Synthesis of cBN-hBN-SiCw Nanocomposite with Superior Hardness, Strength, and Toughness

Abstract

1. Introduction

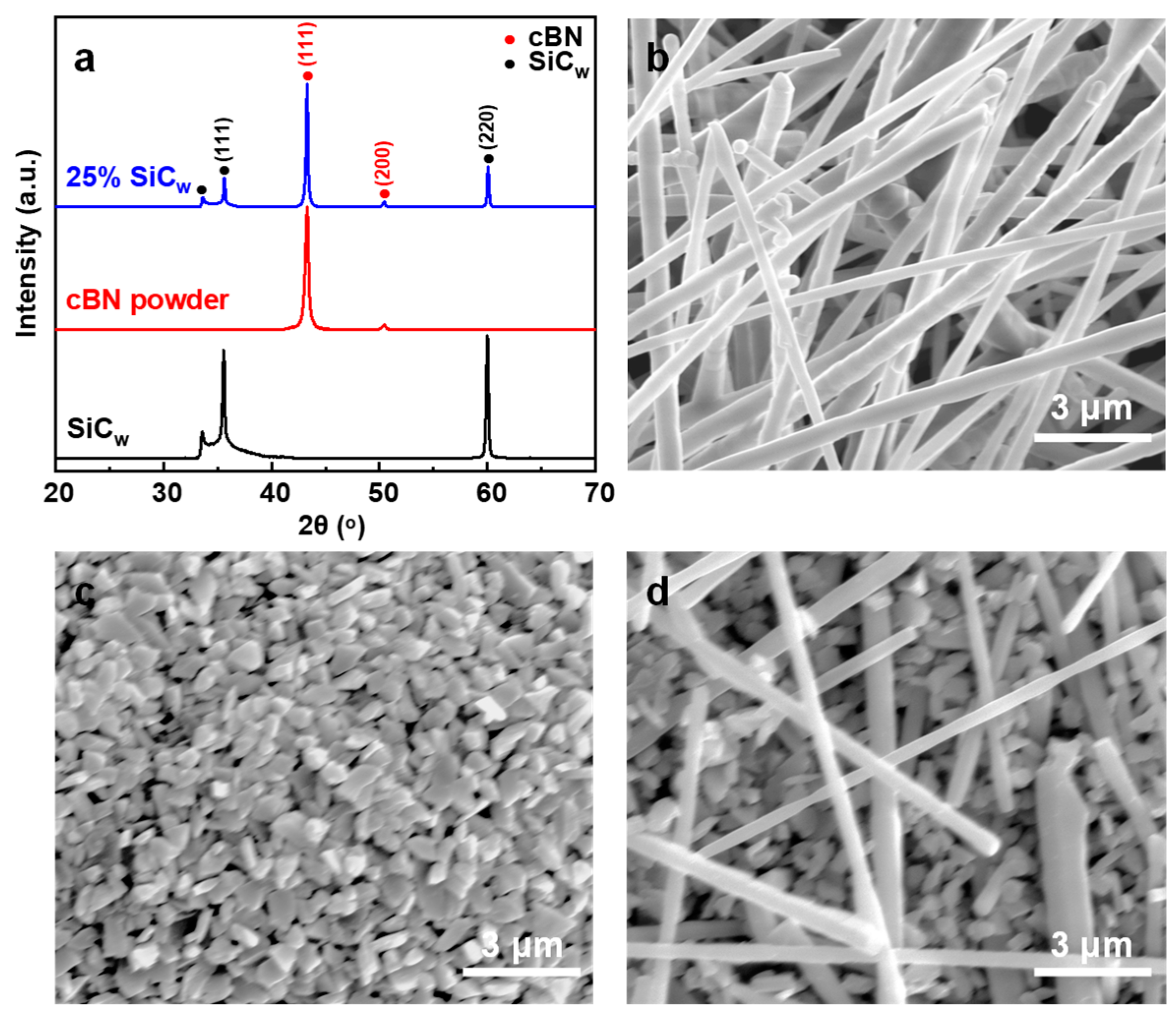

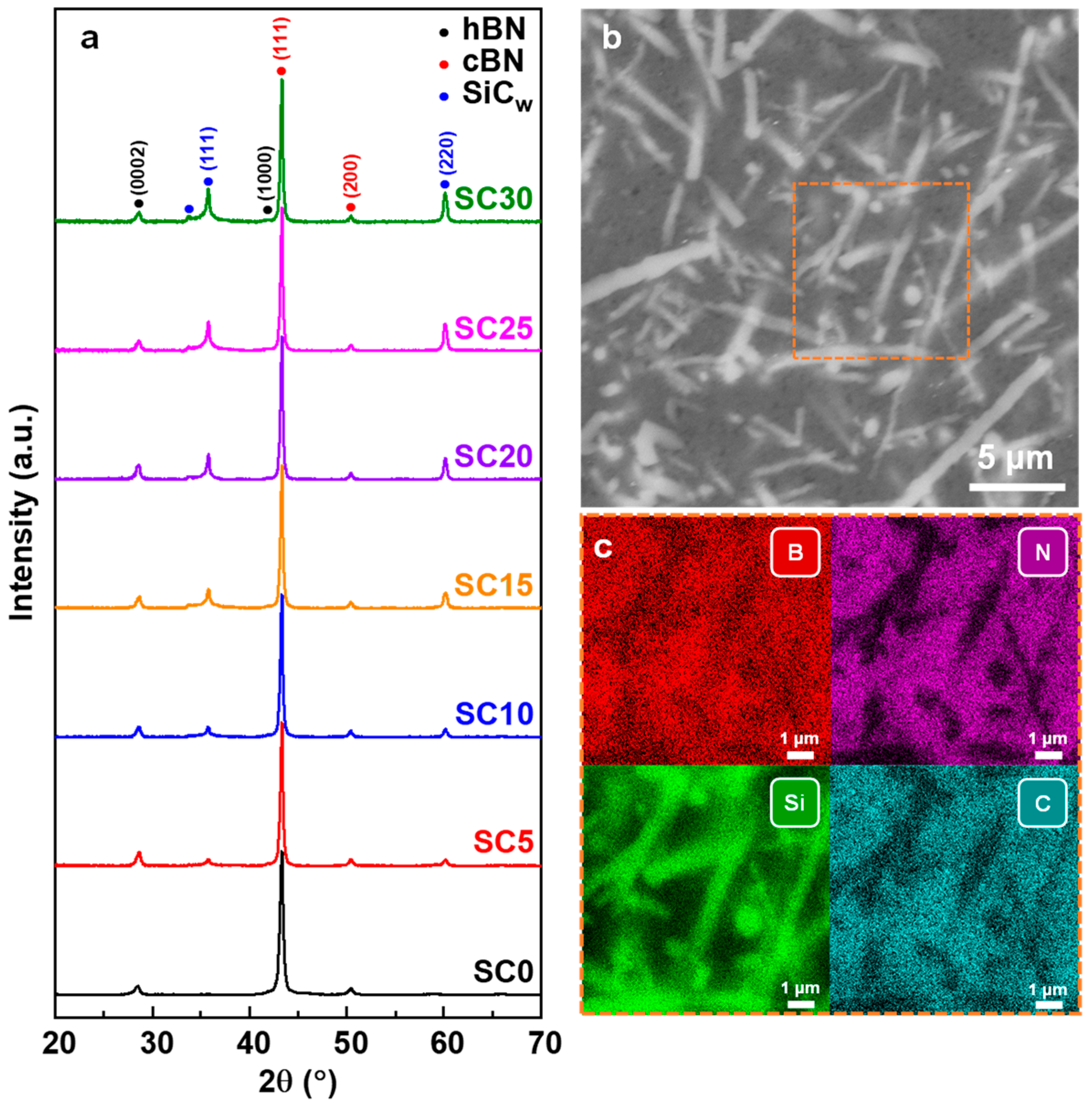

