High-Resolution Patterning of Organic Emitting-Layer by Using Inkjet Printing and Sublimation Transfer Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Materials and Co-Solvented Ink

2.2. Selective Surface Treatment of Donor Substrate

2.3. Inkjet Printing into Microchannel of Donor Substrate

2.4. Drying and Sublimation Transfer Process

2.5. Characteristics

3. Results and Discussion

3.1. Sequence of Patterning Process

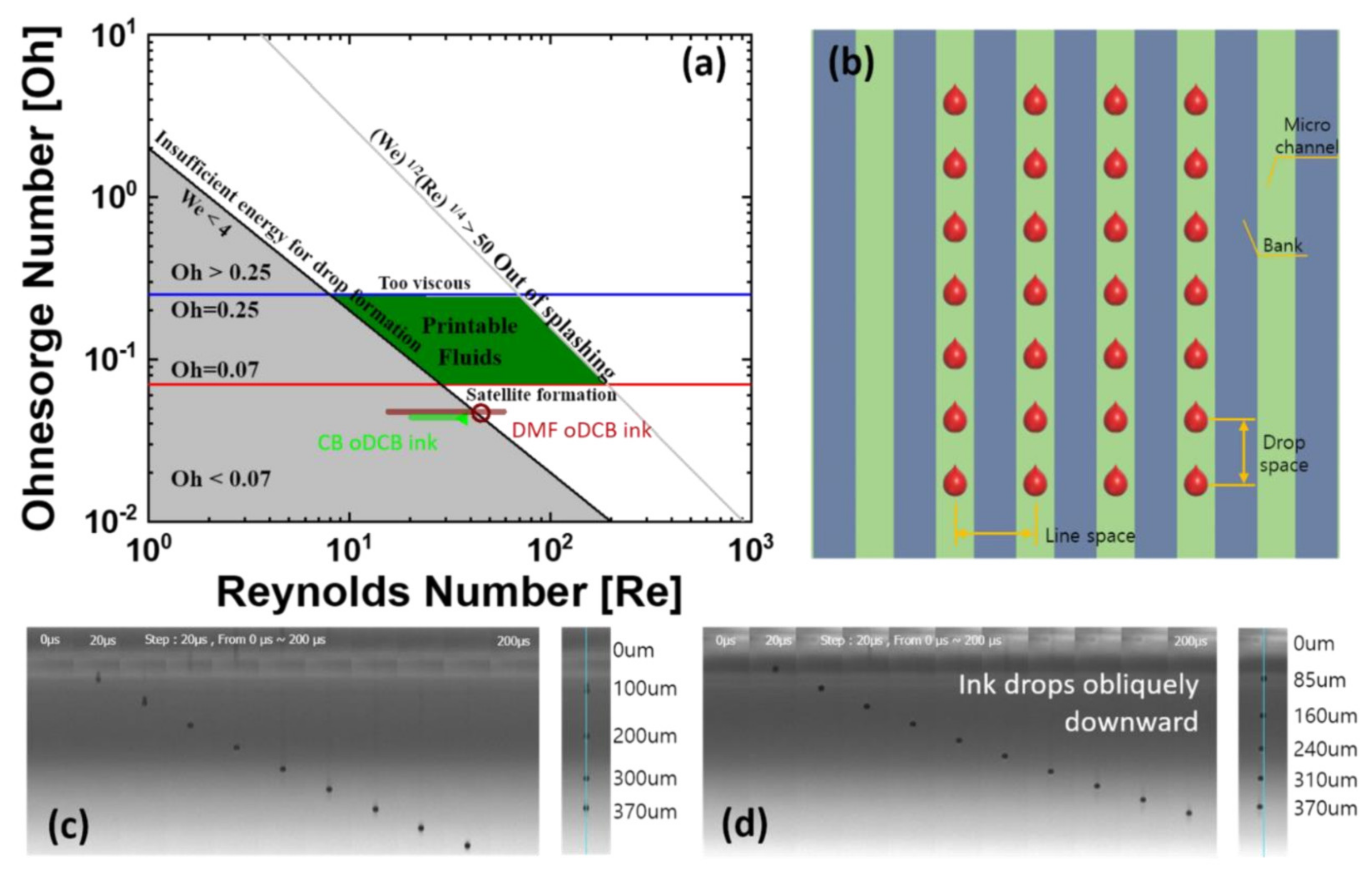

3.2. Optimization of Inkjet Condition of Co-Solvented Ink

3.3. Ink Filling Properties According to Variation of Drop and Line Space

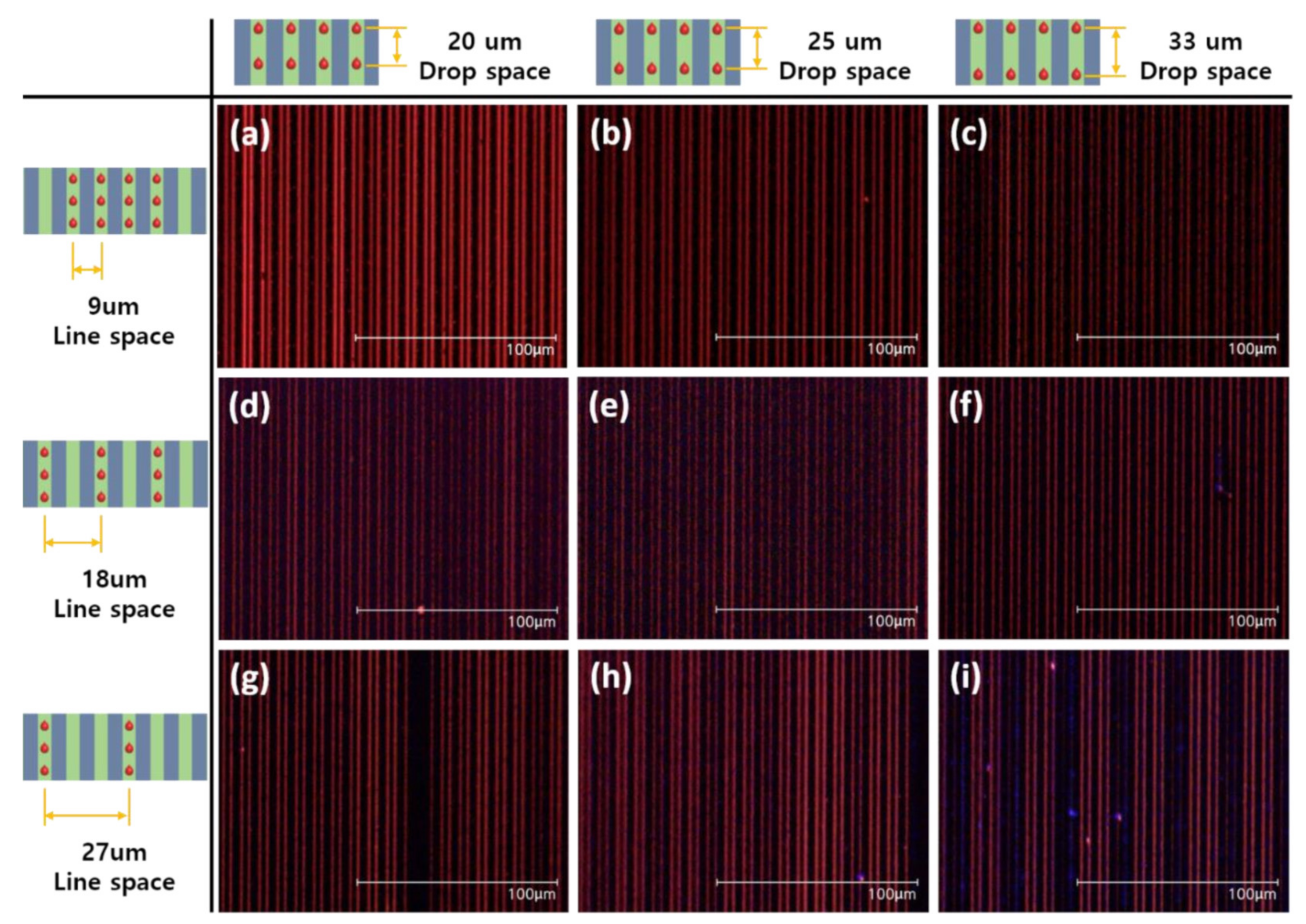

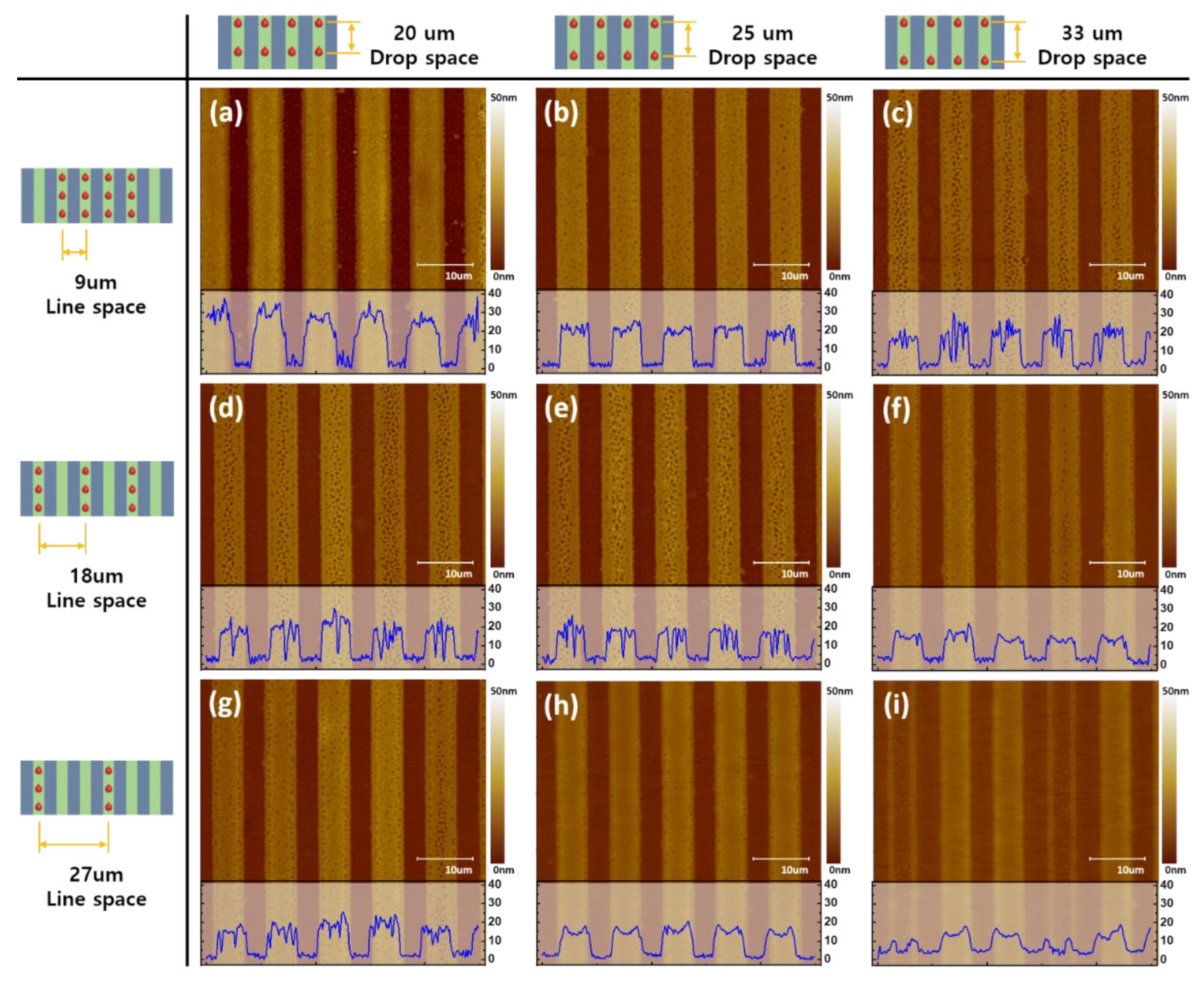

