Preparation of Dispersed Copper(II) Oxide Nanosuspensions as Precursor for Femtosecond Reductive Laser Sintering by High-Energy Ball Milling

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Materials

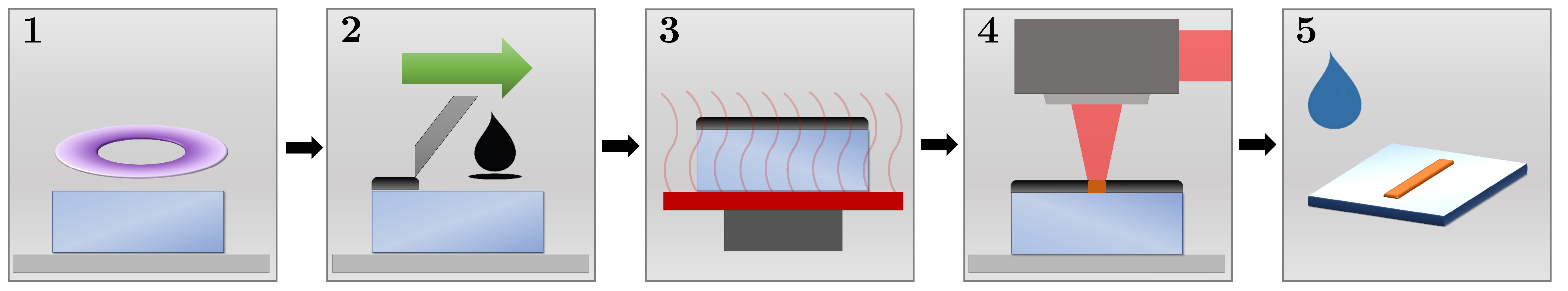

2.2. Preparation of the Nanosuspension

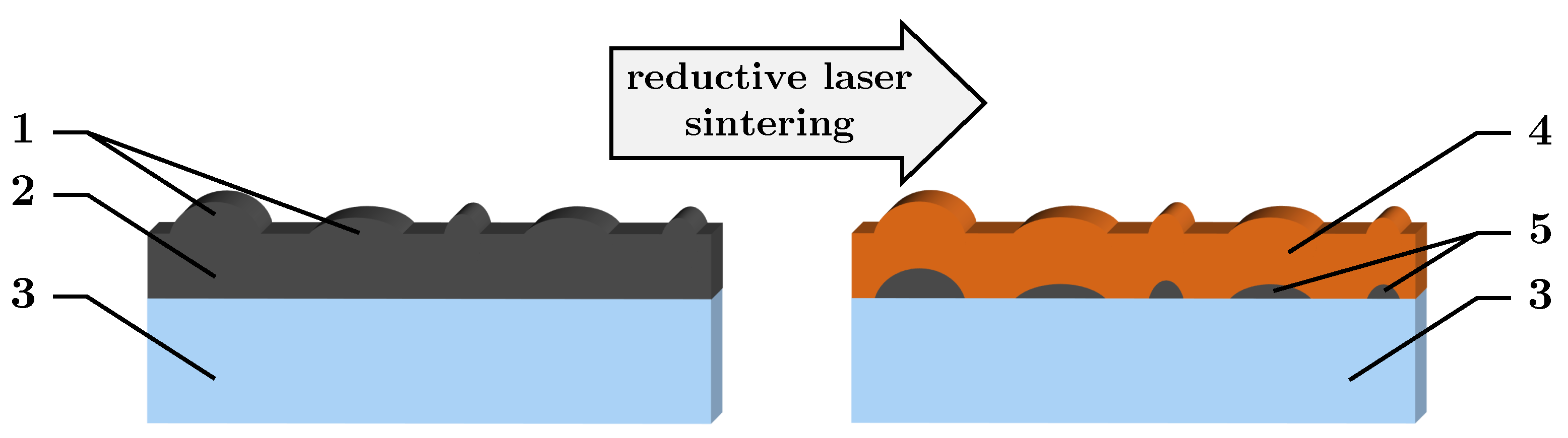

2.3. Generation of Copper Layers by Femtosecond Reductive Laser Sintering

2.4. Evaluation Methods

3. Results and Discussion

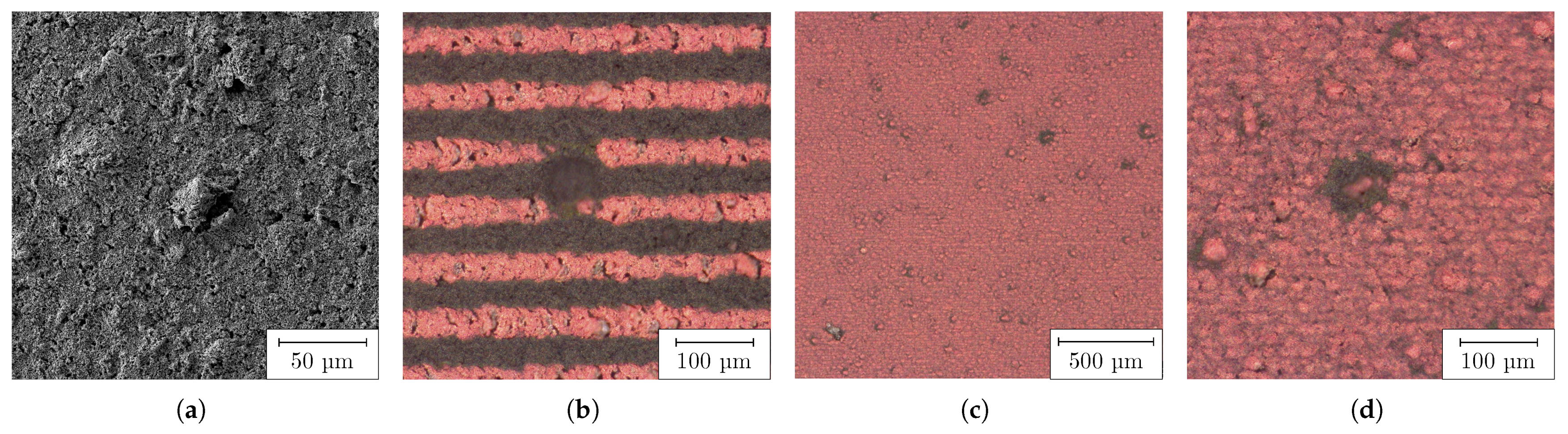

3.1. Undispersed CuO Nanosuspension

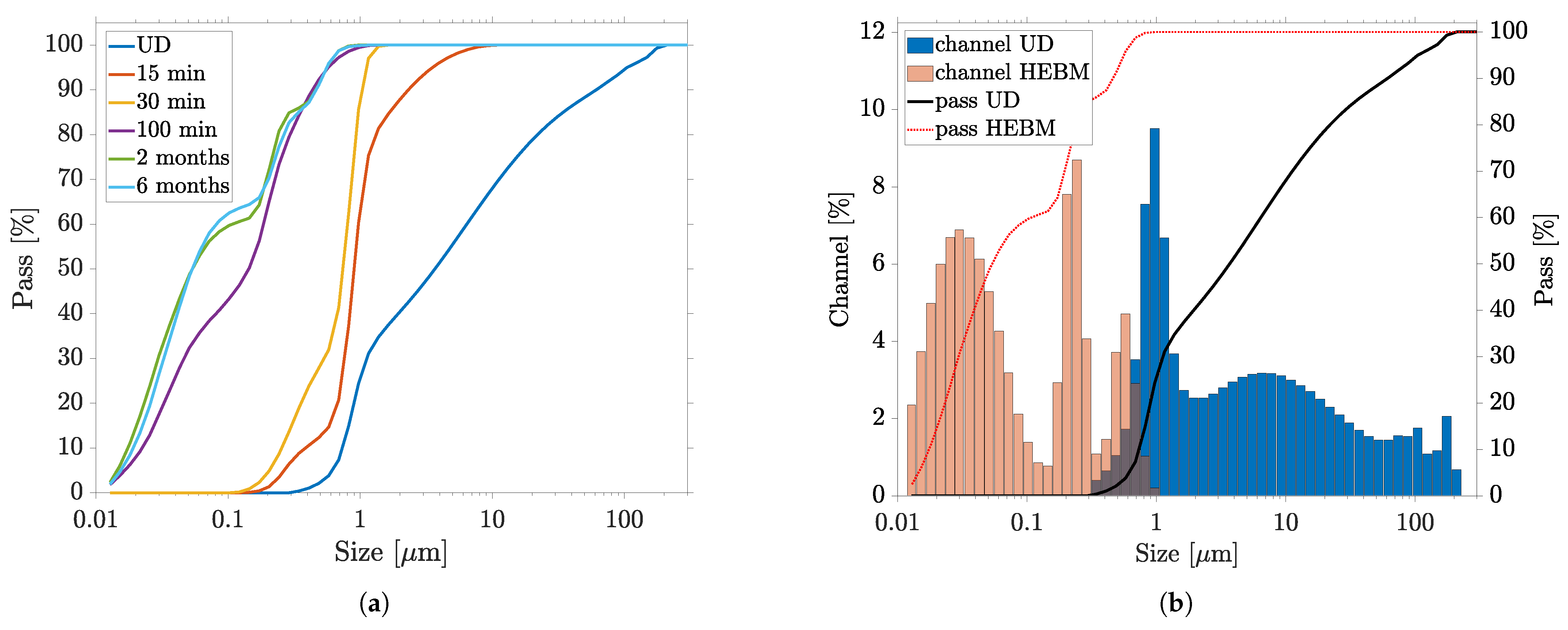