2. Materials and Methods

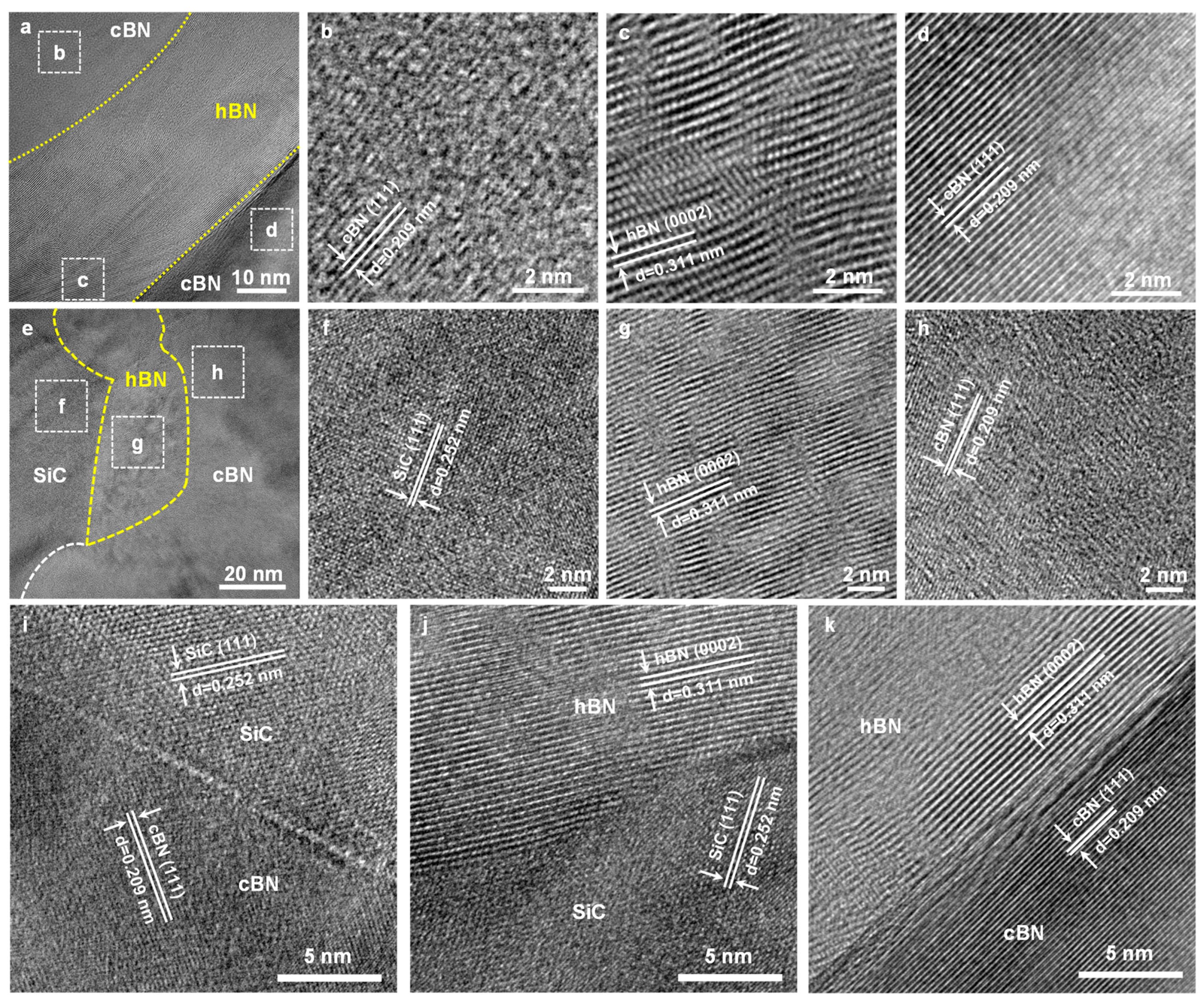

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ji, H.; Li, Z.; Sun, K.; Zhu, Y. Assessment of the performance of TiB2 nanoparticles doped cBN-TiN-Al-Co composites by high temperature high pressure sintering. Mater. Chem. Phys. 2019, 233, 46–51. [Google Scholar] [CrossRef]

