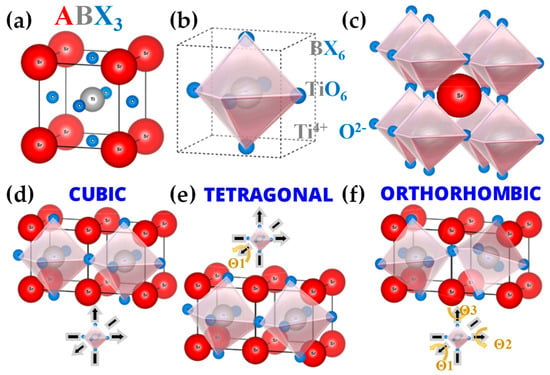

FSP has been established mainly for its ability to engineer a wide range of single-metal oxides [2]. However, establishing FSP process parameters for producing ABO3 perovskite nanomaterials (see Figure 14a–f and Figure 15) is typically more challenging, e.g., avoiding the formation of the separate oxides AOn and BOm.

Figure 14.

The ideal cubic perovskite structure exemplified by SrTiO3. (a) The cubic structure with the Ti4+ at the cell center. (b) The octahedral polyhedron structure TiO6. (c) Sr2+ at the cubic center with the octahedral structure surrounding the strontium. Different perovskite structures: (d) the ideal cubic perovskite, axis X, Y, and Z of the octahedral BX6 have a 180-degree separation. (e) Tetragonal perovskite structure, the octahedral BX6 tilted in only one of the three axes at an angle Θ1. (f) The orthorhombic structure, the octahedral, is titled in all three of the axes, in accordance with the angles Θ1, Θ2, and Θ3.

Figure 15.

FSP formation of perovskite structure ABO3 requires avoidance of the formation of the two separate oxides (A-oxide, B-oxide).

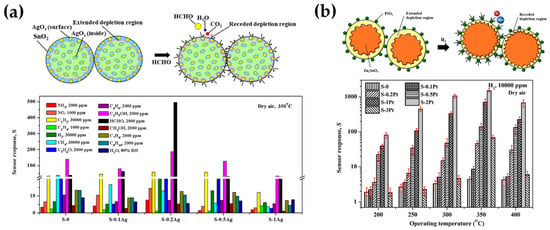

The publications regarding perovskite synthesis by FSP (see Figure 15), listed in Table 6, are rather limited in number so far. The first publication was by Kho et al. who demonstrated the synthesis of BiVO4 by FSP [122], where they noticed a bottleneck disadvantage of crucial importance for FSP perovskite formation—that is the short HTPRT, in the order of milliseconds, was inadequate to induce the perovskite phase (see Figure 16a,b). In situ thermal curing, on the filter, was necessary to achieve the desired scheelite BiVO4 phase [122]. The required filter temperature was T > 310 °C up to 360 °C to reach 100% crystallization, resulting in the scheelite-monoclinic phase, in agreement with the Tammann temperature of BiVO4 [109], which occurred at 300 °C. Stathi et al. [123] demonstrated that FSP can engineer W- and Zr-Doped BiVO4 in tandem with control of the BiVO4 lattice oxygen vacancies (VO). W-doping had a minor change on the BiVO4 XRD peaks, although W-doping (10%) caused a major deterioration of the crystallinity. Zr-doping above 1% showed peaks attributed to cubic-ZrO2 particles of 3 nm diameter. Function-wise, the presence of oxygen vacancies in W-BiVO4 and Zr-BiVO4 drastically improved the O2 production efficiency [123].