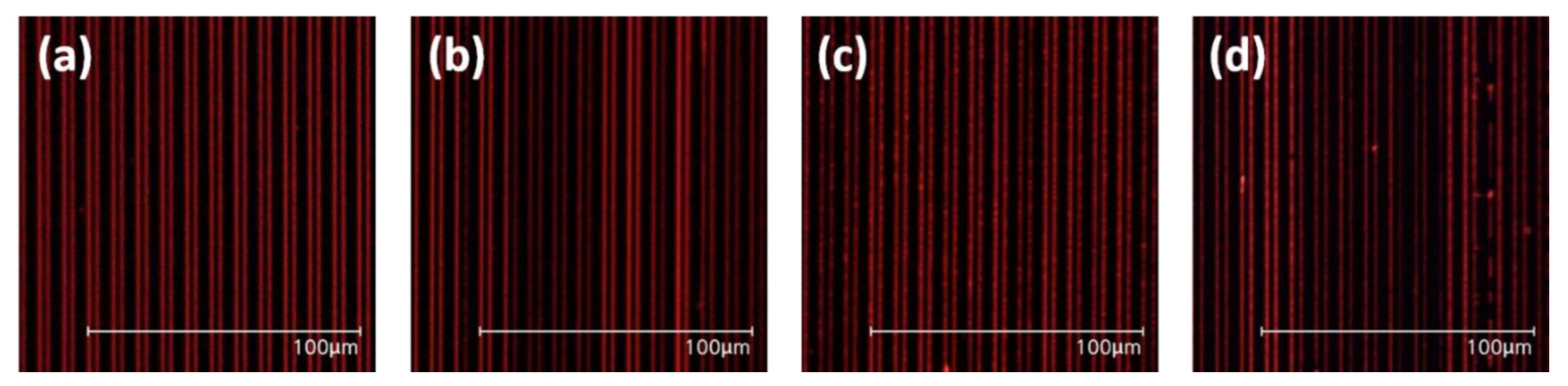

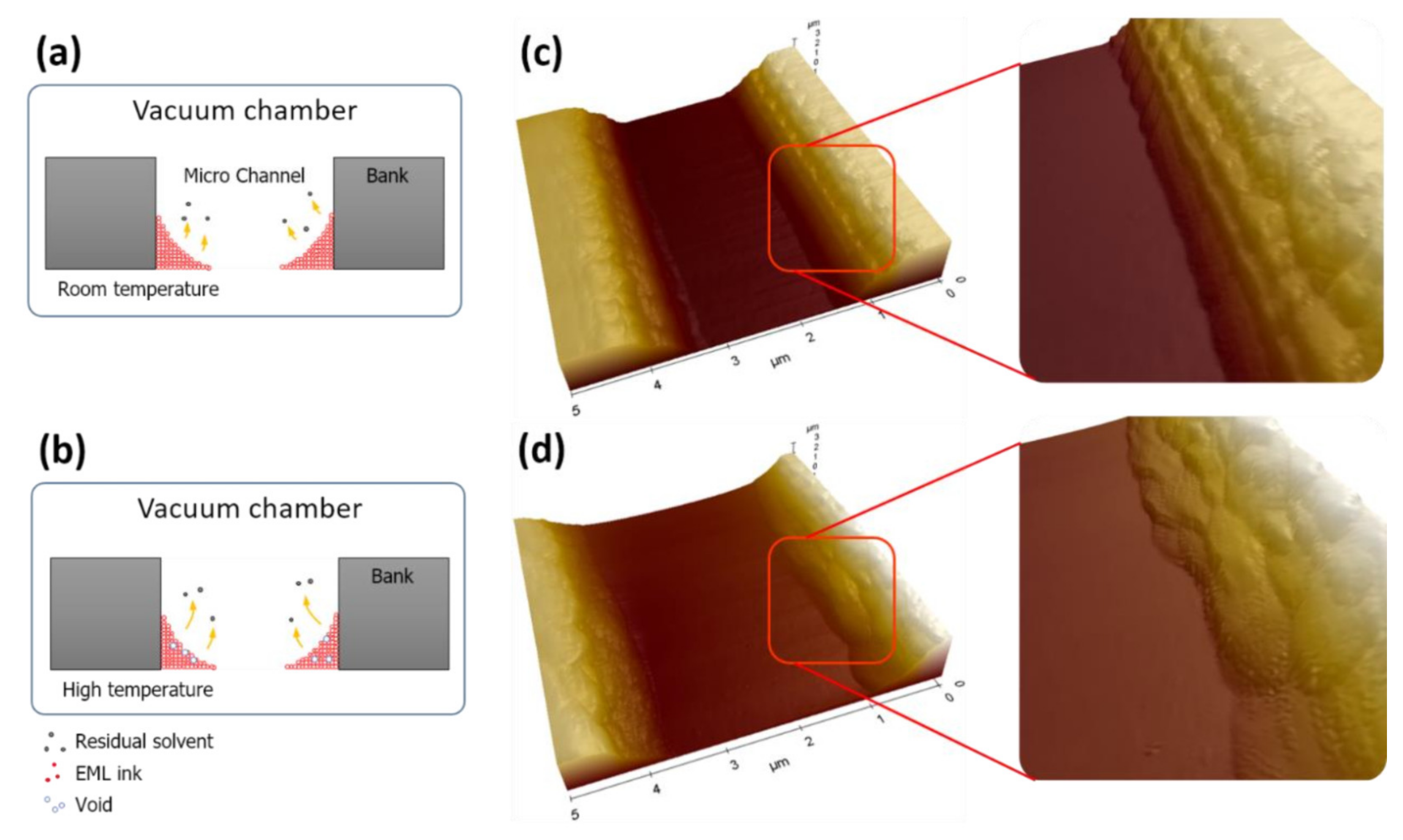

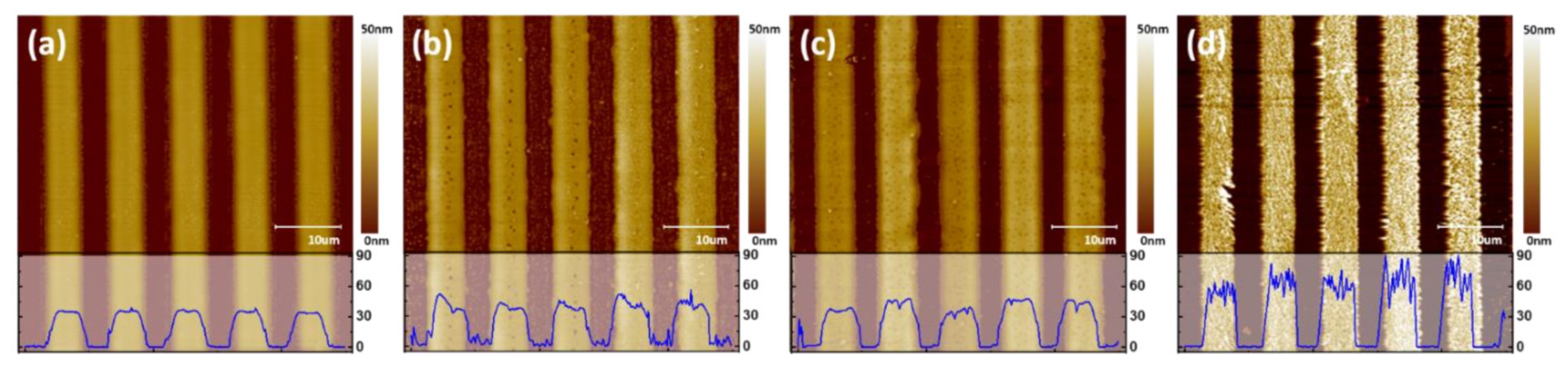

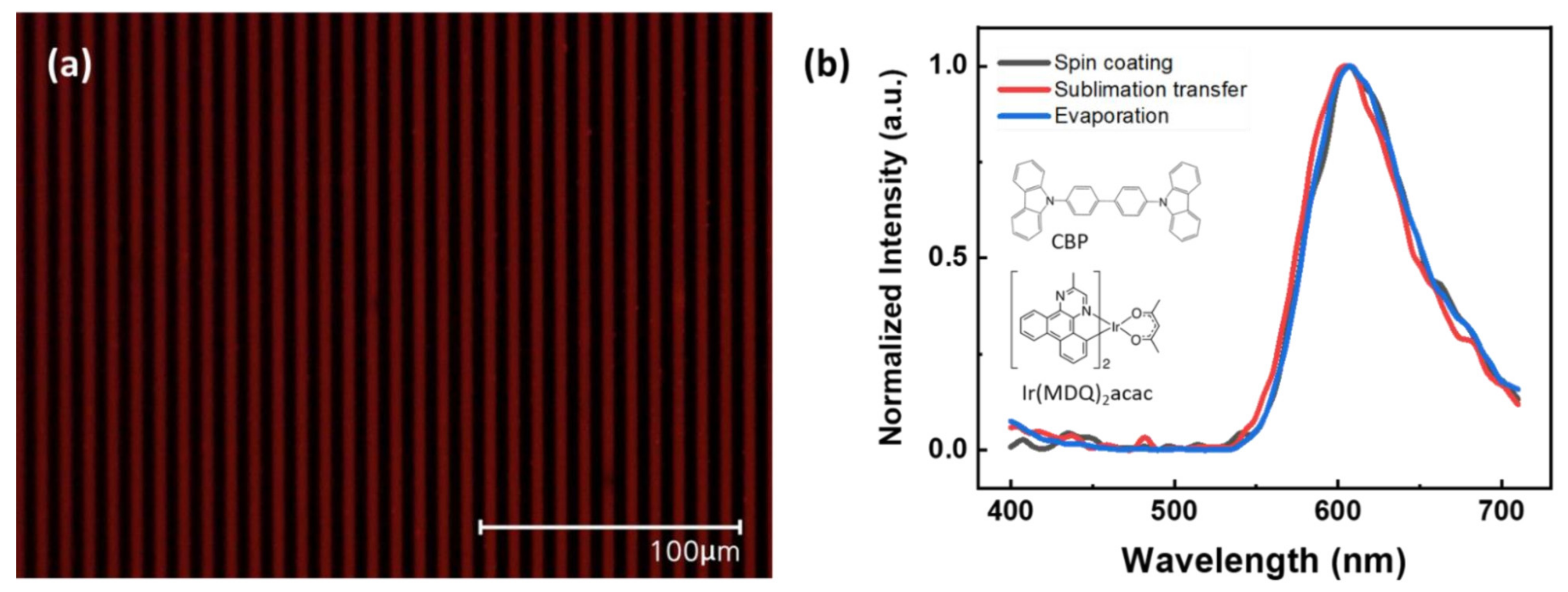

3.4. High-Resolution EML Patterning by Optimization of Vacuum Drying Condition

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yoon, D.G.; Kang, Y.J.; Bail, R.; Chin, B.D. Interfaces and Pattern Resolution of Inkjet-Printed Organic Light-Emitting Diodes with a Novel Hole Transport Layer. J. Inf. Disp. 2021, 22, 91–98. [Google Scholar] [CrossRef]

- Zheng, X.; Liu, Y.; Zhu, Y.; Ma, F.; Feng, C.; Yu, Y.; Hu, H.; Li, F. Efficient Inkjet-Printed Blue OLED with Boosted Charge Transport Using Host Doping for Application in Pixelated Display. Opt. Mater. 2020, 101, 109755. [Google Scholar] [CrossRef]

- Kang, J.; Koo, Y.; Ha, J.; Lee, C. 41-2: Invited Paper: Recent Developments in Inkjet-printed OLEDs for High Resolution, Large Area Applications. SID Symp. Dig. Tech. Pap. 2020, 51, 591–594. [Google Scholar] [CrossRef]

