(Al, Ga)N-Based Quantum Dots Heterostructures on h-BN for UV-C Emission

Abstract

:1. Introduction

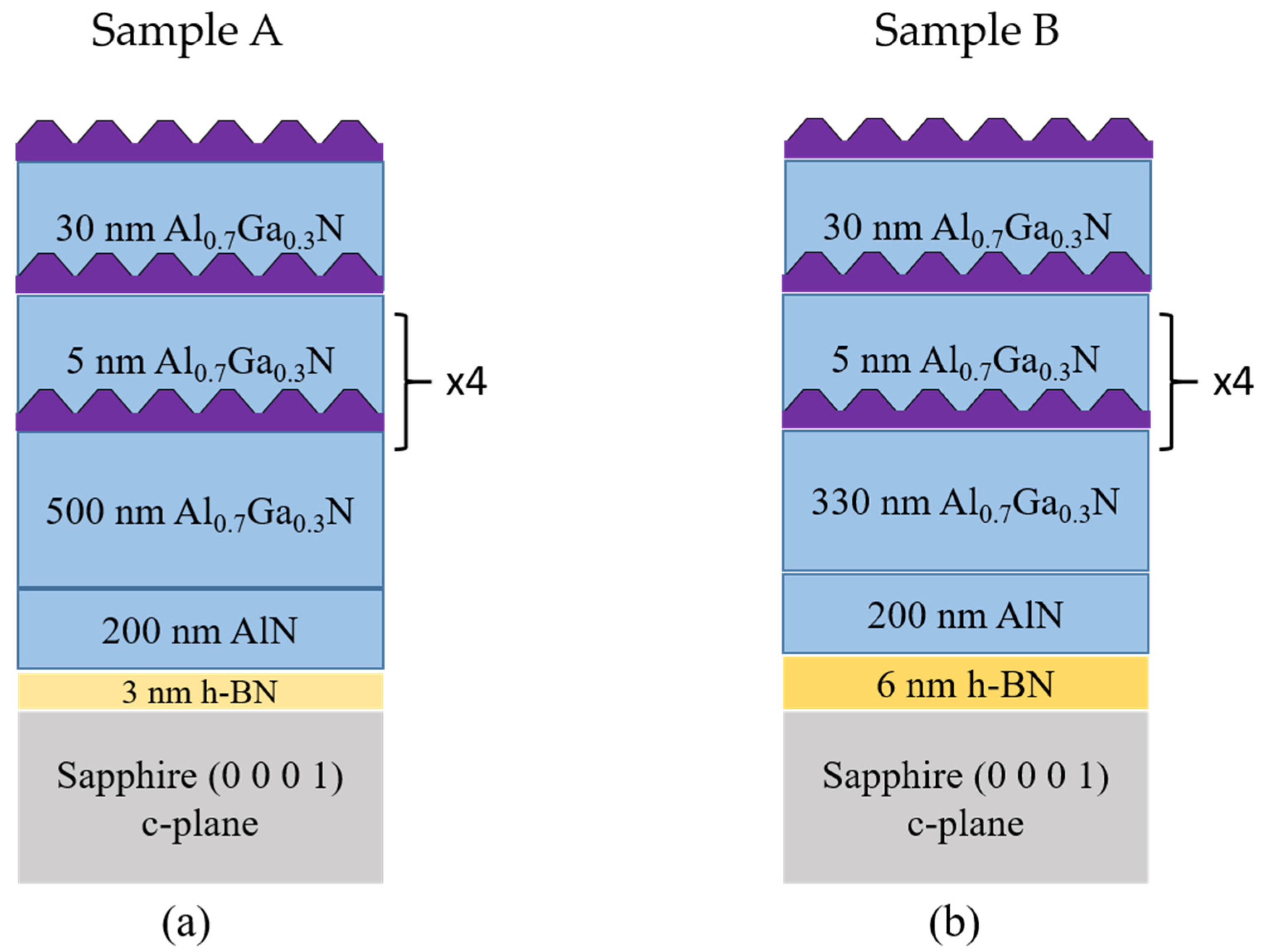

2. Materials and Methods

3. Results

3.1. AlN Growth by MBE

3.1.1. Characterization of h-BN Templates before Growth

3.1.2. AlN Growth on h-BN/Sapphire Templates by MBE

3.2. Al0.3Ga0.7N/Al0.7Ga0.3N QDs Structural and Optical Properties

