Enhancement of Resistive Switching Performance in Hafnium Oxide (HfO2) Devices via Sol-Gel Method Stacking Tri-Layer HfO2/Al-ZnO/HfO2 Structures

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Preparation Method

2.3. Test and Characterization

3. Results

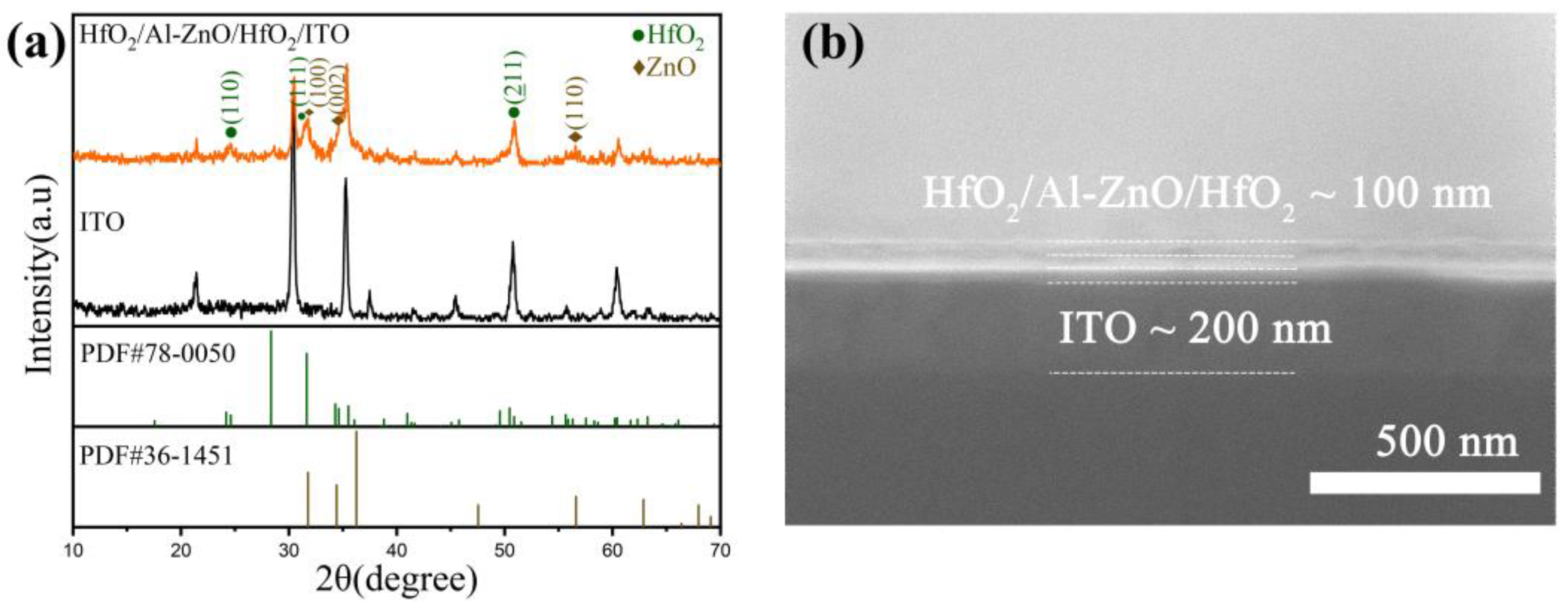

3.1. Structure Analysis

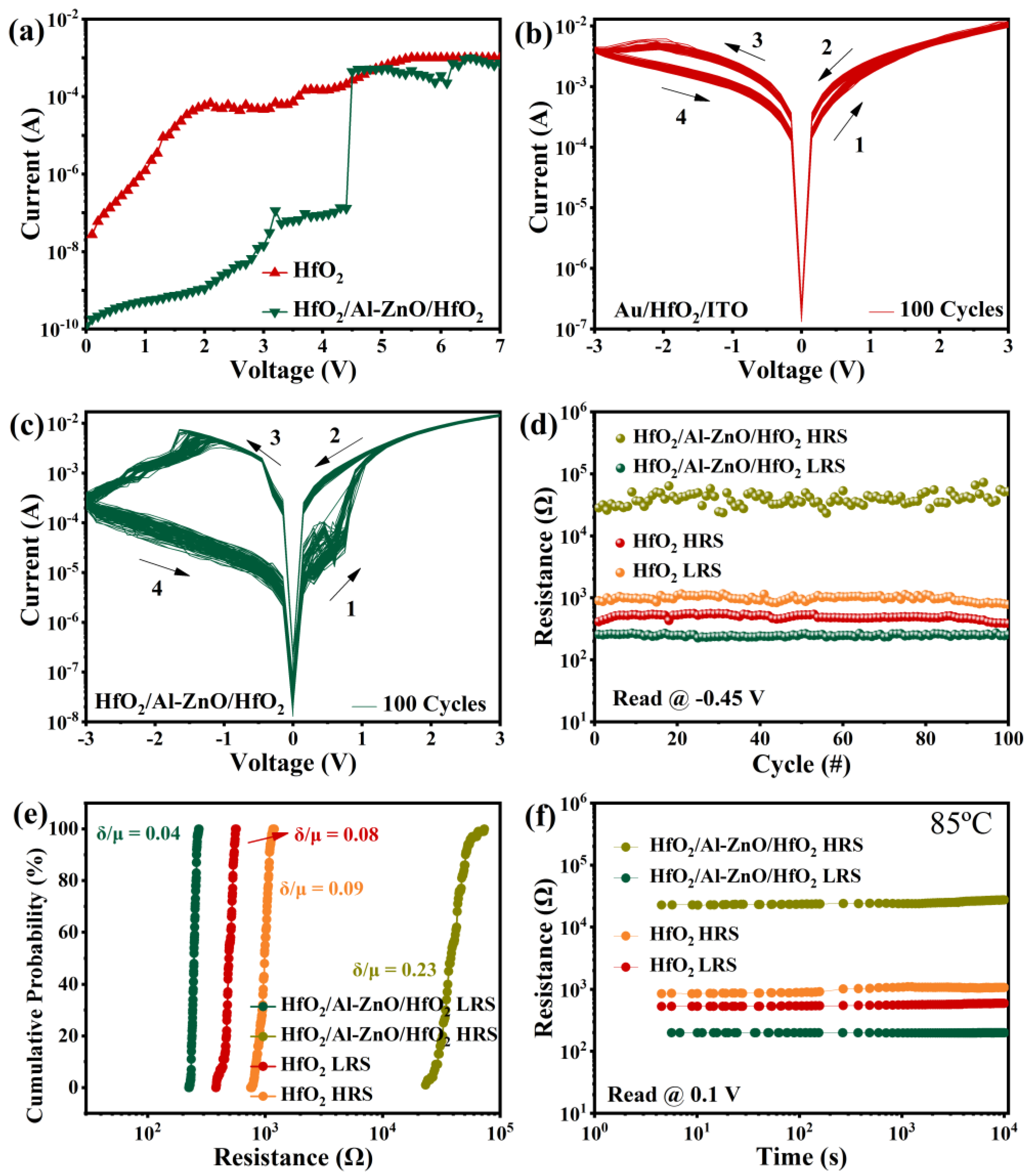

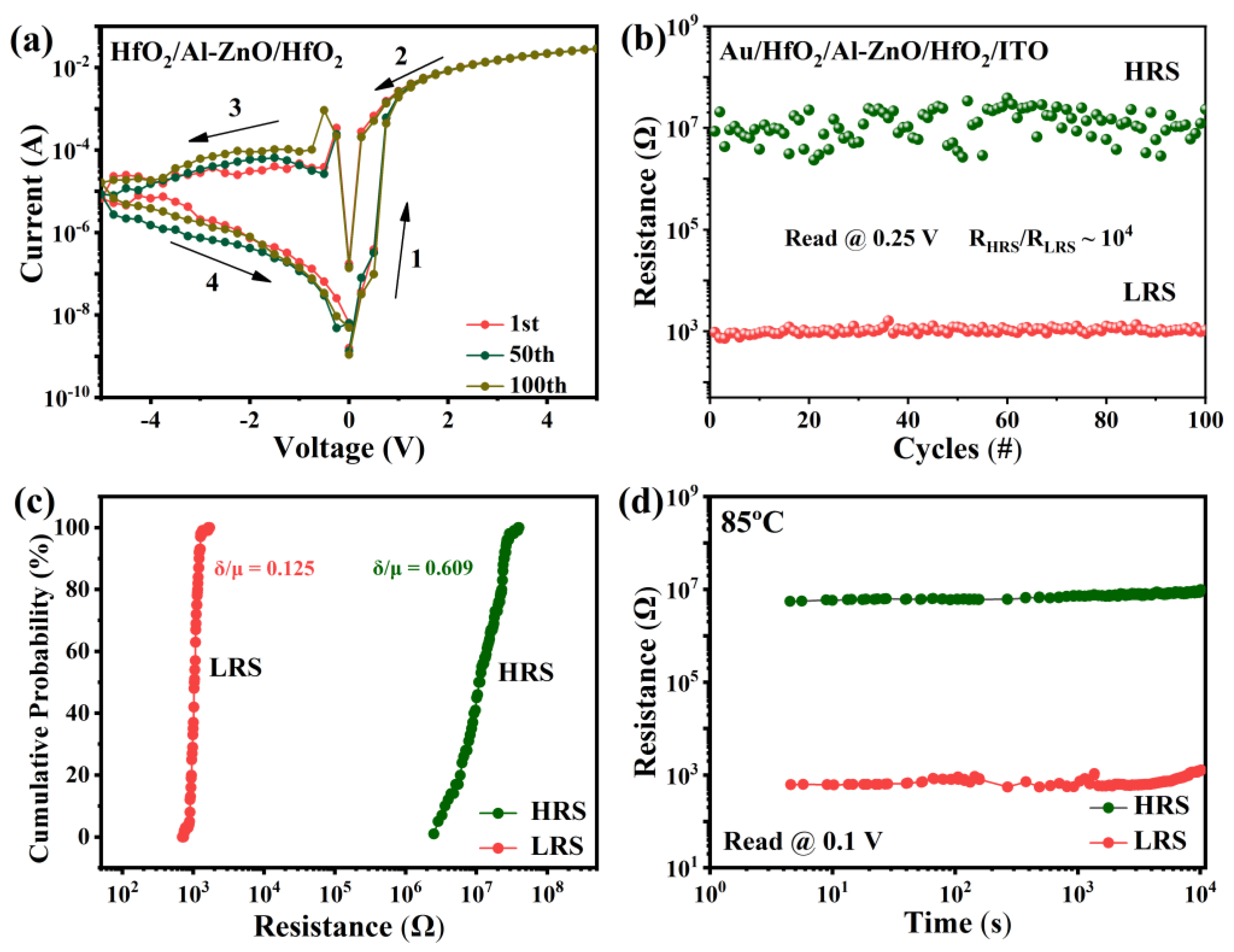

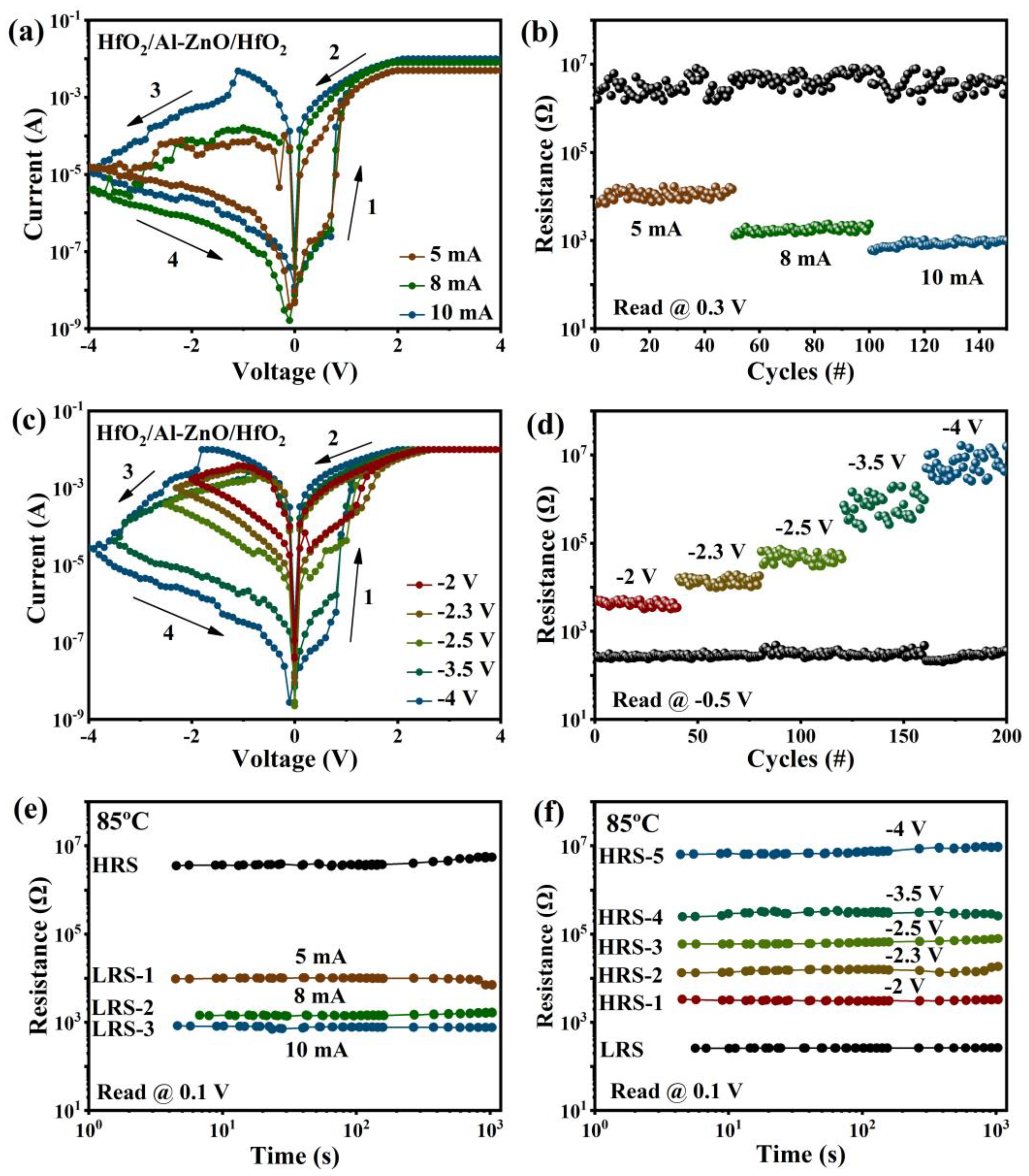

3.2. Electrical Performance

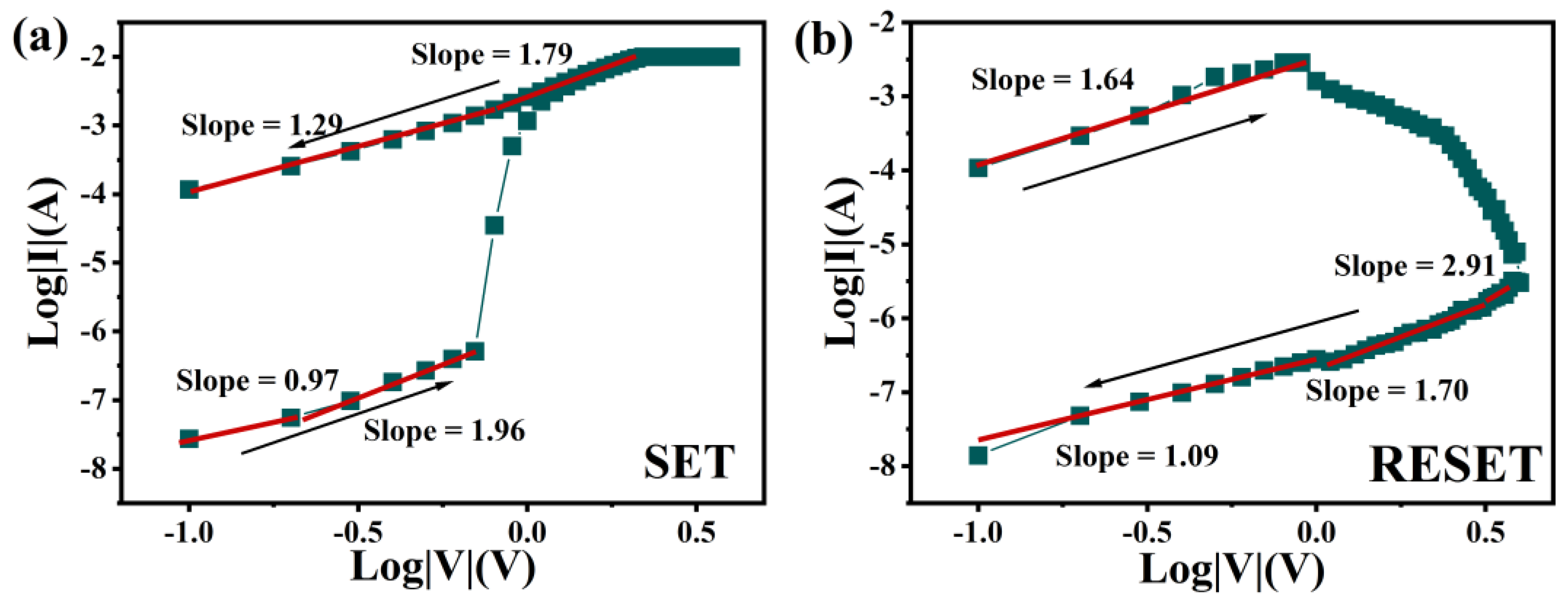

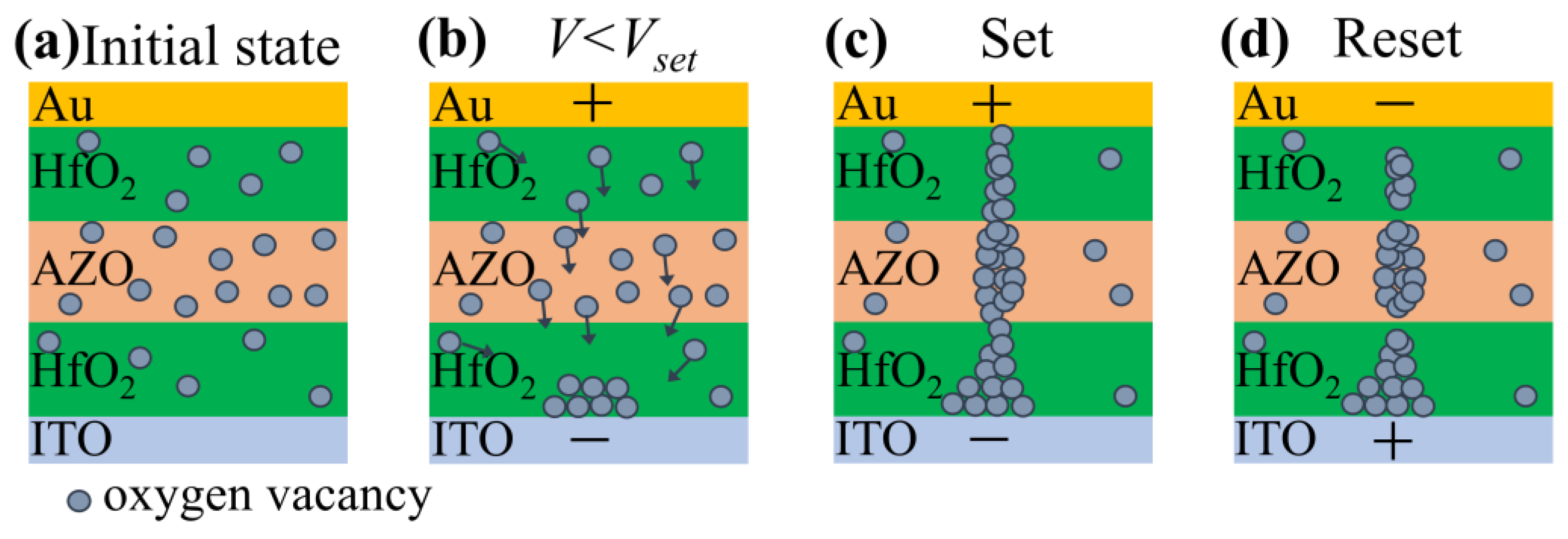

3.3. Mechanism Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, K.-H.; Chang, K.-C.; Chang, T.-C.; Tsai, T.-M.; Liang, S.-P.; Young, T.-F.; Syu, Y.-E.; Sze, S.M. Improvement of bipolar switching properties of Gd:SiOx RRAM devices on indium tin oxide electrode by low-temperature supercritical CO2 treatment. Nanoscale Res. Lett. 2016, 11, 52. