Droplets Patterning of Structurally Integrated 3D Conductive Networks-Based Flexible Strain Sensors for Healthcare Monitoring

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. AgNWs Synthesis and Ink Formulation

2.3. Fabrication of the Strain Sensor

2.4. Characterization

3. Results and Discussion

3.1. Structurally Integrated 3D Conductive Network

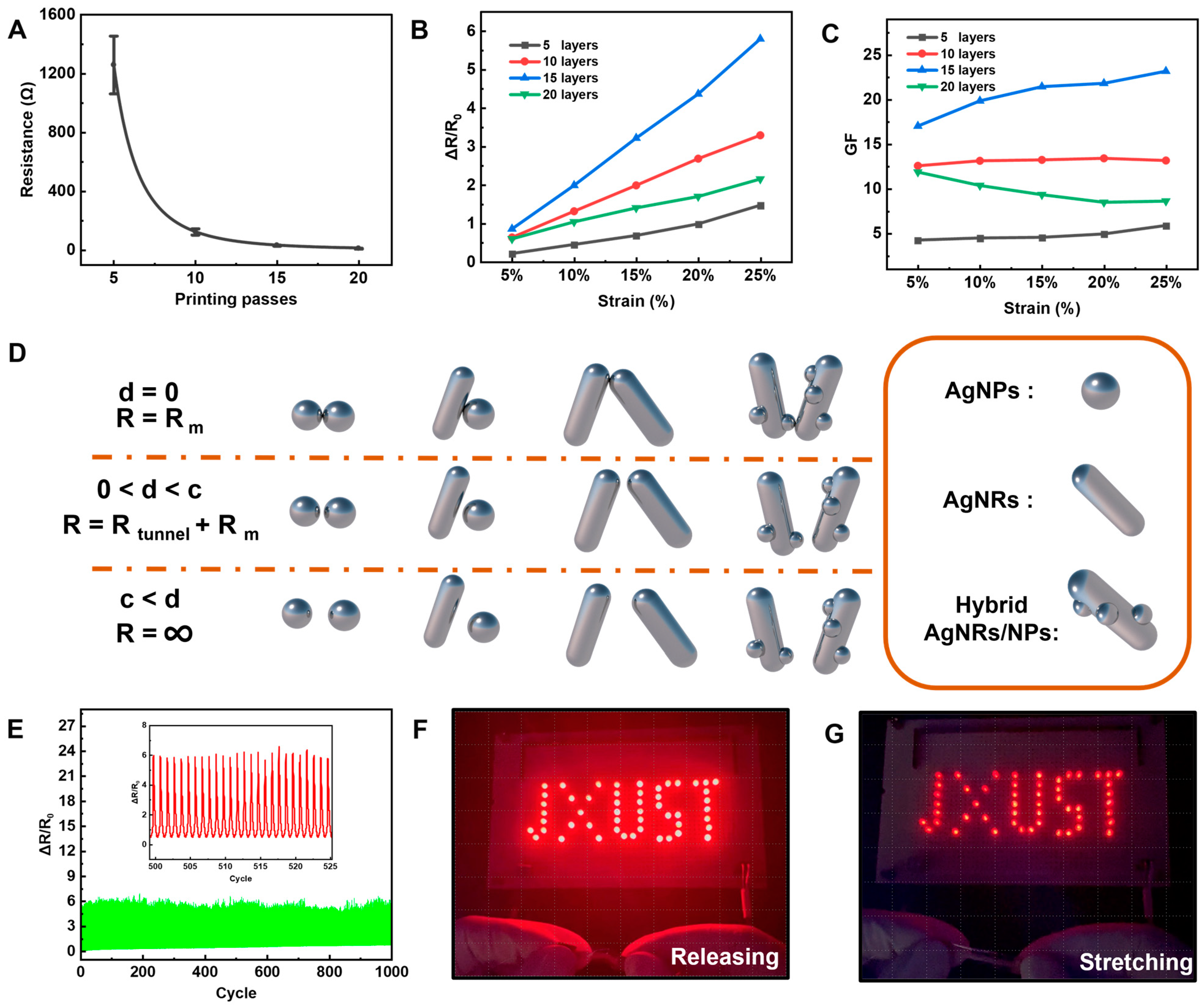

3.2. Strain Sensitivity Investigation of Hybrid Sensors

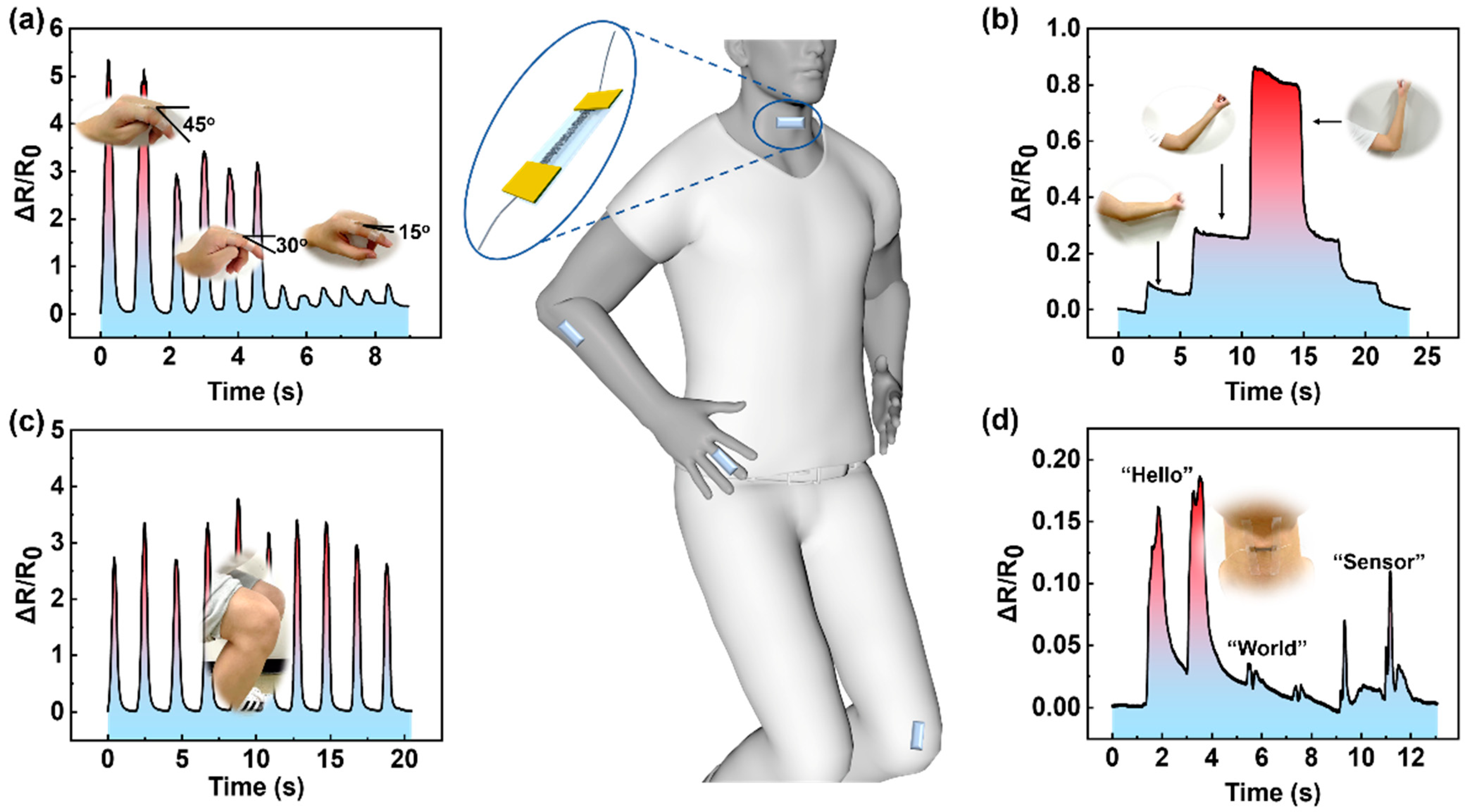

3.3. Wearable Healthcare Hybrid Sensors

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, H.; Kim, E.; Lee, Y.; Kim, H.; Lee, J.; Kim, M.; Yoo, H.-J.; Yoo, S. Toward All-Day Wearable Health Monitoring: An Ultralow-Power, Reflective Organic Pulse Oximetry Sensing Patch. Sci. Adv. 2018, 4, eaas9530. [Google Scholar] [CrossRef] [PubMed]

- Liu, X. The More and Less of Electronic-Skin Sensors. Science 2020, 370, 910–911. [Google Scholar] [CrossRef] [PubMed]