3.2. Ultrasonic Dispersion of the CuO Nanosuspension

3.3. High-Energy Ball Milling of CuO Nanosuspension

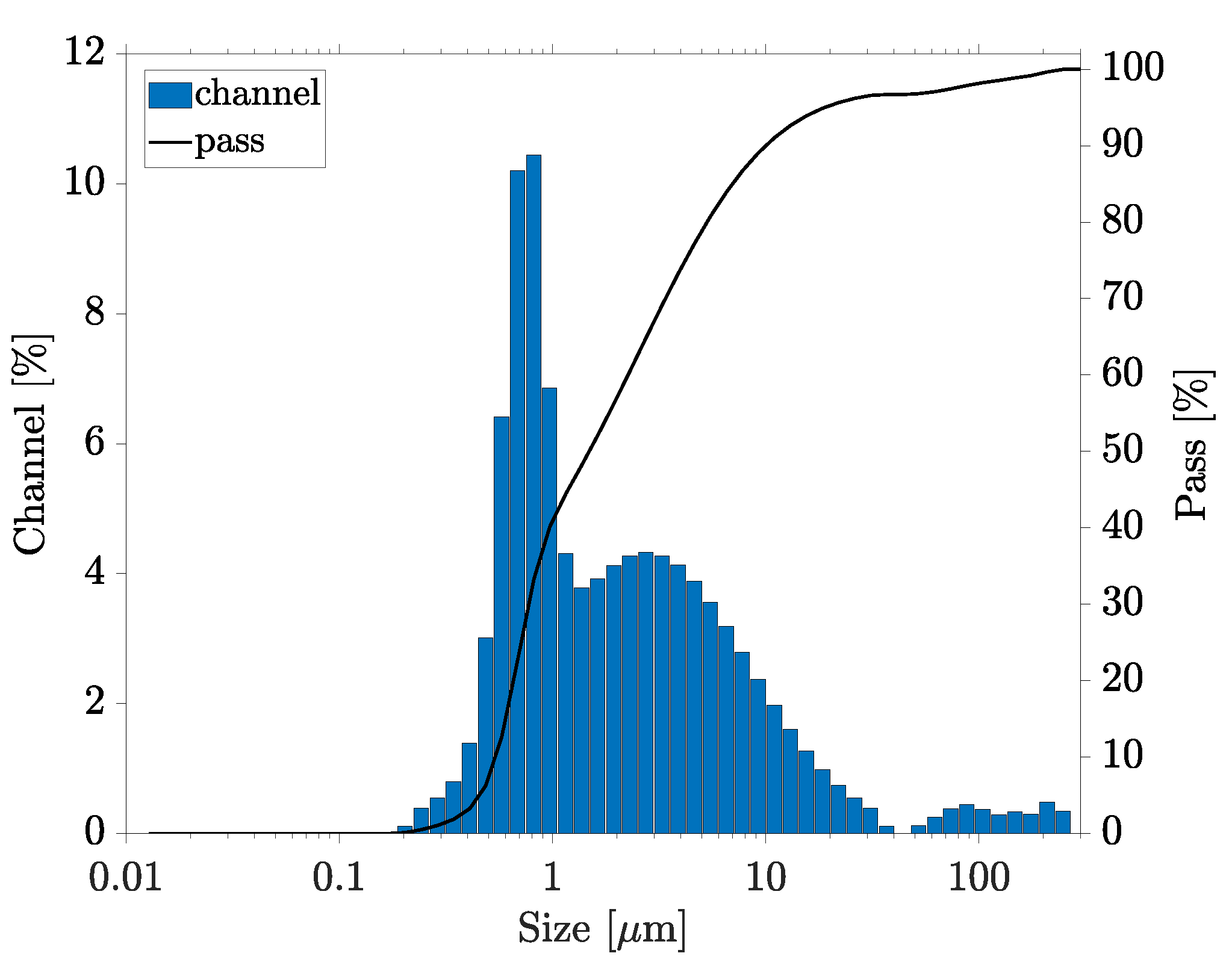

3.3.1. Characterization of the Milling Process

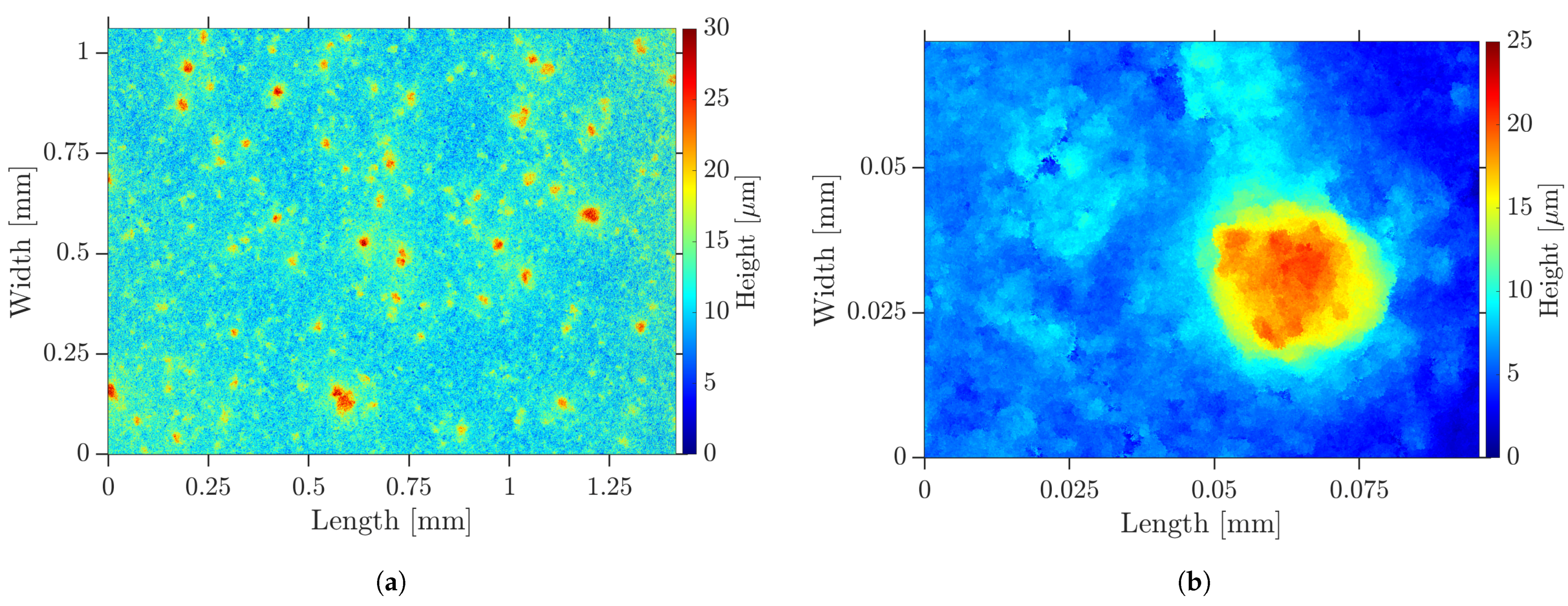

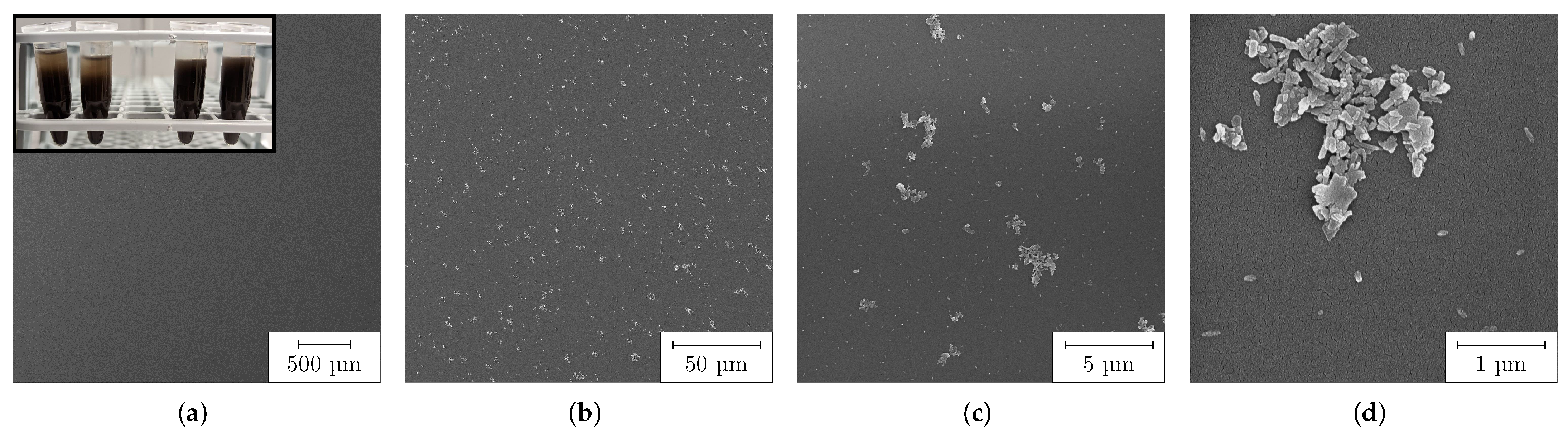

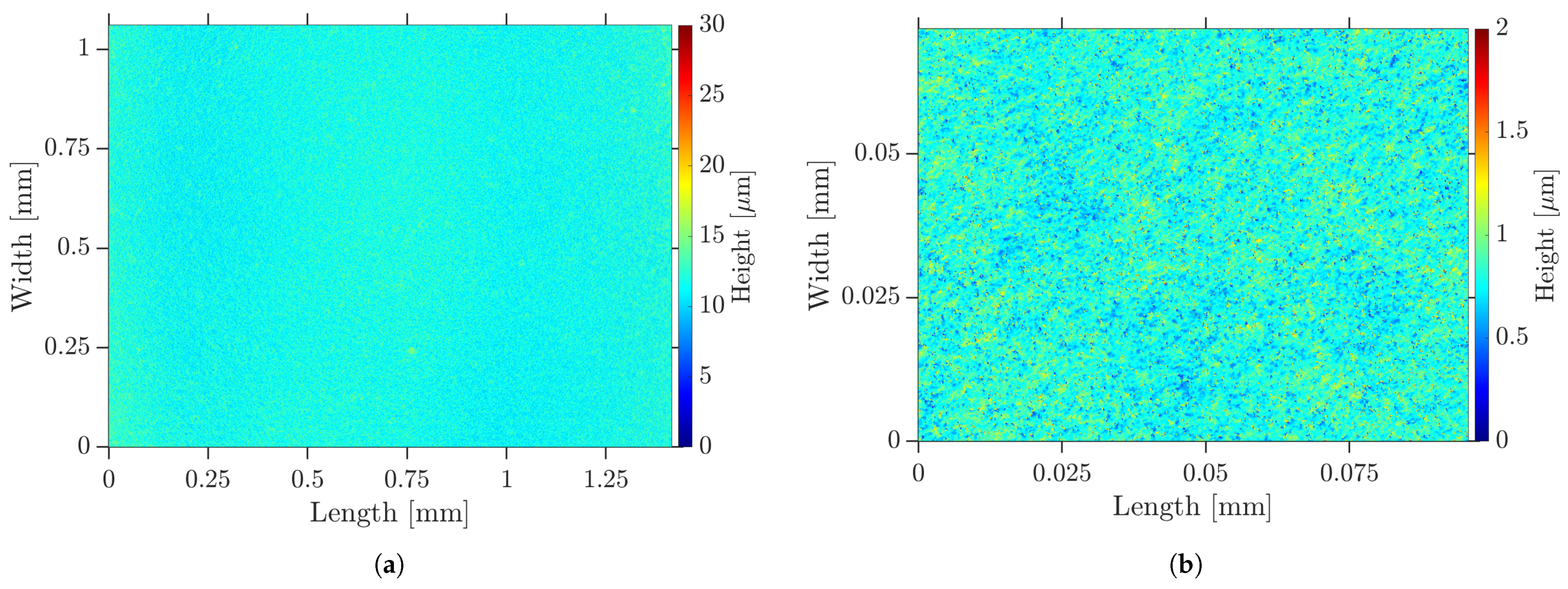

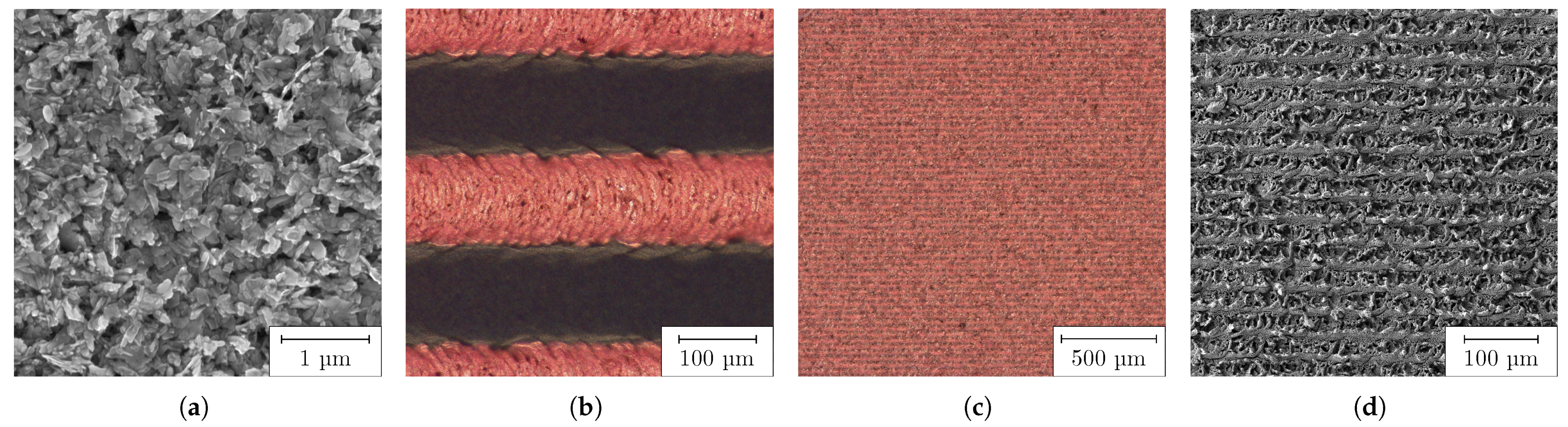

3.3.2. Reductive Laser Sintering with the Milled Precursor

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Copper | Cu |

| Copper(II)-oxide | CuO |

| HEBM | high-energy ball milling |

| LSM | laser scanning microscopy |