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Maikap, S. Performance Improvement in E-Gun Deposited SiOx-Based RRAM Device by Switching Material Thickness Reduction. J. Phys. Conf. Ser. 2022, 2161, 012040. [Google Scholar] [CrossRef]

- Qi, Y.; Zhao, C.Z.; Liu, C.; Fang, Y.; He, J.; Luo, T.; Yang, L.; Zhao, C. Comparisons of switching characteristics between Ti/Al2O3/Pt and TiN/Al2O3/Pt RRAM devices with various compliance currents. Semicond. Sci. Technol. 2018, 33, 045003. [Google Scholar] [CrossRef]

- Chen, L.; Dai, Y.-W.; Sun, Q.-Q.; Guo, J.-J.; Zhou, P.; Zhang, D.W. Al2O3/HfO2 functional stack films based resistive switching memories with controlled SET and RESET voltages. Solid State Ion. 2015, 273, 66–69. [Google Scholar] [CrossRef]

- Lin, C.-L.; Tang, C.-C.; Wu, S.-C.; Juan, P.-C.; Kang, T.-K. Impact of oxygen composition of ZnO metal-oxide on unipolar resistive switching characteristics of Al/ZnO/Al resistive RAM (RRAM). Microelectron. Eng. 2015, 136, 15–21. [Google Scholar] [CrossRef]

- Roy, S.; Niu, G.; Wang, Q.; Wang, Y.; Zhang, Y.; Wu, H.; Zhai, S.; Shi, P.; Song, S.; Song, Z. Toward a reliable synaptic simulation using Al-doped HfO2 RRAM. ACS Appl. Mater. Interfaces 2020, 12, 10648–10656. [Google Scholar] [CrossRef]

- Ku, B.; Abbas, Y.; Sokolov, A.S.; Choi, C. Interface engineering of ALD HfO2-based RRAM with Ar plasma treatment for reliable and uniform switching behaviors. J. Alloys Compd. 2018, 735, 1181–1188. [Google Scholar] [CrossRef]

- Wang, H.; Zou, C.; Zhou, L.; Tian, C.; Fu, D. Resistive switching characteristics of thin NiO film based flexible nonvolatile memory devices. Microelectron. Eng. 2012, 91, 144–146. [Google Scholar] [CrossRef]