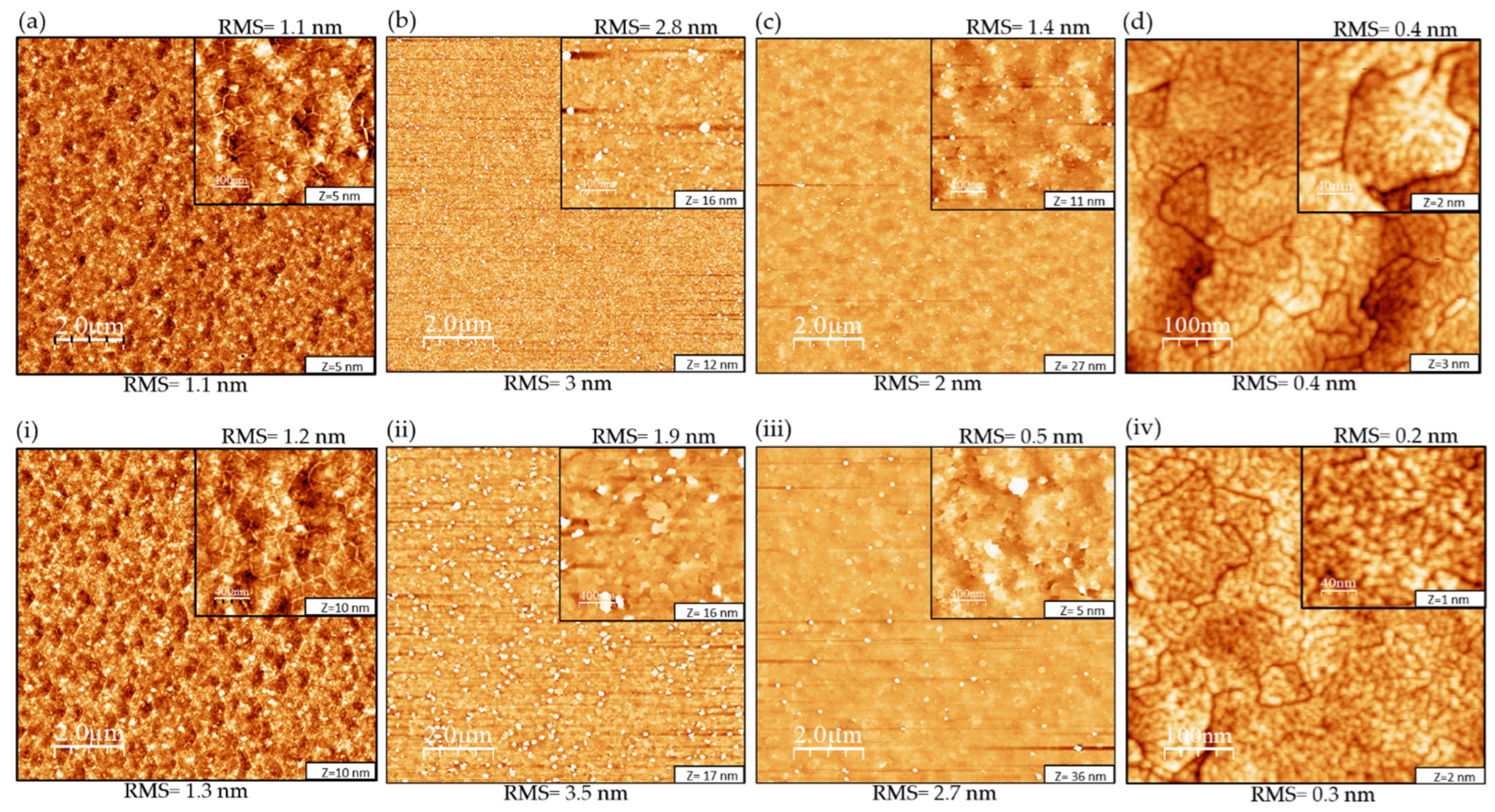

3.2.1. Morphological Properties

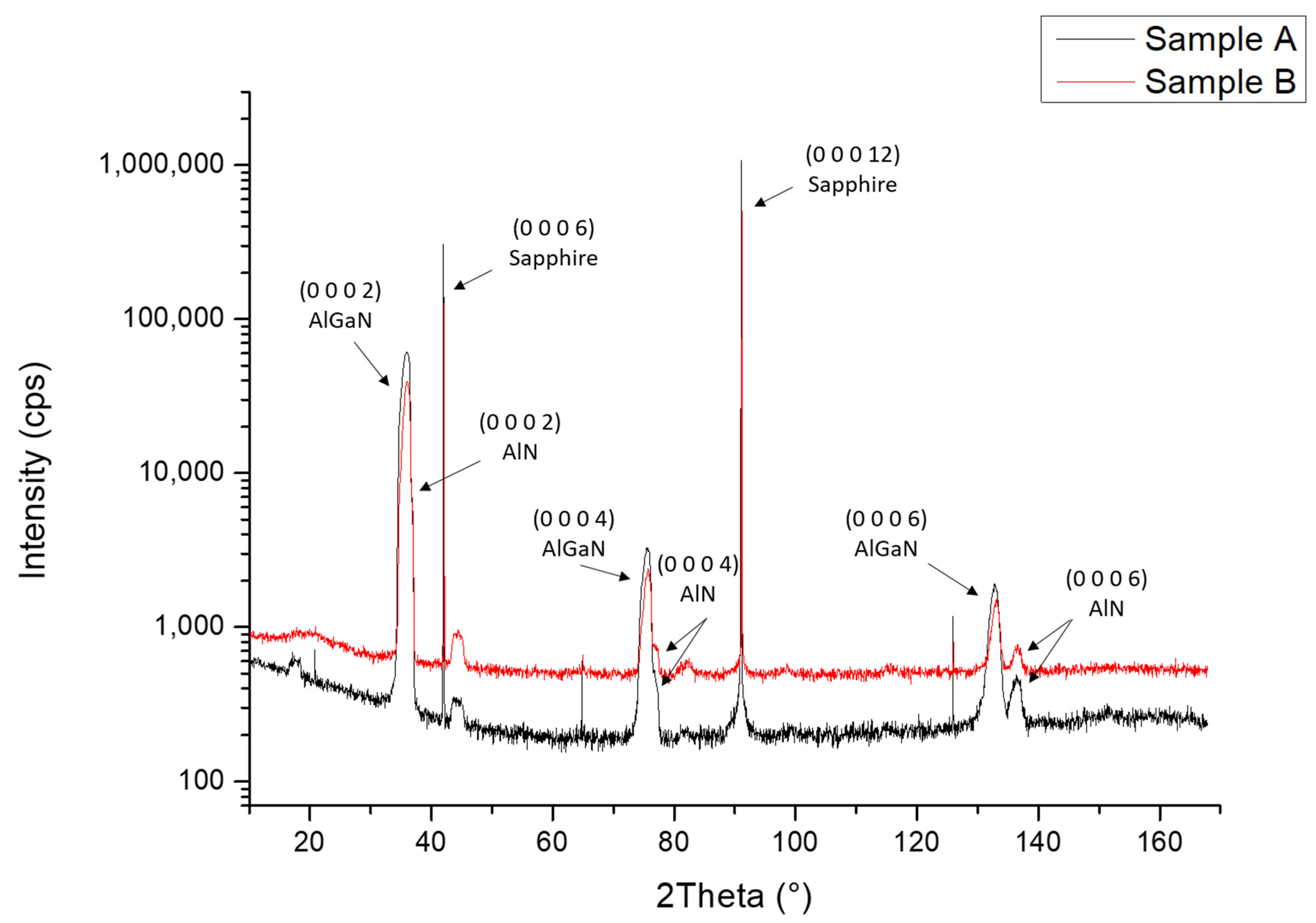

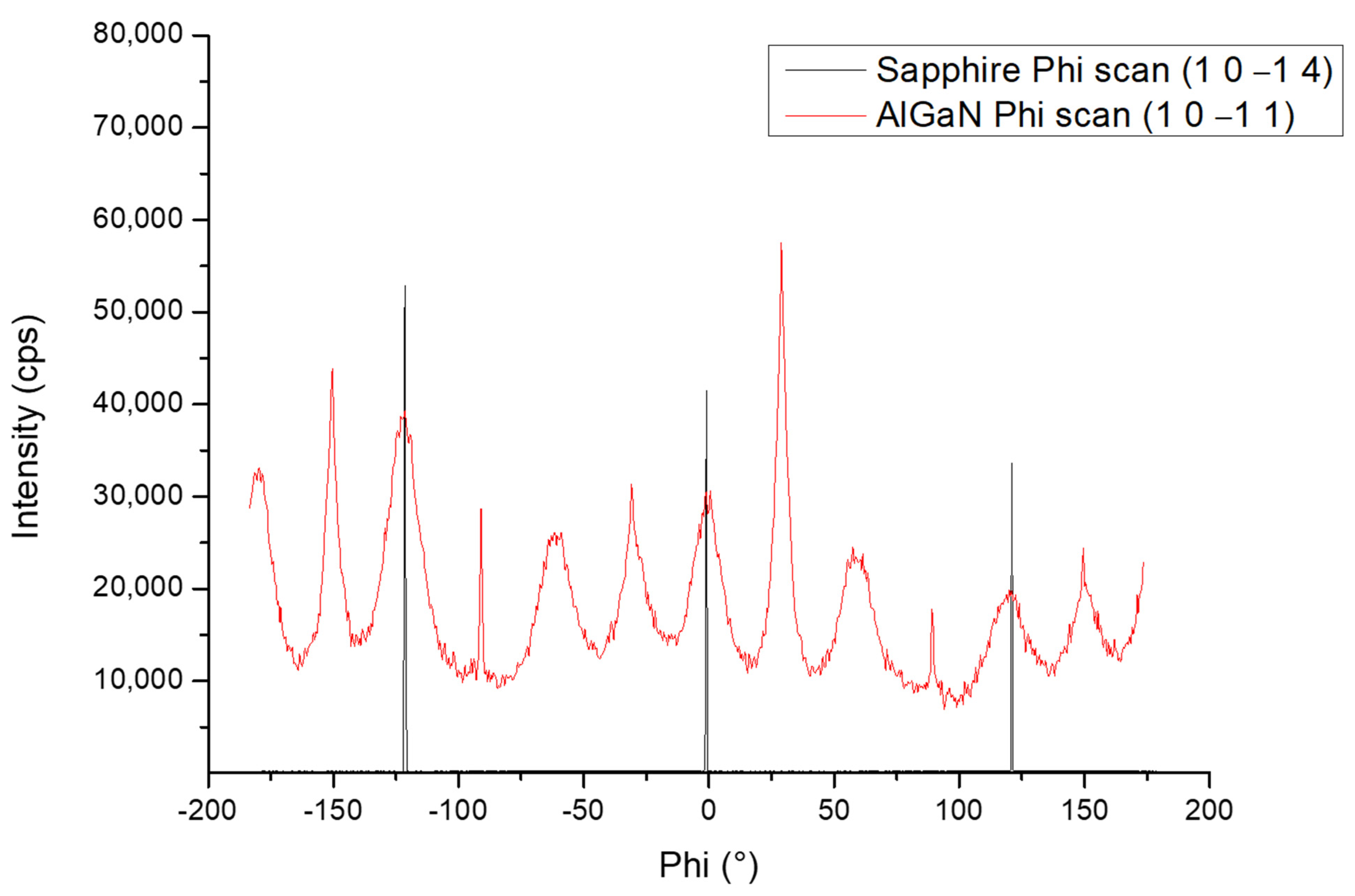

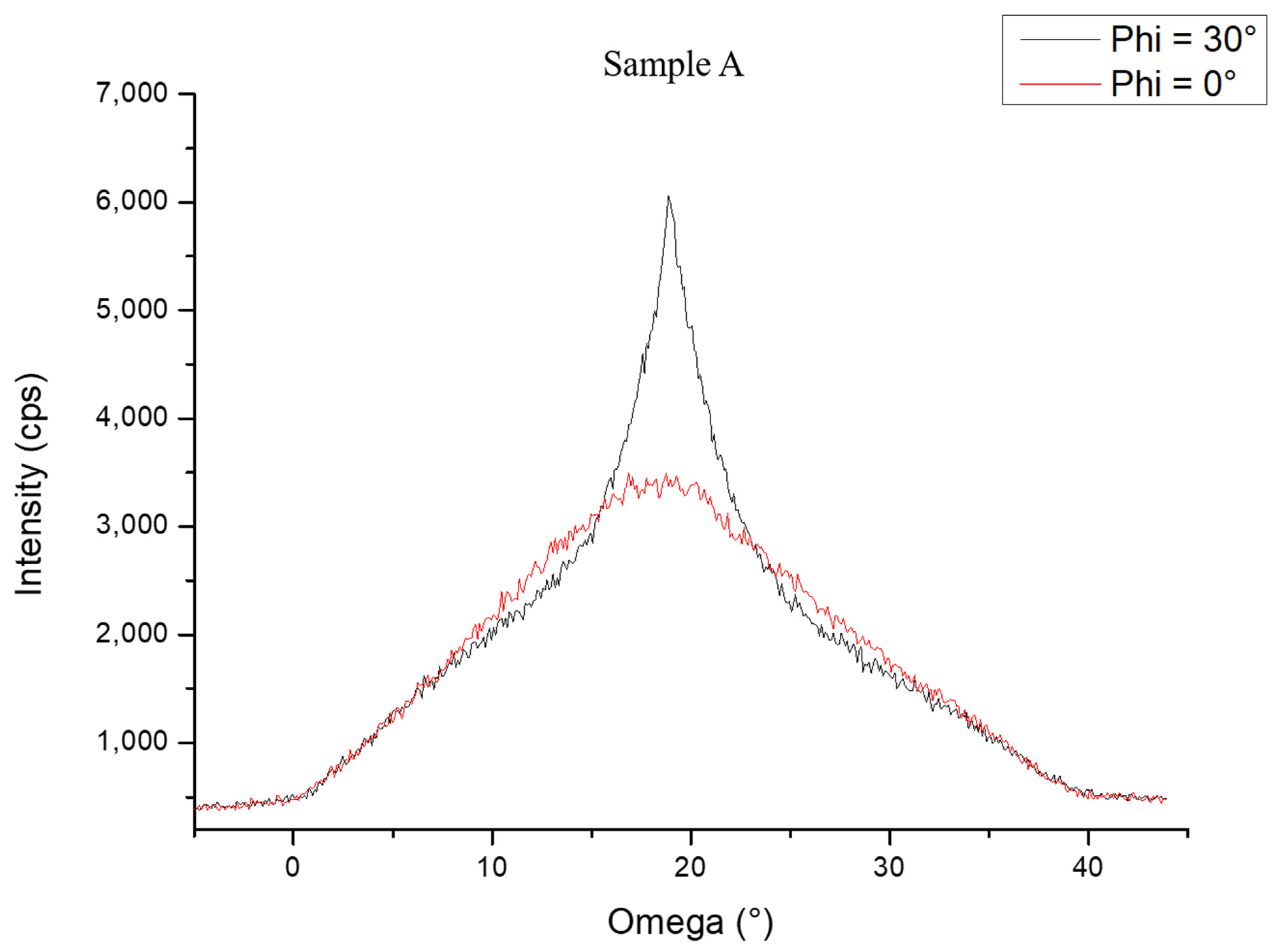

3.2.2. Crystal Properties by X-ray Diffraction

3.2.3. Optical Properties

- Continuous wave photoluminescence

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Homepage|Minamata Convention on Mercury. Available online: https://www.mercuryconvention.org/en (accessed on 24 February 2023).

- Taniyasu, Y.; Kasu, M.; Makimoto, T. An aluminium nitride light-emitting diode with a wavelength of 210 nanometres. Nature 2006, 441, 325–328. [Google Scholar] [CrossRef] [PubMed]

- Bolton, J.R.; Cotton, C.A. The Ultraviolet Disinfection Handbook; American Water Works Association: Washington, DC, USA, 2011; ISBN 1-61300-077-4. [Google Scholar]

- Santos, A.L.; Oliveira, V.; Baptista, I.; Henriques, I.; Gomes, N.C.; Almeida, A.; Correia, A.; Cunha, Â. Wavelength dependence of biological damage induced by UV radiation on bacteria. Arch. Microbiol. 2013, 195, 63–74. [Google Scholar] [CrossRef] [PubMed]

- Takano, T.; Mino, T.; Sakai, J.; Noguchi, N.; Tsubaki, K.; Hirayama, H. Deep-ultraviolet light-emitting diodes with external quantum efficiency higher than 20% at 275 nm achieved by improving light-extraction efficiency. Appl. Phys. Express 2017, 10, 031002. [Google Scholar] [CrossRef]