Psathas et al. [124,125], in their study of the engineering of perovskite BiFeO3 by FSP, concluded that the short HTPRS did not allow for the in situ formation of crystalline BiFeO3. They observed that a very short post-calcination of 5 min at 550 °C allowed for the formation of pure phase BiFeO3. This shows that the FSP-made BiFeO3 material consisted of small nanometric crystallites that were organized in larger BiFeO3 crystalline particles upon a small thermal/calcination boost [124,125]. Additionally, via the same protocol, mullite-type Bi2Fe4O9 was synthesized (see Figure 16c). These BFO materials were employed for the reduction of 4-Nitrophenol to 4-Aminophenol [124] and showed a low-activation energy Ea = 22 kJ mol−1 for BiFeO3, which is comparable to that of noble metal-based catalysts. Highly efficient photocatalytic O2 evolution, as shown in [125], was promoted via the introduction of Fe2+ centers in BiFeO3 via a downshift of the CB and VB edges. FSP-made Bi2Fe4O9 exemplified a highly efficient O2 evolution photocatalyst for the first time [125].

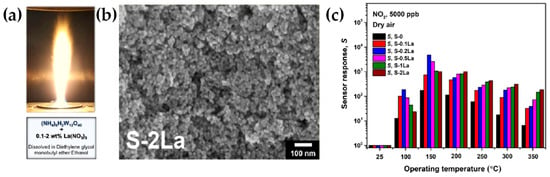

Punginsang et al. [126] reported the engineering of layered perovskite oxide Bi2WO6 consisting of FSP-made orthorhombic phase spherical Bi2WO6 nanoparticles (3–30 nm in diameter) and a very high specific surface area of 197.8 m2g−1. The high thermal stability FSP-Bi2WO6 nanoparticles were applied for gas-sensing measurements and displayed a stable and selective response of 3.72–2000 ppm toward acetone at 350 °C and good selectivity against other gases, surpassing similar materials made by other methods.

Recently, Xiao et al. [127] reported a successful FSP synthesis of LaCo(Fe-dopped) O3. In [127], a LaCo1−xFexO3-based sensing was evaluated as an ammonia sensor, reaching a detection limit of 2 ppm at 475 °C. These effects were corroborated based on the oxygen vacancy and improvement in electrocatalytic performance by doping iron. Moreover, the sensor exhibited good selectivity against other gases and good stability against oxygen and water vapor concentration fluctuation, with long-term stability for 22 days [127].

Perovskite La1−xFeO3−δ sensors (x = 0, 0.02, 0.05, 0.07, and 0.1), with A-site deficiency, were successfully synthesized by FSP [128], with pure orthorhombic phase and size below 10 nm size. The materials were applied for chemo-resistive CO2 sensors, La0.95FeO3−δ was the optimal stoichiometric material for 5–15% CO2 at 425 °C. Due to surface oxygen vacancies attributed to the small amount of Fe4+, this A-site deficiency might be responsible for enhanced sensing performance [128].

Table 6.

The literature summary of characteristics/conditions for FSP-made perovskite-type nanomaterials.

Table 6.

The literature summary of characteristics/conditions for FSP-made perovskite-type nanomaterials.

| Nanomaterial | Precursors | Solvents | Molarity (mol L−1) | Precursor (mL min−1) | Oxygen (L min−1) | Size (nm) | SSA (m2 g−1) | Ref. |

|---|---|---|---|---|---|---|---|---|

| BiVO4 | Bi acetate/V oxytripropoxide | 2-ethylhexanoic acid/xylene | 0.25 (Bi)/ 0.25 (V) | 10 | 5 | 62–71 | 7–12 | [122] |

| W-, Zr-BiVO4 | Bi(III) nitrate pentahydrate/V(V) oxytripropoxide | Ethoxy triglycol, acetic acid (70/30 v/v)/xylene (Total: 50/50 v/v) | 0.5 (Bi)/ 0.5 (V) | 5 | 5 | 15–22 | 38–49 | [123] |

| BiFeO3 | Bi(III) acetate/ Fe(III) acetylacetonate | 2-Ethylhexanoic acid/xylene (50/50 v/v) | 0.1 (Bi)/ 0.1 (Fe) | 3 | 7 | 48–67 | 11–14 | [125] |

| Bi2WO6 | Bi(III) nitrate pentahydrate/ W(VI) ethoxide | Ethanol, acetic acid (70/30 v/v) | – | 5 | 5 | 198 | 3.3 | [126] |