- Lee, Y.; Jung, J.; Shin, D.; Pak, J.J. Effect of UV irradiation on the resistive switching characteristics of low-temperature solution-processed ZrO2 RRAM. Semicond. Sci. Technol. 2021, 36, 085004. [Google Scholar] [CrossRef]

- Fu, L.; Li, Y.; Han, G.; Gao, X.; Chen, C.; Yuan, P. Stable resistive switching characteristics of ZrO2-based memory device with low-cost. Microelectron. Eng. 2017, 172, 26–29. [Google Scholar] [CrossRef]

- Banerjee, W.; Kashir, A.; Kamba, S. Hafnium Oxide (HfO2)–A Multifunctional Oxide: A Review on the Prospect and Challenges of Hafnium Oxide in Resistive Switching and Ferroelectric Memories. Small 2022, 18, 2107575. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.; Liu, H.; Wang, S.; Wang, D.; Wu, L. The Image Identification Application with HfO2-Based Replaceable 1T1R Neural Networks. Nanomaterials 2022, 12, 1075. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, W.; Zhang, X.; Luo, Q.; Lv, H.; Liu, Q.; Long, S.; Liu, M. Design of CMOS compatible, high-speed, highly-stable complementary switching with multilevel operation in 3D vertically stacked novel HfO2/Al2O3/TiOx (HAT) RRAM. Adv. Electron. Mater. 2018, 4, 1700561. [Google Scholar] [CrossRef]

- Xiao, Y.; Wu, X.; Jin, Y.; Cao, G.; Jiang, B.; Ke, S.; Ye, C. Improved artificial synapse performance of Pt/HfO2/BiFeO3/HfO2/TiN memristor through N2 annealing. Ceram. Int. 2022, 48, 34584–34589. [Google Scholar] [CrossRef]

- Pi, S.; Li, C.; Jiang, H.; Xia, W.; Xin, H.; Yang, J.J.; Xia, Q. Memristor crossbar arrays with 6-nm half-pitch and 2-nm critical dimension. Nat. Nanotechnol. 2019, 14, 35–39. [Google Scholar] [CrossRef]