- Lee, Y.; Han, Y.J.; Cho, K.Y.; Cho, K.H.; Jeong, Y.-C. Large-Scale and High-Resolution Patterning Based on the Intense Pulsed Light Transfer of Inkjet-Printed Light-Emitting Materials. Macromol. Res. 2021, 29, 172–177. [Google Scholar] [CrossRef]

- Shi, F.; Liu, Q.; Zhao, H.; Fang, K.; Xie, R.; Song, L.; Wang, M.; Chen, W. Eco-Friendly Pretreatment to the Coloration Enhancement of Reactive Dye Digital Inkjet Printing on Wool Fabrics. ACS Sustain. Chem. Eng. 2021, 9, 10361–10369. [Google Scholar] [CrossRef]

- Le, N.N.; Phan, H.C.T.; Dang, D.M.T.; Dang, C.M. Fabrication of Miniaturized Microfluidic Paper-Based Analytical Devices for Sandwich Enzyme-Linked Immunosorbent Assays Using INKJET Printing. Appl. Biochem. Microbiol. 2021, 57, 257–261. [Google Scholar] [CrossRef]

- Zhuo, L.; Liu, W.; Zhao, Z.; Yin, E.; Li, C.; Zhou, L.; Zhang, Q.; Feng, Y.; Lin, S. Cost-Effective Silver Nano-Ink for Inkjet Printing in Application of Flexible Electronic Devices. Chem. Phys. Lett. 2020, 757, 137904. [Google Scholar] [CrossRef]

- Haas, G. 40-2: Invited Paper: Microdisplays for Augmented and Virtual Reality. SID Symp. Dig. Tech. Pap. 2018, 49, 506–509. [Google Scholar] [CrossRef]

- Haas, G. 52-1: Invited Paper: Microdisplays for Wearable Augmented Reality—OLED vs. LED Based Systems (Invited). SID Symp. Dig. Tech. Pap. 2019, 50, 713–716. [Google Scholar] [CrossRef]

- Abeeluck, A.K.; Iverson, A.; Goetz, H.; Passon, E. 58-2: Invited Paper: High-Performance Displays for Wearable and HUD Applications. SID Symp. Dig. Tech. Pap. 2018, 49, 768–771. [Google Scholar] [CrossRef]

- Liu, B.; Wang, L.; Tao, H.; Xu, M.; Zou, J.; Ning, H.; Peng, J.; Cao, Y. Doping-Free Tandem White Organic Light-Emitting Diodes. Sci. Bull. 2017, 62, 1193–1200. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Hu, S.; Zhang, L.; Xiao, P.; Huang, L.; Liu, C. Blue Molecular Emitter-Free and Doping-Free White Organic Light-Emitting Diodes with High Color Rendering. IEEE Electron Device Lett. 2021, 42, 387–390. [Google Scholar] [CrossRef]

- Yang, P.; Zhang, L.; Kang, D.J.; Strahl, R.; Kraus, T. High-Resolution Inkjet Printing of Quantum Dot Light-Emitting Microdiode Arrays. Adv. Opt. Mater. 2020, 8, 1901429. [Google Scholar] [CrossRef] [Green Version]

- Xuan, T.; Shi, S.; Wang, L.; Kuo, H.-C.; Xie, R.-J. Inkjet-Printed Quantum Dot Color Conversion Films for High-Resolution and Full-Color Micro Light-Emitting Diode Displays. J. Phys. Chem. Lett. 2020, 11, 5184–5191. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.-T.; Lu, K.-T.; Chen, Y.-H.; Lin, K.-H.; Chen, W.-P.; Chen, T.-W.; Chen, K.-K.; Lu, H.-H.; Lin, Y.-H.; Walker, D.; et al. 47-3: High Efficiency and High PPI AMOLED with Cavity Tuned by Inkjet Printed Hole Injection Layer. SID Symp. Dig. Tech. Pap. 2018, 49, 624–626. [Google Scholar] [CrossRef]

- Kashiwabara, M.; Hanawa, K.; Asaki, R.; Kobori, I.; Matsuura, R.; Yamada, H.; Yamamoto, T.; Ozawa, A.; Sato, Y.; Terada, S.; et al. 29.5L: Late-News Paper: Advanced AM-OLED Display Based on White Emitter with Microcavity Structure. SID Symp. Dig. 2004, 35, 1017. [Google Scholar] [CrossRef]

- Jiang, Y.; Tam, B.S.T.; Dong, S.; Tang, C.W. 61-2: 2-inch, 2000-ppi Silicon Nitride Mask for Patterning Ultra-High-Resolution OLED Displays. SID Symp. Dig. Tech. Pap. 2020, 51, 909–912. [Google Scholar] [CrossRef]

- Ke, T.-H.; Sandeheng, C.M.; Alvarez, G.M.; Vandenplas, E.; Ciarnain, R.M.; Malinowski, P.E.; Genoe, J.; Heremans, P. 55.1: Invited Paper: FMM-free OLED Manufacturing Enabled by Photolithographic Patterning Processes. SID Symp. Dig. Tech. Pap. 2021, 52, 655–658. [Google Scholar] [CrossRef]