- Ji, H.; Li, Z.; Sun, K.; Zhu, Y. Effect of Y2O3 additive on properties of cBN composites with Si3N4-Al2O3-Al as binder by high temperature and high pressure sintering. Ceram. Int. 2019, 45, 20478–20483. [Google Scholar] [CrossRef]

- Ji, H.; Sun, K.; Liang, Y.; Li, Z.; Zhu, Y. Effect of Si/Ti additive on the preparation and properties of cBN-diamond composite sintered by high-temperature and high-pressure. Diam. Relat. Mater. 2019, 99, 107513. [Google Scholar] [CrossRef]

- Li, J.; Shao, G.; Ma, Y.; Zhao, X.T.; Wang, H.L.; Zhang, R. Processing and properties of polycrystalline cubic boron nitride reinforced by SiC whisker. Int. J. Appl. Ceram. Technol. 2019, 16, 32–38. [Google Scholar] [CrossRef]

- Sumiya, H.; Uesaka, S.; Satoh, S. Mechanical properties of high purity polycrystalline cBN synthesized by direct conversion sintering method. J. Mater. Sci. 2000, 35, 1181–1186. [Google Scholar] [CrossRef]

- Solozhenko, V.L.; Kurakevych, O.O.; Le Godec, Y. Creation of Nanostuctures by Extreme Conditions: High-Pressure Synthesis of Ultrahard Nanocrystalline Cubic Boron Nitride. Adv. Mater. 2012, 24, 1540–1544. [Google Scholar] [CrossRef]

- Tian, Y.J.; Xu, B.; Yu, D.L.; Ma, Y.M.; Wang, Y.B.; Jiang, Y.B.; Hu, W.T.; Tang, C.C.; Gao, Y.F.; Luo, K.; et al. Ultrahard nanotwinned cubic boron nitride. Nature 2013, 493, 385. [Google Scholar] [CrossRef]

- Liu, G.D.; Kou, Z.L.; Yan, X.Z.; Lei, L.; Peng, F.; Wang, Q.M.; Wang, K.X.; Wang, P.; Li, L.; Li, Y.; et al. Submicron cubic boron nitride as hard as diamond. Appl. Phys. Lett. 2015, 106, 121901. [Google Scholar] [CrossRef]

- Yang, M.; Kou, Z.L.; Liu, T.; Lu, J.R.; Liu, F.M.; Liu, Y.J.; Qi, L.; Ding, W.; Gong, H.X.; Ni, X.L.; et al. Polycrystalline cubic boron nitride prepared with cubic-hexagonal boron nitride under high pressure and high temperature. Chin. Phys. B 2018, 2, 056105. [Google Scholar] [CrossRef]

- Xie, H.; Deng, F.M.; Yang, X.F.; Han, S.L. Study of fragmentation in cBN powders under ultra-high pressure. Ceram. Int. 2020, 46, 1631–1639. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Skury, A.L.D.; de Azevedo, M.G.; Bobrovnitchii, G.S. Cubic boron nitride competing with diamond as a superhard engineering material-an overview. J. Mater. Res. Technol. 2013, 2, 68–74. [Google Scholar] [CrossRef]

- Zhang, J.F.; Tu, R.; Goto, T. Densification of SiO2-cBN composites by using Ni nanoparticle and SiO2 nanolayer coated cBN powder. Ceram. Int. 2012, 38, 4961–4966. [Google Scholar] [CrossRef]