- Wang, Y.-B.; Chang, T.-C.; Lin, S.-K.; Wu, P.-Y.; Zhang, Y.-C.; Tan, Y.-F.; Chen, W.-C.; Wu, C.-W.; Chou, S.-Y.; Zhou, K.-J. Forming-Free HfO2-Based Resistive Random Access Memory by X-ray Irradiation. IEEE Trans. Electron Devices 2022, 69, 6705–6709. [Google Scholar] [CrossRef]

- Kim, G.S.; Park, T.H.; Kim, H.J.; Ha, T.J.; Park, W.Y.; Kim, S.G.; Hwang, C.S. Investigation of the retention performance of an ultra-thin HfO2 resistance switching layer in an integrated memory device. J. Appl. Phys. 2018, 124, 024102. [Google Scholar] [CrossRef]

- Banerjee, W. Challenges and applications of emerging nonvolatile memory devices. Electronics 2020, 9, 1029. [Google Scholar] [CrossRef]

- Chen, X.; Hu, W.; Li, Y.; Wu, S.; Bao, D. Complementary resistive switching behaviors evolved from bipolar TiN/HfO2/Pt device. Appl. Phys. Lett. 2016, 108, 053504. [Google Scholar] [CrossRef]

- Peng, Z.; Wu, F.; Jiang, L.; Cao, G.; Jiang, B.; Cheng, G.; Ke, S.; Chang, K.C.; Li, L.; Ye, C. HfO2-Based Memristor as an Artificial Synapse for Neuromorphic Computing with Tri-Layer HfO2/BiFeO3/HfO2 Design. Adv. Funct. Mater. 2021, 31, 2107131. [Google Scholar] [CrossRef]

- Mahata, C.; Kang, M.; Kim, S. Multi-level analog resistive switching characteristics in tri-layer HfO2/Al2O3/HfO2 based memristor on ITO electrode. Nanomaterials 2020, 10, 2069. [Google Scholar] [CrossRef] [PubMed]

- Jain, N.; Sharma, S.K.; Kumawat, R.; Jain, P.K.; Kumar, D.; Vyas, R. Resistive switching, endurance and retention properties of ZnO/HfO2 bilayer heterostructure memory device. Micro Nanostruct. 2022, 169, 207366. [Google Scholar] [CrossRef]

- Nand, M.; Tripathi, S.; Rajput, P.; Kumar, M.; Kumar, Y.; Mandal, S.K.; Urkude, R.; Gupta, M.; Dawar, A.; Ojha, S. Different polymorphs of Y doped HfO2 epitaxial thin films: Insights into structural, electronic and optical properties. J. Alloys Compd. 2022, 928, 167099. [Google Scholar] [CrossRef]

- Sokolov, A.S.; Jeon, Y.-R.; Kim, S.; Ku, B.; Lim, D.; Han, H.; Chae, M.G.; Lee, J.; Ha, B.G.; Choi, C. Influence of oxygen vacancies in ALD HfO2-x thin films on non-volatile resistive switching phenomena with a Ti/HfO2-x/Pt structure. Appl. Surf. Sci. 2018, 434, 822–830. [Google Scholar] [CrossRef]

- Zhang, W.; Kong, J.-Z.; Cao, Z.-Y.; Li, A.-D.; Wang, L.-G.; Zhu, L.; Li, X.; Cao, Y.-Q.; Wu, D. Bipolar resistive switching characteristics of HfO2/TiO2/HfO2 trilayer-structure RRAM devices on Pt and TiN-coated substrates fabricated by atomic layer deposition. Nanoscale Res. Lett. 2017, 12, 393. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Wang, F.; Li, C.; Shan, X.; Liang, A.; Hu, K.; Li, Y.; Liu, Q.; Hao, Y.; Zhang, K. Insight into interface behavior and microscopic switching mechanism for flexible HfO2 RRAM. Appl. Surf. Sci. 2020, 526, 146723. [Google Scholar] [CrossRef]

- Liu, C.-F.; Tang, X.-G.; Wang, L.-Q.; Tang, H.; Jiang, Y.-P.; Liu, Q.-X.; Li, W.-H.; Tang, Z.-H. Resistive switching characteristics of HfO2 thin films on mica substrates prepared by Sol-Gel process. Nanomaterials 2019, 9, 1124. [Google Scholar] [CrossRef]

- Sabbagh, F.; Kiarostami, K.; Mahmoudi Khatir, N.; Rezania, S.; Muhamad, I.I. Green synthesis of Mg0.99Zn0.01O nanoparticles for the fabrication of κ-Carrageenan/NaCMC hydrogel in order to deliver catechin. Polymers 2020, 12, 861. [Google Scholar] [CrossRef]

- Borkar, H.; Thakre, A.; Kushvaha, S.S.; Aloysius, R.; Kumar, A. Light assisted irreversible resistive switching in ultra thin hafnium oxide. RSC Adv. 2015, 5, 35046–35051. [Google Scholar] [CrossRef]

- Jilani, A.; Abdel-wahab, M.S.; Al-ghamdi, A.A.; sadik Dahlan, A.; Yahia, I. Nonlinear optical parameters of nanocrystalline AZO thin film measured at different substrate temperatures. Physica B 2016, 481, 97–103. [Google Scholar] [CrossRef]