| LaCoO3 | Co(II) nitrate hexahydrate/Fe(III) nitrate nonahydrate | Methanol | 0.3 (La)/ 0.3 (Co) | – | 5 | 10 | – | [127] |

| LaFeO3 | La nitrate hexahydrate/Fe(III) nitrate nonahydrate | Ethanol | – | – | 5 | 10 | – | [128] |

| SrTi1−xBxO3 | Sr acetate/ tetrabutyl titanate | Acetic acid/ethanol (50/50 v/v) | 0.075 (Sr)/ 0.075 (Ti)/ | 3 | 5 | 19–37 | 31–46 | [129,130,131] |

| SrTiO3/CuO | Sr acetate/Ti(VI) iso-propoxide | Acetic acid/xylene (50/50 v/v) | 0.2 (Sr)/ 0.2 (Ti)/ | 5 | 5 | 45–55 | 32–57 | [58] |

| NaTaO3/ NiO–Pt0 | Na 2-ethylhexanoate/ Ta(V) chloride | Ethanol | 0.05–0.3 (Na)/ 0.05–0.3 (Ta) | 3–9 | 3–9 | 12–34 | 19–84 | [72,132] |

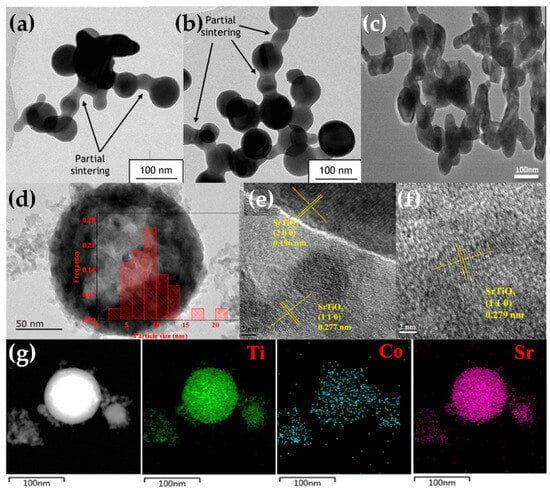

Recently use of FSP to engineer SrTiO3 perovskite (see Figure 14a–f) was established by Yuan et al. [129,130,131] and Psathas et al. [58]. In [129], SrTi1−xBxO3 (B = Co, Fe, Mn, Ni, and Cu) were produced by FSP at different concentrations (10%, 30%, 50% for Co, 10% for everything else). Co cation was shown to be evenly dispersed in the SrTiO3 structure based on EDX mapping, with an increase in dopant and the growing diameter of active Co particles aligning with TEM findings (see Figure 16d–g). As the cobalt concentration increased from 10 to 50 mol%, the size of Co particles progressively expanded, consequently reducing metal dispersion from 6.50% to 2.18%. Substituting B-site in SrTiO3 with varied valence metal cations created vacancies, enhancing CO/CH4 oxidation, with SrTi0.5Co0.5O3 exhibiting the highest activity [129]. In [130], SrTi1−xCuxO3 particles were reported, with different copper concentrations (10%, 15%, 30%), with the copper species either as amorphous species or/and highly dispersed particles below 5 nm, with XRD indicating that copper ions replaced the Ti4+ in the perovskite lattice. Catalytic low-temperature CO oxidation and CH4 combustion at high temperatures were exemplified [130]. In [131], Sr1−xNaxTi1−yByO3 (B = Co, Mn) with x = 0, 0.1 and y = 0, 0.3, 0.5 were produced by FSP [131]. Doping the perovskite with Na and Co resulted in notably larger SSA from 43 to 65 m2 g−1 compared with cobalt doping alone. Sr0.9Na0.1Ti0.5Co0.5O3 demonstrated superior low-temperature reducibility, higher adsorbed oxygen ratio, and well-dispersed Co elements, resulting in outstanding thermodynamic and kinetic activity for formaldehyde oxidation [131].