- Mao, C.; Ren, Y.H.; Gan, H.Y.; Zhang, M.J.; Zhang, J.; Tang, K. Microstructure and mechanical properties of cBN-WC-Co composites used for cutting tools. Int. J. Adv. Manuf. Technol. 2015, 76, 2043–2049. [Google Scholar] [CrossRef]

- Chen, S.N.; Fan, H.Z.; Su, Y.F.; Li, W.S.; Li, J.C.; Yan, B.; Song, J.J.; Hu, L.T.; Zhang, Y.S. Influence of binder systems on sintering characteristics, microstructures, and mechanical properties of PcBN composites fabricated by SPS. J. Adv. Ceram. 2022, 11, 321–330. [Google Scholar] [CrossRef]

- Klimczyk, P.; Cura, M.E.; Vlaicu, A.M.; Mercioniu, I.; Wyzga, P.; Jaworska, L.; Hannula, S.P. Al2O3-cBN composites sintered by SPS and HPHT methods. J. Eur. Ceram. Soc. 2016, 36, 1783–1789. [Google Scholar] [CrossRef]

- Mikinori, H.; Takashi, G. Effect of time on microstructure and hardness of βSiAlON-cubic boron nitride composites during spark plasma sintering. Ceram. Int. 2011, 37, 521–524. [Google Scholar]

- Wang, X.Z.; Ma, Z.L.; Sun, X.; Yu, T.B.; Wang, W.S. Effects of ZrO2 and Y2O3 on physical and mechanical properties of ceramic bond and ceramic CBN composites. Int. J. Refract. Met. Hard. Mater. 2018, 75, 18–24. [Google Scholar] [CrossRef]

- Yue, Z.M.; Yang, L.M.; Gong, J.H.; Gao, J. Experimental Investigation on Microstructure and Mechanical Properties of cBN-Ti3SiC2 Composites. Adv. Eng. Mater. 2016, 18, 1568–1573. [Google Scholar] [CrossRef]

- Li, M.L.; Liang, L.X.; Wang, H.L.; Zhao, P.B.; Zhao, X.T.; Shao, G.; Zhang, R. Processing and properties of PcBN composites fabricated by HPHT using PSN and Al as sintering additive. Rare Met. 2020, 39, 570–576. [Google Scholar] [CrossRef]

- Silvestroni, L.; Sciti, D.; Melandri, C.; Guicciardi, S. Toughened ZrB2-based ceramics through SiC whisker or SiC chopped fiber additions. J. Eur. Ceram. Soc. 2010, 30, 2155–2164. [Google Scholar] [CrossRef]

- Ye, F.; Liu, L.M.; Wang, Y.J.; Zhou, Y.; Peng, B.; Meng, Q.C. Preparation and mechanical properties of carbon nanotube reinforced barium aluminosilicate glass-ceramic composites. Scripta Mater. 2006, 55, 911–914. [Google Scholar] [CrossRef]

- Yamamoto, G.; Omori, M.; Hashida, T.; Kimura, H. A novel structure for carbon nanotube reinforced alumina composites with improved mechanical properties. Nanotechnology 2008, 19, 315708. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, K.; Yokouchi, M.; Lee, S.-K.; Ando, K. Crack-healing behavior of Al2O3 toughened by SiC whiskers. J. Am. Ceram. Soc. 2003, 86, 2143–2147. [Google Scholar] [CrossRef]

- Rumiantseva, Y.; Melnichuk, I.; Garashchenko, V.; Zaporozhets, O.; Turkevich, V.; Bushlya, V. Influence of cBN content, Al2O3 and Si3N4 additives and their morphology on microstructure, properties, and wear of PCBN with NbN binder. Ceram. Int. 2020, 46, 22230–22238. [Google Scholar] [CrossRef]

- Xu, C.; He, D.W.; Liu, C.M.; Wang, H.K.; Wang, P.; Wang, Q.M.; Wang, W.D. Preparation of ZrO2 whiskers through high pressure and high temperature method. Solid State Sci. 2015, 41, 52–55. [Google Scholar] [CrossRef]