| NPs | nanoparticles |

| PC | precursor |

| RLS | reductive laser sintering |

| SEM | scanning electron microscopy |

| UD | undispersed |

| US | ultrasonic dispersion |

References

- Kamyshny, A.; Magdassi, S. Conductive nanomaterials for printed electronics. Small 2014, 10, 3515–3535. [Google Scholar] [CrossRef] [PubMed]

- Chandrasekaran, S.; Jayakumar, A.; Velu, R. A Comprehensive Review on Printed Electronics: A Technology Drift towards a Sustainable Future. Nanomaterials 2022, 12, 4251. [Google Scholar] [CrossRef] [PubMed]

- Martins, P.; Pereira, N.; Lima, A.C.; Garcia, A.; Mendes-Filipe, C.; Policia, R.; Correia, V.; Lanceros-Mendez, S. Advances in Printing and Electronics: From Engagement to Commitment. Adv. Funct. Mater. 2023, 2213744. [Google Scholar] [CrossRef]

- Nam, V.B.; Giang, T.T.; Koo, S.; Rho, J.; Lee, D. Laser digital patterning of conductive electrodes using metal oxide nanomaterials. Nano Converg. 2020, 7, 23. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.; Zhu, Z.; Cheung, C.F.; Yan, F.; Li, G. Digital manufacturing of functional materials for wearable electronics. J. Mater. Chem. C 2020, 8, 10587–10603. [Google Scholar] [CrossRef]

- Ma, Z.C.; Zhang, Y.L.; Han, B.; Chen, Q.D.; Sun, H.B. Femtosecond-Laser Direct Writing of Metallic Micro/Nanostructures: From Fabrication Strategies to Future Applications. Small Methods 2018, 2, 1700413. [Google Scholar] [CrossRef]

- Shacham-Diamand, Y.; Osaka, T.; Okinaka, Y.; Sugiyama, A.; Dubin, V. 30 years of electroless plating for semiconductor and polymer micro-systems. Microelectron. Eng. 2015, 132, 35–45. [Google Scholar] [CrossRef]

- Ghosh, S. Electroless copper deposition: A critical review. Thin Solid Films 2019, 669, 641–658. [Google Scholar] [CrossRef]