Recently, Psathas et al. presented the synthesis of La:SrTiO3/CuO particles by DN-FSP, in tandem with La doping [58]. EDX showed that La doping was homogeneous throughout the SrTiO3 matrix, with no secondary phases formed, such as La2O3. Additionally, a pink-hue color is observed in comparison to the white SrTiO3, evidencing a change in the band gap of the SrTiO3. Interestingly, it was found that La doping significantly increased the SSA and pore volume of La:SrTiO3, from 32 to 53 m2/gr, and more significantly, produced a 300% increase in pore volume to 0.39 cm3 g−1.

As discussed in [58], this is a result of the FSP process where the La doping decreases the packing/aggregation of the SrTiO3. La doping consistently boosted SrTiO3 photocatalytic activity, with 0.9% La doping exhibiting a five-fold increase in H2 production to 12 mmol g−1 h−1 compared with 3 mmol g−1 h−1 for pristine SrTiO3 [58].

Figure 16.

(a,b) TEM images illustrating necked particles of BiVO4. Reprinted (adapted) with permission from [122]. Copyright 2011 American Chemical Society. (c) TEM images of necked-sintered BiFeO3 particles. Reprinted from [124], with permission from Elsevier. (d–f) HRTEM micrographs of SrTi1−xCoxO3 and the miller planes. (g) EDX element mapping of SrTi1−xCoxO3 for the Ti, Co, and Sr atoms. Reprinted (adapted) with permission from [129]. Copyright 2021 American Chemical Society.

Small-size NaTaO3 was achieved by FSP recently [72,132]. As discussed in [72,132] the inherent need for high-temperature FSP, i.e., HTPRT, required for achieving the ABO3-perovskite formation, poses the challenge of retaining low particle size. As shown in [72], this can be achieved by FSP via diligent control of the temperature profile in the FSP reactor. In this way, highly crystalline small NaTaO3 particles < 15 nm were engineered in one step, outperforming conventional synthesis methods where the previous best size reached 25 nm and typical sizes range around 100 nm [72]. An electron paramagnetic resonance study [132] of these ultrasmall NaTaO3 particles, 12 nm, revealed the significant influence of the nanosize on the life time of photoinduced {h+/e−} pairs. As the NaTaO3 particle size increases, the recombination rate increases and this holds the key to unraveling the fundamental photocatalytic capabilities, e.g., in H2 production [72] of such nanomaterials [132].

3.2. Engineering of Metal Non-Oxides by FSP

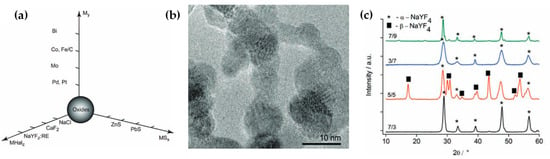

The patent of Grass et al. in 2007 marked a pivotal milestone in reducing flame spray pyrolysis (R-FSP) [44]. Since then, FSP technology has undergone a continuous advancement, exploring the engineering of “metal non-oxides” notably encompassing metal sulfides, carbides, halides, phosphates, and carbonates listed in Table 7.

To the utmost extent of our current knowledge, no investigation in regard to the synthesis of nitrides through the FSP methodology has been documented up to the present date. Nitride synthesis via FSP entails a multitude of intricate factors, encompassing nitrogen reactivity, gas chemistry, temperature control, precursor material selection, and prudent safety considerations, collectively rendering it a formidable and demanding process. Kennedy and his colleagues employed the ceramic crucible method to synthesize gallium zinc oxynitrides (GaxZn1−xOyN1−y), with the objective of potentially producing these oxynitrides using the FSP method in forthcoming endeavors [133]. However, a limited body of research exists wherein, in lieu of nitrides, researchers have generated nitrogen (N)-doped titanium dioxide (TiO2) using single-step FSP technology [134,135,136,137,138,139]. Huo et al. [134] and Bi et al. [135] exhibited a novel approach to the synthesis of N-doped TiO2, utilizing a modified FSP reactor. In this method, a spray nozzle was employed to introduce ammonia water, which subsequently underwent vaporization to form H2O vapor and NH3 gas reacting with the TiO2 nanoparticles. Other investigators [136,137,138,139] successfully attained N-doped TiO2 through a straightforward FSP modification, involving the addition of dilute nitric acid to the precursor during the synthesis process, coupled with the introduction of a secondary nitrogen source, specifically urea.