- Shen, Z.; Liu, F.; Huang, S.; Wang, H.; Yang, C.; Hang, T.; Tao, J.; Xia, W.; Xie, X. Progress of Flexible Strain Sensors for Physiological Signal Monitoring. Biosens. Bioelectron. 2022, 211, 114298. [Google Scholar] [CrossRef] [PubMed]

- Dai, J.; Ogbeide, O.; Macadam, N.; Sun, Q.; Yu, W.; Li, Y.; Su, B.-L.; Hasan, T.; Huang, X.; Huang, W. Printed Gas Sensors. Chem. Soc. Rev. 2020, 49, 1756–1789. [Google Scholar] [CrossRef]

- Ghaffari, R.; Rogers, J.A.; Ray, T.R. Recent Progress, Challenges, and Opportunities for Wearable Biochemical Sensors for Sweat Analysis. Sens. Actuators B Chem. 2021, 332, 129447. [Google Scholar] [CrossRef]

- Chen, S.; Qi, J.; Fan, S.; Qiao, Z.; Yeo, J.C.; Lim, C.T. Flexible Wearable Sensors for Cardiovascular Health Monitoring. Adv. Healthc. Mater. 2021, 10, 2100116. [Google Scholar] [CrossRef]

- Park, J.; Kim, M.; Lee, Y.; Lee, H.S.; Ko, H. Fingertip Skin–Inspired Microstructured Ferroelectric Skins Discriminate Static/Dynamic Pressure and Temperature Stimuli. Sci. Adv. 2015, 1, e1500661. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, Y.; Li, Y.; Hao, Q. Development and Application of Resistance Strain Force Sensors. Sensors 2020, 20, 5826. [Google Scholar] [CrossRef]

- Yan, T.; Wang, Z.; Pan, Z.-J. Flexible Strain Sensors Fabricated Using Carbon-Based Nanomaterials: A Review. Curr. Opin. Solid. St. M. 2018, 22, 213–228. [Google Scholar] [CrossRef]

- Lipomi, D.J.; Vosgueritchian, M.; Tee, B.C.-K.; Hellstrom, S.L.; Lee, J.A.; Fox, C.H.; Bao, Z. Skin-like Pressure and Strain Sensors Based on Transparent Elastic Films of Carbon Nanotubes. Nature Nanotech. 2011, 6, 788–792. [Google Scholar] [CrossRef]

- Rim, Y.S.; Bae, S.; Chen, H.; De Marco, N.; Yang, Y. Recent Progress in Materials and Devices toward Printable and Flexible Sensors. Adv. Mater. 2016, 28, 4415–4440. [Google Scholar] [CrossRef]

- Jiang, S.; Liu, X.; Liu, J.; Ye, D.; Duan, Y.; Li, K.; Yin, Z.; Huang, Y. Flexible Metamaterial Electronics. Adv. Mater. 2022, 34, 2200070, Early View. [Google Scholar] [CrossRef] [PubMed]

- Ke, S.; Guo, P.; Pang, C.; Tian, B.; Luo, C.; Zhu, H.; Wu, W. Screen-Printed Flexible Strain Sensors with Ag Nanowires for Intelligent and Tamper-Evident Packaging Applications. Adv. Mater. Technol. 2020, 5, 1901097. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, M.; Deng, H.; Xu, B.; Wang, H.; Wang, Y.; Jiang, L.; Liu, H. Direct-Writing Large-Area Cross-Aligned Ag Nanowires Network: Toward High-Performance Transparent Quantum Dot Light-Emitting Diodes. CCS Chem. 2020, 2, 2194–2202. [Google Scholar] [CrossRef]

- Tang, H.; Feng, H.; Wang, H.; Wan, X.; Liang, J.; Chen, Y. Highly Conducting MXene–Silver Nanowire Transparent Electrodes for Flexible Organic Solar Cells. ACS Appl. Mater. Interfaces 2019, 11, 25330–25337. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Song, T.; Shi, L.; Wen, N.; Wu, Z.; Sun, C.; Jiang, D.; Guo, Z. Recent Progress for Silver Nanowires Conducting Film for Flexible Electronics. J. Nanostruct. Chem. 2021, 11, 323–341. [Google Scholar] [CrossRef] [PubMed]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly Stretchable and Sensitive Strain Sensor Based on Silver Nanowire–Elastomer Nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef]