- Yin, X.W.; Cheng, L.F.; Zhang, L.T.; Travitzky, N.; Greil, P. Fiber-reinforced multifunctional SiC matrix composite materials. Int. Mater. Rev. 2017, 62, 117–172. [Google Scholar] [CrossRef]

- Fei, J.; Zhang, C.; Luo, D.; Cui, Y.L.; Li, H.J.; Lu, Z.Q.; Huang, J.F. Vertically aligned TiO2 nanorods-woven carbon fiber for reinforcement of both mechanical and anti-wear properties in resin composite. Appl. Surf. Sci. 2018, 435, 156–162. [Google Scholar] [CrossRef]

- Tian, W.B.; Kan, Y.M.; Zhang, G.J.; Wang, P.L. Effect of carbon nanotubes on the properties of ZrB2-SiC ceramics. Mater. Sci. Eng. A Struct. 2008, 487, 568–573. [Google Scholar] [CrossRef]

- Rumiantseva, Y.Y.; Bushlya, V.N.; Turkevich, V.Z. The Influence of SiC and Al2O3 Whiskers on the Properties of Whisker-Reinforced cBN-Based Composites. J. Superhard Mater. 2019, 41, 377–387. [Google Scholar] [CrossRef]

- Asl, M.S.; Ahmadi, Z.; Namini, A.S.; Babapoor, A.; Motallebzadeh, A. Spark plasma sintering of TiC-SiCw ceramics. Ceram. Int. 2019, 45, 19808–19821. [Google Scholar]

- Shchegoleva, N.E.; Evdokimov, S.A.; Osin, I.V.; Chainikova, A.S.; Shavnev, A.A. High-Temperature Ceramic Composites (SiC/SiCw). Glass Ceram. 2020, 77, 47–50. [Google Scholar] [CrossRef]

- Wu, W.W.; Gui, J.Y.; Wei, S.; Xue, W.J.; Xie, Z.P. Si3N4-SiCw composites as structural materials for cryogenic application. J. Eur. Ceram. Soc. 2016, 36, 2667–2672. [Google Scholar] [CrossRef]

- Deng, J.; Ai, X. Microstructure and Mechanical Properties of Hot-Pressed TiB2-SiCw Composites. Mater. Res. Bull. 1998, 33, 575–582. [Google Scholar] [CrossRef]

- Xiong, Z.; Zhong, L.; Wang, H.; Li, X. Structural Defects, Mechanical Behaviors, and Properties of Two-Dimensional Materials. Materials 2021, 14, 1192. [Google Scholar] [CrossRef]

- Walker, L.S.; Marotto, V.R.; Rafiee, M.A.; Koratkar, N.; Corral, E.L. Toughening in Graphene Ceramic Composites. ACS Nano 2011, 5, 3182–3190. [Google Scholar] [CrossRef]

- Liu, L.X.; Wang, Y.; Li, X.H.; Xu, L.; Cao, X.X.; Wang, Y.H.; Wang, Z.G.; Meng, C.M.; Zhu, W.J.; Ouyang, X.P. Enhancing Toughness in Boron Carbide with Reduced Graphene Oxide. J. Am. Ceram. Soc. 2016, 99, 257–264. [Google Scholar] [CrossRef]

- Kitiwan, M.; Iton, A.; Goto, T. Spark plasma sintering of TiN-TiB2-hBN composites and their properties. Ceram. Int. 2015, 41, 4498–4503. [Google Scholar] [CrossRef]

- Lee, B.; Lee, D.; Lee, J.H.; Ryu, H.J.; Hong, S.H. Enhancement of toughness and wear resistance in boron nitride nanoplatelet (BNNP) reinforced Si3N4 nanocomposites. Sci. Rep. 2016, 6, 27609. [Google Scholar] [CrossRef]