- Melentiev, R.; Yudhanto, A.; Tao, R.; Vuchkov, T.; Lubineau, G. Metallization of polymers and composites: State-of-the-art approaches. Mater. Design 2022, 221, 110958. [Google Scholar] [CrossRef]

- Lim, J.; Kim, Y.; Shin, J.; Lee, Y.; Shin, W.; Qu, W.; Hwang, E.; Park, S.; Hong, S. Continuous-Wave Laser-Induced Transfer of Metal Nanoparticles to Arbitrary Polymer Substrates. Nanomaterials 2020, 10, 701. [Google Scholar] [CrossRef]

- Li, W.; Sun, Q.; Li, L.; Jiu, J.; Liu, X.Y.; Kanehara, M.; Minari, T.; Suganuma, K. The rise of conductive copper inks: Challenges and perspectives. Appl. Mater. Today 2020, 18, 100451. [Google Scholar] [CrossRef]

- Kordás, K.; Bali, K.; Leppävuori, S.; Uusimäki, A.; Nánai, L. Laser direct writing of copper on polyimide surfaces from solution. Appl. Surf. Sci. 2000, 154–155, 399–404. [Google Scholar] [CrossRef]

- Manshina, A.A.; Povolotskiy, A.V.; Ivanova, T.Y.; Tver’yanovich, Y.S.; Tunik, S.P.; Kim, D.; Kim, M.; Kwon, S.C. Effect of salt precursor on laser-assisted copper deposition. Appl. Phys. A 2007, 89, 755–759. [Google Scholar] [CrossRef]

- Avilova, E.A.; Khairullina, E.M.; Shishov, A.Y.; Eltysheva, E.A.; Mikhailovskii, V.; Sinev, D.A.; Tumkin, I.I. Direct Laser Writing of Copper Micropatterns from Deep Eutectic Solvents Using Pulsed near-IR Radiation. Nanomaterials 2022, 12, 1127. [Google Scholar] [CrossRef]

- Jones, J.; Snowdon, M.R.; Rathod, S.; Peng, P. Direct laser writing of copper and copper oxide structures on plastic substrates for memristor devices. Flex. Print. Electron. 2023, 8, 015008. [Google Scholar] [CrossRef]

- Mizoshiri, M.; Aoyama, K.; Uetsuki, A.; Ohishi, T. Direct Writing of Copper Micropatterns Using Near-Infrared Femtosecond Laser-Pulse-Induced Reduction of Glyoxylic Acid Copper Complex. Micromachines 2019, 10, 401. [Google Scholar] [CrossRef]

- Lee, H.; Yang, M. Effect of solvent and PVP on electrode conductivity in laser-induced reduction process. Appl. Phys. A 2015, 119, 317–323. [Google Scholar] [CrossRef]

- Cheng, W.H.; Lee, M.T.; Yasuda, K.; Song, J.M. Plasma-Modified PI Substrate for Highly Reliable Laser-Sintered Copper Films Using Cu2O Nanoparticles. Nanomaterials 2022, 12, 3237. [Google Scholar] [CrossRef]

- Khairullina, E.M.; Ratautas, K.; Panov, M.S.; Andriianov, V.S.; Mickus, S.; Manshina, A.A.; Račiukaitis, G.; Tumkin, I.I. Laser-assisted surface activation for fabrication of flexible non-enzymatic Cu-based sensors. Mikrochim. Acta 2022, 189, 259. [Google Scholar] [CrossRef]

- Shin, J.; Jeong, B.; Kim, J.; Nam, V.B.; Yoon, Y.; Jung, J.; Hong, S.; Lee, H.; Eom, H.; Yeo, J.; et al. Sensitive Wearable Temperature Sensor with Seamless Monolithic Integration. Adv. Mater. 2020, 32, e1905527. [Google Scholar] [CrossRef]

- Nam, V.B.; Lee, D. Evaluation of Ni-Based Flexible Resistance Temperature Detectors Fabricated by Laser Digital Pattering. Nanomaterials 2021, 11, 576. [Google Scholar] [CrossRef] [PubMed]

- Mizoshiri, M.; Yoshidomi, K.; Darkhanbaatar, N.; Khairullina, E.M.; Tumkin, I.I. Effect of Substrates on Femtosecond Laser Pulse-Induced Reductive Sintering of Cobalt Oxide Nanoparticles. Nanomaterials 2021, 11, 3356. [Google Scholar] [CrossRef] [PubMed]

- Kang, B.; Han, S.; Kim, J.; Ko, S.; Yang, M. One-Step Fabrication of Copper Electrode by Laser-Induced Direct Local Reduction and Agglomeration of Copper Oxide Nanoparticle. J. Phys. Chem. C 2011, 115, 23664–23670. [Google Scholar] [CrossRef]

- Arakane, S.; Mizoshiri, M.; Hata, S. Direct patterning of Cu microstructures using femtosecond laser-induced CuO nanoparticle reduction. Jpn. J. Appl. Phys. 2015, 54, 06FP07. [Google Scholar] [CrossRef]

- Mizoshiri, M.; Arakane, S.; Sakurai, J.; Hata, S. Direct writing of Cu-based micro-temperature detectors using femtosecond laser reduction of CuO nanoparticles. Appl. Phys. Express 2016, 9, 036701. [Google Scholar] [CrossRef]