- Shengbo, S.; Lihua, L.; Aoqun, J.; Qianqian, D.; Jianlong, J.; Qiang, Z.; Wendong, Z. Highly Sensitive Wearable Strain Sensor Based on Silver Nanowires and Nanoparticles. Nanotechnology 2018, 29, 255202. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, L.; Zhao, D.; Duan, Q.; Ji, J.; Jian, A.; Zhang, W.; Sang, S. Highly Sensitive and Stretchable Strain Sensor Based on Ag@CNTs. Nanomaterials 2017, 7, 424. [Google Scholar] [CrossRef]

- Shen, Y.; Yao, R.-H. Improvement of the Conductivity of Silver Nanowire Film by Adding Silver Nano-Particles. Chin. Phys. Lett. 2016, 33, 4. [Google Scholar] [CrossRef]

- Mishra, S.; Kim, Y.-S.; Intarasirisawat, J.; Kwon, Y.-T.; Lee, Y.; Mahmood, M.; Lim, H.-R.; Herbert, R.; Yu, K.J.; Ang, C.S.; et al. Soft, Wireless Periocular Wearable Electronics for Real-Time Detection of Eye Vergence in a Virtual Reality toward Mobile Eye Therapies. Sci. Adv. 2020, 6, eaay1729. [Google Scholar] [CrossRef] [PubMed]

- Khan, Y.; Thielens, A.; Muin, S.; Ting, J.; Baumbauer, C.; Arias, A.C. A New Frontier of Printed Electronics: Flexible Hybrid Electronics. Adv. Mater. 2020, 32, 1905279. [Google Scholar] [CrossRef] [PubMed]

- Wilkinson, N.J.; Smith, M.A.A.; Kay, R.W.; Harris, R.A. A Review of Aerosol Jet Printing—A Non-Traditional Hybrid Process for Micro-Manufacturing. Int. J. Adv. Manuf. Technol. 2019, 105, 4599–4619. [Google Scholar] [CrossRef]

- Seifert, T.; Sowade, E.; Roscher, F.; Wiemer, M.; Gessner, T.; Baumann, R.R. Additive Manufacturing Technologies Compared: Morphology of Deposits of Silver Ink Using Inkjet and Aerosol Jet Printing. Ind. Eng. Chem. Res. 2015, 54, 769–779. [Google Scholar] [CrossRef]

- Herbert, R.; Lim, H.-R.; Rigo, B.; Yeo, W.-H. Fully Implantable Wireless Batteryless Vascular Electronics with Printed Soft Sensors for Multiplex Sensing of Hemodynamics. Sci. Adv. 2022, 8, eabm1175. [Google Scholar] [CrossRef] [PubMed]

- Meng, L.; Bian, R.; Guo, C.; Xu, B.; Liu, H.; Jiang, L. Aligning Ag Nanowires by a Facile Bioinspired Directional Liquid Transfer: Toward Anisotropic Flexible Conductive Electrodes. Adv. Mater. 2018, 30, 1706938. [Google Scholar] [CrossRef]

- Dai, H.; Dong, Z.; Jiang, L. Directional Liquid Dynamics of Interfaces with Superwettability. Sci. Adv. 2020, 6, eabb5528. [Google Scholar] [CrossRef]

- Goh, G.L.; Agarwala, S.; Yeong, W.Y. Aerosol-Jet-Printed Preferentially Aligned Carbon Nanotube Twin-Lines for Printed Electronics. ACS Appl. Mater. Interfaces 2019, 11, 43719–43730. [Google Scholar] [CrossRef]

- Jehn, J.; Oser, P.; Courrau, M.A.M.; Kaiser, M.; Wu, D.; Grosse, C.U.; Moosheimer, U.; Ruediger, A.; Schindler, C. Fully Inkjet-Printed Carbon Nanotube-PDMS-Based Strain Sensor: Temperature Response, Compressive and Tensile Bending Properties, and Fatigue Investigations. IEEE Access 2021, 9, 72207–72216. [Google Scholar] [CrossRef]

- Kuang, M.; Wu, L.; Huang, Z.; Wang, J.; Zhang, X.; Song, Y. Inkjet Printing of a Micro/Nanopatterned Surface to Serve as Microreactor Arrays. ACS Appl. Mater. Interfaces 2020, 12, 30962–30971. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, D.; Zhang, J.; Lin, A.; Wang, Y.; Cao, L.; Wang, S.; Xiong, S.; Gu, F. Microscale Curling and Alignment of Ti3C2Tx MXene by Confining Aerosol Droplets for Planar Micro-Supercapacitors. ACS Omega 2021, 6, 33067–33074. [Google Scholar] [CrossRef]