- Kovalčíková, A.; Balko, J.; Balázsi, C.; Hvizdoš, P.; Dusza, J. Influence of hBN content on mechanical and tribological properties of Si3N4/BN ceramic composites. J. Eur. Ceram. Soc. 2014, 34, 3319–3328. [Google Scholar] [CrossRef]

- Yang, X.W.; Chen, J.; Xing, R.; Babapoor, A. Hot-pressing and characterization of TiB2-SiC composites with different amounts of BN additive. Ceram. Int. 2021, 47, 16652–16660. [Google Scholar] [CrossRef]

- Sun, J.C.; Niu, B.; Ren, L.; Zhang, J.Y.; Lei, L.W.; Zhang, F. Densification and mechanical properties of boron carbide prepared via spark plasma sintering with cubic boron nitride as an additive. J. Eur. Ceram. Soc. 2020, 40, 1103–1110. [Google Scholar] [CrossRef]

- Wang, W.L.; Sun, G.X.; Chen, Y.F.; Sun, X.N.; Bi, J.Q. Preparation and mechanical properties of boron nitride nanosheets/alumina composites. Ceram. Int. 2018, 44, 21993–21997. [Google Scholar] [CrossRef]

- Evans, A.G.; Charles, E.A. Fracture toughness determinations by indentation. J. Am. Ceram. Soc. 1976, 59, 371–372. [Google Scholar] [CrossRef]

- Sun, R.X.; Wei, X.D.; Hu, W.T.; Ying, P.; Wu, Y.J.; Wang, L.Y.; Chen, S.; Zhang, X.; Ma, M.D.; Yu, D.L.; et al. Nanocrystalline cubic silicon carbide: A route to superhardness. Small 2022, 18, 2201212. [Google Scholar] [CrossRef]

- Wu, J.K.; Wang, H.K.; Zhang, Z.C.; Hou, Z.Q.; Wu, D.Z.; Ouyang, X.P. Analysis of mechanical properties of Al2O3-cBN-hBN composites and identification of main influencing factors. Int. J. Appl. Ceram. Technol. 2022, 19, 3255–3266. [Google Scholar] [CrossRef]

- Yuan, Y.G.; Cheng, X.Z.; Chang, R.; Li, T.H.; Zang, J.B.; Wang, Y.H.; Yu, Y.Q.; Lu, J.; Xu, X.P. Reactive sintering cBN-Ti-Al composites by spark plasma sintering. Diam. Relat. Mater. 2016, 69, 138–143. [Google Scholar] [CrossRef]

- Yang, L.M.; Yue, Z.M.; Gong, J.H.; Zhao, X.D.; Chu, X.R. Compositions, mechanical properties and microstructures of cBN-based composites sintered with Al or TiC. Adv. Appl. Ceram. 2017, 116, 254–259. [Google Scholar] [CrossRef]

- Yang, L.M.; Gong, J.H.; Yue, Z.M.; Chu, X.R. Preparation and characterization of cBN-based composites from cBN-Ti3AlC2 mixtures. Diam. Relat. Mater. 2016, 66, 183–187. [Google Scholar] [CrossRef]

- Kitiwan, M.; Ito, A.; Zhang, J.F.; Goto, T. Densification and mechanical properties of cBN-TiN-TiB2 composites prepared by spark plasma sintering of SiO2-coated cBN powder. J. Eur. Ceram. Soc. 2014, 34, 3619–3626. [Google Scholar] [CrossRef]

| Sample | Raw Materials | Hardness (GPa) | Fracture Toughness (MPa·m1/2) | Flexural Strength (MPa) | Reference |

|---|---|---|---|---|---|

| cBN composites with metal additives | 95 wt.% cBN-5 wt.% Al | 30.23 | N/A | 455.39 | [47] |