- Malinowski, P.E.; Nakamura, A.; Janssen, D.; Kamochi, Y.; Koyama, I.; Iwai, Y.; Stefaniuk, A.; Wilenska, E.; Salas Redondo, C.; Cheyns, D.; et al. Photolithographic Patterning of Organic Photodetectors with a Non-Fluorinated Photoresist System. Org. Electron. 2014, 15, 2355–2359. [Google Scholar] [CrossRef]

- Choi, Y.; Shin, H.; Son, J.; Park, C.; Park, K.-W.; Lee, J.-K.; Jung, B. Two-Color Pixel Patterning for High-Resolution Organic Light-Emitting Displays Using Photolithography. Micromachines 2020, 11, 650. [Google Scholar] [CrossRef]

- Lee, J.Y.; Ju, B.-K.; Cho, K.H. Co-Solvented Solution Filling and Interfacial Phenomena of Sublimation Transferred Emitting Layer for High-Resolution OLED Fabrication. APL Mater. 2021, 9, 101115. [Google Scholar] [CrossRef]

- Cho, H.; Lee, H.-N.; Jeong, Y.-C.; Park, Y.M.; Kang, K.-T.; Cho, K.H. Solution and Evaporation Hybrid Approach to Enhance the Stability and Pattern Resolution Characteristics of Organic Light-Emitting Diodes. ACS Appl. Mater. Interfaces 2020, 12, 45064–45072. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Yang, L.; Yu, M.; Jiang, Y.; Liu, C.-F.; Lai, W.-Y.; Huang, W. Inkjet-Printed Small-Molecule Organic Light-Emitting Diodes: Halogen-Free Inks, Printing Optimization, and Large-Area Patterning. ACS Appl. Mater. Interfaces 2017, 9, 40533–40540. [Google Scholar] [CrossRef] [PubMed]

- Jia, S.; Tang, H.; Ma, J.; Ding, S.; Qu, X.; Xu, B.; Wu, Z.; Li, G.; Liu, P.; Wang, K.; et al. High Performance Inkjet-Printed Quantum-Dot Light-Emitting Diodes with High Operational Stability. Adv. Opt. Mater. 2021, 9, 2101069. [Google Scholar] [CrossRef]

- Kang, Y.J.; Bail, R.; Lee, C.W.; Chin, B.D. Inkjet Printing of Mixed-Host Emitting Layer for Electrophosphorescent Organic Light-Emitting Diodes. ACS Appl. Mater. Interfaces 2019, 11, 21784–21794. [Google Scholar] [CrossRef]

- Han, Y.J.; Kang, K.-T.; Cho, K.H. Residual-Solvent-Induced Morphological Transformation by Intense Pulsed Light on Spin-Coated and Inkjet-Printed ZnO NP Films for Quantum-Dot Light-Emitting Diodes. ACS Appl. Mater. Interfaces 2021, 13, 50111–50120. [Google Scholar] [CrossRef]

- Moradi, M.; Karami Moghadam, M.; Shamsborhan, M.; Bodaghi, M. The Synergic Effects of FDM 3D Printing Parameters on Mechanical Behaviors of Bronze Poly Lactic Acid Composites. J. Compos. Sci. 2020, 4, 17. [Google Scholar] [CrossRef] [Green Version]

- Singh, M.; Kaur, N.; Comini, E. The Role of Self-Assembled Monolayers in Electronic Devices. J. Mater. Chem. C 2020, 8, 3938–3955. [Google Scholar] [CrossRef]

- Alamán, J.; Alicante, R.; Peña, J.; Sánchez-Somolinos, C. Inkjet Printing of Functional Materials for Optical and Photonic Applications. Materials 2016, 9, 910. [Google Scholar] [CrossRef] [Green Version]

- Sung, S.; Park, S.; Cha, S.; Lee, W.-J.; Kim, C.-H.; Yoon, M.-H. Direct Patterning of Sol–Gel Metal Oxide Semiconductor and Dielectric Films via Selective Surface Wetting. RSC Adv. 2015, 5, 38125–38129. [Google Scholar] [CrossRef]

- Cho, K.H.; Jeong, Y.-C.; Lee, H.-N.; Cho, H.C.; Park, Y.M.; Lee, S.-H.; Kang, K.-T. P-73: High-Resolution Color Patterning of an OLED Device via Capillary-Induced Ink Filling and a Sublimation Transfer Process. SID Symposium Digest of Technical Papers 2019, 50, 1507–1510. [Google Scholar] [CrossRef]

- McKinley, G.H.; Renardy, M. Wolfgang von Ohnesorge. Phys. Fluids 2011, 23, 127101. [Google Scholar] [CrossRef] [Green Version]