- Xu, F.; Xu, W.; Mao, B.; Shen, W.; Yu, Y.; Tan, R.; Song, W. Preparation and Cold Welding of Silver Nanowire Based Transparent Electrodes with Optical Transmittances >90% and Sheet Resistances <10 Ohm/Sq. J. Colloid Interface Sci. 2018, 512, 208–218. [Google Scholar] [CrossRef]

- Abdolmaleki, H.; Kidmose, P.; Agarwala, S. Droplet-Based Techniques for Printing of Functional Inks for Flexible Physical Sensors. Adv. Mater. 2021, 33, 2006792. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Moon, S.K.; Ngo, T.H. 3D Printed Electronics of Non-Contact Ink Writing Techniques: Status and Promise. Int. J. Precis. Eng. Manuf.-Green Tech. 2020, 7, 511–524. [Google Scholar] [CrossRef]

- Li, W.; He, Y.; Xu, J.; Wang, W.; Zhu, Z.; Liu, H. Preparation of Ag NWs and Ag NWs@PDMS Stretchable Sensors Based on Rapid Polyol Method and Semi-Dry Process. J. Alloy Compd. 2019, 803, 332–340. [Google Scholar] [CrossRef]

- Wang, X.; Chen, L.; Sowade, E.; Rodriguez, R.; Sheremet, E.; Yu, C.; Baumann, R.; Chen, J. Ultra-Uniform and Very Thin Ag Nanowires Synthesized via the Synergy of Cl−, Br− and Fe3+ for Transparent Conductive Films. Nanomaterials 2020, 10, 237. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, X.; Du, D. Silver Nanowires from Sonication-Induced Scission. Micromachines 2019, 10, 29. [Google Scholar] [CrossRef]

- Sun, J.; Yu, X.; Li, Z.; Zhao, J.; Zhu, P.; Dong, X.; Yu, Z.; Zhao, Z.; Shi, D.; Wang, J.; et al. Ultrasonic Modification of Ag Nanowires and Their Applications in Flexible Transparent Film Heaters and SERS Detectors. Materials 2019, 12, 893. [Google Scholar] [CrossRef]

- Arjmandi-Tash, O.; Kovalchuk, N.M.; Trybala, A.; Kuchin, I.V.; Starov, V. Kinetics of Wetting and Spreading of Droplets over Various Substrates. Langmuir 2017, 33, 4367–4385. [Google Scholar] [CrossRef]

- Liu, T.L.; Kim, C.-J. Turning a Surface Superrepellent Even to Completely Wetting Liquids. Science 2014, 346, 1096–1100. [Google Scholar] [CrossRef]

- Secor, E.B. Principles of Aerosol Jet Printing. Flex. Print. Electron. 2018, 3, 035002. [Google Scholar] [CrossRef]

- Zhou, Z.; Peng, X.; Yang, Z.; Zhang, Z.; Li, M.; Su, X.; Zhang, Q.; Shan, X.; Wang, Q.; Zhang, Z. Tuning Gold Nanorod-Nanoparticle Hybrids into Plasmonic Fano Resonance for Dramatically Enhanced Light Emission and Transmission. Nano Lett. 2011, 11, 49–55. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.; Zhu, P.; Zheng, H.; Zhan, H.; Chen, C.; Li, J.; Wang, L.; Yao, X.; Liu, Y.; Wang, Z. Three-Dimensional Capillary Ratchet-Induced Liquid Directional Steering. Science 2021, 373, 1344–1348. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Li, S.; Ciou, J.; Chen, J.; Gao, D.; Wang, J.; Lee, P.S. A Tailorable Spray-Assembly Strategy of Silver Nanowires-Bundle Mesh for Transferable High-Performance Transparent Conductor. Adv. Funct. Mater. 2021, 31, 2006120. [Google Scholar] [CrossRef]

- Si, Y.; Chen, S.; Li, M.; Li, S.; Pei, Y.; Guo, X. Flexible Strain Sensors for Wearable Hand Gesture Recognition: From Devices to Systems. Adv. Intell. Syst. 2022, 4, 2100046. [Google Scholar] [CrossRef]

- Lim, H.; Kim, H.S.; Qazi, R.; Kwon, Y.; Jeong, J.; Yeo, W. Advanced Soft Materials, Sensor Integrations, and Applications of Wearable Flexible Hybrid Electronics in Healthcare, Energy, and Environment. Adv. Mater. 2020, 32, 1901924. [Google Scholar] [CrossRef]