- Zhang, R.; Huang, H.; Xia, Q.; Ye, C.; Wei, X.; Wang, J.; Zhang, L.; Zhu, L.Q. Role of oxygen vacancies at the TiO2/HfO2 interface in flexible oxide-based resistive switching memory. Adv. Electron. Mater. 2019, 5, 1800833. [Google Scholar] [CrossRef]

- Kim, S.Y.; Yang, J.M.; Choi, E.S.; Park, N.G. Layered (C6H5CH2NH3) 2CuBr4 perovskite for multilevel storage resistive switching memory. Adv. Funct. Mater. 2020, 30, 2002653. [Google Scholar] [CrossRef]

- Qi, M.; Tao, Y.; Wang, Z.; Xu, H.; Zhao, X.; Liu, W.; Ma, J.; Liu, Y. Highly uniform switching of HfO2−x based RRAM achieved through Ar plasma treatment for low power and multilevel storage. Appl. Surf. Sci. 2018, 458, 216–221. [Google Scholar] [CrossRef]

- Napolean, A.; Sivamangai, N.; Naveenkumar, R.; Nithya, N. Electroforming atmospheric temperature and annealing effects on Pt/HfO2/TiO2/HfO2/Pt resistive random access memory cell. Silicon 2022, 14, 2863–2869. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, F.; Hu, K.; She, Y.; Song, S.; Song, Z.; Zhang, K. Improvement of resistive switching performance in sulfur-doped HfOx-based RRAM. Materials 2021, 14, 3330. [Google Scholar] [CrossRef]

- Lin, S.-K.; Wu, C.-H.; Chang, T.-C.; Lien, C.-H.; Yang, C.-C.; Chen, W.-C.; Lin, C.-C.; Huang, W.-C.; Tan, Y.-F.; Wu, P.-Y. Improving Performance by Inserting an Indium Oxide Layer as an Oxygen Ion Storage Layer in HfO2-Based Resistive Random Access Memory. IEEE Trans. Electron Devices 2021, 68, 1037–1040. [Google Scholar] [CrossRef]

- Zheng, H.-X.; Shih, C.-C.; Chang, T.-C.; Shih, L.-Y.; Shih, Y.-K.; Tseng, Y.-T.; Chen, W.-C.; Huang, W.-C.; Yang, C.-C.; Wu, P.-Y. Indium Diffusion Behavior and Application in HfO2-Based Conductive Bridge Random Access Memory. Phys. Status Solidi RRL 2019, 13, 1900285. [Google Scholar] [CrossRef]

- Lee, K.-J.; Weng, Y.-C.; Wang, L.-W.; Lin, H.-N.; Pal, P.; Chu, S.-Y.; Lu, D.; Wang, Y.-H. High Linearity Synaptic Devices Using Ar Plasma Treatment on HfO2 Thin Film with Non-Identical Pulse Waveforms. Nanomaterials 2022, 12, 3252. [Google Scholar] [CrossRef]

- Abdul Hadi, S.; Humood, K.M.; Abi Jaoude, M.; Abunahla, H.; Shehhi, H.F.A.; Mohammad, B. Bipolar Cu/HfO2/p++ Si memristors by sol-gel spin coating method and their application to environmental sensing. Sci. Rep. 2019, 9, 9983. [Google Scholar] [CrossRef]

- Prakash, A.; Hwang, H. Multilevel cell storage and resistance variability in resistive random access memory. Phys. Sci. Rev. 2016, 1, 1–16. [Google Scholar]

- Kim, S.-T.; Cho, W.-J. Improvement of multi-level resistive switching characteristics in solution-processed AlOx-based non-volatile resistive memory using microwave irradiation. Semicond. Sci. Technol. 2017, 33, 015009. [Google Scholar] [CrossRef]

- Ye, C.; Deng, T.; Zhang, J.; Shen, L.; He, P.; Wei, W.; Wang, H. Enhanced resistive switching performance for bilayer HfO2/TiO2 resistive random access memory. Semicond. Sci. Technol. 2016, 31, 105005. [Google Scholar] [CrossRef]

- Ding, G.; Zeng, K.; Zhou, K.; Li, Z.; Zhou, Y.; Zhai, Y.; Zhou, L.; Chen, X.; Han, S.-T. Configurable multi-state non-volatile memory behaviors in Ti3C2 nanosheets. Nanoscale 2019, 11, 7102–7110. [Google Scholar] [CrossRef] [PubMed]

- Chiu, F.-C. A review on conduction mechanisms in dielectric films. Adv. Mater. Sci. Eng. 2014, 2014, 578168. [Google Scholar] [CrossRef]

- Zhao, J.-W.; Sun, J.; Huang, H.-Q.; Liu, F.-J.; Hu, Z.-F.; Zhang, X.-Q. Effects of ZnO buffer layer on GZO RRAM devices. Appl. Surf. Sci. 2012, 258, 4588–4591. [Google Scholar] [CrossRef]

- Bharathi, M.; Balraj, B.; Sivakumar, C.; Wang, Z.; Shuai, J.; Ho, M.-S.; Guo, D. Effect of Ag doping on bipolar switching operation in molybdenum trioxide (MoO3) nanostructures for non-volatile memory. J. Alloys Compd. 2021, 862, 158035. [Google Scholar] [CrossRef]