- Koma, A.; Yoshimura, K. Ultrasharp interfaces grown with Van der Waals epitaxy. Surf. Sci. 1986, 174, 556–560. [Google Scholar] [CrossRef]

- Ajayan, P.; Kim, P.; Banerjee, K. Two-dimensional van der Waals materials. Phys. Today 2016, 69, 38–44. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Kumakura, K.; Akasaka, T.; Makimoto, T. Layered boron nitride as a release layer for mechanical transfer of GaN-based devices. Nature 2012, 484, 223–227. [Google Scholar] [CrossRef]

- Katona, T.M.; Cantu, P.; Keller, S.; Wu, Y.; Speck, J.S.; DenBaars, S.P. Maskless lateral epitaxial overgrowth of high-aluminum-content AlxGa1−xN. Appl. Phys. Lett. 2004, 84, 5025–5027. [Google Scholar] [CrossRef]

- Chugh, D.; Adhikari, S.; Wong-Leung, J.; Lysevych, M.; Jagadish, C.; Tan, H.H. Improving the Morphology and Crystal Quality of AlN Grown on Two-Dimensional hBN. Cryst. Growth Des. 2020, 20, 1811–1819. [Google Scholar] [CrossRef]

- Zaiter, A.; Michon, A.; Nemoz, M.; Courville, A.; Vennéguès, P.; Ottapilakkal, V.; Vuong, P.; Sundaram, S.; Ougazzaden, A.; Brault, J. Crystalline Quality and Surface Morphology Improvement of Face-to-Face Annealed MBE-Grown AlN on h-BN. Materials 2022, 15, 8602. [Google Scholar] [CrossRef]

- Wu, Q.; Yan, J.; Zhang, L.; Chen, X.; Wei, T.; Li, Y.; Liu, Z.; Wei, X.; Zhang, Y.; Wang, J.; et al. Growth mechanism of AlN on hexagonal BN/sapphire substrate by metal-organic chemical vapor deposition. CrystEngComm 2017, 19, 5849–5856. [Google Scholar] [CrossRef]

- Wu, Q.; Guo, Y.; Sundaram, S.; Yan, J.; Zhang, L.; Wei, T.; Wei, X.; Wang, J.; Ougazzaden, A.; Li, J. Exfoliation of AlN film using two-dimensional multilayer hexagonal BN for deep-ultraviolet light-emitting diodes. Appl. Phys. Express 2019, 12, 015505. [Google Scholar] [CrossRef]

- Shin, J.; Kim, H.; Sundaram, S.; Jeong, J.; Park, B.-I.; Chang, C.S.; Choi, J.; Kim, T.; Saravanapavanantham, M.; Lu, K. Vertical full-colour micro-LEDs via 2D materials-based layer transfer. Nature 2023, 614, 81–87. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Sundaram, S.; El Gmili, Y.; Ayari, T.; Puybaret, R.; Patriarche, G.; Voss, P.L.; Salvestrini, J.P.; Ougazzaden, A. Large-area two-dimensional layered hexagonal boron nitride grown on sapphire by metalorganic vapor phase epitaxy. Cryst. Growth Des. 2016, 16, 3409–3415. [Google Scholar] [CrossRef]

- Daudin, B.; Widmann, F.; Feuillet, G.; Samson, Y.; Arlery, M.; Rouvière, J.L. Stranski-Krastanov growth mode during the molecular beam epitaxy of highly strained GaN. Phys. Rev. B 1997, 56, R7069–R7072. [Google Scholar] [CrossRef]

- Bauer, E.; van der Merwe, J.H. Structure and growth of crystalline superlattices: From monolayer to superlattice. Phys. Rev. B 1986, 33, 3657. [Google Scholar] [CrossRef]

- Horcas, I.; Fernández, R.; Gómez-Rodríguez, J.M.; Colchero, J.; Gómez-Herrero, J.; Baro, A.M. WSXM: A software for scanning probe microscopy and a tool for nanotechnology. Rev. Sci. Instrum. 2007, 78, 013705. [Google Scholar] [CrossRef]