- Mizoshiri, M.; Nishitani, K.; Hata, S. Effect of Heat Accumulation on Femtosecond Laser Reductive Sintering of Mixed CuO/NiO Nanoparticles. Micromachines 2018, 9, 264. [Google Scholar] [CrossRef]

- Tumkin, I.I.; Khairullina, E.M.; Panov, M.S.; Yoshidomi, K.; Mizoshiri, M. Copper and Nickel Microsensors Produced by Selective Laser Reductive Sintering for Non-Enzymatic Glucose Detection. Materials 2021, 14, 2493. [Google Scholar] [CrossRef]

- Roth, G.L.; Haubner, J.; Kefer, S.; Esen, C.; Hellmann, R. Fs-laser based hybrid micromachining for polymer micro-opto electrical systems. Opt. Lasers Eng. 2021, 137, 106362. [Google Scholar] [CrossRef]

- Kefer, S.; Bischoff, K.; Roth, G.L.; Haubner, J.; Schmauss, B.; Hellmann, R. Tunable Bulk Polymer Planar Bragg Gratings Electrified via Femtosecond Laser Reductive Sintering of CuO Nanoparticles. Adv. Opt. Mater. 2021, 2002203. [Google Scholar] [CrossRef]

- Huang, Y.; Xie, X.; Li, M.; Xu, M.; Long, J. Copper circuits fabricated on flexible polymer substrates by a high repetition rate femtosecond laser-induced selective local reduction of copper oxide nanoparticles. Optics Express 2021, 29, 4453. [Google Scholar] [CrossRef]

- Paquet, C.; James, R.; Kell, A.J.; Mozenson, O.; Ferrigno, J.; Lafrenière, S.; Malenfant, P.R. Photosintering and electrical performance of CuO nanoparticle inks. Org. Electron. 2014, 15, 1836–1842. [Google Scholar] [CrossRef]

- Kang, H.; Sowade, E.; Baumann, R.R. Direct intense pulsed light sintering of inkjet-printed copper oxide layers within six milliseconds. ACS Appl. Mater. Interfaces 2014, 6, 1682–1687. [Google Scholar] [CrossRef] [PubMed]

- Shin, J.H.; Park, J.H.; Seo, J.; Im, T.H.; Kim, J.C.; Lee, H.E.; Kim, D.H.; Woo, K.Y.; Jeong, H.Y.; Cho, Y.H.; et al. A Flash-Induced Robust Cu Electrode on Glass Substrates and Its Application for Thin-Film μLEDs. Adv. Mater. 2021, 33, e2007186. [Google Scholar] [CrossRef]

- Back, S.; Kang, B. Low-cost optical fabrication of flexible copper electrode via laser-induced reductive sintering and adhesive transfer. Opt. Lasers Eng. 2018, 101, 78–84. [Google Scholar] [CrossRef]

- Chiu, P.H.; Cheng, W.H.; Lee, M.T.; Yasuda, K.; Song, J.M. Low-Thermal-Budget Photonic Sintering of Hybrid Pastes Containing Submicron/Nano CuO/Cu2O Particles. Nanomaterials 2021, 11, 1864. [Google Scholar] [CrossRef] [PubMed]

- Mizoshiri, M.; Hata, S. Direct Writing of Cu-based Micro-temperature Sensors onto Glass and Poly(dimethylsiloxane) Substrates Using Femtosecond Laser Reductive Patterning of CuO Nanoparticles. Res. Rev. J. Mater. Sci. 2016, 4, 47–54. [Google Scholar] [CrossRef]

- Binh Nam, V.; Thi Giang, T.; Lee, D. Laser digital patterning of finely-structured flexible copper electrodes using copper oxide nanoparticle ink produced by a scalable synthesis method. Appl. Surf. Sci. 2021, 570, 151179. [Google Scholar] [CrossRef]

- Zhao, J.; Yu, Z.; Tu, Z.; Bian, H. Influence of Electrode Structure on Performance of Laser Direct Writing Cu-PI Flexible Humidity Sensor. Micromachines 2022, 13, 992. [Google Scholar] [CrossRef]

- Arakane, S.; Mizoshiri, M.; Sakurai, J.; Hata, S. Direct writing of three-dimensional Cu-based thermal flow sensors using femtosecond laser-induced reduction of CuO nanoparticles. J. Micromech. Microeng. 2017, 27, 055013. [Google Scholar] [CrossRef]

- Mizoshiri, M.; Ito, Y.; Sakurai, J.; Hata, S. Direct-writing of copper-based micropatterns on polymer substrates using femtosecond laser reduction of copper (II) oxide nanoparticles. In Proceedings of the Nanosensors, Biosensors, Info-Tech Sensors and 3D Systems 2017, Portland, OR, USA, 25–29 March 2017; p. 101671G. [Google Scholar] [CrossRef]

- Qi, W.H.; Wang, M.P. Size and shape dependent melting temperature of metallic nanoparticles. Mater. Chem. Phys. 2004, 88, 280–284. [Google Scholar] [CrossRef]

- Ghadimi, A.; Saidur, R.; Metselaar, H. A review of nanofluid stability properties and characterization in stationary conditions. Int. J. Heat Mass Transfer 2011, 54, 4051–4068. [Google Scholar] [CrossRef]

- Smaisim, G.F.; Mohammed, D.B.; Abdulhadi, A.M.; Uktamov, K.F.; Alsultany, F.H.; Izzat, S.E.; Ansari, M.J.; Kzar, H.H.; Al-Gazally, M.E.; Kianfar, E. Nanofluids: Properties and applications. J. Sol-Gel Sci. Technol. 2022, 104, 1–35. [Google Scholar] [CrossRef]