- Prakash, S.; Yeom, J. Nanofluidics and Microfluidics: Systems and Applications; Micro and nano technologies, 1st ed.; William Andrew: Waltham, MA, USA, 2014; ISBN 978-1-4377-4469-9. [Google Scholar]

- Jang, D.; Kim, D.; Moon, J. Influence of Fluid Physical Properties on Ink-Jet Printability. Langmuir 2009, 25, 2629–2635. [Google Scholar] [CrossRef]

- Goehring, L. Desiccation Cracks and Their Patterns: Formation and Modelling in Science and Nature; Statistical Physics of Fracture and Breakdown; Wiley-VCH: Weinheim, Germany, 2015; ISBN 978-3-527-41213-6. [Google Scholar]

- Li, Y.; Yang, Q.; Li, M.; Song, Y. Rate-Dependent Interface Capture beyond the Coffee-Ring Effect. Sci. Rep. 2016, 6, 24628. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deegan, R.D.; Bakajin, O.; Dupont, T.F.; Huber, G.; Nagel, S.R.; Witten, T.A. Capillary Flow as the Cause of Ring Stains from Dried Liquid Drops. Nature 1997, 389, 827–829. [Google Scholar] [CrossRef]

- Kazmierski, B.K. The Drying of Inkjet Printed Drops on Patterned Substrates. Ph.D. Thesis, Durham University, Durham, UK, 2018. [Google Scholar]

- Washburn, E.W.; Read, J.W. The Laws of “Concentrated” Solutions. VI. The General Boiling-Point Law. J. Am. Chem. Soc. 1919, 41, 729–741. [Google Scholar] [CrossRef] [Green Version]

- Jiang, C.; Zhong, Z.; Liu, B.; He, Z.; Zou, J.; Wang, L.; Wang, J.; Peng, J.; Cao, Y. Coffee-Ring-Free Quantum Dot Thin Film Using Inkjet Printing from a Mixed-Solvent System on Modified ZnO Transport Layer for Light-Emitting Devices. ACS Appl. Mater. Interfaces 2016, 8, 26162–26168. [Google Scholar] [CrossRef]

- SATO VAC Inc. What Is Vacuum Drying?—Vacuum Pump. Available online: https://web.archive.org/web/20181017071904/http://www.satovac.co.jp/en/seminar/dryness.html (accessed on 28 March 2022).

- Beran, J.A. Laboratory Manual for Principles of General Chemistry, 9th ed.; Wiley: Hoboken, NJ, USA, 2011; ISBN 978-0-470-64789-9. [Google Scholar]

- Chang, Y.-L.; Wang, Z.B.; Helander, M.G.; Qiu, J.; Puzzo, D.P.; Lu, Z.H. Enhancing the Efficiency of Simplified Red Phosphorescent Organic Light Emitting Diodes by Exciton Harvesting. Org. Electron. 2012, 13, 925–931. [Google Scholar] [CrossRef]

- Chang, Y.-L.; Song, Y.; Wang, Z.; Helander, M.G.; Qiu, J.; Chai, L.; Liu, Z.; Scholes, G.D.; Lu, Z. Highly Efficient Warm White Organic Light-Emitting Diodes by Triplet Exciton Conversion. Adv. Funct. Mater. 2013, 23, 705–712. [Google Scholar] [CrossRef]

- Rankin, D.W.H. CRC handbook of chemistry and physics, 89th edition, edited by David R. Lide. Crystallogr. Rev. 2009, 15, 223–224. [Google Scholar] [CrossRef]

- PubChem Compound Summary for CID 7239, 1,2-Dichlorobenzene. National Center for Biotechnology Information. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/1_2-Dichlorobenzene (accessed on 28 March 2022).

- PubChem Compound Summary for CID 6228, N,N-Dimethylformamide. National Center for Biotechnology Information. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/N_N-dimethylformamide (accessed on 28 March 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.Y.; Ju, B.-K.; Cho, K.H. High-Resolution Patterning of Organic Emitting-Layer by Using Inkjet Printing and Sublimation Transfer Process. Nanomaterials 2022, 12, 1611. https://doi.org/10.3390/nano12091611

Lee JY, Ju B-K, Cho KH. High-Resolution Patterning of Organic Emitting-Layer by Using Inkjet Printing and Sublimation Transfer Process. Nanomaterials. 2022; 12(9):1611. https://doi.org/10.3390/nano12091611

Chicago/Turabian StyleLee, Jun Yeub, Byeong-Kwon Ju, and Kwan Hyun Cho. 2022. "High-Resolution Patterning of Organic Emitting-Layer by Using Inkjet Printing and Sublimation Transfer Process" Nanomaterials 12, no. 9: 1611. https://doi.org/10.3390/nano12091611

APA StyleLee, J. Y., Ju, B.-K., & Cho, K. H. (2022). High-Resolution Patterning of Organic Emitting-Layer by Using Inkjet Printing and Sublimation Transfer Process. Nanomaterials, 12(9), 1611. https://doi.org/10.3390/nano12091611