- Saha, S.; Rice, A.; Ghosh, A.; Hasan, S.M.N.; You, W.; Ma, T.; Hunter, A.; Bissell, L.J.; Bedford, R.; Crawford, M.; et al. Comprehensive characterization and analysis of hexagonal boron nitride on sapphire. AIP Adv. 2021, 11, 055008. [Google Scholar] [CrossRef]

- Brault, J.; Matta, S.; Ngo, T.-H.; Al Khalfioui, M.; Valvin, P.; Leroux, M.; Damilano, B.; Korytov, M.; Brändli, V.; Vennéguès, P.; et al. Internal quantum efficiencies of AlGaN quantum dots grown by molecular beam epitaxy and emitting in the UVA to UVC ranges. J. Appl. Phys. 2019, 126, 205701. [Google Scholar] [CrossRef]

- Brault, J.; Rosales, D.; Damilano, B.; Leroux, M.; Courville, A.; Korytov, M.; Chenot, S.; Vennéguès, P.; Vinter, B.; De Mierry, P. Polar and semipolar GaN/Al0. 5Ga0. 5N nanostructures for UV light emitters. Semicond. Sci. Technol. 2014, 29, 084001. [Google Scholar] [CrossRef]

- Ayari, T.; Sundaram, S.; Li, X.; El Gmili, Y.; Voss, P.L.; Salvestrini, J.P.; Ougazzaden, A. Wafer-scale controlled exfoliation of metal organic vapor phase epitaxy grown InGaN/GaN multi quantum well structures using low-tack two-dimensional layered h-BN. Appl. Phys. Lett. 2016, 108, 171106. [Google Scholar] [CrossRef]

- Mansurov, V.; Nikitin, A.; Galitsyn, Y.; Svitasheva, S.; Zhuravlev, K.; Osvath, Z.; Dobos, L.; Horvath, Z.; Pecz, B. AlN growth on sapphire substrate by ammonia MBE. J. Cryst. Growth 2007, 300, 145–150. [Google Scholar] [CrossRef]

- Sundaram, S.; Vuong, P.; Mballo, A.; Ayari, T.; Karrakchou, S.; Patriarche, G.; Voss, P.L.; Salvestrini, J.P.; Ougazzaden, A. MOVPE of GaN-based mixed dimensional heterostructures on wafer-scale layered 2D hexagonal boron nitride—A key enabler of III-nitride flexible optoelectronics. APL Mater. 2021, 9, 061101. [Google Scholar] [CrossRef]

- Himwas, C.; Songmuang, R.; Dang, L.S.; Bleuse, J.; Rapenne, L.; Sarigiannidou, E.; Monroy, E. Thermal stability of the deep ultraviolet emission from AlGaN/AlN Stranski-Krastanov quantum dots. Appl. Phys. Lett. 2012, 101, 241914. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaiter, A.; Nikitskiy, N.; Nemoz, M.; Vuong, P.; Ottapilakkal, V.; Sundaram, S.; Ougazzaden, A.; Brault, J. (Al, Ga)N-Based Quantum Dots Heterostructures on h-BN for UV-C Emission. Nanomaterials 2023, 13, 2404. https://doi.org/10.3390/nano13172404

Zaiter A, Nikitskiy N, Nemoz M, Vuong P, Ottapilakkal V, Sundaram S, Ougazzaden A, Brault J. (Al, Ga)N-Based Quantum Dots Heterostructures on h-BN for UV-C Emission. Nanomaterials. 2023; 13(17):2404. https://doi.org/10.3390/nano13172404

Chicago/Turabian StyleZaiter, Aly, Nikita Nikitskiy, Maud Nemoz, Phuong Vuong, Vishnu Ottapilakkal, Suresh Sundaram, Abdallah Ougazzaden, and Julien Brault. 2023. "(Al, Ga)N-Based Quantum Dots Heterostructures on h-BN for UV-C Emission" Nanomaterials 13, no. 17: 2404. https://doi.org/10.3390/nano13172404

APA StyleZaiter, A., Nikitskiy, N., Nemoz, M., Vuong, P., Ottapilakkal, V., Sundaram, S., Ougazzaden, A., & Brault, J. (2023). (Al, Ga)N-Based Quantum Dots Heterostructures on h-BN for UV-C Emission. Nanomaterials, 13(17), 2404. https://doi.org/10.3390/nano13172404