- Haddad, Z.; Abid, C.; Oztop, H.F.; Mataoui, A. A review on how the researchers prepare their nanofluids. Int. J. Therm. Sci. 2014, 76, 168–189. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Ayoman, E.; Hosseini, S.G. Synthesis of CuO nanopowders by high-energy ball-milling method and investigation of their catalytic activity on thermal decomposition of ammonium perchlorate particles. J. Therm. Anal. Calorim. 2016, 123, 1213–1224. [Google Scholar] [CrossRef]

- El-Eskandarany, M.S.; Al-Hazza, A.; Al-Hajji, L.A.; Ali, N.; Al-Duweesh, A.A.; Banyan, M.; Al-Ajmi, F. Mechanical Milling: A Superior Nanotechnological Tool for Fabrication of Nanocrystalline and Nanocomposite Materials. Nanomaterials 2021, 11, 2484. [Google Scholar] [CrossRef]

- Sezer, N.; Atieh, M.A.; Koç, M. A comprehensive review on synthesis, stability, thermophysical properties, and characterization of nanofluids. Powder Technol. 2019, 344, 404–431. [Google Scholar] [CrossRef]

- Ogi, T.; Zulhijah, R.; Iwaki, T.; Okuyama, K. Recent Progress in Nanoparticle Dispersion Using Bead Mill. KONA Powder Part. J. 2017, 34, 3–23. [Google Scholar] [CrossRef]

- Jeon, S.; Thajudeen, T.; Hogan, C.J. Evaluation of nanoparticle aggregate morphology during wet milling. Powder Technol. 2015, 272, 75–84. [Google Scholar] [CrossRef]

- Avar, E.C.; Logoglu, E. Milling Effect on the Structural and Antibacterial Properties of ZnO and CuO Nanoparticles. Pharm. Chem. J. 2022, 56, 1004–1010. [Google Scholar] [CrossRef]

- Ettefaghi, E.o.l.; Ahmadi, H.; Rashidi, A.; Mohtasebi, S.S.; Alaei, M. Experimental evaluation of engine oil properties containing copper oxide nanoparticles as a nanoadditive. Int. J. Ind. Chem. 2013, 4, 28. [Google Scholar] [CrossRef]

- Bellantone, M.; Scarlett, B.; Merkus, H.G. (Eds.) Particle Size Measurements: Fundamentals, Practice, Quality; Particle Technology Series; Springer: Dordrecht, The Netherlands, 2009; Volume 17. [Google Scholar]

- Devendiran, D.K.; Amirtham, V.A. A review on preparation, characterization, properties and applications of nanofluids. Renew. Sustain. Energy Rev. 2016, 60, 21–40. [Google Scholar] [CrossRef]

- Dörner, L.; Cancellieri, C.; Rheingans, B.; Walter, M.; Kägi, R.; Schmutz, P.; Kovalenko, M.V.; Jeurgens, L.P.H. Cost-effective sol-gel synthesis of porous CuO nanoparticle aggregates with tunable specific surface area. Sci. Rep. 2019, 9, 11758. [Google Scholar] [CrossRef]

- Kowalski, A.J.; Watson, S.; Wall, K. Dispersion of Nanoparticle Clusters by Ball Milling. J. Dispers. Sci. Technol. 2008, 29, 600–604. [Google Scholar] [CrossRef]

- Li, H.; Li, J.; Bodycomb, J.; Patience, G.S. Experimental Methods in Chemical Engineering: Particle Size Distribution by Laser Diffraction—PSD. Can. J. Chem. Eng. 2019, 97, 1974–1981. [Google Scholar] [CrossRef]

- Shestakov, D.; Khairullina, E.; Shishov, A.; Khubezhov, S.; Makarov, S.; Tumkin, I.; Logunov, L. Picosecond laser writing of highly conductive copper micro-contacts from deep eutectic solvents. Opt. Laser Technol. 2023, 167, 109777. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bischoff, K.; Esen, C.; Hellmann, R. Preparation of Dispersed Copper(II) Oxide Nanosuspensions as Precursor for Femtosecond Reductive Laser Sintering by High-Energy Ball Milling. Nanomaterials 2023, 13, 2693. https://doi.org/10.3390/nano13192693

Bischoff K, Esen C, Hellmann R. Preparation of Dispersed Copper(II) Oxide Nanosuspensions as Precursor for Femtosecond Reductive Laser Sintering by High-Energy Ball Milling. Nanomaterials. 2023; 13(19):2693. https://doi.org/10.3390/nano13192693

Chicago/Turabian StyleBischoff, Kay, Cemal Esen, and Ralf Hellmann. 2023. "Preparation of Dispersed Copper(II) Oxide Nanosuspensions as Precursor for Femtosecond Reductive Laser Sintering by High-Energy Ball Milling" Nanomaterials 13, no. 19: 2693. https://doi.org/10.3390/nano13192693

APA StyleBischoff, K., Esen, C., & Hellmann, R. (2023). Preparation of Dispersed Copper(II) Oxide Nanosuspensions as Precursor for Femtosecond Reductive Laser Sintering by High-Energy Ball Milling. Nanomaterials, 13(19), 2693. https://doi.org/10.3390/nano13192693