| 45 vol.% cBN-35 vol.% Ti-20 vol.% Al | 14.1 | 7.6 a | 390.7 | [46] | |

| 45 wt.% cBN-40 wt.% Ti-15 wt.% Al | 14.14 | 3.95 b | 194.31 | [14] | |

| cBN composites with metals and ceramics as additives | 60 vol.% cBN-25 vol.% NbN-5 vol.% Al-10 vol.% Al2O4w | 27.5 | 5.5 c | N/A | [24] |

| 50 vol.% cBN-5 vol.% Al-15 vol.% SiCw-30 vol.% TaN | 33.01 | 6.57 c | [29] | ||

| 50 vol.% cBN-5 vol.% Al-10 vol.% Al2O3w-35 vol.% TaN | 33.09 | 2.59 c | |||

| cBN composites with ceramic additives | 50 wt.% cBN-5 wt.% ZrO2 (3Y)-45 wt.% Al2O3 | 14.83 | 3.52 b | 145 | [14] |

| 50 wt.% cBN-22 wt.% Si3N4-14 wt.% AlN-4 wt.% Y2O3-10 wt.% Al2O3 | 15.59 | 5.62 b | 465 | ||

| 90 wt.% cBN-10 wt.% TiC | 29.02 | N/A | 497.06 | [47] | |

| 80 wt.% cBN-20 wt.% Ti3AlC2 | 33.14 | N/A | 422.4 | [48] | |

| 50 vol.% cBN@SiO2-15 vol.% TiN-35 vol.% TiB2 | 17.9 | 7.3 d | N/A | [49] | |

| 40 vol.% cBN-10 vol.% hBN-50 vol.% Al2O3 | 21.43 | 5.83 c | N/A | [45] | |

| cBN composites with ceramics and whiskers as additives | 85 wt.% cBN-10 wt.% Al3BC3-5 wt.% SiCw | 35 | 5.75 b | 316 | [4] |

| 80 wt.% cBN-10 wt.% Al3BC3-10 wt.% SiCw | 38 | 5.91 b | 345 | ||

| 75 wt.% cBN-10 wt.% Al3BC3-15 wt.% SiCw | 38.2 | 6.31 b | 365 | ||

| 70 wt.% cBN-10 wt.% Al3BC3-20 wt.% SiCw | 42.7 | 6.52 b | 406 | ||

| cBN-hBN-SiCw nanocomposites | SiC25 | 36.5 | 6.2 e | 687.4 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, L.; Zou, Y.; Ma, M.; Li, G.; Wang, X.; Zhang, X.; Zhuge, Z.; Liu, B.; Wu, Y.; Li, B.; et al. Synthesis of cBN-hBN-SiCw Nanocomposite with Superior Hardness, Strength, and Toughness. Nanomaterials 2023, 13, 37. https://doi.org/10.3390/nano13010037

Sun L, Zou Y, Ma M, Li G, Wang X, Zhang X, Zhuge Z, Liu B, Wu Y, Li B, et al. Synthesis of cBN-hBN-SiCw Nanocomposite with Superior Hardness, Strength, and Toughness. Nanomaterials. 2023; 13(1):37. https://doi.org/10.3390/nano13010037

Chicago/Turabian StyleSun, Lei, Yitong Zou, Mengdong Ma, Guangqian Li, Xiaoyu Wang, Xiang Zhang, Zewen Zhuge, Bing Liu, Yingju Wu, Baozhong Li, and et al. 2023. "Synthesis of cBN-hBN-SiCw Nanocomposite with Superior Hardness, Strength, and Toughness" Nanomaterials 13, no. 1: 37. https://doi.org/10.3390/nano13010037

APA StyleSun, L., Zou, Y., Ma, M., Li, G., Wang, X., Zhang, X., Zhuge, Z., Liu, B., Wu, Y., Li, B., & Zhao, Z. (2023). Synthesis of cBN-hBN-SiCw Nanocomposite with Superior Hardness, Strength, and Toughness. Nanomaterials, 13(1), 37. https://doi.org/10.3390/nano13010037