- Wu, Y.T.; Yan, T.; Pan, Z.J. Wearable Carbon-Based Resistive Sensors for Strain Detection: A Review. IEEE Sens. J. 2021, 21, 4030–4043. [Google Scholar] [CrossRef]

- Amjadi, M.; Kyung, K.-U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, H.; Han, W.; Lin, H.; Li, R.; Zhu, J.; Huang, W. 3D Printed Flexible Strain Sensors: From Printing to Devices and Signals. Adv. Mater. 2021, 33, 2004782. [Google Scholar] [CrossRef]

- Gao, J.; Fan, Y.; Zhang, Q.; Luo, L.; Hu, X.; Li, Y.; Song, J.; Jiang, H.; Gao, X.; Zheng, L.; et al. Ultra-Robust and Extensible Fibrous Mechanical Sensors for Wearable Smart Healthcare. Adv. Mater. 2022, 34, 2107511. [Google Scholar] [CrossRef]

- Liu, X.; Miao, J.; Fan, Q.; Zhang, W.; Zuo, X.; Tian, M.; Zhu, S.; Zhang, X.; Qu, L. Recent Progress on Smart Fiber and Textile Based Wearable Strain Sensors: Materials, Fabrications and Applications. Adv. Fiber Mater. 2022, 4, 361–389. [Google Scholar] [CrossRef]

- Herbert, R.; Lim, H.-R.; Yeo, W.-H. Printed, Soft, Nanostructured Strain Sensors for Monitoring of Structural Health and Human Physiology. ACS Appl. Mater. Interfaces 2020, 12, 25020–25030. [Google Scholar] [CrossRef] [PubMed]

- Agarwala, S.; Goh, G.L.; Yeong, W.Y. Aerosol Jet Printed Strain Sensor: Simulation Studies Analyzing the Effect of Dimension and Design on Performance (September 2018). IEEE Access 2018, 6, 63080–63086. [Google Scholar] [CrossRef]

- Saeidi-Javash, M.; Du, Y.; Zeng, M.; Wyatt, B.C.; Zhang, B.; Kempf, N.; Anasori, B.; Zhang, Y. All-Printed MXene–Graphene Nanosheet-Based Bimodal Sensors for Simultaneous Strain and Temperature Sensing. ACS Appl. Electron. Mater. 2021, 3, 2341–2348. [Google Scholar] [CrossRef]

- Borghetti, M.; Serpelloni, M.; Sardini, E. Printed Strain Gauge on 3D and Low-Melting Point Plastic Surface by Aerosol Jet Printing and Photonic Curing. Sensors 2019, 19, 4220. [Google Scholar] [CrossRef] [PubMed]

- Siddique, S.; Park, J.G.; Andrei, P.; Liang, R. M3D Aerosol Jet Printed Buckypaper Multifunctional Sensors for Composite Structural Health Monitoring. Results in Physics 2019, 13, 102094. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhao, D.; Cao, L.; Fan, L.; Lin, A.; Wang, S.; Gu, F.; Yu, A. Droplets Patterning of Structurally Integrated 3D Conductive Networks-Based Flexible Strain Sensors for Healthcare Monitoring. Nanomaterials 2023, 13, 181. https://doi.org/10.3390/nano13010181

Zhang Y, Zhao D, Cao L, Fan L, Lin A, Wang S, Gu F, Yu A. Droplets Patterning of Structurally Integrated 3D Conductive Networks-Based Flexible Strain Sensors for Healthcare Monitoring. Nanomaterials. 2023; 13(1):181. https://doi.org/10.3390/nano13010181

Chicago/Turabian StyleZhang, Yang, Danjiao Zhao, Lei Cao, Lanlan Fan, Aiping Lin, Shufen Wang, Feng Gu, and Aibing Yu. 2023. "Droplets Patterning of Structurally Integrated 3D Conductive Networks-Based Flexible Strain Sensors for Healthcare Monitoring" Nanomaterials 13, no. 1: 181. https://doi.org/10.3390/nano13010181

APA StyleZhang, Y., Zhao, D., Cao, L., Fan, L., Lin, A., Wang, S., Gu, F., & Yu, A. (2023). Droplets Patterning of Structurally Integrated 3D Conductive Networks-Based Flexible Strain Sensors for Healthcare Monitoring. Nanomaterials, 13(1), 181. https://doi.org/10.3390/nano13010181