- Wu, M.-C.; Jang, W.-Y.; Lin, C.-H.; Tseng, T.-Y. A study on low-power, nanosecond operation and multilevel bipolar resistance switching in Ti/ZrO2/Pt nonvolatile memory with 1T1R architecture. Semicond. Sci. Technol. 2012, 27, 065010. [Google Scholar] [CrossRef][Green Version]

- Lim, E.W.; Ismail, R. Conduction mechanism of valence change resistive switching memory: A survey. Electronics 2015, 4, 586–613. [Google Scholar] [CrossRef]

- Lin, M.-H.; Wu, M.-C.; Huang, C.-Y.; Lin, C.-H.; Tseng, T.-Y. High-speed and localized resistive switching characteristics of double-layer SrZrO3 memory devices. J. Phys. D: Appl. Phys. 2010, 43, 295404. [Google Scholar] [CrossRef]

- Wang, L.-G.; Qian, X.; Cao, Y.-Q.; Cao, Z.-Y.; Fang, G.-Y.; Li, A.-D.; Wu, D. Excellent resistive switching properties of atomic layer-deposited Al2O3/HfO2/Al2O3 trilayer structures for non-volatile memory applications. Nanoscale Res. Lett. 2015, 10, 135. [Google Scholar] [CrossRef]

| Structure of Device | VForming [V] | Vset [V] | Vreset [V] | HRS/LRS | Endurance | Retention [s @ °C] | |

|---|---|---|---|---|---|---|---|

| Ti/HfO2/Pt | Free | 0.88 | −0.89 | 11.4 | 104 | 104 @ 100 | [7] |

| Au/HfO2−x/Pt | 2.3 | 1 | - | 100 | 103 | 104 @ 85 | [33] |

| Pt/HfO2/TiO2/HfO2/Pt | 3.2 | 1.5 | −0.5 | <100 | 102 | 104 @ - | [34] |

| Pt/HfO2/TiO2/ITO | 3.1 | 1.6 | −1.5 | >10 | 102 | 104 @ 85 | [31] |

| ITO/S:HfOx/TiN | 0.85 | 0.11 | −0.15 | 90 | 106 | 104 @ 85 | [35] |

| Pt/HfO2/In2O3/TiN | - | 0.59 | −0.52 | 15 | 107 | 104 @ 85 | [36] |

| Pt/HfO2/BiFeO3/HfO2/TiN | 5.2 | - | - | 104 | 106 | 104 @ 85 | [14] |

| Pt/HfO2/TiN | Free | 0.67 | −0.66 | 112 | 104 | 104 @ 85 | [16] |

| In/HfO2/TiN | −5.3 | - | - | 107 | 102 | 104 @ 85 | [37] |

| Al/Ti/HfO2/Pt/Ti | 2 | 1.05 | - | 104 | 102 | 104 @ - | [38] |

| Cu/HfO2/p++Si | - | 3 | −0.5–−1 | 104 | - | 104 @ - | [39] |

| This work | 4.4 | 0.65 | -1.34 | 104 | 102 | 104 @ 85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.-D.; Jiang, Y.-P.; Tang, X.-G.; Liu, Q.-X.; Tang, Z.; Li, W.-H.; Guo, X.-B.; Zhou, Y.-C. Enhancement of Resistive Switching Performance in Hafnium Oxide (HfO2) Devices via Sol-Gel Method Stacking Tri-Layer HfO2/Al-ZnO/HfO2 Structures. Nanomaterials 2023, 13, 39. https://doi.org/10.3390/nano13010039

Xu Y-D, Jiang Y-P, Tang X-G, Liu Q-X, Tang Z, Li W-H, Guo X-B, Zhou Y-C. Enhancement of Resistive Switching Performance in Hafnium Oxide (HfO2) Devices via Sol-Gel Method Stacking Tri-Layer HfO2/Al-ZnO/HfO2 Structures. Nanomaterials. 2023; 13(1):39. https://doi.org/10.3390/nano13010039

Chicago/Turabian StyleXu, Yuan-Dong, Yan-Ping Jiang, Xin-Gui Tang, Qiu-Xiang Liu, Zhenhua Tang, Wen-Hua Li, Xiao-Bin Guo, and Yi-Chun Zhou. 2023. "Enhancement of Resistive Switching Performance in Hafnium Oxide (HfO2) Devices via Sol-Gel Method Stacking Tri-Layer HfO2/Al-ZnO/HfO2 Structures" Nanomaterials 13, no. 1: 39. https://doi.org/10.3390/nano13010039

APA StyleXu, Y.-D., Jiang, Y.-P., Tang, X.-G., Liu, Q.-X., Tang, Z., Li, W.-H., Guo, X.-B., & Zhou, Y.-C. (2023). Enhancement of Resistive Switching Performance in Hafnium Oxide (HfO2) Devices via Sol-Gel Method Stacking Tri-Layer HfO2/Al-ZnO/HfO2 Structures. Nanomaterials, 13(1), 39. https://doi.org/10.3390/nano13010039