In the aim of carbide synthesis, Herrmann et al. [140] reported the engineering of carbon-encapsulated iron carbide (C/Fe3C) via an R-FSP process. In this case, the spray nozzle was placed in a glove box with a nitrogen atmosphere, which was continuously purged with nitrogen; surrounding the flame allowed for radial inflow of N2 at a flow rate of 25 L min−1 and with a carbon content varying between 1.8 and 8.05 wt%, depending on the acetylene flow rate. Iron exhibits a highly intricate Fe/C phase diagram, featuring numerous intermetallic carbon–iron phases that yield a range of technically valuable metals and steel alloys. By methodically modifying the composition of the flame feed, the authors in [140] were able to monitor the successive reduction of iron oxide to iron and iron carbides (refer to Figure 17).

Figure 17.

(a) Reducing FSP configuration for engineering Fe3C or C/Fe3C nanostructures. (b) Controlling the process atmosphere in flame spray synthesis enables the production of diverse iron-based nanoparticles. The resultant composition aligns with the relevant phase diagrams for Fe/O (left side) under oxidizing conditions. Subsequent reduction processes yield iron and iron carbide nanoparticles in accordance with the predictions derived from the Fe/C phase diagram (right side). Reprinted (adapted) with permission from [140]. Copyright 2009, American Chemical Society.

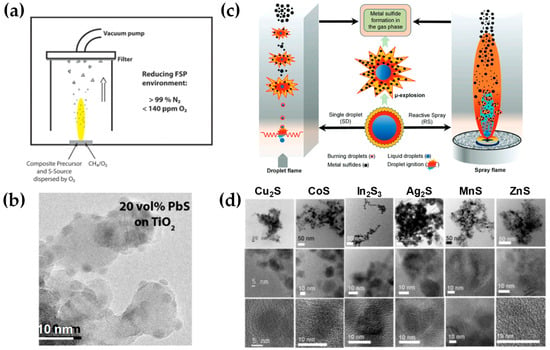

Employing contemporary state-of-the-art methodologies, metal sulfides are typically acquired through diverse chemical processes, including thermolysis, solid-state metathesis, liquid-phase reactions, and thermal decomposition [141]. With respect to flame-made sulfides, a limited number of investigations have been reported in the scientific literature [50,142,143]. Originally, to facilitate the controlled combustion of a ZnS precursor within an environment characterized by oxygen-poor conditions (O2 < 250 ppm), the flame spray nozzle was positioned within a glove box and supplied with nitrogen to establish a reducing atmosphere [50]. Specifically, in [50], Athanassiou et al. mixed ZnO aerosol stream with in situ H2S, which the latter obtained via reductive decomposition of tetrahydrothiophene (THT). Additionally, reducing FSP synthesis was used to investigate the manufacturing of sulfide–oxide PbS−TiO2 heterojunction nanoparticles [142]. Similarly, these investigations were conducted within an enclosed box under a N2 purging environment (as shown in Figure 18a,b). Recently, Pokhrel et al. [143] achieved a significant advancement in this front regarding metal-sulfide nanoparticle synthesis with FSP. As a proof-of-principle [131], MnS, CoS, Cu2S, ZnS, Ag2S, In2S3, SnS, and Bi2S3 are synthesized in an O2-lean and sulfur-rich environment, specifically with metal:sulfur ratios ranging from 1:20 to 1:45 and average primary particle sizes in the range of 10–30 nm (refer to Figure 18d). Explicitly, the researchers mixed all the metal-organic precursors (M = Mn, Co, Cu, Zn, Ag, In, Sn, Bi) with THT directly utilizing enclosed single-droplet (SD) combustion and enclosed reactive spray (RS) FSP configurations (see Figure 18a) [143]. This protocol entailed the need for extreme N2 co-flow, i.e., up to 210 L min−1 of N2 supplied through a quenching ring.

Figure 18.